SPECIFICATIONS

Wingspan:......................................1535mm

Length:...........................................1130mm

Electric Motor:.....................See next pager

Glow Engine:.................... .46 2-T / .70 4-T

Radio:....................8 Channel / 8-9 Servos

Function: Ailerons-Elevator-Rudder-Throttle

Flaps-Optional Retractable Landing Gear.

WARNING! This radio controlled model is NOT a toy. If modified or flown carelessly it could go out of controll and

cause serious human injury or property damage. Before flying your airplane, ensure the air field is spacious enough.

Always fly it outdoors in safe areas and seek professional advice if you are unexperienced.

ACHTUNG! Dieses ferngesteuerte Modell ist KEIN Spielzeug! Es ist für fortgeschrittene Modellflugpiloten bestimmt,

die ausreichende Erfahrung im Umgang mit derartigen Modellen besitzen. Bei unsachgemässer Verwendung kann

hoher Personen- und/oder Sachschaden entstehen. Fragen Sie in einem Modellbauverein in Ihrer Nähe um

professionelle Unterstätzung, wenn Sie Hilfe im Bau und Betrieb benötigen. Der Zusammenbau dieses Modells ist

durch die vielen Abbildungen selbsterklärend und ist für fortgeschrittene, erfahrene Modellbauer bestimmt.

Radio control model / Flugmodel

ALL BALSA, PLYWOOD CONSTRUCTION AND ALMOST READY TO FLY

U.S NAVY FIGHTER

Instruction manual / Montageanleitung

TECHNISCHE DATEN

Spannweite:...................................1535mm

Lange:............................................1130mm

Elektroantrieb.............(siehe nächste Seite)

Verbrennerantrieb:...............7.45cc - 11.5cc

Fluggewicht:.......................................3.5Kg

Fernsteuerung..........8 Kanal / 8-9 Servos

VQ No: VQA120

F6F HELLCAT

RTF Weight: 3.5Kg (will vary with equipment

use)

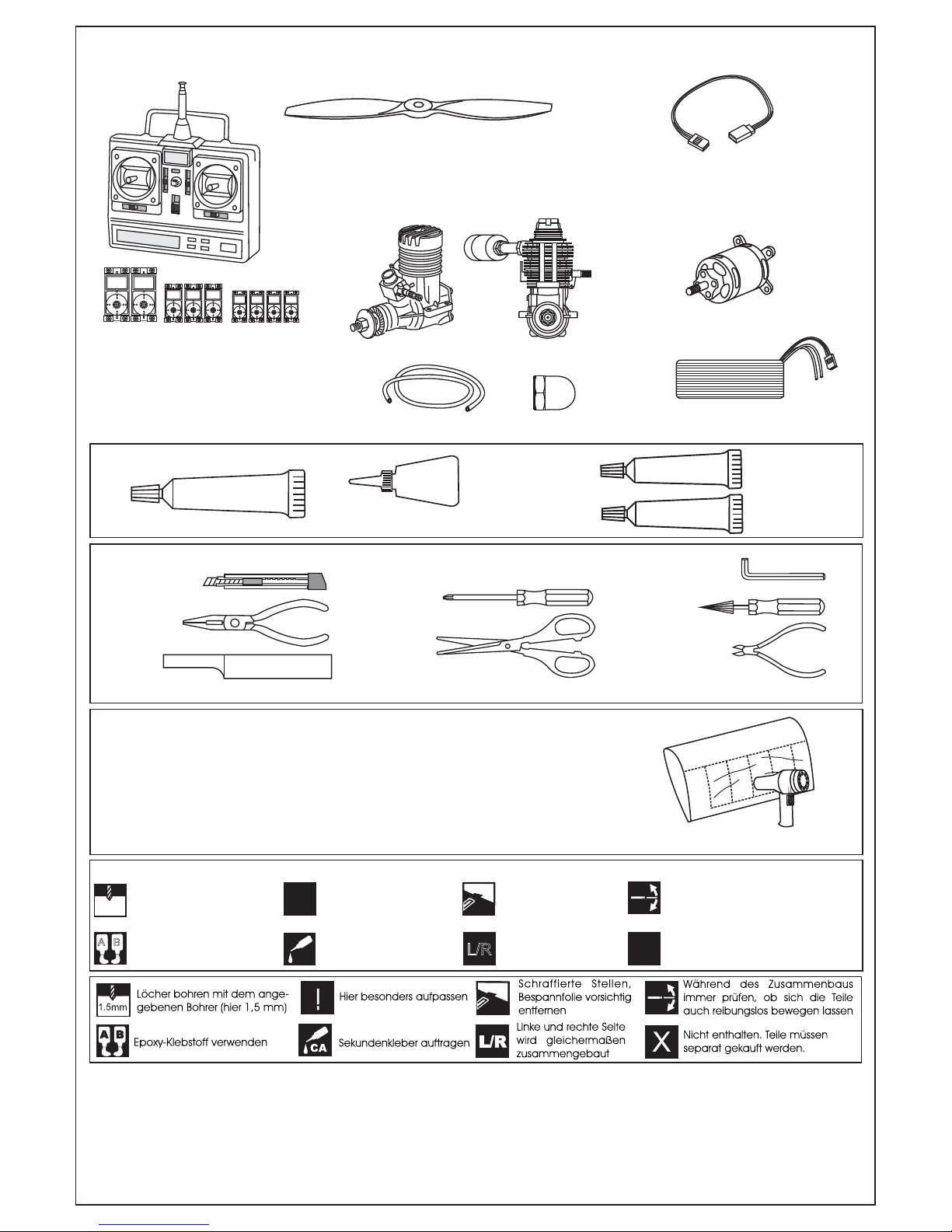

1.5mm

A

B

!

CA

L/R

Assemble left and right

sides the same way.

X

Drill holes using the stated

size of drill

(in this case 1.5 mm )

Use epoxy glue

Take particular care here

Hatched-in areas:

remove covering

film carefully

Not included.

These parts must be

purchased separately

Check during assembly that these

parts move freely, without binding

Apply cyano glue

SILICON

CA

GLUE

Silicon sealer

Cyanoacrylate Glue (thin type)

Minimum 7 channel radio

.60 ~.70 - 4 cycle

10.5x6 for .40 - 2 cycle engine

11x6 for .46 - 2 cycle engine

12x6 for .60 - 4 cycle engine

12x7 for .70 - 4 cycle engine

13x7 - 13x8 for electric motor

Silicone tube

Extension cord for aileron servos: 50cm(x2)

.46 ~ .50 - 2 cycle

TOLLS REQUIRED

Hobby knife

Needle nose Pliers

Phillip screw driver

Awl

Scissors

Wire Cutters

(Purchase separately)

Hex Wrench

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

Sander

Masking tape - Straight Edged Ruler - Pen or pencil - Drill and Assorted Drill Bits

Read through the manual before you begin, so you will have an overall idea of what to do.

Symbols used throughout this instruction manual, comprise:

(Purchase separately)

CONVERSION TABLE

1.0mm = 3/64”

1.5mm = 1/16”

2.0mm = 5/64”

2.5mm = 3/32”

3.0mm = 1/8”

4.0mm = 5/32”

5.0mm = 13/64”

6.0mm = 15/64”

10mm = 13/32”

12mm = 15/32”

15mm = 19/32”

20mm = 51/64”

25mm = 1”

30mm = 1-3/16”

45mm = 1-51/64”

If exposed to direct sunlight and/or heat, wrinkels can appear. Storing the

model in a cool place will let the wrinkles disappear. Otherwise, remove

wrinkles in covering film with a hair dryer, starting with

low temperature. You can fix the corners by using a hot iron.

Bei Sonneneinstrahlung und/oder Wärme kann die Folie erschlaffen bzw. Falten

entstehen. Verwenden Sie ein Warumluftgebläse (Haartrockner) um evtl. Falten aus der Folie

zu bekommen. Die Kanten können Sie mit einem Bügeleisen behandeln. Nicht zuviel Hitze anwenden !

REQUIRED FOR OPERATION (Purchase separately)

Low seting

700-800W Brushless Motor

5 cell 4500mAh LiPo battery

Extension cord for flap servos: 50cm(x4)

Extension cord for retract servos: 30cm(x2)

Extension cord for Rx battery pack: 20cm(x1)

Spinner hub

EPOXY A

EPOXY B

Epoxy Glue

(30 minute type)

Standard

Mini

Micro

Elevator : 1 standard servo

Rudder: 1 standard servo

Aileron: 2 mini servo

Flaps: 4 micro servo

Throttle: 1 mini servo (for glow engine only)

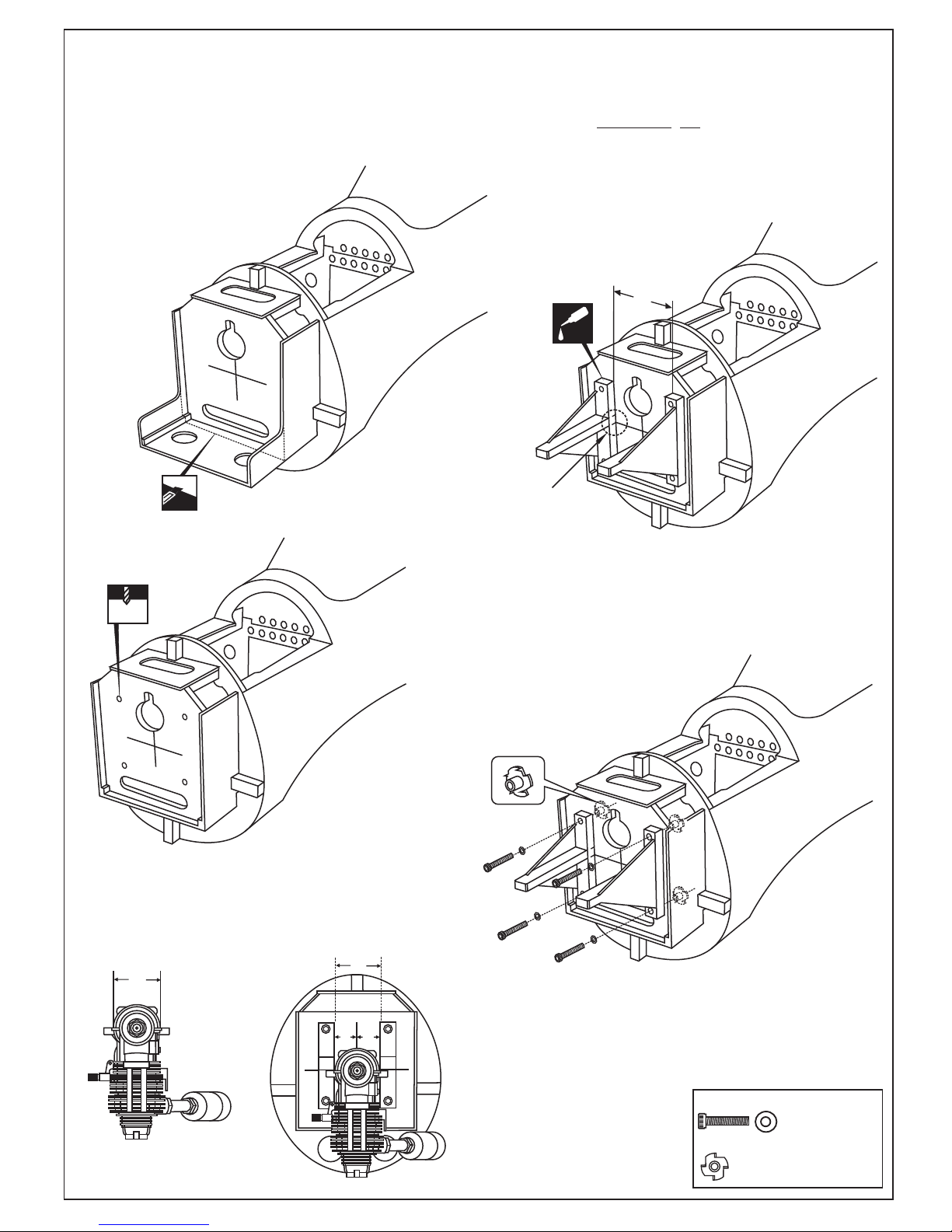

FRONT-VIEW

A

B

B’

A

B=B’

Cut the wood along the line as shown

(1A) in case of 4T engine using

! Align the mark on both engine mount

beams with the mark on the fuselage

Attach the engine mount beams onto the fire-wall

so the distance between of two engine mount beams

is “A”,and B=B’ as show.

Secure the engine mount beams onto the fire-wall

with litter CA glue (1B)

Using a pencil or felt tipped pen, mark

the fire wall where the four holes are to

be drilled(1B))

Carefully remove the engine mount beams

and drill a 6mm hole through the fire-wall

at each of the four marks made above (1C)

6mm

A

Reposition the engine mount beams on to the fire-wall

and secure them with four 4x25mm screw (1D)

...................4

....................4

4x25mm screw - washer

Blind-nut

Insert the blind-nut onto each

of the four holes make above (1D).

! Align the mark on both

engine mount beams with

the mark on the fire-wall.

Push left (or right) the magnetic fuel tank hatch

and full it out of the fuselage.

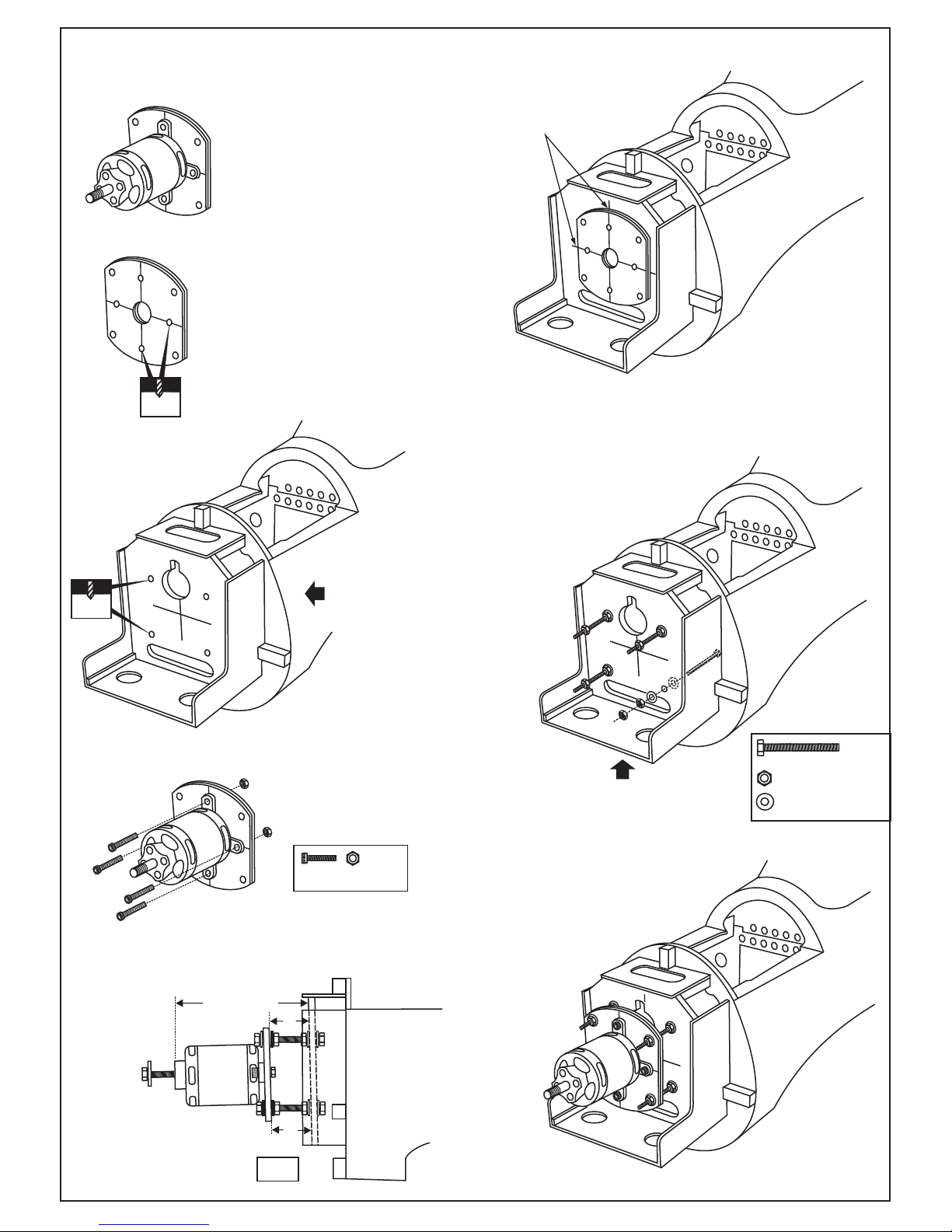

1- ENGINE MOUNT

1A

CA

1B

1C

1D

! Engine thrust on balk head

is already adjust at factory

SIDE-VIEW

106-108mm

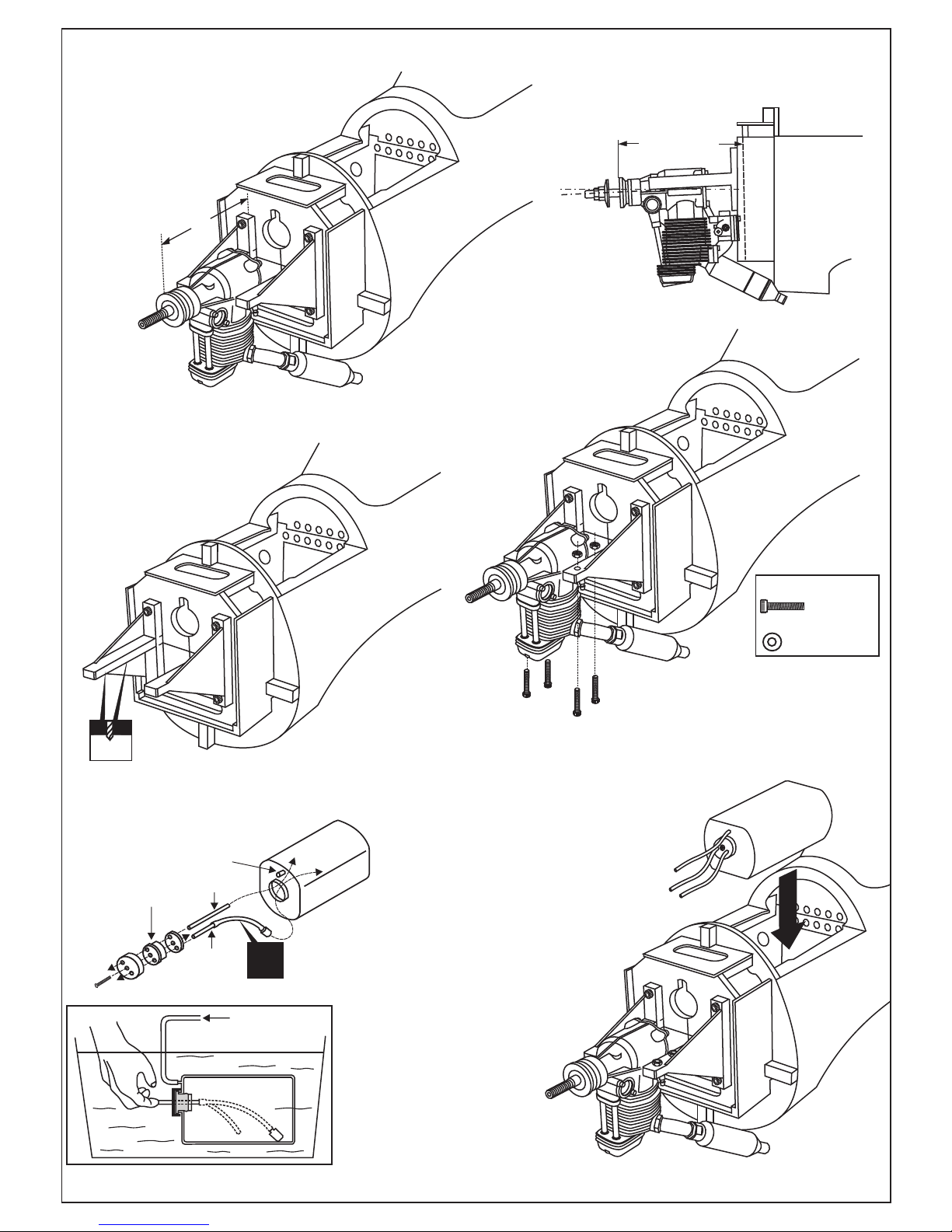

FUSELAGE

Position the engine to the engine mounts so the distance from the prop hub

to the fire-wall is 106-108mm.

Mark the engine mounting plate where the four holes are to be drilled (8B)

Remove the engine and drill a 3mm holes through the beam at each

of the four marks made above (8C)

Reposition the engine on the engine mount

beams, aligning it with the holes. Secure the

engine to the engine mount using four

3x25mm screws (2C)

Note: Apply Silicon sealer to each of the

3x25mm screw and nut.

.......4

3x25mm screw

Washer

.......4

C

C=106-108mm

Marking sure that you drill the hole perpendicular to the beam of the engine mount.

3mm

X

To muffler

Filler tube

To engine

3x35mm screw

Rubber stopper

Checking for leaks - block the vents

and blow into the feed - if in doubt

submersing the tank in a blow of

water will show up any problems.

Blow

Water

Carefully install the fuel tank

to ensure that they will not

shift during flight (2F).

2- ENGINE

2A

2B

2C

2D

2E

2F

B=B’

! Motor thrust on balk head

is already adjust at factory

Using a wooden motor mounting plate as a template,

mark the fire-wall where the four holes are to be drilled.

Remove the wooden motor mounting

plate and drill a 5mm hole through

the fire-wall at each of the four marks

marked .

5x70mm bolt.....4

5mm nut..........12

5mm washer...16

SIDE-VIEW / Seitenansicht

Using a aluminum motor mounting plate

as a template, mark the plywood motor

mounting plate where the four holes are

to be drilled.

Remove the aluminum motor mounting

plate and drill a 1/8”(3mm) hole through

the plywood at each of the four marks

marked .

5mm

3mm

B’

B

FUSELAGE

106-108mm

Attach the four 5x70mm bolts

and nuts to the fire-wall as shown.

3mm bolt / nut...4

Secure the Motor to the wooden

motor mounting plate using the

four 3mm bolts.

3- ELECTRIC MOTOR

3A

3B

3C

! Align the mark on wooden motor

mounting plate with the mark on

the fire-wall.

3D

3E

3F

3G

Ply gear mount

plate x 2

Plywood Gear mount

x 2

3x20mm screw

..........8

3x12mm screw

.......8

Nylon gear strap

.......4

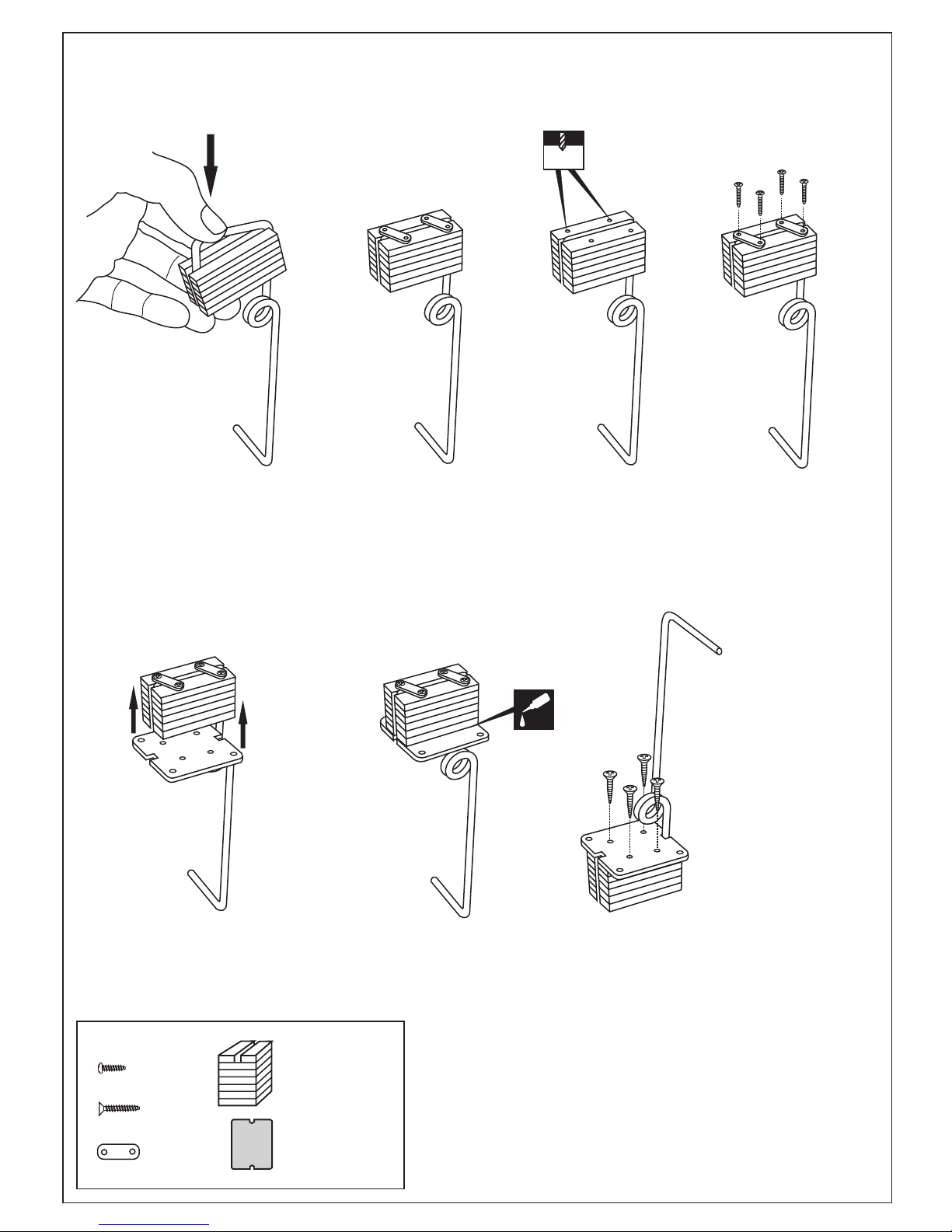

4- FIXED GEAR

4A

Slide the landing gear onto the

plywood gear mount and push

the landing gear as shown.

4B

Using the nylon gear strap

as a template, mark the

plywood gear mount where

the four holes to be drill.

Remove the nylon gear

strap and drill a 2mm hole

at each of the four marks

marked.

4C 4D

4E

Attach the ply gear mount plate

to the plywood gear mount

Secure the ply gear mount

plate in place using CA glue.

4F

4G

Drill a 2mm holes through the

ply gear mount plate.

Secure the ply gear mount

using four 3x20mm screws.

CA

Reposition the nylon gear

strap and secure them in

place using four 3x12mm

screws.

2mm

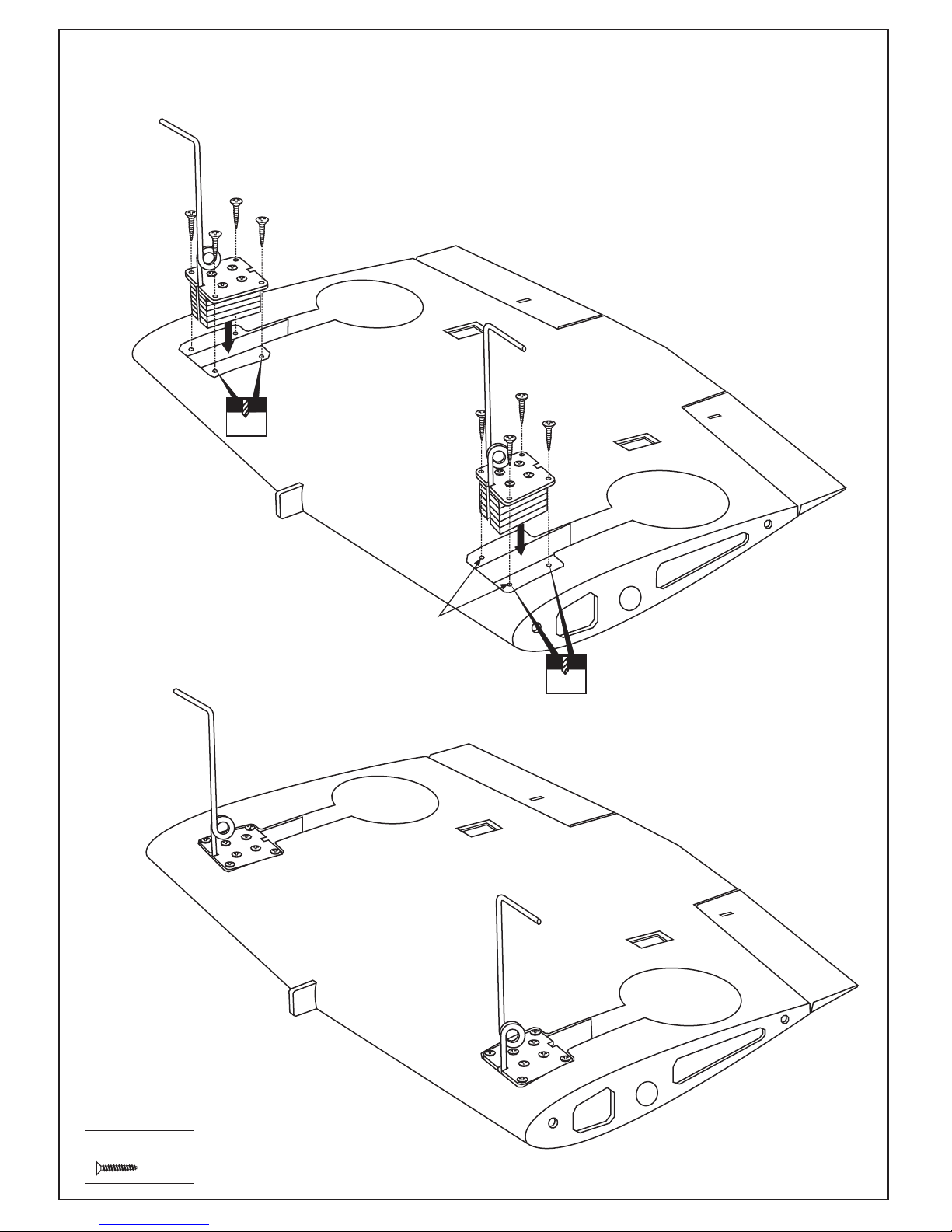

5- FIXED GEAR Continued

Attach the fixed gear onto the wing and mark the gear

mount on the wing where the four holes to be drill.

Attach the fixed gear onto the wing and mark the gear

mount on the wing where the four holes to be drill.

Remove the fixed gear and drill a 2mm hole at each of

the four marks marked.

2mm

2mm

Reposition the fixed gear onto the wing,

secure the fixed gear using eight 3x20 screws.

3x20mm screw

.......8

5A

5A

5B

5B

5B

5A

5C

CENTER WING - BOTTOM VIEW

Slide the two plastic gear door mounts onto each

landing gear.

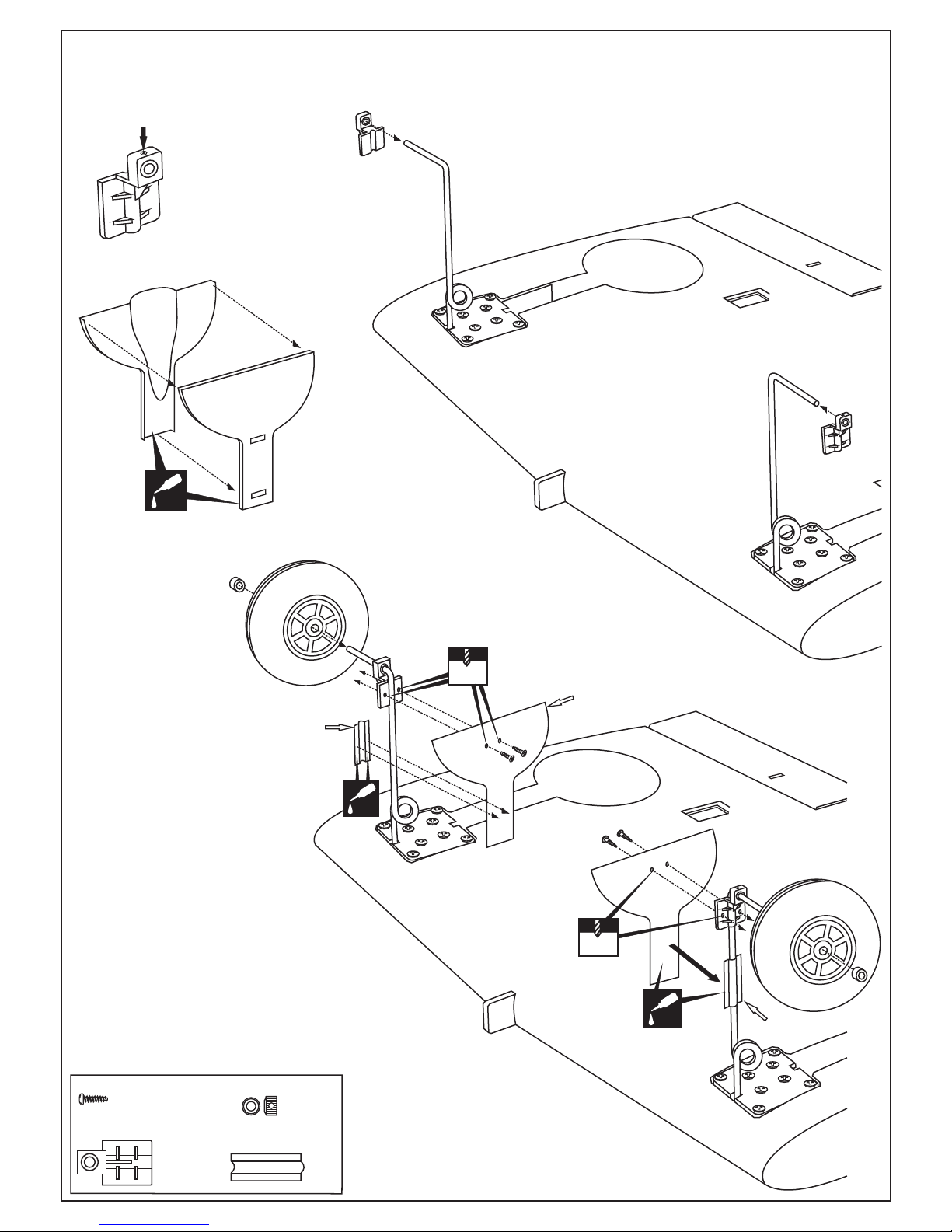

6- FIXED GEAR Continued

CA

Plastic gear door

Attach the plastic gear door to the plastic

gear door mounts, drill the 1.5mm holes through

the plastic gear door and the plastic gear door mount

as shown.

6B

6A

6C

6B

6C

6C

CA

1.5mm

Plastic gear strap

1.5mm

Plastic gear strap

Secure the gear doors using the 2x6mm

screws and plastic gear straps as shown.

6D

2x6mm screw

..........4

....2

...2

4mm collar

Plastic gear door mount

Plastic gear strap

....2

6B

Slide the wheels and 4mm collar onto the

landing gears.

Secure the plastic gear door

mount in place using the

3mm screw set.

CA

Attach the plastic gear door to the plywood gear door.

Plastic gear door mount

6A

6A

6C

6D

6D

6E

6E

6E

2x6mm

2x6mm

7- ELECTRIC RETRACT

Attach the electric retract gear onto the wing and mark

the gear mount on the wing where the four holes to be drill.

Remove the electric retract gear and drill a 2mm hole at

each of the four marks marked.

Reposition the electric retract gear onto the wing and

secure it in place using there 3x20mm and one 3x12mm

screw as show.

7A

7B

7C

7D

Slide the two wooden gear door mounts onto each

landing gear. Do not glue at this time.

Attach the gear door to the wooden gear door mounts,

secure the plastic gear door in place using CA glue.

7E

Slide the main wheel axle onto the landing gear

7F

2mm

3x20mm screw

(flat head)

3x12mm screw

(flat head)

5mm wooden gear door mount

................4

CA

7E

5mm wooden

gear door mount

CA

CA

Attach the plastic gear door to the

plywood gear door .

7G

Attach the plastic gear door to the plywood gear door .

7D

7F

7G

CA

8- ELECTRIC RETRACT Continued

8A

Slide the wheel and collar onto the wheel axle.

Connect the electric retract with the radio to check

the position of the wheel when the electric retract

in retracted position. Ensure smooth non-binding

movement.

Cut the landing gear excess.

Secure the wooden gear door mount with the

landing gear using CA glue

8A

8B

8C

8C

9- SERVO - CONTROL HORN

Cut away only

the covering

Cut away only

the covering

Plastic control horn

......2 set

Roll the towel paper around

the landing gear at here before

glue, because if the CA glue

run down, the landing gear

unrotatable.

!

2 mm

Flap servo

Flap push-rod

3x15mm screw

.........1

A

A’

Note: the hole on the surface of the top

of the wing is pre-drilled at factory.

RIGHT

WRONG

5/64”

2mm

2.mm drill bit

Aluminum

tube inside

3x15mm screw

TOP

Servo wire exit hole

9- SERVO - CONTROL HORN (CENTER WING)

CA

CA

CA

Wooden dowel

Secure the plastic control horn

in place using the thin CA glue.

Wooden dowel

Push the wooden dowel to the hole on the rib as show

Ensure that the dowel is rectangular with the rib.

Secure it in place using the thin CA glue.

9B

9B

9B

Carefully, slide the aluminum tube into the wing, ensure

that A = A’ as show.

Drill the 2mm hole as show.

9C

A=A’

Secure the aluminum tube in place

using 3x15mm screw.

9E

9D

9E

Flap push rod (1.2mm)

............2

............2

2mm

Connector

CENTER WING - TOP VIEW

CA

9A

9D

2 mm

Flap servo

Flap push-rod

2 mm

Aileron servo

Aileron push-rod

............4

2mm

Connector

Plastic control horn

............2 set

2x20mm screw

..............4

Aileron push rod (2mm)

......2

.....2

L/R

Assemble left and right

wings the same way.

2mm

Plastic control horn

............2 set

Steel clevis

Flap push rod (1.2mm)

............2

10- SERVO - CONTROL HORN (RIGHT AND LEFT WING)

CA

Cut away only

the covering

Cut away only

the covering

BOTTOM VIEW

L/R

Assemble left and right

sides the same way.

With the hand, push the right (and left) wing to the center wing with care

until the left wing meet the center wing with no gap.

11- JOINING THE WINGS

6mm

Note: the hole on the surface of the top

of the wing is pre-drilled at factory.

RIGHT

WRONG

5/64”

2mm

2.mm drill bit

Aluminum

tube inside

3x15mm screw

TOP

L/R

Assemble left and right

sides the same way

.

3x15mm screw

.........1

Drill the 2mm as show

.

Secure the left wing in place using 3x15mm screw.

12A

12B

12A

12B

12- JOINING THE WINGS Continued

A = A’

A’

A

Push the horizontal stabilizer into the slot on the fuselage

as show. Check the alignment of the horizontal stabilizer

by measuring from a fixed point along the center line of

the fuselage to the leading edge on each side of the

horizontal stabilizer. The distance must be equal on both

sides . If not, adjust the stabilizer until the measurements

are the same (see picture below: A=A’).

When you are satisfied with the alignment, use

a pencil to trace around the top and bottom of

the stabilizer where it meets the fuselage.

Cut away only

the covering

both side

Remove the horizontal stabilizer

from the fuselage. Using a straight edge

and a sharp hobby knife, carefully cut away

the covering inside the lines which were marked

above. Be cautious not to cut into the wood-this

will weaken the structure.

Pull the left and right elevator out of the horizontal stabilizer.

Using a sharp hobby knife, carefully cut away the covering

around of all slots for the horizontal stabilizer and vertical

fin installation.

Cut away only

the covering

Cut away only

the covering both sides.

13- HORIZONTAL STABILIZER

13A

13A

13B

13B

13C

13C

13D

13D

! Securely glue together. If coming off during fly, you lose control of your air plane.

CA

Apply CA glue

both sides.

(thin CA)

CA

Apply thin CA glue into the slot where

the fuselage meet the horizontal stabilizer.

Install the horizontal stabilizer onto the fuselage and adjust the alignment as described in steep 13B.

Note: it is important to ensure that the horizontal stabilizer is also level in regards to the fuselage.

Apply the thin CA along the area where the covering was removed in the previous step and to the

fuselage where the horizontal stabilizer mounts .

B

B’

B=B’

Trial fit the vertical fin in position. Using

a 90 degree triangle, ensure that the

vertical stabilizer is perpendicular to the

horizontal stabilizer (12B).

Using a pencil, trace around the vertical

stabilizer where it meets the fuselage.

Remove the vertical stabilizer from the

fuselage.

Pull the rudder out of the vertical fin.

Carefully, push the vertical fin into the

slot on the fuselage as shown (12A).

90 degree

triangle

14- HORIZONTAL AND VERTICAL STABILIZER

14A

14A

14B

14C

Insert the vertical fin into the fuselage, precisely align

the vertical stabilizer as described in step 14C.

Apply the thin CA glue on the vertical stabilizer where it

contacts the fuselage.

! Securely glue together. If coming off during fly,

you lose control of your air plane.

Remove the vertical stabilizer from the fuselage.

Using s sharp hobby knife, carefully cut away the

covering below the lines which were drawn in the

previous steep. Do not cut into the woods as this

will affect the structural integrity of thestabilizer (12C).

CA

Apply thin CA

glue both side

90 degree

triangle

CA

Apply thin CA

glue on the top

of the hinge

Without using glue yet, push the elevator and its

hinges into the hinge slots in trailing edge of the

horizontal stabilizer (13A).

Apply a thin layer of petroleum jelly

HORIZONTAL STABILIZER

HORIZONTAL STABILIZER

TOP-SIDE

TOP-SIDE

Do the same way with the bottom side of elevator and

with the second elevator and rudder.

Apply thin CA

glue on the top

and bottom

of the hinge

CA

15- VERTICAL STABILIZER

15A

15B

15B

15C

15D

Cut away only

the covering

VERTICAL STABILIZER

CA

Plastic control horn

2x12mm screw

............................2

.......................4

Plastic back plate

...........................2

Push the rudder push-rod with clevis into the black nylon push-rod

guide.

Using the plastic control horn as a template, mark

the mounting hole positions, where the rudder clevis

meet the rudder control horn with a felt tipped or a pencil.

Remove the control horn and drill two 2mm

holes through the rudder .

Attach the rudder control horn using the hardware provided

(two 2x15mm screws and a back plate).

Control horn Alignment

STABILIZER

Push the elevator push-rod with clevis into the black nylon

push-rod guide.

Using the plastic control horn as a template, mark

the mounting hole positions, where the elevator clevis

meet the rudder control horn with a felt tipped or a pencil.

Move the plastic control horn and drill two 2mm holes

through the elevator.

Plastic control horn

2x12mm screw

............................1

.......................2

Plastic back plate

...........................1

2mm

2mm

Attach the elevator control horn using the hardware provided

(two 2x12mm screws and a back plate).

16- ELEVATOR CONTROL HORN

17- RUDDER

RUDDER

17A

17B

25mm wheel

Insert the tail wheel push-rod into the hole on the

tail gear control horn (as show).

Install the tail wheel control horn in place.

Secure the tail wheel control horn in place using a

2mm screw set, ensure smooth non-binding movement.

...............1

Tail landing gear

..........1

............1

3x3mm screw

............4

3x10mm screw

.................1

Tail wheel controlhorn

2mm I.D collar

Instal the tail wheel gear in place.

..........1

1mm

2x8mm screw

.........6

18- TAIL WHEEL

18A

18B

18B

...................................1

1.2x880mm rod

19- TAIL WHEEL COVER

2 mm

Throttle servo

Throttle push-rod

................2

....................1

2mm

Connector

X

Elevator pushrod

D=5/64”(2mm)

3mm set Screw

2 mm

Elevator pushrod

ELEVATOR SERVO

X

Rudder pusshrod

D=5/64”(2mm)

Tail wheel pushrod

D=.050”(1.2mm)

3mm set Screw

2 mm

Rudder pushrod

RUDDER SERVO

Tail wheel pushrod

FUSELAGE - BOTTOM VIEW

.......3

2x950mm rod

In case of Glow engine using

Steel clevis

.......3

20- LINKAGES

FUSELAGE

FUEL TANK

Servo tray

Servo tray

Elevator servo

Throttle servo

(2 x120mm) rod

............2

(1.2 x500mm) throttle rod

............1

USS PRINCETON

VF-27

VF-27

USS PRINCETON

Note: Cut out the stickers and apply them in the proper area. Do not peel the backing paper off all at once.

Peel off one corner of the backing and cut off with scissors.

Arrange sticker on model and when satisfied adhere the corner without backing.

Carefully peel back the rest of the backing while at the same time adhering the rest of the sticker.

Try not to make air bubbles, if there are some, carefully puncture sticker (center of bubble) but not model surface with

the tip of the knife or sharp pin and squeeze out the air.

At curves stretch sticker and apply a little heat so that no ceases occur.

Cut off the excess that is produced.

FUSELAGE

1.5-2mm

1.5mm

1.5mm

2.5x10mm screw

.........4

21- COWLING

6x50mm nylon bolt

6x50mm nylon bolt

.....2

22- INSTALLING THE WING

CA

Plastic cover

Cut to open the hole

23- INSTALLING THE BOTTOM COVER

AILERON STROKE

ELEVATOR STROKE

RUDDER STROKE

Adjust the travel of the control surfaces to achieve the values stated in the diagrams.

These value will be suitable for average flight requirements. Adjust the values to suit your particular needs.

(92 ~ 96mm)

Note: Adjust the location of the battery pack to achieve this C.G location.

DO NOT try to fly an out-of balance model!

Wing center section

FLAPS STROKE

(35mm)

(15mm)

(15mm)

(25mm)

(25mm)

(10mm)

(10mm)

IMPORTANT: Please do not clean your model with strong solvent or pure alcohol, only use kerosene to keep the

colour of your model not fade.

22-BALANCE

23-CONTROL SURFACE

Loading...

Loading...