Page 1

1

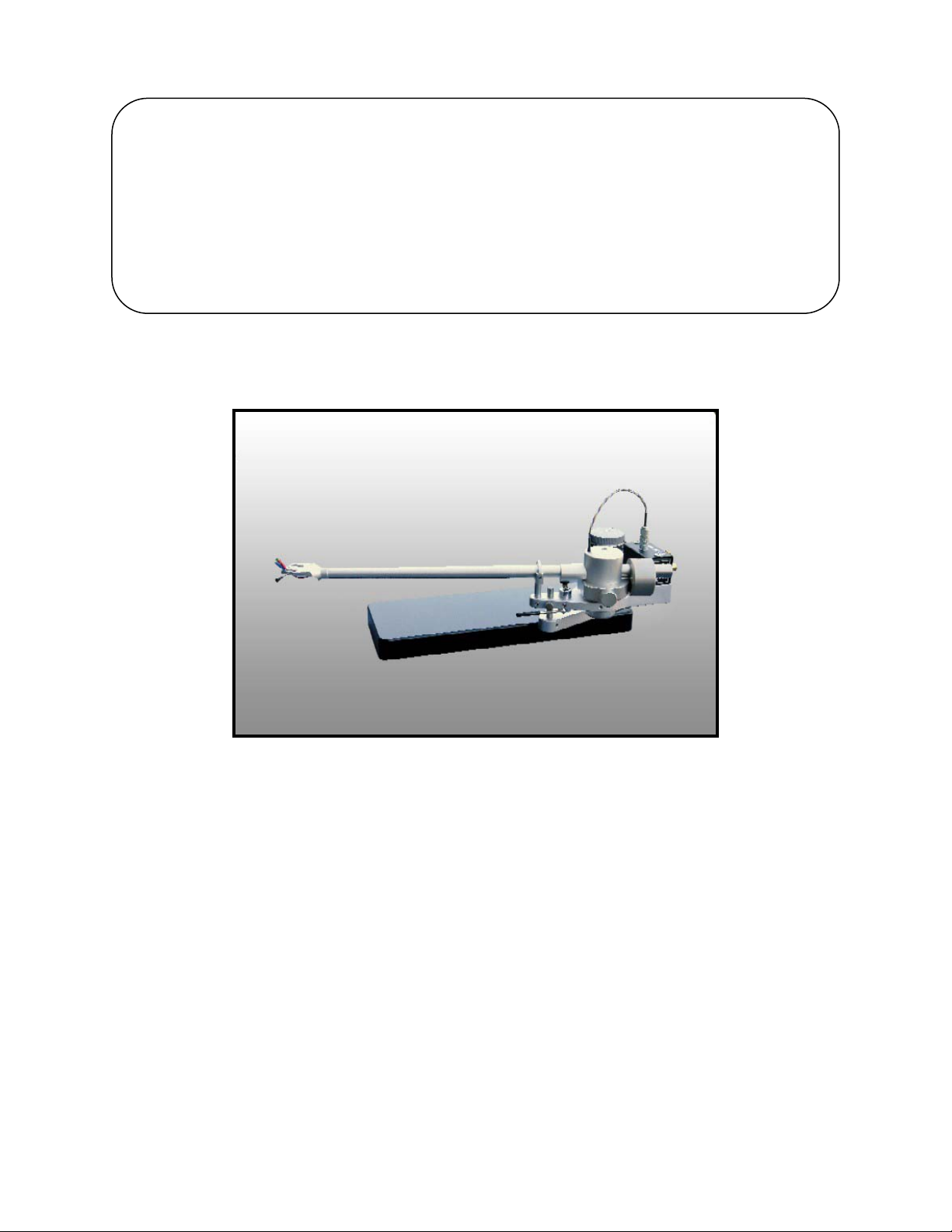

THE JMW-12.7 TONEARM

SETUP AND INSTRUCTION

MANUAL

VPI INDUSTRIES INC., 77 CLIFFWOOD AVE #3B, CLIFFWOOD N.J. 07721

PHONE: 732-583-6895, FAX: 732-946-8578

www.vpiindustries.com

Page 2

2

SETTING YOUR JMW 12.7 MEMORIAL TONE ARM

• You will see a number of th ings in pl astic ba gs:

• Allen wrenches

• Hex nuts, and washers (for cartridge mounting)

• Ar m mounting and alignment tool

• Shure stylus gauge

• Take all these items out and set them aside

A. CARTRIDGE MOUNTING:

• Remove the arm tube from the box (taking special care not to strain or damage, the delicate 4-

color wire and Lemo connector) and place it right side up o n t he foam pad.

FOR CARTRIDGES WITH THREADED MOUNTING HOLES:

• Use the screws supplied by the cartridge manufacturer to mount the cartridge. Any other

screws may not fit the thread pr operly and may even damage the threads and cart ridge. USE

ONE OF THE SUPPLIED WASHERS UNDER THE S CREW HEAD.

• For all cartridges with pass t hrough mounting holes use the hardware supplied with the arm.

Remember t o use the washers under the screw heads to pr event damage to the finish on the

JMW arm.

• In this step, the connecto r s will be att ached to the cartridge's terminals. Disregard the color of

the insulato r s on the cartridge clips.

THE COLOR COD E OF TH E WIRES IS AS FOLLOWS:

WHITE = left hot

RED = right hot

GREEN = right ground

BLUE = left ground

IF YOUR PHONO SECTION INVERTS P HASE, THE HOT BECOMES

THE GROUND COLOR

• The arm tube should be on its s ide on the foam pad when doing t his.

• Using tweezers or fine tipped pliers, grip the center of the red wire's connector (do not grip

the wire) and push it o nto the cartridge's right hot terminal pin. In the same way, connect

each of the remaining connectors to its respective cartridge terminal. Do not push the

connectors all the way on, as this could damage the cartr idge. Always back up the cart ridge

with yo ur finger when pushing on the c lips.

Page 3

3

• At the rear o f the arm base assembly is the connector block. Plug the Lemo connecto r into its

receptacle on top of the block. N otice that the connector can plug in only one way. Align the

red dot s on the arms plug with the red dot on the receptacle. Push gently do not force the

plug.

B. THE COUNTERWEIGHT:

• The JMW 12.7 tone arm comes with one large co unter weight installed on the rear shaft of the

tonearm. For most cart ridges you will only need this large weight. The counter weight is held

in position by a setscrew.

• The counterweight is used for setting the azimuth (lateral balance) of the cartridge and the

vertical tracking force.

• For now, po sition t he large count erweight t o give a minimum of tracking force, just enough

force to keep the cartridge on the alignment jig.

• In some rare cases it may be necessary to use two counterweights together. Contact your

dealer if a second counter weight is needed.

C. OVERHANG ADJUSTMENT & ALIGNMENT

• Th is adj ustme nt w ill yie ld t h e low e s t over a ll di s tor tion whe n pl a yin g a typi c a l 12" r e co rd. Do

not go crazy over this adjustment. You do not know if the stylus is aligned properly on the

cantilever. Yo u are also facing a constantly moving tar get when playing a record. The arm is

moving in 3-dimensions and will only approximate the accuracy you have built into your

alignment.

• Wit h t he a rm wa nd r emo ve d pla ce the Align ment Jig into po sit io n by slidi ng t he “V” cut o ut

against the male bearing and the hole over the spindle. If loose, adjust using the two scr ews.

Page 4

4

• Place the arm in its rest and apply enough tracking force to keep the stylus from moving.

Loosen the screws that hold the cartridge just enough so that t he cartridge can be moved back

and fo rt h.

• Carefully swing t he arm over the grid at the far end of the jig and place the stylus as close to

the do t in t he c en t e r of th e grid a s po s s ible . Us ing a ligh t e d magn ifie r will ma ke t his jo b ve ry

easy.

BE VERY CAREFUL NOT TO DAMAGE THE CARTRIDGE STYLUS:

• Move the cartridge so that the stylus rests on the dot. Now, viewing the cartridge from

abo ve, line it up so t hat its sides are symmetrically positioned bet ween the lines of the grid. If

the cartridge has parallel sides, these should be made parallel to the grid lines. Also make sure

that the cartridge is centered between the sets of lines. Follow figure 3 in the back of the

manual.

(JIG SHOWN IN WHITE FOR CLARITY)

• Double check the adjustments made above. The cartridge needs to be both centered and

"square" between the grid lines and have the stylus resting on the dot.

• The alignment gauge does no t h a ve a hole or di mple to h old the stylus. Wh ile the printe d dot

makes it harder t o ke ep the stylus in place, this method was cho sen to avoid the possibility of

damaging the stylus cantilever or t he diamond tip as the cartridge is positioned.

• Place the arm back in its rest.

• Without letting the cartridge move, tighten the screws holding the cart ridge to t he arm head.

Make it tight, but don't over do it and strip the threads or distort the cartridge body.

D. TRACKING FORCE:

• Moving the c ounter weight forward and back adjusts tracking force.

Page 5

5

• A Shure Stylus Force Gauge is supplied with your unit. Follow the gauge instruct ions and set

the tracking force to t he cartridge manufacturer’s highest recommendation plus 1/10 of a

gram more. We always recommend go ing t o the high side when it comes to tracking force.

High frequency vibrations can make a light t racking cartridge do more damage to t he gro oves

than running a cartr idge at a heavy setting.

E. AZIMUTH

• Next, the lateral balance or azimut h must be set. Because the phono cart ridge is offset, there

is an unbalancing for ce that t ilts t he arm to one side. For the cart ridge to pro perly tr ack the

record groove, the stylus must be ninety degrees to the record surface. Move the

counterweight so a slight tracking force is applied and the stylus just sits on the record

surface.

• By rotating the counter weight you can t ip the arm in either direct ion. Set the counterw eight

so t he cartridge sits as shown below. Do not move the counter weight front and back while

doing this, just side to side. If the arm is tipped to war ds t he left side rot at e the counterweight

so the botto m mass moves towards t he right. This will level t he arm.

Long thin rod

90 degrees

E. ANTI-SKATING:

• A piv o t e d ar m w ithout an o ffset head would not be subject to skating force. How ever, it will

also have no correction for tracking error and the resulting distortion is unacceptable. As

soon as the arm's head is offset to lower tracing distortion, skating force arises. Greater

offsets result in great er skat ing force. The 12” arm has a very small offset angle and therefore

a very low skat ing force to de al with.

Page 6

6

• After very careful listening tests we have determined that every tonearm we tried sounded

better with their mechanical anti-skating disabled and the tracking force very slightly

increased. All mechanical anti-skate devices add a negative sound t o the music because they

are made of parts that can vibrate. We solve the problem in a unique way:

• As me ntio n ed e a rlie r, t he arm wire applies the anti-skating force. The degree o f force applied

can be adjusted as explained below.

• To increase or decrease t he amount of anti-skating force applied, simply unplug the Lemo

connector and twist it in the direction you want the force applied.

• For example, to increase anti-skating force give the connector a counterclockwise twist,

unwinding the coiled wire. Likewise, to decrease t he force, give the connector a clockwise

twist. Remember, t he Lemo co nnect or can only be "adjusted" in increment s o f who le tur ns.

If it is not, its key will no t lin e up wit h t he gro ov e in the r eceptacle.

• We could go on discussing the pros and cons of how much anti-skate is correct, but t he sonic

answer is very simple. Adjust the wire as mentioned above until the tonearm drifts outward

when set to neutr al balance. When you push the neutral balance floating tonearm towards

the center of the reco rd, it should push back out towards the rim of the record. Very little

force is needed to do t his, and the wire acts like a spring to supply this force.

• If you try adjusting the anti-skate with a groove less record or a test record you will

ruin the twist in the wire and void your warrantee

• Double check the horizontal balance, lateral balance, and tracking force and adjust as needed.

Increase the tracking force by 1/10 of a gram above the cartridge manufacturers highest

recommended force.

G. ARM HEIGHT:

NOTE: THE TWO THUMBSCREWS MUST BE RELEASED WHEN MOVING THE

VTA KNOB. THE THUMBSCREWS S H O U LD BE TIGHTENED WHEN LIS TEN ING .

Unlike many t o ne a rms, t he JMW's height is bo t h eas y and r epe at able t o var y. The kno b next t o

the bearing housing bears a scale numbered from zero to ninety-nine. Belo w the kn o b t he r e is a n

index mark engrave d on t he fro nt of t he supp ort pillar. Rot ating the knob clockw ise lowers t he

arm and rotating it counterclockwise raises it.

Set t he arm height as follows:

• Place a recor d o n the platt er surface. Lower t he arm onto t he record and make the arm tube

parallel to the record surface by rotat ing the arm-height knob a s ne eded.

• This is a good initial setting. You may wish to vary it depending on the cartridge you are

using and or the part icular record being played. The knob's scale makes it easy to retur n to a

previous sett ing by making a not e of t he number abo ve the index mar k and the number o f

complete turns taken.

Page 7

7

• The old wisdom, which had the arm tube parallel to the reco rd surface, assumed not only that

all cartridges had the same internal geometry and stylus rake angle but also that all records

were cut with the same equipment set t he same way. The idea was that everything would line

up properly with the arm parallel to the record. This is not true and the VTA should be

adjusted for best sound in your system.

• Rule of thumb: Raising VTA lowers bass and increases treble. Lowering VTA increases

bass and decreases treble.

H. CONNECTING TO THE PREAMPLIFIER/AMPLIFIER

• ONLY USE INTERCONNECTS THAT ARE SHIELDED AND PROPERLY GROUNDED. NON-

SHIELDED INTERCONNECTS CAN HUM AND PICK UP RF .

• The connecto r block at t he rear of the arm base has, in addition to the Lemo receptacles two

phono recept acles and a ground connector.

• Plug one end of the output cable into the phono jacks. The jack with the red ring is the right

channel and the jack with the black or w hit e r ing is the left.

• Plug the other end of the ca ble into the tur ntable inputs on your pre-preamplifie r, preamplifier,

or integrated amplifier as appropriate.

The ground connection is available to eliminate hum if necessary. If hum is present, first connect

a gro und lead from the co nnecto r block t o t he preamplifier or amplifier t o which the output cable

is connected. If this does not eliminate t he hum, run a ground wire from the turntable chassis to

the connector block as well. The block's connector will accept bare wires, spade lugs, or ring

tongue connectors.

I. D AMPING THE ARM

• The JMW-12.7 has v is c ous dampi n g prov is ion a ro und its ma le b e a ring point. Lif t o ff the a rm

tube and fill the cup roughly ¾ full with the damping fluid provided.

• Pla c e t h e ar m ba c k o n t h e b ea r ing a nd lift it s ligh t ly t o s e e if th e dampi ng flui d lift s up w it h it

in a thin line. That means you ar e making contact with the fluid and you are damped.

J. FINE TRACKING FORCE ADJUSTMENT

• At the rear of the counterweight stem there is an adjustment screw that allows fine

adjustment of the tracking for ce. This screw may feel tight when first engaging it but it will

turn with the supplied 3/16” Allen wrench.

• Use this screw for very fine adjustment of the tracking force.

Page 8

Loading...

Loading...