VOSS.farming easyCUT, easyCUT pro Series, easyCUT pro 85291, easyCUT pro 85290, easyCUT pro 85292 Instruction Manual

...

DE EN FR NL

VOSS.farming

easyCUT

Schermaschine

Clipper

Tondeuse

Scheermachine

Head o ce : VOSS GmbH & Co. KG, Ohrs tedt-Bhf. N ord 5, 25885 Weste r-Ohr stedt, German y

Ser vice center : VOSS GmbH & Co. KG, Ole B ahndamm 2, 2588 4 Viöl , Germany

DE EN FR NL

DE Bedienungsanleitung Schermaschine

EN Instruction Manual Clipper

FR Notice d’utilisation tondeuse

NL Gebruiksaanwijzing scheermachine

VOSS.farming easyCUT

Art. 85285 pink | Art. 85286 blue

Table of contents

1. CONTENTS

2. SAFETY INSTRUCTIONS

3. LUBRICATION

4. BLADES

A. ADJUST CLIPPING BLADES CORRECTLY

B. REPLACE CLIPPING BLADES

5. INITIAL SET UP AND OPER ATION

A. IMPORTANT OPERATING INSTRUCTIONS

B. POWER LEVEL S WITCH

6. ATTACHMENT COMB ASSEMBLY

7. CLEANING THE AIR FILTER

8. MAINTENANCE

9. TROUBLESHOOTING

10. TECH NICAL DATA

11. LEGAL CONTENT

1. CONTENTS

A hard shell carr y case for transpor t and storage with:

- 1 x clipper

- 1 x set of blades 3 mm

- 2 x attachment comb 3mm + 5mm

- 1 x bottle of special clipping machine oil

- 1 x universal wrench

- 1 x cleaning brush

- 1 x manual

2. SAFET Y INSTRUCTIONS

This section describes the mandatory safety regulations which must be observed when

using the clipper. Prior to using the product please read the operating instructions carefully and operate the product in accordance with the instructions so that the product

can ser ve you for a long time.

The operational safety and function of the device can only be guaranteed if both general safety and state accident prevention regulations as well as the safety instructions in

this operating manual are obser ved. We accept no liability for damage resulting from

improper use or incorrect operation.

Please keep the operating instructions in a safe place so that you can consult them at

any time. In the event that the device is passed on, it is important to provide the operating instructions so that the new owner is also aware of the safety instructions.

Notes on avoiding hazards and misuse

Only plug the clipper into a properly installed socket, otherwise it may result in a shor t

circuit or elec tric shock. The socket used should be equipped with a residual current

circuit breaker (RCCB).

Maintenance and cleaning may only be carried out when the plug is disconnected. Never leave the machine unattended. Never use a damaged machine. If there is a defect,

it may only be repaired by authorised specialist technicians.

Operators of the clipper must have experience in handling the animals that are to be

clipped. Children must not operate the clipper, frail persons only under supervision.

DE EN FR NL

Use this clipper only for clipping horses and other equine breeds. Especially the use on

humans is strictly forbidden. The clipping machine should be inaccessible to children.

Other hazards

If there are dangers and risks during operation which are not linked directly to the

clipping of the animals, please let us know. This also applies to technical defects which

cause danger.

3. LUBRICATION

Note:

every

10 min

tighten Loosen

Lubrication is essential for a good result.

It also prevents overheating and signicantly prolongs the life of the machine

and the blades. For this purpose, a thin

lm of oil must always be present on the

moving parts of the head.

Drip the oil every 10 minutes onto the blades and into the opening as shown in the

pictures. Make sure that both elements

do not run dry under any circumstances.

Please only use special clipping machine

oil for this purpose.

4. Blades

Caution: Before making any adjustments

to the blades, make sure that your machi-

ne is switched o and disconnected from

the power supply. Always pull the plug of

your clipper out of the socket.

4a. Adjusting the blades correctly

Before clipping: Adjust the tension nut

(see picture) while the clipper is switched

o. Turn the nut until rst resistance is

felt. Afterwards, rotate another ¼ of a turn at most and start clipping. If the result is not

satisfactory, adjust the tension between the blades slightly. If the following result is still

not good, your blades are probably dull.

If the tension between the blades is too low then hairs accumulate between them,

which results in a considerably bad cut. In this case, remove the blades, clean them and

reattach them as described above. Do not forget to oil them.

During clipping: Since the tension between the blades loosens during clipping, turn

the screw approx. ¼ turn as soon as the clipping result deteriorates. If the result does

not improve after retightening, your blades must be sharpened.

Make sure that tension is not too high.

4b. Fit ting blades

A blade set consists of an upper and a larger, lower blade, the sharpened sides of which

should always lie on top of each other, as shown in the picture.

To remove the blades, rst release the tension by turning the tensioning nut. If the blades are loose, place the machine on a hard, stable surface with the xing screws of the

lower blade pointing upwards and loosen the screws. You can now remove the blades.

Before you insert the new blades, check that they are clean and that the grinding surfaces are particularly free of all dirt.

Now insert the upper blade into the guide points of the oscillating head and then drip

oil onto the grinding sur faces. Slide the lower blade between the loosened screws.

Make sure that the grinding surface of the lower blade protrudes approx. 1.5 to 2 mm

beyond the edge of the upper blade. You can now tighten the xing screws.

DE EN FR NL

5. Initial set up and operation

ca 1,5 to 2 mm

mains must match. Additionally, only alternating current may be used.

- Blades must be properly installed. The clipper must not be operated without them.

- Avoid any contact with the moving blades. Even when the clipping machine is swit-

ched o, the blades must not be touched until the clipper is completely disconnected

from the power supply.

- Avoid any contact of the machine with liquids during storage or clipping. Do not clip

wet animals. Liquid and moisture in the machine reduces electrical insulation and increases the risk of electric shock or short circuit. The machine should only be cleaned

with a dry cloth or brush.

- Cables can also be dangerous. Lay them securely so that neither humans nor animals

can trip over them or step on them. Keep the cables away from heat sources.

- Do not wrap the cable around the machine as it may cause insulation breakage and

cable damage. Check the cable regularly for damage.

- Before unplugging the clipper make sure it is switched o.

- Never shear with damaged or blunt blades. Only use original blades.

- The sound of the clipper can unsettle animals. They may kick or injure themselves, so

secure the animal suciently beforehand.

- Make sure that unauthorised persons are not present in the clipping area.

- Choose well ventilated rooms and never near objec ts or gases likely to explode.

- Do not inser t foreign objects into openings on the machine.

5a. Important operating instructions

The following measures serve to avoid

problems and accidents and should

always be followed:

- Use the clipper for approx. 30 minutes

and then let it rest for 10 minutes. This

protects the machine and blades and

increases service life.

- The voltage on the nameplate and in the

5b. Power level switch

The clipper has 2 power levels. We recommend the rst stage for sensitive, frightened

animals or sensitive areas. The second stage is suitable for regular shearing.

Before plugging the machine into a power outlet, make sure that the switch is set to 0

(switched o ).

6. Attachment comb assembly

With the attachment comb you can regulate

the cutting length. Recommended for horses

with Cushing‘s syndrome.

The lower blade must be removed before

assembly. The attachment comb is pushed

onto the lower blade and then secured with

an tensioning nut.

7. Cleaning air lter

The air lter is located at the rear end of

the machine and must be cleaned regu-

larly. The lter can be pushed out without

tools. Ensure that no foreign matter or dirt

enters the housing. Af ter cleaning, reinstall

the lter. Do not use the clipper without

an air lter!

DE EN FR NL

8. Maintenance

Prior to performing maintenance make sure the clipper is switched o and completely

disconnected from the power supply.

Cleaning:

After clipping, remove the oil from the machine, head and blades with a dry cloth and

remove hair with a brush. Then lightly oil all parts to prevent rust build-up. Even the

smallest rust spots can impair the clipping result. The assembly of the blades is described in point 2.b. Fitting blades.

Blade sharpening:

Sharpening can only be done on special machines and by specialist dealers. Work only

with sharp knives, never with blunt or damaged knives.

Storage:

The clipper must be kept well cleaned and oiled. Place the case out of the reach of children and animals and in a moisture-free environment. If there is

a suspicion of ingress of moisture, do not use the machine any more. Bring them for

inspec tion as there is a risk of a short circuit or electric shock.

Cleaning the clipper head:

The clipper head must also be cleaned regularly. First, remove the blades. Then loosen

the two screws and remove the head from the drive. Now you can thoroughly clean the

head inside as well as all individual parts. If you reassemble it afterwards, you should

oil it again (lubrication is described in section 3).

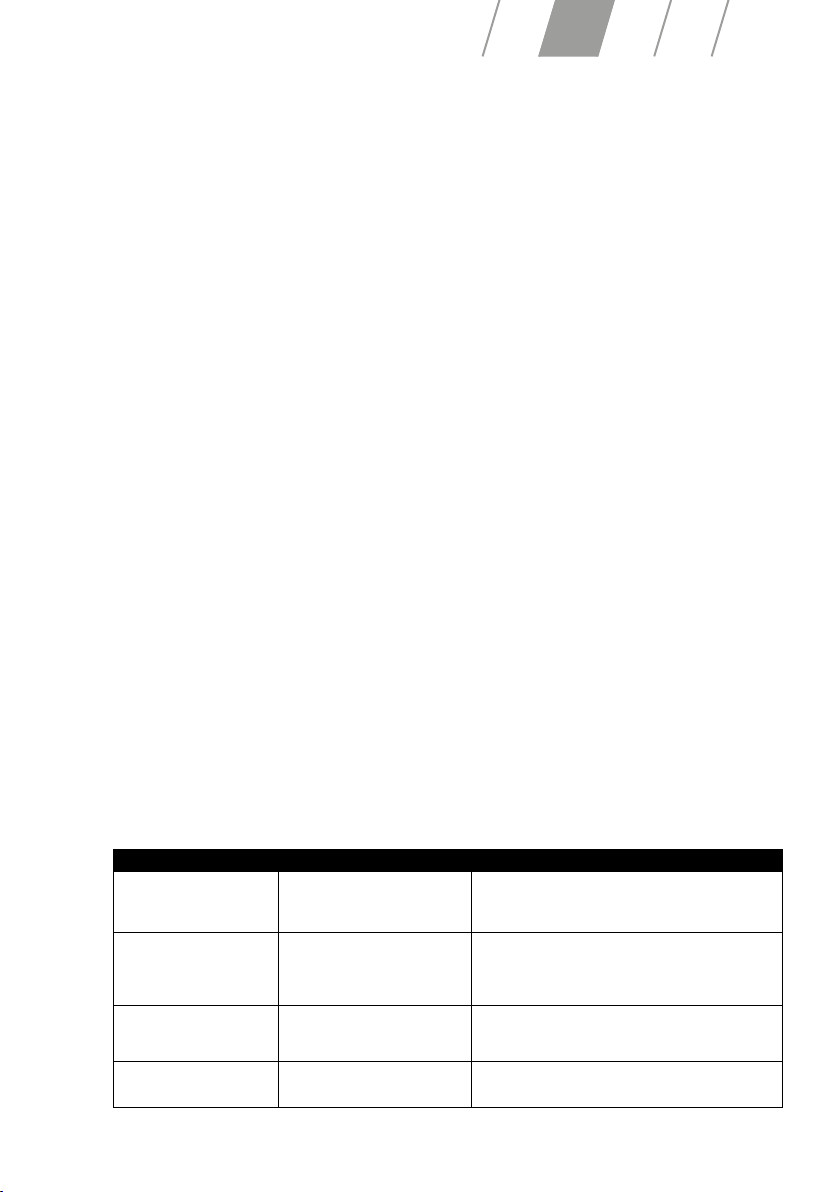

9. Troubleshooting

Motor

Problem Cause Solution

Motor do es not run · no curr ent

Motor ge ts hot · air lte r is blocked

Motor vibrates · rotor r uns out of round

Motor ha s a very loud

running noise

· cable defective

· swit ch or motor defe ctive

· blade te nsion is too hig h

· defective ball bearing

· blade s or clipper hea d run dry

· beari ngs are worn ou t

· fan whe el broken

· jammed bearing have it re placed by a spe cialist work shop

· check s ocket and fuse

· have checked /replaced by a specialist

· have it re placed by a spe cialist work shop

· clean or r eplace air lt er

· slight ly loosen th e tensioning nu t; if the blad es still

do not cu t please sharp en them

· have rep laced by a speci alist work shop

· lubri cate

· have it re placed by a spe cialist work shop

Clipper head

Problem Cause Solution

Upper b lade does not mo ve · defec tive reduc tion drive · h ave it replace d by a specialis t workshop

Upper b lade does not mo ve

over th e entire runni ng

surface

Clipper head gets very hot · blade te nsion too high

Blade s cut badly · blades are blunt

· eccentric knocked out

· eccent ric shaft de fective

· blade s and/or eccent ric run dry

· blade s are badly shar pened

· blade te nsion too low

· blade s have rust

· have it re placed by a spe cialist work shop

· have it re placed by a spe cialist work shop

· have bla des sharpen ed by a speciali st worksho p

· have bla des sharpen ed by a speciali st worksho p

· increase tension by tightening the tensioning nut

· have bla des sharpen ed by a speciali st worksho p or if

too much r ust replace t he blades

Blade s do not cut · eccentric defective

· defec tive reduc tion drive

· clipper head knocked out

· have it re placed by a spe cialist work shop

If your problem is not listed here, or continues to exist, please feel free to contact our

customer service.

10. Technical data

Device type/Model VOSS.f arming easy CUT Horse C lipper

Supply voltage 230 -240 V/AC

Motor power 150 W

Stroke s: Power level 1 / 2 1 = ca. 220 0/min, 2 = ca. 26 00/min

Max. am bient temper ature 0° - 40° C

Max. ai r humidity 10% - 90% (re lative)

Spare parts

Only spare par ts expressly approved or oered by the manufacturer may be used.

If necessar y, please contact your specialist dealer.

Attention:

Unauthorized modications or alterations to the clipper are not permitted!

Disposal

The user is responsible for the proper disposal of the clipping blades and the clipping

machine at the end of their service lives. Observe the relevant regulations in your country. Do not dispose of the clipper in household waste. Proper disposal preserves the

environment and prevents possible harmful eects. In accordance with the EU directives 2012/19/EU on disposal of electrical and electronic equipment, your device will be

DE EN FR NL

accepted free of charge at municipal collection points or rec ycling centres, or you can

take it to specialist dealers who oer a take-back service. If you cannot nd a collection

point in your area, we oer you, as a manufacturer or online retailer and member of a

recycling system, a return service in accordance with the requirements of the European

Directives. Please contact us at info@voss-group.eu

11. Legal content

CE-CONFORMITY DECLARATION

VOSS GmbH & Co. KG hereby declares that the product / device described in these

instructions complies with the fundamental requirements and other relevant

stipulations and regulations. The CE mark conrms compliance with the

Directives of the European Union.

Version 2019 - 07

Head oce : VOSS GmbH & Co. KG, O hrs tedt- Bhf. No rd 5, 25 885 We ster- Ohrsted t, Germany

Ser vice center : VOSS GmbH & Co. KG, Ole B ahndamm 2, 2588 4 Viöl , Germany

Loading...

Loading...