SEMI SCALE MODEL

60 Class

90 Class

2-cycle engine

4-cycle engine

CESSNA 188

AGWAGON

SPECIFICATIONS

Wingspan 1920mm

Length 1300mm

Electric Motor 1000 Watt (BOOST 90)

Glow Engine .60 2-T / .90 4-T

Radio 6 Channel / 8 Servos

WARNING! This radio controlled model is NOT a toy. If modified or flown carelessly it could go out of controll and

cause serious human injury or property damage. Before flying your airplane, ensure the air field is spacious enough.

Always fly it outdoors in safe areas and seek professional advice if you are unexperienced.

ACHTUNG! Dieses ferngesteuerte Modell ist KEIN Spielzeug! Es ist für fortgeschrittene Modellflugpiloten bestimmt,

die ausreichende Erfahrung im Umgang mit derartigen Modellen besitzen Bei unsachgemäßer Verwendung kann

hoher Personen- und/oder Sachschaden entstehen. Fragen Sie in einem Modellbauverein in Ihrer Nähe um

professionelle Unterstützung, wenn Sie Hilfe im Bau und Betrieb benötigen. Der Zusammenbau dieses Modells ist

durch die vielen Abbildungen selbsterklärend und ist für fortgeschrittene, erfahrene Modellbauer bestimmt.

TECHNISCHE DATEN

Spannweiter 1920mm

Lange 1300mm

Elektroantrieb 1000 Watt (BOOST 90)

Verbrennerantrieb 10cc 2-T / 15cc 4-T

Fernsteuerung 6 Kanal / 8 Servos

MONTAGEANLEITUNG

INSTRUCTION MANUAL

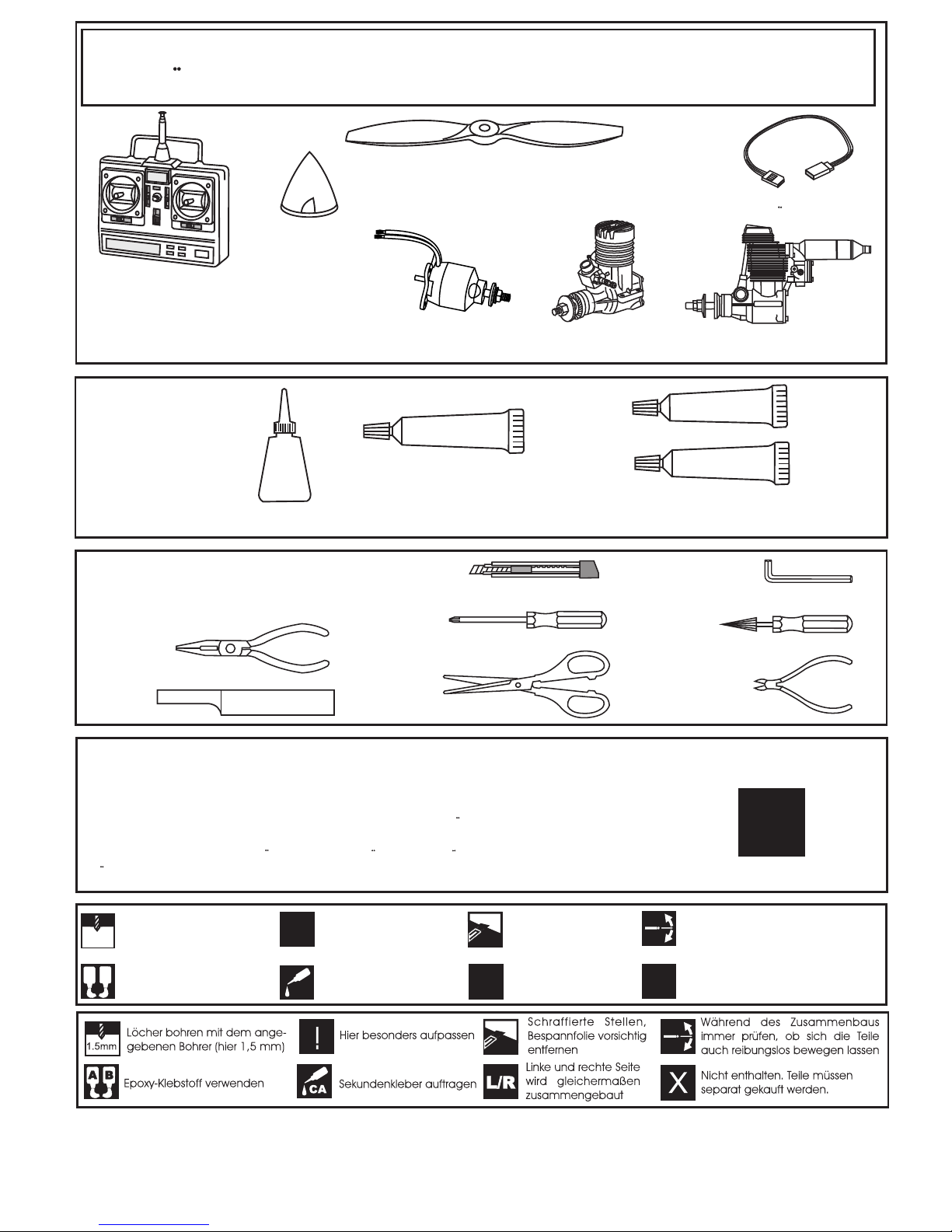

Or Electric equivalent

70mm Spinner

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

1.5mm

A

B

!

CA

L/R

Assemble left and right

sides the same way.

X

Drill holes using the stated

size of drill

(in this case 1.5 mm Ø)

Use epoxy glue

Take particular care here

Hatched-in areas:

remove covering

film carefully

Not included.

These parts must be

purchased separately

Check during assembly that these

parts move freely, without binding

Apply cyano glue

SILICON

EPOXY A

EPOXY B

CA

Epoxy Glue (30 minutes type)

Silicon Glue

Cyanoacrylate Glue

Sekundenkleber

Epoxy-Klebstoff (30min)

Minimum 6 channel radio

for airplane

.90 cu.in (8.5cc)

Extension cord

.60 cu.in. (7.5cc)

REQUIRED FOR OPERATION (Purchase separately)

Minimum 6 Kanal

Fernsteuerung

Servoverlangerungskabel

BENOTIGTE KOMPONENTEN (Nicht im Lieferumfang enthalten)

Brushless Motor

PICHLER BOOST 90

Brushless ESC

Brushless Regler

Battery / Flugakku LEMONRC 5300-22.2V

Silikonkleber

Tool Required/ Erfoderliches Werkzeug

The pre-covered film on ARF kit may wrinkle due to variations of temperature.

Store model in a cool and dry place for awile.

Then, staring with low heat, you may carefully use a hair dryer to smooth out wrinkels.

Die Bespannung des Modells kann durch Temeratureinflusse erschlaffen oder Falten

werfen z.b bei zu starker Sonnenenstrahlung oder Hitze.

Stellen Sie das Modell zunachst an einen kuhlen Platz fur eine bestimmte Zeit. Danach

konnen Sie versuchen die restlichen Falten vorstichtig mit einem Haartrockner zu behandeln.

!

CONVERSION TABLE

1.0mm = 3/64”

1.5mm = 1/16”

2.0mm = 5/64”

2.5mm = 3/32”

3.0mm = 1/8”

4.0mm = 5/32”

5.0mm = 13/64”

6.0mm = 15/64”

10mm = 13/32”

12mm = 15/32”

15mm = 19/32”

20mm = 51/64”

25mm = 1”

30mm = 1-3/16”

45mm = 1-51/64”

A

B

A

B

A

B

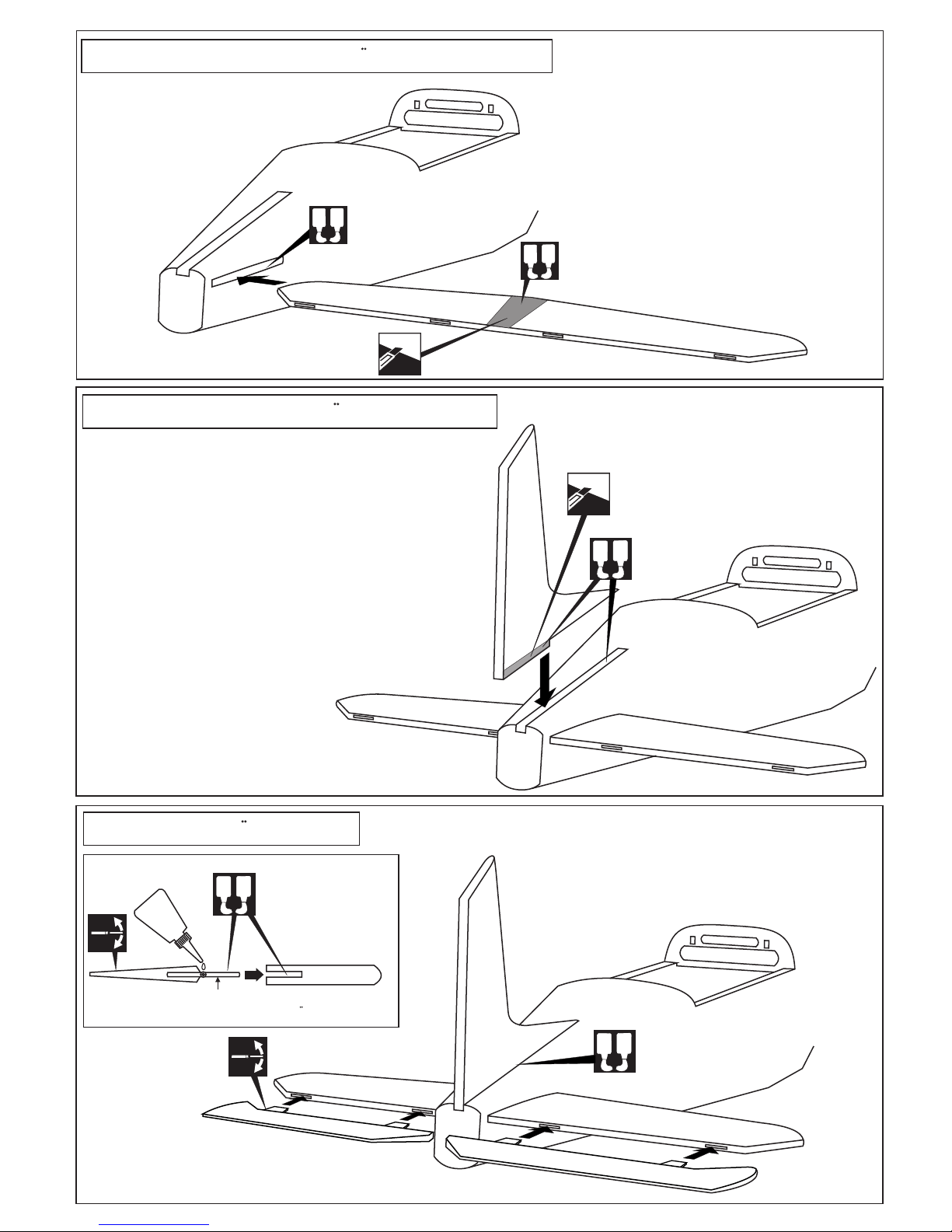

Cut away only the covering

Cut away only the covering

(Both the top and bottom)

(Both the left and right)

5 min.

(5 min.)

Hinge

Petroleum jelly

STABILIZER

A

B

Apply 5 min.

Epoxy both the

top and bottom.

Trial fit the horizontal stabilizer in place on the

fuselage. Check the alignment of the horizontal

stabilizer by measuring from a fixed point along

the center line of the fuselage to the leading edge

on each side of the horizontal stabilizer. The

distance must be equal on both sides.

Using the pencil trace around the top and bottom

of the stabilizer where it meets the fuselage.

Remove the horizontal stabilizer from the fuselage

Remove the covering material from the

gluing surfaces on both the top and bottom of the

horizontal stabilizer.

Spread epoxy onto the top and bottom of the

horizontal stabilizer where it contacts the fuselage.

Trial fit the vertical stabilizer in place on the

fuselage. Check the alignment of the vertical

stabilizer.

Using the pencil trace around the right and left

of the stabilizer where it meets the fuselage.

Remove the vertical stabilizer from the fuselage.

Remove the covering material from the gluing

surfaces on both the right and left of the vertical

stabilizer.

Spread the epoxy on the vertical stabilizer where

it contacts the fuselage and to the bottom of the

stabilizer.

Insert the vertical fin into the fuselage, ensuring

that it is seated properly on the fuselage.

3- Elevator / Hohenruder

1- Horizontal Stabilizer / Hohenruder

2- Vertical Stabilizer / Hohenleiwerk

Scharnier

Hohenlleiwerk

A

B

Both the right

and left

Both the top and bottom

Drill a 3/32”(2.5mm) diameter hole in torque rod mounting slot,

marking sure that you drill the hole perpendicular to the leading

edge of the rudder.

Position each hole 38mm (+/- 1mm) out from the edge of the rudder.

38mm

Test-fit the torque rod into the rudder.

When satisfied with the fit and alignment, remove the torque rod.

Apply a thin layer of petroleum jelly to only the pivot point of the

torque rod bearing

Hinge the rudder to the vertical stabilizer, using 5 minute epoxy. Make sure

to apply a thin layer of epoxy to the left and right of both hinges and to the

inside the torque rod mounting slot and to the end of the torque rod itself.

2.5mm

Hinge / Scharnier

Petroleum jelly

STABILIZER

A

B

Apply 5 min.

Epoxy both the

left and right.

5- Rudder / Hohenleiwerk

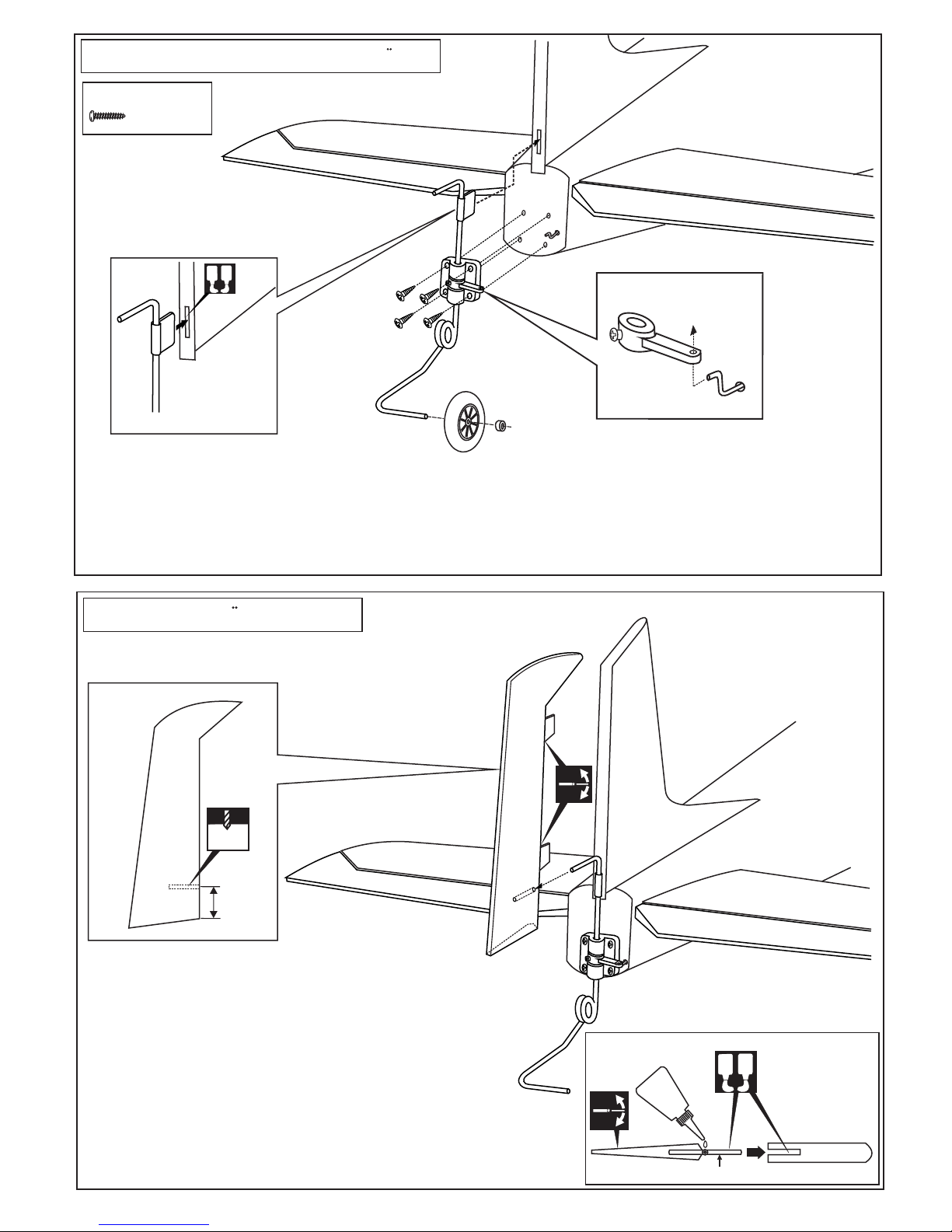

Tail wheel control arm

Tail wheel push-rod

1

1- Insert the tail wheel pushrod into the hole on the tail wheel control arm (as show).

2- Re-install the rudder torque rod and tail wheel mount in place.

3- Secure the tail wheel mount in place using four 3x12mm screws.

Secure the tail wheel control horn in place using a 1/8”(3mm) screw set, Ensure smooth non-binding movement.

1

2

1

A

B

Test-fit the rudder torque

rod into the slot.

3

Rudder torque rod

NOTE: You may need to open up the slots so

that the torque rod bearing are not too difficult

to push in

3x12mm screw

...........4

4- Tail wheel leg / Spornradtrager

Note: All holes on the fuselage and bilnd-nuts

are pre-installed at factory.

6- Main landing gear / Fahrwerk

4x15mm screw

Aluminum landing gear

7- Wheel / Radl

8- Engine mount / Motortrager

4X15mm screw

...........6

4X30mm screw

......2

..............2

..............2

! Align the mark on both mounts

with the mark on the fuselage

4X25mm screw

......4

..............4

..............4

4.5mm

.............2

Aluminum Haupfahrwerk

Rudder servo

Throttle servo

Switch

Nylon pushrod guide

Nylon pushrod guider

Rudder and tail wheel pushrod

Elevator servo

Elevator servo

9- Engine / Motor

10- Servo installation

11- Linkage / Alenkungen

140-141mm

140 - 141mm

! Engine thrust on balk

head is already adjust

at factory

1.5

TOP-VIEW

.........2

2x20mm

.......4

TOP VIEW / Draufsicht

BOTTOM - VIEW / Unteransicht

FUEL TANK

RECEIVER BATTERY

2.5x10mm.....4

Attach the board or transparent plastic on the side of the fuselage with the adhesive tape as show.

Using a pencil or felt tipped pen trace around the engine head where it meet the cowl. Cut the opening the board or transparent plastic for the engine head as marked above.

Remove the engine and insert the cowl on to the fuselage so the distance from the fire wall to the front of the cowl is

138 to 139mm.

Remove the cowl from the fuselage and carefully cut the opening for the engine head as marked above. Do the same way

with the hole for needle-valve and silencer.

Again. Insert the cowl on to the fuselage and secure it in place with five 2x5mm screws.

138mm

Ruler

12- Fuel tank / Kraftstofftank

13- Cowling / Motorhaube

SIDE-VIEW / Seitenansicht

BATTER

Y ST

AND

F3

F3

F2

F3A

FUEL TANK STAND

FUEL TANK

BATTERY STAND

LI-PO BATTERY

Magnetic Battery stopper

(3mm plywood)

IN CASE OF LI-PO BATTERY USING

Slide the battery stand throughout the slots

on the bottom of F3

One end of the battery stand touched the

rear of the fire-wall

IN CASE OF GLOW ENGINE USING

IN CASE OF ELECTRIC MOTOR USING

Slide the battery stand (P1) throughout the slots

on the bottom of F3 so that the end of the battery

stand touched the rear of the fire-wall.

Secure the battery stand in place using the

magnetic battery stopper (P4).

P1

Place the Li-po battery on to the battery stand

and secure it in place with the nylon cable tie.

Nylon cable tie

F3

F2

Fire-wall

14- Li-po battery / Li-po akku

SIDE-VIEW / Seitenansicht

Insert the 18x500mm aluminum

tube throughout the fuselage

(do not using glue)

L/R

2x10mm

screw

X

X

Flap servo hatch

(plywood)

Flap push rod exit

Aileron servo

Aileron

push rod

305mm

CA

1-Using the ABS shield as a template, trace around the

outside edge of the ABS air-scoop,and then remove it.

2-Using a sharp hobby knife, cut away the covering inside

the lines. Not to cut into the wood.

3-Apply the ABS shield in place and secure with CA glue.

Do the same way with another half wing.

Cut away the

covering only

WING - TOP VIEW

15- Servo

16- ABS Shield

17- Wing installation / Flachenbefestigung

BOTTOM - VIEW / Unteransicht

5x20mm screw

5mm washer

5mm blindnut

pre-installed

inside.

Wood dowel

Wood dowell

CA

1- Test-fit the dowel into the hole.

2- Secure the dowel in place

using CA glue.

Do the same way with another

haft wing.

Secure the half wing in place

using 5x20mm screw.

Do the same way with another

half wing.

Lightly, push the half wing

to the side of fuselage.

CA

19- Cockpit

18- Wing installation / Flachenbefestigung

5X20mm screw

......2

..............2

CA

Black nylon tube

20- Cockpit

21- Canopy / Kabinenhaube

2x12mm screw

3x15mm screw

22- Cockpit installation

2x12mm screw

...........5

3X15mm screw

...........2

Fiberglass shield

23- Wing brace

24- Tail shield

3x15mm

..........2

3x10mm screw

12mm

35mm

80mm

ELEVATOR CONTROL RANGE

RUDDER CONTROL RANGE

Adjust the travel of each control surface to the values

in the diagrams these values fit general flight capabilites.

Readjust according to your needs and flight level.

Position for

right diagram.

AILERON CONTROL RANGE

FLAP CONTROL RANGE

CG

40mm

Position for right diagram.

Position for right diagram.

NEVER FLY BEFORE CHECKING THE CG’S REQUIRED POSITION.

Carefully install the battery pack to ensure that they will not shift during flight.

Shift the location of the battery pack as needed to obtain the specification.

Position for

right diagram(CG)

25- Tail shield

26- Control surface & Balance

Schwerpunkt & Ruderausschlage

150 - 153mm

40mm

12mm

80mm

All details are subject to change without notice !

Technische Anderungen und Irrtumer vorbehalten !

IMPORTANT:

Please do not clean your model with pure alcohol, only use liquid soap with water or use glass cleaner

to clean on surface of your model to keep the colour not fade.

3x10mm screw

...........4

2mm

Loading...

Loading...