Vox Power VCCM600 Series User Manual

VCCM600 Series

AC/DC conduction cooled configurable power supplies

User Manual

_____________________________________________________________________________________________________

VCCM600 Series User Manual | DOC6103r00 | Release date 02/03/2017

Vox Power Limited | Unit 2, Red Cow Interchange Estate, Ballymount, Dublin 22, D22 Y8H2, Ireland | T +353 1 4591161 | www.vox-power.com

Cool it your way. Conduction | Convection | Forced Air

4”x7”x1.61”

SMALL

600W

POWERFUL

SILENT

FAN-LESS

The VCCM600 series user manual has been prepared by our design team to assist qualified engineers in correctly

designing in the VCCM600 product into their application to achieve the best reliability and performance possible.

All specifications are believed to be correct at time of publishing. Vox Power Ltd reserves the right to make changes to any of its products and to change or improve any part of the

specification, electrical or mechanical design or manufacturing process without notice. Vox Power Ltd does not assume any liability arising out of the use or application of any of its

products and of any information to the maximum extent permitted by law. No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted by this

document or by any products of Vox Power Ltd. VOX POWER LTD DISCLAIMS ALL WARRANTIES AND REPRESENTATIONS OF ANY KIND WHETHER EXPRESS OR IMPLIED, INCLUDING, BUT

NOT LIMITED TO, IMPLIED WARRANTIES OF SUITABILITY, FITNESS FOR PURPOSE, MERCHANTABILITY AND NONINFRINGEMENT.

Please consult your local distributor or Vox Power directly to ensure that you have the latest revision before using the product and refer to the latest relevant user manual for further

information relating to the use of the product. Vox Power Ltd products are not intended for use in connection with life support s ystems, human implantations, nuclear facilities or systems,

aircraft, spacecraft, military or naval missile, ground support or control equipment used for the purpose of guidance navigation or direction of any aircraft, spacecraft or military or naval

missile or any other application where product failure could lead to loss of life or catastrophic property damage. The user will hold Vox Power Ltd harmless from any loss, cost or damage

resulting from its breach of these provisions.

VCCM600 Series Overview

The VCCM600 series of conduction cooled configurable power platform delivers a silent 600 Watts and up to 750 Watts of peak power for 5

seconds in a rugged 4” x 7” package and is the ultimate power solution for applications where reliability or audible noise are of concern. The

product combines the advantages of a modular power supply with the high reliability of a fan-less architecture. Depending on your application,

the VCCM600 can be configured as a conduction, convection or forced air cooled solution and this versatility allows the unit to be seamlessly

integrated across a vast range of applications, which makes it perfect for standardising your power platform.

Designed with highest reliability and versatility in mind, the VCCM600 is suitable for applications ranging from the most controlled environments

to the harshest conditions. Each configured modular solution can accommodate up to 4 isolated DC output modules which utilize 100% SMT

components for increased reliability. Standard features include full output voltage adjust range, externally controllable voltage and current and

series & paralleling of outputs. The unique design approach and heat dissipation techniques allows the unit to be mounted in virtually any

orientation giving system designers even more flexibility. The series is approved to latest safety and EMC standards and features market leading

specifications and design in application support.

2 | Page

VCCM600 Series User Manual | DOC6103r00 | Release date 02/03/2017

Vox Power Limited | Unit 2, Red Cow Interchange Estate, Ballymount, Dublin 22, D22 Y8H2, Ireland | T +353 1 4591161 | www.vox-power.com

Contents

VCCM600 Series Overview 1

Part Numbers and Ordering Information 3

Important installation information 4

Theory of Operation 5

Input Module Operation 6

Input Module Protections 7

Efficiency Performance 8

Power Ratings 9

System Cooling 9

Signalling 13

Output Module Operation (A, B, C & D) 15

Advanced Output Module Features 18

Series Connected Outputs 22

Parallel Connected Outputs 23

Mechanical Dimensions and Mounting 26

Connector details 27

Safety 28

EMC Compliance 29

Reliability 31

Configuring Your VCCM Product 32

Accessories 37

3 | Page

VCCM600 Series User Manual | DOC6103r00 | Release date 02/03/2017

Vox Power Limited | Unit 2, Red Cow Interchange Estate, Ballymount, Dublin 22, D22 Y8H2, Ireland | T +353 1 4591161 | www.vox-power.com

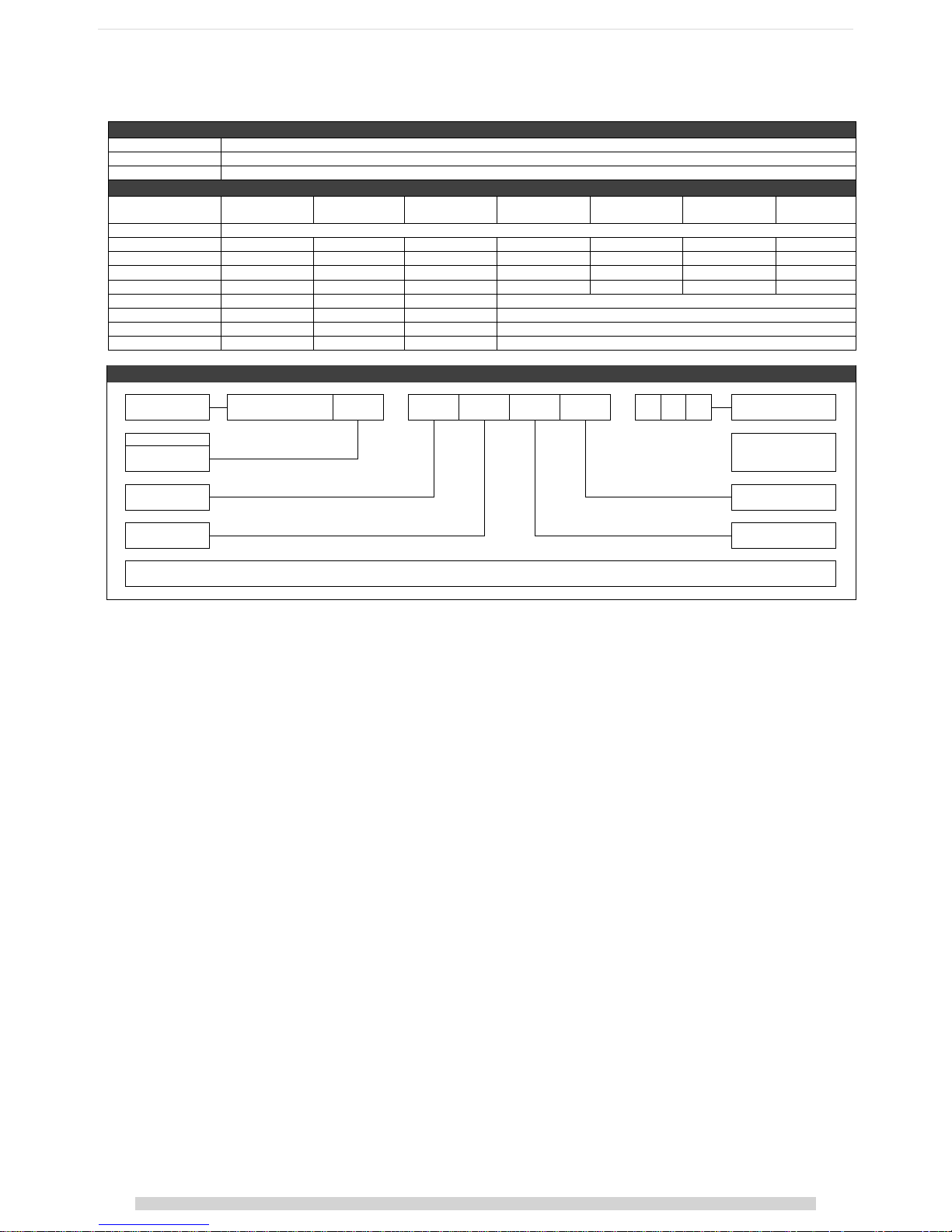

Part Numbers and Ordering Information

INPUT MODULES

Input Module

Details

VCCM600S

600 Watt Input Module with ITE Approvals (IEC60950 Edition 2)

VCCM600M

600 Watt Input Module with Medical Approvals (IEC60601 Edition 3 + IEC60601-1-2 Edition 4 EMC)

OUTPUT MODULES

Module

Nominal voltage

Rated current

Rated Power

Adjustment

range

Load regulation

Line regulation

OVP

OP 0

Unused slots

OP A

5V

25A

125W

1.5V-7.5V

±50mV

±0.1%Vnom

9V

OP B

12V

15A

150W

4.5V-15V

±100mV

±0.1%Vnom

18V

OP C

24V

7.5A

150W

9V-30V

±150mV

±0.1%Vnom

36V

OP D

48V

3.5A

150W

18V-58V

±300mV

±0.1%Vnom

66V

OP E

5v

100A

500W

Future release (4 slot module)

OP F

12v

50A

600W

Future release (4 slot module)

OP G

24V

25A

600W

Future release (4 slot module)

OP H

48V

12.5A

600W

Future release (4 slot module)

PART NUMBERING SYSTEM

VCCM Input

Module

VCCM600 S - A B C D - 0 0 0

Factory use

Product Type

USE '0' for unused slots.

S - Standard

M - Medical

Slot 1 - Output #

Slot 4 - Output #

Slot 2 - Output #

Slot 3 - Output #

Contact your Distributor or Vox Power for sp ecial configuration requirem ents. The factory may allocate a 3-digit suffix to identify such r equirements.

4 | Page

VCCM600 Series User Manual | DOC6103r00 | Release date 02/03/2017

Vox Power Limited | Unit 2, Red Cow Interchange Estate, Ballymount, Dublin 22, D22 Y8H2, Ireland | T +353 1 4591161 | www.vox-power.com

Important installation information

The VCCM600 series of configurable power supplies are intended for use within end customer applications which restrict access to un-authorized personnel. The

instructions in this manual and all warning labels on the product must be adhered to carefully.

SAFETY

The VCCM600S and VCCM600M series are designed in accordance with the relevant safety requirements of UL60950-1, IEC/EN60950-1, UL60601-1, IEC/EN606011, CSA22.2 no 601-1, Low voltage Directive LVD 2014/35/EU and EMC directive EMC 2014/30/EU.

All VCCM600 series power supplies must be installed correctly in a controlled environment which restricts access to any un-authorised personnel. Equipment and

system manufacturers must protect service personnel against unintentional contact with the output terminals.

HAZZARDS

Dangerous voltages are present within the power supply. It should only be handled by qualified personnel when the power supply has been disconnected from

the mains supply voltage for more than 3 minutes.

External surfaces of the power supply may become extremely hot during and after operation. Appropriate care should be taken.

If series and/or parallel combinations of outputs exceed safe voltage and/or energy levels, the final equipment manufacturer must provide the appropriate

protection for both users and service personnel.

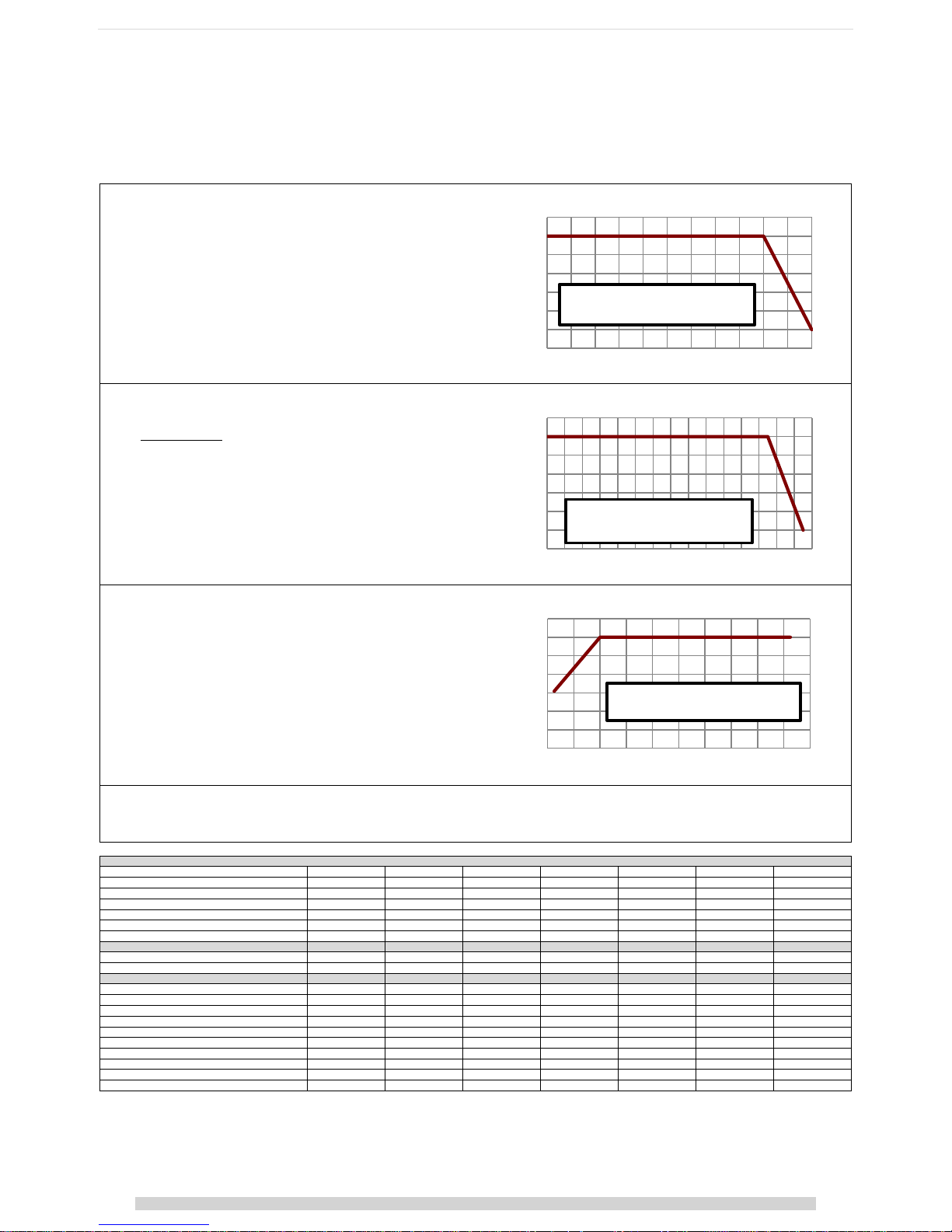

DE-RATINGS

Ambient Temperature

The input module power must be de-rated by 2.5%/°C above 50°C ambient up to a maximum ambient temperature of

70°C.

Baseplate Temperature

The output module power and current must be de-rated by 2.5%/°C above 85°C baseplate up to a maximum baseplate

temperature of 105°C.

Input Voltage

The input module power must be de-rated by 5W/VRMS below120 VRMS (600W @ 120 VRMS, 450W @ 90 VRMS)

Remember to take the appropriate de-rating into consideration before specifying any VCCM600 power supply for an application. If in any doubt, please contact

Vox Power directly or your local Vox Power representative.

HEALTH AND SAFETY

To comply with section 6 of the health and safety at work act, a label that is clearly visible to service personnel must be placed on the final equipment. These

labels warn that surfaces of the power supply may be hot and should not be touched when the product is operating.

FUSING

The power supply has internal dual pole fusing. One fuse in each line.

Fuses should only be replaced by authorised personnel and to ensure continued protection against risk of fire, fuses must be replaced with the same type and

rating of fuse.

For DC operation, an appropriately rated DC fuse must be included in the end application.

SERVICING

The power supply contains no user serviceable parts. Repairs must be carried out by authorised personnel only. Contact Vox Power for further information.

APPROVAL LIMITATIONS – NORTH AMERICA

When this product is used with 180VAC–253VAC mains where no neutral is present, connect the two live wires to L (Live) and N (Neutral) on the input connector.

COOLING

For proper operation of the power supply, the user must ensure sufficient cooling to maintain all component temperatures within specifications. A thorough

review of the user manual should be carried out for details of thermal performance.

EARTH TERMINAL MARKING

To comply with the requirements of UL60950-1, IEC/EN60950-1, CSA22.2 no. 60950-1, UL60601-1, IEC/EN60601-1, CSA22.2 no 601-1 where the incoming wiring

earth is intended for connection as the main protective earth conductor and where the terminals for such a connection is not supplied on a component or

subassembly, the user shall add an appropriate label displaying a protective earth symbol in accordance with 60417-2-IEC-5019 directly adjacent to the terminal.

The label should be durable and legible and should withstand the 15 second rub test as per UL60950-1 section 1.7.15.

WARRANTY

Contact your sales agent or Vox Power for product repairs. See Vox Power standard terms and conditions for warranty conditions.

PRODUCT LABELS

The external product label contains information relevant to the power system. The label contains input voltage, maximum input current, input frequency,

maximum output power, fuse rating and type, serial number, approvals and product part number in form VCCM600x-yyyy-zzz.

VCCM OUTPUT MODULES

Each output module label contains information relevant to that output. The label contains voltage adjustment range, maximum output current, serial number,

approvals and the part number in format OPx.

OTHER

• A label warning that external surfaces are hot during operation and that the unit should be allowed to cool down properly should be placed on the

unit where such a label is clearly visible.

• The VCCM600 series is designed to comply with EMC standards but it does not imply that the end system will comply.

• To prolong the life of the unit, use in dust free environment.

• Units can sometimes be damaged during transit. In the event of transit damage, DO NOT connect power to the unit. Contact your sales agent or Vox

Power.

• Always use adequately sized cables and ensure good crimp connections. Use cable supports to minimise stress on connectors.

• Avoid excessive shock or vibration.

5 | Page

VCCM600 Series User Manual | DOC6103r00 | Release date 02/03/2017

Vox Power Limited | Unit 2, Red Cow Interchange Estate, Ballymount, Dublin 22, D22 Y8H2, Ireland | T +353 1 4591161 | www.vox-power.com

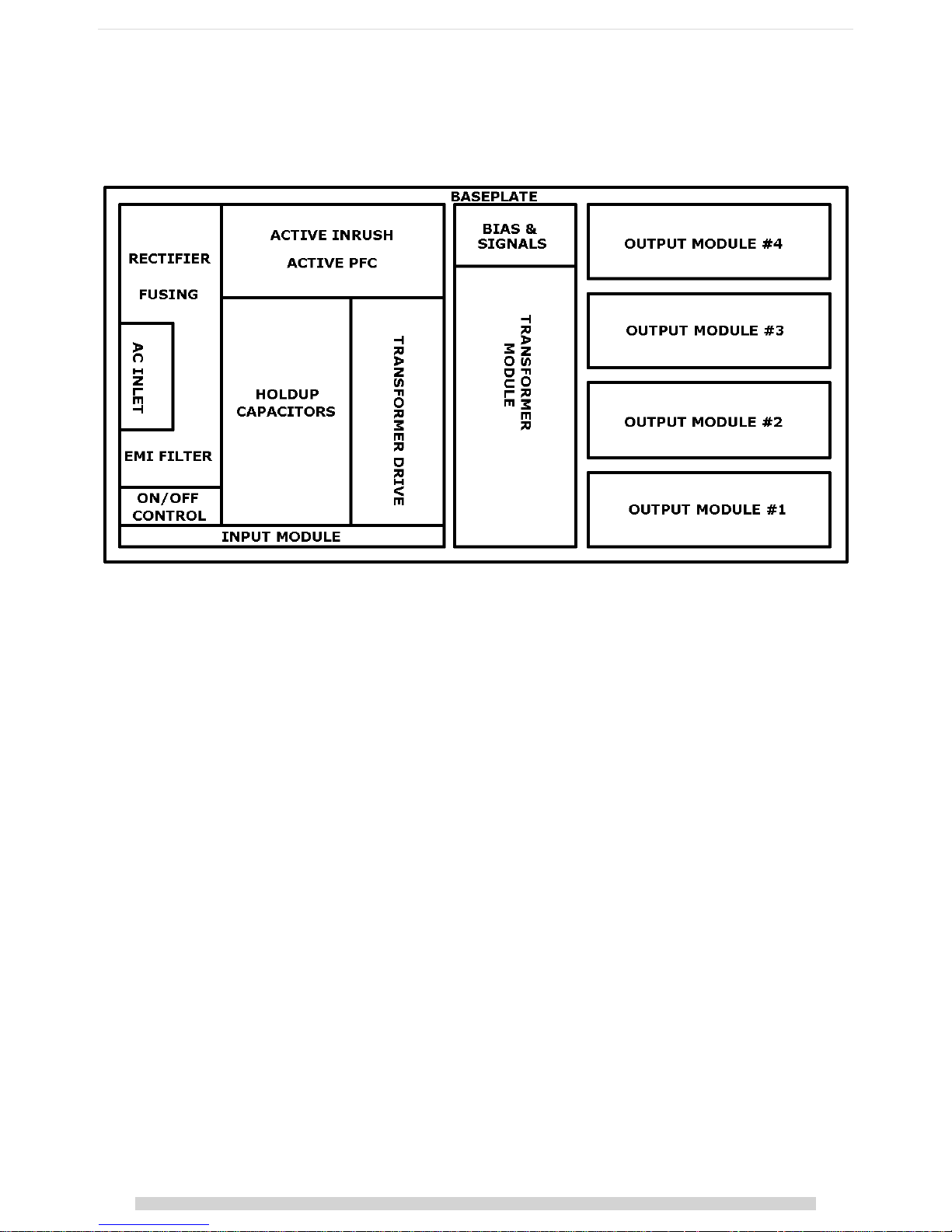

Theory of Operation

The diagram below outlines the topology and major internal components of a fully assembled VCCM600 configurable power supply. Four output slots are

provided and can be populated by any combination of

output modules

. The remaining components in the block diagram are housed in the

input

and

transformer modules

.

The

input module

is responsible for receiving the AC mains line voltage and converting it to an appropriate DC voltage whilst providing protection from AC line

disturbances and preventing excessive EMI emissions and current harmonics. The integrated EMI filter attenuates high frequency current emissions to levels

below EN55022 class B. It also provides dual pole fusing, one fuse in each conductor and protection from line disturbances as outlined in EN61000.

Inrush current is controlled by a resistive element upon initial connection to the AC line. Once the internal capacitances have been charged, the resistive element

is bypassed to reduce losses.

Active Power Factor Correction (PFC) is used to ensure an accurate input current waveform with extremely low harmonic content, exceeding the requirements of

EN61000. This stage also provides active input current limiting which prevents overloading of the input stage while maintaining high power factor.

The output of the PFC stage charges the hold-up electrolytic capacitors which store enough energy to allow the VCCM600 configured product to continue

operating during minor line disturbances. Long lifetime and high temperature capacitors are used which ensures extended lifetime and product reliability.

A highly efficient zero voltage switching circuit is used to drive the isolated transformer from the hold-up capacitors. The output modules connect to the

transformer secondary and provide safe isolated power to a high performance synchronous rectifier power converter. This power converter is controlled using

the latest analog control technology to produce superior output performance in a miniature size.

6 | Page

VCCM600 Series User Manual | DOC6103r00 | Release date 02/03/2017

Vox Power Limited | Unit 2, Red Cow Interchange Estate, Ballymount, Dublin 22, D22 Y8H2, Ireland | T +353 1 4591161 | www.vox-power.com

Input Module Operation

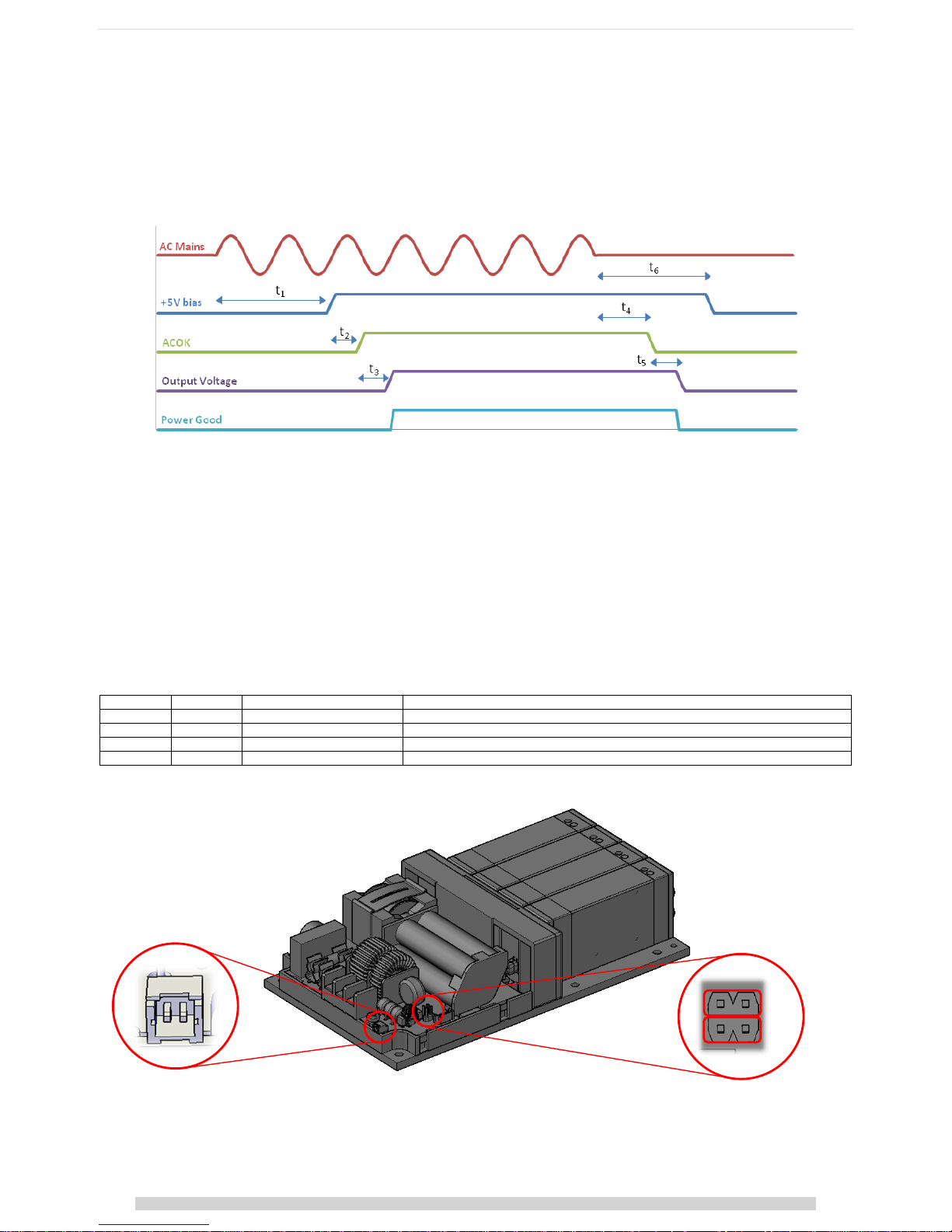

Startup & Shut Down

The VCCM input module operates from a universal input voltage range and starts automatically upon application of adequate AC mains voltage (>84Vrms). After

a short delay, the global 5V bias supply starts and the ACOK signal goes high to indicate that the mains voltage is present and input stage is operating correctly.

Once the ACOK signal is high, the output modules turn on and deliver power to the application loads. The power good signals will indicate that the output

voltages are within specification. The diagram below shows the normal start up/shut down sequence and gives typical timings.

Typical timing values: t

1

ϕ ≤2000 ms, t2ϕ ≤400 ms, t3ϕ ≤600 ms, t4ϕ ≥15 ms, t5ϕ ≥5ms (minimum), t6ϕ ≥100 ms

When the AC mains voltage is removed, the internal hold-up capacitors will supply power to the load for typically 20 ms (t

4+t5

) at maximum power. The ACOK

signal will go low at least 5ms before the output voltages fall below the power good threshold level. This allows the application to prepare for the impending loss

of power. The 5V bias supply will remain on for typically 100ms, after the output modules have turned off.

Standby control

The unit may be completely shut down by shorting (<10Ω) the terminals of J2. The unit will restart once the short is released.

The control uses transformer coupled pluses to detect the short and is fully isolated to 2xMOPP. The voltage present on J2 ranges from +3.3V to -0.8V with a peak

current of 15mA. In active mode, the control is pulsed every 1.3mS while in standby mode the control is pulsed every 400mS. A signal MOSFET or switch may be

used to activate this control. This shutdown will not generate the ACOK warning signal.

Programmable start-up state

The start-up and standby control logic can be inverted by shorting J11 with a jumper. The functionality is shown in the table below.

J11

J2

Operational mode

Comments

Open

Open

NORMAL

Default. Unit will start into NORMAL mode

Open

Closed

STANDBY

<1W power consumption

Closed

Open

STANDBY

Unit will start into STANDBY mode. <1W power consumption

Closed

Closed

NORMAL

Note - J12 is reserved for internal use. Do not short J12

J11 LOC ATION

J2 LOCATION

- +

J11

J12

7 | Page

VCCM600 Series User Manual | DOC6103r00 | Release date 02/03/2017

Vox Power Limited | Unit 2, Red Cow Interchange Estate, Ballymount, Dublin 22, D22 Y8H2, Ireland | T +353 1 4591161 | www.vox-power.com

Hold-up

For short line distubances (<20ms), the output voltages will not be affected*. However, the ACOK signal may still go low to warn that there is an impending loss

of output power. The ACOK signal will return to the high state once the unit has recovered from the disturbance.

*Output modules that are adjusted above the hold-up voltage (as detailed in their respective datasheets), may experience a dip in voltage but never below the

hold-up voltage specified.

No Load Power/Standby Power Consumption

The no-load power consumption of the VCCM600 series PSU is extremely low when compared to similar configurable power supplies. With the output modules

enabled the unit typically only requires less than 15W with no output load. To reduce the no-load power further the outputs can be disabled using the inhibit

pins. With the outputs disabled the unit typically requires less than 10W. When the unit is in the standby (latched off) state, the power consumption is less than

1W.

Peak Power capability

The input module can provide a peak output power of up to 750W for a period of up to 5 seconds, provided the input current remains below the over current

protection threshold. Peaks of power lower than 750W can be supported for longer times provided the excess watt-seconds are equivalent. For example, 750W

peak for 5 seconds is an excess power of 150W*5s = 750Ws. 650W can be supported for 750Ws/50W = 15s. When using peak power capability, the user must

ensure the average power remains within ratings. Note that input module de-ratings apply to both rated power and peak power.

Input Module Protections

Over current protection (OCP)

The input module is protected from excessive input current by means of an over current protection circuit which limits the input current to approximately 7Arms.

If the OCP threshold is exceeded the unit may shut down and attempt to automatically restart. This shutdown will generate the usual ACOK warning.

Under voltage protection (UVP) & Brown-Out Protection (BOP)

The input module is protected from excessively low input voltages by under voltage and brown out protection circuits that senses the input line voltage. The

under-voltage protection circuit maintains the unit in standby mode until the input voltage rises above the UVP threshold as detailed in the datasheet. Once the

unit is active, the brown out protection monitors the input voltage and shuts down the unit when input voltage goes below approximately 60Vrms. This

shutdown will generate the usual ACOK warning. The unit will restart once the input voltage increases above the UVP threshold.

Over Temperature Protection (OTP)

The input module is protected from excessive temperatures by means of various internal temperature sensors. If temperature thresholds are exceeded the entire

unit may latch off, with no ACOK warning. To re-enable the unit, it must be allowed to cool, then either disconnect the AC mains for approximately 20 seconds, or

toggle the standby control on J2.

Over Power Protection (OPP)

The input module is protected from excessive power by means of an over power protection circuit. Should the rated power be exceeded the unit will shut down

and attempt to recover automatically. This shutdown will not generate the usual ACOK warning.

8 | Page

VCCM600 Series User Manual | DOC6103r00 | Release date 02/03/2017

Vox Power Limited | Unit 2, Red Cow Interchange Estate, Ballymount, Dublin 22, D22 Y8H2, Ireland | T +353 1 4591161 | www.vox-power.com

Efficiency Performance

The efficiency of the configured VCCM600 product is dependent on parameters such as input line voltage, load level and on the combination of output modules.

The plots below show typical efficiencies of a VCCM600 product fitted with all modules A, B, C or D. The plots cover the full load and line voltage range. All

modules are adjusted to nominal voltages and are equally loaded.

An estimate of the overall efficiency for any configured system may be obtained from these graphs.

0.73

0.74

0.75

0.76

0.77

0.78

0.79

0.80

0.81

0.82

0.83

0.84

0.85

0.86

0.87

0.88

0.89

0.90

0.91

0 50 100 150 200 250 300 350 400 450 500 550 600

Efficiency

Output Power (Watts)

Typical Load Efficiency at 120V

RMS

input voltage

OPA OPB OPC OPD

0.73

0.74

0.75

0.76

0.77

0.78

0.79

0.80

0.81

0.82

0.83

0.84

0.85

0.86

0.87

0.88

0.89

0.90

0.91

0 50 100 150 200 250 300 350 400 450 500 550 600

Efficiency

Output Power (Watts)

Typical Load Efficiency at 220V

RMS

input voltage

OPA OPB OPC OPD

0.73

0.74

0.75

0.76

0.77

0.78

0.79

0.80

0.81

0.82

0.83

0.84

0.85

0.86

0.87

0.88

0.89

0.90

0.91

0 50 100 150 200 250 300 350 400 450

Efficiency

Output Power (Watts)

Typical Load Efficiency at 85V

RMS

input voltage

OPA OPB OPC OPD

0.73

0.74

0.75

0.76

0.77

0.78

0.79

0.80

0.81

0.82

0.83

0.84

0.85

0.86

0.87

0.88

0.89

0.90

0.91

80 100 120 140 160 180 200 220 240 260

Efficiency

InputVoltage (V

RMS

)

Typical Line Efficiency at maximum rated power

OPA OPB OPC OPD

9 | Page

VCCM600 Series User Manual | DOC6103r00 | Release date 02/03/2017

Vox Power Limited | Unit 2, Red Cow Interchange Estate, Ballymount, Dublin 22, D22 Y8H2, Ireland | T +353 1 4591161 | www.vox-power.com

Power Ratings

VCCM600 series products must always be operated within stated operating limits. Equipment manufacturers and other users must take the appropriate de-rating

into account when specifying a unit for the intended application. If in doubt, contact your sales representative or Vox Power for assistance.

There are three main de-ratings for the VCCM600 series of configurable power supplies when used in a conduction cooled application,

1. Ambient air temperature

(1)

Ambient air temperature de-ratings apply to the input module rated and peak

power only.

(3)

The input module must be de-rated by 2.5% per degree Celsius above 50°C, up to

a maximum of 70°C.

2. Baseplate temperature

(2)

Baseplate temperature de-ratings apply to output module rated power, peak

power and rated current

, and bias supply power.

The output module parameters must be de-rated by 2.5% per degree Celsius

above 85°C, up to a maximum of 105°C.

3. Input line voltage

Input line voltage de-ratings apply to the rated power and peak power for both

the input module and output module.

(3)

All parameters must be de-rated by 2.5% for every 3 volts below 120Vrms, down

to a minimum of 85Vrms.

Notes:

1. Ambient air temperatu re is the air temperature im mediately surrounding the PSU.

2. Baseplate temperature is measur ed at baseplate temperature sensing location TS1.

3. A normalized value of 1 is equivalent to 100%.

4.

Input line voltage deratings are cumulative with temperature deratings.

Examples of power ratings calculation for various input voltages, ambient temperatures and baseplate temperatures

1 2 3 4 5 6

7

VIN (V

RMS

)

120

85

85

120

120

100

120

Normalised VIN Rating [A]

1

0.708

0.708 1 1

0.833

1

T

AMBIENT

(⁰C)

70

50

70

50

60

60

50

Normalised T

AMBIENT

Rating [B]

0.5 1 0.5 1 0.75

0.75

1

T

BASE

(⁰C)

85

85

85

95

105

95

105

Normalised T

BASE

Rating [C]

1 1 1

0.75

0.5

0.75

0.5

Normalised Total input rating [A*B = D]

0.5

0.708

0.354 1 0.75

0.624

1

Normalised Total output rating [A*C = E]

1

0.708

0.708

0.75

0.5

0.624

0.5

Input module P

RATED/PEAK

[600W/750W*D]

300/375

424.8/531

212.4/265.5

600/750

450/562.5

374.4/468

600/750

Bias supply power [5W*C]

5 5 5

3.75

2.5

3.75

2.5

OPA P

RATED/PEAK

[125W/187.5W*E]

125/187.5

88.5/132.75

88.5/132.75

93.75/140.625

62.5/93.75

78/117

62.5/93.75

OPA I

RATED

[25A*C]

25

25

25

18.75

12.5

18.75

12.5

OPB P

RATED/PEAK

[150W/225W*E]

150/225

106.2/159.3

106.2/159.3

112.5/168.75

75/112.5

93.6/140.4

75/112.5

OPB I

RATED

[15A*C]

15

15

15

11.25

7.5

11.25

7.5

OPC P

RATED/PEAK

[150W/225W*E]

150/225

106.2/159.3

106.2/159.3

112.5/168.75

75/112.5

93.6/140.4

75/112.5

OPC I

RATED

[7.5A*C]

7.5

7.5

7.5

5.625

3.75

5.625

3.75

OPD P

RATED/PEAK

[150W/217.5W*E]

150/217.5

106.2/154

106.2/154

112.5/163.125

75/108.75

93.6/135.72

75/108.75

OPD I

RATED

[3.75A*C]

3.75

3.75

3.75

2.8125

1.875

2.8125

1.875

System Cooling

0.4

0.5

0.6

0.7

0.8

0.9

1

1.1

-40 -30 -20 -10 0 10 20 30 40 50 60 70

Normalised output powe r r a t ing

Ambient Temperature (Celcius)

Ambient Temperature Derating

Derate at 2.5% per degree celcius

above 50 degree celcius

0.4

0.5

0.6

0.7

0.8

0.9

1

1.1

80 100 120 140 160 180 200 220 240 260 280

Normalised Output P owe r r a ting

Input Voltage (RMS)

Input Line voltage Derating

Derate at 2.5% per every

3 volts below 120Vrms

0.4

0.5

0.6

0.7

0.8

0.9

1

1.1

-40 -30 -20 -10 0 10 20 30 40 50 60 70 80 90 100 110

Normalised Power & Current Rating

Baseplate Temperature (Celcius)

Temperature Derating

Derate at 2.5% per degree celcius

above 85 degree celcius

10 | Page

VCCM600 Series User Manual | DOC6103r00 | Release date 02/03/2017

Vox Power Limited | Unit 2, Red Cow Interchange Estate, Ballymount, Dublin 22, D22 Y8H2, Ireland | T +353 1 4591161 | www.vox-power.com

The power ratings shown in the previous section are for conduction cooling, however the unit may be operated with forced air cooling, convection cooling or

combinations of all three. To assist in specifying the product for these applications, the typical thermal performance has been characterised under controlled

conditions. The ratings achieved are based on maintaining the baseplate temperature within the conduction cooled ratings specified on page 9.

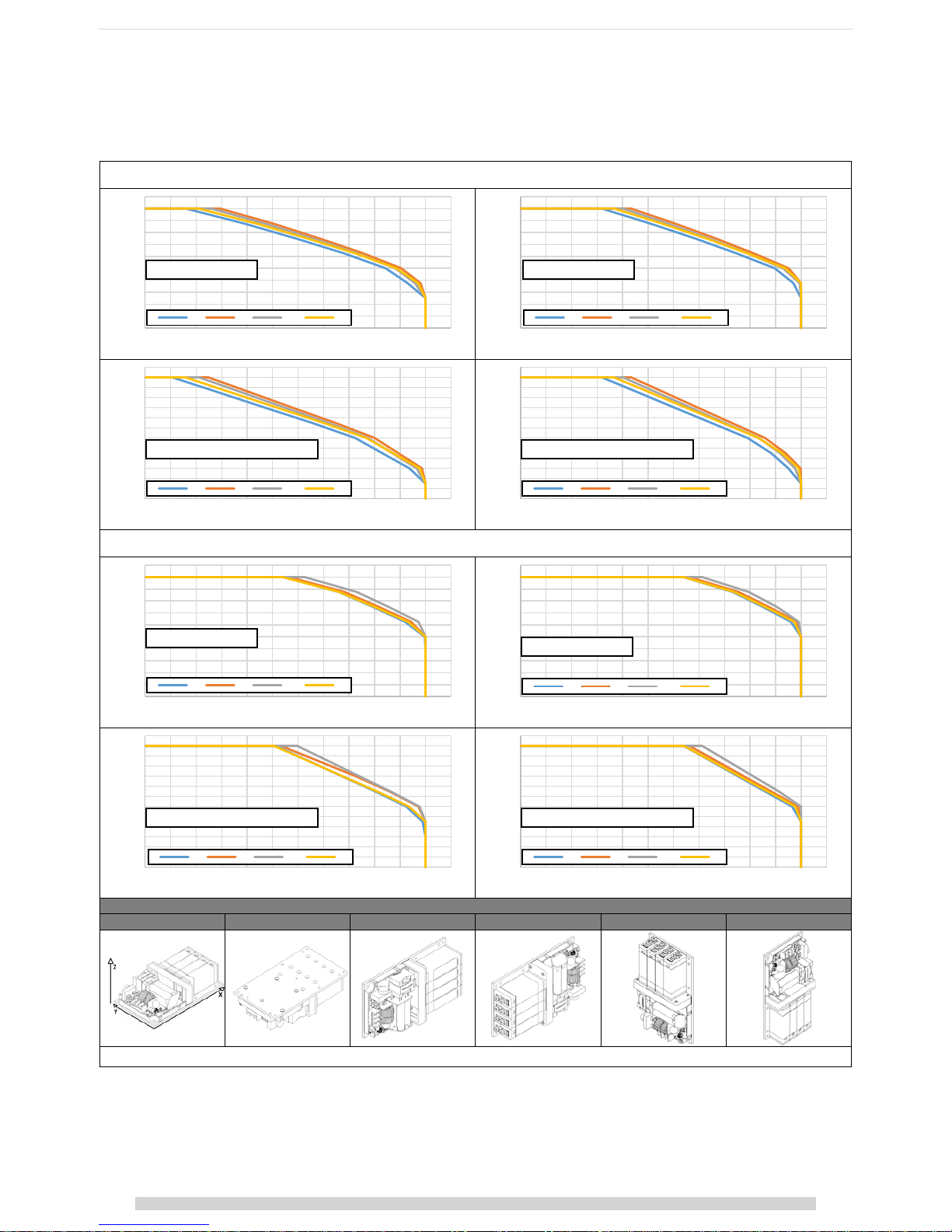

CONVECTION PERFORMANCE

Natural Convection, No Heatsink, Free Air, Mounting Orientations A/B/C/D/E/F

CONVECTION PERFORMANCE WITH HEATSINK

(1)

Natural Convection, With Heatsink, Free Air, Mounting Orientations A/B/C/D/E/F

Orientation definitions

A B C D E

F

Orientation

definitions

Notes

1. Standard Vox heatsin ks type 1 and type 2 used. Type 1 u sed for mounting orientation s A, B, E and F. Type 2 used for mounting orientations A, B, C and D.

0

50

100

150

200

250

300

350

400

450

500

550

-40 -30 -2 0 -10 0 10 20 30 40 50 60 70 80

Pout

Ambient Temperature

OPA 120Vin, 4x5Vout

A B CD EF

0

50

100

150

200

250

300

350

400

450

500

550

-40 -30 -2 0 -10 0 10 20 30 40 50 60 70 80

Pout

Ambient Temperature

OPA 220Vin, 4x5Vout

A B CD EF

0

50

100

150

200

250

300

350

400

450

500

550

600

650

-40 -30 -2 0 -10 0 10 20 30 40 50 60 70 80

Pout

Ambient Temperature

OPB/C/D 120Vin, 4x10/20/40Vout

A B CD EF

0

50

100

150

200

250

300

350

400

450

500

550

600

650

-40 -30 -2 0 -10 0 10 20 30 40 50 60 70 80

Pout

Ambient Temperature

OPB/C/D 220Vin, 4x10/20/40Vout

A B CD EF

0

50

100

150

200

250

300

350

400

450

500

550

-40 -30 -2 0 -10 0 10 20 30 40 50 60 70 80

Pout

Ambient Temperature

OPA 120Vin, 4x5Vout

A B CD EF

0

50

100

150

200

250

300

350

400

450

500

550

-40 -30 -2 0 -10 0 10 20 30 40 50 60 70 80

Pout

Ambient Temperature

OPA 220Vin, 4x5Vout

A B CD EF

0

50

100

150

200

250

300

350

400

450

500

550

600

650

-40 -30 -2 0 -10 0 10 20 30 40 50 60 70 80

Pout

Ambient Temperature

OPB/C/D 120Vin, 4x10/20/40Vout

A B CD EF

0

50

100

150

200

250

300

350

400

450

500

550

600

650

-40 -30 -2 0 -10 0 10 20 30 40 50 60 70 80

Pout

Ambient Temperature

OPB/C/D 220Vin, 4x10/20/40Vout

A B CD EF

11 | Page

VCCM600 Series User Manual | DOC6103r00 | Release date 02/03/2017

Vox Power Limited | Unit 2, Red Cow Interchange Estate, Ballymount, Dublin 22, D22 Y8H2, Ireland | T +353 1 4591161 | www.vox-power.com

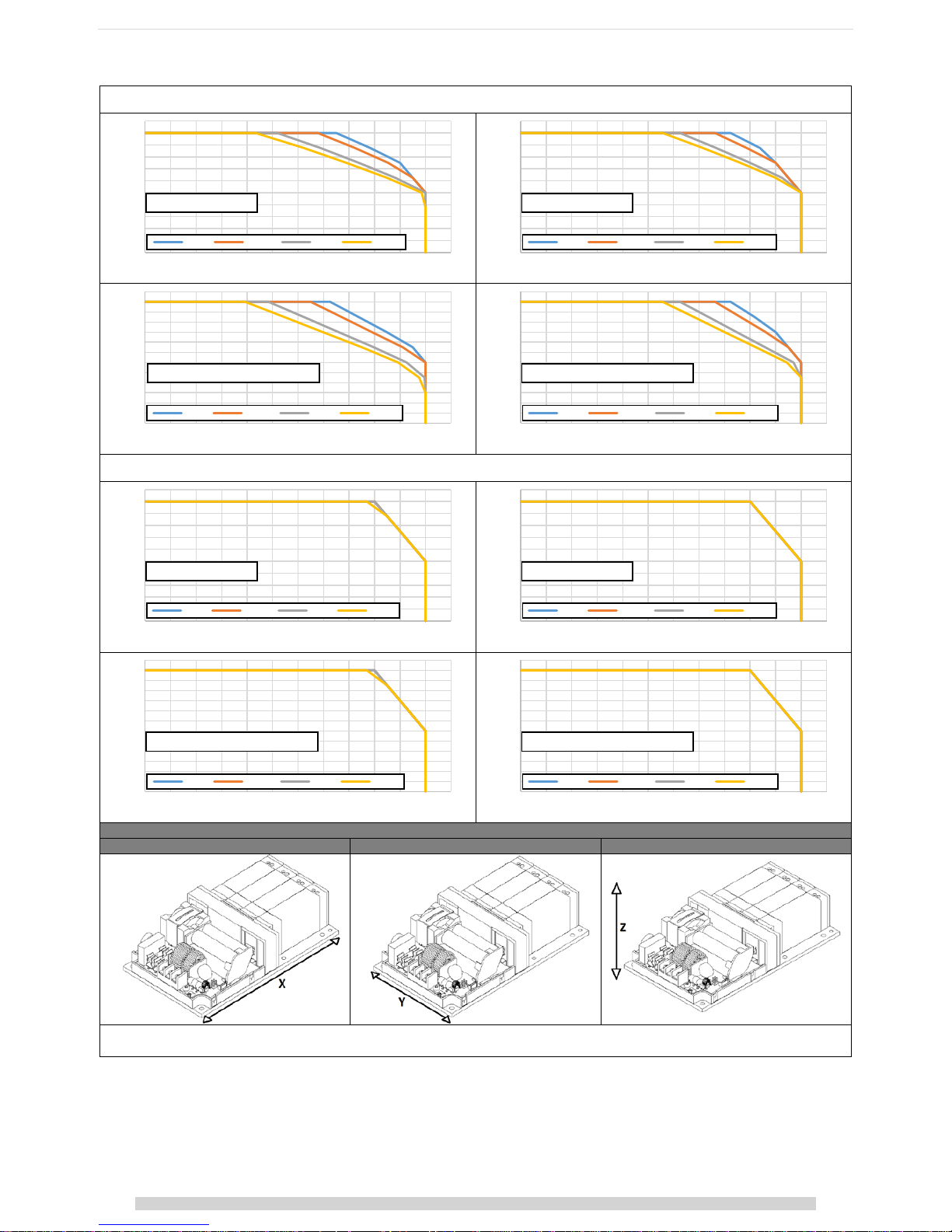

FORCED AIR PERFORMANCE

No Heatsink, Air Direction X or Y at 2MS-1/1.5MS-1/1MS-1/0.5MS-1

FORCED AIR PERFORMANCE WITH HEATSINK

(2)

With Heatsink, Air Direction X or Y at 2MS-1/1.5MS-1/1MS-1/0.5MS-1

Airflow definitions

X Y Z

Notes

1. Each 0.5MS-1 is approximatel y 100LFM. Eg. 2MS-1 ≈ 400LFM, 1.5MS-1 ≈ 300LFM etc.

2. Standard Vox heatsin ks type 1 and type 2 used. Type 1 u sed for airflow direction X. Type 2 used for airflow direction Y.

The ratings provided above are for guidance only and all VCCM600 configured solutions must be evaluated in the end application to ensure the conditions set

out in the power ratings section are met.

0

50

100

150

200

250

300

350

400

450

500

550

-40 -30 -2 0 -10 0 10 20 30 40 50 60 70 80

Pout

Ambient Temperature

OPA 120Vin, 4x5Vout

2MS-1 1.5MS-1 1MS-1 0.5MS-1

0

50

100

150

200

250

300

350

400

450

500

550

-40 -30 -2 0 -10 0 10 20 30 40 50 60 70 80

Pout

Ambient Temperature

OPA 220Vin, 4x5Vout

2MS-1 1.5MS-1 1MS-1 0.5MS -1

0

50

100

150

200

250

300

350

400

450

500

550

600

650

-40 -30 -2 0 -10 0 10 20 30 40 50 60 70 80

Pout

Ambient Temperature

OPB/C/D 120Vin, 4x10/20/40Vout

2MS-1 1. 5MS-1 1MS-1 0.5MS-1

0

50

100

150

200

250

300

350

400

450

500

550

600

650

-40 -30 -2 0 -10 0 10 20 30 40 50 60 70 80

Pout

Ambient Temperature

OPB/C/D 220Vin, 4x10/20/40Vout

2MS-1 1. 5MS-1 1MS-1 0.5MS-1

0

50

100

150

200

250

300

350

400

450

500

550

-40 -30 -2 0 -10 0 10 20 30 40 50 60 70 80

Pout

Ambient Temperature

OPA 120Vin, 4x5Vout

2MS-1 1.5MS-1 1M S-1 0.5MS-1

0

50

100

150

200

250

300

350

400

450

500

550

-40 -30 -2 0 -10 0 10 20 30 40 50 60 70 80

Pout

Ambient Temperature

OPA 220Vin, 4x5Vout

2MS-1 1.5MS -1 1MS-1 0.5MS-1

0

50

100

150

200

250

300

350

400

450

500

550

600

650

-40 -30 -2 0 -10 0 10 20 30 40 50 60 70 80

Pout

Ambient Temperature

OPB/C/D 120Vin, 4x10/20/40Vout

2MS-1 1.5MS-1 1MS-1 0.5M S-1

0

50

100

150

200

250

300

350

400

450

500

550

600

650

-40 -30 -2 0 -10 0 10 20 30 40 50 60 70 80

Pout

Ambient Temperature

OPB/C/D 220Vin, 4x10/20/40Vout

2MS-1 1. 5MS-1 1MS-1 0.5MS-1

12 | Page

VCCM600 Series User Manual | DOC6103r00 | Release date 02/03/2017

Vox Power Limited | Unit 2, Red Cow Interchange Estate, Ballymount, Dublin 22, D22 Y8H2, Ireland | T +353 1 4591161 | www.vox-power.com

Specifying the VCCM600 product for convection or forced air cooling

To specify a VCCM600 series product for an end application, the required output power, minimum input line voltage, maximum ambient, mounting orientation

and air flow rate (if applicable) should be determined. Check the requirements against the closest characteristic plot from the tables above to ensure ratings can

be achieved. Be conservative when specifying the product as convection and forced air cooling can be highly dependent on the end application enclosure and

power supply mounting. The estimated performance must be verified in the end application and temperatures may exceed predicted levels. It is also important

to note that ambient temperature refers to the ambient temperature immediately surrounding the PSU. If the PSU is mounted within an enclosure the enclosure

ambient temperature is likely to be higher than the external air ambient temperature.

Evaluating the VCCM600 product in the end application

To ensure the product is operating within its ratings in the end application the following procedure should be performed during the design stage.

1. Install a thermocouple in position TS1 of the product. (See Mechanical dimensions and mounting for details.) The thermocouple wire should exit on

the top side between slots 2 and 3. The bottom side should be flush for heatsink mounting if necessary. Glue should be used to hold the

thermocouple in place.

2. Setup the application in worst case conditions, considering Input line voltage, Output power, ambient temperature, airflow and cooling restrictions.

3. Power the system and monitor the baseplate temperature until it reaches steady state.

4. Ensure that under worst case conditions, the baseplate temperature cannot exceed the rated temperature as outlined in the power ratings section of

this manual.

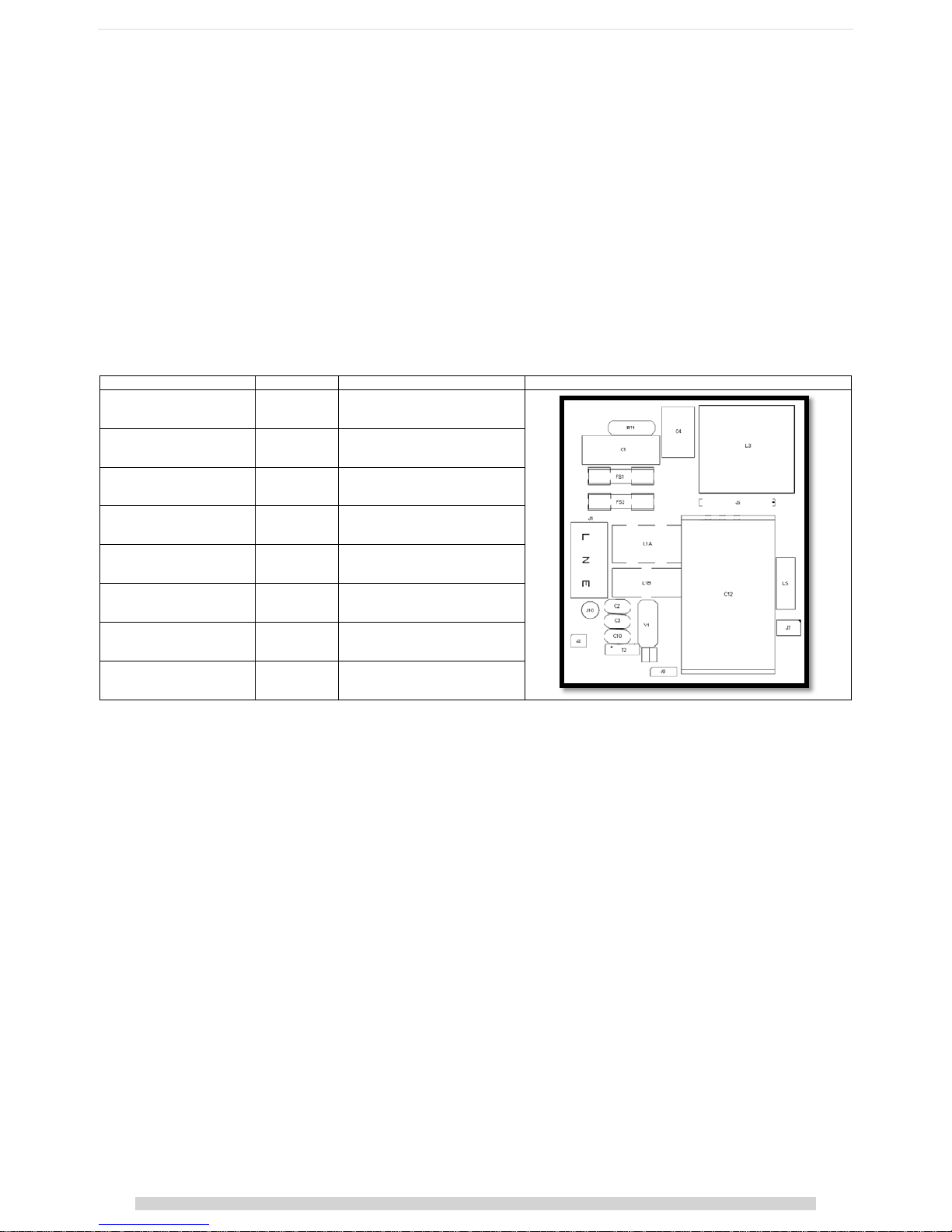

If a cover is placed over the primary components, then the following component temperatures must also be measured to ensure they are below the maximum

specified temperatures.

Description

Reference

Maximum allowed temperature

Drawing

Fuse FS1, FS2

125°C

Electrolytic capacitors C12

105°C

Inductors L1, L2, L3, L5

130°C

Other capacitors C1, C4

110°C

If excessive temperatures are measured during this evaluation, then one or more of the following remedies may improve thermal performance.

• Increase heatsink size

• Increase airflow rate

• Improve air intake & outlet

• Reduce power requirement

Using the internal temperature sensor to control external application cooling

An internal temperature sensor T

SNS

is available on J3 pin 9 (See page 14 for details). The output voltage of this sensor gives a measurement of the internal

transformer temperature and can be used to control external cooling systems or to provide a warning of impending over temperature protection.

The internal temperature (T

SNS

) should never exceed 120⁰C (2.74V), however, system reliability will be maximised if the PSU temperature is maintained as low as

possible in any given application.

Loading...

Loading...