WARNING!

Please do not clean your model with pure alcohol, only use liquid soap with water or use glass cleaner to

clean on surface of your model to keep the colour not fade.

RADIO CONTROL MODEL

ASSEMBLY INSTRUCTION

.40 ARF LOW WING TRAINER

Wingspan: 59in.(1520mm)

Fuselage length: 48in.(1220mm)

Engine: 40 - 46 2T / 48 - 52 4T

Electric Motor: 600W

Radio: 5 channel / 5 servo

RC Functions: Rudder - Elevator - Aileron - Throttle

WARNING! This radio controlled model is NOT a toy. If modified or flown carelessly it could go out of control and

cause serious human injury or property damage. Before flying your airplane, ensure the air field is spacious enough.

Always fly it outdoors in safe areas and seek professional advice if you are unexperienced.

MARACANA

MARACANA

EP

GP

You can use both

Gas or Electric power

VQA085

Every body can fly

Awl

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

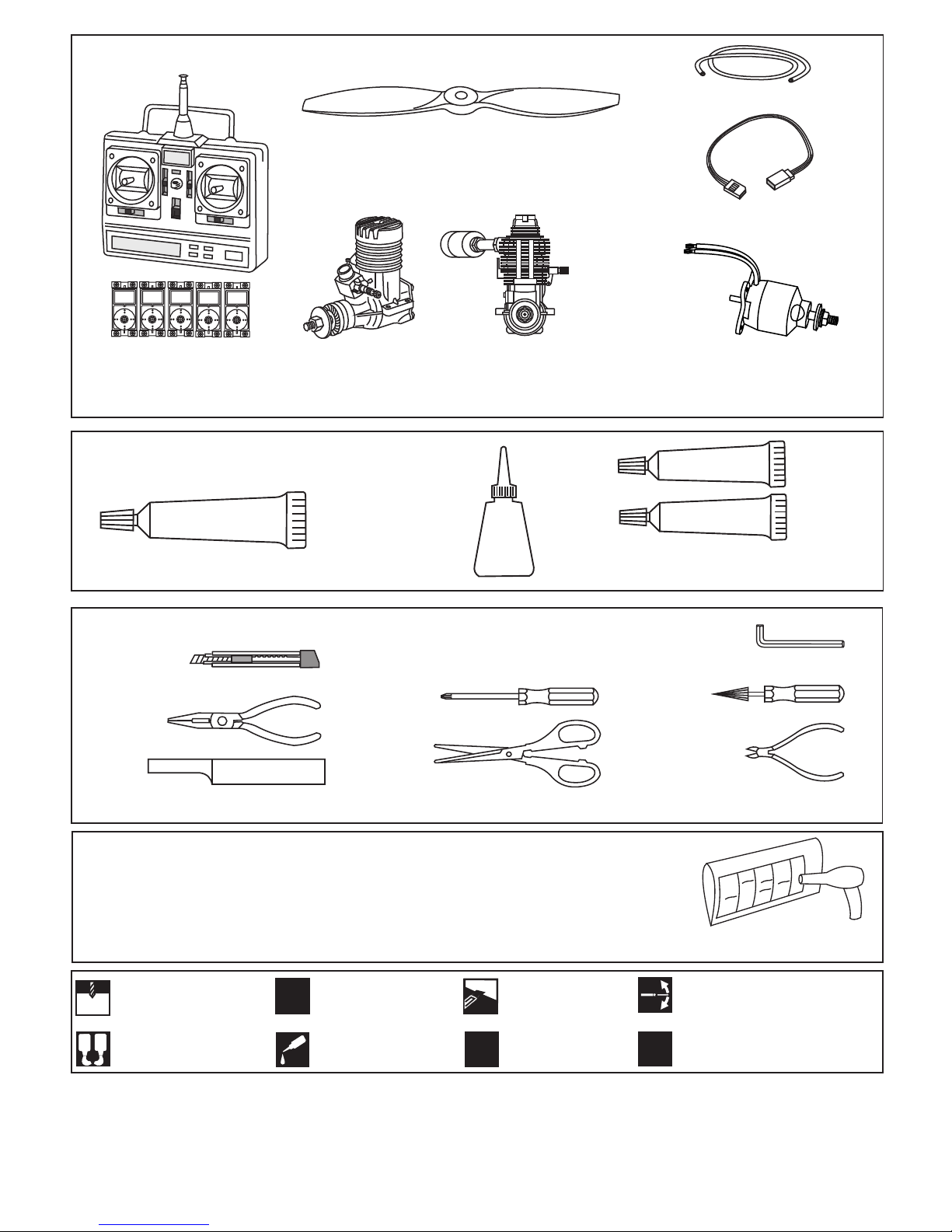

SILICON

EPOXY A

EPOXY B

CA

Silicon sealer

Silicone tube

Extension for aileron servo.

Read through the manual before you begin, so you will have an overall idea of what to do.

Brushless Motor

600-720W

or equivalent.

LiPo 4500 mAh (5-6)S

REQUIRED FOR OPERATION (Purchase separetely)

10.5x6 for .40 - 2 cycle engine

11x6 for .46 - 2 cycle engine

11x7 for .52 - 4 cycle engine

12x7 ~13x6 - Electric motor

.40 - .46 - 2T

.48 - .52 4T

Radio a 5 channel (min)

5 servo standard (Motorx1,

Rudderx1, Elevatorx1,

Aileronx2)

GLUE

(Purchase)

Cyanoacrylate

Glue

Epoxy glue (5 minute type)

Epoxy glue (30 minute type)

TOOL REQUIRED

Hobby knife

Needle nose Plier

Sander

Phillip screw driver

Scissor

Hex Wrench

Wire Cutters

Masking tape - Straight Edged Ruler - Drill and Assorted Drill Bits

TABELLA DI CONVERSIONE

1.0mm = 3/64”

1.5mm = 1/16”

2.0mm = 5/64”

2.5mm = 3/32”

3.0mm = 1/8”

4.0mm = 5/32”

5.0mm = 13/64”

6.0mm = 15/64”

10mm = 13/32”

12mm = 15/32”

15mm = 19/32”

20mm = 51/64”

25mm = 1”

30mm = 1-3/16”

45mm = 1-51/64”

If exposed to direct sunlight and / or heat, wrinkles can appear. Storing the model in a coll

place will let the wrinkles disappear. Otherwise, remove wrinkles in covering film with a hairdryer, starting with low temperature. You can fix the corners by using a hot iron.

1.5mm

A

B

!

CA

L/R

Assemble left and right

sides the same way.

X

Drill holes using the stated

size of drill

(in this case 1.5 mm Ø)

Use epoxy glue

Take particular care here

Hatched-in areas:

remove covering

film carefully

Not included.

These parts must be

purchased separately

Check during assembly that these

parts move freely, without binding

Apply cyano glue

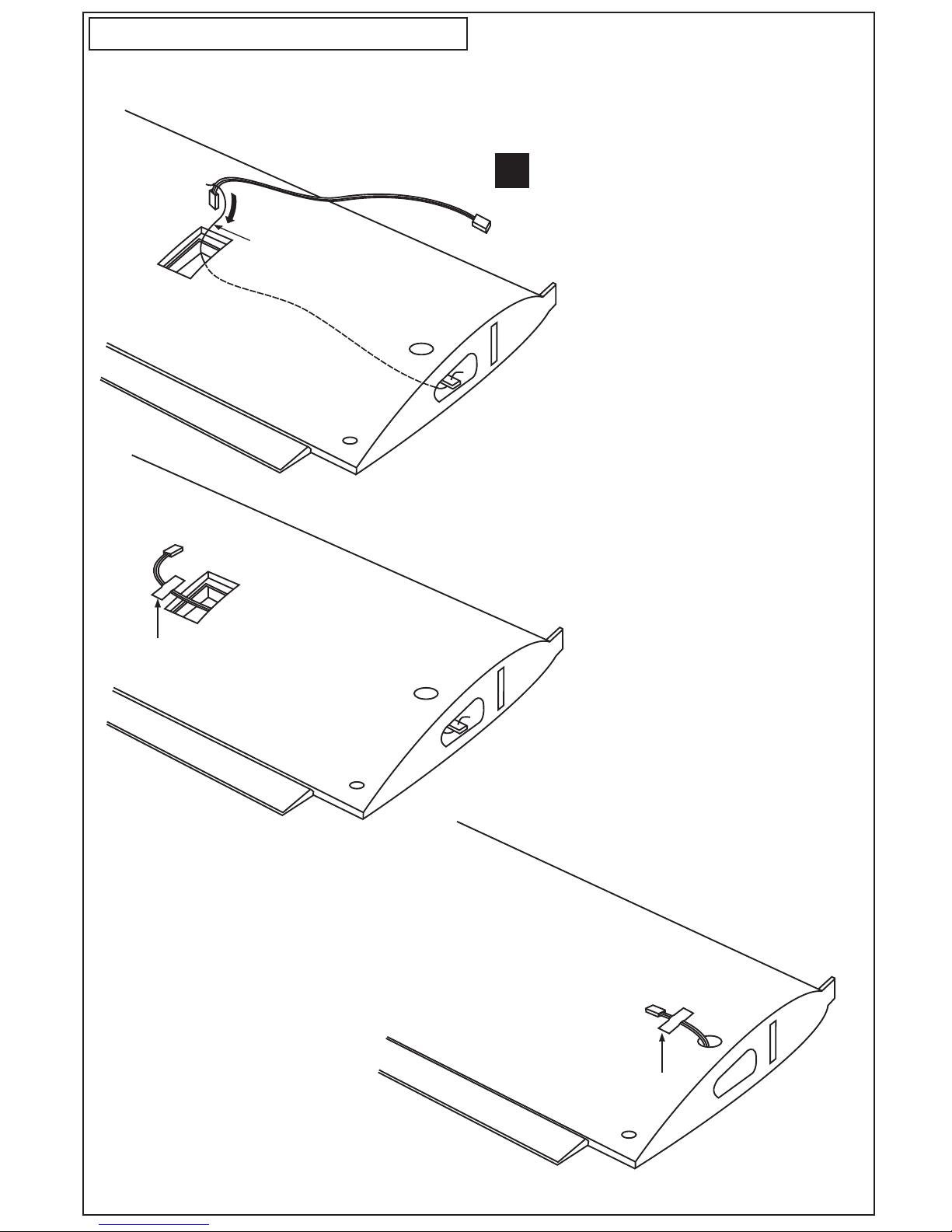

1-Aileron extension cord installation

WING BOTTOM-VIEW

30cm Extension cord

Thread (pre-installed

at factory)

Using the thread (pre-installed at factory) to slide

the aileron extension cord into the wing half.

Using the adhesive tape to secure the one

end of the aileron extension cord in place.

Adhesive tape

Using the adhesive tape to secure the one

end of the aileron extension cord in place.

Adhesive tape

WING BOTTOM-VIEW

WING TOP-VIEW

X

A

B

! Make sure to glue

securely, If not properly

glued, a failure in flight may occur.

2- Joining the wing

A

B

Draw the center line

on the wing joiner

- Trial fit each part before gluing . Be certain that there are no gaps.

If the parts will join, but with a gaps, sand or trim the parts a little

at a time until the parts meet exactly with no gaps.

- Check for the correct dihedral angle

A

B

Glue must go inside

Wing joiner

Glue

Wing half

Rubber band

(not include)

Paper clamp

(not include)

Nylon wing bolt

(included)

Hold the wing halves together with paper clamp

and rubber band

A

B

Before gluing:

- Draw the center line on the wing joiner.

Note: The two wing halves roots must fit together perfectly.

IMPORTANT:

Please do not clean off the excess epoxy on the

wing with strong solvent or pure alcohol, only use kerosene to

keep the colour of your model not fade.

3-Aileron servo installation

1-Cut away the covering of the wing bottom

where the aileron servo goes.

2-Connect the aileron servo cord to the aileron

extension cord.

3-Install the aileron servo on the servo mount.

WING BOTTOM-VIEW

WING BOTTOM-VIEW

Plastic control horn

..........2

...................4

..........2

Included with the

radio set.

X

3mm set Screw

2 mm

Aileron pushrod

D=5/64”(2mm)

-Switch on the radio (trims centered)

then mount the ailerons servo horn

in neutral position.

-The servo horn should be

perpendicular to the servo

YES

NO

WING BOTTOM-VIEW

Hinge Line/Control horn Alignment

A

I

L

E

R

O

N

Depending on the position of

the linkage, determine the location

of aileron control horn.

The horn holes must be perfectly aligned

with the axis of articulation.

Mark the position of the “foot” of the horn on the

aileron. Then, with the drill, make the 2 holes.

Install the aileron control horn as shown.

Adhesive

tape

4- Aileron likage

5- Installing the main gear

3x12 mm screw

4mm collar

Cut away only the film

BOTTOM VIEW

Nylon strap

Main gear

1- Locate the main landing gear struts and place

them into the landing gear slot as show. Make

sure that the ends of the struts are inserted into

the holes in the landing gear channel.

2- Position the four nylon straps across the landing

gear struts. Using the eight 3x12mm screws

located in the hardware bag, fasten the landing

gear to the bottom of the wing as show.

3- Slide one wheel onto each of the

landing gear axles and secure them

with the supplied wheel collars

* WARNING: When removing any covering from the airframe, please ensure that

you secure the cut edge with CA or similar cement. This will ensure the covering remain tight.

Cut away only the

covering both the

left and right side*

Note: Check the alignment of the horizontal stabilizer by measuring from

a fixed point along the center line of the fuselage to the leading edge on

each side of the horizontal stabilizer. The distance must be equal on both

sides. If not, adjust the stabilizer until the measurements are the same.

1-Slide the vertical and horizontal stabilizer on the fuselage, use a pencil to trace

around the bottom and the top (horizontal stabilizer) and the right and the left

(vertical stabilizer).

2-Remove the vertical and horizontal stabilizer from the fuselage. Careful cut

away the covering inside the lines which were marked in steep 1.

Cut away only the covering both

the top and bottom side*

Realign the vertical stabilizer and horizontal stabilizer, then glue

the vertical stabilizer and horizontal stabilizer into the fuselage,

using a generous amount of thin CA.

Note: glue both the right and left of the vertical stabilizer, and

both the top and bottom of the horizontal stabilizer.

CA

Thin CA

Attach the Vertical Stabilizer and the Horizontal Stabilizer

Incorrect

Correct

Incorrect

A

A’

A=A’

A

A’

A=A’

/

B

B’

B=B’

/

B

B’

B=

B’

Nylon strap...4

3x12mm screw...8

4mm collar...2

6- Stabilizer

Rudder rod

Elevator rod

Nose wheel steering

Rudder servo

FUSELAGE - BOTTOM VIEW

8-Servo

Elevator servo

Note: The slots for the control horn

installation are pre- cut at factory.

Push the elevator and its hinges into the hinge slots in the trailing edge of the horizontal stabilizer. There should be a minimal hinge gap.

When satisfied with the and alignment, hinge the elevator to the horizontal stabilizer using thin CA glue.

Do the same way with other elevator and rudder.

Trial fit the hon. Actuate elevator

linkage manually it should not be

hard spot. Adjust if necessary.

Insert the plate through the foot of

the horn.

Bond with thin CA glue.

Do the same way with other elevator

and rudder

CA

ELEVA

TOR

Thin CA

Set elevator to neutral, then cut elevator linkages to length and insert

into the triple connector as pictured.(2)

Adjust neutral and tighten everything. You can use thread lock to

prevent inadvertent loosening.

Insert the rudder linkages from the rear of the fuselage. Screw the

clevis mid-thread, then connect to the rudder horn.(3)

Set the rudder to neutral, then cut rudder linkages to length and insert

into the connector as pictured (4).

Insert “Z” bend of steering wheel linkage inside the hole of front landing

gear steering horn (5).

Insert steering wheel linkage inside outer tube already installed inside

the fuselage from the front.

Elevator

pushrod

Triple connector

Rod stopper

......1

......3

Elevator

pushrod

FUSELAGE - BOTTOM VIEW

Insert the elevator linkages from the rear of the fuselage. Screw the

clevis mid-thread, then connect to the elevator horn.(1)

1

3

2

4

1

5

Set screw

Landing gear steering horn

1-Position the steering horn inside the front landing gear mount already

attached to the firewall.

2-Slide front leg into the bearing and through the horn.

3-Screw steering horn on the leg.

4-Insert steering linkage into rod stopper installed on rudder servo arm.

Adjust neutral position of the nose wheel. Tighten adjustable rod

stopper.

7- Rudder and elevator

9- Front landing gear

Nose gear mount...1

3x12mm screw....4

Steering horn...1

X

To muffler

Filler tube

To engine

3x35mm screw

Rubber stopper

11-Fuel tank

Ensure that the fuel tank clunk

does not touch the rear of the

fuel tank.

Checking for leaks - block the

vents and blow into the feed if in doubt submersing the tank

in a blow of water will show up

any problems.

Blow

Water

2

1

3

After confirming the direction .

Insert this assembly, clunk end

first, into the fuel tank and

tighten and screw the fuel tank

cap on firmly.

Carefully install the fuel tank to ensure that they will not

shift during flight (secure the fuel tank in place using foam padding).

2-Secure foam padding with rubber bands or tape.

3-Shift the location of the receiver and battery pack as

needed to obtain the specified CG.

4-Carefully install the receiver and battery pack to ensure

that they will not shift during flight.

8mm

25mm

AILERON STROKE

ELEVATOR STROKE

RUDDER STROKE

8mm

12mm

12mm

25mm

13-Control surface-balance

CG

In order to obtain the CG specified, reposition the receiver and

power pack

85mm

Wing center section

Switch

FUSELAGE

BOTTOM VIEW

Throttle servo

Install the engine

Throttle linkage

1-Attach with the delivered screws the engine mount in place.

2-Install the engine.

3-Install throttle servo inside the fuselage.

4-Slide the throttle linkage in its outer tube from the front of the fuselage and

insert the “Z” bend in the carburetor throttle lever.

5-Install an adjustable rod stopper on the servo arm, the attach the equipped arm on the servo.

6-Insert the rod into the stopper, adjust throttle linkage travel. Caution should never force at end points

(full throttle and idle). Once the throttle control set up, tighten the rod stopper.

FUSELAGE - BOTTOM VIEW

RECEIVER

Rx battery

pack

1-Install RC switch (the hole is already cut on fuselage side.

(3.3in.)

10- Engine installation

Magnetic tank hatch.

Pull here to open

12-Radio

Loading...

Loading...