Page 1

PAGE: 1 LP-41 REV: 3/1/03

member

gamagama

OPERATING, INSTALLATION, AND

SERVICE MANUAL FOR THE

VOYAGER GAS FIRED WATER HEATER

SUPER HIGH EFFICIENCY GAS FIRED WATER HEATING COMBINATION APPLIANCE

ANSI Z 21.10.3

MANUFACTURED BY: HEAT TRANSFER PRODUCTS, INC.

P.O. BOX 429, 120 BRALEY ROAD

EAST FREETOWN, MA 02717

TEL.: 1-508-763-8071 and (outside of MA) 1-800-323-9651

FAX: 1-508-763-3769 (sales, cust. svc.)

1-508-763-3448 (purchasing)

1-508-763-5269 (engineering, technical)

......or visit our website at: WWW.HTPRODUCTS.COM

Page 2

PAGE: 2 LP-41 REV: 3/1/03

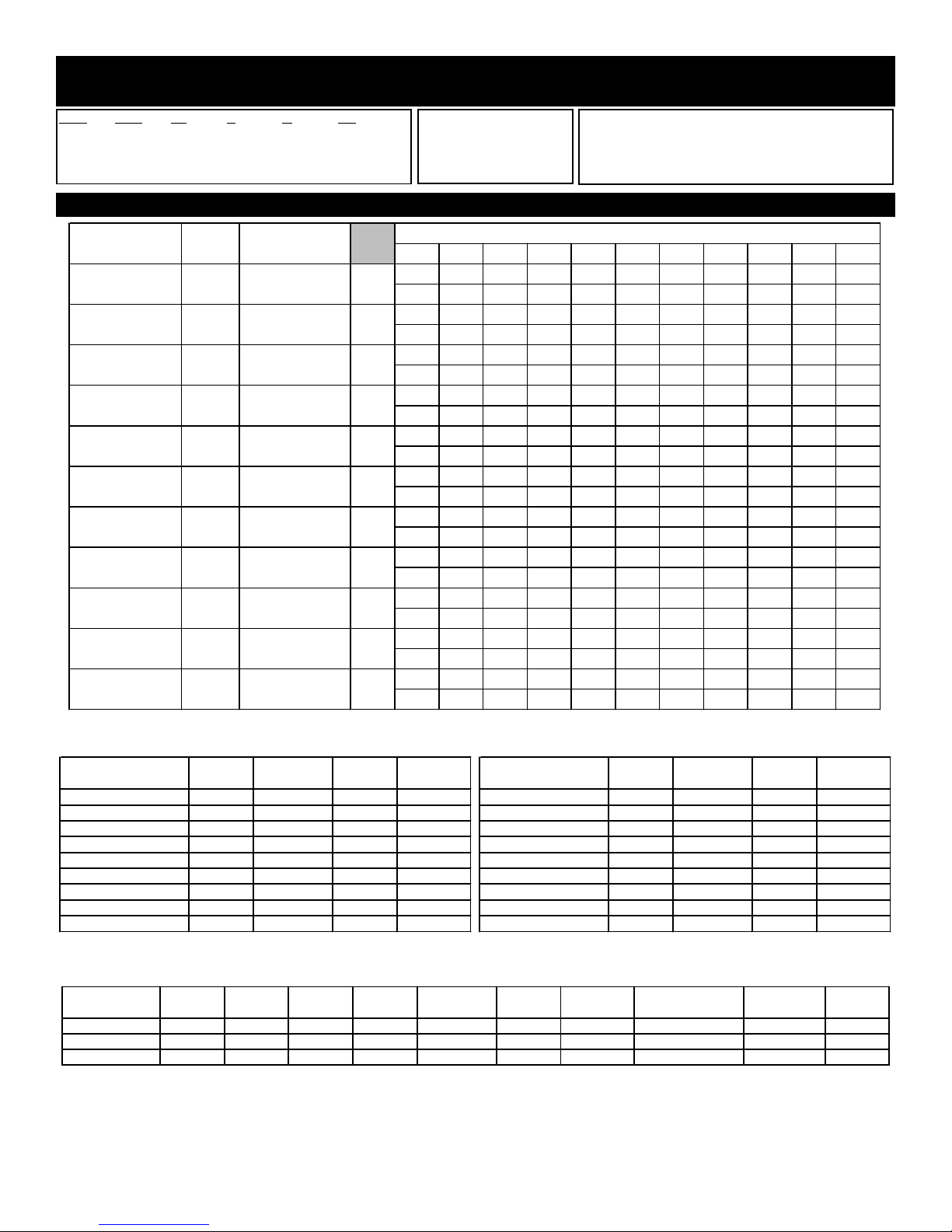

SPECIFICATIONS

Recovery on rating plate is based at 94% thermal efficiency at 100 degrees Fahrenheit rise, as required by A.N.S.I.

THESE MODELS ARE ONLY AVAILABLE AS "R" MODELS WITH 160 DEGREES F. MAX. SETPOINT

*THIS MODEL IS ALSO AVAILABLE AS AN "S" MODEL WITH 180 DEGREE F. MAX. SETPOINT AND 3" VENT

TO REFERENCE VOYAGER MODEL NUMBERS, PLEASE

USE THE FOLLOWING GUIDELINES:

SSVH MODELS HAVE OPTIONAL HEAT EXCHANGER FOR FLOOR RADIANT AND COMBINED HEAT

CONNECTION SIZES ARE 1" NPT DOMESTIC INLET, DOMESTIC OUTLET FOR THE 45 GALLON UNITS.

CONNECTION SIZES ARE 1 1/2" NPT DOMESTIC INLET, DOMESTIC OUTLET FOR THE 80 & 119 GALLON UNITS.

Note: These overall dimensions are approximate within +/– 1".

Heat Transfer Products reserves the right to change specifications or discontinue models without notice.

SSV 130 -45 S A LP

Series BTU U.S. Temp. Warr. Gas Type

Gal. (Deg. F.)

Temperature

(Degrees Fahrenheit)

R = 160

S = 180

Warranty

A = 6 yrs. parts; 6 yrs. comm.; 10 yrs. res.

B = 1 yr. parts; 3 yrs. comm.; 10 yrs. res.

GALLON INPUT BTU/HR. TEMPERATURE RISE IN DEGREES FAHRENHEIT

MODEL CAPACITY NATURAL & LP GAS 40 50 60 70 80 90 100 110 120 130 140

GPH 545 436 363 311 272 242 218 198 181 167 155

SSV199-119R

SSV & SSVH199-80R

SSV199-45S

SSV160-45S

SSV130-80R

SSV130-119R

SSV130-45R/S

SSVH130-45S

SSV100-45R

SSV90-45S

SSVH90-45S

119 199,000 GPM 97654.543.53.332.72.5

GPH 545 436 363 311 272 242 218 198 181 167 155

80 199,000 GPM 97654.543.53.332.72.5

GPH 545 436 363 311 272 242 218 198 181 167 155

45 199,000 GPM 97654.543.53.332.72.5

GPH 436 349 290 249 218 193 174 158 145 134 124

45 160,000 GPM 7 5.8 4.8 4 3.6 3.2 2.9 2.6 2.4 2.2 2

GPH 354 283 236 202 177 157 141 128 118 109 101

80 130,000 GPM 5.9 4.7 3.9 3.9 2.9 2.6 2.3 2.1 1.9 1.8 1.6

GPH 354 283 236 202 177 157 141 128 118 109 101

119 130,000 GPM 5.9 4.7 3.9 3.9 2.9 2.6 2.3 2.1 1.9 1.8 1.6

GPH 354 283 236 202 177 157 141 128 118 109 101

45 130,000 GPM 5.9 4.7 3.9 3.9 2.9 2.6 2.3 2.1 1.9 1.8 1.6

GPH 354 283 236 202 177 157 141 128 118 109 101

45 130,000 GPM 5.9 4.7 3.9 3.9 2.9 2.6 2.3 2.1 1.9 1.8 1.6

GPH 269 215 179 154 134 119 108 98 89 82 77

45 100,000 GPM 4.4 3.5 2.9 2.5 2.2 1.9 1.7 1.5 1.4 1.3 1.2

GPH 245 196 163 140 122 109 98 89 81 75 70

45 90,000 GPM 4 3.2 2.7 2.3 2 1.8 1.6 1.4 1.3 1.2 1.1

GPH 245 196 163 140 122 109 98 89 81 75 70

45 90,000 GPM 4 3.2 2.7 2.3 2 1.8 1.6 1.4 1.3 1.2 1.1

SHIP.

MODEL HEIGHT WIDTH WEIGHT DEPTH

SSV199-119R

SSV199-80R

SSV199-45S

SSV160-45S

SSV130-119R

SSV130-80R

SSV130-45R*

SSV100-45R

SSV90-45S

74"

72"

42 1/2"

42 1/2"

74"

72"

42 1/2"

42 1/2"

42 1/2"

27 1/4"

23 1/4" 235 Lbs. 32"

23 1/4" 175 Lbs. 32"

23 1/4" 175 Lbs. 32"

27 1/4"

23 1/4" 230 Lbs. 32"

23 1/4" 175 Lbs. 32"

23 1/4" 175 Lbs. 32"

23 1/4" 175 Lbs. 32"

405 Lbs. 36"

400 Lbs. 36"

MODEL INPUT RATING SIZE EFFIC. %

SSV199-119R

SSV199-80R

SSV199-45S

SSV160-45S

SSV130-119R

SSV130-80R

SSV130-45R*

SSV100-45R

SSV90-45S

199,000 335 3" 94%

199,000 300 3" 94%

199,000 270 3" 94%

160,000 220 3" 94%

130,000 250 2" 94%

130,000 220 2" 94%

130,000 180 S-3"/R-2" 94%

100,000 138 2" 95%

90,000 125 3" 95%

FIRST HOUR VENT RECOVERY

FIRST HOUR VENT RECOVERY HEAT HEAT SHIP.

MODEL HEIGHT WIDTH DEPTH INPUT RATING SIZE EFFIC. % EXCHANGER BTU EXCHANGER WEIGHT

SSVH199-80R 32" 199,000 300 Gallons 3" 94% 140,000 32 sq. ft. 255 Lbs.

SSVH130-45S 23 1/4" 32" 130,000 180 Gallons 3" 94% 110,000 32 sq. ft. 205 Lbs.

72"

42 1/2"

SSVH90-45S 32" 90,000 125 Gallons 3" 95% 81,000 32 sq. ft. 205 Lbs.

24 1/4"

23 1/4"42 1/2"

Page 3

PAGE: 3 LP-41 REV: 3/1/03

WARNING:

IF THE INFORMATION IN THESE INSTRUCTIONS ARE NOT FOLLOWED EXACTLY, A FIRE OR EXPLOSION MAY

RESULT; CAUSING PROPERTY DAMAGE, PERSONAL INJURY, OR DEATH.

- Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance;

WHAT TO DO IF YOU SMELL GAS:

- Do not try to light any appliance;

- Do not touch any electrical switch; do not use any phone in your building;

- Immediately call your gas supplier from a neighbor's phone;

- Follow the gas supplier's instructions;

- If you cannot reach your gas supplier; call the fire department;

- Installation and service must be performed by a qualified installer; service agency or the gas supplier.

DANGER:

Water temperature over 125 degrees F. can cause severe burns instantly, or death from

scalds. Children, disabled, and elderly are at highest risk of being scalded. See

instruction manual before setting temperature at water heater. Feel water before

bathing or showering! Temperature limiting valves are available.

LOCATION

Choose a location for your water heater centralized to the piping system, along with consideration to vent pipe length. As the length of

vent pipe increases the firing rate of the appliance decreases. You must also locate the Voyager where it will not be exposed to freezing temperatures. Additionally, you will need to place the water heater so that the controls, drain, inlet/outlet, and gas valve are easily

accessed. This appliance must not be installed outdoors, as it is certified as an indoor appliance, and must be kept vertical and on a

level surface. Also, care must be exercised when choosing the location of this appliance; where leakage from the relief valve, leakage

from related piping, or leakage from the tank or connections, will not result in damage to the surrounding areas or to the lower floors of

the building. A water heater should always be located in a area with a floor drain or installed in a drain pan suitable for water

heaters. Proper clearance must be provided around the Voyager as follows: Sides, bottom, top, and back are 0" (zero clearance).

Front of the appliance needs 24" service clearance minimum. This front service may be achieved by a non-rated or combustible door

or access panel; providing the 24" service clearance is achieved when the door is opened or panel is removed. Under no circum-

stances, shall Heat Transfer Products Inc. be held liable for any such water damage whatsoever. This water heater must not

be located near flammable liquids such as gasoline, adhesives, solvents, paint thinners, butane, liquefied propane, etc.; as

the controls of this appliance could ignite those vapors, causing an explosion.

TEMPERATURE AND PRESSURE RELIEF VALVE

A temperature and pressure relief valve is installed into the marked port (upper right), we recommend a WATTS 100XL-4 valve or

equivalent for 100,000 BTU models or below input, 40XL5 valve or equivalent for 130,000 BTU models or above input, meeting the

requirements for relief valves for hot water heaters as per ANSI Z21.22B-1984 by a nationally recognized lab that maintains a periodic

inspection of production of such listed safety device. The pressure rating of the valve must not exceed the listed working pressure of

this appliance, and must be rated to the proper BTU/hr capacity of the water heater. Do not, under any circumstances, thread a cap

or plug into the relief valve! Explosion, serious injury or death may result! Relief valve piping must be directed to the floor or to

an open drain, but not connected directly. There must be a 6" space between the outlet of relief valve piping and drain or floor. Do not

hook up to drain system directly without an air space. The relief valve must be periodically checked for proper operation.

Page 4

PAGE: 4 LP-41 REV: 3/1/03

EXPANSION TANK

A potable hot water expansion tank may be required to offset the water expansion as the water is heated. In most city plumbing systems, the water meter has a no return or back flow device built into the system to prevent back flowing of water back into city mains.

Some require back flow preventers on all incoming water supplies. Under these circumstances, you will need a hot water expansion

tank listed for potable water use. The expansion tank should be located on the cold inlet piping close to the water heater. The expan-

sion tank must be suitable for hot potable water.

DOMESTIC WATER CONNECTIONS

WARNING!!

NEVER USE DIELECTRIC UNIONS OR GALVANIZED STEEL FITTINGS ON ANY DOMESTIC WATER CONNECTIONS.

USE ONLY COPPER OR BRASS FITTINGS. TEFLON THREAD SEALANT MUST BE USED ON ALL CONNECTIONS.

The domestic water connections must be installed in accordance to all local and national plumbing codes, or any applicable standard

which prevails. The inlet and outlet ports of the Voyager are 1" on 45 gallon models. On the 80 and 119 gallon models, the inlet and

outlet ports are 1 ½". On the cold inlet, (bottom left), install a 1" brass tee on 45 gallon models, or a 1 ½" tee on 80 and 119 gallon

models. On the run of the 1" brass tee, install with pipe sealant compound, a 1" brass drain cock or equivalent. Into the branch of the

1" or a 1 ½" brass tee, install a copper male adapter to match your copper plumbing system. For convenience, you may install a sweat

shut off valve and a union in the cold inlet piping to ease servicing in the future. If there is a back flow preventer, or any type of a no

return valve in the system, then you must install an additional tee here for a suitable potable hot water expansion tank. In the hot outlet, (top left), install a suitable adapter to match the copper tubing of the plumbing system. A thermal trap or heat trap loop may be

installed here, to provide additional energy savings and prevent the thermal siphoning of domestic hot water. Refer to pages 23 or 24

for typical installations. A domestic hot water tempering/anti-scald valve should be installed into hot water line to prevent the maximum

outlet water temperature from exceeding 119 degrees F. as per the national standard plumbing code, to prevent scald injury.

ELECTRICAL CONNECTION

The electrical connection for the Voyager is on the left side of the combustion shroud. There is a 1/2" knockout location for electrical

connection. All electrical wiring must be performed by a qualified licensed electrician, and in accordance with National Electrical Code,

or to the applicable local codes and standards. The electrical requirements are for standard 120 volts, 60 Hz 10 amp service. It is recommended that an electrical disconnect switch be placed on a nearby wall, and that the connection to the Voyager be made using 3/8"

extra-flex, or 3/8" greenfield (or equivalent). This unit must be wired with #14 awg, and fused for no more than 15 amps.

It is of

extreme importance that this unit be properly grounded

! Ground the water heater, by connecting the green wire in the electrical access compartment, directly to the main building ground system. It is very important that the building system ground is

inspected by a qualified electrician, prior to making this connection. The black wire is the hot lead and the white wire is the

neutral lead. Once all connections have been made the electrical access may be closed. It is very important that the electri

-

cal power is not turned on at this time

! A green LED is provided on the main control board. This LED must be luminated

when appliance is turned on for proper operation. Failure to luminate means bad or missing ground or reverse polarity.

GAS CONNECTION

Gas supply shall have a maximum inlet pressure of less than 14" water column (350 mm), 1/2 pound pressure (3.4 kPa), and a minimum of 7" water column. The entire piping system, gas meter, and regulator must be sized properly to prevent pressure drop greater

than 0.5" as stated in the National Fuel Gas Code. This information is listed on the rating plate. It is very important that you are

connected to the type of gas as noted on the rating plate. "LP" or liquefied petroleum, or propane gas; or "Nat" natural gas or city

gas. All gas connections must be approved by the local gas supplier, or utility in addition to the governing authority, prior to turning the

gas supply on. The nipple provided is 1/2", and it is mandatory that a 3/4" to 1/2" reducing bushing (provided) is used, threaded into

the branch of a 3/4" tee, and a drip leg fabricated, as per the national Fuel Gas Code. You must ensure that the entire gas line to

the connection at the Voyager is no smaller than 3/4". Once all the inspections have been performed, the piping must be leak tested. If the leak test requirement is a higher test pressure than the maximum inlet pressure, you must isolate the Voyager from the gas

line. In order to do this, you must disconnect the union and cap the inlet gas line. In the event the gas valve is exposed to a pressure

greater than 1/2 PSI, 14" water column, the gas valve must be replaced. Never use an open flame (lit match, lighter) to check gas

connections.

Page 5

PAGE: 5 LP-41 REV: 3/1/03

GAS CONNECTION (CONTINUED)

Failure to follow all precautions could result in fire, explosion or death! It is recommended that a soapy solution be used to

detect leaks. Bubbles will appear on pipe to indicate a leak is present. The gas piping must be sized for the proper flow and length of

pipe, to avoid pressure drop. Both the gas meter and the gas regulator must be properly sized for the total gas load. If you experience

a pressure drop greater than 1" WC, the meter or regulator or gas line is undersized or in need of service. On the inlet side of the gas

valve, there is a 1/8" NPT plug, which can be removed to attach a hose barb, hose, and inches of water column meter. Also, you can

attach a meter to the incoming gas drip leg, by removing the cap and installing the meter. The gas pressure must remain between 7"

and 14" during stand-by and unit running heat cycle. If an in-line regulator is used, it must be a minimum of 10 feet from the Voyager.

It is very important that the gas line is properly purged by the gas supplier or utility. Failure to properly purge the lines or

improper line sizing, will result in the failure of the Voyager lighting off. This problem is especially noticeable in NEW LP installa-

tions, and also in empty tank situations. This can also occur when a utility company shuts off service to an area to provide maintenance to their lines. The gas valve is a special gas valve which has a Pressure Augmented Regulator feature, as well as negative outlet pressure. This valve must not be replaced with a conventional valve under any circumstances. Make sure valve is in the “OFF”

position prior to turning gas supply on. As an additional safety feature, this valve has a left hand thread on the outlet end, and a special

tamper resistant electrical connector.

VENTING

FOR ALL MODELS 3" VENTED EXCEPT

SSV100-45R AND SSV130-45R (WHICH ARE 2" VENTED)

(FOR 2" VENTED MODELS SSV100-45R AND SSV130-45R, SEE TOP OF PAGE 8)

For inlet air supply, top pipe on the right of the shroud, use 3" PVC schedule 40. It is very important that you plan the location properly,

to eliminate long pipe runs and excessive fittings. Inlet pipe size must not be reduced. Do not combine the inlet air with any other inlet

pipe including an inlet to an additional similar appliance. The joints must be properly cleaned, primed, and cemented. The piping must

also be properly supported as per local and national standard plumbing codes. It is important that the piping must be clean and free

from burs, debris, ragged ends, and particles of PVC.

For exhaust piping, lower pipe on the right of the shroud, for the first 7’, use 3” ABS sch 40 or 3”CPVC sch 40 or 80. For concrete construction or to meet certain fire codes, exhaust piping - lower pipe on right of shroud, and inlet air piping - top pipe on the right of the

shroud, must be 3" CPVC schedule 40 or 80, (only to meet local fire codes). The balance of the inlet and exhaust piping may be PVC

schedule 40 or 80, or ABS solid only, NOT FOAM CORE. For residential style wooden construction exhaust piping, lower pipe on right

of shroud, must be 3" ABS solid (NON FOAM CORE) or 3" CPVC schedule 40 or 80 for the first 7’ only. The balance of the inlet and

exhaust piping may be PVC or ABS solid NON FOAM CORE or CPVC to meet local codes.

The only approved exhaust vent materials are ABS solid NON FOAM CORE; first 84" or CPVC. The balance of the exhaust piping

must be ABS solid NON FOAM CORE, CPVC or PVC sch 40 NON FOAM CORE ONLY. Exhaust piping should be sloped back to the

connection on the Voyager, at least 1/4" per foot to remove additional condensate that forms within the pipe. The total combined

length of pipe (intake piping plus exhaust piping added together) including elbow allowances intake and exhaust (each elbow = 5' of

pipe) should not exceed 85'. The combined vent length should not be less than a combined length of 6' plus two 90 degree elbows.

Choose your vent termination locations carefully; see pages 21 and 22

. You must additionally make certain that exhaust gas does not

re-circulate back into the intake pipe. You must place them in a open area, and follow the following guidelines.

1) Never vent into a walkway or patio area, or an alley, or otherwise public area less than 7' from the ground;

2) Never vent over or under a window or over a doorway;

3) Never install a heat saver or similar product to capture waste heat from exhaust;

4) Always have vent location at least 1' above maximum snow level;

5) Always have vent 1' above ground level, away from shrubs and bushes;

6) Follow local gas codes in your region or refer to National Fuel Gas Code, or Can B149;

7) Always have vent at least 3' from an inside corner of outside walls;

8) Maintain at least 4' clearance to electric, gas meters, and exhaust fans or inlets;

9) Very Important

! Inlet air must be taken from outside of building, next to exhaust outlet, no closer than 8";

10) Always place screens in all openings in intake and exhaust to prevent foreign matter from entering the Voyager.

Page 6

PAGE: 6 LP-41 REV: 3/1/03

VENTING

FOR ALL 3" VENTED MODELS EXCEPT SSV100-45R AND SSV130-45R (WHICH ARE 2” VENTED)

(FOR 2" VENTED MODELS SSV100-45R AND SSV130-45R, SEE MIDDLE OF PAGE 8)

11) The vent intake and exhaust must be properly cleaned and glued, for pressure tight joints. Several methods for venting the

Voyager can be found on pages 21 and 22

. Use the following layout as a guideline; certain site conditions such as multiple

roof lines/pitches may require venting modifications-consult factory. The air inlet must be a minimum of 1' vertically above the

maximum snow level or 24" which ever is greater. The air inlet must also be a minimum of 10' horizontally from the roof, and

terminated with a tee. The exhaust must be a minimum of 24" above the air inlet opening, and terminated with a coupling. It

is very important that there are no other vents, chimneys, or air inlets in any direction for at least 4'. Please refer to typical

venting on pages 21 and 22

. All venting must be properly supported, as the Voyager is not intended to support any

venting whatsoever. All piping, glue, solvents, cleaners, fittings, and components, must conform to ASTM (American

Society for Testing and Materials), and ANSI (American National Standard Institute).

12) It is recommended that you use one of the mentioned vent kits specifically for Voyager installations; either KGAVT0501CVT

(2 in.), KGAVT0601CVT (3 in.), or V1000.

CLEANER / CEMENT

Cement for all venting must be ALL PURPOSE Cement, and must conform to ASTM D-2235, D-2564 and F-493, and cleaner for the

piping and fittings must conform to ASTM F-656. For joining ABS to PVC, you must use transition green cement listed by NSF and

IAPMO and exceeds ASTM D-3138 to make solid liquid tight joints and gas tight joints.

PIPE / FITTINGS

The first 84" (7’) of exhaust piping, must be of 3" ABS solid only (provided) or CPVC; (NEVER cellular foam core pipe on exhaust

piping), and conform to ASTM D-3965 for ABS or ASTM F-441 for CPVC, and fittings to ASTM D2661 & D3311 for ABS and ASTM F-

439 for CPVC, the balance of exhaust piping, and all of intake piping, use standard 3" PVC sch. 40 or 3" ABS schedule 40, conforming

to ASTM D2665, or ABS conforming to ASTM D-3965 & ASTM R-441 for ABS; and fittings conforming to ASTM D-2665 & D331. ABS

may also be used for intake venting as long as pipe conforms to ASTM D3965 & D2661 and fittings meet ASTM D2661 & D3311.

Foam core pipe may be used for the entire intake system providing it conforms to ASTM F-891, and is cemented together using above

materials.

FOR LONGER VENT LENGTHS

All venting must be 3", both intake and exhaust, NEVER use any piping less than 3", or different size pipe on the intake and

exhaust. You may use 4" venting on both intake and exhaust, to lower the pressure drop, to provide additional venting length. It is

imperative when using 4", to follow these instructions very carefully. For longer venting lengths, the first 10' of both the

intake and exhaust piping are 3". For the intake 10' of 3" PVC plus one 90 degree or two 45 degree elbows and for the

exhaust 10' of ABS solid NON FOAM CORE, or CPVC plus one 90 degree or two 45 degree elbows. Then use a 4" x 3" PVC or

4" x 3" ABS reducing coupling. Then proceed with PVC 4" NON FOAM CORE pipe and fittings for both the intake and exhaust piping.

On 4" piping you may go an additional 125 equivalent feet of pipe and fittings, combined total length. The 4" fittings have a friction loss

allowance as follows: 4" 90 degree = 3' , and a 4" 45 degree = 1'. The total maximum venting length can be 125', plus the first

10' of each 3", and a maximum fitting allowance of the 3", total two 90 degree or four 45 degree before increasing to 4". Total

equivalent would be 30' of 3" plus 125' of 4". Never

use different pipe sizes for intake and exhaust. The vent system must be

balanced by friction loss equivalent.

NOTE

:

THE METHODS DESCRIBED ARE SUGGESTED GENERIC METHODS ONLY. SPECIFIC JOB SITE OBSERVATIONS AND SIZING MAY REQUIRE ALTERNATE INSTALLATION METHODS. CONSULT THE FACTORY WITH SPECIFIC JOB REQUIREMENTS FOR ADDITIONAL RECOMMENDATIONS.

Page 7

PAGE: 7 LP-41 REV: 3/1/03

FITTING

DESC.

EQUIVALENT

FEET

OF PIPE FITTING DESC.

EQUIVALENT

FEET

OF PIPE

FITTING DESC.

EQUIVALENT

FEET OF

PIPE

3” 90 5’ 2” 90 5’ 4” 90 3’

3” 45 3’ 2” 45 3’ 4” 45 1’

3” Coupling 0’ 2” Coupling 0’ 4” Coupling 0’

3” Tee 0’ 2” Tee 0’ 4” Pipe 1’ = 1’

3” Pipe 1’ = 1’ 2” Pipe 1’ = 1’ 4” Tee 0’

3” Concentric vent kit 3’ 2” Concentric vent kit 3’

3” V1000 vent kit 0’

VENTING EXAMPLES (NOTE: SHOWN AS INTAKE & EXHAUST PIPE AND FITTINGS ADDED TOGETHER)

* = MINIMUM VENT LENGTH ** = MAXIMUM VENT LENGTH

TOTAL

COMBINED

VENT LENGTH

(FEET)

INTAKE &

EXHAUST

QTY.

OF 90

°°

ELBOWS

EQUIVALENT

FRICTION

LOSS

(FEET)

FOR EACH

ELBOW

TOTAL

FRICTION

LOSS

FOR

ELBOWS

GRAND TOTAL

VENT LENGTH

(FEET)

WITH FITTING

FRICTION

LOSS ADDED

*12 2 5 10 22

20 2 5 10 30

20 3 5 15 35

20 4 5 20 40

20 5 5 25 45

20 6 5 30 50

20 7 5 35 55

20 8 5 40 60

20 9 5 45 65

20 10 5 50 70

20 11 5 55 75

20 12 5 60 80

20** 13 5 65 85**

30 3 5 15 45

30 4 5 20 50

30 5 5 25 55

30 6 5 30 60

30 7 5 35 65

30 8 5 40 70

30 9 5 45 75

30 10 5 50 80

30** 11 5 55 85**

40 3 5 15 55

40 4 5 20 60

40 5 5 25 65

40 6 5 30 70

40 7 5 35 75

40 8 5 40 80

40** 9 5 45 85**

50 3 5 15 65

50 4 5 20 70

50 5 5 25 75

50 6 5 30 80

50** 7 5 35 85**

60 3 5 15 75

60 4 5 20 80

60** 5 5 25 85

70** 3 5 15 85

FRICTION LOSS EQUIVALENCE TABLES

2" VENTED MODELS AFTER THE FIRST 10’ OF 3"

3" VENTED MODELS SSV100-45R/SSV130-45R ONLY4" EQUIVALENT TABLE

Page 8

PAGE: 8 LP-41 REV: 3/1/03

WARNING:

IT IS EXTREMELY IMPORTANT TO FOLLOW THESE INSTRUCTIONS EXACTLY. FAILURE TO FOLLOW INSTRUCTIONS

EXACTLY COULD RESULT IN FIRE, INJURY OR DEATH.

SPECIAL VENTING INSTRUCTIONS FOR 2" VENTED SSV100R, & SSV130R MODELS ONLY

.

FOR 3" VENTED MODELS, SEE PAGE 5.

VENTING

SSV100R AND SSV130R ONLY

Inlet air supply, top pipe on the right of the shroud. Use 2" PVC, schedule 40, or 2" ABS for all inlet air piping. It is very important that

you plan the location properly, to eliminate long pipe runs, and excessive fittings. Inlet pipe size must not be reduced. Do not combine

the inlet air with any other inlet pipe including an inlet to an additional similar appliance. The joints must be properly cleaned, primed,

and cemented. The piping must also be properly supported as per local and national standard plumbing codes. It is important that the

piping must be clean and free from burs, debris, ragged ends, and particles of PVC, or ABS. Exhaust piping, lower pipe on right of

shroud, must be of 2" PVC schedule 40 NON FOAM CORE or 2" ABS NON FOAM CORE, 2" CPVC may also be used. 3" PVC, 3"

ABS solid NON FOAM CORE, or 3" CPVC can also be used. Exhaust piping should be sloped back to the connection on the Voyager,

at least 1/4" per foot to remove additional condensate that forms within the pipe. The total combined length of pipe including elbow

allowances (each elbow = 5' of pipe) should not exceed 85', both the intake pipe added to the exhaust pipe. The combined vent length

should not be less than a combined length of 6', plus two 90 degree elbows. Choose your vent termination locations carefully; see

pages 21 and 22

. You must place them in a open area, and use the guidelines found on page 20.

CLEANER / CEMENT

Cement for exhaust & intake piping, must be All Purpose Cement, and conform to ASTM D-2235, D-2564, F-493 and cleaner for piping

and fittings must conform to ASTM F-656. For joining ABS to PVC, you must use transition green cement listed by NSF and IAPMO

and exceeds ASTM D-3138 to make solid liquid tight joints and gas tight joints.

PIPE / FITTINGS

The exhaust piping, and all of intake piping, standard 2" PVC sch. 40, conforming to ASTM D-1785, and fittings to ASTM D-2466, and

ABS pipe conforming to ASTM D3965 and ASTM D2661 and fittings conforming to ASTM D2661 & ASTM D3311. Foam core pipe

may be used for the entire intake system providing it conforms to ASTM F-891, and is cemented together using above materials, never

use foam core pipe for the exhaust pipe!

VERY IMPORTANT

SSV100R & SSV130R MODELS ONLY!

All venting must be 2", both intake and exhaust, NEVER use any piping less than 2", or different size pipe on the intake and

exhaust. You may use 3" or 4" venting on both intake and exhaust, to lower the pressure drop, to provide additional venting length. It

is imperative when using 3" to follow these instructions very carefully. For longer venting lengths, the first 10' of both the intake and

exhaust piping are 2". For the intake 10' of 2" PVC or ABS or CPVC, plus one 90 degree or two 45 degree elbows and for the exhaust

10' of 2" PVC NON FOAM CORE or ABS solid NON FOAM CORE or CPVC, plus one 90 degree or two 45 degree elbows. Then use a

2" x 3" PVC or ABS reducing coupling. Then proceed with ABS solid NON FOAM CORE, CPVC, or PVC 3" NON FOAM CORE pipe

and fittings for both the intake and exhaust piping. On 3" piping you may go an additional 125 equivalent feet of pipe and fittings, combined total length. Total equivalent would be 30' of 2" plus 125' of 3". Never use different pipe sizes for intake and exhaust. The vent

system must be balanced by friction loss equivalent.

CONDENSATE

This is a condensing high efficiency appliance, therefore this unit has a condensate removal system. Condensate is nothing more than

water vapor, derived from the combustion products, similar to an automobile when it is initially started. This condensate does have a

low PH and should be treated with a condensate filter. This filter contains either lime crystals or marble crystals, which will neutralize

the condensate. The outlet of the filter is sized for 5/8" ID (Inside diameter) plastic tubing. It is very important that the condensate line

is sloped away from and down to a suitable inside drain, if the condensate outlet on the Voyager is lower than the drain, you must use

a condensate removal pump. A condensate filter and a condensate pump kit are available from HTP. It is also very important that the

condensate line is not exposed to freezing temperatures, or any other type of blockage. Plastic tubing should be the only material used

for the condensate line; as steel, brass, copper, or others will be subject to corrosion and deterioration. A second vent may be necessary to prevent condensate line vacuum lock if a long horizontal run is used. Also an increase to 1" tubing may be necessary, (See the

diagram on page 24

).

Page 9

PAGE: 9 LP-41 REV: 3/1/03

SSVH MODEL PERFORMANCE AND SET-UP INFORMATION

The SSVH models are available in the 90,000 BTU/hr, 130,000, and 199,000 BTU/hr. firing rates. The illustration on page 43 show the

location of the heat exchanger and other ports. For maximum output, the bronze circulator provided must be attached between the hot

outlet and cold inlet as shown on page 22

. For complete SSVH information and sizing, refer to pages 42 and 43.

CONTROL DESCRIPTION

The fully integrated water heater control is an all electronic, fully automatic controller which will provide many years of trouble free service. The control requires no periodic maintenance and includes a built-in microprocessor which performs a number of diagnostic tests

to verify proper appliance and control operation. Should an unsafe condition occur, the burner will shut down and the appropriate status

indicators will illuminate indicating the need for service. Consisting of two printed circuit board assemblies, the controller's main board

is attached to inside left of the shroud while the display board is mounted to the front top of the shroud. This arrangement simplifies

access to the user adjustments while enhancing the visibility of the temperature display and status indicators. A power step-down

transformer and blower pressure switch are also mounted on the inside left of the shroud. The controller display functions include a

high visibility three digit LED readout which is used to display the actual water temperature within the tank along with the programmed

desired water temperature (set point temperature). Nine individual LED indicators are also mounted on the display board which are

used to determine the operating status of the appliance and provide assistance when troubleshooting any problems which may occur.

All indicators are of the solid state variety and should last for the life of the appliance. The controller has sufficient built-in memory to

retain the programmed temperature set point in the event input power is ever interrupted. The final component of the control system

includes a temperature sensing probe which is threaded into the side of the tank. This probe is of unique construction in that both the

temperature sensing/control and safety limit functions are performed by this single device. All probe components are of solid state construction to provide extended operational life.

START UP PROCEDURE

1. Make sure that the Voyager has been installed to these instruction procedures; along with all applicable province and local

codes;

2. Make sure all gas piping and connections have been verified and inspected by all applicable inspectors. Turn on gas supply.

Insure that the gas line and the LP tank, if applicable, have been properly purged. Failure to properly purge the gas lines will

result in failure to operate;

3. Make sure that the cold water supply has been turned on and that the Voyager is completely filled with water. Verify this by

opening a hot water faucet, and allowing water to flow until all air is removed and a clear water flow is present;

4. Turn on electrical supply;

5. The control will first display "102", then "88.8", which is the control display test; and finally the actual tank temperature at the

probe.

SET POINT ADJUSTMENT PROCEDURE

The three digit LED display will illustrate actual water temperature within the tank under normal operating conditions. However, this

display is also used to indicate the temperature set point when in the programming mode; and also ignitor amp draw and flame current.

The controller has a temperature set point range 70 degrees F. to 160 degrees F. The factory set point is 118 degrees F.

VERY IMPORTANT NOTE

:

POWER MUST BE APPLIED TO THE CONTROLLER PRIOR TO ANY PROGRAMMING OPERATIONS.

Page 10

PAGE: 10 LP-41 REV: 3/1/03

SET POINT ADJUSTMENT PROCEDURE (CONTINUED)

To change or access the programmed temperature set point value, utilize the red button on the display panel. Momentarily depressing

the button will briefly illustrate the existing set point value. If the button is held down for more than one second, the programming mode

is entered and the set point value will begin incrementing by one degree per second. When the desired set point value is reached, simply release the button and the controller will automatically retain this value in temporary memory. After 30 seconds, this new set point

will be retained in permanent memory.

NOTE

:

IF POWER IS INTERRUPTED DURING THIS 30 SECOND PERIOD, THE NEW SET POINT WILL NOT BE RETAINED IN PERMANENT MEMORY. IT IS A GOOD PRACTICE TO RE-CHECK THE SET POINT VALUE APPROXIMATELY 60 SECONDS AFTER A

NEW VALUE HAS BEEN RE-ENTERED.

If the button is held down long enough, the set point will reach 160 degrees F. and stop, since this is its maximum value. At this point,

if the desired set point has not been obtained, release the button and depress it again, the set point will decrement down to 70 degrees

F. and stop. The set point value will now restart at 70 degrees F. (its minimum) and once again increase in value for as long as the

button is pressed.

DIFFERENTIAL ADJUSTMENT PROCEDURE

To allow proper water heater operation, the control has a 8 degree F. "window" around the set point. This means that the burner will

be turned on when the water temperature drops to 4 degrees F. below the set point, and it will be turned off when the water temperature reaches 4 degrees F above the set point. Thus, if the set point is set to 120 degrees F., the control will turn on the burner when

the water temperature drops to 116 degrees F., and will continue to heat the water until the temperature reaches 124 degrees F. The

differential is factory set to 8 degrees F. (+ or- 4 degrees F.) If another differential is required, the value of the differential can be field

adjusted by holding the set point button when power is applied to the control. Shut off power to the control. Next hold in the set point

button. Now reapply power to the control. Using the set point button, the value of the differential can be incremented or decremented

as above. When the proper value is reached, release the button and the new differential has been stored into permanent memory.

OVERALL APPLIANCE AND CONTROL OPERATION

A normal operating sequence is as follows:

1. The control determines that the actual water temperature inside tank is 4 degrees F., with the factory set 8 degree F.

differential, below programmed temperature set point;

2. The control performs selected system diagnostic checks;

3. If all checks are successfully passed, the combustion blower is energized for the 40 second pre-purge cycle;

4. During the pre-purge cycle is complete, power is applied to the ignitor element for the ignitor warm-up period (blower should

continue to run);

5. The ignitor warm-up period will last for 30 seconds, then gas valve will be opened, allowing gas to enter the burner chamber;

6. The ignitor will remain on for an additional 4 seconds, then it will be turned off;

7. After an additional 2 seconds, the control will verify the presence of flame. If the flame was not established, the gas valve will

be closed, power will be removed from the ignitor element, and the control will run the blower for 30 seconds. At this point,

the control will return to step 2;

8. If flame is present, the control will enter the heating mode where it will continue heating the tank water until the set point

temperature plus 4 degrees F. is reached. At this point, the gas valve is closed and the control enters the post-purge cycle.

The flame can be viewed through a window on the lower right of combustion blower flange;

9. The post-purge cycle continues to run the combustion blower for an additional 30 seconds to purge the system of all

combustion gases. After this time period, the blower is de-energized and will coast to a stop;

10. The control will now enter the idle state while continuing to monitor internal tank water temperature. If the temperature drops

to 4 degrees F. below the set point value, the control will automatically return to step 1.

Page 11

PAGE: 11 LP-41 REV: 3/1/03

STATUS INDICATORS

Pages 15, 16, and 17 contain seven individual diagrams which illustrate the various operating states of the appliance and their relation

to the LED status indicators found on the controller. These diagrams reflect normal water heater operation.

MAINTENANCE

The control system requires no periodic maintenance under normal conditions. However, in unusually dirty or dusty conditions, periodic vacuuming of the cover to maintain visibility of the display and indicators is recommended. In dirty environments, construction sites,

building constructions, care must be taken to keep the appliance door in place and drywall or saw dust away from appliance. Failure

to do so VOIDS WARRANTY!

INTERNAL WIRING

For specific wiring information, please refer to the diagrams on pages 18 and 19

.

SHUTDOWN PROCEDURE

If the burner is operating, lower the set point value to 70 degrees F. and wait for the burner to shut off. Continue to wait for the combustion blower to stop so all latent combustion gases are purged from the system. This should take a maximum of 40 to 90 seconds.

Disconnect the electrical supply. If the burner is not operating, disconnect the electrical supply.

VACATION PROCEDURE

If there is danger of freezing, change the set point to 70 degrees F. DO NOT

turn off electrical power. If there is no danger of

freezing, follow the "Shutdown Procedure".

FAILURE TO OPERATE

Should the burner fail to light, the control will perform two more ignition trials prior to entering a lockout state (“LOC”). Note that each

subsequent ignition trial will not occur immediately. After a failed ignition trial, the blower must run for approximately 10 seconds to

purge the system, then the ignitor element must complete a 30 second warm-up period. Therefore, a time period of approximately 40

to 90 seconds will expire between each ignition trial. If the burner lights during any one of these three ignition trails, normal operation

will resume. If the burner lights, but goes off in about 4 seconds, check the polarity of the wiring. See electrical on page 4. If the burner does not light after the third ignition trial, the control will enter a lockout state. This lockout state indicates that a problem exists with

either the appliance, the controls, or the gas supply. Under such circumstances, a qualified service technician should be contacted

immediately to properly service the appliance and correct the problem. If a technician is not available, depressing the red button once

will remove the lockout state so additional trials for ignition can be performed. Any time “LOC” is shown, you must look for an LED

out, or flashing. The LED that is out or flashing will assist you in diagnosing lock out condition.

Page 12

PAGE: 12 LP-41 REV: 3/1/03

Page 13

PAGE: 13 LP-41 REV: 3/1/03

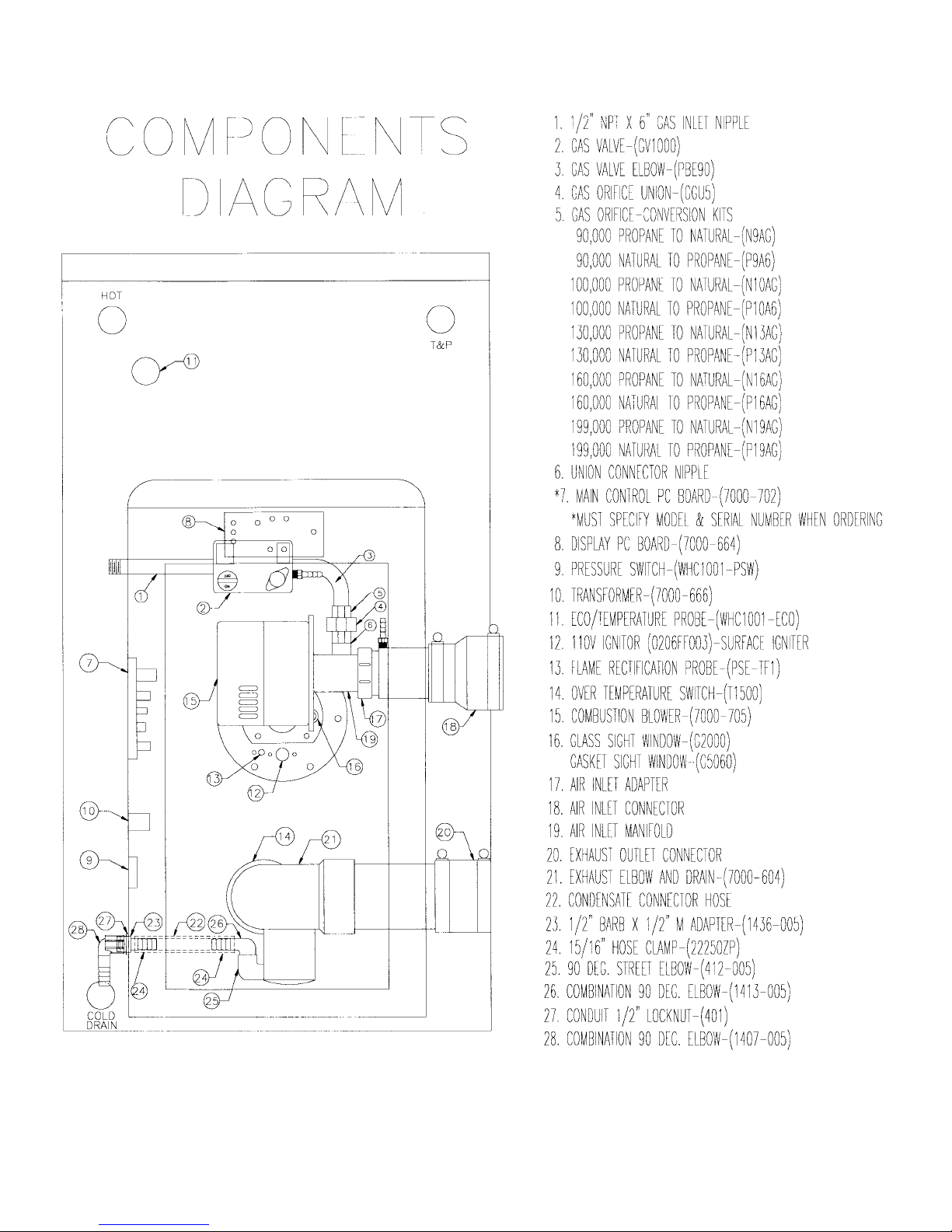

REPLACEMENT PARTS NOT SHOWN

LOW VOLTAGE CABLE ASSEMBLY (710B0041)

INTERCONNECT RIBBON CABLE (7000-665)

LINE CABLE (710B0048)

PUSH BUTTON (7000-667)

TRANSFORMER (7000-666)

GASKET BURNER MOUNTING FLANGE (G5010)

GASKET BLOWER OUTLET FLANGE (G5020)

GASKET AIR INLET (G5030)

GASKET BURNER MOUNTING FLANGE WHITE (G5040)

ORIFICES

All of the Voyager gas fired water heaters have unique air and gas orifice sizes. Special attention should be paid to these sizes whenever converting a heater from one fuel type to another, or when the orifice is changed for any reason. Below is a list of orifice sizes for

conversions to other fuel types and the sizes the voyager was shipped with from the factory. Please note that air orifices do not have

to be changed when switching from one fuel type to another. This information is not intended to allow field conversions by drilling orifices. This is only a guide to correct orifice sizing. If orifices are drilled the result will be poor ignition, a VOIDED WARRANTY,

severe bodily injury, death and/or explosion. All orifices must be obtained through the factory with all necessary labels and the serial number must be provided to the factory or warranty will be voided.

199,000 BTU VOYAGERS- GAS ORIFICE SIZES-

AIR ORIFICE = 1.375" NATURAL GAS = .379" PROPANE/LP GAS = .295"

160,000 BTU VOYAGERS- GAS ORIFICE SIZES-

AIR ORIFICE = 1.375" NATURAL GAS = .362" PROPANE/LP GAS = .295"

130,000 BTU VOYAGERS- GAS ORIFICE SIZES-

AIR ORIFICE = 1.125" NATURAL GAS = .280" PROPANE/LP GAS = .235"

NATURAL GAS CONVERSION FROM PROPANE/LP = .285"

PROPANE/LP GAS CONVERSION FROM NATURAL GAS = .250"

100,000 BTU VOYAGERS- GAS ORIFICE SIZES-

AIR ORIFICE = 1.125" NATURAL GAS = .280" PROPANE/LP GAS = .235"

NATURAL GAS CONVERSION FROM PROPANE/LP = .285"

PROPANE/LP GAS CONVERSION FROM NATURAL GAS = .250"

90,000 BTU VOYAGERS- GAS ORIFICE SIZES-

AIR ORIFICE = 1.000" NATURAL GAS = .261" PROPANE/LP GAS = .205"

NATURAL GAS CONVERSION FROM PROPANE/LP = .253"

PROPANE/LP GAS CONVERSION FROM NATURAL GAS = .215"

Page 14

PAGE: 14 LP-41 REV: 3/1/03

CAUTION:

THERE ARE NO USER SERVICEABLE PARTS WITHIN THE CONTROL SYSTEM. TO MAINTAIN SAFETY AND PROPER APPLIANCE PERFORMANCE, REFER ALL TROUBLE-SHOOTING TO QUALIFIED SERVICE PERSONNEL.

TROUBLESHOOTING

The appliance controller has many inherent diagnostic and fault detection routines built into its operating software and hardware.

These routines, along with the three digit LED display and nine LED status indicators present on the display panel, can greatly assist

the service person in quickly pinpointing the source of problems that may occur with the appliance. In certain circumstances, multiple

LED's may be lit or flashing to better pinpoint the problem. Also, there is a green LED on the main control board to indicate proper

polarity and grounding. The following charts, diagrams, and information can be used during

troubleshooting procedures:

LED

CONTROLLER FUNCTION MEANING

LINE MONITORS INCOMING AC LINE VOLTAGE “ON” WHEN LINE VOLTAGE IS PRESENT

BLOWER MONITORS THE BLOWER MOTOR OUTPUT “ON” WHEN OUTPUT IS ENERGIZED

(POWER APPLIED TO BLOWER)

IGNITOR MONITORS IGNITOR ELEMENT OUTPUT “ON” WHEN OUTPUT IS ENERGIZED

(POWER APPLIED TO IGNITOR)

24V MONITORS INCOMING VOLTAGE FROM THE “ON” WHEN SECONDARY VOLTAGE IS PRESENT

TRANSFORMER SECONDARY

ECO MONITORS STATE OF THE ECO SWITCH “ON” WHEN ECO SWITCH IS IN CLOSED POSITION

(NORMAL POSITION)

PRESSURE MONITORS STATE OF THE AIR SWITCH “ON” WHEN THE PRESSURE SWITCH IS CLOSED

(SUFFICIENT COMBUSTION AIRFLOW EXISTS)

GAS VALVE MONITORS THE GAS VALVE OUTPUT “ON” WHEN OUTPUT IS ENERGIZED

(POWER APPLIED TO GAS VALVE)

WATER TEMP. MONITORS WATER TEMP. WITHIN TANK “ON” WHEN TEMP. DROPS BELOW SET POINT

CONTROL MONITORS INTERNAL STATE OF THE “ON” WHEN CONTROLLER FUNCTIONALITY IS O.K.

HEALTH CONTROLLER’S HARDWARE AND SOFTWARE

GREEN ON MONITORS POLARITY AND GROUND CIRCUIT “ON” WHEN GROUND AND POLARITY ARE O.K.

MAIN CONTROL

BOARD

VERY IMPORTANT SET-UP INSTRUCTIONS!

IF YOU HAVE A COMBUSTION ANALYZER, THE FOLLOWING RATINGS WILL BE VERY HELPFUL IN SETTING UP

YOUR VOYAGER:

FOR NATURAL GAS - CO2 READING SHOULD BE BETWEEN 9 ½% & 10 ½%

O2 READING SHOULD BE BETWEEN 3 ½% & 4 ½%

CO READING SHOULD BE UNDER 10 PPM

FOR PROPANE GAS - CO2 READING SHOULD BE BETWEEN 10 ½% & 11 ½%

O2 READING SHOULD BE BETWEEN 3 ½% & 4 ½%

CO READING SHOULD BE UNDER 10 PPM

Page 15

PAGE: 15 LP-41 REV: 3/1/03

Page 16

PAGE: 16 LP-41 REV: 3/1/03

Page 17

PAGE: 17 LP-41 REV: 3/1/03

Page 18

PAGE: 18 LP-41 REV: 3/1/03

Page 19

PAGE: 19 LP-41 REV: 3/1/03

Page 20

PAGE: 20 LP-41 REV: 3/1/03

TYPICAL VENTING

Page 21

PAGE: 21 LP-41 REV: 3/1/03

Page 22

PAGE: 22 LP-41 REV: 3/1/03

Page 23

PAGE: 23 LP-41 REV: 3/1/03

Page 24

PAGE: 24 LP-41 REV: 3/1/03

Page 25

PAGE: 25 LP-41 REV: 3/1/03

Page 26

PAGE: 26 LP-41 REV: 3/1/03

COMPLETE TEAR DOWN PROCEDURE

TOOLS REQUIRED: 5/16" NUT DRIVER ¼" FLAT HEAD SCREWDRIVER

3/8" DEEP SOCKET #2 PHILLIPS HEAD SCREWDRIVER

7/16" DEEP SOCKET 10" PIPE WRENCH

½" DEEP SOCKET 1 ¼" DRIVE INCH POUND TORQUE

3/8" WRENCH WRENCH (RANGE 0-200)

7/16" WRENCH SNAP RING OR NEEDLE NOSE PLIERS

NOTE

:

SEE END OF THIS SECTION FOR PARTS DIAGRAMS.

1. DISCONNECT POWER FROM UNIT.

2. SHUT OFF GAS SUPPLY.

3. REMOVE CABINET DOOR.

4. SHUT OFF GAS VALVE BY TURNING THE BLUE KNOB ON THE GAS VALVE.

5. DISCONNECT THE AIR INLET PIPE AT THE SMALL END OF THE AIR INLET CONNECTOR BY LOOSENING THE HOSE

CLAMP WITH A 5/16" NUT DRIVER.

6. REMOVE THE CLEAR VINYL HOSE THAT RUNS FROM THE GAS VALVE TO THE AIR INLET ADAPTER.

7. BREAK THE GAS ORIFICE UNION BY TURNING THE UNION CLOCKWISE WITH A 10" PIPE WRENCH.

NOTE

:

BE SURE NOT TO LOOSE THE GAS ORIFICE HELD INSIDE THE UNION.

8. REMOVE THE BRASS BARB FROM THE AIR INLET ADAPTER WITH A 7/16" DEEP SOCKET.

9. LOOSEN THE AIR INLET ADAPTER AND PULL THE AIR INLET ADAPTER THROUGH THE SIDE OF THE CABINET.

NOTE

:

BE SURE NOT TO LOOSE THE AIR ORIFICE SNAPPED INTO THE END OF THE ALUMINUM PIPE.

10. REMOVE THE FOUR BRASS NUTS HOLDING THE ALUMINUM AIR INLET MANIFOLD TO THE BLOWER, WITH A 3/8"

DEEP SOCKET.

11. REMOVE THE BLOWER OUTLET FLANGE GASKET FROM THE BLOWER.

12. REMOVE THE GAS VALVE WIRING HARNESS FROM THE GAS VALVE BY PRESSING ON THE TABS ON THE TOP

AND BOTTOM OF THE PLUG, AND PULLING.

13. REMOVE THE TWO GREEN GROUNDING WIRES FROM THE TOP/REAR OF THE BLOWER BY TAKING OUT THE

GREEN GROUNDING SCREW WITH A 5/16" NUT DRIVER.

14. REMOVE THE BLACK WIRE FROM THE FLAME RECTIFICATION PROBE, BY PULLING ON IT.

15. REMOVE THE IGNITOR WIRING HARNESS FROM THE CONTROL BOARD BY PRESSING ON THE TABS ON THE TOP

AND BOTTOM OF THE PLUG, AND PULLING.

16. REMOVE THE TWO BRASS NUTS RETAINING THE IGNITOR, WITH A 3/8" DEEP SOCKET.

17. GENTLY PRY THE IGNITOR BACK ABOUT 1/16 OF AN INCH, WITH A ¼" FLAT HEAD SCREWDRIVER. NOW PULL

THE IGNITOR STRAIGHT BACK. BE VERY CAREFUL THAT YOU DO NOT WIGGLE THE IGNITOR AT ALL!

18. REMOVE THE FLAME RECTIFICATION PROBE BY REMOVING THE SCREW TO THE LEFT OF THE ELECTRICAL

CONNECTOR WITH A #2 PHILLIPS HEAD SCREWDRIVER AND PULLING IT STRAIGHT BACK.

19. REMOVE THE CLEAR VINYL HOSE FROM THE LEFT/BACK OF THE BLOWER.

20. REMOVE THE BLOWER WIRING HARNESS FROM THE LEFT/BOTTOM OF THE BLOWER BY PULLING STRAIGHT OUT

ON IT.

21. REMOVE THE FOUR BRASS NUT RETAINING THE BLOWER TO BURNER MOUNTING FLANGE WITH A 7/16"

WRENCH.

22. PULL THE BLOWER STRAIGHT BACK BEING CAREFUL NOT TO LOSE THE SIGHT GLASS.

23. REMOVE THE BURNER BY PRYING IT AWAY FROM THE BURNER MOUNTING FLANGE AND THEN PULLING IT

STRAIGHT BACK.

24. REMOVE THE OLD BURNER MOUNTING FLANGE GASKET BY REMOVING THE SIX NUTS WITH A ½" DEEP SOCKET.

25. REMOVE ALL OF THE OLD GASKET MATERIAL FROM ALL SURFACES EXCEPT FOR THE SIGHT GLASS WINDOW

GASKET.

Page 27

PAGE: 27 LP-41 REV: 3/1/03

ASSEMBLY

1. REPLACE THE WHITE FIBER BURNER MOUNTING FLANGE GASKET WITH A NEW GASKET.

2. PUT THE BURNER MOUNTING FLANGE BACK IN PLACE WITH THE ½" HOLE NEXT TO THE LARGE HOLE IN THE

CENTER OF THE PLATE TO THE RIGHT AND WITH THE STUDS FACING OUT.

3. TIGHTEN THE SIX ½" NUTS TO 50 INCH POUNDS TORQUE AND THEN 200 INCH POUNDS TORQUE IN THE

FOLLOWING ORDER:

4. REPLACE THE BURNER MOUNTING FLANGE GASKET WITH A NEW GASKET, BE SURE THAT BOTH SIDES OF THE

GASKET ARE SPRAYED WITH PERMATEX HIGH TACK SPRAY-A-GASKET ADHESIVE SEALANT (PART #99MA).

5. RE-INSERT THE BURNER WITH THE FLAT SIDE OF THE FLANGE FACING DOWN.

6. REPLACE THE BLOWER OUTLET FLANGE GASKET WITH A NEW GASKET. BE SURE THAT BOTH SIDES OF THE

GASKET ARE SPRAYED WITH PERMATEX HIGH TACK SPRAY-A-GASKET ADHESIVE SEALANT (PART #99MA).

7. PLACE BLOWER ON BURNER MOUNTING FLANGE. BE SURE THAT THE SIGHT GLASS IS IN PLACE AND THE

GASKET IS INSTALLED CORRECTLY AS SHOWN BELOW:

NOTE

:

IF GASKET OR SIGHT WINDOW ARE DAMAGED IN ANY WAY, REPLACE THEM WITH NEW ONES.

8. TIGHTEN THE BLOWER BOLTS FIRST TO 50 INCH POUNDS TORQUE, THEN TO 150 INCH POUNDS TORQUE, IN

THE FOLLOWING ORDER:

9. PLACE THE IGNITOR BACK INTO THE BURNER MOUNTING FLANGE, BEING VERY CAREFUL OF THE ELEMENT,

WHICH IS EXTREMELY FRAGILE.

SIGHT GLASS G2000

GASKET G5060

Page 28

PAGE: 28 LP-41 REV: 3/1/03

10. TIGHTEN THE TWO 3/8" IGNITOR NUTS TO 50 INCH POUNDS TORQUE.

11. PLACE THE FLAME RECTIFICATION PROBE BACK INTO THE BURNER MOUNTING FLANGE AND TIGHTEN THE

SCREW WITH A #2 PHILLIPS HEAD SCREWDRIVER.

12. RE-INSTALL THE AIR INLET GASKET TO THE RIGHT SIDE OF THE BLOWER WITH THE TWO ANGLE CUTS FACING

TOWARD THE WATER HEATER.

13. RE-INSTALL THE ALUMINUM AIR INLET ASSEMBLY WITH THE TWO ANGLE CUTS FACING THE WATER HEATER.

14. TIGHTEN THE FOUR 3/8" NUTS TO 5 INCH POUNDS TORQUE IN THE FOLLOWING ORDER:

NOTE

:

IF THESE BOLTS ARE OVER TIGHTENED, THE BLOWER WILL BE DAMAGED AND WILL HAVE TO BE REPLACED.

15. SNAP THE AIR ORIFICE INTO THE END OF THE AIR INLET MANIFOLD.

16. SLIDE THE AIR INLET ADAPTER OVER THE END OF THE AIR INLET MANIFOLD UNTIL THE STOP INSIDE THE AIR

INLET ADAPTER CONTACTS THE END OF THE AIR INLET MANIFOLD.

17. TIGHTEN THE TRAP ADAPTER BY HAND, WITH 1/8" PIPE THREAD FACING UP.

18. RE-INSTALL THE 1/8" BRASS BARB BACK INTO THE TRAP ADAPTER WITH A 7/16" DEEP SOCKET.

19. PLACE GAS ORIFICE ON TOP OF THE SPLIT UNION WITH HOLE FACING UP, AS SHOWN BELOW:

20. RE-CONNECT THE GAS VALVE TO THE AIR INLET MANIFOLD BY TURNING THE UNION COUNTER-CLOCKWISE AND

TIGHTENING IT WITH A 10" PIPE WRENCH.

21. RE-CONNECT THE CLEAR VINYL HOSE FROM THE GAS VALVE TO THE AIR INLET ADAPTER.

22. PLUG THE BLOWER POWER WIRE INTO THE LEFT-BOTTOM OF THE BLOWER WITH THE WHITE TOWARDS THE

TOP.

23. RE-CONNECT THE CLEAR VINYL HOSE FROM THE PRESSURE SWITCH TO THE BARB ON THE BACK-LEFT OF THE

BLOWER.

24. PLUG THE IGNITOR WIRING HARNESS BACK INTO THE CONTROL BOARD.

25. RE-CONNECT THE BLACK WIRE TO THE FLAME RECTIFICATION PROBE, BY PUSHING THE CONNECTOR OVER

THE BLADE ON THE FLAME RECTIFICATION PROBE.

26. SCREW THE TWO GREEN GROUNDING WIRES TO THE TOP-BACK OF THE BLOWER WITH THE GREEN

GROUNDING SCREW, USING A 5/16" NUT DRIVER.

27. PLUG THE GAS VALVE WIRING HARNESS BACK INTO THE GAS VALVE WITH THE BLUE WIRE TOWARDS THE

BOTTOM OF THE CONNECTOR.

28. RE-CONNECT THE AIR INLET PIPING BY LOOSENING THE SMALLER HOSE CLAMP ON THE AIR INLET

CONNECTOR ALL THE WAY, AND THEN SLIDING THE BOOT OVER THE END OF THE AIR INLET ADAPTER, THEN

TIGHTEN, USING A 5/16" NUT DRIVER.

Page 29

PAGE: 29 LP-41 REV: 3/1/03

PARTS ILLUSTRATIONS

AIR INLET ADAPTER

NI110

AIR INLET MANIFOLD

A5000

Page 30

PAGE: 30 LP-41 REV: 3/1/03

GASKET AIR INLET

G5030

GAS ORIFICE UNION

GGU5

Page 31

PAGE: 31 LP-41 REV: 3/1/03

GAS ORIFICE

01000

AIR ORIFICE

A3001 = 1.0 SIZE; A3002 = 1.125 SIZE; A3003 = 1.375 SIZE

FLAME RECTIFICATION PROBE

PSE-TF1

Page 32

PAGE: 32 LP-41 REV: 3/1/03

GASKET BURNER MOUNTING FLANGE

G5010

BURNER MOUNTING FLANGE

7000-616

Page 33

PAGE: 33 LP-41 REV: 3/1/03

GAS VALVE

GV1000

AIR INLET CONNECTOR

F3000

Page 34

PAGE: 34 LP-41 REV: 3/1/03

110V IGNITOR - SURFACE IGNITER

0206FF003

GASKET BURNER MOUNTING FLANGE WHITE

G5040

GASKET BLOWER OUTLET FLANGE

G5020

Page 35

PAGE: 35 LP-41 REV: 3/1/03

GAS ORIFICE CONVERSION INSTRUCTIONS

1. IF UNIT IS INSTALLED, TURN OFF POWER AND GAS SUPPLY BEFORE PERFORMING ANY CONVERSIONS.

2. TO CHANGE GAS ORIFICE, DISCONNECT UNION (#6) BETWEEN THE GAS VALVE AND AIR INLET; REMOVE OLD

GAS ORIFICE (#5), AND INSTALL THE NEW GAS ORIFICE IN THE UNION THAT CORRESPONDS TO THE UNIT MODEL

NUMBER AND FUEL BEING USED. SEE KIT CONTENT LIST FOR THE CORRECT ORIFICE TO BE USED. DISCARD

ORIFICES NOT USED.

3. FOR LABELING, CHANGE THE RATING PLATE LABEL FROM THE ORIGINAL FUEL TYPE TO THE NEW FUEL TYPE BY

PLACING THE NEW LABEL OVER THE EXISTING LABEL.

Page 36

PAGE: 36 LP-41 REV: 3/1/03

4. REPLACE GAS TYPE LABEL (LS2000 E OR F) OVER GAS INLET PIPE.

5. IF YOU ENCOUNTER COMBUSTION PROBLEMS, REFER TO PROCEDURE "1" ON PAGE 40.

GAS VALVE REPLACEMENT - REMOVAL

1. SHUT OFF POWER TO THE VOYAGER.

2. REMOVE THE DOOR FROM THE VOYAGER CABINET.

3. SHUT OFF THE GAS VALVE BY TURNING THE BLUE KNOB ON THE VALVE TO THE "OFF" POSITION.

4. SHUT OF THE GAS SUPPLY TO THE VOYAGER.

5. BREAK THE UNION ON THE GAS LINE LOCATED BEFORE THE GAS VALVE, AND REMOVE THE HALF OF THE

UNION THAT IS CONNECTED TO THE GAS VALVE INLET PIPE.

6. REMOVE THE CLEAR VINYL HOSE THAT CONNECTS BETWEEN THE GAS VALVE AND THE TRAP ADAPTER.

Page 37

PAGE: 37 LP-41 REV: 3/1/03

7. BREAK THE UNION THAT CONNECTS THE GAS VALVE TO THE AIR INLET MANIFOLD.

8. SLIDE THE GAS VALVE OUT THROUGH THE FRONT OF THE VOYAGER CABINET. REMOVE THE GAS VALVE

WIRING HARNESS FROM THE GAS VALVE.

GAS VALVE REPLACEMENT - INSTALLATION

NOTE:

IF YOU HAVE TWO MANOMETERS AVAILABLE, THEN FOLLOW INSTALLATION PROCEDURE #2. IF NO MANOMETERS ARE

AVAILABLE, USE INSTALLATION PROCEDURE #1.

PROCEDURE #1

1. RE-CONNECT THE GAS VALVE WIRING HARNESS TO THE GAS VALVE.

2. SLIDE THE GAS VALVE BACK INTO POSITION BY PUTTING THE GAS VALVE INLET THROUGH THE GAS VALVE

INLET HOLE IN THE LEFT-TOP OF THE VOYAGER CABINET.

3. PLACE THE GAS ORIFICE BACK ON THE BOTTOM HALF OF THE UNION, AND TIGHTEN THE UNION.

4. RE-CONNECT THE CLEAR VINYL HOSE TO THE GAS VALVE AND TO THE TRAP ADAPTER.

Page 38

PAGE: 38 LP-41 REV: 3/1/03

9. TURN THE LINE VOLTAGE BACK ON, TO THE VOYAGER.

GAS VALVE ADJUSTMENT

I. LET THE UNIT START TO CYCLE AND LISTED CAREFULLY TO THE IGNITION. IF THE IGNITION WAS QUIET, THE

VALVE WILL NEED NO ADJUSTMENT. IF IT WAS A LOUD IGNITION OR THERE WAS NOT IGNITION AT ALL, FOLLOW

THESE STEPS:

A. IF THERE WAS NO IGNITION:

1. MAKE SURE THE GAS VALVE IS IN THE "ON" POSITION; GAS IS ON TO THE UNIT; AND THE GAS

VALVE WIRING HARNESS IS PLUGGED INTO THE GAS VALVE AND INTO THE CONTROL BOARD

2. TURN THE ADJUSTMENT SCREW UNDER THE BRASS CAP YOU REMOVED IN STEP #8 ABOVE.

TURN ONE FULL TURN CLOCKWISE WITH A SMALL FLATHEAD SCREWDRIVER.

A. IF THE UNIT STILL DOES NOT LIGHT OFF, TURN THE ADJUSTMENT

SCREW TWO FULL TURNS COUNTERCLOCKWISE

5. RE-CONNECT THE SUPPLY GAS PIPING TO THE VALVE.

6. TURN ON THE GAS TO THE VOYAGER.

7. TURN THE BLUE KNOB ON THE GAS VALVE TO THE "ON" POSITION.

8. REMOVE THE SMALL ROUND BRASS PLUG FROM THE GAS VALVE BY TURNING IT COUNTER-CLOCKWISE WITH A

PAIR OF SNAP RING OR NEEDLE NOSE PLIERS.

Page 39

PAGE: 39 LP-41 REV: 3/1/03

B. IF IGNITION WAS POOR:

1. LOOK AT THE COLOR OF THE FLAME WHILE THE UNIT IS RUNNING, THROUGH THE SIGHT GLASS.

IF IT IS GREEN OR RED IN COLOR, OR THE HEATER WHISTLES ON IGNITION, TURN THE

ADJUSTMENT SCREW COUNTERCLOCKWISE AT ½ TURN INTERVALS, UNTIL THE FLAME TURNS

BLUE/LIGHT BLUE IN COLOR, OR THE WHISTLING AT IGNITION STOPS. IF THE FLAME IS VERY

WEAK OR PULSING, TURN THE ADJUSTMENT SCREW CLOCKWISE UNTIL THE FLAME STEADIES.

2. PUT THE GAS VALVE ADJUSTMENT SCREW COVER BACK IN PLACE AND TIGHTEN.

3. PUT THE VOYAGER CABINET DOOR BACK INTO PLACE.

PROCEDURE #2

1. REMOVE THE OUTLET PRESSURE TAP PLUG FROM THE RIGHT SIDE OF THE GAS VALVE WITH A 3/16" ALLEN

WRENCH.

2. PUT A 1/8" NPT HOSE BARB IN PLACE OF THE OUTLET PRESSURE TAP PLUG. NO SEALANT IS REQUIRED ON THIS

FITTING.

3. RE-CONNECT THE GAS VALVE WIRING TO THE GAS VALVE.

4. SLIDE THE GAS VALVE BACK INTO POSITION BY PUTTING THE GAS VALVE INLET PIPE THROUGH THE GAS VALVE

INLET HOLE IN THE LEFT-TOP OF THE VOYAGER CABINET.

5. PLACE THE GAS ORIFICE BACK ON THE BOTTOM HALF OF THE UNION AND TIGHTEN THE UNION.

Page 40

PAGE: 40 LP-41 REV: 3/1/03

6. CONNECT THE VACUUM HOSING ACCORDING TO THE FOLLOWING DIAGRAM:

7. RE-CONNECT THE SUPPLY GAS PIPING TO THE VALVE.

8. TURN ON THE GAS TO THE VOYAGER.

9. TURN THE BLUE KNOW ON THE GAS VALVE TO "ON".

10. REMOVE THE SMALL ROUND BRASS PLUG FROM THE GAS VALVE BY TURNING IT COUNTER-CLOCKWISE WITH A

SMALL PUNCH AND HAMMER.

11. TURN THE LINE VOLTAGE BACK ON TO THE VOYAGER.

Page 41

PAGE: 41 LP-41 REV: 3/1/03

12. LET THE VOYAGER CYCLE. AFTER THE VOYAGER STARTS, LET IT RUN FOR 30 SECONDS, THEN ADJUST THE

GAS VALVE BY USING THE GAS VALVE ADJUSTMENT SCREW, SO THAT MANOMETER #2 READS EXACTLY THE

SAME AS MANOMETER #1.

EXAMPLE: IF MANOMETER #1 READS -.35" AND MANOMETER #2 READS .1"; YOU WOULD ADJUST THE GAS

VALVE BY USING THE GAS VALVE ADJUSTMENT SCREW, SO THAT THE MANOMETER #2 ALSO

READS -.35".

13. IF THERE WAS NO IGNITION:

A. MAKE SURE THE GAS VALVE IN THE "ON" POSITION, GAS IS ON TO THE UNIT, AND THE GAS VALVE

WIRING HARNESS IS PLUGGED INTO THE GAS VALVE AND INTO THE CONTROL BOARD.

B. TURN THE ADJUSTMENT SCREW UNDER THE BRASS CAP YOU REMOVED IN STEP #8. TURN ONE FULL

TURN CLOCKWISE WITH SMALL FLATHEAD SCREWDRIVER. IF THE UNIT STILL DOES NOT LIGHT OFF,

TURN THE ADJUSTMENT SCREW TWO FULL TURNS COUNTERCLOCKWISE.

14. SHUT THE VOYAGER DOWN, THEN START IT UP AGAIN; LET IT RE-LIGHT. IF THE IGNITION WAS GOOD, THE

VALVE NEEDS NO FURTHER ADJUSTMENT. IF THE IGNITION WAS POOR, SHUT DOWN THE UNIT AND LET IT

CYCLE AGAIN. TURN THE GAS VALVE ADJUSTMENT SCREW SO THAT MANOMETER #2 READS .10" MORE THAT

MANOMETER # 1. EXAMPLE: MANOMETER #1 READS -.35"; ADJUST MANOMETER #2 SO THAT IT READS -.25". IF

THIS DOES NOT STOP THE POOR IGNITION, ADJUST THE GAS VALVE ADJUSTMENT SCREW ANOTHER .10".

EXAMPLE: IF MANOMETER #1 READS -.35", MANOMETER #2 SHOULD BE ADJUSTED TO NOW READ -.15".

15. PUT THE GAS VALVE ADJUSTMENT SCREW COVER BACK IN PLACE AND TIGHTEN.

16. REMOVE ALL THE CLEAR VINYL HOSES FROM THE GAS VALVE.

17. REMOVE THE BARB IN THE OUTLET PRESSURE TAP, REPLACE IT WITH THE ORIGINAL PLUG, AND TIGHTEN.

18. RE-CONNECT THE CLEAR VINYL HOSE TO THE GAS VALVE, AND TO THE TRAP ADAPTER.

20. PUT THE VOYAGER CABINET DOOR BACK IN PLACE.

Page 42

PAGE: 42 LP-41 REV: 3/1/03

IMPORTANT INSTRUCTIONS FOR SSVH MODELS

HOW THE SYSTEM WORKS WITH RADIANT HEAT

BOTH THE VOYAGER SSV AND SSVH MODELS ARE VERY EFFICIENT AND POWERFUL WATER HEATING DEVICES. THE

VOYAGER SSV AND SSVH MODELS PRODUCE LARGER AMOUNTS OF HOT WATER IN A VERY SMALL COMPACT DESIGN,

WHEN COMPARED WITH CONVENTIONAL WATER HEATERS. HEAT TRANSFER PRODUCTS HAS DESIGNED THE VOYAGER

SSVH MODEL EXCLUSIVELY AS A COMBINED HOT WATER/RADIANT SPACE WATER HEATER. THE UNITS ARE BUILT WITH

A SECONDARY HEAT EXCHANGER TO TRANSFER HEAT FROM THE STORED WATER INTO THE CIRCULATOR LOOP FOR

THE FLOOR, CEILING, OR BASEBOARD RADIANT SYSTEM. THIS SECONDARY HEAT EXCHANGER ALLOWS THE VOYAGER

SSVH MODEL TO HEAT BOTH THE DOMESTIC WATER AND PROVIDE OUTPUT BY THE INSTALLATION OF A RE-CIRCULATION LINE CONNECTED FROM DOMESTIC HOT WATER OUTLET TO DOMESTIC COLD WATER INLET. THE VOYAGER

SSVH-130 MODEL CAN TRANSFER UP TO 110,000 BTU’s IN THE SECONDARY HEAT EXCHANGER AND ALSO DELIVER 180

GALLONS OF HOT WATER IN THE FIRST HOUR OF OPERATION. EVEN VOYAGER SSV MODELS MAKE GREAT RADIANT

HEATERS, WHEN DOMESTIC HOT WATER IS NOT NEEDED IN THE INSTALLATION. ANOTHER IMPORTANT FEATURE IS

THAT BOTH SSV AND SSVH MODELS HAVE THE ABILITY TO DIRECT VENT WITH A ZERO CLEARANCE TOLERANCE TO ANY

COMBUSTIBLE SURFACE, WHICH ENABLES THE VOYAGER TO BE INSTALLED VIRTUALLY ANYWHERE! THIS TYPE OF

POWER, EFFICIENCY, AND INSTALLATION FLEXIBILITY IN SSV AND SSVH MODEL APPLIANCES IS A VOYAGER EXCLUSIVE

THAT NO OTHER WATER HEATER MANUFACTURER CAN OFFER!

HOW THE SYSTEM WORKS WITH HEATING/COOLING

BOTH SSV AND SSVH MODELS CAN WORK IN CONNECTION WITH AIR HANDLING EQUIPMENT TO PROVIDE AIR OR RADIANT HEATING, COOLING, AND DOMESTIC HOT WATER. THESE TYPES OF SYSTEMS PROVIDE THE ADVANTAGE OF

ZONED HEATING AND COOLING; WHICH PROVIDE MUCH GREATER COMFORT AND OPERATING EFFICIENCY VERSUS

CONVENTIONAL SYSTEMS.

HOW TO INSTALL THE SYSTEM

IN THIS MANUAL YOU WILL FIND SAMPLE DRAWINGS WHICH CAN PROVIDE YOU WITH IDEAS ON HOW TO LAY OUT THE

SYSTEM. THE USE OF A MIXING VALVE IS ALWAYS RECOMMENDED TO ACHIEVE FLEXIBILITY IN ADJUSTING TEMPERATURE TO MEET THE SYSTEM DEMAND. IT IS ESSENTIAL TO READ THIS INSTALLATION MANUAL TO ASSURE PROPER

OPERATION OF THE VOYAGER SYSTEM. AREAS IN THIS MANUAL THAT NEED SPECIAL ATTENTION ARE “CONDENSATE

REMOVAL”; “VENTING OF COMBUSTION GASES”; AND “CONNECTION OF A BRONZE CIRCULATOR BETWEEN DOMESTIC

HOT WATER OUTLET, DOMESTIC COLD WATER INLET”.

NOTE

:

IT IS VERY IMPORTANT TO FOLLOW EITHER LOCAL OR FEDERAL PLUMBING CODES WHEN INSTALLING AND OPERATING

A MIXING VALVE FOR A DOMESTIC HOT WATER SYSTEM!

HOW TO SIZE THE COMBINATION SYSTEM FOR RADIANT HEATING

IT IS IMPORTANT TO SIZE BOTH HEATING LOAD AND DOMESTIC HOT WATER LOAD, IN CHOOSING WHICH VOYAGER SSVH

MODEL YOU WILL NEED TO PURCHASE FOR THE JOB. ON THE FOLLOWING PAGE IS A CHART WHICH REPRESENTS

DESIGN OUTPUTS OF THE SECONDARY HEAT EXCHANGER IN THE VOYAGER SSVH MODEL. THIS CHART OUTLINES OUTPUT CHARACTERISTICS IN TERMS OF FLOW RATE THROUGH THE SECONDARY HEAT EXCHANGER, TEMPERATURE RISE,

AND BTU OUTPUT. IT IS IMPORTANT TO CHECK WITH YOUR RADIANT SUPPLIER ON THE OUTPUT TEMPERATURE,

DESIGN TEMPERATURE RISE OR DELTA TEE, AND THE TOTAL BTU OUTPUT REQUIRED FOR THE JOB. A BRONZE CIRCULATOR BETWEEN DOMESTIC HOT WATER OUTLET AND DOMESTIC COLD WATER INLET IS REQUIRED. ONCE YOU HAVE

DETERMINED YOUR SYSTEM OUTPUT REQUIREMENTS, REFER TO “VOYAGER SSVH MODEL SIZING CHART” ON NEXT

PAGE TO DETERMINE MODEL AND FLOW RATE REQUIRED THROUGH THE SECONDARY HEAT EXCHANGER; IN ORDER TO

MEET THE LOADS OF THE SYSTEM. EXAMPLES ARE PROVIDED TO GUIDE THROUGH THE SELECTION PROCESS. ONCE

WE KNOW THAT THE SECONDARY HEAT EXCHANGER HAS BEEN SIZED CORRECTLY TO MEET THE RADIANT HEAT LOAD,

WE MUST NOW LOOK INTO THE HOT WATER LOAD. FIRST YOU NEED TO UNDERSTAND THE DIFFERENCE BETWEEN

FIRST DRAW CAPACITY AND FIRST HOUR CAPACITY. FIRST DRAW CAPACITY IS ESTABLISHED AS THE TIME FRAME AT

DIFFERENT OUTPUT RATES WHICH THE VOYAGER SSVH MODEL CAN DELIVER THE DESIRED TEMPERATURE BEFORE

THE TANK RATE INPUT AND STORAGE ARE CONSUMED. THIS USUALLY OCCURS WHEN THERE IS A LARGER DRAW OF

HOT WATER IN A VERY SHORT TIME FRAME. (EXAMPLE: HOT TUB 80 GALLON WITH A FILL RATE OF 10 MINUTES) FIRST

HOUR RATING IS ESTABLISHED AS A RATING SYSTEM TO COMPARE THE WATER HEATER’S ABILITY TO RECOVER OVER A

ONE HOUR PERIOD. THE FIRST HOUR RATING CAN BE VERY MISLEADING WHEN THE HOT WATER LOAD IS REQUIRED IN

A VERY SHORT PERIOD OF TIME. NOW WE CAN DETERMINE WHICH VOYAGER SSVH MODEL WILL SUIT YOUR NEEDS

FOR THE JOB. TO DO THIS, REFER TO THE DOMESTIC HOT WATER CHART. IF THE DOMESTIC HOT WATER DEMANDS

EXCEED THE VOYAGER SSVH’S CAPACITY, THEN A STORAGE RE-CIRCULATION TANK CAN BE INSTALLED TO MEET THE

SYSTEM HOT WATER LOAD. AFTER YOU HAVE SIZED YOUR DOMESTIC LOAD AND HEATING LOAD, YOU ARE NOW READY

TO CHOOSE THE VOYAGER SSVH MODEL SUITABLE FOR THE JOB!

Page 43

PAGE: 43 LP-41 REV: 3/1/03

NOTE:

A BRONZE CIRCULATOR BETWEEN THE DOMESTIC HOT WATER OUTLET AND DOMESTIC COLD WATER INLET IS

REQUIRED TO ACHIEVE RATINGS BELOW:

VOYAGER SSVH MODEL SIZING CHART

Flow TEMPERATURE RISE (DEGREES F.)

GPM 15 20 25 30

2 15,000 20,000 25,000 30,000

3 22,500 30,000 37,500 45,000

4 30,000 40,000 50,000 60,000

5 37,500 50,000 62,500 75,000

6 45,000 60,000 75,000 90,000*

7 52,500 70,000 87,500* 105,000*

8 60,000 80,000 100,000* N/R

9 71,400** 95,200** 119,000** 124,500**

10 85,000** 113,250** 140,000** 140,000**

* FOR SSVH-130 MODELS ONLY! **FOR SSVH-199-80 MODELS ONLY!

NOTE:

THE VOYAGER MUST BE SET 25 DEGREES F. ABOVE THE SYSTEM TEMPERATURE. THE ABOVE CHART IS BASED ON

USING THE CIRCULATOR BETWEEN THE DOMESTIC COLD WATER INLET AND THE DOMESTIC HOT WATER OUTLET. FOR

SET POINT TEMPERATURES ABOVE 120 DEGREES F., YOU MUST USE AN ANTI-SCALD TEMPERING VALVE ON THE OUTLET TO DOMESTIC HOT WATER FIXTURES.

VOYAGER FIRST DRAW CAPACITY (In minutes) AT 140 DEGREES F.

Model

2 GPM 3 GPM 4 GPM 5 GPM 6 GPM 7 GPM 8 GPM

SSVH90-45 20 15 9 7 5 4 3

SSVH130-45 20 16 12 10 9 7 6

SSVH199-80 00 00 15 14 13 12 10

VOYAGER FIRST DRAW CAPACITY (In minutes) AT 115 DEGREES F.

Model

2 GPM 3 GPM 4 GPM 5 GPM 6 GPM 7 GPM 8 GPM

SSVH90-45 30 23 14 10 8 6 5

SSVH130-45 31 24 18 16 14 11 10

SSVH199-80 00 00 23 21 20 18 15

MODEL

HEIGHT WIDTH DEPTH INPUT FIRST HR. RATING

SSVH90-45 42" 24" 32" 90,000 125 U.S. gallons

SSVH130-45 42" 24" 32" 130,000 180 U.S. gallons

SSVH199-80 72" 24" 32" 199,000 300 U.S. gallons

MODEL

HEAT EXCH. HEAT EXCH. BTU RECOVERY VENT WEIGHT

SSVH90-45 32 Sq. Ft. 81,000 95% 3" 205 Lbs.

SSVH130-45 32 Sq. Ft. 110,000 94% 3" 205 Lbs.

SSVH199-80 32 Sq. Ft. 140,000 94% 3" 255 Lbs.

Note: These overall dimensions are approximate within +/– 1".

Heat Transfer Products reserves the right to change or discontinue models without notice.

VOYAGER DIMENSIONS *

45 GAL. 80 GAL. 119 GAL.

A

3 3/4"

B

C

D

E

F

G

H

I

K

M

N

O

P

R

5 1/4"

5 1/4"

5 1/2"

25 1/2"

27 1/4"

34 1/2"

35 1/4"

18 1/2"

33 1/2" 64" 66 1/2"

42 1/2"

23 1/4"

25 3/4"J25 3/4"

31 1/4"

27 1/4"L27 1/4"

33 3/4"

21 1/2" 23 1/4"

28 1/4"Q29 3/4"

37"

64"

15" 15" 15"

6"

7 1/2"

20"

72"

23 1/4"

31 1/4"

5 1/4"

5 1/2"

60 3/4"

L

HOT OUT

CONTROL

(SSVH

MODELS

ONLY)

OPTIONAL

HEAT

EXCHANGER

COLD IN

N

7 1/2"

7 3/4"

29 1/2"

40 1/2"

66 1/2"

9 3/4"

22 1/4"

74"

27 1/4"

29 3/4"

35 1/4"

31 1/4"

N/A

N/A

25 1/2"

K

STAINLESS STEEL HIGH EFFIENCY WATER HEATER

HOT OUT

T&P

CONTROL

GAS INLET

J

E

D

AIR INLET

I

P

VOYAGER

C

H

DRAIN

EXHAUST

OUTLET

F

G

O

COLD

IN

B

32"

A

CONDENSATE

M

GAS

INLET

ELECTRICAL

CONNECTION

CONDENSATE

DRAIN

R

Q

Page 44

PAGE: 44 LP-41 REV: 3/1/03

VERY IMPORTANT!!!

THIS VOYAGER HAS THE NEW 1200 BOARD AND BLOWER SYSTEM! THE ADDITIONAL FEATURES ARE LISTED BELOW:

1. THE BOARD WILL DETECT PROPER POLARITY BY ILLUMINATING THE GREEN LED LIGHT LOCATED ON THE LOWER RIGHT

CORNER OF THE BOARD. NO LIGHT MEANS IMPROPER POLARITY!

2. THE BLOWER CABLE AND THE CURRENT LIMITER HAVE BEEN ELIMINATED.

3. THE LED DISPLAY IS FIVE TIMES BRIGHTER; GIVING GREATER VISIBILITY IN BRIGHT LIGHT.

4. THE PUSH BUTTON IN THE FRONT OF THE CABINET ALLOWS THE USER TO READ IGNITOR DRAW IN

AMPS (2.5 - 3.5), AND FLAME QUALITY IN MICRO AMPS (4.5 - 5.1). TO READ IGNITOR DRAW, WAIT FOR THE LED LIGHT FOR THE

IGNITOR TO COME ON, THEN SIMPLY PUSH THE BUTTON IN ON THE FRONT OF THE CABINET. TO READ FLAME QUALITY, WAIT

FOR THE GAS VALVE TO BE ACTIVATED AND THE IGNITOR LIGHT TO GO OFF, THEN SIMPLY PUSH IN THE BUTTON ONCE. THIS

WILL TAKE PLACE IN THE NORMAL OPERATING SEQUENCE IN A HEAT CYCLE.

5. THE 1200 BOARD AND BLOWER SYSTEM PARTS ARE NOT INTERCHANGEABLE WITH THE VOYAGER PARTS (1000 SYSTEM)

PREVIOUS TO THE 1200 SYSTEM. PARTS FOR THE OLD 1000 VOYAGER SYSTEM ARE STILL AVAILABLE THROUGH OUR

STANDARD DISTRIBUTION.

MOST COMMON VOYAGER INSTALLATION CONCERNS

VENTING:

VENT LENGTH TOO LONG - OVER 85’

VENTING NOT PITCHED PROPERLY - CONDENSATE BUILD UP IN VENT

EXHAUST GAS RE-CIRCULATION - VENT TERMINALS NOT USED, WRONG FITTINGS USED, SIGHT PROBLEMS

BUSH IN FRONT OF VENT TERMINAL

INSIDE CORNER OF BUILDING FOR VENT LOCATION

OVERHANG WITH VENT UNDERNEATH

COMPOUND ROOF PITCH, OR ABOVE ROOF FIRE WALL

ADDITIONAL FITTINGS INSTALLED INTO TERMINALS

VENT SIZED FROM 3" TO 4" BY USING BUSHINGS - INSTEAD OF REDUCING COUPLING OR REDUCING ELBOW

VENT CHANGED FROM 3" TO 4" - WITHOUT GOING REQUIRED 10’ ON BOTH INTAKE AND EXHAUST

VENTING NOT CLEANED AND GLUED TOGETHER FOR PRESSURE TIGHT JOINTS

INTAKE AIR CONTAINING EXHAUST FROM ANOTHER VENT OR APPLIANCE

GAS SUPPLY

:

GAS PRESSURE TOO LOW - NEED 7" GAS PRESSURE UP TO 14" GAS PRESSURE

GAS METER TOO LOW IN CAPACITY

GAS REGULATOR NOT SIZED PROPERLY - TOO LOW IN CAPACITY

GAS PIPE TOO SMALL - ¾" MINIMUM GAS SUPPLY SIZE

GAS REGULATOR TOO CLOSE TO APPLIANCE - NEED 10’ OF PIPE FOR EVERY 200,000 BTU’S PER HOUR

GAS REGULATOR WITH LONG VENT OR BLEED VENT ORIFICE - REGULATOR SLOW TO RESPOND

GAS METER RESTRICTION, OR IN NEED OF REPAIR/REPLACEMENT

GAS SUPPLY PRESSURE DROPS BELOW 3½" WHEN APPLIANCE FIRES

ELECTRICAL

:

APPLIANCE NOT GROUNDED

ELECTRICAL POLARITY REVERSED - FLAME WILL LIGHT BUT GO BACK OUT IN 4-6 SECONDS VOLTAGE TOO LOW OR TOO HIGH

APPLIANCE CYCLES, BUT NO IGNITION - LOOK FOR GLOW FROM IGNITOR, IF NOT, REPLACE IGNITOR

PLUMBING:

SSVH MODELS WITHOUT RE CIRCULATING PUMP INSTALLED & WITHOUT WIRING IN PARALLEL WITH HEATING CIRCULATOR

DIELECTRIC UNIONS INSTALLED - RUSTY WATER

CONDENSATE

:

CONDENSATE LINE NOT PITCHED TO DRAIN

CONDENSATE LINE NOT DRAINING DUE TO LONG RUN WITHOUT VENT

CONDENSATE PUMP NOT WORKING

CONDENSATE TRAP PLUGGED WITH PVC SHAVINGS

BURNER

:

EXTREMELY LOUD BANG ON IGNITION - BURNER FAILED OR END CAP OFF

RED BURNER DECK AS SEEN THROUGH VIEW PORT - GAS VALVE NEEDS ADJUSTMENT, PAGE 38

GAS VALVE:

PUFFING ON IGNITION - ADJUST GAS VALVE, SEE PAGE 38

LOUD POP ON IGNITION, THEN RUNNING SMOOTH - ADJUST GAS VALVE, SEE PAGE 38

HUFF AND PUFF DURING OPERATION - ADJUST GAS VALVE, SEE PAGE 38

RUNNING GREAT BUT INTERMITTENTLY HUFFING OR POPPING - CHECK FOR RE-CIRCULATION UNDER VENTING

Loading...

Loading...