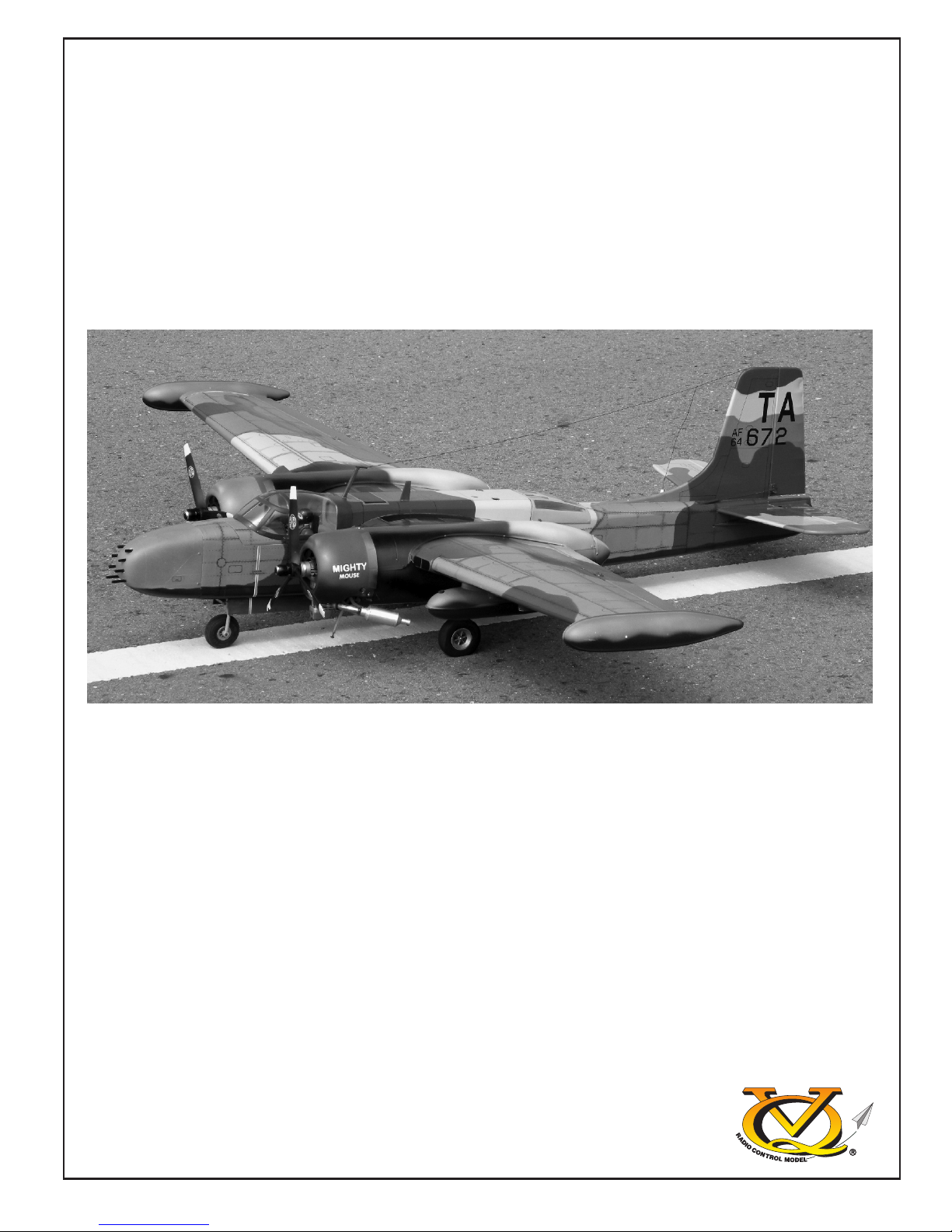

Radio control model / RC Motorflugmodell

WINGSPAN: 68.in. / SPANNWEITER: 173cm

TWIN .25 - .32 CLASS - 2 CYCLE ENGINE

TWIN .40 - .52 CLASS - 4 CYCLE ENGINE

ZWEITAKTMOTOREN: 4 - 5.2cc (X2)

VIERTAKTMOTOREN : 6.5 - 8.5cc (X2)

WARNING: This radio control model is not a toy. If modifier or flow carelessly, it could go out of

control and cause serious bodily injury or propety damage, It is you responsi-bility to build this kit

correctly, to properly install all components and to seek the help of an experi-enced R/C pilot for a

pre-flight safety inspection and test flying

Achtung: Dieses Modell ist kein Spielzeug!

Sollten Sie mit solch motorisiertem Modell keine Erfahrung haben, wenden

Sie sich bitte an erfahrene Modellflieger, die Sie unterstützen können.

Es könnte zu Verletzungen kommen, wenn das Modell ohne Vorkenntnisse

in Betrieb genommen wird. Denken Sie immer an die Sicherheit und Ihre Gesundheit.

ASSEMBLY INSTRUCTION / AUFBAUANLEITUNG

A26K COUNTER INVADER

Teppichmesser

Needle nose Pliers

Kreuzschlitzschraubenzieher

Awl

Scissors

Wire Cutters

Hex Wrench

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

.........................................................

Sander

1.5mm

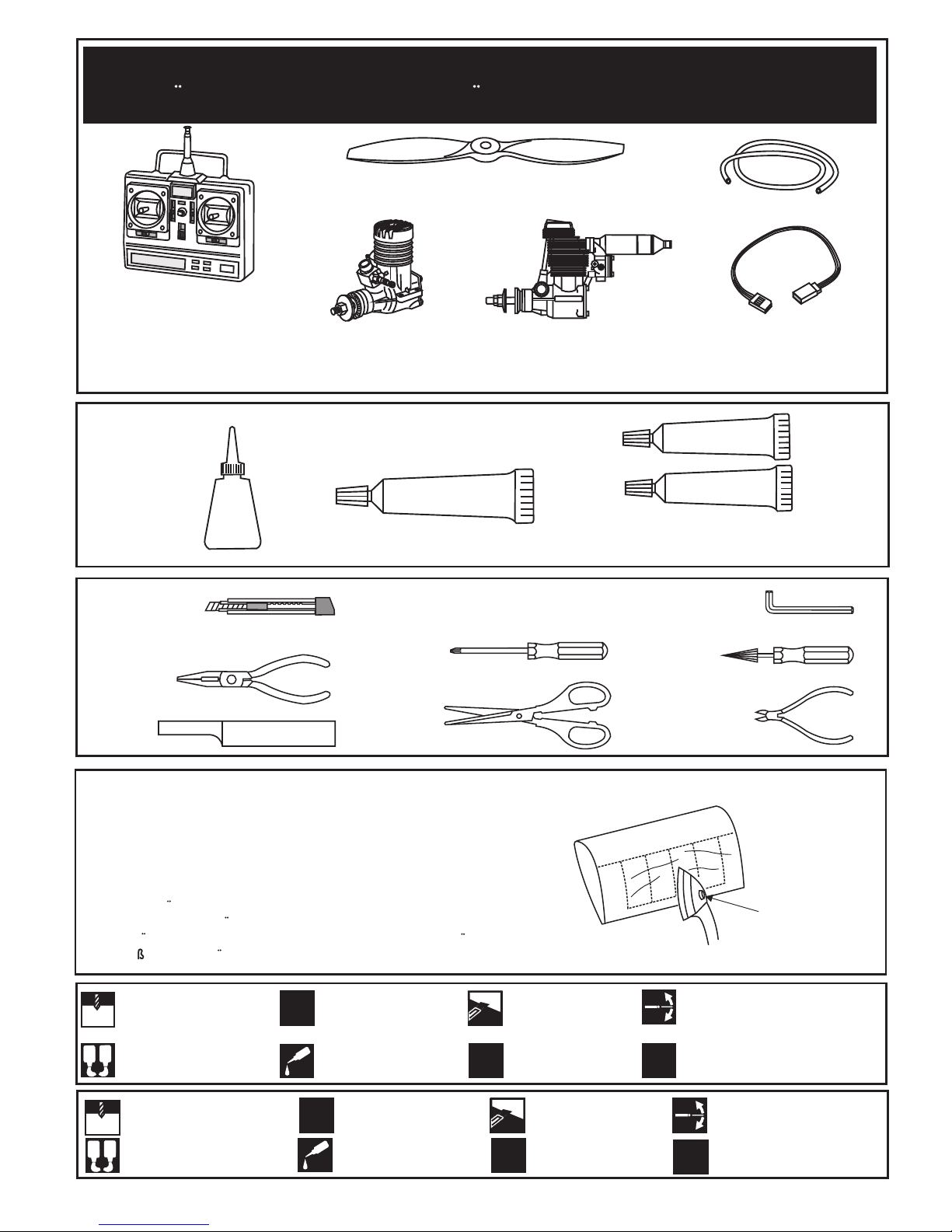

A

B

!

CA

L/R

Assemble left and right

sides the same way.

X

Drill holes using the stated

size of drill

(in this case 1.5 mm Ø)

Use epoxy glue

Take particular care here

Hatched-in areas:

remove covering

film carefully

Not included.

These parts must be

purchased separately

Check during assembly that these

parts move freely, without binding

Apply cyano glue

SILICON

EPOXY A

EPOXY B

CA

Epoxy Glue (30 minutes type)

Silicon sealer

Cyanoacrylate Glue

Klebstoff

Epoxy-Klebstoff (30min-Typ)

Hobby knife

Nadelzange

Pfeile

Phillip screw driver

Schere

Pfriem

Kneiftzange

1.5mm

A

B

!

CA

L/R

X

Schraffi er te Stelle n,

Bespannfolie vorsichtig

entfernen

Epoxy-Klebstoff verwenden

Linke und rechte Seite

wir d gleic he rmaßen

zusammengebaut

Hier besonders aufpassen

Während des Zusammenbaus

immer prüfen, ob sich die Teile

auch reibungslos bewegen lassen

Nicht enthalten. Teile müssen

separat gekauft werden.

Sekundenkleber auftragen

Löcher bohren mit dem angegebenen Bohrer (hier 1,5 mm)

The pre-covered film on ARF kit may wrinkle due to variations

of temperature. Smooth out as explained right.

* Use an iron or heat gun. Start as low setting. Increase the

setting if necessary. If it is too high, you may damage the

film.

Die Bespannung des ARF-Kits kann je nach Temperatur Falten

werfen. Glatten Sie diese, wie rechts auf der Abbildung ersichtlich.

Benutzen Sie ein Bugeleisen. Starten Sie in einer niedrigen Stufe,

un erhohen Sie diese nur wenn notwendig. Wenn das Bugeleisen

zu hei wird, beschadigen Sie die Bespannung.

Low setting

Niedrige Stufe

Minimum 6 channel radio

for airplane / 6 servos.

.40 ~ .52 cu.in. (X2)

9 x 7 for .32 - 2 cycle engine (x2)

10x7 for .52 - 4 cycle engine (x2)

Silicone tube

Extension cord x 4

.25 ~ .32 cu.in. (X2)

REQUIRED FOR OPERATION (Purchase separately)

Minimum 6 Kanal

Fernsteuerung / 6 servos.

Servoverlangerungskabe x 4l

BENOTIGTE KOMPONENTEN FUR DEN ABFLUG (Nicht enthalten)

4 ~ 5.2 cc (x2)

6.5 ~ 8.5cc (x2)

Throtle servo x2, Aileron servo x 2

Rudder servo x 1, Elevator x 1

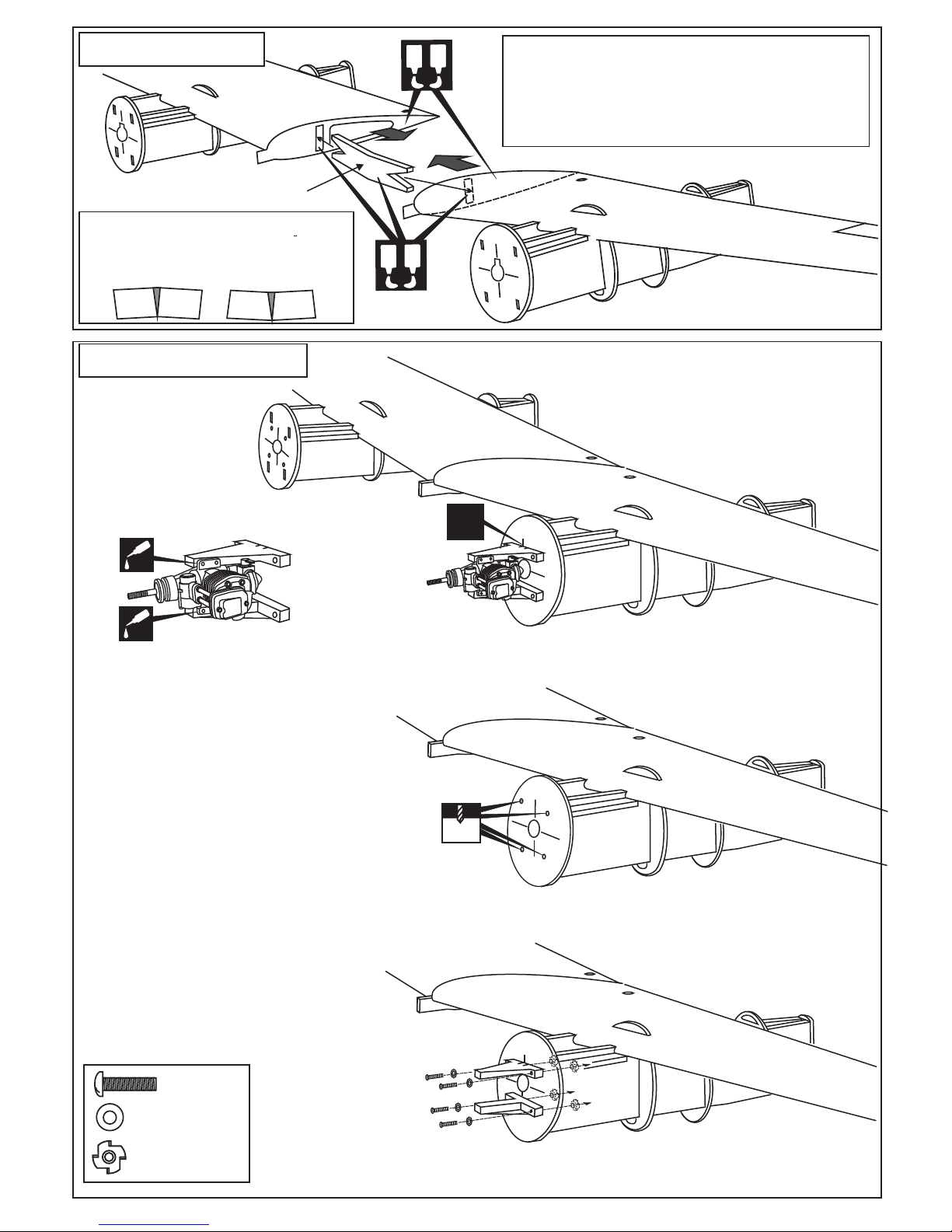

A

B

A

B

Securely glue together, If coming off during flights,

you lose control of your airplane which leads to

accidents !

Use epoxy glue to bury the opening

!

4x15mm...(8)

Washer....(8)

Blind nut 4mm (8)

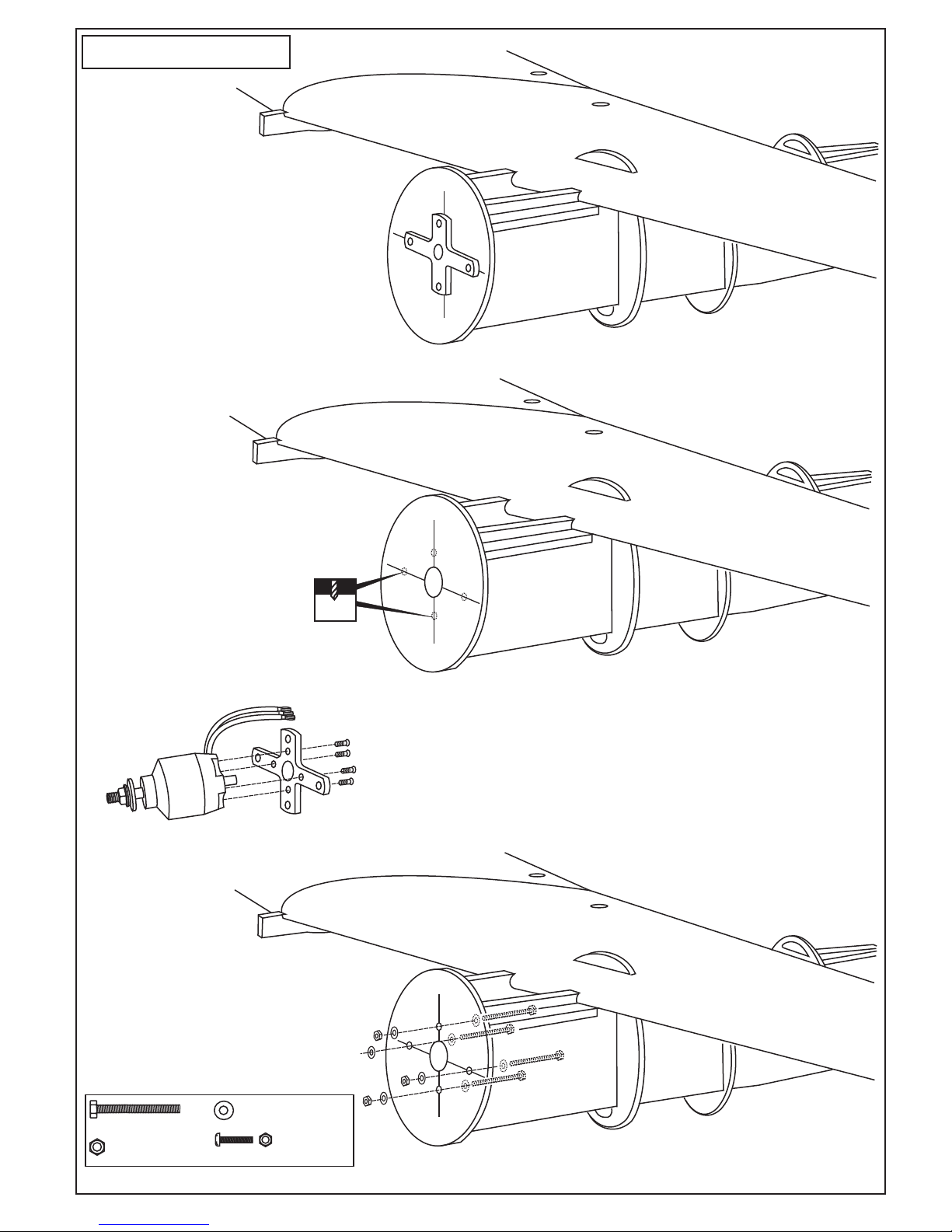

Set the engine on the engine mount and

secure it in place using little CA glue

Apply the engine mount on the fire wall

as shown (Align the mark on both mounts

with the mark on the fire wall).

Mark the mounting hole positions with

a felt tipped pen or pencil.

Remove the engine mount and drill four 4mm

holes through the

fire wall as shown.

Remove the engine out of the engine

mount, then secure the engine mount

to the fire wall with four 4x15mm screw.

1- Wing

/ Fläche

Tragflächenverbinder

Wing joinner

2.Engine / Motor

Nehmen Sie Epoxykleber, um die Tragflachen fest

miteinander zu Verbinden und streifen Sie den

herausquellenden Kleber nach dem Verbinden mit

einem fusselfreien Tuch SOFORT ab!

Vergewissern Sie sich, sauber geklebt zu haben

Andernfalls konnen Probleme mit der

Flugeigenschaft auftreten !

!

!

!

4mm

5/32”

1

1

2

2- 3

3

4

4

5

5

CA

CA

In case of

4-cycle engine

In case of 2-cycle

engine

Mark

Zweitaktmotoren

Viertaktmotoren

Filler tube

Foam

X

To muffler/

Filler tube /

To engine

3x35mm screw / schraube

Rubber stopper

1

4-Fuel tank /

WING - TOP VIEW / AUFSICHT

After confirming the direction . Insert this

assembly, clunk end first, into the fuel tank

and tighten and screw the fuel tank cap on

firmly.

3x35 mm screw

4mm

2

1

2

3

L/R

Kraftstofftank

Überlauf

Tanken

zum Motor

zum Motor

Überlauf

Tanken

Tanken

Filler tube /

3mm

1/8”

- Reposition the engine on the engine mount beams, aligning it with

the holes. Secure the engine to the engine mount using four

1/8x51/64”(3x25mm) screws.

Note: Apply Silicon sealer to

each of the screw and nut.

Mark

3.Engine / Motor

6

Checking for leaks - block the vents and blow into

the feed - if in doubt submersing the tank in a blow

of water will show up any problems.

Blow

Water

3

Attach the aluminum motor mounting plate on to the motor and

secure it in place with four screws ( included with motor set).

Push the four 4x60mm bolts through the

fire-wall as shown.

4x60mm.......4

4mm nut....12

4mm washer...16

3mm screw/nut...4

Using a aluminum motor mounting plate as

a template, mark the plywood motor

mounting plate where the four holes are

to be drilled .

Remove the aluminum motor mounting

plate and drill a 5/32”(4mm) hole through

the plywood at each of the four marks

marked .

4mm

5/32”

1

1

2

2

3

3

4

4

5.Electric motor

3x10 mm screw

Nylon strap /

Gear mount

Ply gear

Square plastic

Main gear /

Apply epoxy

glue

3x10

mm

1/8x25/64” screw

L/R

7- Fixed gear / Fahrgestell

....X 16

3x10mm schraube

WING - BOTTOM VIEW / UNTERSICHT

Kunststoffstreifen

Landegestange

Mount plate

2 mm

5/64”

3x10mm schraube

2 mm

L/R

X

X

Throttle servo

Air retract

landing gear (option)

Einziehbares

Fahrwerk (optional)

Throttle

rod

WING - BOTTOM VIEW

UNTERSICHT

Drosselservo

Gewindestift M3

CA

CA

Throttle servo mount

(3mm plywood)

6x6mm

hard wood

IN CASE OF 2T ENGINE (ZWEITAKTMOTOREN)

BOTTOM VIEW / UNTERSICHT

CA

Throttle servo mount

(3mm plywood)

IN CASE OF 4T ENGINE (VIERTAKTMOTOREN)

6x6mm

hard wood

BOTTOM VIEW / UNTERSICHT

L/R

L/R

TYPICAL INSTALLATION

“T” connector

Filler valve

Wheel collar on air line will provide

control of retract speed for scale

use.

Air tank

Retract servo

Valve

8- Air Retract landing gear

Einziehbares Fahrwerk (optional)

9- Air Retract landing / Einziehbares Fahrwerk (optional)

CA

L/R

3 ~ 5 mm

13. Cowling / Motorhaube

1.5mm

1/16”

2 mm

5/64”

5/64x25/64”screw screw

2x10mm schraube

3/32x25/64”(2.5x10mm)

................6

Cut the opening

1/8 ~ 13/64”

3/32x25/64”screw

2.5x10mm schraube

5/64x25/64”screw

2x10mm schraube

..................46

5/64x25/64”screw screw

2x10mm schraube

X

X

Cut away

only the covering

2x10mmschraube

X

Aileron pushrod

Aileron servo arm

Aileron servo extension cord

Use the fishing line inside each wing to lead the aileron and

throttle servo extension cord all through the wing.

5/64x31/64” screw

2x12mm schraube

CA

15- Control horn /

L/R

Cut away only the

covering both side

A

A’

!

A=A’

Securely glue together. If

coming off during flights.

You lose control of your plane

B

B’

B=B’

Cut away only the

covering both side

C

C’

D

D’

C

=

C’

=

D

D’

A

B

A

B

14- Stabilizers /

Fin

Horizontal tail

Horizontal tail

Fuselage

1

2

3

1

2

3

Trial fit each part before gluing . Be certain

that there are no gaps. If the parts will join,

but with a gaps, sand or trim the parts a

little at a time until the parts meet exactly

with no gaps.

When joining the stabilizer it is extremely

important to use plenty of epoxy (30 minutes)

Carefully slide the stabilizer onto the fuselage,

ensuring that they are accurately aligned,

Firmly press they are together, allowing the

excess epoxy run out. Using rubbing alcohol

and paper towel, clean off the excess

epoxy.

Höhenruder -

Höhenleitwerk

Einbau RC-Ruderhorner

Sc h r a f f i e r t e St e l l e n ,

Bespannfolie vorsichtig

entfernen

Sc h r a f f i e r t e St e l l e n ,

Bespannfolie vorsichtig

entfernen

Vergewissern Sie sich, sauber geklebt

zu haben Andernfalls konnen Probleme

mit der Flugeigenschaft auftreten !

Plastic control horn

...............3

....................6

5/64x31/64” screw

2x12mm schraube

HORIZONTAL STABILIZER

TOP

BOTTOM

X

Elevator pushrod

3mm set Screw

2 mm

Elevator servo

Rudder servo

Retract servo here

Air tank here

Elevator pushrod

Rudder pushrod

Elevator pushrod

Elevator servo

X

Rudder pushrod

3mm set Screw

2 mm

Rudder servo

FUSELAGE - TOP VIEW / AUFSICHT

Rudder pushrod:

E2&E1

R

Elevator pushrod:

17- Linkages /

Linkage stopper

....................1

....................3

...........................6

3x4mm set crew

Elevator servo

Rudder servo

E1

E2

R

E1

E2

R

16- Installing the radio /

Einbau RC-Anlage

Höhenruderservo

Rudergestänge

Gewindestift M3

Gewindestift M3

Rudergestänge

Seitenruderservo

Höhenruderservo

Ruderanlenkung

Höhenruderservo

Seitenruderservo

Höhenruderservo :

E2&E1

Seitenruderservo :

R

Nose gear pushrod

(In case of mechanic

retract)

Nose gear pushrod:N

N

Nose gear pushrod: N

Seitenruderservo

Seitenruderservo

19-canopy /

Kabinenhaube

5/64x13/64”screw

2x5mm schraube

..............4

6X50mm

...2

15/64x2” bolt

15/64x2” bolt

Nose gear servo tray

(for electric retract)

CA

CA

A-26

F3

VBT

A-26

18- Linkages /

Ruderanlenkung

In case of mechanic retract landing gear

A-26

F3

A-26

20- Linkages /

Ruderanlenkung

In case of electric retract landing gear

Rudder servo

Nose gear servo

4mm nose gear

To rudder servo

Nose gear pushrod

Nose gear base (plastic)

Nose gear arm

3x15mm screw

X

Nose gear mount

21- Nose gear (Fix gear)

Bugfahrwerk

1/8”(3mm) nut

X

Air tube

3x15mm schraube

1/8”(3mm) nut

.................4

...4

1/8x19/32” screw

FUSELAGE BOTTOM VIEW

UNTERSICHT

Nose gear arm

5/32” ID collar

.................1

.............1

4mm stellring

5/32” ID collar

4mm stellring

22- Installation R/C /

Ruderanlenkung

Batterie

Empfänger

Nose gear (air retract)

Bugfahrwek

X

FUSELAGE BOTTOM VIEW

UNTERSICHT

Air tank here

AILERON

RUDDER

ELEVATOR

½ in (13mm)

½ in (13mm)

½ in (13mm)

½ in (13mm)

¾ in (20mm)

¾ in (20mm)

4.3 in. (110mm)

25- Balance

/ Schwerpunkt -

Ruderausschläge

SEITENRUDER

QUERRUDER

HÖHENRUDER

CA

Cut away only

the covering

Cut away only the covering

23- Wing shield

When you are satisfied with the alignment, use a pencil trace around the bottom of the

wing shield where it meets the wing, Remove the wing shield from the wing, cut away

the covering inside the pencil lines. Not to cut into the wood.

Sc hraffi erte St ellen,

Bespannfolie vorsichtig

entfernen

CA

Cut away only

the covering

24- Decor / Dekor

CAUTION

PROPELLER ROTATION

26- Decor / Dekor

T

A

AF

FIRE EXTINGUISHER

T

A

AF

A26 - VIET-NAM WAR - DECAL SHEET .VQ MODEL

FIRE EXTINGUISHER

FIRE EXTINGUISHER

NO STEP NO STEP

NO STEP NO STEP

T

A

AF

Loading...

Loading...