VTAC HSD USER MANUAL

TABLE OF CONTENTS

SECTION 1 VTAC HSD PART IDENTIFICATION

SECTION 2 VTAC HSD INSERT INSTALLATION/REMOVAL INSTRUCTIONS

SECTION 3 VTAC HSD RAILS INSTALLATION/REMOVAL INSTRUCTIONS

SECTION 4 VTAC HSD 90 SERIES MODULES INSTALLATION/REMOVAL INSTRUCTIONS

SECTION 5 VTAC HSD ACCESSORIES

SECTION 6 SIM RIGHT ANGLE INSERT PART IDENTIFICATION

SECTION 7 SIM RIGHT ANGLE INSERT INSTALLATION/REMOVAL INSTRUCTIONS

SECTION 8 SMALL PCB AND RETENTION INSERT USAGE

SECTION 9 VTAC HSD VERTICAL INSERT PART IDENTIFICATION

SEC TION 10 VTAC HSD VERTICAL INSERT PCB INSTALLATION INSTRUCTIONS

SEC T ION 11 TROUBLESHOOTING

SECTION 12 PRODUCT PERFORMANCE SPECIFICATIONS

Please note that any printed or downloaded User Manuals or Procedure Sheets may not reect the

most current revisions. The information contained in these materials is subject to change.

For the most current information available, visit vpc.com.

1/9/19

VTAC HSD USER MANUAL: SECTION 1 VIRGINIA PANEL CORPORATION

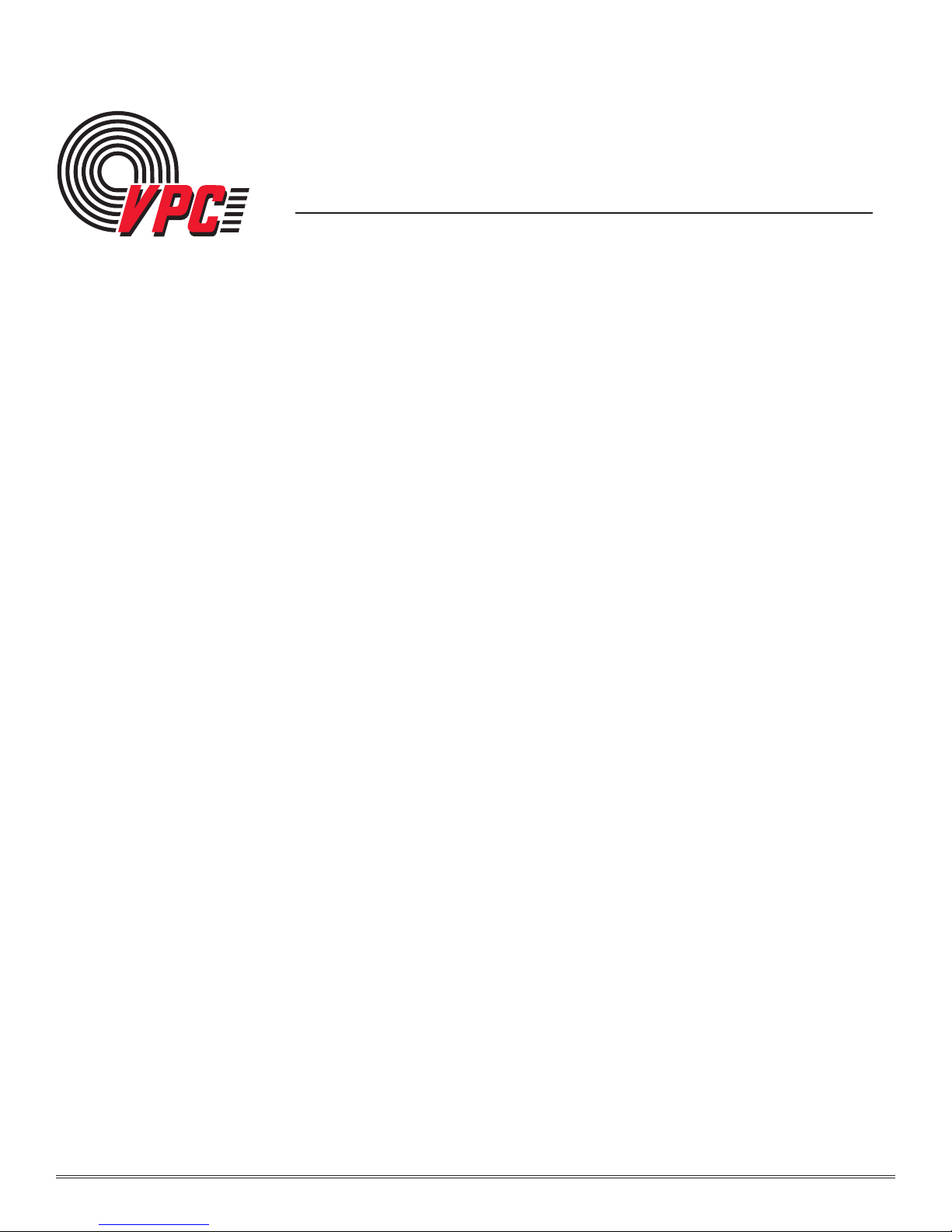

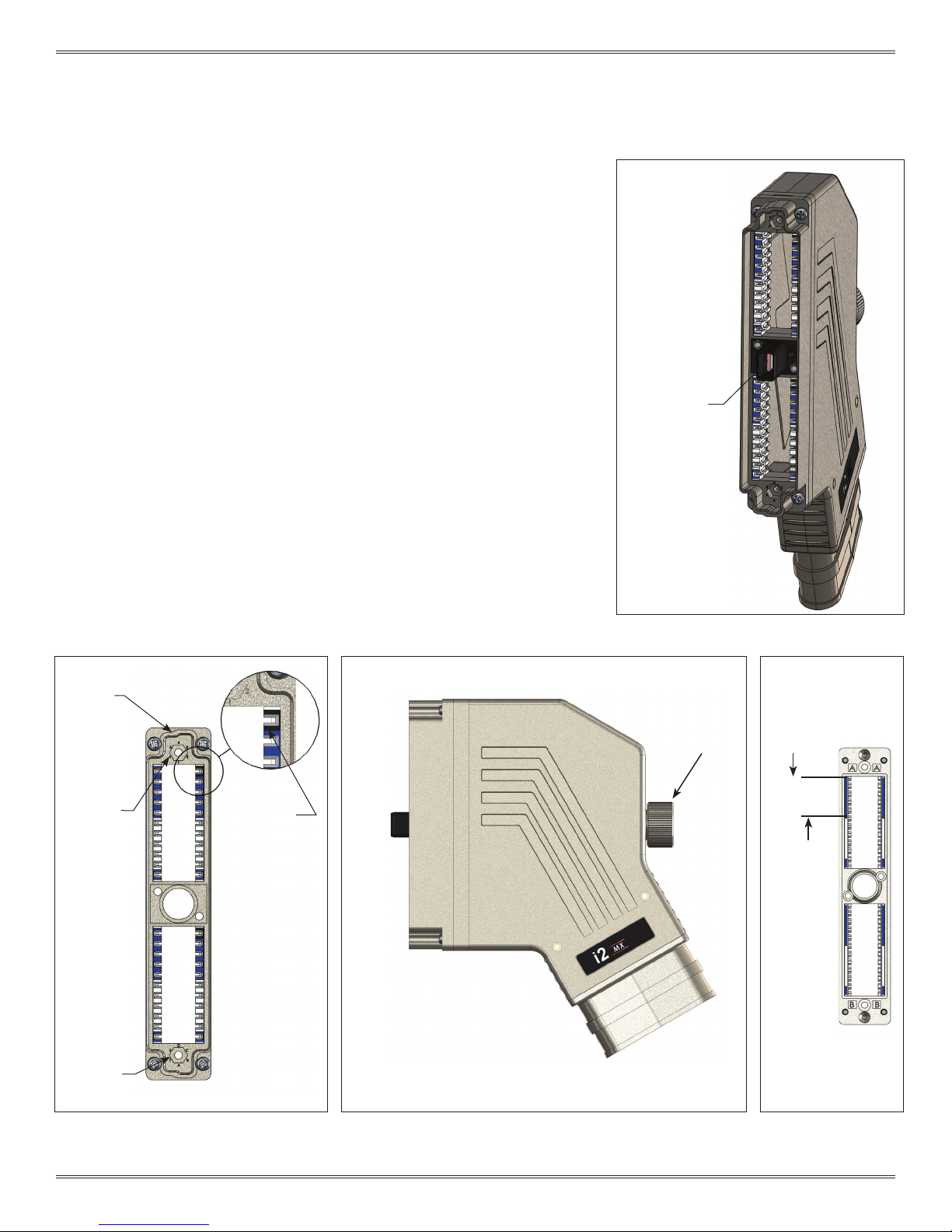

VTAC HSD 90 SERIES RECEIVER MODULE PART IDENTIFICATION

PART # 510 170 101

This section will point out features designed to help determine the proper orientation

of the VTAC HSD 90 Series receiver module (Figure A), as well as distinguishing

features.

The top of the VTAC HSD 90 Series receiver module can be determined by the position

A1 indicator, designated by the notch shown in Figure B. When the module is oriented

correctly, the position A1 notch will be visible in the upper left corner.

The front and rear of the VTAC HSD 90 Series receiver module are shown in Figure C.

The front has the position A1 notch. The front side mates with the VTAC HSD 90 Series

ITA module.

The rear of the VTAC HSD 90 Series receiver module has silkscreening along the side.

Wires exit the VTAC HSD 90 Series receiver module from the rear side.

NOTE: The blue silkscreen indicates ve slot positions, as shown in Figure D.

POSITION A1

INDICATOR

TOP

EXTRACTION TOOL CAVITY

DETAIL A

FRONT

MATING

SIDE

REAR

WIRING

SIDE

Figure A. Receiver Module.

2-56 TAPPED HOLES FOR

STRAIN RELIEF PLATE SCREWS

TYP. 2 PLCS

INDICATES 5 POSITIONS

MOUNTING SCREWS

TYP. 2 PLCS

BOTTOM

Figure B. Receiver module front view

(mating side).

1-1 For the most current information available, visit vpc.com

Figure C. Receiver module

side view.

Figure D. Receiver module

rear view (wiring side).

1/9/19

VTAC HSD USER MANUAL: SECTION 1 VIRGINIA PANEL CORPORATION

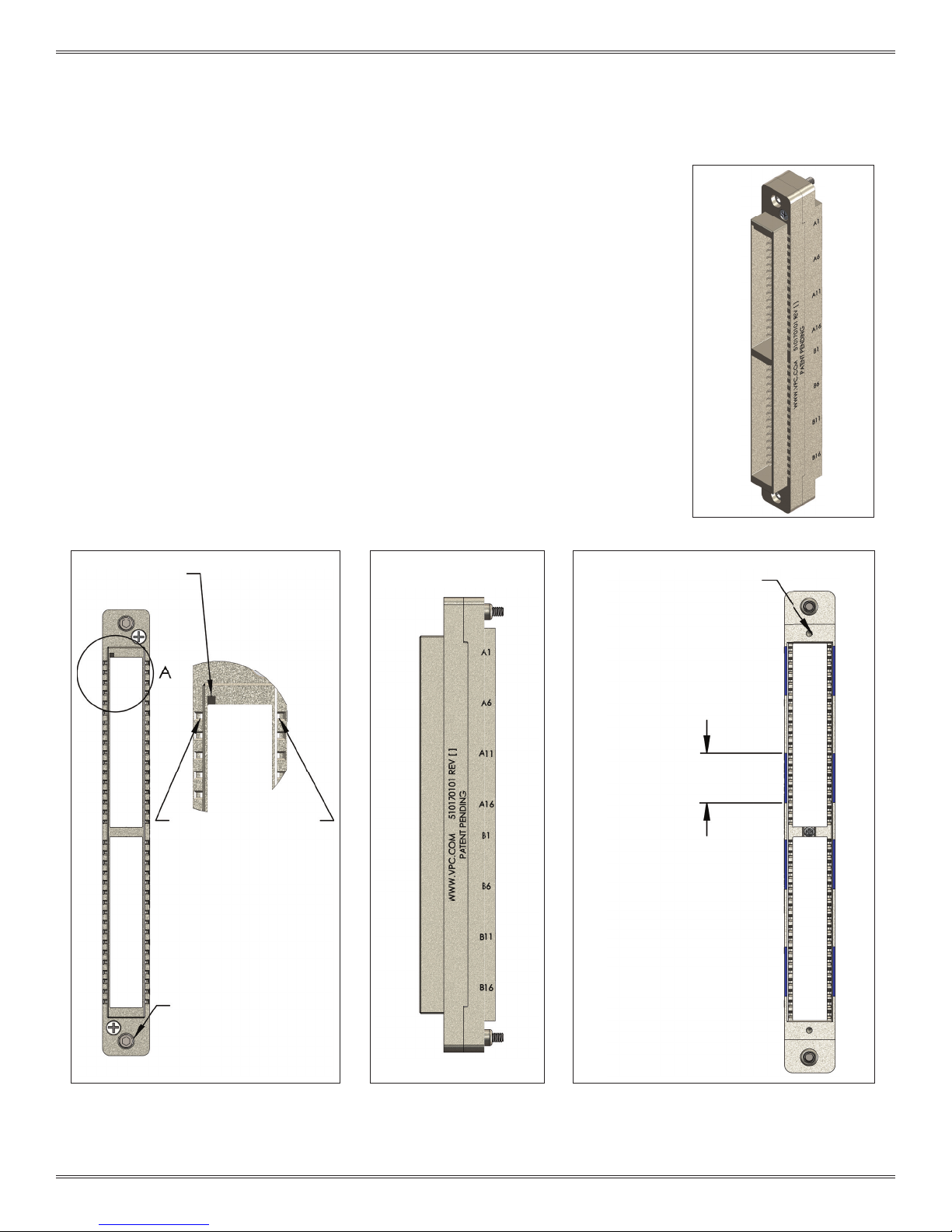

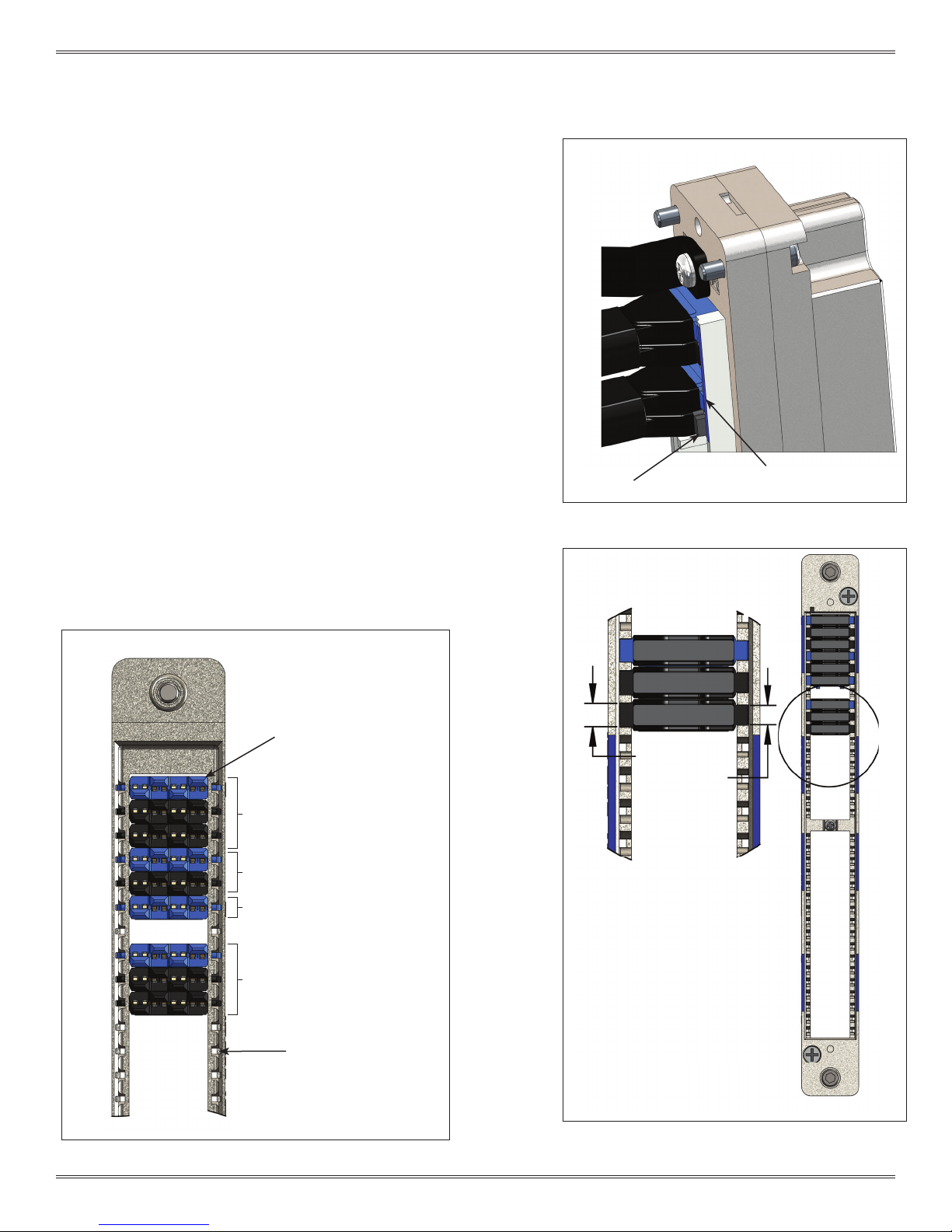

VTAC HSD 90 SERIES ITA MODULE PART IDENTIFICATION

PART # 510 171 101

This section will point out features designed to help determine the proper orientation

of the VTAC HSD 90 Series ITA module (Figure A), as well as distinguishing features.

The top of the VTAC HSD 90 Series ITA module (Figure B) can be determined by the

position A1 indicator on the rear side, designated by the notch shown in Figure D.

When the module is oriented correctly, the position A1 notch will be visible in the

upper left corner.

The front and rear of the VTAC HSD 90 Series ITA Module are shown in Figure C. The

front mates with the VTAC HSD 90 Series Receiver Module.

The rear has the position A1 notch. The rear of the VTAC HSD 90 Series ITA module has

silkscreening along the side (Figure D). Wires exit the VTAC HSD 90 Series ITA module

from the rear side.

NOTE: The blue silkscreen indicates ve slot positions, as shown in Figure D.

TOP

EXTRACTION TOOL CAVITY

DETAIL B

FRONT

MATING

SIDE

Figure A. ITA module.

MOUNTING SCREWS TYP. 2 PLCS

POSITION A1 INDICATOR

INDICATES 5 POSITIONS

REAR

WIRING

SIDE

BOTTOM

Figure B. ITA module front view

(mating side).

1-2 For the most current information available, visit vpc.com

Figure C. ITA module side

vi ew.

2-56 TAPPED HOLES FOR

STRAIN RELIEF PLATE SCREWS

TY. 2 PLCS

Figure D. ITA module rear

view (wiring side).

1/9/19

VTAC HSD USER MANUAL: SECTION 1 VIRGINIA PANEL CORPORATION

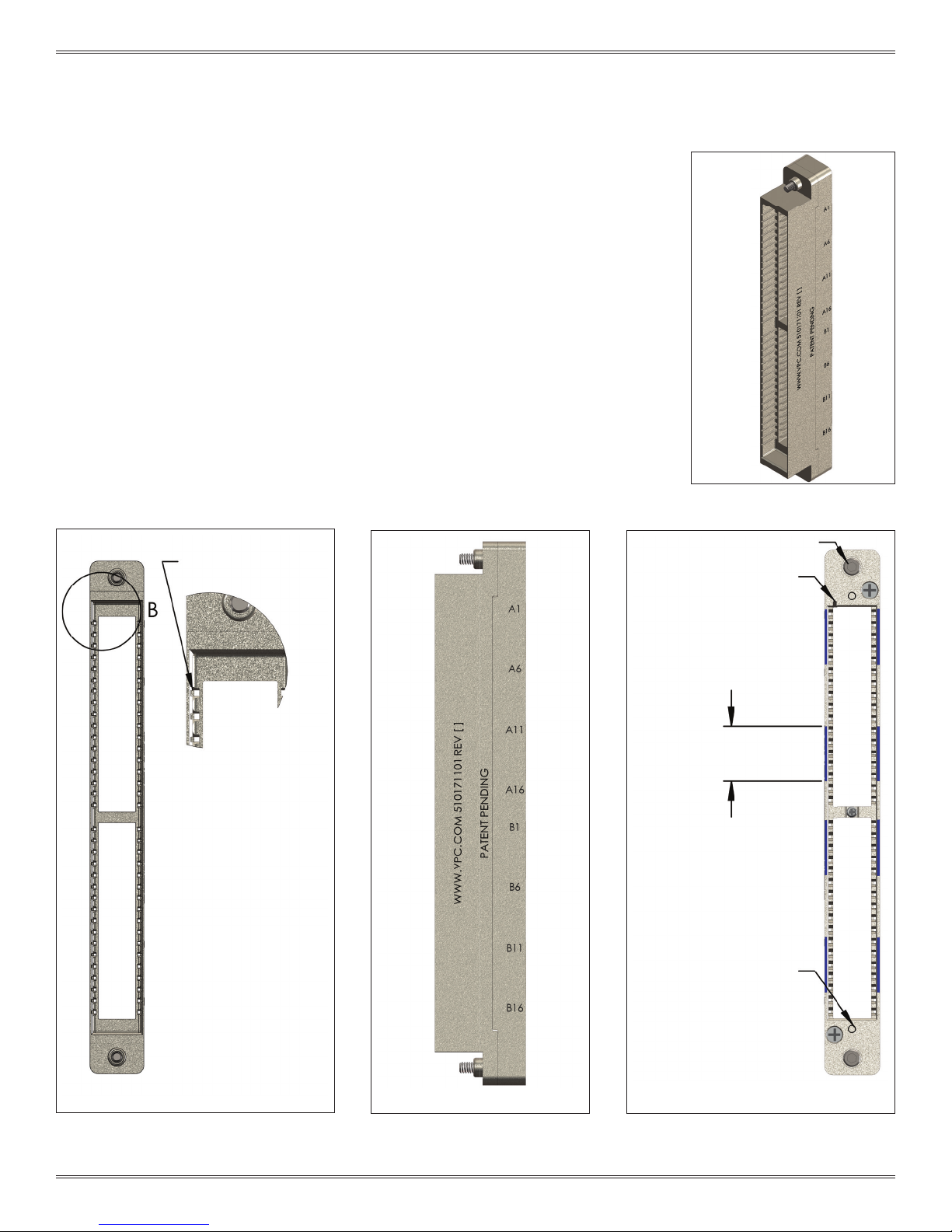

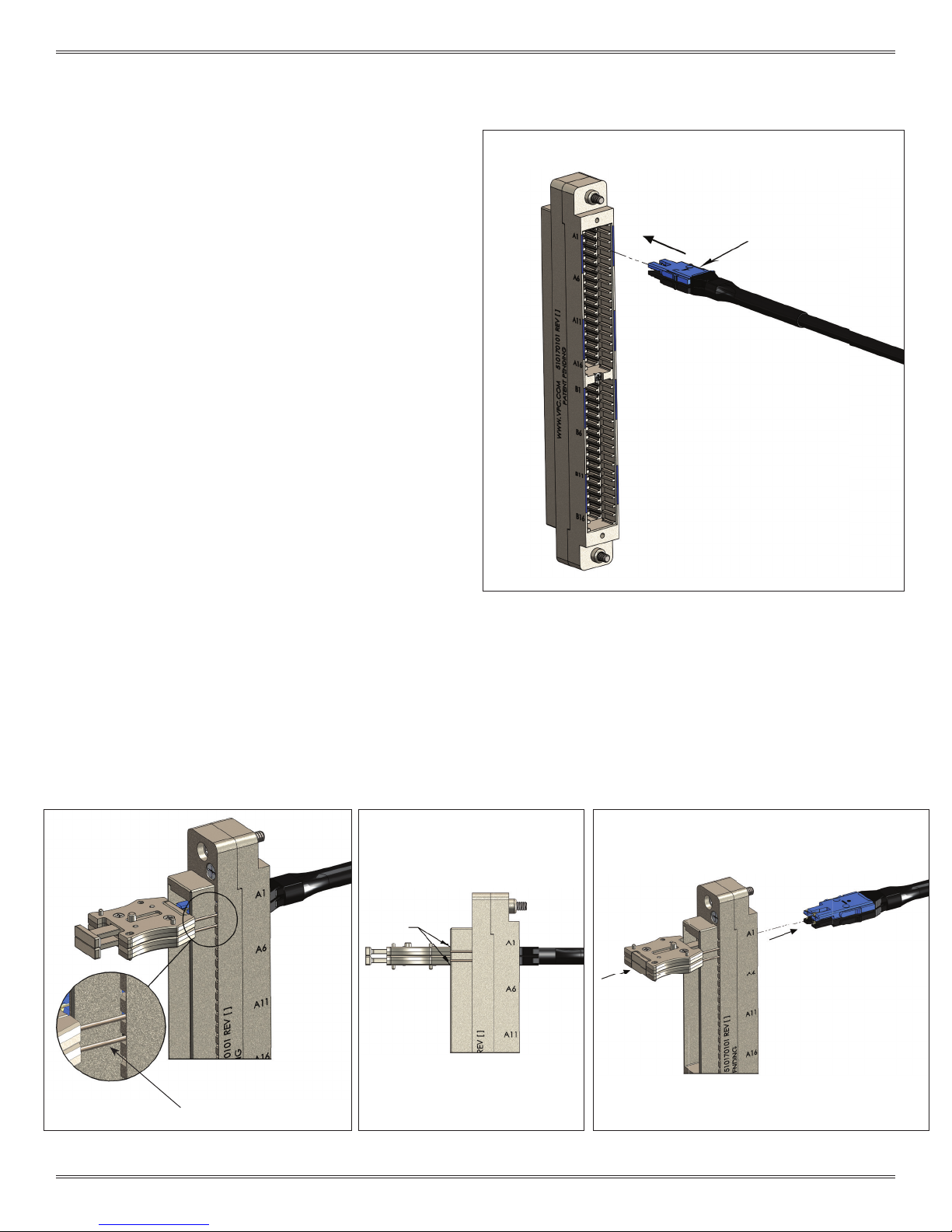

i2 MX RECEIVER PART IDENTIFICATION

PART # 310 130 XXX

Figure B points out distinguishing features of the i2 MX receiver so that the top and

bottom can be identied. Features to look for are the numeric keying receptacle at

the top and the alpha keying receptacle on the bottom.

When holding the i2 MX receiver, the top can be determined when the letters and

numbers are oriented as shown in Figure B. The top position is designated by a black

marking around the upper slot in Tier A and Tier B module locations (Figure B).

The front and rear of the i2 MX receiver are shown in Figure C. The front has a

polarizing feature which prevents the ITA and receiver from being engaged in the

incorrect orientation. The front of the i2 MX receiver can be identied as the side with

the latching feature (Figure A).

Figure D shows the rear silkscreen that aides in indicating positions.

The front side mates with the i2 MX ITA. Wires exit the i2 MX receiver from the rear side.

LATCHING

FEATURE

POSITION

A1

INDICATOR

NUMERIC KEYING

RECEPTACLE

TOP

TIER A

TIER B

POLARIZING

FEATURE

FRONT

MATING

SIDE

Figure A. i2 MX receiver

INDICATES 5

POSITIONS

REAR

WIRING

SIDE

MOUNTING

SCREWS TYP. 4

PLCS

ALPHA KEYING

RECEPTACLE

BOTTOM

Figure B. i2 MX receiver front view.

1-3 For the most current information available, visit vpc.com

Figure C. i2 MX receiver side view.

Figure D. i2 MX receiver rear

vi ew.

1/9/19

VTAC HSD USER MANUAL: SECTION 1 VIRGINIA PANEL CORPORATION

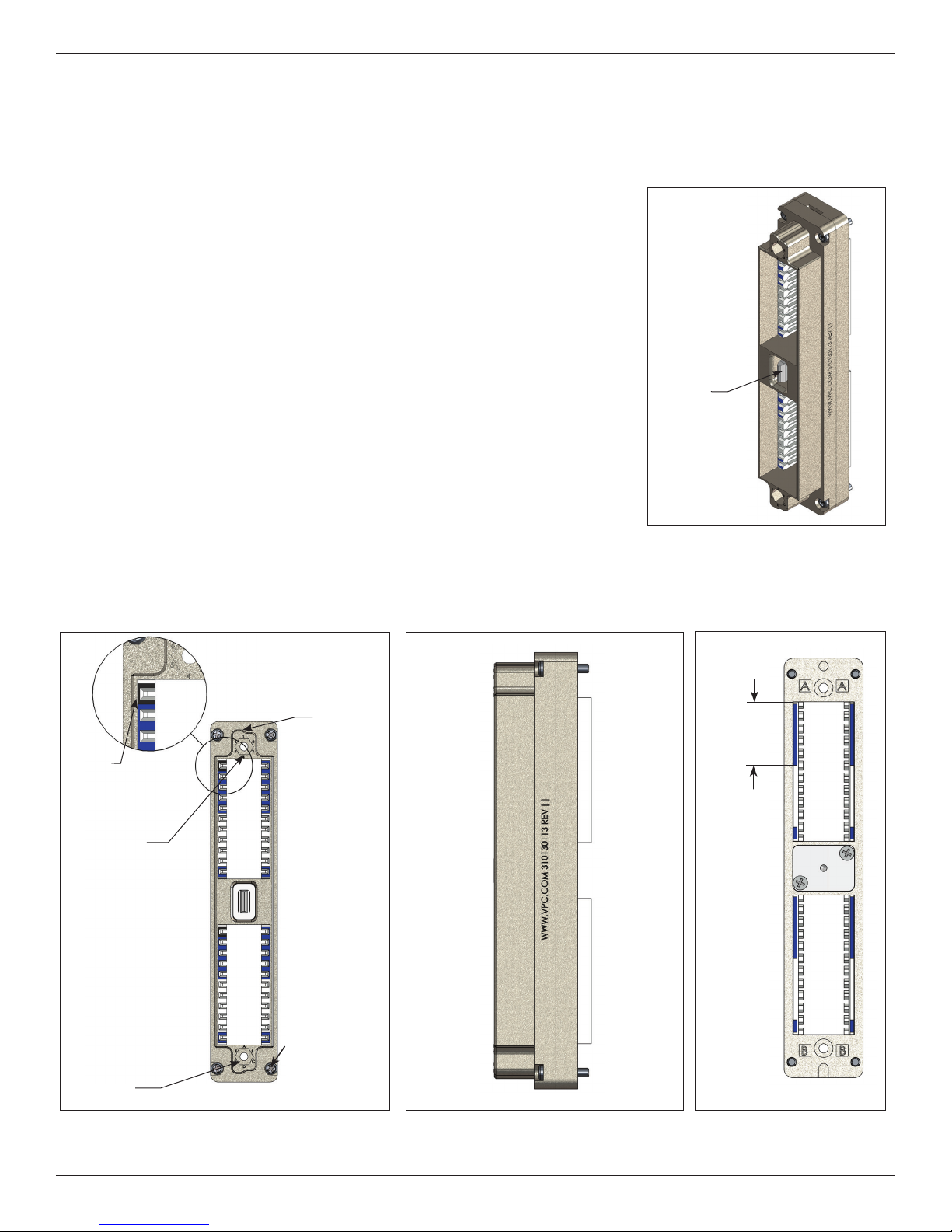

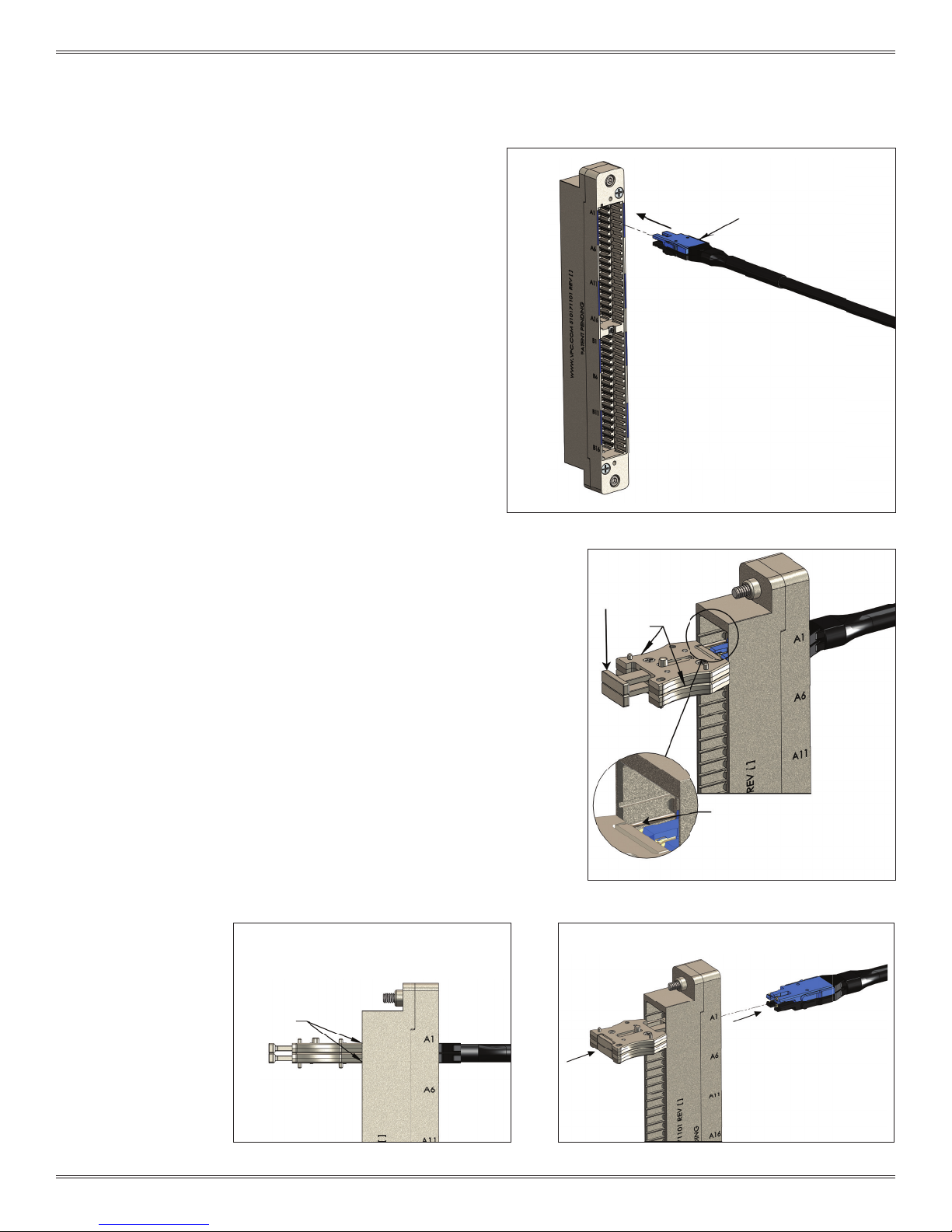

i2 MX ITA PART IDENTIFICATION

PART # 410 130 XXX

Figure B points out distinguishing features of the i2 MX ITA so that the top and bottom

can be identied. Features to look for are the numeric keying receptacle at the top

and the alpha keying receptacle on the bottom.

When holding the i2 MX ITA, the top can be determined when the letters and numbers

are readable. The top position is designated by a black marking around the upper slot

in Tier A and Tier B module locations (Figure B).

The front and rear of the i2 MX ITA are easily distinguished as shown in Figure C. The

front has a protruding guide plate with locking tabs (Figure A) and the rear has the

knob.

Figure D shows the rear silkscreen that aides in indicating positions.

The front side mates with the i2 MX receiver. The front has a polarizing feature which

prevents the ITA and receiver from being engaged in the incorrect orientation. Wires

exit the i2 MX ITA through the 30° cable exit (Figure C).

POLARIZING

FEATURE

NUMERIC

KEYING

RECEPTACLE

TOP

POSITION A1

INDICATOR

TIER A

FRONT

MATING

SIDE

LOCKING TABS

Figure A. i2 MXITA

KNOB

INDICATES 5

POSITIONS

REAR

WIRING

SIDE

TIER B

ALPHA

KEYING

RECEPTACLE

Figure B. i2 MX ITA front view (backshell removed)

BOTTOM

1-4 For the most current information available, visit vpc.com

Figure C. i2 MX ITA side view.

30° CABLE EXIT

Figure D. i2 MX ITA rear

view (backshell

removed).

1/9/19

VTAC HSD USER MANUAL: SECTION 2 VIRGINIA PANEL CORPORATION

VTAC HSD INSERT INSTALLATION/REMOVAL INSTRUCTIONS

TOOLS REQUIRED

VTAC Extraction Tool Kit, Receiver and ITA, Part # 910 112 130

VTAC HSD INSERT INSTALLATION INSTRUCTIONS

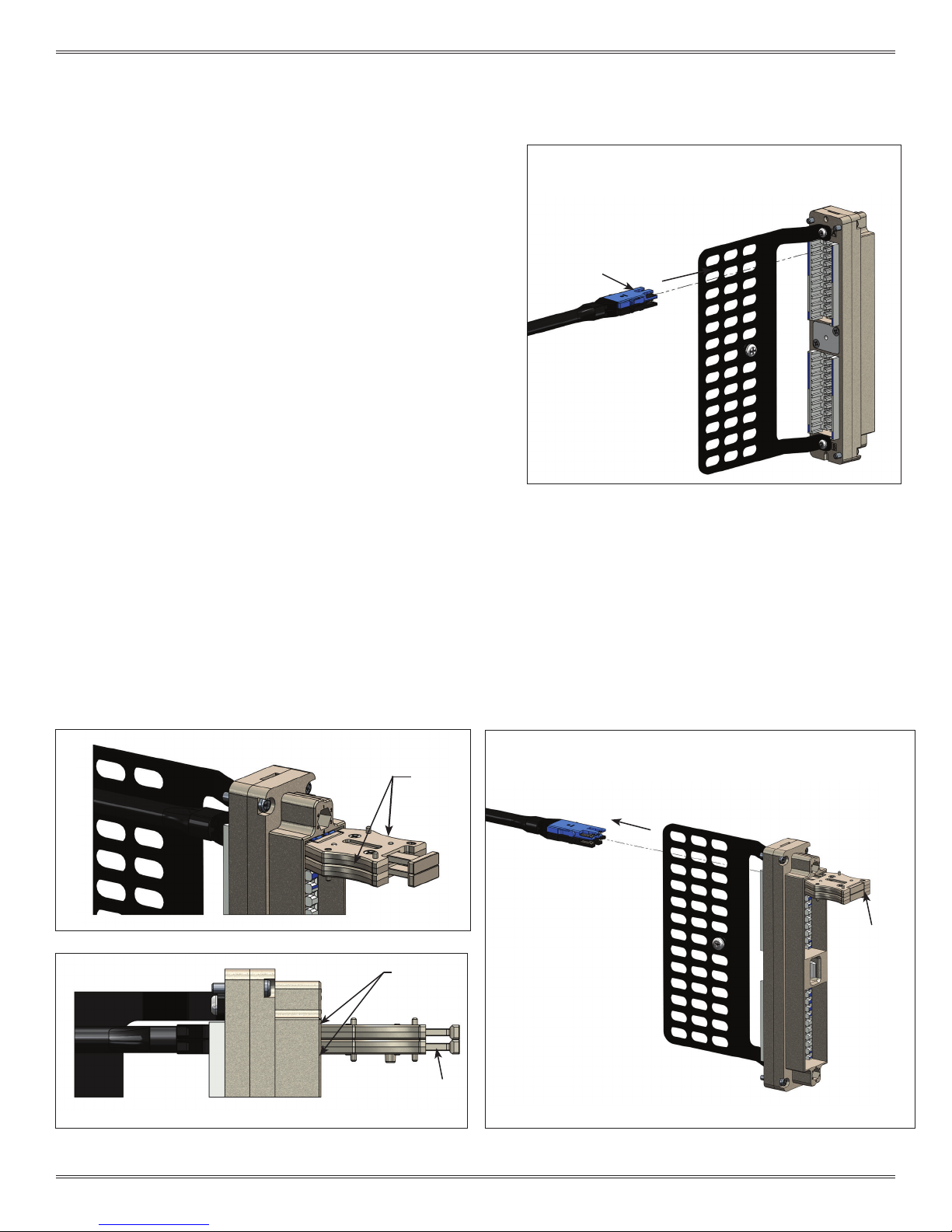

When inserting a VTAC HSD Insert stack, the blue insert is on top as shown

1.

in Figure B. Inserts are fully seated when the back of the inserts are ush

with the module (Figure A).

VTAC HSD INSERT REMOVAL INSTRUCTIONS

1. Group the required number of extraction tools together for the given VTAC

HSD patchcord. For example, a USB 3.0 patchcord requires two tools as

shown in Figure B.

WARNING: All inserts within each patchcord must be extracted simultaneously

to prevent damage to VTAC HSD Inserts.

NOTE: The extraction tools are magnetic to aid in stacking them together.

2. The indivdual patchcords can be identi ed by a blue insert, indicating the

beginning of a new stack or single insert patchcord as shown in Figure B.

NOTE: The slots on one side of the module are a slightly

different width than the other side to ensure the insert is

oriented correctly, as shown in Detail C in Figure C.

NOT FLUSH

Figure A. VTAC Insert alignment.

FLUSH

NOTE: For patchcords with more than 3 inserts, multiple VTAC tool kits (910 112

130) will be required.

BLUE INSERT

EXAMPLE OF A HDMI PATCHCORD

3 EXTRACTION TOOLS REQUIRED

EXAMPLE OF AN USB PATCHCORD

2 EXTRACTION TOOLS REQUIRED

SINGLE PATCHCORD 1 EXTRACTION

TOOL REQUIRED

EXAMPLE OF A HDMI PATCHCORD

3 EXTRACTION TOOLS REQUIRED

DETAIL C

C

Y1 LARGE SIDE

Y2 SMALL SIDE

EXTRACTION TOOL CAVITY

MATING FACE

Figure B. VTAC HSD Insert install and removal detail (ITA Shown).

2-1 For the most current information available, visit vpc.com

WIRING SIDE

Figure C. VTAC HSD Inser t install and removal detail (ITA

Shown).

1/9/19

VTAC HSD USER MANUAL: SECTION 2 VIRGINIA PANEL CORPORATION

VTAC HSD INSERT INSTALLATION/REMOVAL INSTRUCTIONS FOR RECEIVER MODULE

PART # 510 170 101

TOOLS REQUIRED

VTAC Extraction Tool Kit, Receiver and ITA, Part # 910 112 130

VTAC HSD INSERT INSTALLATION INSTRUCTIONS

Ensure that the VTAC HSD Insert(s) is in-line with the

1.

corresponding module location. Apply gentle pressure and

insert the VTAC HSD Insert(s) into the rear (wiring side) of the

module shown in Figure A. The VTAC HSD Insert(s) can only go

into one side. Once in place, gently pull the wire to ensure

the insert(s) is fully seated.

NOTE: To be fully seated, the insert(s) back shoulder should be ush

or below the module rear face as shown in Section 2-1 Figure C.

When plugging a stack of inserts, the blue insert will always be on

top as shown in Section 2-1 Figure A.

VTAC HSD INSERT REMOVAL INSTRUCTIONS

1. Group the required number of extraction tools together for

the given VTAC HSD patchcord shown in Figure B. The tool

pins should be on the mating side of the module.

BLUE INSERT

WARNING: All inserts within each patchcord must be extracted

simultaneously to prevent damage to VTAC HSD Inserts.

NOTE: The extraction tools are magnetic to aid in stacking them

together.

2. While grasping the extraction tool(s) body from the sides

(Figure B), slide tool pins into module’s extraction cavity

square holes until the tool frame is seated against the body

shown in Figure C.

WARNING: The extraction tool(s) need to be seated against

the module front face before the plunger is pushed in. Otherwise

damage to insert(s) may occur.

3. Push plunger of extraction tool(s) in to extract VTAC HSD

Insert(s). The insert(s) will be ejected out the wiring side of the

module shown in Figure D.

PLUNGER

GRIP

SEAT

Figure A. VTAC HSD Insert installation.

EXTRACTION TOOL

DETAIL A

Figure B. Inser t removal tool pins.

PINS

2-2 For the most current information available, visit vpc.com

Figure C. Seat removal tool

to module frame.

PUSH

PLUNGER

Figure D. Push removal tool plunger.

1/9/19

VTAC HSD USER MANUAL: SECTION 2 VIRGINIA PANEL CORPORATION

VTAC HSD INSERT INSTALLATION/REMOVAL INSTRUCTIONS FOR ITA MODULE

PART # 510 171 101

TOOLS REQUIRED

VTAC Extraction Tool Kit, Receiver and ITA, Part # 910 112 130

VTAC HSD INSERT INSTALLATION INSTRUCTIONS

Ensure that the VTAC HSD Insert(s) is squared up with the

1.

corresponding module location. Apply gentle pressure and insert

the VTAC HSD Insert(s) into the rear (wiring side) of the module

shown in Figure A. The VTAC HSD Insert(s) can only go into one

side. Once in place, gently pull the wire to ensure the insert(s) is

fully seated.

NOTE: To be fully seated, The insert(s) back shoulder should be ush or

below the module rear face as shown in Section 2-1 Figure C. When

plugging a stack of inserts, the blue insert will always be on top as

shown in Section 2-1 Figure A.

VTAC HSD INSERT REMOVAL INSTRUCTIONS

1. Group the required number of extraction tools together for the

given VTAC HSD patchcord shown in Figure B. The tool pins should

be on opposite sides of the patchcords or wires to be removed.

WARNING: All inserts within each patchcord must be extracted

simultaneously to prevent damage to VTAC HSD Inserts.

NOTE: The extraction tools are magnetic to aid in stacking them

together.

2. While grasping the extraction tool(s) body from the sides, (Figure

B), slide tool pins into module’s extraction cavity slots until the tool

frame is seated against the body shown in Figure C.

BLUE INSERT

Figure A. VTAC HSD insert installation.

PLUNGER

GRIP

WARNING: The extraction tool(s) need to be seated against the

module front face before the plunger is pushed in. Otherwise

damage to insert(s) may occur.

3. Push plunger of extraction tool(s) in to extract VTAC HSD Insert(s).

The insert(s) will be ejected out the wiring side of the module

shown in Figure D.

SEAT

EXTRACTION TOOL

PINS

DETAIL A

Figure B. Inser t removal tool pins.

PUSH

PLUNGER

Figure C. Seat removal tool to module frame.

2-3 For the most current information available, visit vpc.com

Figure D. Push removal tool plunger.

1/9/19

VTAC HSD USER MANUAL: SECTION 2 VIRGINIA PANEL CORPORATION

VTAC HSD INSERT INSTALLATION/REMOVAL INSTRUCTIONS FOR i2 MX RECEIVER

PART # 310 130 XXX

TOOLS REQUIRED

VTAC Extraction Tool Kit, Receiver and ITA, Part # 910 112 130

VTAC HSD INSERT INSTALLATION INSTRUCTIONS

Ensure that the VTAC HSD Insert(s) is squared up with the

1.

corresponding module location. Apply gentle pressure and insert the

VTAC HSD Insert(s) into the rear (wiring side) of the module shown in

Figure A. The VTAC HSD Insert(s) can only go into one side. Once in

place, gently pull the wire to ensure the insert(s) is fully seated.

NOTE: To be fully seated, The insert(s) back shoulder should be ush or

below the module rear face as shown in Section 2-1 Figure C. When

plugging a stack of inserts, the blue insert will always be on top as shown in

Section 2-1 Figure A.

VTAC HSD INSERT REMOVAL INSTRUCTIONS

1. Group the required number of extraction tools together for the given

VTAC HSD patchcord shown in Figure B. The tool pins should be on

opposite sides of the patchcords or wires to be removed.

BLUE INSERT

WARNING: All inserts within each patchcord must be extracted

simultaneously to prevent damage to VTAC HSD Inserts.

NOTE: The extraction tools are magnetic to aid in stacking them together.

2. While grasping the extraction tool(s) body from the sides (Figure B).

slide tool pins into module’s extraction cavity slots until the tool frame

is seated against the body shown in Figure C.

3. Push plunger of extraction tool(s) in to extract VTAC HSD Insert(s). The

insert(s) will be ejected out the wiring side of the module shown in

Figure D.

GRIP

Figure B. Inser t Removal.

SEAT

Figure A. VTAC HSD Insert installation

WARNING: The extraction tool(s) need to be seated against

the module front face before the plunger is pushed in. Otherwise damage to insert(s) may occur.

PUSH

PLUNGER

Figure C. Seat Removal tool

2-4 For the most current information available, visit vpc.com

PLUNGER

Figure D. Push removal tool plunger.

1/9/19

VTAC HSD USER MANUAL: SECTION 2 VIRGINIA PANEL CORPORATION

VTAC HSD INSERT INSTALLATION/REMOVAL INSTRUCTIONS FOR i2 MX ITA

PART # 410 130 XXX

TOOLS REQUIRED

VTAC Extraction Tool Kit, Receiver and ITA, Part # 910 112 130

VTAC HSD INSERT INSTALLATION INSTRUCTIONS

Ensure that the VTAC HSD Insert(s) is squared up with the

1.

corresponding module location. Apply gentle pressure

and insert the VTAC HSD Insert(s) into the rear (wiring

side) of the module shown in Figure A. The VTAC HSD

Insert(s) can only go into one side. Once in place, gently

pull the wire to ensure the insert(s) is fully seated.

NOTE: To be fully seated, The insert(s) back shoulder should

be ush or below the module rear face as shown in Section

2-1 Figure C. When plugging a stack of inserts, the blue insert

will always be on top as shown in Section 2-1 Figure A.

NOTE: Backshell removal instructions start in Section 2-6.

BLUE INSERT

NOTE: For i2 MX ITA Cable Assembly and Backshell Installation

Instructions, refer to the i2 MX User’s manual Section 5.

NOTE: To take advantage of the larger area for bend radius,

it is recommended to plug VTAC patchcords in Tier A as

shown in Section 1-4 Figure B.

Figure A. VTAC HSD Insert installation

2-5 For the most current information available, visit vpc.com

1/9/19

VTAC HSD USER MANUAL: SECTION 2 VIRGINIA PANEL CORPORATION

VTAC HSD INSERT REMOVAL INSTRUCTIONS FOR i2 MX ITA

PART # 410 130 XXX

TOOLS REQUIRED

Phillips Head Screwdriver

Flat Head Screwdriver

1/4” Nut Driver, hollow shaft

VTAC Extraction Tool Kit, Receiver and ITA, Part # 910 112 130

REMOVAL INSTRUCTIONS

1. Disengage the ITA from the receiver.

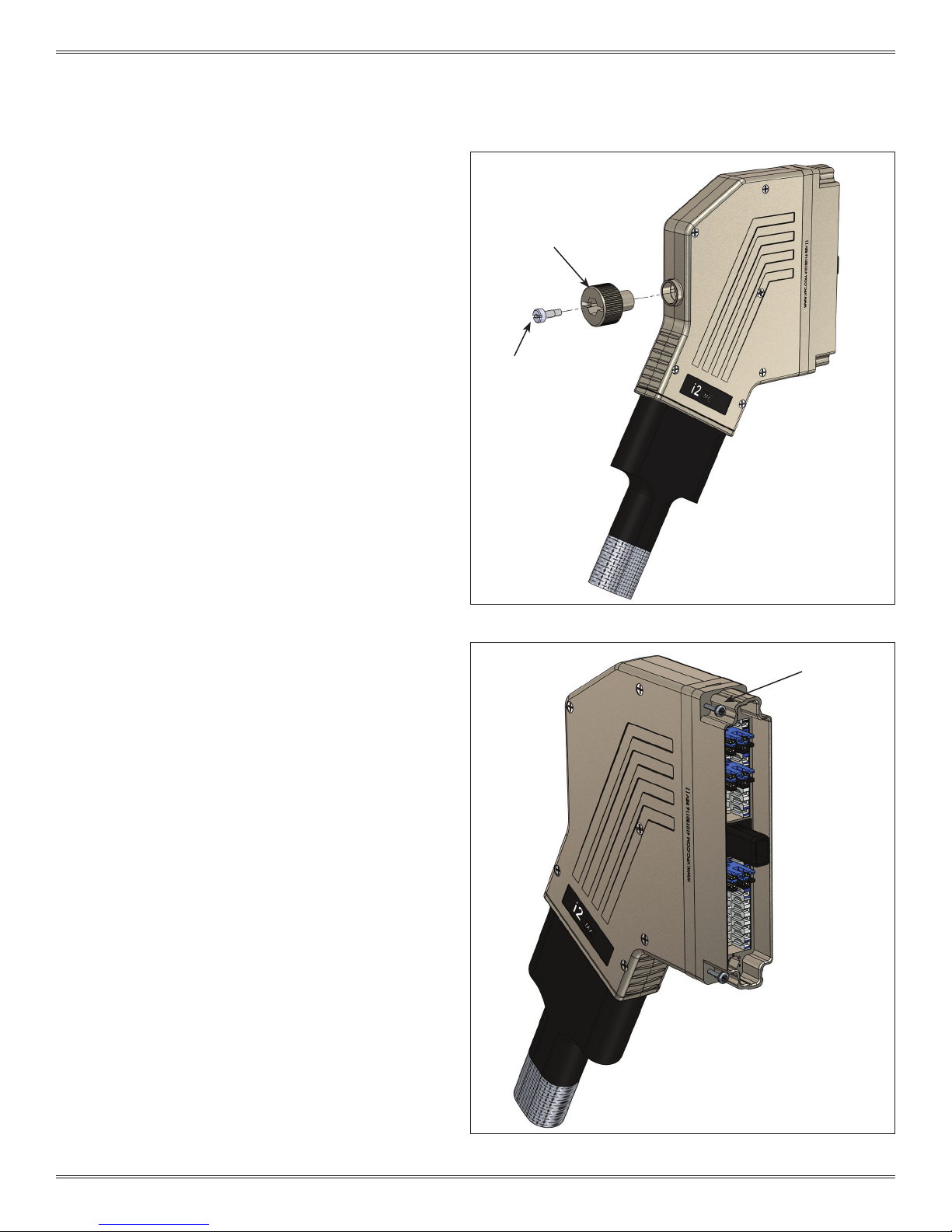

2. Using a at head screwdriver, remove the engagement

knob screw and engagement knob (Figure A).

3. Using a Phillips head screwdriver, loosen the four screws

(captive) that secure the backshell to the ITA frame

(Figure B).

KNOB SCREW

KNOB

Figure A. ITA knob removal.

FRA ME TO

BACKSHELL

SCREWS

2-6 For the most current information available, visit vpc.com

Figure B. Remove frame to backshell screws.

1/9/19

VTAC HSD USER MANUAL: SECTION 2 VIRGINIA PANEL CORPORATION

VTAC HSD INSERT REMOVAL INSTRUCTIONS FOR i2 MX ITA

PART # 410 130 XXX

REMOVAL INSTRUCTIONS (CONTINUED)

4. Using a Phillips head screwdriver, loosen the six screws

(captive) that secure the backshell halves. Remove the

half with the screws (Figure C).

5. Using a nut driver remove nuts on the strain relief clamp,

then remove the clamp (Figure D).

BACKSHELL

SCREWS

Figure C. Backshell cover removal.

NUT

STRAIN RELIEF

CLAMP

Figure D. Strain relief clamp removal.

2-7 For the most current information available, visit vpc.com

1/9/19

VTAC HSD USER MANUAL: SECTION 2 VIRGINIA PANEL CORPORATION

VTAC HSD INSERT REMOVAL INSTRUCTIONS FOR i2 MX ITA

PART # 410 130 XXX

VTAC HSD INSERT REMOVAL INSTRUCTIONS (CONTINUED)

1. Group the required number of extraction tools

together for the given VTAC HSD patchcord shown in

Figure E. The tool pins should be on opposite sides of

the patchcords or wires to be removed.

WARNING: All inserts within each patchcord must be

extracted simultaneously to prevent damage to VTAC HSD

Inserts.

SEATE D

FLUSH

NOTE: The extraction tools are magnetic to aid in stacking

them together.

2. While grasping the extraction tool(s) body from the

sides (Figure E), slide tool pins into module’s extraction

cavity slots until the tool plunger is ush with the tool

body and the plunger is in contact with the VTAC HSD

insert tips shown in Figure E.

WARNING: The extraction tool(s) need to be seated against

the module front face before the plunger is pushed in.

Otherwise damage to insert(s) may occur.

3. Push plunger of extraction tool(s) in to extract VTAC

HSD Insert(s). The insert(s) will be ejected out the wiring

side of the module shown in Figure F.

GRIP

PLUNGER

Figure E. Seat removal tool.

2-8 For the most current information available, visit vpc.com

PUSH

PLUNGER

Figure F. Inser t removal.

1/9/19

VTAC HSD USER MANUAL: SECTION 3 VIRGINIA PANEL CORPORATION

VTAC HSD RAIL(S) INSTALLATION/REMOVAL INSTRUCTIONS

PART # 310 130 XXX AND 410 130 XXX

TOOLS REQUIRED

Phillips Head Screwdriver

VTAC HSD RAIL(S) REMOVAL INSTRUCTIONS

1. If working with a receiver, use a Phillips head screwdriver to

remove strain relief by removing screws (Figure A).

The ITA will require removal of backshell rst. See Section 2 of this

User’s Manual for instructions.

2. After removing strain relief/backshell, use a Phillips head

screwdriver to remove the two Phillips at head screws that are

holding the frame halves together (Figure A).

For ITA use Phillips head screwdriver to loosen the two captive

screws on the back of the rear frame (Figure B).

3. Pull halves apart.

4. Remove VTAC HSD Rail(s).

VTAC HSD RAIL(S) INSTALLATION INSTRUCTIONS

1. To install VTAC HSD Rail(s), orient rail(s) as shown in (Figure A).

Figure C illustrates the identiers to aid in orientation (receiver rails

shown). The receiver rails are marked with ‘RR’ (receiver right)

and ‘RL’ (receiver left) when viewing from mating face. The ITA

rails are marked with ‘IR’ (ITA right) and ‘IL’ (ITA left) when viewing

from rear/wiring side.

2. Place rail(s) ledge on at surface shown in (Figure D), then put

halves together and tighten the two Phillips at head screws using

a Phillips head screwdriver.

NOTE: Receiver/ITA frame halves are keyed to be placed together

only one direction.

PHILLIPS

FLAT HEAD

SCREWS (2)

TOP OF

RAIL

Figure A. VTAC HSD Rail(s) install/removal (receiver shown).

PHILLIPS

CAPTIVE

SCREWS (2)

Figure B. ITA frame separation.

3-1 For the most current information available, visit vpc.com

BLACK POSITION

AI I NDICATOR

‘RL’ RECEIVER

LEFT

Figure C. VTAC HSD Rail(s) - Identiers.

‘RR’ RECEIVER

RIGHT

TOP

BOTTOM

FLAT SURFACE

Figure D. VTAC HSD Rail(s) install/removal

(receiver shown).

1/9/19

VTAC HSD USER MANUAL: SECTION 4 VIRGINIA PANEL CORPORATION

VTAC HSD 90 SERIES MODULES INSTALLATION/REMOVAL INSTRUCTIONS

TOOLS REQUIRED

3

/32 Allen Wrench

INSTALLATION INSTRUCTIONS

1. Place the module in the receiver or ITA until the upper

and lower module screws touch the mating holes in

the inner frame (Figure A & B). Ensure that position A1 is

located at the top for systems in which the modules are

oriented vertically or to the left for systems in which the

modules are oriented horizontally.

2. Using a 3/32 Allen wrench, tighten the top screw 1 to 2 full

revolutions, while pushing lightly against the face of the

module.

3. Maintain this pressure while tightening the bottom screw 1

to 2 full revolutions.

4. Repeat this sequence until the module is seated. Torque

the screws to 4 in-lbs [0.45 Nm].

REMOVAL INSTRUCTIONS

1. To remove, loosen the top screw 1 to 2 full revolutions.

Loosen bottom screw 1 to 2 full revolutions.

2. Repeat this sequence until the module is separated from

the receiver or ITA.

NOTE: For optimum performance and system longevity,

distribute the contact load evenly throughout the module.

Figure A. Receiver module.

Figure B. ITA module.

4-1 For the most current information available, visit vpc.com

1/9/19

VTAC HSD USER MANUAL: SECTION 5 VIRGINIA PANEL CORPORATION

VTAC HSD 90 SERIES MODULES ACCESSORIES ● RECEIVER STRAIN RELIEF ASSEMBLY

PART # 510 109 568

TOOLS REQUIRED

Phillips Head Screwdriver

Wiring Ties

Wire Cutters (to cut wire ties)

ASSEMBLY INSTRUCTIONS

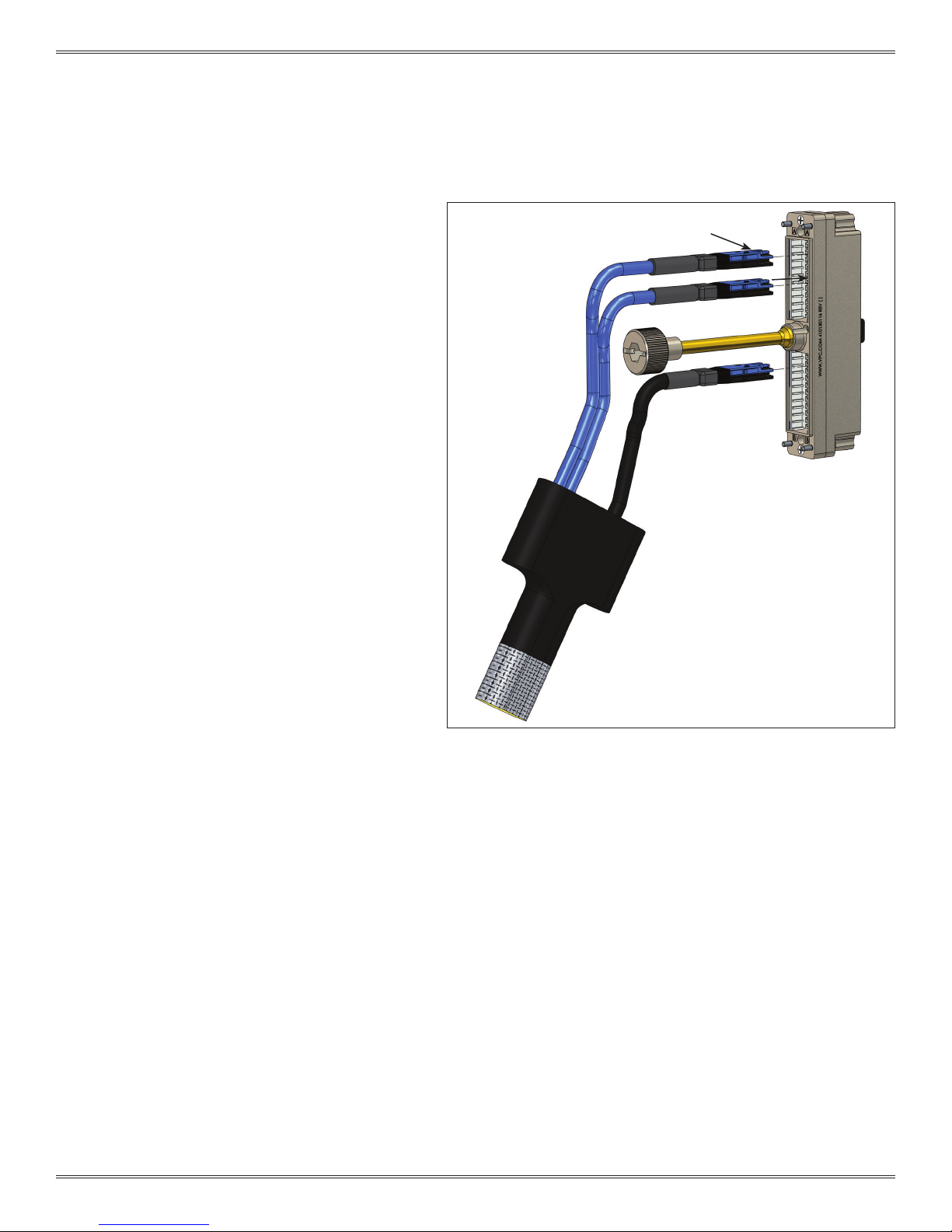

1. Using the Phillips head screwdriver, fasten the strain relief to

the rear (wiring) side of the VTAC HSD 90 Series Module with

the 2-56 screws provided as shown in Figure A.

2. Torque screws to 2 in-lbs [0.23 Nm].

3. Secure wires with wiring ties included with strain relief for

restraining wires.

NOTE: Strain relief is required for optimal performance.

STRAIN RELIEF

2-56 SCREW

5-1 For the most current information available, visit vpc.com

Figure A. VTAC HSD 90 Series strain relief.

1/9/19

VTAC HSD USER MANUAL: SECTION 6 VIRGINIA PANEL CORPORATION

REAR

VTAC HSD DOUBLE ENDED INSERT PART IDENTIFICATION

PART # 610 151 103

This section will point out features designed to help determine the proper orientation of the VATC HSD Double Ended Insert (Figure A),

as well as distinguishing features.

The Front Mating Side of the VATC HSD Double Ended Insert is shown in Figure A. The Rear Mating Side is shown in Figure B. The Rear

Mating Side mates with the VTAC HSD Right Angle Insert.

The Pin 1 position is shown in Figure C. The VATC HSD Double Ended Insert is keyed with a large and small side to ensure the insert is

oriented correctly and can only be inserted into a module one way as shown in Figure C.

PIN 1

FRONT

MATING

SIDE

Figure A. VTAC HSD Double Ended Insert.

PIN 1

LARGE SIDE

(Keying)

Figure B. VTAC HSD Double Ended Insert (Rear Mating Side).

PIN 8

SMALL SIDE

(Keying)

REAR

MATING

SIDE

Figure C. VTAC HSD Double Ended Insert (Front Mating View).

6-1 For the most current information available, visit vpc.com

1/9/19

VTAC HSD USER MANUAL: SECTION 6 VIRGINIA PANEL CORPORATION

VTAC HSD RIGHT ANGLE INSERT PART IDENTIFICATION

PART # 610 151 104

This section will point out features designed to help determine the proper orientation

of the VTAC HSD Right Angle Insert (Figure A), as well as distinguishing features.

The top of the VTAC HSD Right Angle Insert is opposite the Compliant Pins shown in

Figure A.

The Compliant Pins and PCB Mounting Surface mates with the PCB. The Compliant

Pins and PCB Mounting Surface is shown in Figure A.

The front mating side of the VTAC HSD Right Angle Insert is shown in Figure B. The front

side mates with the VATC HSD Double Ended Insert.

NOTE: VTAC HSD Right Angle Insert can be mated to VTAC HSD Double Ended Insert in

two different orientations, which will change the location of Pin 1.

PIN 1 (8)*

TOP

PCB ALIGNMENT POST

PCB MOUNTING

SURFACE

Figure A. VTAC HSD Right Angle Insert (side view).

PIN 1 (8)*

FRONT

MATING

SIDE

COMPLIANT PINS

Figure B. VTAC HSD Right Angle Insert.

INSERTION TOOL SLOTS

6-2 For the most current information available, visit vpc.com

1/9/19

VTAC HSD USER MANUAL: SECTION 6 VIRGINIA PANEL CORPORATION

VTAC HSD RETENTION INSERT PART IDENTIFICATION

PART # 610 151 105

This section will point out features designed to help determine the proper orientation of the VTAC HSD Retention Insert (Figure A), as well

as distinguishing features.

The top of the VTAC HSD Retention Insert Insert is opposite the PCB Mounting Surface shown in Figure A.

The Alignment Post and PCB Mounting Surface mate with the PCB shown in Figure A.

The VTAC HSD Retention Insert Insert is secured to the the PCB with two 0-42 Flat head screws, which are fastened in the PCB Mounting

Holes shown in Figure B.

NOTE: VTAC HSD Retention Insert is not keyed.

LATCHES

Figure A. VATC HSD Retention Insert.

TOP

ALIGNMENT POST

PCB MOUNTING

SURFACE

PCB MOUNTING HOLES

Figure B. VTAC HSD Retention Insert (side view).

6-3 For the most current information available, visit vpc.com

1/9/19

VTAC HSD USER MANUAL: SECTION 7 VIRGINIA PANEL CORPORATION

VTAC HSD RIGHT ANGLE INSERT PCB INSTALLATION INSTRUCTIONS

PART # 610 151 104

TOOLS REQUIRED

VTAC HSD Right Angle Insert Installation Tool, Part # 910 112 132

INSERT INSTALLATION INSTRUCTIONS

1. Load the desired number of inserts into the tool.

be loaded starting from the center of the tool and evenly

distributed outward. The center position is marked by the holes as

shown in Figure A.

2. Align the front of each insert with the edge of the tool as shown in

Figure B.

3. Position the insert(s) so that the top surface of each insert(s) is

ush with the inner surface of the tool as shown in Figure C.

The insert(s) should

CENTER POSITION

LOCATING HOLES

FRONT

FLUSH

Figure A. Installing the VTAC HSD Right Angle Insert (Insertion Tool).

TOP

SURFACE

Figure B. Install insert(s) with contact surface ush with tool edge.

7-1 For the most current information available, visit vpc.com

FLUSH

Figure C. Top surface of insert(s) must sit ush with tool surface.

1/9/19

VTAC HSD USER MANUAL: SECTION 7 VIRGINIA PANEL CORPORATION

VTAC HSD RIGHT ANGLE INSERT PCB INSTALLATION INSTRUCTIONS

PART # 610 151 104

TOOLS REQUIRED

VTAC HSD Right Angle Insert Installation Tool, Part # 910 112 132

INSERT INSTALLATION INSTRUCTIONS

Push each insert to the rear of the tool. Ensure that the rear of each insert is against the rear of the tool as shown in Figure D.

4.

Make sure that the insert(s) stay in position until located in the board.

5. If necessary you may push on the tab to help seat each insert(s) as shown in Figure E.

PUSH

TAB

DETAIL A

FLUSH

Figure D. Back end of insert(s) should sit ush with tool

edge.

7-2 For the most current information available, visit vpc.com

Figure E. Installing the VTAC HSD Right Angle Insert(s).

1/9/19

VTAC HSD USER MANUAL: SECTION 7 VIRGINIA PANEL CORPORATION

TOOLS REQUIRED

VTAC HSD Right Angle Insert Installation Tool, Part # 910 112 132

INSERT INSTALLATION INSTRUCTIONS

6. Position the board so that the contacts and alignment pins are aligned to the proper holes as shown in in Figure F.

7. Then place the board onto the contacts and hold the board in position as shown in Figure G.

8. Place the other half of the tool on the top and hold the two halves together with the board in between them. Make sure that the

contacts and the alignment pins are going into the correct holes as shown in Figure H and I.

POSITION

BOARD

ALIGNMENT

PINS

CONTACTS

Figure F. Installing the VTAC HSD Right Angle Insert(s).

Figure H. Join two halves of tool.

Figure G. Place board onto insert(s). Ensure alignment of

contacts and pins.

CHECK

ALIGNMENT

Figure I. Check alignment of contacts and alignment pins with holes.

7-3 For the most current information available, visit vpc.com

1/9/19

VTAC HSD USER MANUAL: SECTION 7 VIRGINIA PANEL CORPORATION

VTAC HSD RIGHT ANGLE INSERT PCB INSTALLATION INSTRUCTIONS

PART # 610 151 104

TOOLS REQUIRED

VTAC HSD Right Angle Insert Installation Tool, Part # 910 112 132

INSERT INSTALLATION INSTRUCTIONS (CONT’D)

9. The loaded tool is ready to be transferred to the press. The parts should be held rmly together so the insert(s) do not come

out of the board. The tool can be pressed with either side up as shown in Figure J.

10. Using the press, gentlely push the base and top of tool together until the contacts are seated. Be careful not to over-press.

11. Remove the base the tool as shown in Figure K.

12. Remove top half of the tool from the PCB assembly by pushing on the front surface. After the tool has been released, lift it

off the PCB as shown in Figure L.

13. Verify that the insert(s) are fully seated against the board along the edge as shown in Figure M.

OR

Figure J. Press insert(s) onto board.

PRESS

REMOVE BASE

PRESS

Figure K. Remove base.

ONCE THE TOOL

IS RELEASED

LIFT OFF INSERTS

PUSH TO

RELEASE

TOOL

Figure L. Release insert(s). Figure M. Installing the VTAC HSD Right Angle insert(s).

7-4 For the most current information available, visit vpc.com

FULLY SEATED

1/9/19

VTAC HSD USER MANUAL: SECTION 7 VIRGINIA PANEL CORPORATION

INSERT INSTALLATION/REMOVAL INSTRUCTIONS FOR ITA AND RECEIVER MODULE

PART # 510 170 101 AND 510 171 101

TOOLS REQUIRED

Philips screw driver

INSERT INSTALLATION INSTRUCTIONS

1. Install VTAC HSD Right Angle Insert(s) onto PCB see Section 7-1.

2. Ensure that the VTAC HSD Double Ended Insert(s) is aligned with

the corresponding module position. Apply gentle pressure and

insert the VTAC HSD Double Ended Insert(s) into the rear (wiring

side) of the module as shown in Figure A. The VTAC HSD Double

Ended Insert(s) can only go in one way.

3. Engage Module with VTAC HSD Double Ended Insert(s) onto

VTAC HSD Right Angle Insert(s) as shown in Figure B.

4. Attach bracket to PCB with the PCB to bracket mounting screws,

do not tighten completely. Then secure the PCB Assembly to the

module with module to bracket mounting screws. Torque #2-56

aand M2 screws to 1.5 in-lbs [0.17Nm] shown in Figure C.

FRONT

REAR WIRING SIDE

Figure A. VTAC HSD Double Ended Insert Installation

BRACKET MOUNTING

HOLE (2)

BRACKET

PCB TO BRACKET MOUNTING

REAR MATING SIDE

OF 610151103

SCREW (4) M2

Figure B. Engage Module with VTAC HSD Double

Ended Inserts onto VTAC HSD Right Angle Inserts

7-5 For the most current information available, visit vpc.com

MODULE TO BRACKET

MOUNTING SCREW (2)

2-56

BRACKET

Figure C. Install PCB to Module Brackets

1/9/19

VTAC HSD USER MANUAL: SECTION 7 VIRGINIA PANEL CORPORATION

INSERT INSTALLATION/REMOVAL INSTRUCTIONS FOR RECEIVER MODULE

PART # 310 130 XXX

TOOLS REQUIRED

Philips screw driver

INSERT INSTALLATION INSTRUCTIONS

1. Install

2.

VTAC HSD Right Angle Insert(s) onto PCB see Section 7-1.

Ensure that the VTAC HSD Double Ended Insert(s) is aligned with

the corresponding module position. Apply gentle pressure and

insert the VTAC HSD Double Ended Insert(s) into the rear (wiring

side) of the module as shown in Figure A. The VTAC HSD Double

Ended Insert(s) can only go in one way.

3. Engage Module with VTAC HSD Double Ended Inserts onto VTAC

HSD Right Angle Inserts as shown in Figure B.

4. Attach the bracket to PCB with the PCB to bracket mounting

screws, do not tighten completely. Then secure the PCB

Assembly to module with module to bracket mounting screws.

Torque #2-56 and M2 screws to 1.5 in-lbs [0.17 Nm] shown in

Figure C.

FRONT

REAR WIRING SIDE

Figure A. SIM Double HSD Insert Installation.

REAR MATING SIDE

OF 610151103

PCB TO BRACKET

MOUNTING SCREW (2)

M2

Figure B. Engage Module with VTAC HSD Double

Ended Insert onto SIM Right Angle HSD Inserts

7-6 For the most current information available, visit vpc.com

BRACKET

MOUNTING HOLE

BRACKET

MODULE TO BRACKET

MOUNTING SCREW (1)

2-56

Figure C. Install PCB to Module Brackets

1/9/19

VTAC HSD USER MANUAL: SECTION 8 VIRGINIA PANEL CORPORATION

INSERT INSTALLATION/REMOVAL INSTRUCTIONS FOR ITA AND RECEIVER MODULE

PART # 610 151 105

TOOLS REQUIRED

VTAC Extraction Tool Kit, Receiver and ITA, Part # 910 112 130

INSERT INSTALLATION INSTRUCTIONS

1. Install VTAC HSD Right Angle Insert(s) onto PCB see Section 7-1.

2. Fasten VTAC HSD Retention Insert to PCB with M1x 0.59" screws.

3.

Ensure that the VTAC HSD Double Ended Insert(s) is aligned with

the corresponding module position. Apply gentle pressure and

insert the VTAC HSD Double Ended Insert(s) into the rear (wiring

side) of the module shown in Figure A Section 7-2 and Section

7-3. The VTAC HSD Double Ended Insert(s) can only go in one

way.

4. Insert VTAC HSD Right Angle Inserts into Module and VTAC HSD

Double Ended Inserts shown in Figure A.

INSERT REMOVAL INSTRUCTIONS

5. Extract VTAC HSD Right Angle Insert(s). The PCB assembly will

extract as shown in Figure B.

NOTE: VTAC HSD Double Ended Inserts will remain in module.

6. Extract VTAC HSD Double Ended Insert per Section 2-2

NOTE: VTAC HSD Right Angle Retention Insert’s latches will retain the

small PCB assembly.

NOTE: (1) Retention Grid limited to (6) VTAC HSD Right Angle Inserts.

VTAC HSD

RETENTION INSERT

Figure A. Insert VTAC HSD Right Angle Inserts into

Module and VTAC HSD Double Ended Inserts

(Receiver Module Shown)

PUSH

PLUNGER

Figure B. Small PCB Extraction (Receiver Module Shown)

8-1 For the most current information available, visit vpc.com

1/9/19

VTAC HSD USER MANUAL: SECTION 10 VIRGINIA PANEL CORPORATION

COMPLIANT PINS

MATING

SIDE

SIDE

FACE A

FACE B

VTAC HSD VERTICAL HEADER INSERT PART IDENTIFICATION

PART # 610 151 107

This section will point out features designed to help determine the proper orientation of the VTAC HSD Vertical Header Insert as well as

its distinguishing features. The mating side of the VTAC HSD Vertical Header Insert is opposite the compliant pins as shown in Figure A.

The faces of the contact are symmetrical. The rst pin location can either be Pin 1 or Pin 8 (Figure B).

The compliant pins are used to mount the insert to the PCB with use of insertion tool # 910 112 133 (Figure C).

FRONT

MATING

SIDE

COMPLIANT PINS

Figure A. Identifying key features of the insert.

SIDE

MATING

SIDE

FACE A FACE B

Figure B. Both faces of the insert are symmetrical.

First pin location can be Pin 1 or Pin 8.

RECESSED SHOULDER

FOR INSERTION TOOL

9-1 For the most current information available, visit vpc.com

Figure C. Shoulders of insert are recessed for

insertion tool use.

1/9/19

VTAC HSD USER MANUAL: SECTION 10 VIRGINIA PANEL CORPORATION

VTAC HSD VERTICAL INSERT PCB INSTALLATION

INSTRUCTIONS FOR 90 SERIES MODULES

PART # 610 151 107

TOOLS REQUIRED

VTAC HSD Vertical Header Insert Installation Tool, Part # 910 112 133

INSERT INSTALLATION INSTRUCTIONS

1. The insertion tool is a two-piece assembly, comprised of a base and a top. Orient the assembly so that it matches Figure A.

2. Remove the top from its base. Notice the alignment pins on either side of the base. These alignment pins will be later used to

locate the PCB and the base (Figure B).

3. Load the desired number of inserts into the base as shown. Position the inserts so that the mating-side of the inserts are

oriented towards the base and the compliant pins are oriented towards the top (Figure C).

TOP

BASE

Figure A. Proper orientation of part # 910 112 133. Figure B. Remove the top of the insertion tool from its base.

ALIGNMENT

PINS

ENSURE SIDES OF

INSERT(S) ARE FULLY

SEATED

Figure C. Load the desired number of inserts into the base.

10-1 For the most current information available, visit vpc.com

Figure D. Ensure that the edges of the insert are fully

seated in the base of the insertion tool.

1/9/19

VTAC HSD USER MANUAL: SECTION 10 VIRGINIA PANEL CORPORATION

VTAC HSD VERTICAL INSERT PCB INSTALLATION

INSTRUCTIONS FOR 90 SERIES MODULES

PART # 610 151 107

INSERT INSTALLATION INSTRUCTIONS (CONT’D)

4. To use the vertical header insertion tool, the PCB must be designed to accept the alignment pins of the insertion tool. The distance

between these two alignment holes is identi ed on the drawing of part # 610 151 107.

5. With the tool’s top removed from its base, insert the alignment pins into the alignment holes of the PCB (Figure A).

6. Ensure that the compliant pins of the insert align with the plated thru-holes on the PCB board. For info on the spacing of these holes,

consult the drawing for part # 610 151 107 (Figure B).

7. With the base and PCB together, place the top on to the base of the insertion tool (Figure C).

8. Press the top insertion tool onto the base, pushing the compliant pins of the insert into the PCB. Do not over press. Remove the PCB

from the tool, and verify the installation of each insert in the PCB is correct. The insert should be ush to the PCB with a gap of no more

than .004” [.10 mm].

NOTE: Each insert requires 10 lbs [4.54 kg] of force to create a gas-tight seal when installed. Inserts should not be removed once

in place. Visually inspect the pin side of the PCB to ensure proper pin insertion with the PCB.

ALIGNMENT HOLES FOR

THE ALIGNMENT PINS OF

INSERTION TOOL

Figure A. The PCB should have alignment holes to

accept the alignment pins of the insertion tool.

PRESS-FIT TAILS OF INSERT

SHOULD ALIGN WITH

THRU HOLES

Figure B. Compliant pins align with the thru-holes of the PCB.

10-2 For the most current information available, visit vpc.com

Figure D. Finished inserts installed properly on a PCB.Figure C. Insertion tool is ready to press.

1/9/19

VTAC HSD USER MANUAL: SECTION 10 VIRGINIA PANEL CORPORATION

TROUBLESHOOTING

ITA frame is not lined up when in the process of engagement with receiver

This may indicate that the ITA is out of alignment or that a module is not mating with its intended mate.

• Remove and inspect the ITA for proper alignment.

• Check for foreign objects/tools that may impede engagement.

• Inspect the matching of modules - Signal ITA module to mate with signal receiver module, etc.

Forceful engagement of the Receiver and the ITA

will result in serious damage to multiple par ts of the

system (modules, Receiver, ITA and contacts)!

11-1 For the most current information available, visit vpc.com

1/9/19

VTAC HSD USER MANUAL: SECTION 10 VIRGINIA PANEL CORPORATION

Product Performance Specications

1. Scope

1.1. Content

This specication covers the performance, tests and quality requirements for the VTAC HSD insert

and connector system. The VTAC HSD insert is a separable electrical connection device utilizing 8

contacts housed within a hermaphroditic protective shroud. The individual inserts are to be used with

connector modules with .125 inch centerline spacing.

1.2. Qualication Testing

All inspections shall be performed using applicable inspection plans and product drawings. Upon

completion of qualication testing, this specication will be assigned a number and be classied as a

Product Qualication Report, which will be identied in section 2.

2. Applicable Documents

2.1. Content

The following documents form a part of this specication to the extent specied herein. Unless other-

wise specied, the latest edition of the document applies. In the event of a conict between requirements of this specication and product drawing, product drawing will take precedence. In the event

of a conict between requirements of this specication and referenced documents, this specication

shall take precedence.

2.2. Documents

A. EIA Standards

• EIA 364-5

• EIA 364-06

• EIA 364-13

• EIA 364-20

• EIA 364-21

• EIA 364-29

• EIA 364-70

• EIA 364-108

• AMS 2422

B. Product Drawings for the following part numbers

Housings

• 510170101

• 510171101

Contacts

• 610151101

3. Requirements

3.1. Design and Construction Product shall be of design, construction and physical dimensions specied

on applicable product drawings.

3.2. Materials

A. Contacts

• Beryllium Copper

B. Insert Shroud

• 30% Glass Filled LCP

C. Potting Compound

• OM 678

D. Housings

• Zamak 3

12-1 For the most current information available, visit vpc.com

1/9/19

VTAC HSD USER MANUAL: SECTION 10 VIRGINIA PANEL CORPORATION

Product Performance Specications

3.3. Ratings

A. Voltage

• 600 Volt Max. DC or Peak AC, use of wire M22759/11

B. Temperature

• -40°C to 125°C

3.4. Performance and Test Description Product is designed to meet electrical, mechanical, and

environmental requirements specied in Table 3 1. Unless otherwise specied, all tests should

be performed at free air, room temperature, and ambient environmental conditions.

3.5. Test Requirements and Procedures Summary

Table 3.1: Test requirements and procedure summary.

Category Test Description Requirement Procedure

Preliminary Examination of Product

Contact Resistance 30 mΩ EIA-364-06

Insulation Resistance 1000 MΩ minimum

Dielectric Withstanding Voltage

Electrical

Cross Talk

Impedance 100Ω ±10Ω Per Differential Pair

Insertion Loss -1dB to 6.25 GHz

Durability See test sequence: Table 3-2

Retention Force: Receiver

Retention Force: ITA Contact

Insertion Force: Receiver

Mechanical

1

Shall meet visual requirement, show no physical damage and shall meet requirement of additional tests as specied in Test

Sequence in Table 3.2.

Insertion Force: ITA Contact

Contact

Contact

Mating Force 0.75 lbf Max per insert

Un-mating Force ≤ 1 lbf per insert

Meets requirements of product

drawing

1050 VDC test voltage at sea

-30dB to 6.25 GHz

-40dB to 6.25 GHz

Contact shall not dislodge from

Force to insert contacts into

module ≤ 1.5 lbf

1

level

module

Visual, dimensional, and

functional examination per

applicable quality inspection

plan

EIA-364-21: Test between

adjacent contacts assembled in

housing at 500VDC

EIA-364-20: Test between

adjacent contacts at 0.5 mA

Cross talk between adjacent

differential pair within the same

insert

Cross talk between differential

pair in adjacent inserts

EIA-364-09: Mate and un-mate

sample for 10,000 cycles

EIA-364-29: Apply axial load of 5

lbs to contact

EIA-364-05

EIA-364-13: Measure force

necessary to mate samples at a

normal rate of engagement of

the ITA

EIA-364-13: Measure force

necessary to un-mate samples at

a normal rate of disengagement

of the ITA

12-2 For the most current information available, visit vpc.com

1/9/19

VTAC HSD USER MANUAL: SECTION 10 VIRGINIA PANEL CORPORATION

Product Performance Specications

3.6. Product Qualication and Requalication Test Sequence

Table 3.2: Test Sequence

Test or Examination

Characteristic Impedance 2,11

Contact Resistance 4,10

Cross Talk Between Pairs

(Adjacent Inserts)

Cross Talk Between Pairs

(Same Insert)

Dielectric Withstanding Voltage 5,11

Durability 8,15 7

Examination of Product 1,16 1,13 1

Insert Insertion Force 2

Insert Retention 3

Insertion Loss 3,12

Insulation Resistance 6,12

Mating Force 6,9 2,8

Un-mating Force 7,10 3,9

1 2 3

4,13

5,14

Test Group

Numbers indicate the sequence in which the tests are performed. For test group sample selection see 4.1.

3.7. Contact Resistance Measurement Setup.

Figure 1: Contact resistance measurement setup.

12- 3 For the most current information available, visit vpc.com

1/9/19

VTAC HSD USER MANUAL: SECTION 10 VIRGINIA PANEL CORPORATION

Product Performance Specications

3.8. Insertion Loss

Figure 2: Insertion loss SFP+ cables de-embedded at 0 cycles and 10,000 cycles.

3.9. Return Loss

Figure 3: Return loss comparison between SFP+ cable only and SFP+ cable with terminated to VTAC inserts at 0 cycles and 10,000

cycles.

12- 4 For the most current information available, visit vpc.com

1/9/19

VTAC HSD USER MANUAL: SECTION 10 VIRGINIA PANEL CORPORATION

Product Performance Specications

3.10. Crosstalk

Between Differential Pairs Within the Same Insert.

Figure 4: Crosstalk between two differential pairs within the same VTAC insert at 0 cycles and 10,000 cycles. The crosstalk

between the two differential pairs within the SFP+ cable without VTAC is shown for reference.

Between Vertically Adjacent Differential Pairs

Figure 5: Crosstalk between vertically adjacent differential pairs in two VTAC inserts at 0 cycles and 10,000 cycles. The crosstalk

between the two differential pairs within the SFP+ cable without VTAC is shown for reference.

Between Diagonally Adjacent Differential Pairs

Figure 6: Crosstalk between diagonally adjacent differential pairs in two VTAC inserts at 0 cycles and 10,000 cycles. The crosstalk

between the two differential pairs within the SFP+ cable without VTAC is shown for reference.

12- 5 For the most current information available, visit vpc.com

1/9/19

VTAC HSD USER MANUAL: SECTION 10 VIRGINIA PANEL CORPORATION

Product Performance Specications

4. Quality Assurance Provisions

4.1. Qualication Testing

4.1.1. Sample Selection

Samples shall be prepared in accordance with applicable instruction sheets and shall be selected at random from current

production.

4.1.2. Test Sequence

Qualication inspection shall be veried by testing samples as specied in Table 3 2.

4.2. Requalication Testing

If changes signicantly affecting form, t or function are made to product or manufacturing process, product assurance shall

coordinate requalication testing, consisting of all or part of original testing sequence as determined by development/product

and reliability/quality engineering.

4.3. Acceptance

Acceptance is based on verication that product meets requirements of Table 3 1. Failures attributed to equipment, test set-up

or operator deciencies shall not disqualify product. When product failure occurs, corrective action shall be taken and samples

resubmitted for qua lication. Testing to conrm corrective action is required before resubmittal.

4.4. Quality Conformance Inspection

A Certicate of Conformance (C of C) dimensional inspection must be completed for all samples prior to Qualication testing.

The applicable quality inspection plan will specify sampling acceptable quality level to be used. Dimensional and functional

requirements shall be in accordance with applicable product drawing and this specication.

12- 6 For the most current information available, visit vpc.com

1/9/19

Loading...

Loading...