VPC G12, G12x User Manual

G12/G12x USER’S MANUAL

TABLE OF CONTENTS

SECTION 1 SLIDE CONFIGURATION

SECTION 2 SLIDE CONFIGURATION ACCESSORIES

SECTION 3 TABLETOP CONFIGURATION

SECTION 4 TABLETOP CONFIGURATION ACCESSORIES

SECTION 5 RACK MOUNT CONFIGURATION

SECTION 6 RACK MOUNT CONFIGURATION ACCESSORIES

SECTION 7 HANDLE REMOVAL AND REPOSITIONING

SECTION 8 ITA ENCLOSURES

SECTION 9 ACCESSORIES

SECTION 10 ITA AND RECEIVER ENGAGEMENT

SECTIO N 11 TROUBLESHOOTING AND PRECAUTIONARY NOTES

Please note that any printed or downloaded User Manuals or Procedure Sheets may not reect the most current

revisions. The information contained in these materials is subject to change.

For the most current information available, visit www.vpc.com.

10/17/18

G12/G12 x USER’S MANUAL: SECTION 1 VIRGINIA PANEL CORPORATION

TOP VIEW

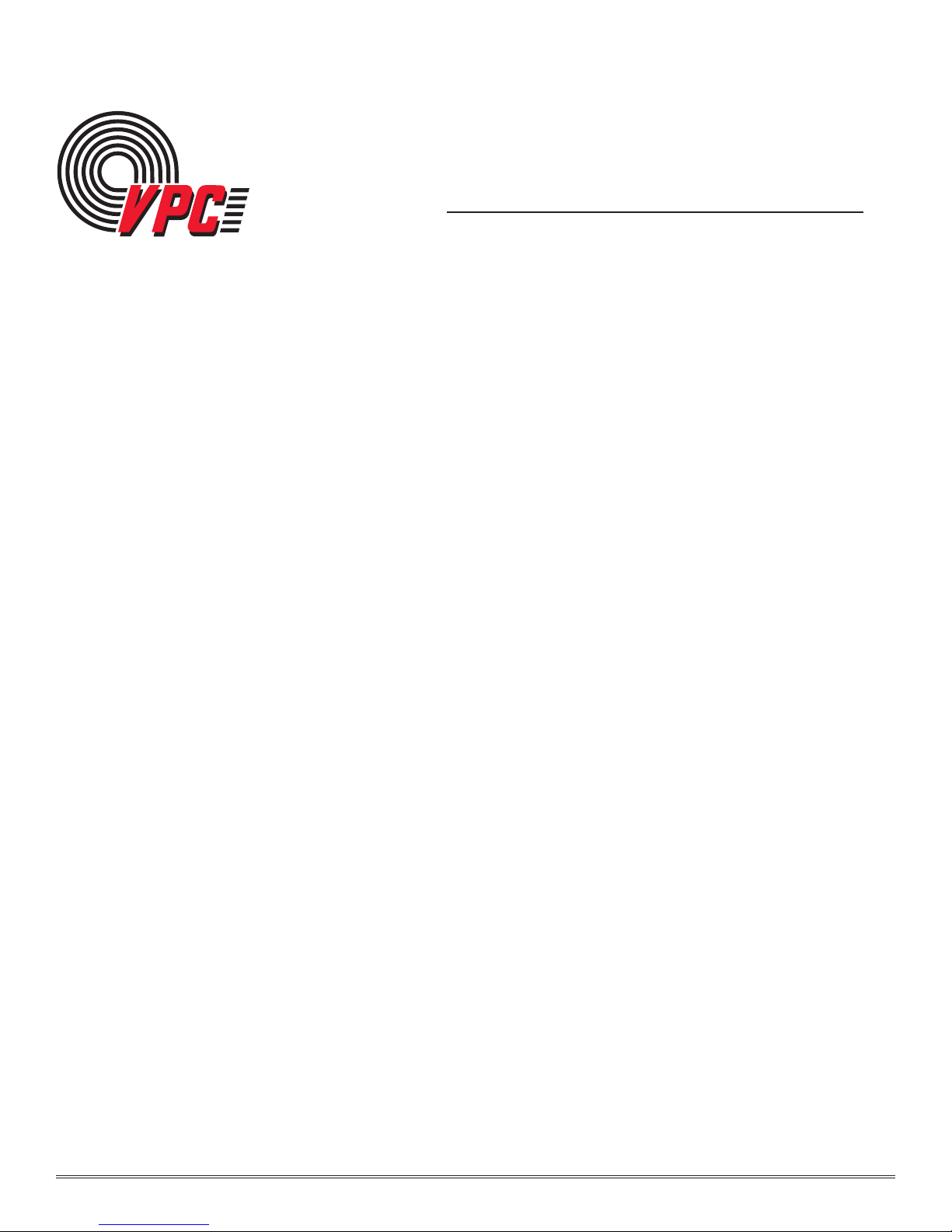

SLIDE CONFIGURATION INSTALLATION

20” SLIDE KIT (FITS 20” – 22” DEEP RACKS [508 - 558.8]) • PART # 310 113 409

24” SLIDE KIT (FITS 24” – 26” DEEP RACKS [609.6 - 660.4]) • PART # 310 113 410

28” SLIDE KIT (FITS 28” - 30” DEEP RACKS [711.2 - 762]) • PART # 310 113 451

30” SLIDE KIT (FITS 30” – 32” DEEP RACKS [762 - 812.8]) • PART # 310 113 411

36” SLIDE KIT (FITS 34” – 38” DEEP RACKS [863.6 - 965.2]) • PART # 310 113 500

Slides can be used with both the 15" and 20" G12/G12x

receivers. The slide kits include a mounting bracket kit, slides

and hardware. Choose your slide kit based on the distance

from rail to rail and verify that the slides will not interfere with

the rack enclosure. Each kit will suppor t 180 lbs.

TOOLS REQUIRED

Phillips Head Screwdriver

Flat Head Screwdr iver

³/

Allen Wrench

32

DETERMINE YOUR SLIDE KIT

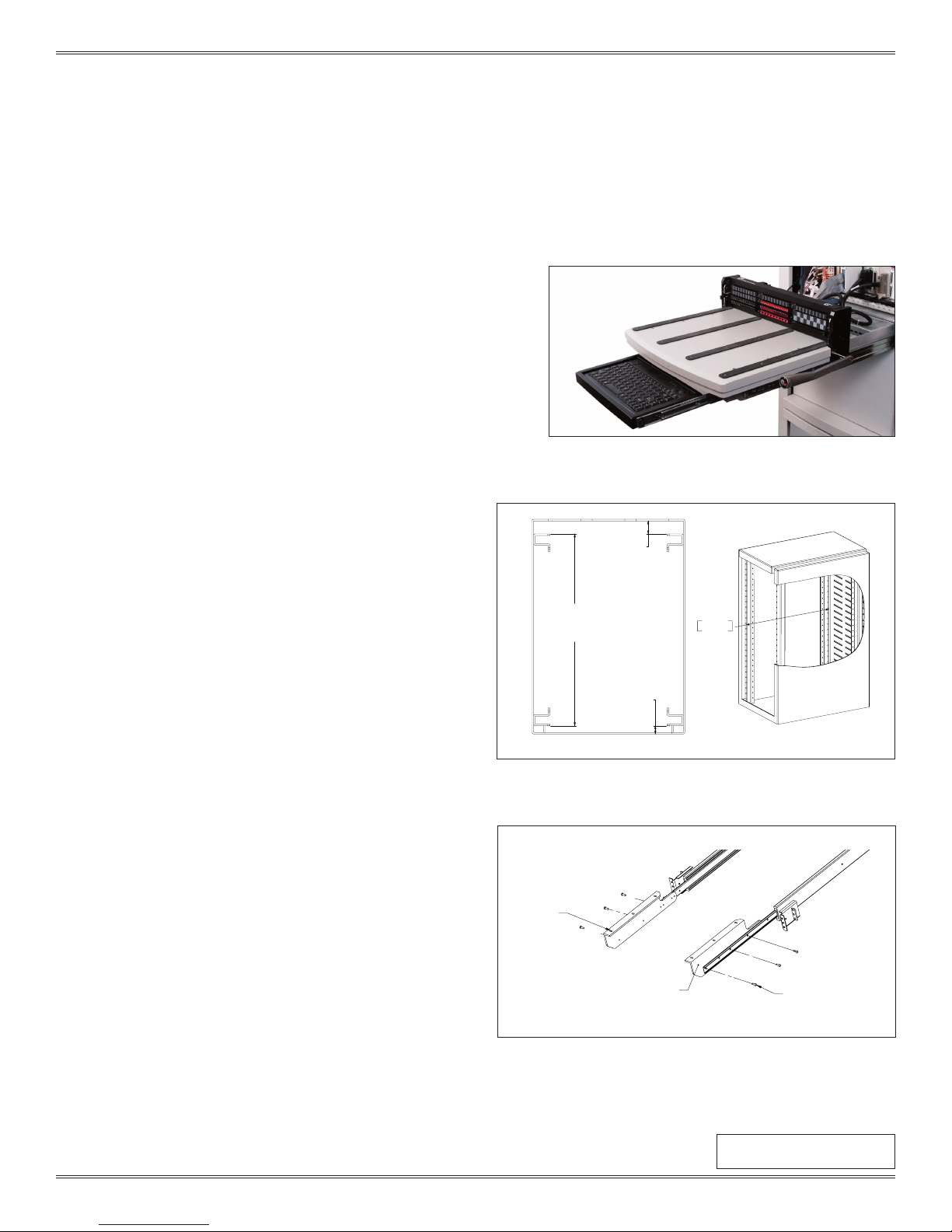

1. Measure dimension A as shown in Figure A to determine the

proper slide kit.

NOTE: Make sure the slide length does not exceed dimensions A

plus B.

DIMENSION B

[50.8]

2.00

INSTALLATION

1. Install slides using manufacturer’s instructions. A hard copy is

included with the slide kit.

( ww w.accuride.com/Resources/pdf/3507-r4-0309.pdf)

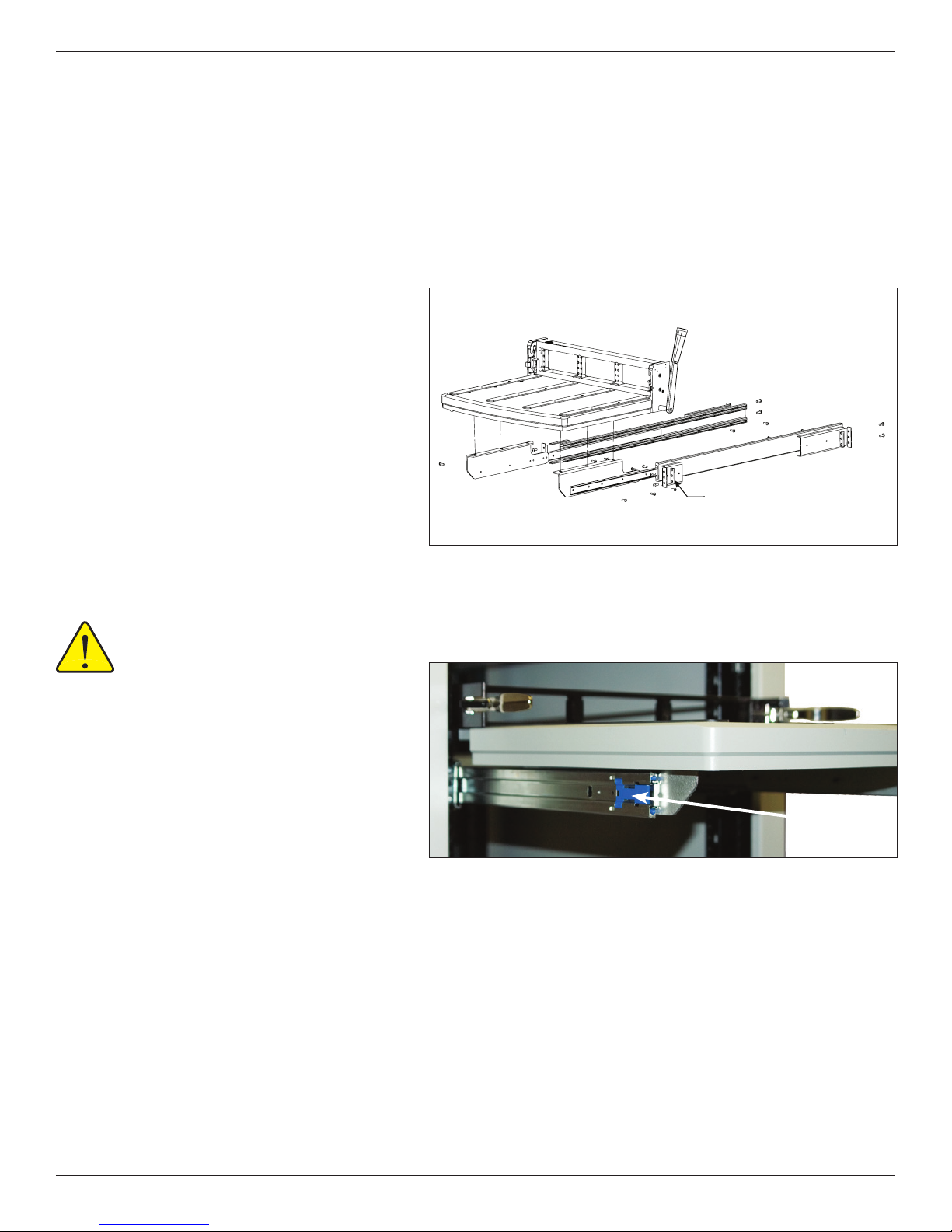

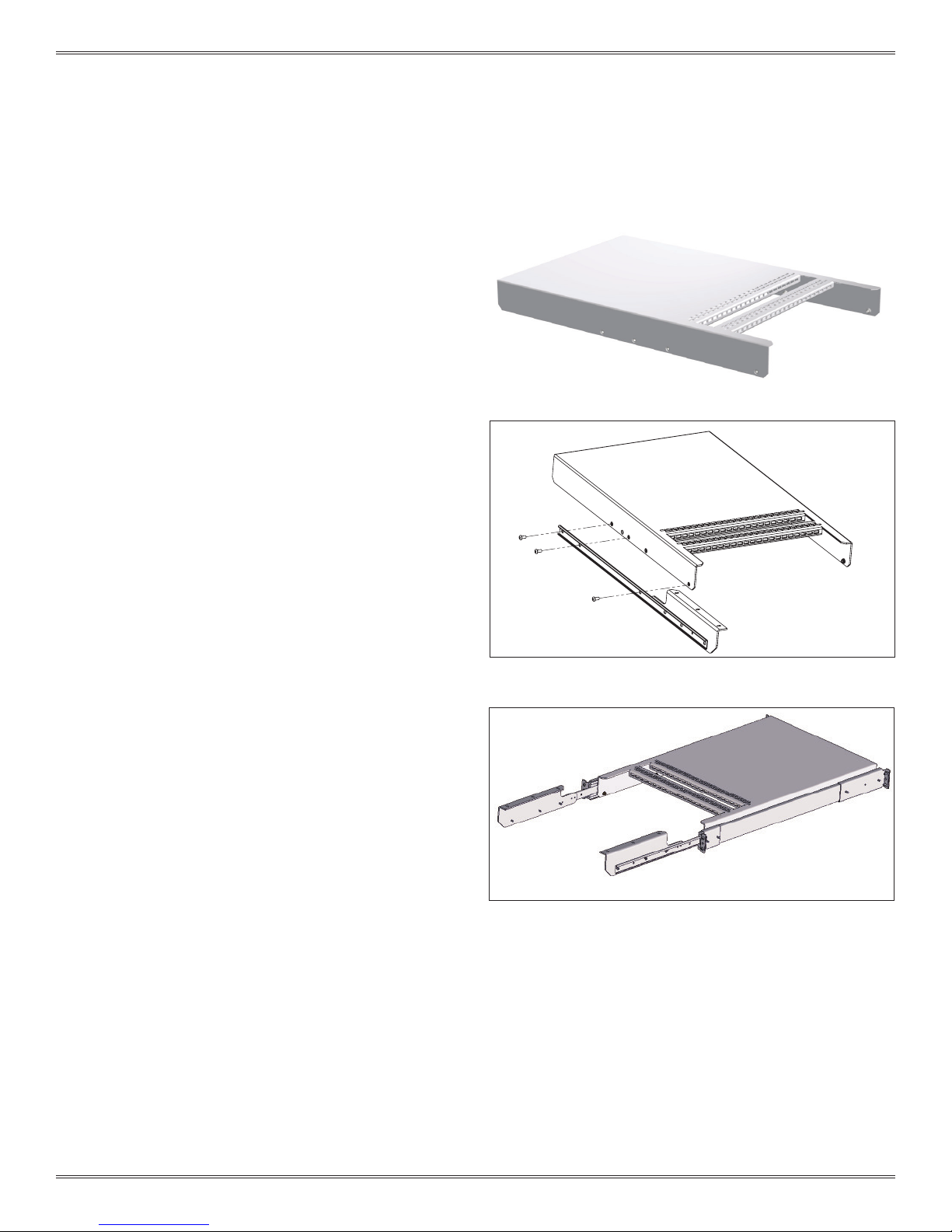

2. Attach platform mounting brackets to slides (Figure B).

NOTE: The screws will overhang the bracket holes by 3/8". These

screws will also be used to mount the keyboard tray kit, Part #

310 113 43 9.

Continued on next page...

DIMENSION A

[749.3]

29.50

DIMENSION C

FRONT OF RACK

[31.75]

1.25

749.30

29.50

Figure A. If dimension C exceeds 1" use the Rack Extender Kit,

Part # 310 113 406 for G12 or Part # 310 113 519 for G12x.

PLATFORM

MOUNTING

BRACKETS

G12 RECEIVER SUPPORTS

FOR MOUNTING PLATFORM

TO SLIDES

SLIDE TO BRACKET

MOUNTING HARDWARE

Figure B. The platform mounting brackets are threaded so

washers and nuts will not need to be locked.

1-1

For the most current information available, visit www.vpc.com

Dimensions shown: [millimeters]

inches

10/17/18

G12/G12 x USER’S MANUAL: SECTION 1 VIRGINIA PANEL CORPORATION

SLIDE CONFIGURATION INSTALLATION

20” SLIDE KIT (FITS 20” – 22” DEEP RACKS [508 - 558.8]) • PART # 310 113 409

24” SLIDE KIT (FITS 24” – 26” DEEP RACKS [609.6 - 660.4]) • PART # 310 113 410

28” SLIDE KIT (FITS 28” - 30” DEEP RACKS [711.2 - 762]) • PART # 310 113 451

30” SLIDE KIT (FITS 30” – 32” DEEP RACKS [762 - 812.8]) • PART # 310 113 411

36” SLIDE KIT (FITS 34” – 38” DEEP RACKS [863.6 - 965.2]) • PART # 310 113 500

3. Remove the rubber feet.

4. Attach the G12/G12x platform to the platform

mounting brackets after removing the rubber feet

(Figure C).

NOTE: If you are installing a cable tray or instrument

brackets, do not attach the platform until those

accessories are installed.

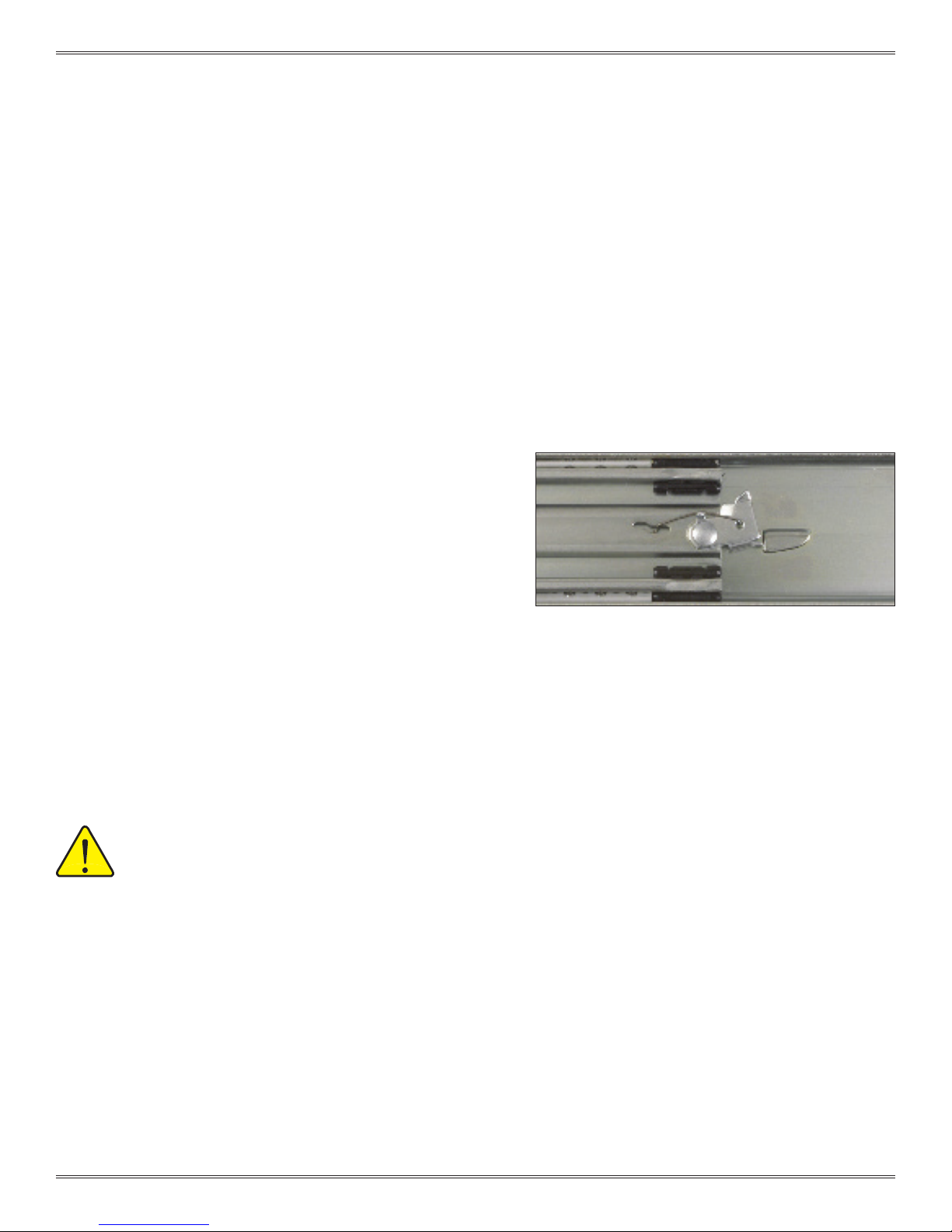

5. Pull the receiver out as far as possible. The slides

will lock in position. Push the blue tabs located on

the middle section of the slides (Figure D). Apply

pressure to push the receiver back in toward the

rack. The smaller inner slides move into the middle

section, which should not move. Push receiver until

it backs into the rack. The mounting screws can now

be used.

Figure C. Use the existing #8-32 at head screws, washers, and hex nuts to

secure the platform to the brackets.

BAR NUT

ALWAYS SUPPORT THE RECEIVER AND

PLATFORM WITH THE MOST ROBUST

(MIDDLE) SECTION OF THE SLIDES.

ensure proper support when extending the

receiver and table away from the rack, stop

the receiver and platform at approximately 6” from the

rack. Reach around to the rear of the receiver to the

slides underneath on both sides. Manually extend the

middle section of the slides forward until fully underneath

the platform. The receiver and platform may then be

extended while holding this middle slide in place. If

completed properly, the middle section of the slides will

remain underneath the platform and offer the strongest

support.

6. Secure receiver to rack.

To

BLUE TAB

Figure D. The slides will support 180 pounds. VPC recommends removing the

ITA/Fixture when extending the slides for wiring access and maintenance.

1-2

For the most current information available, visit www.vpc.com

10/17/18

G12/G12 x USER’S MANUAL: SECTION 2 VIRGINIA PANEL CORPORATION

SLIDE CONFIGURATION ACCESSORIES

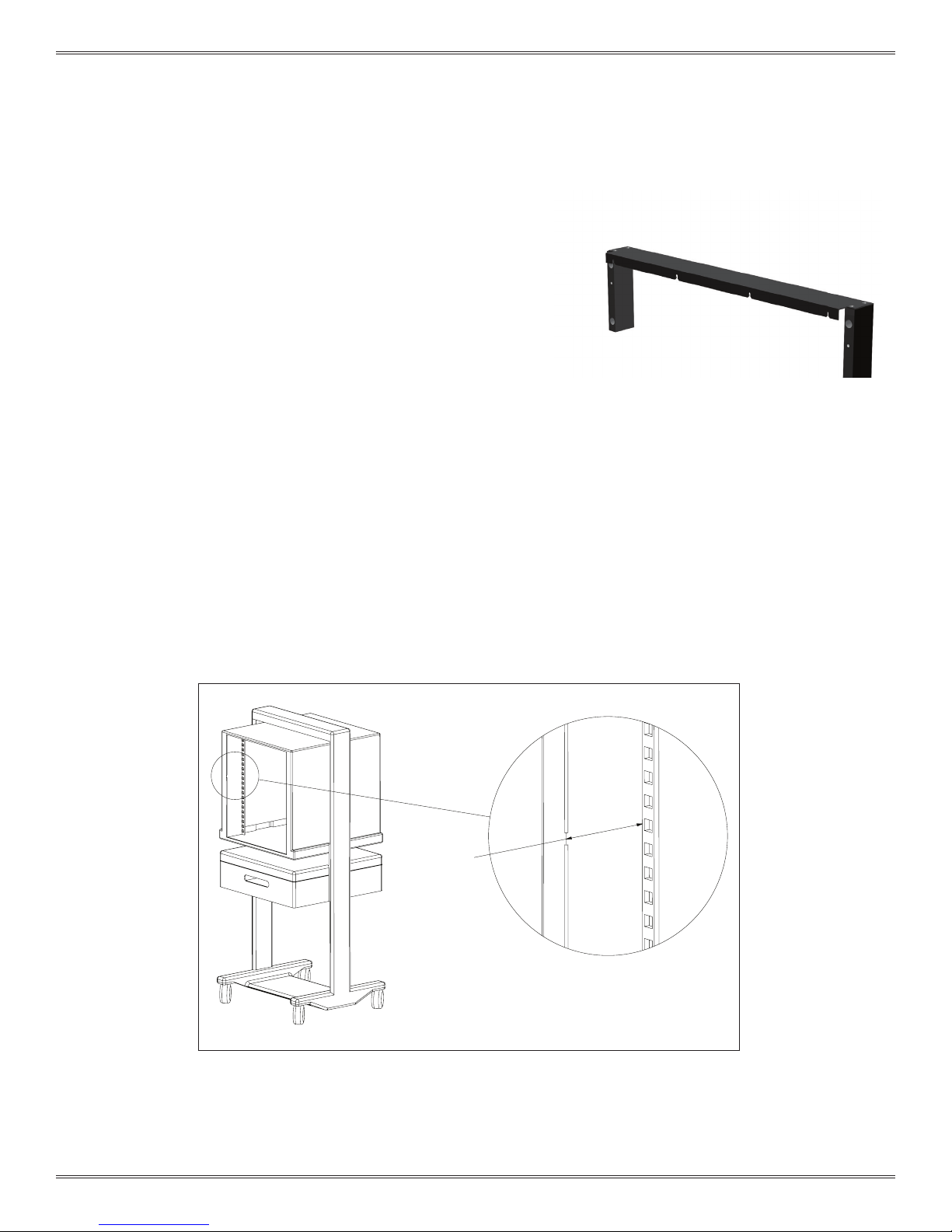

RACK EXTENDER KIT, G12, 1.5" DEEP • PART # 310 113 406

RACK EXTENDER KIT, G12X, 1.5” DEEP • PART # 310 113 519

The G12/G12x is designed to easily t 19" standard racks when

used in the slide con guration. Although mounting rail dimensions

are standardized, there may be variances in the rack enclosure

design. VPC offers a rack extender kit for rails that are recessed

more than 1". The Rack Extender Kit has a maximum depth of 2.5".

TOOLS REQUIRED

5

/32 Allen Wrench

Phillips Head Screwdriver

INSTALLATION

1. To determine if a Rack E xtender Kit is needed, verify that the distance bet ween the front of the rack enclosure and the rail is between

1" and 2.5" (Figure A).

2. Attach the mounting rack mating sur face on the extender brackets to the recessed rail with the cap screws. Do not fully tighten until

until the cover plate is attached.

3. Attach the cover to the brackets with the fl at head screws.

4. With the extender kit in place, secure the G12 receiver to the mating surface on the extender brackets with #10-32 cap screws.

NOTE: The #10-32 cap screws are provided with the G12 receiver.

DIMENSION C

DIMENSION C

2.5“[63.5mm]

[101.6]

4.00

Figure A. Rack Extender Kits are used when the rails are recessed more than 1".

2-1

For the most current information available, visit www.vpc.com

10/17/18

G12/G12 x USER’S MANUAL: SECTION 2 VIRGINIA PANEL CORPORATION

INSTRUMENT BRACKET INSTALLATION

PART # 310 113 453

The instrument brackets mount to the inner sl ide and provide

maintenance access to the chassis and the instruments.

NOTE: This instrument bracket kit does not work with the 20”

or 24” slide kits.

TOOLS REQUIRED

5

/32 Allen Wrench

Phillips Head Screwdriver

INSTALLATION

1. Depress the blue tab on the inner slide and remove.

2. Attach one of the brackets to the slide using three #8-32

button head screws. The left bracket assembly is shown in

Figure A.

3. Attach the remaining bracket to the other inner slide. If you

are also installing a cable tray, do so before reinstalling the

slides and attaching the plate. See Cable Tray Installation

instructions in this section.

Continued on next page...

Figure A. The brackets are identical par ts and only the front two

holes on each bracket are designed to line up with the slides.

Figure B. The slots on the instrument brackets are designed to

accept a strap should you want to secure your chassis.

2-2

For the most current information available, visit www.vpc.com

10/17/18

G12/G12 x USER’S MANUAL: SECTION 2 VIRGINIA PANEL CORPORATION

INSTRUMENT BRACKET INSTALLATION

PART # 310 113 453

5. Reinstall the inner slides.

• Slide the left mid-section of the slide all the way out, you will feel it

lock into position.

• Feed the matching inner slide into position and ensure the inner

section rides into place with the roller bearings seated into the

groove.

• Push the inner slide in about 6-8 inches and then pull out the right

side. Slide the track of the mid-section over the right side of the

inner slide.

• Pull the slide out until the position matches the left side.

• Reach to the back of the middle slides and release the spr ing

locking mechanism (Figure C).

NOTE: At this time, both sides should be partially installed when it will

no longer proceed into the rack because the support tab on the

instrument brackets will hit the slide mounting bracket.

6. Rotate both instrument brackets inward so the support tabs

can pass the mounting brackets. Continue to push (install slides

simultaneously) into position. Remember to push the blue tabs

to allow the inner slide to continue to travel into the middle slide

section.

NOTE: The middle section will not go into the outer section until the

inner section has been fully installed into the middle section.

7. Tighten the slide mounting screws.

MAKE SURE ALL SCREW HEADS HAVE BEEN SECURELY

TIGHTENED. ONLY USE 8-32 BUTTON HEAD SCREWS.

Figure C. Spring-locking mechanism.

2-3

For the most current information available, visit www.vpc.com

10/17/18

Loading...

Loading...