G12/G12x USER’S MANUAL

TABLE OF CONTENTS

SECTION 1 SLIDE CONFIGURATION

SECTION 2 SLIDE CONFIGURATION ACCESSORIES

SECTION 3 TABLETOP CONFIGURATION

SECTION 4 TABLETOP CONFIGURATION ACCESSORIES

SECTION 5 RACK MOUNT CONFIGURATION

SECTION 6 RACK MOUNT CONFIGURATION ACCESSORIES

SECTION 7 HANDLE REMOVAL AND REPOSITIONING

SECTION 8 ITA ENCLOSURES

SECTION 9 ACCESSORIES

SECTION 10 ITA AND RECEIVER ENGAGEMENT

SECTIO N 11 TROUBLESHOOTING AND PRECAUTIONARY NOTES

Please note that any printed or downloaded User Manuals or Procedure Sheets may not reect the most current

revisions. The information contained in these materials is subject to change.

For the most current information available, visit www.vpc.com.

10/17/18

G12/G12 x USER’S MANUAL: SECTION 1 VIRGINIA PANEL CORPORATION

TOP VIEW

SLIDE CONFIGURATION INSTALLATION

20” SLIDE KIT (FITS 20” – 22” DEEP RACKS [508 - 558.8]) • PART # 310 113 409

24” SLIDE KIT (FITS 24” – 26” DEEP RACKS [609.6 - 660.4]) • PART # 310 113 410

28” SLIDE KIT (FITS 28” - 30” DEEP RACKS [711.2 - 762]) • PART # 310 113 451

30” SLIDE KIT (FITS 30” – 32” DEEP RACKS [762 - 812.8]) • PART # 310 113 411

36” SLIDE KIT (FITS 34” – 38” DEEP RACKS [863.6 - 965.2]) • PART # 310 113 500

Slides can be used with both the 15" and 20" G12/G12x

receivers. The slide kits include a mounting bracket kit, slides

and hardware. Choose your slide kit based on the distance

from rail to rail and verify that the slides will not interfere with

the rack enclosure. Each kit will suppor t 180 lbs.

TOOLS REQUIRED

Phillips Head Screwdriver

Flat Head Screwdr iver

³/

Allen Wrench

32

DETERMINE YOUR SLIDE KIT

1. Measure dimension A as shown in Figure A to determine the

proper slide kit.

NOTE: Make sure the slide length does not exceed dimensions A

plus B.

DIMENSION B

[50.8]

2.00

INSTALLATION

1. Install slides using manufacturer’s instructions. A hard copy is

included with the slide kit.

( ww w.accuride.com/Resources/pdf/3507-r4-0309.pdf)

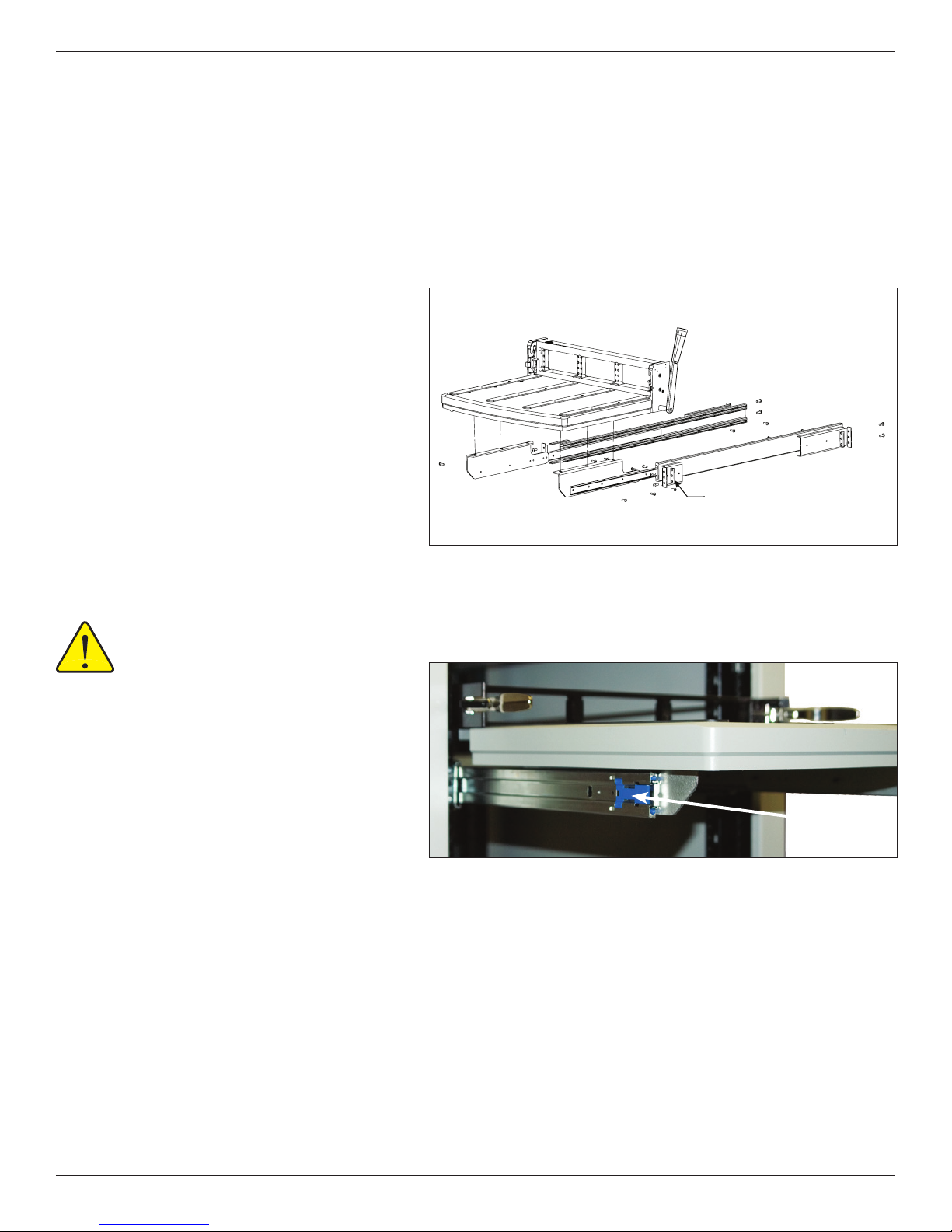

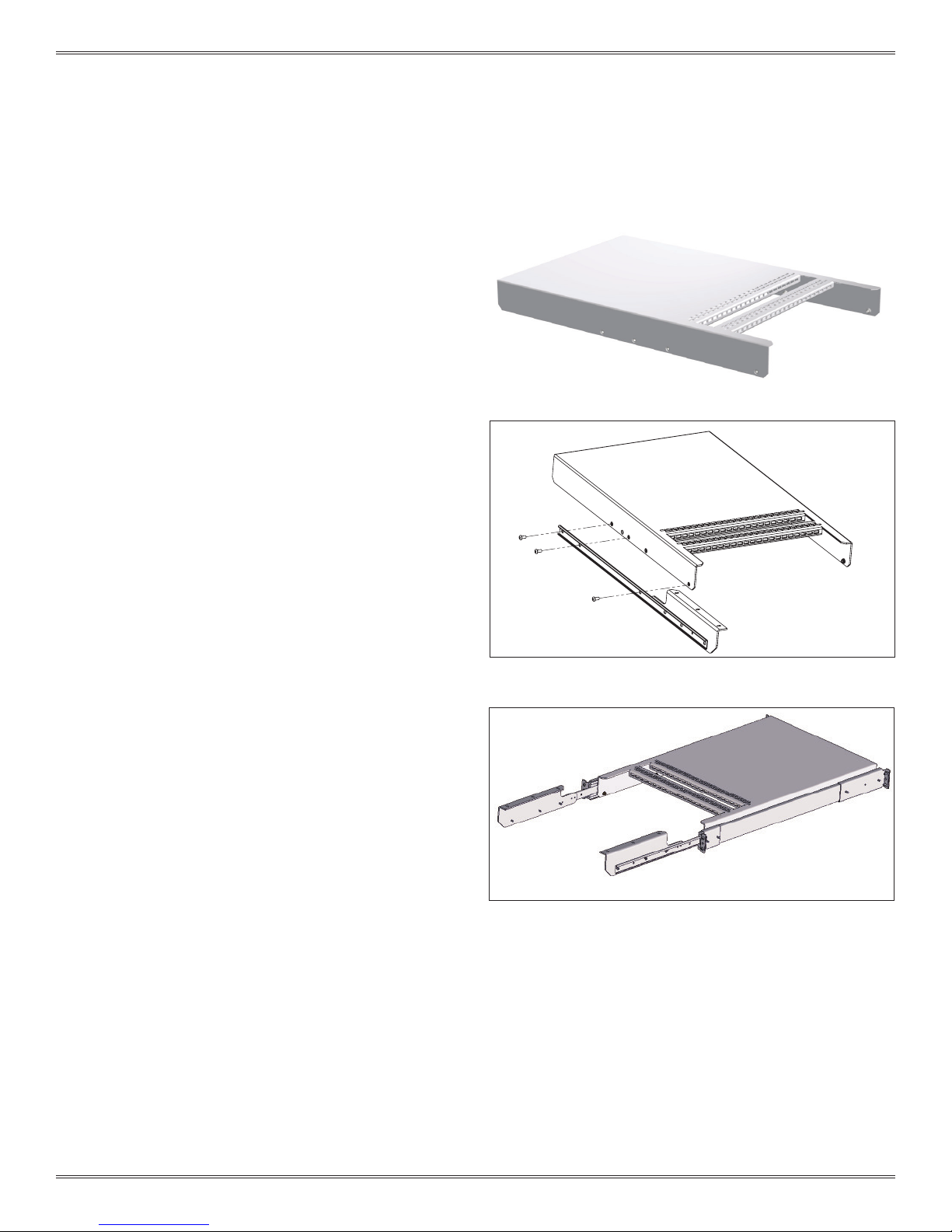

2. Attach platform mounting brackets to slides (Figure B).

NOTE: The screws will overhang the bracket holes by 3/8". These

screws will also be used to mount the keyboard tray kit, Part #

310 113 43 9.

Continued on next page...

DIMENSION A

[749.3]

29.50

DIMENSION C

FRONT OF RACK

[31.75]

1.25

749.30

29.50

Figure A. If dimension C exceeds 1" use the Rack Extender Kit,

Part # 310 113 406 for G12 or Part # 310 113 519 for G12x.

PLATFORM

MOUNTING

BRACKETS

G12 RECEIVER SUPPORTS

FOR MOUNTING PLATFORM

TO SLIDES

SLIDE TO BRACKET

MOUNTING HARDWARE

Figure B. The platform mounting brackets are threaded so

washers and nuts will not need to be locked.

1-1

For the most current information available, visit www.vpc.com

Dimensions shown: [millimeters]

inches

10/17/18

G12/G12 x USER’S MANUAL: SECTION 1 VIRGINIA PANEL CORPORATION

SLIDE CONFIGURATION INSTALLATION

20” SLIDE KIT (FITS 20” – 22” DEEP RACKS [508 - 558.8]) • PART # 310 113 409

24” SLIDE KIT (FITS 24” – 26” DEEP RACKS [609.6 - 660.4]) • PART # 310 113 410

28” SLIDE KIT (FITS 28” - 30” DEEP RACKS [711.2 - 762]) • PART # 310 113 451

30” SLIDE KIT (FITS 30” – 32” DEEP RACKS [762 - 812.8]) • PART # 310 113 411

36” SLIDE KIT (FITS 34” – 38” DEEP RACKS [863.6 - 965.2]) • PART # 310 113 500

3. Remove the rubber feet.

4. Attach the G12/G12x platform to the platform

mounting brackets after removing the rubber feet

(Figure C).

NOTE: If you are installing a cable tray or instrument

brackets, do not attach the platform until those

accessories are installed.

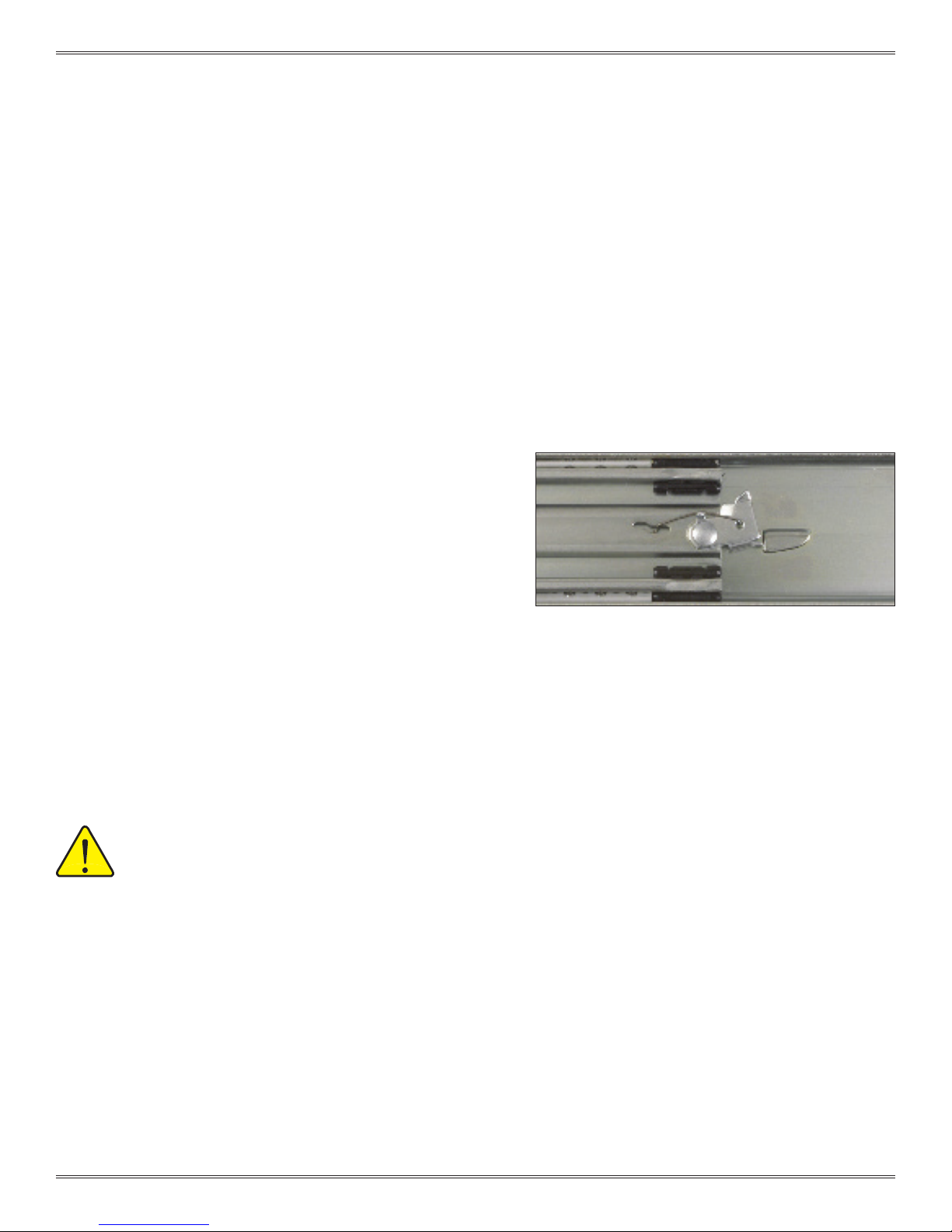

5. Pull the receiver out as far as possible. The slides

will lock in position. Push the blue tabs located on

the middle section of the slides (Figure D). Apply

pressure to push the receiver back in toward the

rack. The smaller inner slides move into the middle

section, which should not move. Push receiver until

it backs into the rack. The mounting screws can now

be used.

Figure C. Use the existing #8-32 at head screws, washers, and hex nuts to

secure the platform to the brackets.

BAR NUT

ALWAYS SUPPORT THE RECEIVER AND

PLATFORM WITH THE MOST ROBUST

(MIDDLE) SECTION OF THE SLIDES.

ensure proper support when extending the

receiver and table away from the rack, stop

the receiver and platform at approximately 6” from the

rack. Reach around to the rear of the receiver to the

slides underneath on both sides. Manually extend the

middle section of the slides forward until fully underneath

the platform. The receiver and platform may then be

extended while holding this middle slide in place. If

completed properly, the middle section of the slides will

remain underneath the platform and offer the strongest

support.

6. Secure receiver to rack.

To

BLUE TAB

Figure D. The slides will support 180 pounds. VPC recommends removing the

ITA/Fixture when extending the slides for wiring access and maintenance.

1-2

For the most current information available, visit www.vpc.com

10/17/18

G12/G12 x USER’S MANUAL: SECTION 2 VIRGINIA PANEL CORPORATION

SLIDE CONFIGURATION ACCESSORIES

RACK EXTENDER KIT, G12, 1.5" DEEP • PART # 310 113 406

RACK EXTENDER KIT, G12X, 1.5” DEEP • PART # 310 113 519

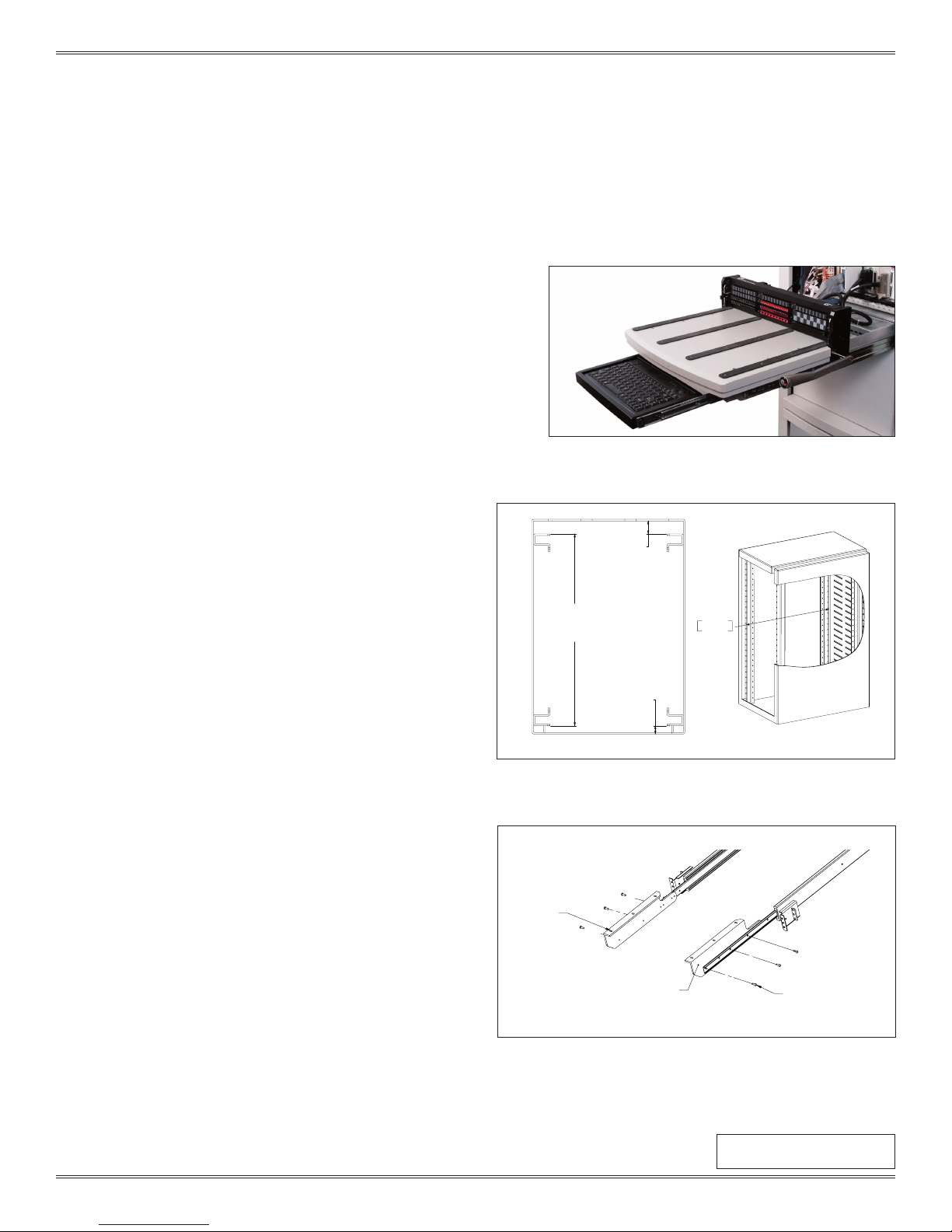

The G12/G12x is designed to easily t 19" standard racks when

used in the slide con guration. Although mounting rail dimensions

are standardized, there may be variances in the rack enclosure

design. VPC offers a rack extender kit for rails that are recessed

more than 1". The Rack Extender Kit has a maximum depth of 2.5".

TOOLS REQUIRED

5

/32 Allen Wrench

Phillips Head Screwdriver

INSTALLATION

1. To determine if a Rack E xtender Kit is needed, verify that the distance bet ween the front of the rack enclosure and the rail is between

1" and 2.5" (Figure A).

2. Attach the mounting rack mating sur face on the extender brackets to the recessed rail with the cap screws. Do not fully tighten until

until the cover plate is attached.

3. Attach the cover to the brackets with the fl at head screws.

4. With the extender kit in place, secure the G12 receiver to the mating surface on the extender brackets with #10-32 cap screws.

NOTE: The #10-32 cap screws are provided with the G12 receiver.

DIMENSION C

DIMENSION C

2.5“[63.5mm]

[101.6]

4.00

Figure A. Rack Extender Kits are used when the rails are recessed more than 1".

2-1

For the most current information available, visit www.vpc.com

10/17/18

G12/G12 x USER’S MANUAL: SECTION 2 VIRGINIA PANEL CORPORATION

INSTRUMENT BRACKET INSTALLATION

PART # 310 113 453

The instrument brackets mount to the inner sl ide and provide

maintenance access to the chassis and the instruments.

NOTE: This instrument bracket kit does not work with the 20”

or 24” slide kits.

TOOLS REQUIRED

5

/32 Allen Wrench

Phillips Head Screwdriver

INSTALLATION

1. Depress the blue tab on the inner slide and remove.

2. Attach one of the brackets to the slide using three #8-32

button head screws. The left bracket assembly is shown in

Figure A.

3. Attach the remaining bracket to the other inner slide. If you

are also installing a cable tray, do so before reinstalling the

slides and attaching the plate. See Cable Tray Installation

instructions in this section.

Continued on next page...

Figure A. The brackets are identical par ts and only the front two

holes on each bracket are designed to line up with the slides.

Figure B. The slots on the instrument brackets are designed to

accept a strap should you want to secure your chassis.

2-2

For the most current information available, visit www.vpc.com

10/17/18

G12/G12 x USER’S MANUAL: SECTION 2 VIRGINIA PANEL CORPORATION

INSTRUMENT BRACKET INSTALLATION

PART # 310 113 453

5. Reinstall the inner slides.

• Slide the left mid-section of the slide all the way out, you will feel it

lock into position.

• Feed the matching inner slide into position and ensure the inner

section rides into place with the roller bearings seated into the

groove.

• Push the inner slide in about 6-8 inches and then pull out the right

side. Slide the track of the mid-section over the right side of the

inner slide.

• Pull the slide out until the position matches the left side.

• Reach to the back of the middle slides and release the spr ing

locking mechanism (Figure C).

NOTE: At this time, both sides should be partially installed when it will

no longer proceed into the rack because the support tab on the

instrument brackets will hit the slide mounting bracket.

6. Rotate both instrument brackets inward so the support tabs

can pass the mounting brackets. Continue to push (install slides

simultaneously) into position. Remember to push the blue tabs

to allow the inner slide to continue to travel into the middle slide

section.

NOTE: The middle section will not go into the outer section until the

inner section has been fully installed into the middle section.

7. Tighten the slide mounting screws.

MAKE SURE ALL SCREW HEADS HAVE BEEN SECURELY

TIGHTENED. ONLY USE 8-32 BUTTON HEAD SCREWS.

Figure C. Spring-locking mechanism.

2-3

For the most current information available, visit www.vpc.com

10/17/18

G12/G12 x USER’S MANUAL: SECTION 2 VIRGINIA PANEL CORPORATION

SLIDE CONFIGURATION ACCESSORIES

CABLE TRAY • PART # 310 113 424

The cable tray is used for strain relief and cable management.

The horizontal and vertical anges provide tie down options that

allow you to bend and route your cables as needed and also

present a secure and reliable way to protect your investment.

NOTE: The cable tray does not work with the 20” or 24” slide kits

or the instrument bracket kit with strain relief.

TOOLS REQUIRED

3

32

/

Allen wrench

CABLE TRAY INSTALLATION

1. Loosen the slide mounting screws by one turn.

2. Depress the blue tab and remove the inner slides.

3. Attach the cable tray to the slides with #8-32 screws as shown in Figure A.

Figure A. The angled side of the cable tray should face the G12/G12x receiver, and with shorter

slide kits the cable tray will sit below the lip of the instrument brackets.

4. Install the inner slides and cable tray assembly into the rack. See Instrument Bracket Installation instructions in this section for more

detail.

5. Tighten the slide mounting screws.

2-4

For the most current information available, visit www.vpc.com

10/17/18

G12/G12 x USER’S MANUAL: SECTION 2 VIRGINIA PANEL CORPORATION

KEYBOARD WITH TOUCHPAD

[721.36]

KEYBOARD TRAY KIT INSTALLATION

PART # 310 113 439

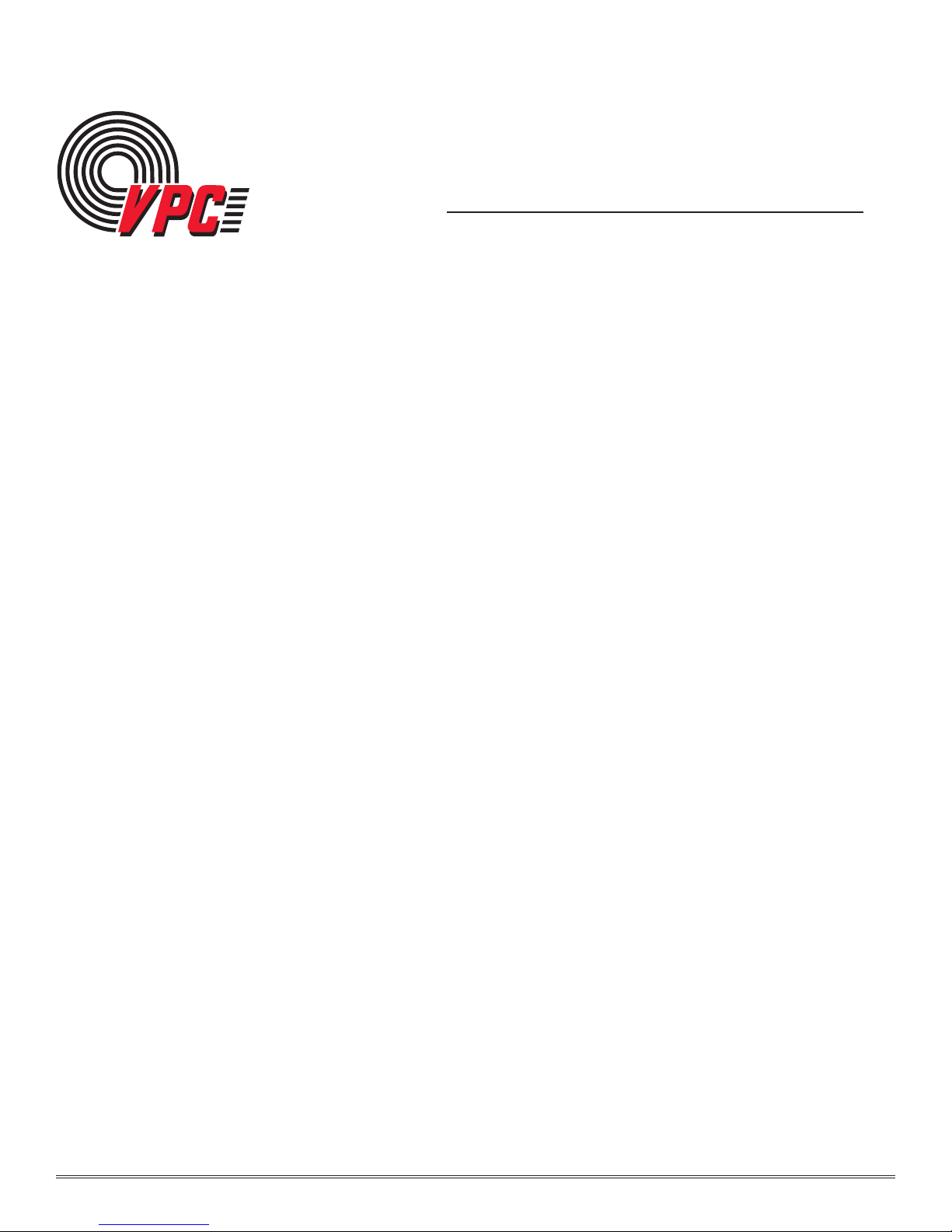

The Keyboard Tray Kit mounts below the platfor m on the

G12 or G12x receiver. The kit includes a keyboard with

touchpad and 58" long USB connector, keyboard tray,

and 12" slides.

TOOLS REQUIRED

3

32

/

Allen wrench

28.4

12 INCH SLIDE

MOVEMENT

13.0

[330.2]

13.3

[337.82]

MOUNTING BRACKET, RIGHTMOUNTING BRACKET, LEFT

USB KEYBOARD

CONNECTOR.

12 INCH SLIDES

RUBBER GROMMET

KEYBOARD TRAY

1.2

[30.48]

Figure A. Keyboard Tray Kit, Part # 310 113 439, includes components listed above and

mounting hardware.

Continued on next page...

2-5

For the most current information available, visit www.vpc.com

Dimensions shown: [millimeters]

inches

10/17/18

G12/G12 x USER’S MANUAL: SECTION 2 VIRGINIA PANEL CORPORATION

KEYBOARD TRAY KIT INSTALLATION

PART # 310 113 439

INSTRUCTIONS

1. Attach the keyboard mounting brackets to the existing

platform mounting brackets. Use the #8-32 nuts

and lock washers to secure the keyboard mounting

brackets to the three screws extending from the

platform mounting brackets (Figure B).

2. Use the #8 -32 button head screws to attach the 12"

slides to the inner side of the keyboard brackets. The

manufacturer stamped identication on the slides

should be placed toward the rack. You need to adjust

the position of the slides to access the hole locations.

Hole locations are shown in Figure C.

3. Insert the keyboard into the keyboard tray. Wrap the

plastic strain relief around the cable near the back of

the keyboard and press into the hole provided on the

keyboard tray.

PLATFORM MOUNTING BRACKET

EXISTING #8-32 SCREWS

Figure B. Orient the keyboard mounting brackets to align with the three

screws that extend beyond the platform mounting bracket.

MOUNTING BRACKET, LEFT

4. Fully extend the 12” slides and mount the keyboard

tray, (Figure D). The different hole patterns allow for

variations in the overall extension of the keyboard tray.

Figure C. There are oating, self-locking fasteners in the keyboard

mounting brackets which prevent the screws from backing out. You will

notice the snug t when tightening the screws.

Figure D. The remaining 4 #8-32 button head screws are used to attach

the keyboard tray to the slides.

2-6

For the most current information available, visit www.vpc.com

10/17/18

G12/G12 x USER’S MANUAL: SECTION 3 VIRGINIA PANEL CORPORATION

TABLETOP CONFIGURATION

RECEIVER, G12, 12 MODULE • PART # 310 104 408 / 310 104 409

RECEIVER, G12X, 18 MODULE • PART # 310 104 410 / 310 104 411 / 310 104 422

G12/G12x receivers are shipped with four rubber feet

for portable tabletop applications. The four feet are

removable to expose ¼ -20 tapped holes and allow for

permanent mounting applications.

PERMANENT TABLETOP MOUNTING

1. Remove rubber feet from ¼-20 tapped holes beneath the platform.

2. Prepare the mounting surface using the dimensions provided in Figure A or B, and drill 0.257" [6.53 mm] minimum thru holes.

3. Secure the receiver to the mounting surface with ¼-20 screws and washers.

449.58

17.70

292.10

11.50

16.51

.65

Figure A. Receiver with 15" Platform, Part # 310 104 408 &

310 104 410.

85.60

3.37

449.58

17.70

419.10

16.50

16.51

Figure B. Receiver with 20" Platform, Par t # 310 104 409 &

310 104 411.

.65

85.60

3.37

3-1

For the most current information available, visit www.vpc.com

Dimensions shown: [millimeters]

inches

10/17/18

G12/G12 x USER’S MANUAL: SECTION 4 VIRGINIA PANEL CORPORATION

1.35

15.00

P

TABLETOP CONFIGURATION ACCESSORIES

REAR COVER, G12, TABLETOP CONFIGURATION • PART # 310 113 421

REAR COVER, G12X, TABLETOP CONFIGURATION • PART # 310 113 520

The rear cover is used to protect the wiring from the

tabletop mounted receiver to the instruments. The rear

cover includes neces sar y hardware to attach the G12/

G12x receiver to the tabletop.

TOOLS REQUIRED

³/32 Allen Wrench

REAR COVER INSTALLATION

1. Use the ³/32 Allen wrench with the provided #8 -32 screws and washers to attach the rear cover to the G12/G12x receiver. An

exploded view of the assembly is provided in Figure A.

Figure A. Rear cover, Part # 310 113 421, is designed to attach to the G12 receiver, Part # 310 104

408/409. Part # 310 113 520 is designed to attach to the G12x receiver, Part # 310 104 410/411.

OPTIONAL INSTALLATION

1. Rear covers can be permanently mounted to the tabletop using the dimensions provided in Figure B. Hardware is not included.

287.19

11.307

34.29

Figure B. The rubber feet included with the rear cover are not

necessary when permanently mounting the G12/G12x receiver.

381

6.60

.26 TY

Dimensions shown: [millimeters]

inches

4-1

For the most current information available, visit www.vpc.com

10/17/18

G12/G12 x USER’S MANUAL: SECTION 5 VIRGINIA PANEL CORPORATION

RACK MOUNT CONFIGURATION

RECEIVER, G12, 12 MODULE • PART # 310 104 338

The 15” G12 Receiver provides a platform for use with large

xtures. When this Receiver is xed mounted, it can support

up to 275 lbs.

TOOLS REQUIRED

5

/32 Allen Wrench

INSTALLATION

1. Place receiver over clip/cage nuts on rack, making sure they are aligned (Figure A).

Figure A.

2. Tighten screws in a cr iss-cross pattern to ensure even torque is applied.

5-1

For the most current information available, visit www.vpc.com

10/17/18

G12/G12 x USER’S MANUAL: SECTION 6 VIRGINIA PANEL CORPORATION

RACK MOUNT CONFIGURATION ACCESSORIES

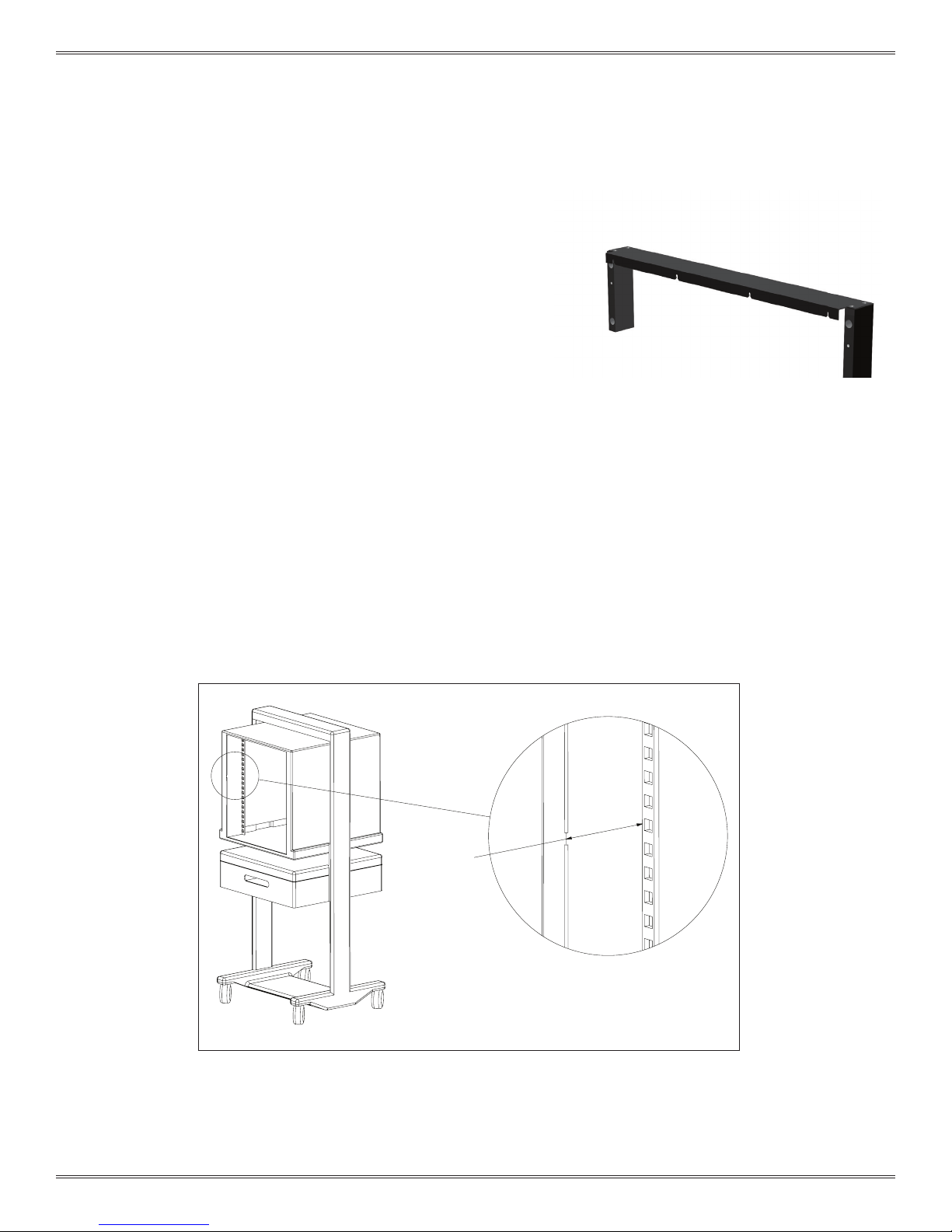

RACK EXTENDER KIT, G12 • PART # 310 113 413

The Rack Mount Extender Block Kit is used for

mounting to racks with recessed mounting

rails. It is made of aluminum with a black

anodized nish. The Rack Extender Kit will allow

for a maximum rack depth of 3.5”.

TOOLS REQUIRED

5

/32 Allen Wrench

Phillips Head Screwdriver

Flat Head Screwdr iver

INSTALLATION

1. Verify that the distance from the front of

the rack enclosure to the rail is between 1"

and 3.5" (Figure A).

2. Attach the mounting rack mating surface

on the extender brackets (Figure B), to the

recessed rail with the cap screws. Do not

fully tighten until until the cover plate is

attached.

3. Attach the cover to the brackets with the

fl at head screws.

4. With the extender kit in place, secure the

G12 receiver to the G12 receiver mating

surface on the extender brackets with

#10-32 cap screws.

NOTE: The #10-32 cap screws are

provided with the G12 receiver.

*For a larger and easier-to-read drawing please

consul t the of fi cial drawing online at vpc.com.

Enter part # 310113413 and select the drawing link on

the right side of the Product Page.

Figure B.

DIMENSION C

DIMENSION C

3.5“[88.9mm]

[101.6]

4.00

Figure A. Rack Extender Kits are used when the rails are recessed more than 1".

4-4 0 Flat Hea d Screws

for mountin g Extender

10-32 x . 75 Button He ad

Socket Sc rews to secure

rack. 4 places .

M6 x 20 scr ews may

also be used (not

included).

Kit Top to r eceiver

6-1

For the most current information available, visit www.vpc.com

Left Extension

Figure B.

RIght Extension

10/17/18

G12/G12 x USER’S MANUAL: SECTION 7 VIRGINIA PANEL CORPORATION

310104325, 310104286, 310104408 & 310104409, : G12/G12x receiver

HANDLE REMOVAL AND REPOSITIONING

RECEIVER, G12 • PART # 310 104 325 / 310 104 334 / 310 104 408 / 310 104 409

RECEIVER, G12, LEFT HANDLE • PART # 310 104 356 & 310 104 359

RECEIVER, G12X • PART # 310 104 385 / 310 104 386 / 310 104 410 / 310 104 411

The G12/G12x receiver handle requires approximately 90° of

counter-clockwise travel for engagement and 90° of clockwise

travel for disengagement of the ITA. This handle is removable and

adjustable to accommodate different mounting conguration

requirements and for transport purposes.

TOOLS REQUIRED

3

32

/

Allen Wrench

REMOVAL INSTRUCTIONS

1. Remove the handle set screw with a 3/32 Allen wrench.

2. Remove the handle and reposition in 90˚ increments.

3. Replace the screw and tighten until the handle is secured tightly.

with a 15” platform show with handle in the

standard disengaged position.

310104334, 310104385, 310104410 & 310104411, : G12/G12x receiver

with a 20” platform show with handle in the

standard engaged position.

HANDLE CAN BE LOOSENED AND

ROTATED IN 90 DEGREE INCREMENTS.

362.79

14.28

430.10

16.93

560.32

22.06

493.01

19.41

7-1

For the most current information available, visit www.vpc.com

HANDLE CAN BE LOOSENED AND

ROTATED IN 90 DEGREE INCREMENTS.

Dimensions shown: [millimeters]

inches

10/17/18

G12/G12 x USER’S MANUAL: SECTION 8 VIRGINIA PANEL CORPORATION

44.45

G12 ITA ENCLOSURE

ENCLOSURE, G12 , FRONT MOUNT • PART # 410 112 665

ENCLOSURE, G12, FOR DISCRETE WIRING, 4" X 18" X 12 " • PART # 410 112 739

The front mounting G12 enclosure is available to meet your

testing needs. Custom enclosures are also available if the

standard is not applicable to your test system.

TOOLS REQUIRED

3 mm Allen Wrench

Phillips Head Screwdriver

ENCLOSURE MUST BE FLUSH TO BOTTOM OF ITA

FRAME. THE WIDTH MAY GROW TO CUSTOMERS

NEEDS WITH A SIMPLE ADJUSTMENT OF THE HANDLE

ON THE RECEIVER. THERE IS NO LIMIT TO THE HEIGHT

OF THE ENCLOSURE.

Figure A. Enclosures must be ush with the ITA bottom to ensure the proper function of the G12 system.

8-1

1.75

For more information visit vpc.com

84.84

3.34

Dimensions shown: [millimeters]

inches

10/17/18

G12/G12 x USER’S MANUAL: SECTION 8 VIRGINIA PANEL CORPORATION

31.75

ENCLOSURE MUST BE FLUSH TO BOTTOM OF IT

FRAME. THE WIDTH MAY GROW TO CUSTOMER

NEEDS WITH A SIMPLE ADJUSTMENT OF THE HANDLE

ON THE RECEIVER. THERE IS NO LIMIT TO THE HEIGH

OF THE ENCLOSURE.

G12X ITA ENCLOSURE

ENCLOSURE, G12X , FRONT MOUNT • PART # 410 112 849

ENCLOSURE, G12X, FOR DISCRETE WIRING, 4" X 18" X 12 " • PART # 410 112 856

The front mounting G12x enclosure is available to meet your

testing needs. Custom enclosures are also available if the

standard is not applicable to your test system.

TOOLS REQUIRED

3 mm Allen Wrench

Phillips Head Screwdriver

Figure A. Enclosures must be ush with the ITA bottom to ensure the proper function of the G12x system.

8-2

1.25

A

S

T

136.40

5.37

For more information visit vpc.com

Dimensions shown: [millimeters]

inches

10/17/18

G12/G12 x USER’S MANUAL: SECTION 9 VIRGINIA PANEL CORPORATION

KEYING PIN KIT, RECEIVER AND ITA ASSEMBLY

PART # 310 118 112

TOOLS REQUIRED

Allen Wrench

³/

32

INSTALLATION

1. Determine which locations in the receiver and ITA

will have keying pins installed and which will be open

according to Tabl e 1.

2. Install the required keying pin combination with the

3/32 Hex Wrench (Figure A).

NOTE: One keying pin kit will allow 6 variations. By using a

second keying pin kit, you can have up to 36 variations.

Table 1.

KEYING PIN LOCATIONS

PATTERN 1 PATTERN 4

RECEIVER ITA RECEIVER ITA

PIN A

INSTALLED

PIN B

OPEN

PIN A

INSTALLED

PIN B

INSTALLED

PIN A

OPEN

PIN B

OPEN

PIN C

INSTALLED

PIN D

OPEN

RECEIVER ITA RECEIVER ITA

PIN C

OPEN

PIN D

OPEN

RECEIVER ITA RECEIVER ITA

PIN C

INSTALLED

PIN D

INSTALLED

SCREW A

SCREW B

INSTALLED

PATTERN 2 PATTERN 5

SCREW A

SCREW B

PATTERN 3 PATTERN 6

SCREW A

INSTALLED

SCREW B

INSTALLED

OPEN

OPEN

OPEN

SCREW C

OPEN

SCREW D

INSTALLED

SCREW C

INSTALLED

SCREW D

INSTALLED

SCREW C

OPEN

SCREW D

OPEN

PIN A

OPEN

PIN B

INSTALLED

PIN A

OPEN

PIN B

INSTALLED

PIN A

INSTALLED

PIN B

OPEN

PIN C

OPEN

PIN D

INSTALLED

PIN C

INSTALLED

PIN D

OPEN

PIN C

OPEN

PIN D

INSTALLED

SCREW A

INSTALLED

SCREW B

OPEN

SCREW A

INSTALLED

SCREW B

OPEN

SCREW A

OPEN

SCREW B

INSTALLED

SCREW C

INSTALLED

SCREW D

OPEN

SCREW C

OPEN

SCREW D

INSTALLED

SCREW C

INSTALLED

SCREW D

OPEN

A

DETAIL A

SCALE 1 : 1.5

Figure A.

9-1

For the most current information available, visit www.vpc.com

Figure B.

DETAIL B

SCALE 1 : 1.5

B

10/17/18

G12/G12 x USER’S MANUAL: SECTION 10 VIRGINIA PANEL CORPORATION

G12 ITA & RECEIVER ENGAGEMENT

Prior to engaging an ITA with the receiver for the rst time, ensure all modules (ITA and receiver) are properly installed. This involves

inspection of modules to ensure proper mounting and to verif y module positioning. Module positions are shown in Figures A and B.

Modules must be installed such that Pin 1 of each respective mating receiver and ITA module pair are adjacent. VPC recommends that

Pin 1 always be positioned to the left in the receiver and ITA frames. All ITA Modules must match the respective receiver Modules. It is

crucial for all modules to be installed properly. G12x Only: The lower four module rows share the same description as on G12 (i.e. A1-A4).

The extended tier of the G12x is considered to be rows 5 or 6.

MODULE POSITION C5

MODULE POSITION C6

MODULE POSITION C1

MODULE POSITION C2

MODULE POSITION C3

MODULE POSITION C4

MODULE POSITION C5

MODULE POSITION C6

MODULE POSITION C1

MODULE POSITION C2

MODULE POSITION C3

MODULE POSITION C4

MODULE POSITION A1

MODULE POSITION A2

MODULE POSITION A3

MODULE POSITION A4

MODULE POSITION A1

MODULE POSITION A2

MODULE POSITION A3

MODULE POSITION A4

MODULE POSITION B1

MODULE POSITION B2

MODULE POSITION B3

MODULE POSITION B4

MODULE POSITION B1

MODULE POSITION B2

MODULE POSITION B3

MODULE POSITION B4

MODULE POSITION C1

MODULE POSITION C2

MODULE POSITION C3

MODULE POSITION C4

MODULE POSITION C1

MODULE POSITION C2

MODULE POSITION C3

MODULE POSITION C4

MODULE POSITION A5

MODULE POSITION A6

MODULE POSITION A1

MODULE POSITION A2

MODULE POSITION A3

MODULE POSITION A4

MODULE POSITION A5

MODULE POSITION A6

MODULE POSITION A1 MODULE POSITION B1

MODULE POSITION A2

MODULE POSITION A3

MODULE POSITION A4

MODULE POSITION B5

MODULE POSITION B6

MODULE POSITION B1

MODULE POSITION B2

MODULE POSITION B3

MODULE POSITION B4

MODULE POSITION B5

MODULE POSITION B6

MODULE POSITION B2

MODULE POSITION B3

MODULE POSITION B4

Figure A. G12 receiver shown from the mating side, ITA shown

from the wiring side.

Figure B. G12x receiver shown from the mating side; G12x ITA shown

from the wiring side.

1. The receiver should be checked for any foreign objects that may interfere with engagement.

2. After inspection, the ITA is ready for engagement with the receiver. The ITA may be placed onto the receiver platform and properly

positioned relative to the receiver guide pins. Ensure that the ITA roller bearings are aligned with the receiver slide openings when the

receiver handle is in the open position.

3. Carefully rotate the handle forward to actuate the receiver slide engagement mechanisms, which will draw the ITA into engagement

position with the receiver. Once the handle reaches a positive stop at the end of its travel and latches into place, the modules are

engaged.

4. Upon completing use of the ITA, rotate the receiver handle to the open position, remove the ITA, reinstall the receiver protective cover

and rotate the handle to the closed position.

5. Always protect the contacts when the system is not in use. The receiver contacts are protected when either the ITA or receiver

protective cover is engaged. VPC recommends use of both receiver and ITA protective covers to avoid potential contact damage.

IMPROPER INSTALLATION WILL DAMAGE THE

MODULES, AND POSSIBLY THE ITA AND/OR

RECEIVER.

10-1

For the most current information available, visit www.vpc.com

IN THE EVENT OF COMPLICATIONS, A TRAINED

TECHNICIAN SHOULD BE NOTIFIED IMMEDIATELY

TO AVOID ANY DAMAGE TO THE SYSTEM. THIS

APPLIES TO ANY DIFFICULTIES THAT MAY BE

EXPERIENCED DURING ENGAGEMENT.

10/17/18

G12/G12 x USER’S MANUAL: SECTION 11 VIRGINIA PANEL CORPORATION

TROUBLESHOOTING

ITA Frame is not lined up when in the process of engagement with receiver

• This may indicate that the ITA is out of alignment or that a module is not mating with its intended Module.

• Remove and inspect the ITA for alignment

• Check for foreign objects/tools.

• Inspect the matching of modules -power ITA module to mate with power receiver module, etc.

Excessive force is needed to engage the Handle

• With a typical contact load, approximately 35lbs force is needed to engage the handle. Consult with a VPC application engineer

for detailed contact loading information.

• If excessive force is required, this may indicate that the ITA is out of alignment or that a module is not mating with its intended

module.

• Remove and inspect the ITA for alignment. Contact Vi rginia Panel Corporation – unauthorized user adjustments to system will void

the war ranty.

• Check for foreign objects/tools.

• Contact damage may provide enough resistance to notice. Upon replacing a contact in the ITA, the mating contact on the receiver

side should also be inspected and replaced if necessary.

• Verify the orientation of the receiver and ITA modules.

• Inspect the matching modules - power ITA module to mate with power receiver module, etc.

ITA will not engage with the receiver after diagnosing the above problems

• Contact Virginia Panel Corporation – unauthorized user adjustments to the System will void the warranty.

No continuity upon engagement

• When replacing an ITA contact, the mating contact on the receiver side should also be inspected and replaced if necessary.

• Check wiring and replace if necessary.

• Contact not secured in module.

• A contact may be damaged. Visually check all contacts for damage to potentially isolate damaged pin prior to checking for

continuity with a multi-meter.

A “short ” in the wiring upon engagement

• A damaged contact(s) may cause high resistance. Upon replacing a contact in the ITA, the mating contact on the receiver side

should also be inspected and replaced if necessar y.

• Check wiring and replace if necessary.

Receiver and ITA will not disengage

• This may indicate that the engagement mechanism within the receiver is faulty -contact Virginia Panel Corporation immediately-

user adjustments to system, unless authorized, will void the warranty.

FORCEFUL ENGAGEMENT OF THE RECEIVER

AND THE ITA WILL RESULT IN SERIOUS DAMAGE

TO MULTIPLE PARTS OF THE SYSTEM (MODULES,

RECEIVER, ITA AND CONTACTS)!

11-1

For the most current information available, visit www.vpc.com

10/17/18

G12/G12 x USER’S MANUAL: SECTION 11 VIRGINIA PANEL CORPORATION

PRECAUTIONARY NOTES

The following is a listing of precautionary notes found within this Manual and otherwise. They should be noted and followed for the

equipment to operate in an optimum state.

• Never probe a contact without using a mating patchcord as a test lead.

• Never forcefully engage a system if there is an excessive amount of resistance on the handle.

• Never allow an ITA to drop as this may cause misaligned engagement and/or irreparable damage.

• Always insert and extract a contact insertion/extraction tool in line with the contact. Never apply pressure to the side as this may

break either contact or tool. This also applies to forming and enlarging tools.

• It is advisable that power to the interface system be disconnected prior to handling and maintenance.

• Caution should always be used when engaging, making sure that all foreign objects are removed from the system.

• The foremost precautionary step that needs to be taken is to protect the inter face system from damage caused by people

(bumping into the receiver/ITA assembly with a box, chair or electronic equipment for example). To prevent this, VPC recommends

engaging either the ITA or the receiver Protective Cover to the receiver when not in use.

11-2

For the most current information available, visit www.vpc.com

10/17/18

Loading...

Loading...