Page 1

VORT HR 200

VORTICE LIMITED

Beeches House - Eastern Avenue

Burton on Trent

DE13 0BB

Tel. (+44) 1283-492949

Fax (+44) 1283-544121

UNITED KINGDOM

VORTICE FRANCE

72 Rue Baratte-Cholet

94106 Saint Maur Cedex

Tel. (+33) 1- 55.12.50.00

Fax (+33) 1-55.12.50.01

FRANCE

VORTICE ELETTROSOCIALI S.p.A.

Strada Cerca, 2 - frazione di Zoate

20067 TRIBIANO (MI)

Tel. (+39) 02-90.69.91

Fax (+39) 02-90.64.625

ITALIA

COD. 5.371.084.820 28/02/2011

Libretto istruzioni

Instruction booklet

Notice de pose et d’entretien

Gebrauchsanleitung

Manual de instrucciones

Page 2

Prima di installare ed utilizzare il prodotto, leggere

attentamente le istruzioni contenute nel presente

libretto. Vortice non potrà essere ritenuta

responsabile per eventuali danni a persone o cose

causati dal mancato rispetto delle indicazioni di

seguito elencate, la cui osservanza assicurerà

invece la durata e l’affidabilità, elettrica e

meccanica, dell’apparecchio. Conservare perciò

sempre questo libretto d’istruzioni.

Indice IT

Descrizione ed impiego . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Garanzia e responsabilità . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Attenzione . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Avvertenza . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Struttura e dotazione . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Accessori in dotazione . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installazione . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Collegamenti elettrici . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Funzionamento . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Manutenzione/pulizia. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Impostazioni iniziali . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Informazione importante per lo smaltimento . . . . . . . . . . . . .

ambientalmente compatibile . . . . . . . . . . . . . . . . . . . . . . . . 19

Before installing and using your product, read

these instructions carefully. Vortice will not accept

any responsibility for damage to property or

personal harm resulting from failure to abide by

the conditions listed below.

Following these instructions will ensure long

service life and overall electrical and mechanical

reliability. Keep this instruction booklet in a safe

place for reference purposes.

Table of Contents EN

Compliance with Building Codes . . . . . . . . . . . . . . . . . . . . 20

Description and operation . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Guarantee and responsibility. . . . . . . . . . . . . . . . . . . . . . . . 20

Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Caution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Items supplied . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Accessories supplied. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Maintenance/cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Initial settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Important information regarding

eco-compatible disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Building Regulations Document F1 2006 . . . . . . . . . . . . . . 36

Avant d’installer et d’utiliser l’appareil, lire

attentivement les instructions contenues dans

cette notice. Vortice décline toute responsabilité

concernant les dommages causés aux personnes

et aux biens si les instructions ci-dessous ne sont

pas respectées. Les indications données dans ce

livret garantissent la durée de vie et la fiabilité

électrique et mécanique de l’appareil.

Conserver cette notice.

Vor der Installation und der Benutzung des

Gerätes muss die vorliegende

Gebrauchsanweisung aufmerksam durchgelesen

werden. Vortice haftet nicht für auf die

Nichtbeachtung der in diesem Handbuch

enthaltenen, für einen korrekten Betrieb, die

mechanische und elektrische Sicherheit und eine

lange Lebensdauer des Gerätes wichtigen

Hinweise bzw. Anleitungen zurückzuführende

Personen- und/oder Sachschäden. Diese

Betriebsanleitung ist gut aufzubewahren.

Sommaire FR

Description et mode d’emploi . . . . . . . . . . . . . . . . . . . . . . . 37

Garantie et responsabilité . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Attention . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Avertissement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Structure de l’appareil et accessoires de série . . . . . . . . . . 39

Accessoires de série . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Branchements électriques. . . . . . . . . . . . . . . . . . . . . . . . . . 44

Fonctionnement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Entretien / Nettoyage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Paramétrage initial . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Information importante pour éliminer

l’appareil en respectant l’environnement. . . . . . . . . . . . . . . 52

Inhaltsverzeichnis DE

Beschreibung und Gebrauch. . . . . . . . . . . . . . . . . . . . . . . . 53

Garantie und Haftung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Achtung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Hinweis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Aufbau und Ausstattung . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Standard-Zubehör . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Stromanschlüsse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Funktionsbeschreibung . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Wartung/Reinigung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Erste Einstellung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Wichtige Information für die

Umweltgerechte Entsorgung. . . . . . . . . . . . . . . . . . . . . . . . 68

2

Page 3

20

Compliance with Building Codes

The most recent laws introduced to reduce energy

consumption require compliance with a series of

constraints which concern the performance provided

and the energy consumption of ventilation equipment.

In particular, the 2006 Edition of the U.K “Building

Regulations Document F1”: Means of Ventilation (ADF

applicable in England and Wales) details 4 clearly

dened systems of ventilation to dwellings. System 4 Continuous mechanical extract with heat recovery

(MVHR) is complied with by the new VORT HR 200 ultrahigh efciency whole house heat recovery ventilation

system.

In addition the unit fully complies with the requirements

of the “Code for Sustainable Homes” which details 6

levels of C02emission improvement over 2006 Building

Requirements. In order to operate in accordance with

ADF, the unit must be set by the installer to deliver air

volumes a stated in the Approved Document and as per

the extract of ADF on page 38 of this brochure.

Description and operation

VORT HR 200 (henceforth “the appliance”) is an

extremely high efciency centralised heat recovery

ventilation system that can be oor mounted using the

special optional kit or wall mounted using the special

hooks provided.

Normally, stale air is extracted from “service” rooms

such as kitchens, bathrooms and laundries; at the same

time, fresh air from outdoors is ducted into rooms that

are normally lived in such as bedrooms, studies and

sitting rooms. The air ows required are detailed in

current national regulations; in the UK, the UK “Building

Regulations Document F1” apply.

During normal operation the total volumes of air

extracted and air fed back in are essentially the same.

The incoming and outgoing air ow are perfectly

separate and suitably ltered. During the cold season,

heat from expelled air is transferred to incoming air. The

condensation created in the process, which is collected

inside the product, must then be piped to the outside.

The appliance silently and continuously ventilates the

house removing stale air and replacing it with ltered

fresh air from the outside. Inside the heat exchanger,

which is the key element in the appliance, heat is

exchanged between the two ows of air and this

guarantees the energy savings that the VORT HR 200

offers.

Guarantee and responsibility

Guarantee

The appliance is guaranteed for 2 years from the date of

purchase.

The guarantee does not apply to:

• installation/removal costs;

• damage caused by improper or negligent use of the

appliance;

• damage caused by repairs or attempted repairs or by

third parties not authorised by Vortice.

Responsibility

The appliance is designed for “balanced ventilation

systems”. Any other use that has not been previously

discussed with a Vortice expert shall be considered

improper. In this case, Vortice shall not be held

responsible for any malfunction or failure.

Vortice shall not be held responsible for breakdowns

due to:

• improper use of the appliance;

• normal wear and tear of the appliance;

• the user’s failure to comply with the instructions

provided in this manual.

ENGLISH

Page 4

21

• Follow the safety instructions to prevent any harm to

the user.

• Do not use this appliance for functions other than

those described in this booklet.

• After removing the appliance from its packaging,

ensure that it is complete and undamaged: if in any

doubt, contact a professionally qualified electrician or

a Vortice Service Centre.

• Do not leave packaging within the reach of children or

less able persons.

• Certain fundamental rules must be observed when

using any electrical appliance:

• never touch appliances with wet or damp

hands;

• never touch appliances while barefoot.

• This appliance is not suitable for use by individuals

(including children) with reduced physical, sensorial or

mental capacities, or by inexperienced or untrained

individuals, unless they are supervised or instructed in

its use by a person responsible for their safety.

Children must always be supervised to ensure that

they do not play with the appliance.

• Do not us the appliance near inflammable substances

and vapours (alcohol, insecticides, petrol, etc.).

• Store the appliance out of the reach of children and

less able persons if you decide to disconnect it from

the power supply and use it no more.

• Do not make modifications of any kind to this

appliance.

• The maintenance instructions must be followed to

prevent any damage to and/or excessive wear and tear

of the appliance.

• Do not expose the appliance to the elements (rain, sun,

etc.).

• Do not leave objects standing on the appliance.

• The interior of the appliance must only be cleaned by

qualified personnel.

• Regularly inspect the appliance for visible defects. If

the appliance does not function correctly, do not use it

and contact a Vortice Service Centre immediately

• If the appliance does not function correctly or develops

a fault, contact a Vortice Service Centre immediately

and ensure that only genuine original Vortice spares

are used for any repairs.

• Should the appliance be dropped or suffer a heavy

blow, have it checked immediately by a Vortice Service

Centre.

• The appliance must be installed by a professionally

qualified electrician.

• The appliance must be mounted in such a way as to

ensure that under normal operating conditions, no one

can come into contact with any of the moving parts or

live electrical components.

• For maintenance work (e.g. removing the heat

exchanger), the appliance should first be turned OFF

then disconnected from the mains.

• The electrical system to which the appliance is

connected must conform to applicable standards.

• A multi-pole switch must be used to install the

appliance. The gap between the switch contacts must

be no less than 3 mm.

• The electrical power supply/socket to which the

appliance is to be connected must be able to provide

the maximum electrical power required by the

appliance. If it cannot do so, arrange for a qualified

electrician to make the necessary modifications.

• Switch OFF the system’s main switch:

• if the appliance does not function correctly;

• before cleaning the outside of the appliance;

• if you decide not to use the appliance for any

length of time.

• The appliance cannot be used in combination with

water heaters, room heaters, etc., nor must it be used

to drain hot water away from such appliances.

• The appliance must expel air directly to the outside

through a dedicated outlet.

• The flow of extracted air must be clean (that is free of

grease, soot, chemical and corrosive agents and

explosive or flammable mixtures).

• Keep the appliance intake and outlet grilles free to

ensure optimum air flow.

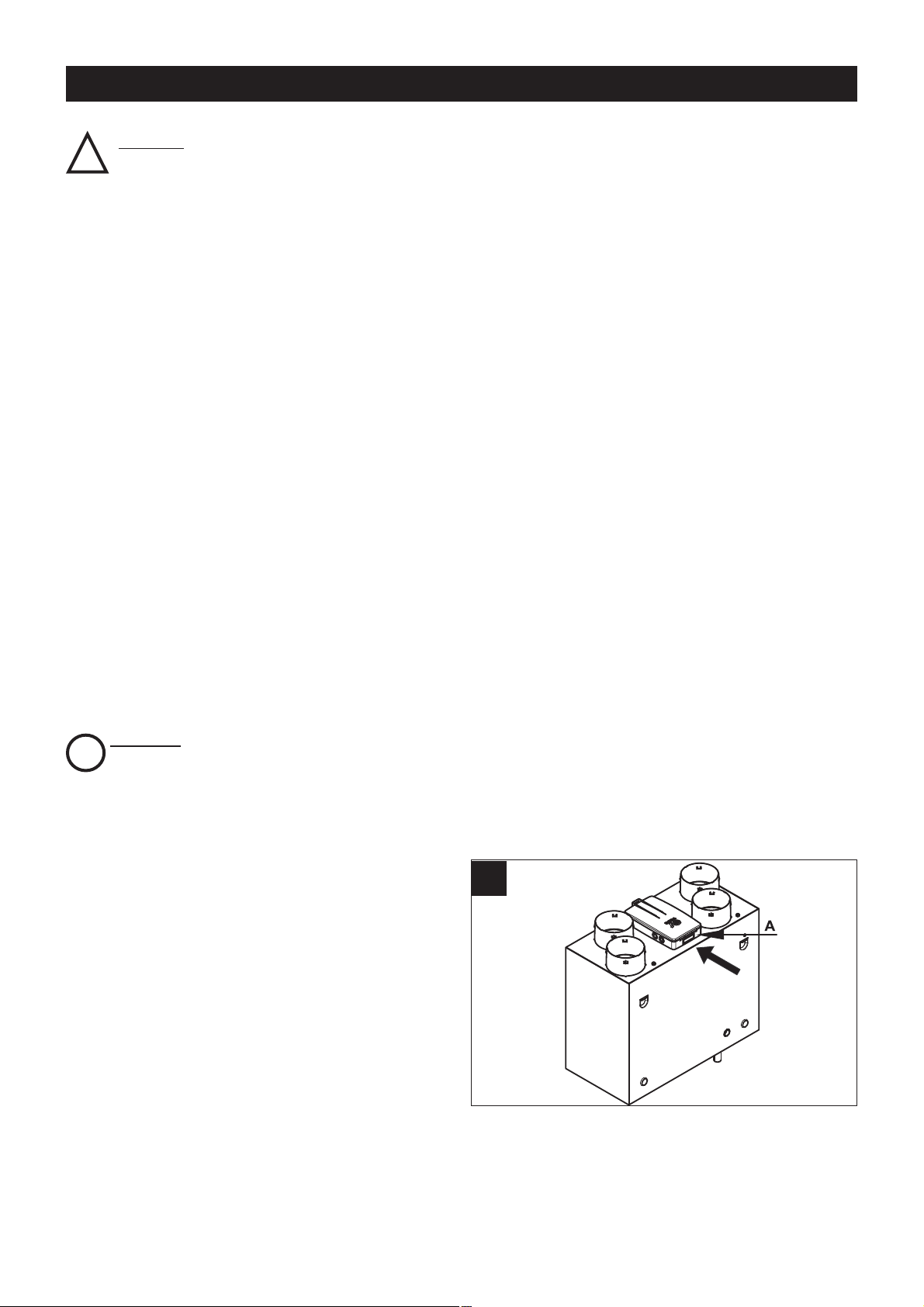

• Specifications for the power supply must correspond

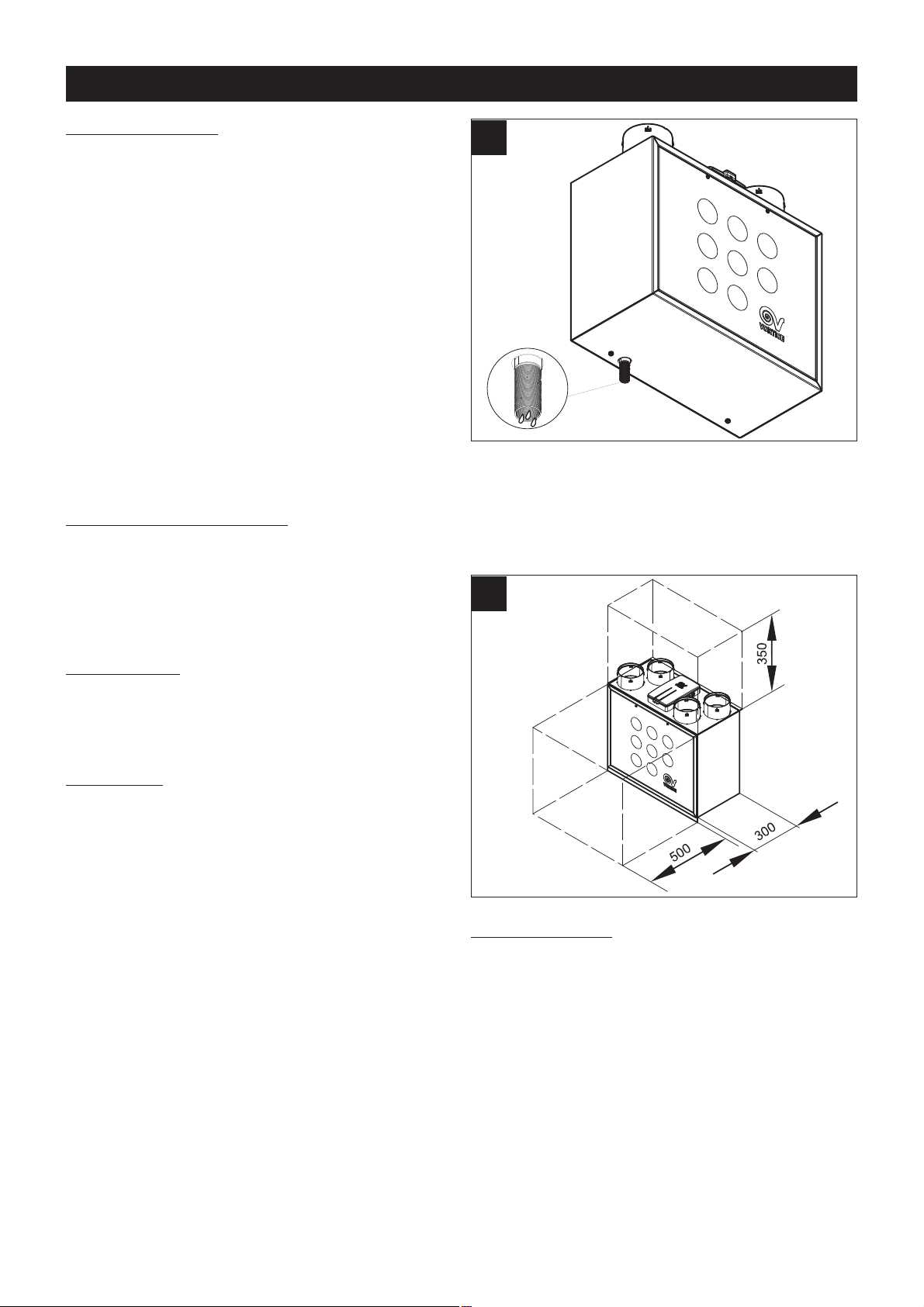

to the electrical data on ID plate A (fig. 1).

ENGLISH

1

Caution:

This symbol indicates precautions that must

be taken to avoid damaging the appliance

!

Warning:

This symbol indicates precautions that must

be taken to avoid personal injury

!

Page 5

22

Items supplied

The main appliance components are as follows:

• an outer casing and front cover in painted sheet metal;

the casing houses the intake/outlet hose connections

and the electrical connection box; the casing also

houses the internal components and heat exchanger

in an air tight housing;

• internal ducts in EPP (expanded polypropylene) that

distribute ow of air while maximising heat insulation

and minimising losses.

• the plastic resin, counterow, heat exchanger whose

particular shape guarantees the highest possible

efciency in terms of heat exchange (up to 93%);

• 2 lters with G3 level particle retention;

• 2 brushless motors connected to centrifugal fans;

• the electronic circuit board that processes power

supply, appliance commands and controls;

• a temperature sensor that is essential to stop the

formation of frost on the heat exchanger;

Accessories supplied

The accessories supplied as standard include:

• 1 x condensation drainage hose coupling

• 1 x condensation drainage hose;

• 2 x rawlplugs with hooks for wall-mounting the

appliance

Installation

The appliance must be installed according to the safety

regulations currently in force in the country of

destination, and the instructions provided by this

booklet.

Prerequisites

The appliance must be tted to an internal surface or

wall of the home that is structurally sound enough to

bear its weight.

The ducts used for carrying ducting must be of the

correct size.

Ducts to and from the exterior must be thermally

insulated and not subject to vibration.

The 125 mm standard diameter inlet and outlet pipes

must be xed to the corresponding spigots on the

appliance by means of clips or some other suitable

fastening system.

Under normal operating conditions, condensation

gathers at the bottom of the appliance. In order to

dispose of it, the small hose provided must be attached

to the coupling on the underside of the appliance and

connected to a drainage hose (see Assembly).

The appliance must be easily accessible for

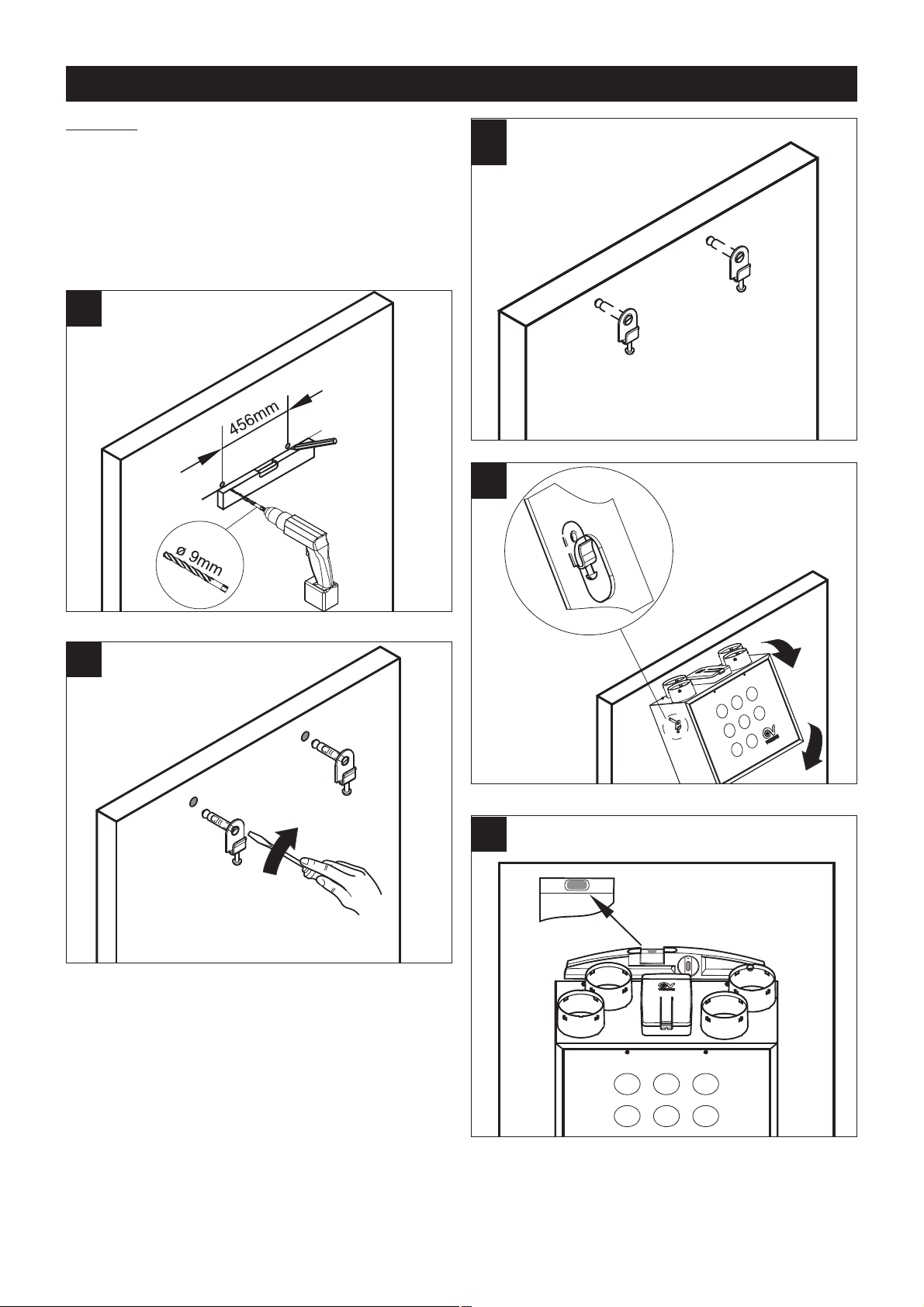

servicing/maintenance purposes. It is important to leave

a space of at least 50 cm in front of the front panel to

facilitate the cleaning and replacement of the heat

exchanger and lters (g. 3).

Checks on delivery

On delivery, check the appliance for any faults before

proceeding with the installation. More specically:

• rstly remove it from the packaging ensuring that the

name and description shown on the box correspond;

• when the appliance has been removed from the

packaging, check that there is no visible damage then

make sure that the small condensation drainage hose

is present along with the instruction manual.

ENGLISH

2

3

Page 6

23

Assembly

The appliance comes with 2 rawlplugs with hooks for

wall-mounting.

Establish exactly where the appliance is to be

positioned, bearing in mind the installation

requirements.

Vertical mounting

Fix the hooks to the wall as shown in the diagrams that

follow (gs. 4,5,6,7,8).

ENGLISH

4

5

6

7

8

Page 7

24

Floor mounting (optional kit)

The appliance can be horizontally oor mounted using

the special optional kit.

Pipework connections

(g. 9).

The spigots on the appliance measure 125 mm in

diameter. Ducts may be connected to the appliance inlet

and outlets. Each connection is illustrated below with a

diagram that shows the direction of the air ow (in and

out).

Stale air outlet

(g. 10).

This outlet is used to expel stale air once it has been

treated by the heat exchanger. The ducting for this stale

air must be thermally insulated (to prevent the formation

have condensation on internal and external

components) and devices tted to absorb vibration. If

the drainage system is on the roof, it must be designed

so as to prevent the formation of condensation and the

entry of rain water.

Fresh air inlet

(g. 11)

This inlet is used for carrying fresh air from the exterior;

the duct must be thermally insulated and have devices

tted to absorb vibration. If air intake system is on the

roof, it must be designed so as to prevent the formation

of condensation and the entry of rain water.

Stale air extraction inlet

(g. 12)

This inlet carries extracted stale air from the house. The

duct needs to be thermally insulated.

ENGLISH

EXTRACT

TO

EXTERNAL

SUPPLY

FROM

EXTERNAL

EXTRACT

FROM

INTERNAL

SUPPLY

TO

INTERNAL

9

10

11

12

Page 8

25

Air outlet

(g. 13)

This outlet delivers fresh air into the house once it has

been treated in the heat exchanger.

Connecting the condensation drainage hose.

The connection point for this hose is located on the

underside of the appliance; it is to be connected

following the description below (gs.14,15,16,

17,18,19,20).

ENGLISH

13

14

15

16

17

18

Page 9

26

Condensation is drained away by connecting the hose

provided to the condensation drainage coupling.

To prevent formation of air locks a U-bend must be

created with the hose as shown in g. 21.

ENGLISH

19

20

21

Page 10

27

Electrical connections

Power supply wiring: you will need a cable with

5 X 1.5mm2 cores [4 plus earth] (g. 22)

Connecting the power supply (N1, L1 and earth) and maximum speed terminals (g. 23).

Wiring diagram with switch (g. 24)

Wiring diagram with timer (g. 25)

ENGLISH

22

24

25

23

Page 11

28

Function

Motors

The appliance is equipped with:

• two brushless motors specically designed to

guarantee very low energy consumption thanks to

their high efciency. These motors drive two

centrifugal fans which extract the stale damp air from

service rooms (kitchens, bathrooms, washrooms, etc)

and introduce fresh external air into living areas (sitting

rooms, dining rooms, bedrooms, etc.);

Heat exchanger

The two air ows, intake and extract, meet in the

appliance, (without ever actually coming into direct

contact so as not to jeopardise the quality of incoming

air) inside the heat exchanger where the warm

outgoing/extracted air passes its heat to the cold

incoming air, thus minimising the temperature variation

in the areas served.

Filters

Two G3 lters housed in the inlet and extraction ducts

close to the heat exchanger and accessible by removing

the front panel, protect the appliance from impurities in

the extracted stale air and prevent the introduction of

polluted air into the areas served by the system.

The condition of the lters can be checked by removing

the front panel and extracting them from their holders.

Replacing a standard G3 lter in the air intake system

with an optional G5 lter enhances the degree of

ltering.

Anti-frost protection

When weather conditions deteriorate and the formation

of frost on the heat exchanger walls become more likely,

the electronic circuit board automatically adjusts fan

speeds and air ow parameters.

While the automatic de-frosting cycle is in operation, the

user cannot change the appliance operating speed.

Setting fan speed

Using the switch to set fan speed (g. 26).

The appliance usually operates at minimum speed

(V

min

); the user can switch to the maximum speed

(V

max

) with the switch.

Setting fan speed using the timer (g. 27).

The fan speed can also be set using timer mode.

The keypad can be used to change the operating speed

to V

max

for 30 mins.; after this period is up, the

appliance returns to V

min.

ENGLISH

26

27

Page 12

29

Maintenance/Cleaning

Filters

The user is responsible for the periodical maintenance

of lters. The lters have to be periodically cleaned to

ensure that the appliance continues operating efciently.

They should be replaced at least once a year.

To access the lters, follow the instructions below:

• disconnect the appliance from the mains.

• remove the lters from the appliance (gs. 28,29,30)

• clean the lters using a vacuum cleaner; you are

advised to replace the lters after cleaning them a few

times but least once a year.

• ret the lters (gs. 31,32,33)

ENGLISH

28

29

30

31

Page 13

30

If the appliance remains out of use for extended periods,

we advise removing the lters to prevent any possible

damage from the build-up of condensation.

Heat exchanger

Heat exchangers do not usually need frequent cleaning.

Any need for cleaning can be determined by a high

degree of air pollution (both entering and leaving the

house) and by the lters being in poor condition.

The heat exchanger should however be replaced every

six years even if the lters have been regularly serviced.

To access the heat exchanger, follow the instructions

below:

• disconnect the appliance from the mains;

• remove the heat exchanger (gs. 34,35,36);

• clean the heat exchanger;

• ret the heat exchanger (gs. 37,38,39)

ENGLISH

32

33

34

35

36

Page 14

31

Cleaning the outside

To clean the outside of the appliance, follow the

instructions below:

• disconnect the appliance from the mains;

• only use a soft slightly damp cloth (fig. 40);

• do not use abrasive and/or corrosive products (fig. 41);

• do not use a rough and/or soaking cloth; any water

that gets inside the appliance could cause serious

damage.

ENGLISH

37

38

39

40

41

Page 15

32

Initial settings

(for installer only)

There are two ways for the installer to make the initial appliance settings:

• Remote mode using the (RF) remote control unit and

radio module.

• Appliance mode using the trimmer and dip-switch.

In addition to altering the speed settings, the initial

conguration will also include the adjustment of the air

inlet and outlet openings to and from the rooms served.

Appliance/remote control coupling

Each remote control must be initialised before use. This

activity is entrusted to the installer (for remote controls sold

separately from the product), or factory set (for remote

controls sold with the product).

The activity comprises the following steps:

a. turn the power off for at least 30 sec.;

b. turn the power back on;

c. within 60 sec. perform the procedure described below.

In detail, holding down the ENTER key for at least 3

seconds, the appliance will couple with the remote control.

Completion of coupling will be conrmed by an acoustic

signal (constant 3 second BEEP) from the remote control

itself.

Using the remote control/radio mode

(g. 42)

The initial appliance settings can be made by means of

the (RF) remote control unit and external radio module

that do not come as standard with the appliance.

N.B. Some of the functions included on the remote

control unit do not apply to this appliance.

1) Before connecting the appliance to the mains,

connect the external radio module to the electronic

circuit board and congure the dip-switch as shown

(gure 43).

In this way, the system will be able to recognise the

settings made using the remote control unit even when

it is no longer connected to the external radio module (in

effect, in this case ignoring the trimmer reading).

2) When the appliance is connected to the power supply,

the system recognises the external radio module and

keeps the motors in the OFF state.

3) Turn ON the (RF) remote control unit (fig. 44) and

check the system status (brushless motor

diagnostics, assessment of temperature sensor

reading). Subsequently, the system - unless a fault is

indicated - will start the motors at V

min

and V

max

by

default. Below are details of the settings made using

the remote control:

V

min

: set 30 (about 1100 rpm);

V

max

: set 43 (about 1360 rpm);

ENGLISH

88:88

SUMMER

MAN

AUTO

T(°C) CO2(ppm) RH(%) O

Mo Tu We Th Fr Sa Su

DISPLAY

TIMER

MODE

SET NEXT ENTER

42

43

Page 16

33

ON/OFF key (g. 44)

To turn the appliance ON and OFF. The command is only

carried out if the key is kept pressed for at least half a

second.

4) Setting the required motor speed using the remote

control unit (fig. 45).

SET key (g. 45)

For setting the minimum (V

min

) and maximum (V

max

)

speeds. To move from one parameter to the next, use

the NEXT key.

V

min

setting (g. 46):

• to display the setting, press SET, NEXT (starting from

the main menu);

• to set the value of the ashing eld with the + and keys (from 0 to 60); press ENTER or NEXT to conrm.

The display will switch to the V

max setting.

V

max

setting (g. 47):

• to display the setting, press: SET, NEXT (starting from

the main menu);

• to set the value of the ashing eld with the + and keys (from V

max

+10 to 99); press ENTER or NEXT to

conrm. The display will switch to the main screen.

5) When you have finished making the settings, turn the

remote control unit OFF (the motors will also stop) and

remove the connection with the external radio

module.

6) Disconnect the power supply to the appliance. When

restarted, the system will operate using the configured

settings. the trimmer reading will be ignored.

N.B.

After a certain period of inactivity (about 5 secs) the

remote control unit goes into “stand-by” mode; pressing

any key for a few seconds will reactivate the unit.

ENGLISH

14:38

SUMMER

Fr

DISPLAY

TIMER

MODE

SET NEXT ENTER

MAN

44

14:38

AUTO

Fr

SET

NEXT ENTER

DISPLAY

TIMER

MODE

45

SL03

46

SH50

47

Page 17

34

Manually making settings using the dip-switch

1) Before connecting the appliance to the mains,

congure the dip-switch using the following method:

(g. 48).

2) Position both the trimmers fully to the left so that they

can be turned clockwise (g. 49).

ATTENTION: do not apply excessive force to the

trimmers

3) Connect the appliance to the mains and the

appliance will start at 500 Rpm speed.

4) Set the switch for selecting speed in the position

matching the lowest setting V

min

The pre-selected conguration has to match the type of

installation (number of rooms served, length of

pipework, etc.) to be carried out.

The system is now enabled for setting with the

trimmer/dip-switch.

5) If you need to change this speed, use trimmer R1

turning it clockwise until you reach the desired setting

(g. 50).

6) Turn the switch to the position matching the selection

of the maximum operating speed (V

max

).

7) The appliance will start operating at the speed

matching the conguration of the dip-switch

selected. Select the dip-switch conguration that

presents the most suitable range of speed variations.

Turn trimmer R9 until you reach the desired value.

8) When you have nished making the settings, turn the

appliance OFF and disconnect the power supply.

N.B.

This procedure must only be carried out within one

hour of turning the appliance ON. Once this period

has elapsed, all other attempts at applying a new

speed will be ignored and the parameter set before

the appliance was turned on will be used. To apply a

new speed setting, turn the appliance OFF and turn

the trimmers anti-clockwise then reconnect the

appliance and repeat the procedure described above.

.

50

49

ENGLISH

48

Page 18

35

Activating the timer

.

In timer mode, the appliance will operate for 30 minutes

at V

max

and then return automatically to V

min

; to permit

new settings, connect the appliance to a keypad (not to

a switch).

Timer mode can be set by turning switch 1 on the dipswitch to the ON position (g. 51) .

The details above apply for other dip-switch

congurations.

N.B.

To ensure that the appliance operates properly, you are

advised to carry out the initial setting procedure using all

the steps described in the relative preselected setting

mode.

Important information on eco-compatible

disposal

IN CERTAIN EUROPEAN UNION COUNTRIES, THIS

PRODUCT DOES NOT FALL WITHIN THE

REQUIREMENTS OF THE NATIONAL LAWS

IMPLEMENTING DIRECTIVE RAEE, AND, IN THESE

COUNTRIES THE PRODUCT IS NOT SUBJECT TO

SEPARATE DISPOSAL OPERATIONS AT THE END OF

ITS WORKING LIFE.

This product complies with European Directive

2002/96/EC.

At the end of its useful life, the product

marked with the crossed out wheeled bin

must be disposed of separately from

urban waste. It must be taken to a

differentiated disposal centre for

electrical and electronic appliances or be returned to the

retailer when a new equivalent appliance is bought.

Subject to current legislation on waste disposal, the

user is legally responsible for taking the appliance at the

end of its useful life to a suitable disposal centre.

Appropriate differentiated waste collection for

subsequent recycling, treatment and environmentfriendly disposal of the discarded equipment helps to

prevent possible negative environmental and health

effects and encourages recycling of the component

materials of the equipment.

For further information about available waste disposal

systems, contact your local waste disposal service or

the shop where you bought the product.

The manufacturers and importers comply with their

responsibility for recycling, treating, and environmentally

compatible disposal of waste both directly and

collectively.

51

ENGLISH

Page 19

Table 1.1 A

Room Minimum intermittent extract rate Continuous rate

Minimum high rate Minimum low rate

Kitchen 30 l/s (adjacent to hob); Total extract rate

or 60 l/s elsewhere 13 l/s must be at least

Utility room 30 l/s 8 l/s

the whole building

Bathroom 15 l/s 8 l/s

ventilation rate in

Sanitary Accomodation 6 l/s

Table 1.1B

Table 1.1 B

Number of bedrooms in dwelling

1 2 3 4 5

Whole building ventilation rate (l/s) 13 17 21 25 29

Minimum value in any dwelling of 0,3 l/s per m

2

oor area

BUILDING REGULATIONS DOCUMENT F1 2006

CONTINUOUS MECHANICAL SUPPLY & EXTRACT

VENTILATION WITH HEAT RECOVERY

A continuous balanced mechanical central supply and extract system to

be positioned in loft or cupboard space. An integral heat exchanger

recovers a large percentage of heat energy that would have otherwise

been lost. In employing this type of system, there is no need to install

background ventilators in the dwelling.

CONTINUOUS SUPPLY AND EXTRACT

1 Determine the whole building ventilation rate from Table 1.1B

Allow for inltration by subtracting

- for multi storey dwellings: 0.04 x gross internal volume of dwelling

heated space (m3)

- for single storey dwellings: 0.06 x gross internal volume of dwelling

heated space (m3)

2 Calculate the whole dwelling extract rate at maximum operation by

adding the individual room rates for ‘minimum high rate’ from Table 1.1A

3 The required air flow rates as as follows:

Maximum Extract Rate (boost) is the greater step of 1 and 2 above.

The Minimum individual room extract rates sholuld be at least those

given in Table 1.1A for minimum high rate

Minimum air supply rate should be at least the whole building

ventilation rate in 1 above.

4 No Background ventilators are required with System 4

In addition, the minimum ventilation rate should not be less than 0.3 l/s per m2internal oor area (this includes each oor, e.g.

for a two-storey building, add the ground and rst oor areas).

This is based on two occupants in the main bedroom and a single occupant in all other bedrooms. This should be used as the

default value. If a greater level of occupance is expected, then add 4 l/s per occupant.

SYSTEM 4

36

Table 1.1 A

etar suounitnoC etar tcartxe tnettimretni muminiMmooR

Minimum high rate Minimum low rate

etar tcartxe latoT;)boh ot tnecajda( s/l 03nehctiK

tsael ta eb tsums/l 31 erehwesle s/l 06 ro

s/l 8 s/l 03 moor ytilitU

the whole building

s/l 8 s/l 51 moorhtaB

ventilation rate in

s/l 6 noitadomoccA yratinaS

Table 1.1B

Table 1.1 B

Number of bedrooms in dwelling

1 2 3 4 5

9252127131 )s/l( etar noitalitnev gnidliub elohW

Minimum value in any dwelling of 0,3 l/s per m

2

BUILDING REGULATIONS DOCUMENT F1 2006

CONTINUOUS MECHANICAL SUPPLY & EXTRACT

VENTILATION WITH HEAT RECOVERY

A continuous balanced mechanical central supply and extract system to

be positioned in loft or cupboard space. An integral heat exchanger

recovers a large percentage of heat energy that would have otherwise

been lost. In employing this type of system, there is no need to install

background ventilators in the dwelling.

CONTINUOUS SUPPLY AND EXTRACT

1 Determine the whole building ventilation rate from Table 1.1B

- for multi storey dwellings: 0.04 x gross internal volume of dwelling

heated space (m3)

- for single storey dwellings: 0.06 x gross internal volume of dwelling

heated space (m3)

2 Calculate the whole dwelling extract rate at maximum operation by

adding the individual room rates for ‘minimum high rate’ from Table 1.1A

3 The required air ow rates as as follows:

Maximum Extract Rate (boost) is the greater step of 1 and 2 above.

The Minimum individual room extract rates sholuld be at least those

given in Table 1.1A for minimum high rate

Minimum air supply rate should be at least the whole building

ventilation rate in 1 above.

4 No Background ventilators are required with System 4

In addition, the minimum ventilation rate should not be less than 0.3 l/s per m

2

This is based on two occupants in the main bedroom and a single occupant in all other bedrooms. This should be used as the

default value. If a greater level of occupance is expected, then add 4 l/s per occupant.

SYSTEM 4

BATHR OO M

BED ROO M

HEAT RE COV ERY

UNI T

KIT CHE N

LIV ING

ROO M

Loading...

Loading...