VPEB Dinamo, OC32/NG, RM-C/1+, TM44, OC32 User Manual

Manual DINAMO Plug & Play Control your miniature world

Page 32 of 32 Version 1.2 – Dec 21st, 2017 2017 Leon van Perlo

(This page is intentionally left blank)

Author: Leon J.A. van Perlo

Version: 1.2

Date: December 21st, 2017

DINAMO Plug & Play

Manual

VPEB

Van Perlo Elektronica

& Besturingstechniek

VPEB

Van Perlo Elektronica

& Besturingstechniek

Smart electronics for your miniature world

Manual DINAMO Plug & Play Control your miniature world

Page 2 of 32 Version 1.2 – Dec 21st, 2017 2017 Leon van Perlo

Release Management

This manual applies to the kit consisting of:

Module:

•

RM-C/1+ Rev00/01

•

TM44 Rev01

•

OC32/NG Rev10

If you have an RM-U P&P and/or an OC32 (not /NG version) please refer to version 1.1 of

this manual for the hardware description of the respective parts. You can however use

all firmware and software described in this manual version 1.2.

Firmware:

•

RM-C Firmware 1.30A

•

TM44 Firmware 1.20

•

OC32 Firmware 3.01

Software:

•

DinamoConfig 1.30A

•

OC32Config 3.01

Preface

The Dinamo Control System is a versatile solution to control analogue trains, digital trains,

digital cars and all accessories on your miniature world in scale 00 (1:6 7.2) to scale Z

(1:220) including all intermediate scales. Application of Dinamo with larger scales is

possible, however some limitations may apply.

The versatility of Dinamo may confuse less electronic mind users. For th is reason VPEB

released Plug&Play. In this version, the number of different types of modu les and the

possible choices are reduced in favor of clarity and simplicity. Dinamo P&P is in contrast to

Dinamo “Classic” not suited for application with larger scales than H0/0 0 (and so primarily

intended for scales from 00 to Z).

This manual describes strictly the Dinamo Plug&Play concept and its application for the

operation of trains for the novice user as simply as possible. Dinamo P&P can be enhanced

with additional modules from the Dinamo “Classic” range e.g. the UCCI/E -s for controlling of

digital cars. There are also other choices not described in this manua l that are possible,

however these are outside the scope of this manual. The user is adv ised to refer to the

individual manuals for the other modules for in-depth details.

Even though the application of Dinamo P&P has been significant ly simplified compared to the

"Classic" version, before you apply this to your final model layout it is important to

understand the principles and to understand how the software and D inamo system

cooperate with each other. Creating a temporary simple test layout has proven to be very

effective way to learn and most of the items can be reused afterwa rds in your final layout.

2017 This document, or any information contained herein, may not be copied or distributed, in whole

or in parts, in whatever form, without the explicit written approval of the original author. The making of

copies and prints by users of the Dinamo system and/or Dinamo modules for their own use is allowed.

Control your miniature world Manual DINAMO Plug & Play

2017 Leon van Perlo Version 1.2 – Dec 21st, 2017 Page 31 of 32

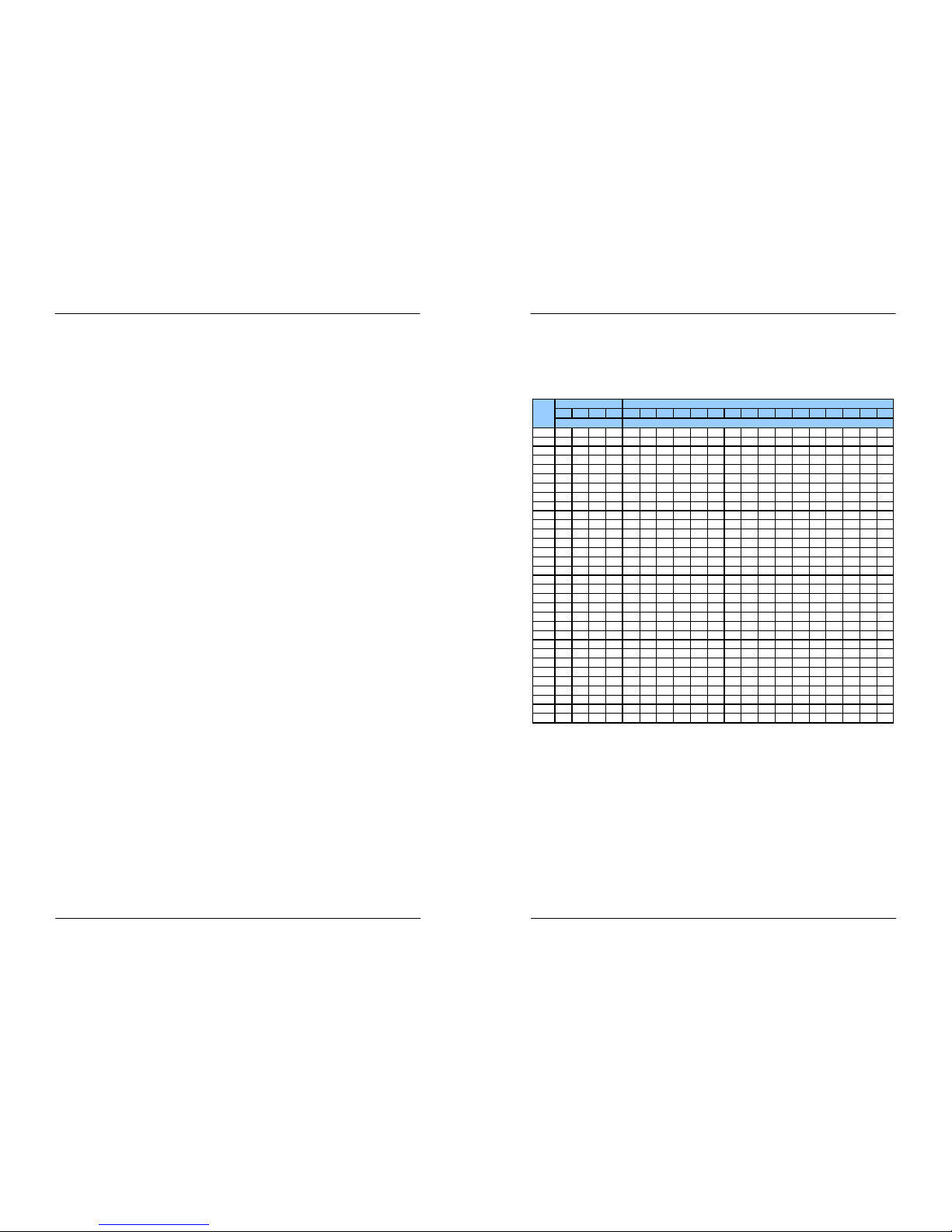

Appendix A: TM44 Address Table

This table applies if your control software uses linear addressing a nd adds an offset +1 to

block and feedback addresses.

Note that the TM44 numbering is kept as in this manual, starting fro m 0.0

TM440123

0B0

0B1

0B2

0B3

1B0

1B1

1B2

1B3

2B0

2B1

2B2

2B3

3B0

3B1

3B2

3B3

0.0123412345678910111213141516

0.1567865666768697071727374757677787980

1.0 9 10 11 12 129 130 131 132 133 134 135 136 137 138 139 140 141 142 143 144

1.1 13 14 15 16 193 194 195 196 197 198 199 200 201 202 203 204 205 206 207 208

2.017181920

257

258

259

260

261

262

263

264

265

266

267

268

269

270

271

272

2.121222324

321

322

323

324

325

326

327

328

329

330

331

332

333

334

335

336

3.025262728

385

386

387

388

389

390

391

392

393

394

395

396

397

398

399

400

3.129303132

449

450

451

452

453

454

455

456

457

458

459

460

461

462

463

464

4.033343536

513

514

515

516

517

518

519

520

521

522

523

524

525

526

527

528

4.137383940

577

578

579

580

581

582

583

584

585

586

587

588

589

590

591

592

5.0 41 42 43 44 641 642 643 644 645 646 647 648 649 650 651 652 653 654 655 656

5.145464748

705

706

707

708

709

710

711

712

713

714

715

716

717

718

719

720

6.049505152

769

770

771

772

773

774

775

776

777

778

779

780

781

782

783

784

6.153545556

833

834

835

836

837

838

839

840

841

842

843

844

845

846

847

848

7.057585960

897

898

899

900

901

902

903

904

905

906

907

908

909

910

911

912

7.161626364

961

962

963

964

965

966

967

968

969

970

971

972

973

974

975

976

8.065666768

1025

1026

1027

1028

1029

1030

1031

1032

1033

1034

1035

1036

1037

1038

1039

1040

8.169707172

1089

1090

1091

1092

1093

1094

1095

1096

1097

1098

1099

1100

1101

1102

1103

1104

9.0 73 74 75 76 1153 1154 1155 1156 1157 1158 1159 1160 1161 1162 1163 1164 1165 1166 1167 1 168

9.177787980

1217

1218

1219

1220

1221

1222

1223

1224

1225

1226

1227

1228

1229

1230

1231

1232

10.081828384

1281

1282

1283

1284

1285

1286

1287

1288

1289

1290

1291

1292

1293

1294

1295

1296

10.185868788

1345

1346

1347

1348

1349

1350

1351

1352

1353

1354

1355

1356

1357

1358

1359

1360

11.089909192

1409

1410

1411

1412

1413

1414

1415

1416

1417

1418

1419

1420

1421

1422

1423

1424

11.193949596

1473

1474

1475

1476

1477

1478

1479

1480

1481

1482

1483

1484

1485

1486

1487

1488

12.0979899100

1537

1538

1539

1540

1541

1542

1543

1544

1545

1546

1547

1548

1549

1550

1551

1552

12.1 101 102 103 104 1 601 1602 1603 1604 1605 1606 1607 1608 1609 1 610 1611 1612 1613 1614 1615 1616

13.0 105 106 107 108 1 665 1666 1667 1668 1669 1670 1671 1672 1673 1 674 1675 1676 1677 1678 1679 1680

13.1

109

110

111

112

1729

1730

1731

1732

1733

1734

1735

1736

1737

1738

1739

1740

1741

1742

1743

1744

14.0

113

114

115

116

1793

1794

1795

1796

1797

1798

1799

1800

1801

1802

1803

1804

1805

1806

1807

1808

14.1

117

118

119

120

1857

1858

1859

1860

1861

1862

1863

1864

1865

1866

1867

1868

1869

1870

1871

1872

15.0

121

122

123

124

1921

1922

1923

1924

1925

1926

1927

1928

1929

1930

1931

1932

1933

1934

1935

1936

15.1

125

126

127

128

1985

1986

1987

1988

1989

1990

1991

1992

1993

1994

1995

1996

1997

1998

1999

2000

Block Address

Block

Feedback Address

Section

Table 4: TM44 block –and section numbers

Manual DINAMO Plug & Play Control your miniature world

Page 30 of 32 Version 1.2 – Dec 21st, 2017 2017 Leon van Perlo

7.4 Delivering Track-power to Turnouts via Relays

In paragraph 7.3 we explained that in some cases it is necessary to power the track s on

turnout groups separately. If you don’t want to do that with an ad ditional block-output or if

you cannot do that because your software does not support it, you can solve this with a

relay, controlled from an OC32 output. Since the track, the relay pow ers, is only occupied

while the train passes to or from the adjacent blocks there is funct ionally no disadvantage,

except that it requires an electromechanical component and it ma y be slightly more complex

to wire.

We look again at the example from paragraph 7.3, the crossing turnout. To deliver power to

the tracks you need a relay with two crossover contacts (DPCO = Dual Pole Cross Over).

Each contact has 3 terminals on the relay: C (common), B (break) and M (make). If the relay

is not activated, C is connected to B and M is isolated. If the re lay is activated, C is

connected to M and B becomes isolated. Besides the 2 x 3 terminal s, on the relay you’ll find

2 additional terminals for the relay activation-coil. On some model s you will encounter an

explicit + (plus) and – (minus) pole, but in most cases it will be irre levant in which direction

current flows through the coil.

The relay activation-coil is connected to an OC32 output with sink-dr iver. In the example

below (figure 35) both “C” terminals are wired to rail A and B of turnout T1. The “B”

terminals are wired to the A and B3 connections of block 1. The “M” terminals are wired to

the A and B3 connections of block 3. We assume in this example that sections B3 of blocks

1 and 3 are not in use by the block itself.

If you have wired the setup according to figure 35, you need to instruct your PC control

software when the relay shall be activated. When a train passes fro m or to block 1, the

relay shall not be activated. When a train passes from or to block 3, the r elay shall be

activated.

Fig 35: Connecting turnout tracks by relays

Relays for this application can be obtained from a regular electronic s components store.

Types that are specified to switch 1Amp per contact are fine. Also th e VPEB partners offer

ready-made modules with one or more relays, equipped with plugg able connectors or screwtype terminals for easy wiring. Often you’ll find an additional LED, that shows whether the

relay is activated. Not absolutely necessary, but it may come in hand y while troubleshooting.

1A

3B23B1

1B1 1B2

block 3

block 1

block 4

T1 block 2

M

C B

M

C B+-

3A

3B3

1B3

1A

3A

TM44

OC32

Vp

OC32 output, sink driver

1A

3B23B1

1B1 1B2

block 3

block 1

block 4

T1 block 2

M

C B

M

C B+-

M

C B

M

C B+-

3A

3B3

1B3

1A

3A

TM44

OC32

Vp

OC32 output, sink driver

Control your miniature world Manual DINAMO Plug & Play

2017 Leon van Perlo Version 1.2 – Dec 21st, 2017 Page 3 of 32

Contents

1 Dinamo .................................................................................................................. 4

1.1 Principle .......................................................................................................... 4

1.2 Blocks and sections.......................................................................................... 4

1.3 Dinamo Plug & Play........................................................................................... 5

2 RM-C/1+................................................................................................................ 7

2.1 Introduction..................................................................................................... 7

2.2 Communication, power supply and mounting ....................................................... 7

2.3 LED indicators ................................................................................................. 7

2.4 PC Connection ................................................................................................. 7

2.5 Testing using DinamoConfig (Windows) and learn some of the basics .................... 8

3 TM44................................................................................................................... 11

3.1 Functions ...................................................................................................... 11

3.2 Overview of the TM44 and location of connections and functions ........................ 11

3.3 Mounting ....................................................................................................... 12

3.4 Connect Power Supply to the TM44................................................................. 12

3.5 Capacity and Choice of Power Supply ............................................................... 13

3.6 Safety ........................................................................................................... 13

3.7 Power Supply Cabling...................................................................................... 13

3.8 Connecting Blocks to the TM44....................................................................... 14

3.9 Cabling of Blocks ............................................................................................ 14

4 OC32/NG ............................................................................................................. 16

4.1 Introduction................................................................................................... 16

4.2 Overview of the OC32/NG and location of connections and function s .................. 17

4.3 Mounting the OC32/NG .................................................................................. 17

4.4 OC32/NG Power Supply .................................................................................. 18

5 The Dinamo RS485 network ................................................................................. 19

5.1 Wiring the network......................................................................................... 19

5.2 Terminators................................................................................................... 20

5.3 Addressing .................................................................................................... 22

5.3.1 TM44 Addressing .................................................................................... 22

5.3.2 TM44 Master/Slave ................................................................................. 23

5.3.3 OC32 Adressing ...................................................................................... 23

5.3.4 Changing Addresses ................................................................................ 24

6 Commissioning your Dinamo system ....................................................................... 25

6.1 Power-up your system .................................................................................... 25

6.2 Testing communication ................................................................................... 25

6.3 Some additional words on DinamoConfig ........................................................... 27

6.4 Configuring your OC32/NG’s ............................................................................ 27

7 Turnouts .............................................................................................................. 28

7.1 Provide track power to turnouts ..................................................................... 28

7.2 Turnout groups, Block Separations, Section Separations .................................. 28

7.3 Addtitional Pseudo-blocks ............................................................................... 29

7.4 Delivering Track-power to Turnouts via Relays................................................... 30

Appendix A: TM44 Address Table .................................................................................. 31

Manual DINAMO Plug & Play Control your miniature world

Page 4 of 32 Version 1.2 – Dec 21st, 2017 2017 Leon van Perlo

1 Dinamo

1.1 Principle

The control-principle of Dinamo is derived from the way train-traffic is usually secured: By

means of a block-system. The block-system means that the layout is subdivided into blocks.

A train may enter a block only when the block is free. This means an y block can contain no

more than a single train.

When using Dinamo, the layout is not only divided into blocks secur ity-wise, but also every

block has it’s individual electrical power circuit. Since every block can cont ain no more than a

single train, in this setup every train can be controlled individual ly as that specific train

requires at that specific moment. With Dinamo this applies to d igital (DCC) AND analogue

trains.

To determine in what way every block needs to be driven, at every momen t it must be known

which train is in which block. In practice this is achieved using con trol software on a PC that

keeps track of the positions of all trains on the layout. So the contr ol software not only

secures the traffic, but at the same time ensures the most opti mal control of every train.

In theory Dinamo can function without a PC, but in practice it is hard ly ever done.

To be clear: Controlling your layout by PC does not mean by definition ever ything runs

automatically. It is perfectly possible to control your layout by a PC a nd still make many

decisions yourself or even control trains “manually” and individually. Man y digital control

systems on the market are nothing more or less than specialised comput ers with

specialised software. In case of Dinamo this is no different, just th e control unit is not a

specialised “box”, but any ordinary PC with software.

Blocks can be connected sequentially, but also be separated by turn outs, so the train can

“choose” what the next block on it’s route will be. Security-wise the c ollection of turnouts

by which the train is routed from one block to the next is never par t of any block, however

electrically this can be the case (see chapter 7).

In the real World, the passage between 2 blocks is secured by signa ls. Signals are at the

exit of each block. If the next block in the route of the train is free, is reserved by that train

and the turnouts leading to the destination Block is free and safe, th e signalling system will

allow the train to pass on.

1.2 Blocks and sections

Dinamo drives blocks individually and symmetrically. Symmetric mean s that both tracks are

driven with an identical but exactly opposite electrical signal. So there is no track having

zero voltage or “ground”. Consequently Dinamo demands that ever y block has its both

tracks electrically separated from the surrounding blocks. In other w ords, between two

blocks both rails shall be electrically separated.

To control trains on the layout by software, it is necessary that the software is aware of

the position of the trains. Usually it is insufficient to know just in wh ich block the train is. In

addition the software needs to know where in the block the train is. To achieve that, blocks

are split in sections. The precise split in sections depends mainl y on the requirements of the

software, so for details you should consult the manual of your contro l software.

Dinamo P&P provides 4 sections per block. It is not necessary to u se all of them. In most

cases 2 or 3 sections per block will be sufficient. To be able to distingu ish between different

sections in the same block, between sections one of the rails needs to b e electrically

isolated.

Control your miniature world Manual DINAMO Plug & Play

2017 Leon van Perlo Version 1.2 – Dec 21st, 2017 Page 29 of 32

2. Do not make sections extremely short. Dinamo is by the design of the detector unit

capable to generate an event even at the shortest possible sect ions. However, to do

that, there must be something to detect. Some loco’s have a nu mber of wheels with

rubber tires that will not generate detection. If that loco runs w ith the isolated wheels

in front, only the second axle will generate the event. If the section th at generates a

stop in front of a signal starts just a few cm before that signal you will r isk the train

sticking it’s front past the signal, or even worse, over the turnout the signal should

protect.

Also bear in mind that an event needs to go from Dinamo to the PC , the PC-software

has to process it and then the PC has to send a command to Dina mo, that also has to

process it in order to stop the train. If the train has a decoder with mass-simulation it

may take some distance before the train actually stops. Even if ever ything is processed

fast, there is no guarantee that the response is immediate, so don’t bu ild it all too

critical in terms of lengths and distances.

Since a turnout is never part of a block security-wise, it makes sense to assign a turnout

group that is fed from an adjacent block a separate section. If your softw are supports it, it

can then ‘see’ if the train is actually in the block itself or in the adjace nt turnout. In most

cases you’ll have sufficient sections available to do this.

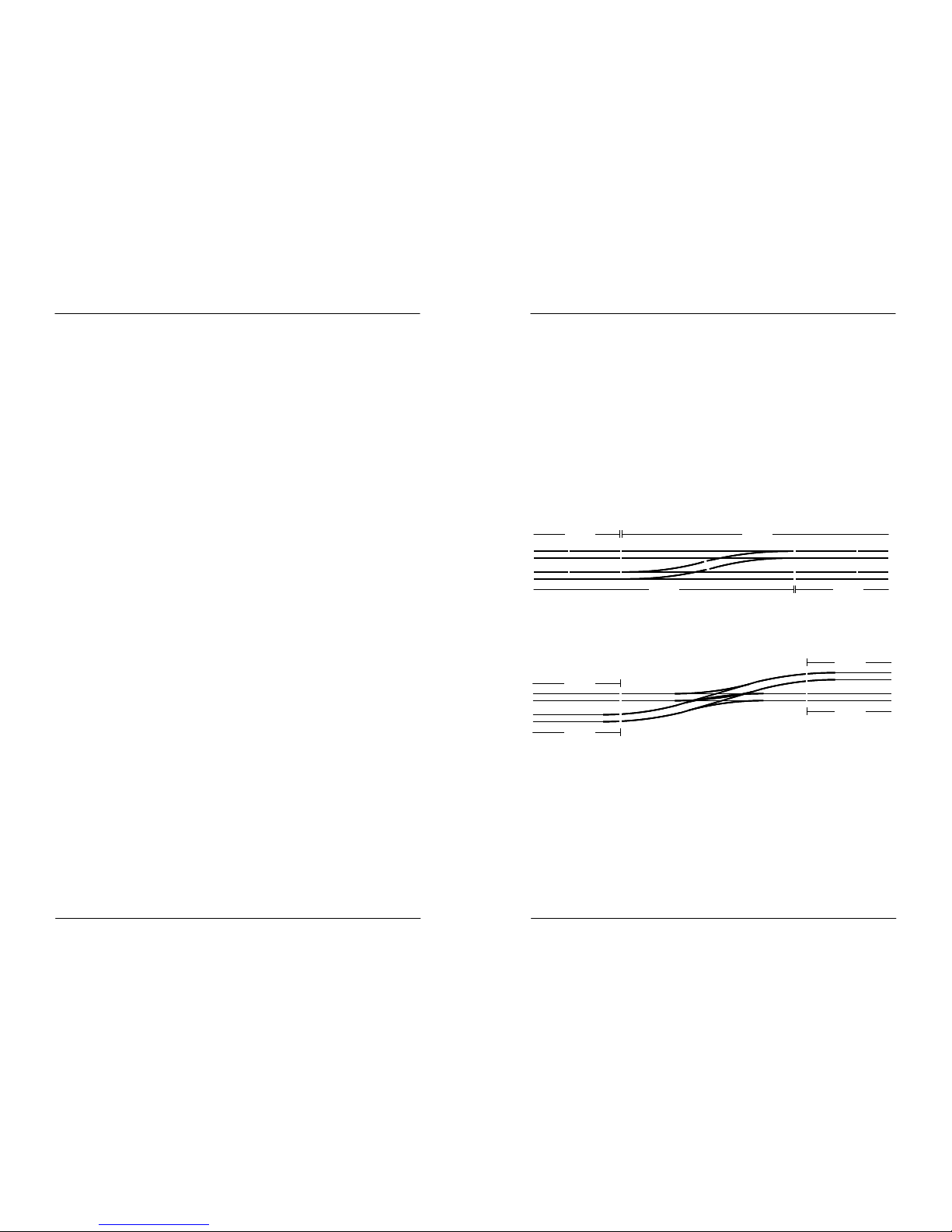

Fig 33: Connected turnouts in separate sections

7.3 Addtitional Pseudo-blocks

In some cases a turnout cannot be passed to or from one single adj acent block only. An

example of such situation is the crossing turnout:

Fig 34: Crossing turnout

In the example above T1 can be passed from block 1 to block 2, but a lso from block 3 to

block 4. So there is no possibility to feed the tracks of T1 from either of the adjacent

blocks. There are two solutions for this problem:

1. Define T1 as a separate pseudo-block. Since a tu rnout is never part of any block this is

not a real block, but a piece of track that is powered separately as if it was a block.

2. Use a relay with 2 change-over contacts to conn ect the tracks on T1 to one of the

adjacent blocks, dependent on the selected route. See paragraph 7.4. In the above

example from figure 34, T1 can be connected to block 1 or block 2, becau se in any case

one of these blocks is part of the route the train follows.

Note that the capabilities of your control software may limit your cho ices to apply the above

options.

block 2

block 3

block 1

block 4

section 1.2 section 2.0

section 3.3section 3.2 section 4.0

section 2.1 section 2.2

section 4.1

section 1.1

section 3.1

block 2

block 3

block 1

block 4

section 1.2 section 2.0

section 3.3section 3.2 section 4.0

section 2.1 section 2.2

section 4.1

section 1.1

section 3.1

block 3

block 1

block 4

T1 block 2

block 3

block 1

block 4

T1 block 2

Manual DINAMO Plug & Play Control your miniature world

Page 28 of 32 Version 1.2 – Dec 21st, 2017 2017 Leon van Perlo

7 Turnouts

7.1 Provide track power to turnouts

As indicated in paragraph 1.1, turnouts and turnout-groups are not part of any block. The

rails on a turnout however will need power supply to allow the train to p ass over it. In a

Dinamo system a turnout usually is electrically attached to an adjacent bl ock when the

turnout can only be accessed when running to or from that block. As an example:

Fig 31: Attaching turnouts to an adjacent block

T1 can only be passed from or to block 2. So it is allowed to attach th e rails of T1

electrically to block 2. Also T2 can be passed only from or to block 3. Therefore it is allowed

to derive the power for T2 from block 3.

Rule: At the “sharp side” of a turnout (at the side where the track s join) there will

never be an electrical block-separation.

Even when multiple turnouts are lined up this rule counts. Have a look at the example in

figure 32:

Fig 32: Multiple turnouts in-line

T1, T2 and T3 all can only be accessed from or to block 1, so they are al l electrically

connected to block 1.

7.2 Turnout groups, Block Separations, Section Separations

The exact location where you make the block-separation is of no great importance to

Dinamo, however it may be important for your control software. Theref ore, read the

documentation of your control software product and/or make a test- layout before you apply

this to your target layout. Mind that a block separation is also a section separation by

definition, so it is a means for the software to determine where exact ly the train is. We

mention 2 important points of interest:

1. If you are using ‘full detection’, which means al l axles of all your rolling stock shall draw

some current from the tracks, your software can determine, if it sup ports this feature,

in which block and section something is present. So, for instance , your software can see

that a turnout-section is completely free before it is reserved for another train. In this

case it is important that ‘free’ means ‘truly free’ and not that the last tiny part of your

train still ‘hangs over’ the turnout. Therefore always keep some distan ce between the

block-separation and the adjacent turnout, as shown in figure 31.

Also if you do not use full detection, or if your software does not sup port it, it is good to

keep the above rule in mind. What is not the case now may become the ca se in the

future. Changing software is normally a lot easier than changing your physical layout.

block 2

block 3

block 1

block 4

T1

T2

block 2

block 3

block 1

block 4

T1

T2

block 2

block 1 T3T2T1

block 3

block 4

block 5

block 2

block 1 T3T2T1

block 3

block 4

block 5

Control your miniature world Manual DINAMO Plug & Play

2017 Leon van Perlo Version 1.2 – Dec 21st, 2017 Page 5 of 32

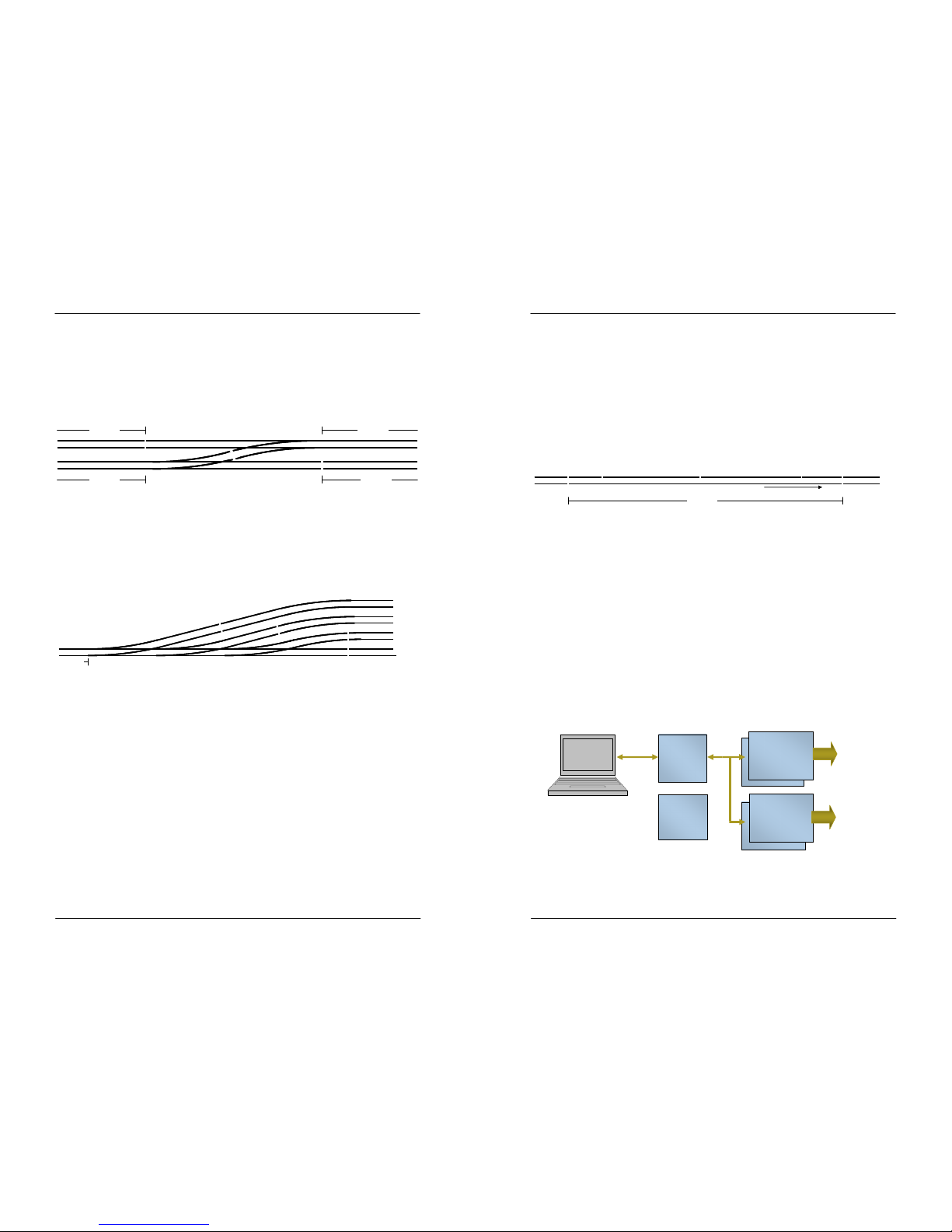

As a result, within one block, we have a continuous rail and a non-cont inuous rail split into

sections. Since every block offers the possibility to drive in both dire ctions and in case we

use digital (DCC) control, the signal is a square-wave alternating signa l it makes no sense to

talk about “plus” and “minus”. Therefore Dinamo talks about the A-rail and B-rail. The A-rail

always is continuous, the B-rail can be interrupted between sect ions. To identify the

direction in which the train travels, within Dinamo the “positive direct ion” is the direction

with the A-rail on the right hand side. To be clear: There is no need or r eason to have the

“positive direction” equal to the direction the train normally travels. “ Positive” and

“negative” directions are just names to identify in which way the tra in travels with respect

to the A-rail and B-rail. We explicitly do not use “forward” or “reverse” because this would

apply to the front and rear of the loco.

The general advise is to choose the rail in which you make the section-separations as

consistently as possible without taking into account normal direction of t ravel.

Fig 1: Subdivision of a block in a Dinamo system

1.3 Dinamo Plug & Play

Dinamo P&P consists of just 3 different modules, by which all pos sible parts of your layout

can be controlled, including analogue trains, digital trains, turnouts, signals and many other

accessories.

The modules that are part of the Plug & Play concept are:

•

RM-C/1+: This module handles communication with the PC, communi cation to all other

modules and ensures that all modules, for which this is necessar y, operate fully

synchronized;

•

TM44: This module controls trains and reads positions by mean s of current detection.

Each TM44 can drive 4 blocks and detects trains in 4 sections per b lock. Each system

(RM-C) can connect up to 32 TM44 modules for a total capacit y up to 128 blocks.

•

OC32(/NG): This module controls turnouts, signals, decouplers, railroad crossings and

virtually all other accessories you may find on your miniature world, requir ing control.

One system can host a maximum of 16 OC32 modules.

Schematically the topology looks as follows:

Fig 2: Dinamo P&P Diagram

A

B0 B1 B2 B3

block Nblock N-1 block N+1

positive direction

A

B0 B1 B2 B3

block Nblock N-1 block N+1

positive direction

OM32

RM-C

OC32/NG

Power

TM51

TM44

Trains

Turnouts

Signals

Decouplers

Scenery

…

Loading...

Loading...