Page 1

VPFlowScope 35 bar

VPINSTRUMENTS.COM

User manual

© 2018 Van Putten Instruments BV

AN-VP-SP35-UK-1800 Date:23-02-2018

Page 2

All rights reserved. No parts of this document may be reproduced in any form or by any means - graphic,

electronic, or mechanical, including photocopying, recording, taping, or information storage and retrieval

systems - without the written permission of the publisher.

Products that are referred to in this document may be either trademarks and/or registered trademarks of the

respective owners. The publisher and the author make no claim to these trademarks.

While every precaution has been taken in the preparation of this document, the publisher and the author

assume no responsibility for errors or omissions, or for damages resulting from the use of information

contained in this document or from the use of programs and source code that may accompany it. In no event

shall the publisher and the author be liable for any loss of profit or any other commercial damage caused or

alleged to have been caused directly or indirectly by this document.

Creation date: 23-02-2018 in Delft

VPFlowScope 35 bar

© 2018 Van Putten Instruments BV

Publisher

Van Putten Instruments BV

Buitenwatersloot 335

2614 GS Delft

The Netherlands

Page 3

3Contents

3

Table of Contents

1

Warning - Read this first

4

2

Installation step by step

5

3

Specifications

7

Page 4

© 2018 Van Putten Instruments BV | AN-VP-SP35-UK | Revision:1800 | Date:23-02-2018

4 VPFlowScope 35 bar

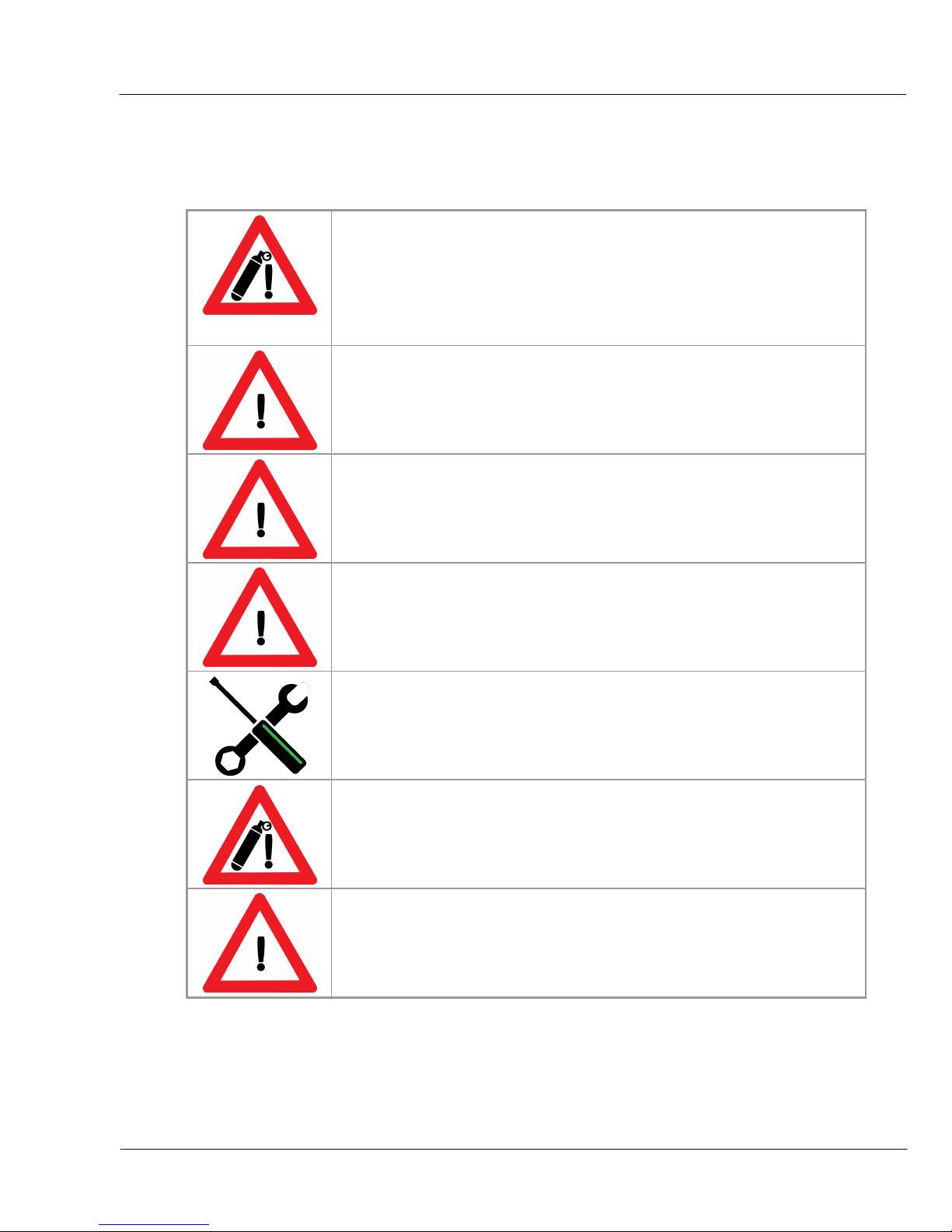

1 Warning - Read this first

Compressed air can be dangerous! Please familiarize yourself with the

forces under pressurized conditions. Respect the local guidelines and

regulations for working with pressurized equipment.

The pressure on the probe at 35 bar / 500 psi is around 40 Kilogram / 88

pounds force

! WARNING Mounting of this unit should be in De-Pressurized lines only !

Mount two safety chains, one to keep the probe in place, one for safety. Make

sure the hooks are completely closed. Make sure that the chains are strained as

these chains will keep the probe in position.

Use both safety eyes, to keep the force on the probe equal. Securing the probe

on one side will cause the probe to bend.

Use compression fittings with stainless steel ferrules. Please note that stainless

steel will permanently indent the probe and it cannot be used for any other

installation anymore.

Pressurize the system gently, 250 mbar per second. Fast pressurization may

result in shifting of the probe due to the pressure shock.

INSPECT the system after 30 minutes to see if the probe is still at the same

height. Systems with VIBRATIONS may be causing shifting of the probe.

Order numbers:

High pressure option for VPFlowScope probe

VPA.0001.092

Compression fitting with stainless steel ferrule

VPA.0001.003

Page 5

© 2018 Van Putten Instruments BV | AN-VP-SP35-UK | Revision:1800 | Date:23-02-2018

5

2 Installation step by step

The following cartoons show how to install the probe in a 35 bar system. in addition to the

compression fitting with stainless steel ferrules (rated well over 35 bar) we recommend to use two

safety chains, for redundancy.

Page 6

© 2018 Van Putten Instruments BV | AN-VP-SP35-UK | Revision:1800 | Date:23-02-2018

6 VPFlowScope 35 bar

Compression fitting instructions

NOTE: the following instructions apply to stainless steel ferrules only. For use with teflon ferrules,

there are no specific guidelines. This is why we do NOT recommend to use teflon ferrules in high

pressure systems.

Step 1:

Before tightening the nut, mark the 6 'o clock position

Step 2:

When fixing, use a wrench. Tighten the nut 1 ¼ turns. The mark on the nut turns 1-1/4

and will end at the 9 o’clock pos ition. Make sure the probe stays aligned during the

process.

If not, gently loosen the nut, align the probe and tighten it again. Rough turning of the

probe can cause scratches in the stainless steel and this might result in leakage.

Page 7

© 2018 Van Putten Instruments BV | AN-VP-SP35-UK | Revision:1800 | Date:23-02-2018

7

3 Specifications

Please always check the label of your product for the specifications.

Specifications are subject to change as we are continuously improving our products.

Please contact us to obtain the latest specification sheet.

Flow sensor

(minimum detection level and max flow rate shown)

Flow range

0.5...150 mn/sec

1.7…492 sfps

Accuracy

2% of reading under calibration condition

Recommended pipe diameter: 40mm | 1.5 inch and up

Reference conditions

0°C, 1013.25 mbar - DIN1343

32°F, 14.65 psi

Gas temperature

0...60°C

32...140°F

Gases

Compressed air, non aggressive gases and non combustible gases,

95% non condensing gases

Pressure sensor

Range

0...35 bar gauge

0…500 psi gauge

Accuracy

+/- 1.5% FSS (0...60°C)

+/- 1.5% FSS (32...140°F)

Temperature sensor

Range

0...60°C

32...140°F

Accuracy

+/- 1° (from 10 mn/sec and up) (At zero flow conditions, temperature

reading increases due to self-heating by the flow sensor)

Display

Technology

Liquid crystal

Back light

Blue with auto power save

Memory

2.000.000 point memory

Mechanical

Probe length

400 mm

15 inch

Probe diameter

12.7 mm

0.5 inch

Process connection

Compression fittings, 0.5 inch, NPT thread

Pressure rating

See product label. Only rated for high pressure when fixed with

stainless steel ferrules.

IP grade

IP52 when mated to display module

IP63 when mated to connector cap

Wetted materials

Alu, SS316, epoxy

Ambient temperature

0...60°C

32...140°F

Ambient humidity

10 - 95%. Avoid condensation at all times

Inputs and outputs

Analog

4..20mA or pulse, selectable via installation software

Serial IO

Modbus RTU

Supply

12..24 VDC +-10% CLASS 2 (UL)

Power consumption

150mA at 24VDC

Page 8

EASY INSI GHT I NTO ENERGY FLOWS

AN-VP-SP35-UK-1800

Date: 23 -02-201 8

Bui tenwaters loot 335

261 4 GS Del ft

The Nether lands

info@vpinstruments.com

www.vpinstruments.com

VPInstruments

Loading...

Loading...