Vortice NRG EC 600, NRG EC 800, NRG EC 2500, NRG EC EH 600, NRG EC 1500 Operating And Commissioning Instructions

...Page 1

Manuale di uso e attivazione

Operating and commissioning instructions

Manuel d’utilisation et de mise en marche

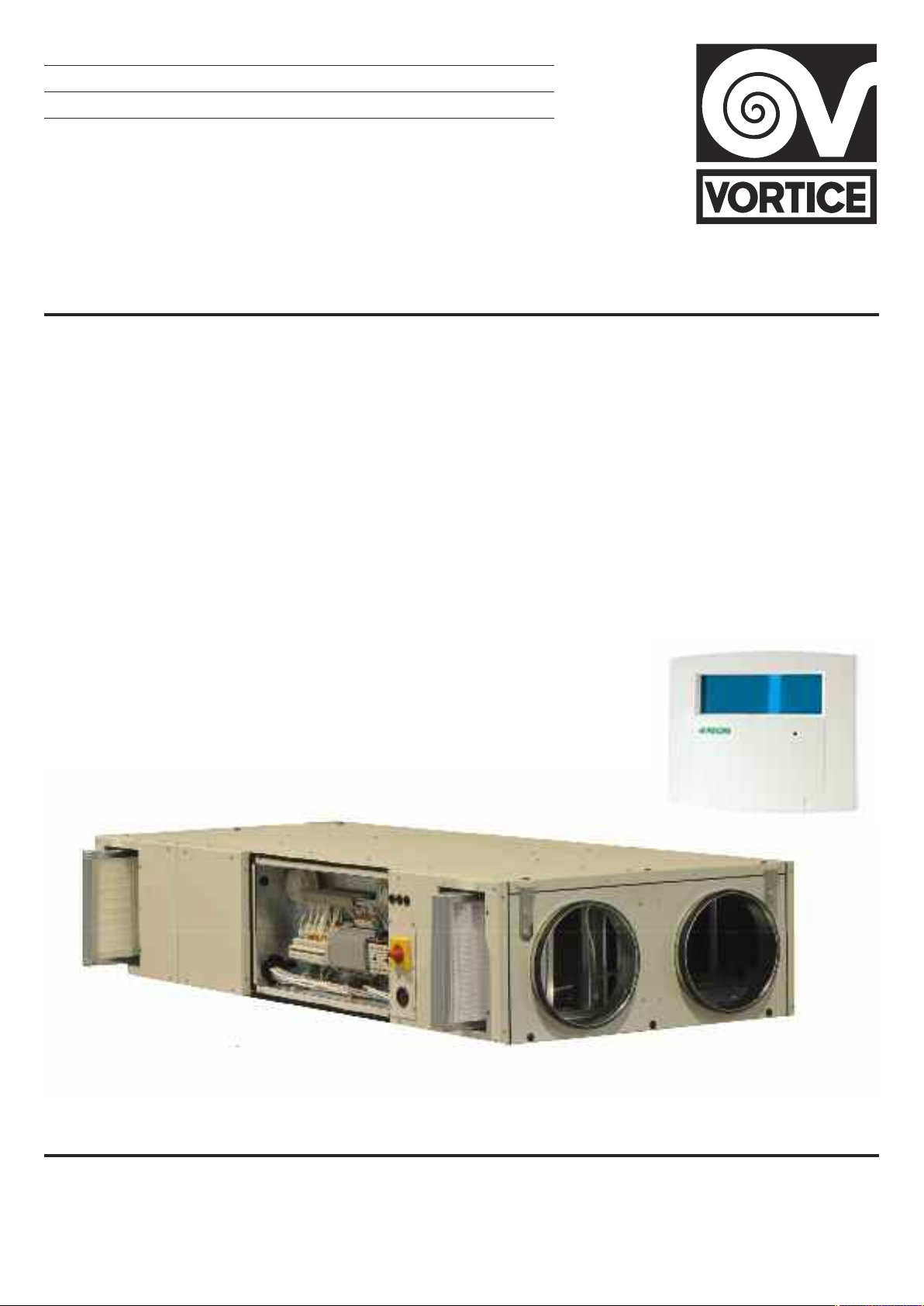

VORT NRG EC / EC EH

600 - 800 - 1500 - 2000 - 2500

COD. 5.471.084.301

VORTICE LIMITED

Beeches House - Eastern Avenue

Burton on Trent

DE13 0BB

Tel. (+44) 1283-492949

Fax (+44) 1283-544121

UNITED KINGDOM

VORTICE FRANCE

15-33, Rue Le Corbusier Europarc

CS 30007

90046 CRETEIL CEDEX

FRANCE

15/02/2016

VORTICE ELETTROSOCIALI S.p.A.

Strada Cerca, 2 - frazione di Zoate

20067 TRIBIANO (MI)

Tel. (+39) 02-90.69.91

Fax (+39) 02-90.64.625

ITALIA

Page 2

Prima di usare il prodotto leggere attentamente

le istruzioni contenute nel presente libretto.

ortice non potrà essere ritenuta responsabile

V

per eventuali danni a persone o cose causati

dal mancato rispetto delle indicazioni di seguito

elencate, la cui osservanza assicurerà invece la

durata e l’affidabilità, elettrica e meccanica,

ell’apparecchio.

d

Conservare sempre questo libretto istruzioni.

Before installing and using your product, read these

instructions carefully. Vortice will not accept any

responsibility for damage to property or personal

harm resulting from failure to abide by conditions

given in this booklet.

Following these instructions will ensure long service

life and overall electrical and mechanical reliability.

Keep this instruction booklet in a safe place for

reference purposes.

Vor der Benutzung des Gerätes muss die vorliegende

Anleitung aufmerksam durchgelesen werden.

Vortice haftet nicht für Personen- und/oder

Sachschäden, die auf die Nichtbeachtung der in

diesem Handbuch enthaltenen und für einen

korrekten Betrieb, die mechanische und

elektrische Sicherheit sowie eine lange Lebensdauer

des Gerätes wichtigen Hinweise bzw. Anleitungen

zurückzuführen sind.

Bewahren Sie diese Betriebsanleitung

gewissenhaft auf.

Avant d’utiliser l’appareil, lire attentivement les

instructions données dans cette notice.

La société Vortice ne pourra être tenue pour

responsable des dommages causés aux personnes

ou aux biens si les consignes ci-dessous ne sont

pas respectées car elles garantissent la durée de vie

et la fiabilité électrique et mécanique de l’appareil.

Toujours conserver ce livret d’instructions.

Prije korištenja proizvoda, pažljivo pročitajte upute koje

sadrži ovaj priručnik.

Tvrtka Vortice se ne može smatrati odgovornom za

eventualnu štetu nanesenu osobama ili stvarima uslijed

nepoštivanja uputa koje se u nastavku navode, a

pridržavanjem kojih se osigurava trajnost te električna i

mehanička pouzdanost uređaja.

Brižljivo čuvajte ove upute za uporabu.

Před použitím výrobku si pozorně přečtěte pokyny

obsažené v této příručce.

Podnik Vortice neodpovídá za případná zranění osob nebo

poškození věcí způsobené nedodržením dále uvedených

pokynů; jejich dodržování naopak zajistí dlouhodobou

životnost výrobku, jak elektrickou, tak i mechanickou.

Tento návod kobsluze si proto uschovejte.

2

Pred používaním spotrebiča si pozorne prečítajte všetky

pokyny v tomto návode.

Vortice nebude zodpovedať za žiadne poranenia osôb ani

škody na majetku spôsobené nedodržaním upozornení

uvedených v nasledujúcom texte, ktorých dodržiavanie,

naopak, zaručí dlhodobú elektrickú a mechanickú

spoľahlivosť, spotrebiča.

Tento návod na používanie si starostlivo odložte.

Page 3

ENGLISH

I RECEIVING THE EQUIPMENT ................................................................................................................52

I.1 Checks on receipt ...................................................................................................................................52

I.2 Unpacking................................................................................................................................................52

I.3 Storage ....................................................................................................................................................52

II INSTALLATION........................................................................................................................................52

II.1 Handling..................................................................................................................................................52

II.2 Space required .......................................................................................................................................53

II.3 Positioning ..............................................................................................................................................54

III GENERAL OPERATION .........................................................................................................................54

III.1 General ..................................................................................................................................................54

III.2 OPERATING SEQUENCE ......................................................................................................................54

III.3 CONTROL MODES................................................................................................................................55

III.3.a. VORT NRG EC .......................................................................................................................................55

III.3.b. ECO:......................................................................................................................................................55

III.3.c. DIVA........................................................................................................................................................55

III.3.d. LOBBY® ................................................................................................................................................55

III.4. COMPOSITION ......................................................................................................................................56

III.5.b. SEASON CONTROL ..............................................................................................................................57

III.5. POSITIONING OF THE CONTROL PANEL ELEMENTS........................................................................57

III.5.a. ECO/DIVA/LOBBY CONTROL ...............................................................................................................57

IV.3. CONNECTION OF TEMPERATURE SENSORS....................................................................................58

IV.2. VORT NRG EC DIAGRAM ....................................................................................................................58

IV. ELECTRICAL WIRING...........................................................................................................................58

IV.1. ELECTRICAL POWER SUPPLY............................................................................................................58

VI.4 CONNECTION TERMINALS - VORT NRG EC FIRST/DIVA/LOBBY.....................................................59

IV.5. Electrical connection and operation of the plate heat exchanger.........................................................60

IV.5.a. VORT NRG EC version ...........................................................................................................................60

IV.5.b. FIRST PREMIUM INFINITE AND SMART version..................................................................................60

IV.6. Auto defrost ...........................................................................................................................................61

IV.6.a. VORT NRG EC version ...........................................................................................................................61

IV.6.b. FIRST PREMIUM INFINITE and VORT NRG EC EH version..................................................................61

IV.7. Connection of the filter pressure switches ............................................................................................61

IV.8. Connection of the fan pressure switches..............................................................................................61

IV.9. Connection of pressure senders for LOBBY® ......................................................................................62

IV.10. Connection of motors ..........................................................................................................................62

IV.11. CO2 sender connection.......................................................................................................................62

IV.12. Night Cooling .......................................................................................................................................63

IV.13. Changeover coil...................................................................................................................................63

IV.14. Direct expansion coil for cooling only or reversible coil......................................................................64

IV.15. Electric heater battery..........................................................................................................................64

IV.16. Defrost heater battery..........................................................................................................................65

IV.17. Fire protection function........................................................................................................................65

IV.18. Dehumidification function ....................................................................................................................65

IV.19. MODBUS/WEB/BACNET connection..................................................................................................66

IV.20. Repeater connection............................................................................................................................66

IV.21. LON ......................................................................................................................................................67

49

Page 4

ENGLISH

V. PARAMETER DEFINITION ......................................................................................................................67

V.1. Control (integral or remote control).........................................................................................................67

V.2. Example parameter settings...................................................................................................................68

V.3. Standard settings (operator menu) .........................................................................................................68

V.3.a. Operation Mode menu ............................................................................................................................69

V.3.c. Ventilation control menu..........................................................................................................................70

V.3.b. Temperature control menu ......................................................................................................................70

V.3.d. Timer setting menu .................................................................................................................................71

V.4. Modification of operator parameters (password 3333 required)............................................................72

V.4.a. Setting different time and date clocks ....................................................................................................72

V.4.a.1. Date and time o the CORRIGO controller[(1) section V.3.d]...................................................................72

V.4.a.2. Programming system operation times [(2) (3) chapter V.3.d]..................................................................72

V.4.a.3. Vacation period [(4) section V.3.d] (password 3333 required).................................................................72

V.4.b. Modifying the speed/pressure for LS and HS operation........................................................................72

V.4.b.1. STANDARD (ECO)/DIVA [(5) section V.3.c]............................................................................................72

V.4.b.2. LOBBY [(5) section V.3.c]........................................................................................................................72

V.4.c. Modifying the temperature setpoint........................................................................................................73

V.4.d. Forced shutdown of control panel or forced LS or HS run of remote control .......................................73

V.4.e. Language selection .................................................................................................................................73

V.5. Intermediate settings (function level) ......................................................................................................73

V.5.a. Configuration menu with function level access ......................................................................................73

V.5.b. Modification of function parameters (password 2222 required).............................................................74

V.5.b.1. System control mode ...............................................................................................................................74

V.5.b.2. Ventilation parameters.............................................................................................................................74

V.5.b.3. CO2 setpoint for DIVA QUATTRO option ................................................................................................74

V.6. Administrator settings.............................................................................................................................74

V.6.a. Configuration menu with admin level access .........................................................................................75

V.7. Modification of function parameters.......................................................................................................75

V.7.a. MODBUS.................................................................................................................................................75

V.7.a.1. Repeaters and EXO communication .......................................................................................................76

V.7.a.2. WEB communication ...............................................................................................................................76

V.8.a.3. BACNET IP communication with BASC type ..........................................................................................76

V.8.a.4. LON communication (if CORRIGO with LON option)..............................................................................77

V.8.a.5. Activation of fire protection function.........................................................................................................77

V.8.a.6. Activation of the dehumidification function ..............................................................................................77

VI. PROBLEM SOLVING.............................................................................................................................78

VI.1. Different types of fault ...........................................................................................................................78

VI.2. Alarms list ..............................................................................................................................................79

VI.3. Cancelling the “Servicing required” alarm ............................................................................................80

VII. MAINTENANCE ....................................................................................................................................81

VII.1. Essential maintenance..........................................................................................................................81

VII.2. Battery replacement .............................................................................................................................81

VIII. APPENDICES .....................................................................................................................................82

VIII.1. Control diagram ...................................................................................................................................82

VIII.2. Connection of motors for VORT NRG EC / EC EH 600 - 800 ............................................................83

VIII.3. Connection of motors for VORT NRG EC / EC EH 1500-2000-2500 .................................................84

VORT NRG EC / EC EH 1500........................................................................................................................85

VORT NRG EC / EC EH 800..........................................................................................................................85

VORT NRG EC / EC EH 600..........................................................................................................................85

50

Page 5

ENGLISH

III.4. Curves..................................................................................................................................................85

V

VORT NRG EC / EC EH 2500........................................................................................................................86

ORT NRG EC / EC EH 1800........................................................................................................................86

V

VIII.5. MODBUS and BACNET table..............................................................................................................87

VIII.5.a. MODBUS information ..........................................................................................................................87

VIII.5.b. BACNET description............................................................................................................................89

VIII.5.c. TABLE...................................................................................................................................................91

INPUT REGISTER................................................................................................................................................91

HOLDING REGISTER ..........................................................................................................................................92

IX. NOTES...................................................................................................................................................94

INPUT STATUT REGISTER .................................................................................................................................94

51

Page 6

ENGLISH

SAFETY INSTRUCTIONS

In compliance with the current standards, the machine should be installed only by technical personnel who are

qualified to work on equipment of this type.

Use the required personal protection equipment to avoid risk of injury from electrical, mechanical (injury from contact

ith steel sheets, sharp edges, etc.) eye protection (UVC hazard; wear goggles to EN170) or noise hazards.

w

Do not use this equipment for any purpose other than that for which it is designed. This machine may be used

exclusively for the distribution of air that is free of hazardous substances.

he machine should be handled in accordance with the indications given in the relative section of this manual.

T

The machine must be connected to earth in accordance with the applicable regulations. Never start a unit that has

not been connected to earth.

Before carrying out any work on a unit, make sure that its is switched off and before opening panels or doors, wait

until all the moving parts have come to a stop (damper, fan and rotary heat exchanger).

During operation, all panels, inspection hatched and doors must always be fitted and closed.

The unit must only be started or stopped using the proximity switch.

Safety and control devices must not be removed, by-passed or deactivated.

When working on the unit, be aware that certain components can reach high temperatures (water coil or electric

heater).

The system must be installed in accordance with fire prevention regulations.

All waste materials must be disposed of in accordance with the applicable regulations.

The manufacturer accepts no liability for damages ensuing from the incorrect use of the equipment, unauthorized

repair or modification, or failure to follow the instructions given in this manual.

I RECEIVING THE EQUIPMENT

Systems are supplied fixed to guides or plates and wrapped in plastic film.

I.1 Checks on receipt

On receipt of the equipment, carefully inspect the packaging and the contents. If damaged, record an accurate

description of the damage on the delivery note.

I.2 Unpacking

When unpacking the equipment, check the following:

- The total number of packages is present.

- All the accessories (dampers, covers, electrical equipment. etc.) ordered are present.

After unpacking the equipment, all packaging materials should be disposed of in accordance with the applicable

regulations.

Dispose of waste materials responsibly.

I.3 Storage

The equipment must be stored in a dry enclosed area, at a temperature between -20 and 40°C; note that the packaging

does not offer sufficient protection against bad weather.

II INSTALLATION

II.1 Handling

The units must only be moved to their installation position.

If the equipment is handled using a fork-lift truck, ensure the forks support the load-bearing structure. Check that the load

capacity of the handling equipment used is suitable for the weight of the equipment received (refer to the weight data in

the manual).

If the equipment is handled using a crane, use 4 lifting ropes of the length indicated. The ropes must be at least as long

as the greatest distance between two attachment points.

_

If the length + width + height > 5 metres

the packing crate must lifted using a sling bar.

52

Page 7

ENGLISH

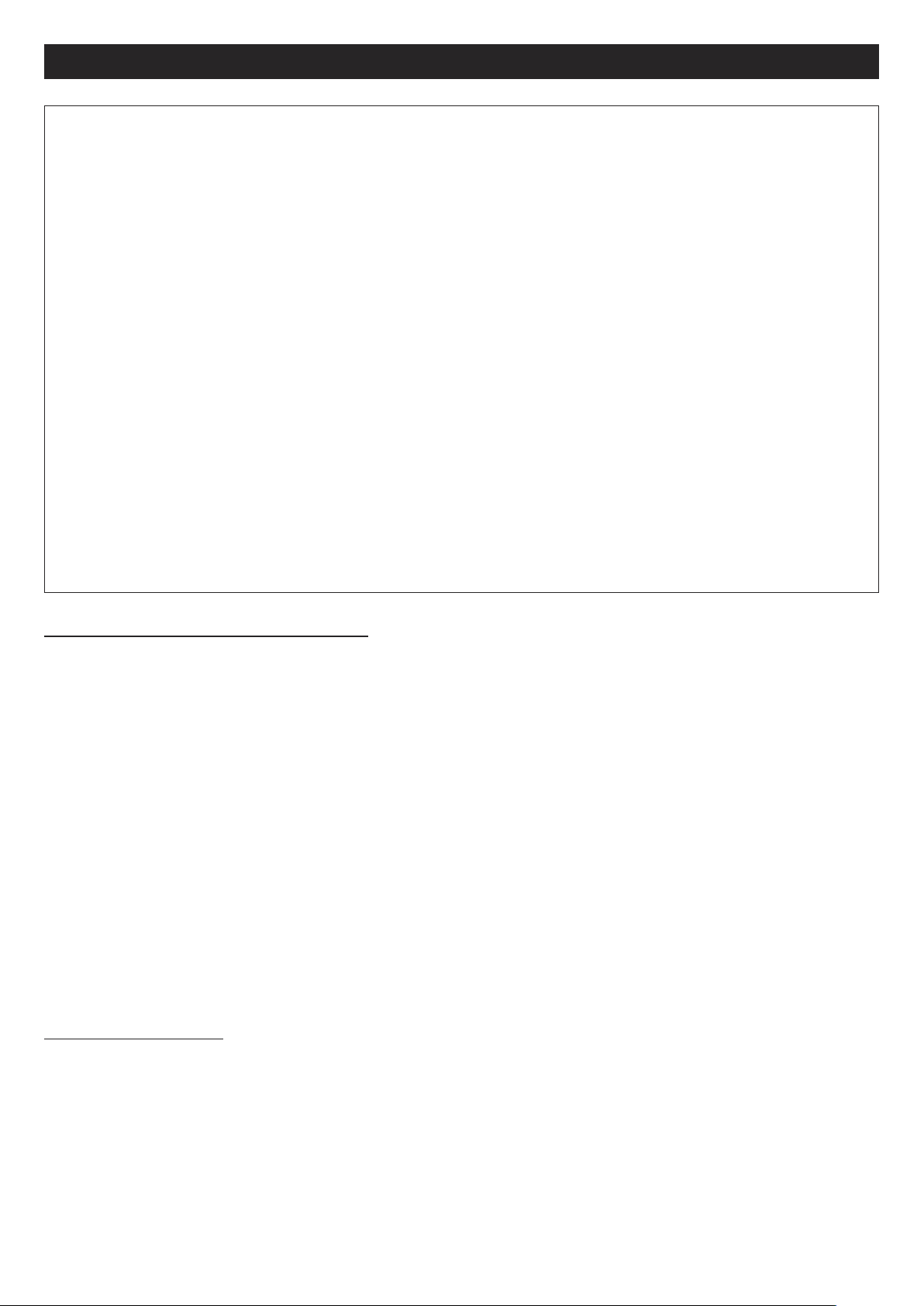

II.2 Space required

Generally there should be a free space of at least half the width of casing at each side to allow access for maintenance.

hese units require a siphon and therefore must be installed at a sufficient height to allow this to be installed.

T

dimensions

600 400 490 225 470 - - - - - - 135

00

8

1500 520 850 380 670 1170 510 510 795 735 660 275

2000 520 430 435 670 1115 580 580 915 725 635 295

NRG EC / EC EH

2500 690 430 435 1020 1235 580 580 840 785 770 405

L1

mm mm mm mm mm mm mm mm mm mm kg

00640

4

L2

Heat exchangerL2Fan

20

3

L2

CO coil

60

5

M1 M2 M3 F1 F2 F3

- - - - - - 2

Weigh

ts

00

dimensions

600 250 1700 780 330 160 370 150 50 145 170 170 645

800 315 2020 965 415 210 460 150 50 145 250 250 780

1500 355 2190 1220 415 190 600 430 50 425 250 250 880

2000 400 2275 1220 495 245 600 430 50 425 330 330 885

NRG EC / EC EH

2500 400 2395 1740 495 235 910 430 50 425 330 330 985

mm mm mm mm mm mm mm mm mm mm mm mm

A B C D E G G1 G2 J K M

53

Page 8

ENGLISH

II.3 Positioning

The system must be suspended above or supported on a sufficiently rigid surface (use a vibration damping mounts if

ecessary). For ductwork connections, select duct sections to suit the dimensions of the flexible hoses, which should be

n

properly tensioned. The ducts should be insulated and the first accessories should be installed at a distance of 2.5 times

the duct diameter from the unit (T junction, etc.). Install the unit in such a way that internal components cannot be

damaged by bad weather or ambient temperature either during the installation or subsequent use of the unit.

Install a siphon on each condensate drain pipe.

condensate drain pipe. Caution: the siphons must be connected in the correct manner in order to

nsure that the condensate can drain freely.

e

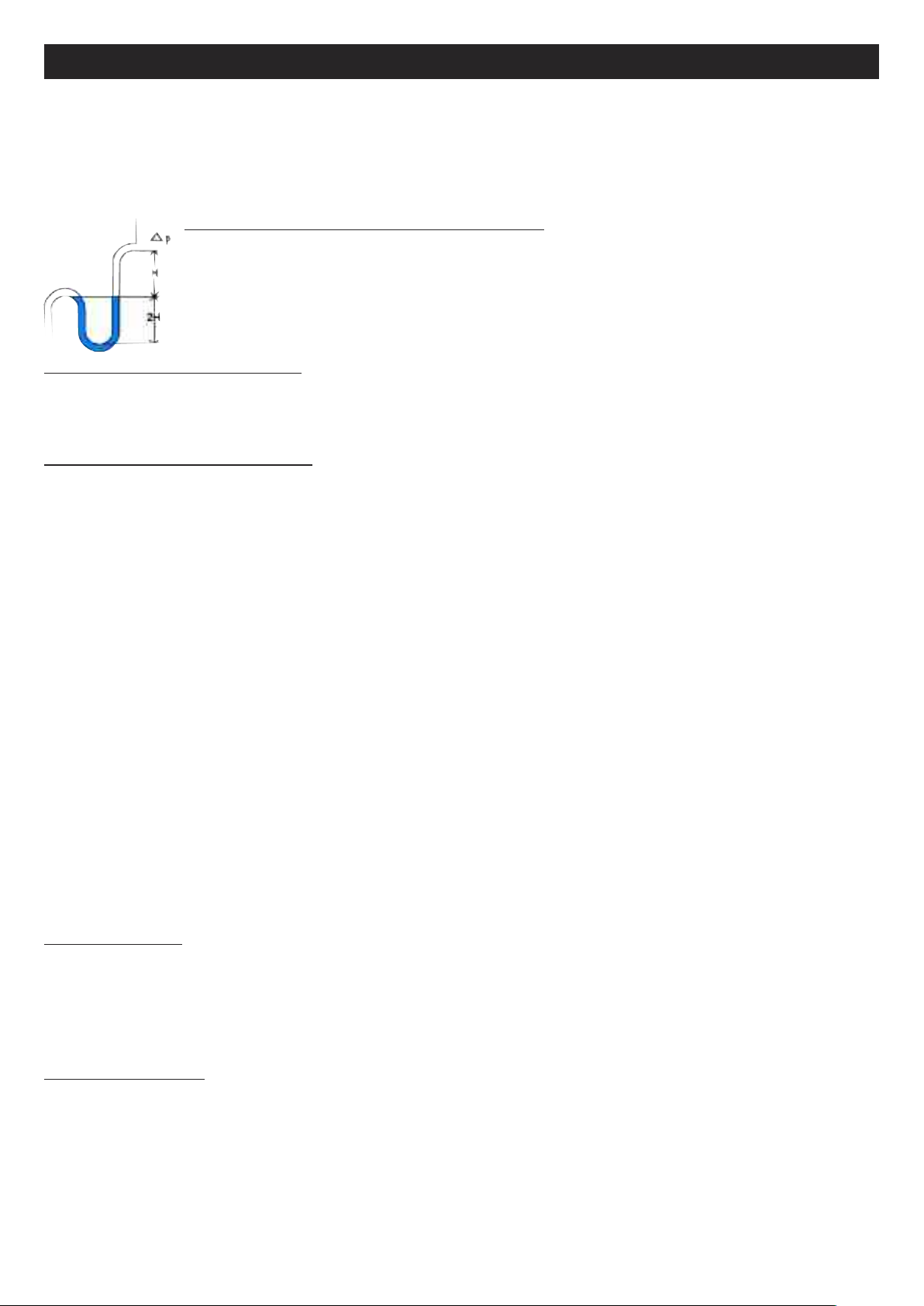

The value H must correspond (in mm) to at least the maximum internal negative pressure of the

system x 1.

Example: Dp = 500 Pa = 50 mm CE

_

H > 50 mm 2H > 100 mm

Installation of systems in ceilings: units can be suspended on threaded rods. They can also be supported on a frames

attached to the structure of the building, provided that the frames have sufficient load capacity (frames to supplied by the

installer).

A siphon must not be used for more than one

III GENERAL OPERATION

III.1 GENERAL

The VORT NRG EC EC/EH 600-2500 range consists of a programme of dual-flow systems with self-regulating energy

recovery, with high efficiency and high performance, designed for the service sectors and industrial installations.

Performance exceeds 90%.

VORT NRG EC: Management of fans by potentiometer and bypass. Cannot be used with coils.

VORT NRG EC FIRST: Econological management of fans and the bypass. Allows management of a non-integrated coil

changeover (or a hot water coil and/or a cold water coil non-integrated) or an electrical non-integrated heater battery. On

request, it can be adapted for use with a non-integrated electrical heater battery and a non-integrated cold water coil.

VORT NRG EC PREMIUM BC: Econological management of fans and the bypass. Integral changeover coil.

VORT NRG EC PREMIUM BE: Econological management of fans and the bypass. Integral electrical heater battery and

provision for the addition of an extra non-integrated cold water coil.

VORT NRG EC INFINITE BC: Econological management of fans and the bypass. Integral changeover coil and integral

defrost coil.

VORT NRG EC INFINITE BE: Econological management of fans and the bypass. Integral electrical heater battery and

integral defrost coil and provision for the addition of an extra non-integrated cold water coil.

VORT NRG EC EH: Econological management of fans and the bypass. Integral defrost heater battery and provision for

the addition of one non-integrated changeover coil or (one non-integrated hot water and/or one non-integrated cold water

coil).

III.2 OPERATING SEQUENCE

Except VORT ENERGY EC versions

Start-up sequence:

• The recovery fan or VAR pressure monitoring mode starts at the same moment the fresh air damper is operated.

• The blower fan or VAR pressure monitoring mode starts at the same moment the recovery air damper is operated.

• Temperature control starts in accordance with the configured control mode. Electrical heating (if configured) starts on

the flow controller only (flow reversal). Pumps that have not yet been activated will start up.

• The alarm management function is activated after the pre-set time period. At this point the system is operating in

normal mode.

Conditions for startup:

The system starts up when one of the following conditions is met:

• The programmed schedule (timer) for normal speed or low speed operation is on “Run”.

• The system is started manually from the CORRIGO controller.

• One of the digital inputs for forced run is activated.

54

Page 9

ENGLISH

!

Shutdown sequence:

The system shutdown procedure is as follows:

• Deactivation of the alarm management function.

• Deactivation of electrical heating (if configured).

After a certain time interval (individually pre-set for each fan), the fans are switched off.

•

• The fresh air and return air dampers are closed.

• The signals sent to the actuators are re-set to zero and the pumps are stopped.

Conditions for shutdown:

The system shuts down when one of the following conditions is met:

• The programmed schedule (timer) for normal speed or low speed operation is on “Stop” and the forced run signal is

also on “Stop”.

• Activation of the external shutdown command.

• The system is shut down manually from the CORRIGO controller.

• Intervention of an alarm configured with the supplementary shutdown function. The system will restart automatically

once the alarm has been reset.

III.3 CONTROL MODES

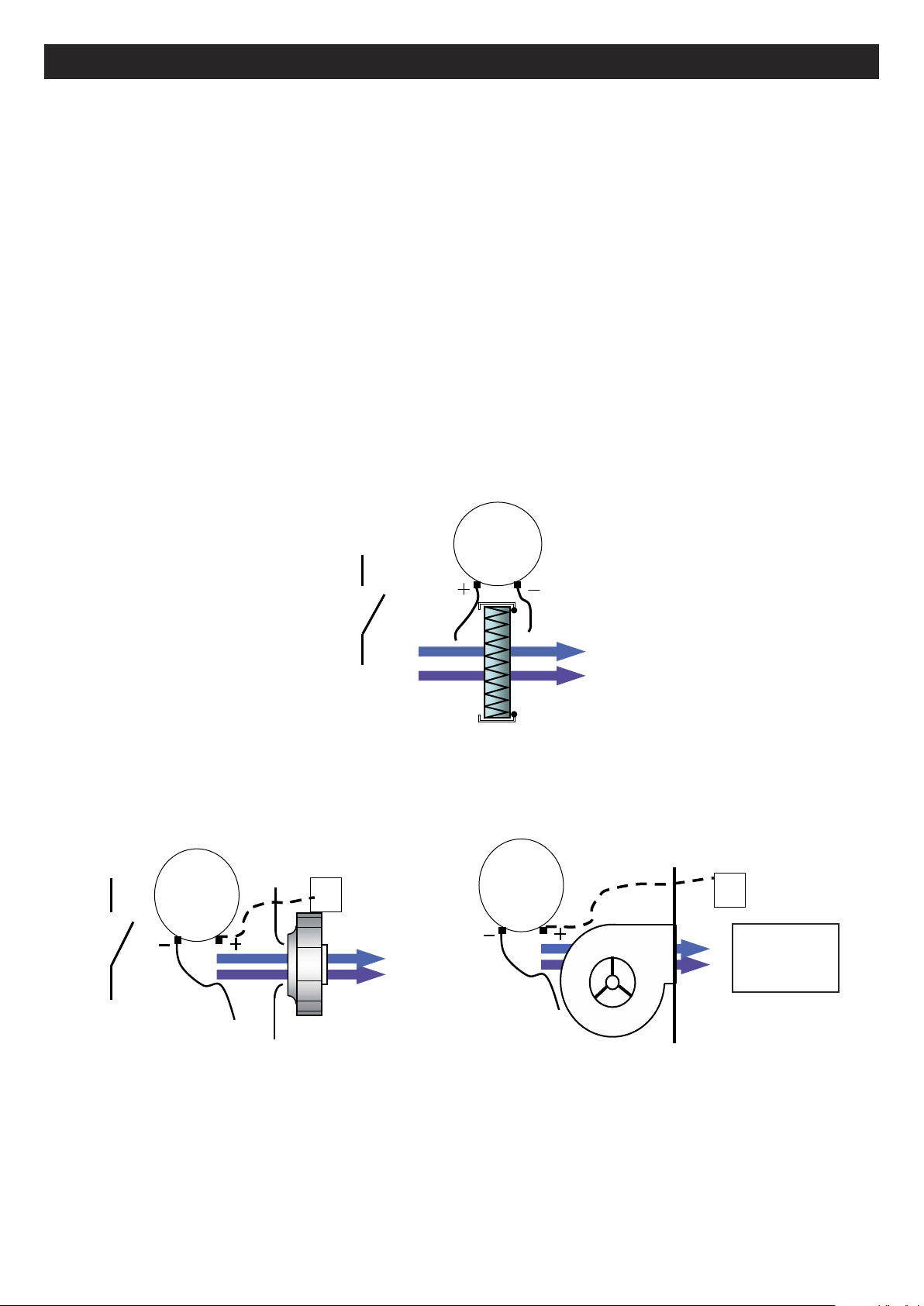

III.3.a. VORT NRG EC

1 speed that can be controlled by potentiometer

Each fan can be controlled individually by a potentiometer integrated in the system.

Possibility to add a remote forced shutdown control connected in series to the contactor (not supplied).

III.3.b. ECO:

1 or 2 speeds that can be controlled via the display/remote control/external control “VENTIL. MODE (%)”

Setting of a minimum speed (LS - 1/2) and a maximum speed (HS - 1/1 as %.

Pa

GV Speed

Equipped with factory-set timer:

• (HS - 1/1) from 06:00 to 22:00

• (LS - 1/2) from 22:00 to 06:00

PV Speed

Possibility to add a remote forced run control (LS - 1/2) or (HS - 1/1)

Possibility to add a remote forced shutdown control

III.3.c. DIVA

Proportional ventilation between two flow rates (HS/LS) with “AUTOMATIC CO2CONTROL MODE”.

Setting of a minimum speed (LS - 1/2) and a maximum speed (HS - 1/1) as %.

The CO2setpoint is factory-set to 1000 ppm (in accordance with RT2012).

The transition between (LS - 1/2) and (HS - 1/1) is controlled in accordance with the CO

level.

Equipped with continuous run factory-set timer (LS - 1/2).

Possibility to add a remote forced run control (LS - 1/2) or (HS - 1/1) (NO volt-free contacts)

Possibility to add a remote forced shutdown control (NO volt-free contacts)

Note: In order for the CO2 control to function correctly, the system must meet the following conditions:

• Timer (HS - 1/1) on 0 (inactive) (Normal speed timer)

• Timer (LS - 1/2) in operation (Low speed timer)

• Forced run (HS - 1/1) and Forced shutdown not activated.

Pa

2

PV flow rate

GV Speed

PV Speed

flow rate

flow rate

III.3.d. LOBBY

®

Constant ventilation pressure. (Pa) “CONSTANT Pa MODE”

Setting a constant pressure (Pa).

Equipped with continuous running factory-set timer (LS - 1/2);

Possibility to add a remote forced run control (LS - 1/2)

Possibility to add a remote forced shutdown control

Pa

Constant pressure

flow rate

55

Page 10

ENGLISH

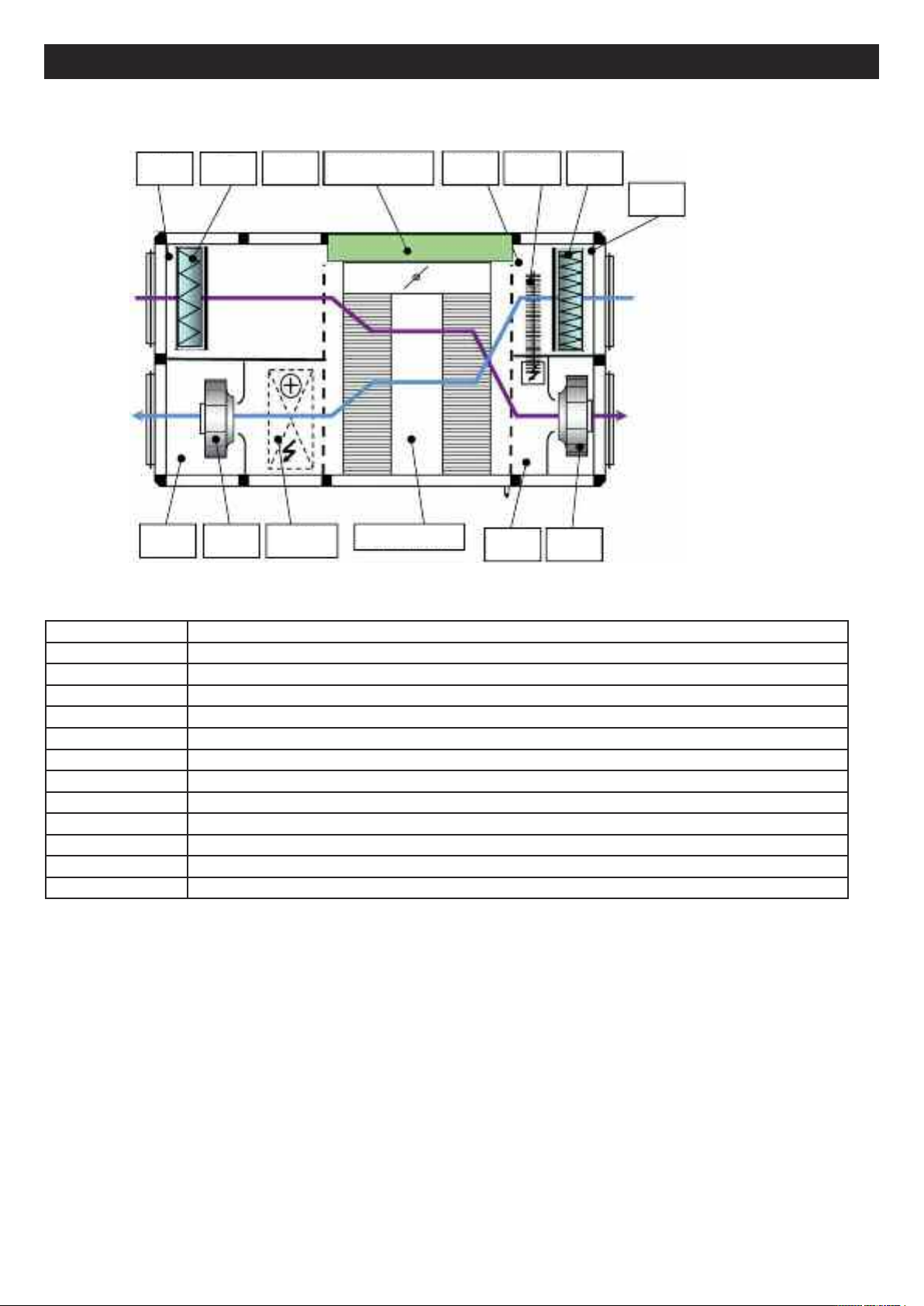

III.4. COMPOSITION

SRG

SSG VS

FR SM

CO/BE

CONTROLS

HEAT EXCHANGER

The sensor group is not integrated in the SEASON version

SBD DBE

SDG

FS

SEG

VR

NAME Description

VS Blower fan

VR Recovery fan

SSG Recovery air pressure switch or recovery air pressure sender for LOBBY version

SDG 230/24 V power transformer

SEG Duct recovery sensor

SRG CO2sensor (DIVA version only)

SDB Lockable proximity switch

FS Supply filter

FR Recovery filter

SM 100% bypass servomotor

CO/BE Changeover heater battery or electric heater battery (depending on version)

DBE Defrost heater battery for INFINITE model only

56

Page 11

ENGLISH

II.5. POSITIONING OF THE CONTROL PANEL ELEMENTS

I

III.5.a. ECO/DIVA/LOBBY CONTROL

N° NAME Description

1 DEPFS Supply filter pressure switch

2 DEPS or TRPS Supply pressure switch or supply pressure sender for LOBBY version

3 DEPR or TRPR Recovery air pressure switch or recovery air pressure sender for LOBBY version

4 TRAFO 230/24 V power transformer

5 SRG Duct recovery sensor

6 CO2 CO2sensor (DIVA version only)

7 IPC Lockable proximity switch

8 K1 Electrical heating coil contactor

9 KD Contactor for the electric defrost heater battery

10 CONTROLLER CORRIGO E283W3 Controller

11 TERMINAL BOARD Control terminal board

12 THA/THS/THSD The overheating and antifreeze thermostats are integrated in the panel

III.5.b. SEASON CONTROL

N° NAME Description

1 DEPFS Supply filter pressure switch

2 DEPS Supply pressure switch

3 DEPR Recovery pressure switch

4 IPC Lockable proximity switch

5 THD Defrost thermostat (+5°C)

6 TERMINAL BOARD Connection terminals

7 TH2 Summer setpoint thermostat for bypass closure

8 TH1 Winter setpoint thermostat for bypass closure

57

Page 12

ENGLISH

IV. ELECTRICAL WIRING

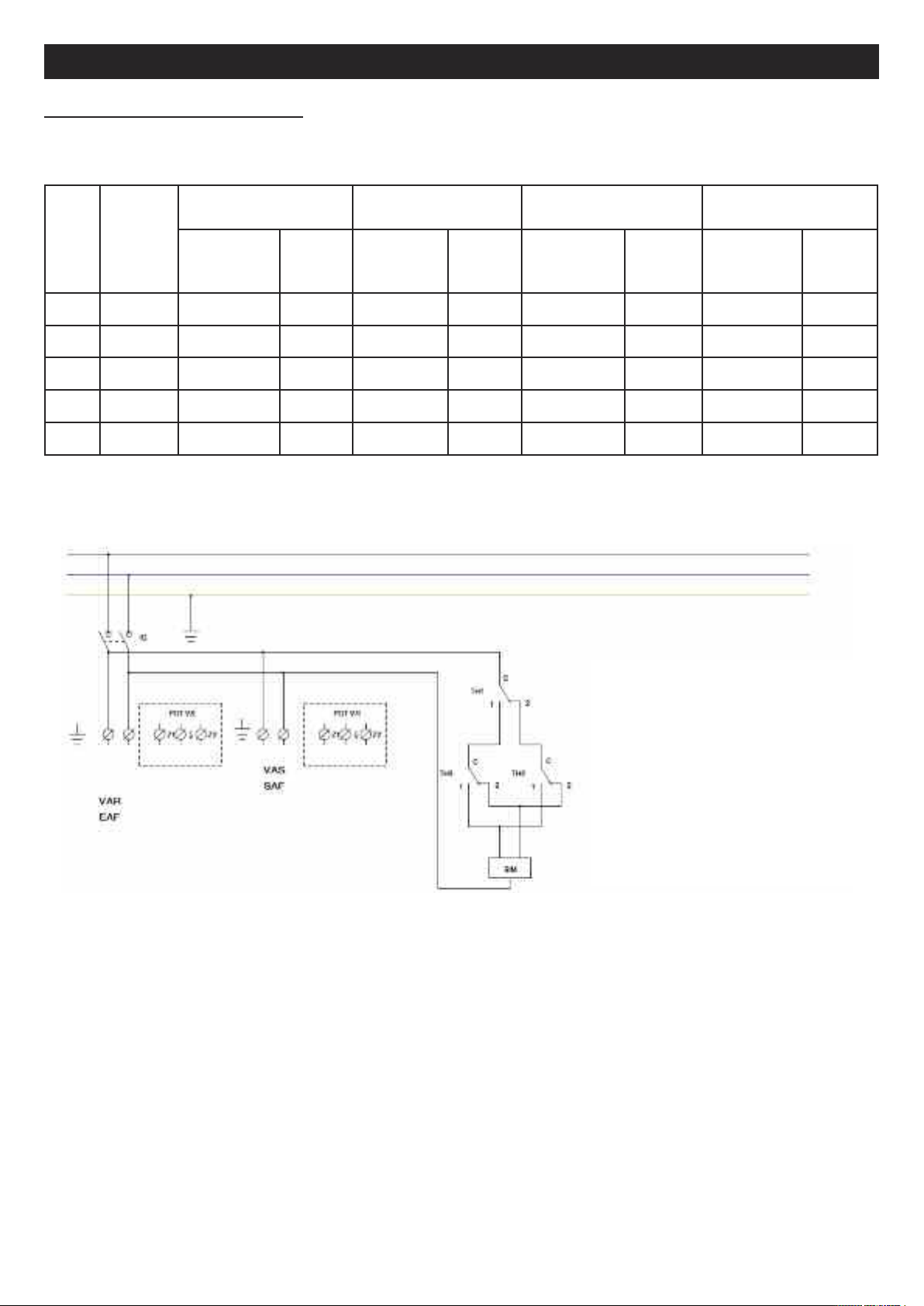

IV.1. ELECTRICAL POWER SUPPLY

Electric

motor

Model

600 2 x 169W 230 / 1 / 50 2.8 230 / 1 / 50 8.2 230 / 1 / 50 8.2 230 / 1 / 50 13.7

800 2 x 220W 230 / 1 / 50 3.4 230 / 1 / 50 14.3 230 / 1 / 50 11.0 230 / 1 / 50 21.9

1500 2 x 400W 230 / 1 / 50 8.6 230 / 1 / 50 23.8 230 / 1 / 50 19.5 230 / 1 / 50 34.7

2000 2 x 400W 230 / 1 / 50 8.6 230 / 1 / 50 24.9 230 / 1 / 50 24.9 400 / 3+N / 50 15.1

2500 2 x 400W 230 / 1 / 50 8.6 230 / 1 / 50 31.4 230 / 1 / 50 31.4 400 / 3+N / 50 19.5

power

rating

(W)

VORT NRG EC

FIRST & PREMIUM BC

ower supply

P

voltage

(V / Ph / Hz)

rotection

P

rating

(A)

INFINITE CO

& VORT NRG EC EH

ower supply

P

voltage

(V/Ph/Hz)

P

rotection

rating

(A)

PREMIUM BE INFINITE BE

ower supply

P

voltage

(V/Ph/Hz)

rotection

P

rating

(A)

ower supply

P

voltage

(V/Ph/Hz)

P

IV.2. VORT NRG EC DIAGRAM

rotection

rating

(A)

TH1= External temperature for heat recovery via

heat exchanger (factory setting: 18°C)

TH2= External temperature for cold recovery via

heat exchanger (factory setting: 24°C)

TH3= Temperature of emission for defrost via

bypass (factory setting: 5°C) -> Do not change this

setting

IV.3. CONNECTION OF TEMPERATURE SENSORS

Except VORT NRG EC version

The temperature sensors are connected directly to the controller

• SSG : Duct supply sensor connected to Agnd(30) and AI1(31)

• SEG : Duct external sensor connected to Agnd(30) and AI1(32)

• SDG : Duct defrost sensor connected to Agnd(33) and AI1(34)

• SRG : Duct recovery sensor connected to Agnd(33) and AI1(35)

• SBD : Defrost heater battery sensor connected to Agnd(36) and AI4(37) on SMART and INFINITE versions (replaced

by 1030 Ohm resistance on other versions)

58

Page 13

ENGLISH

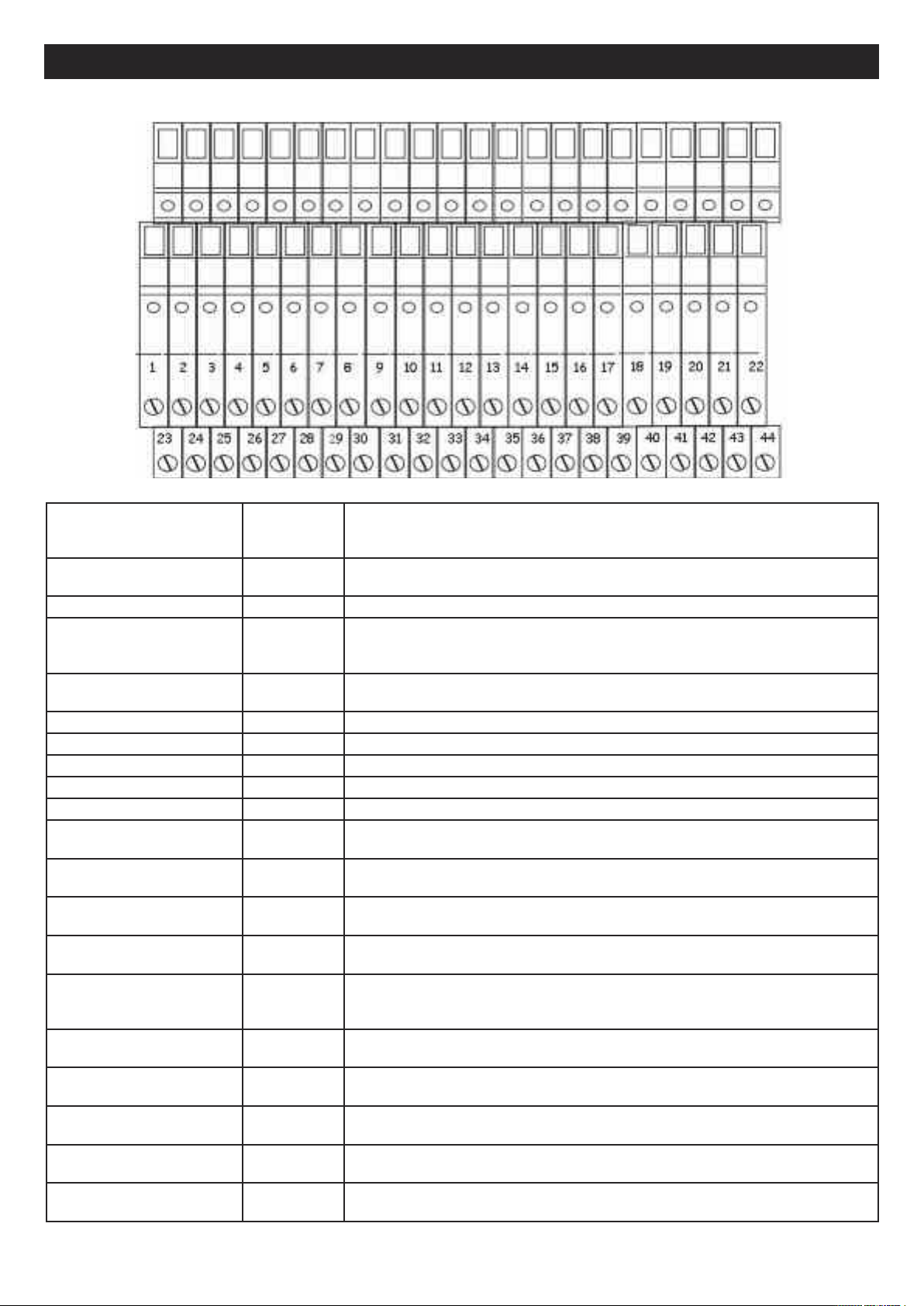

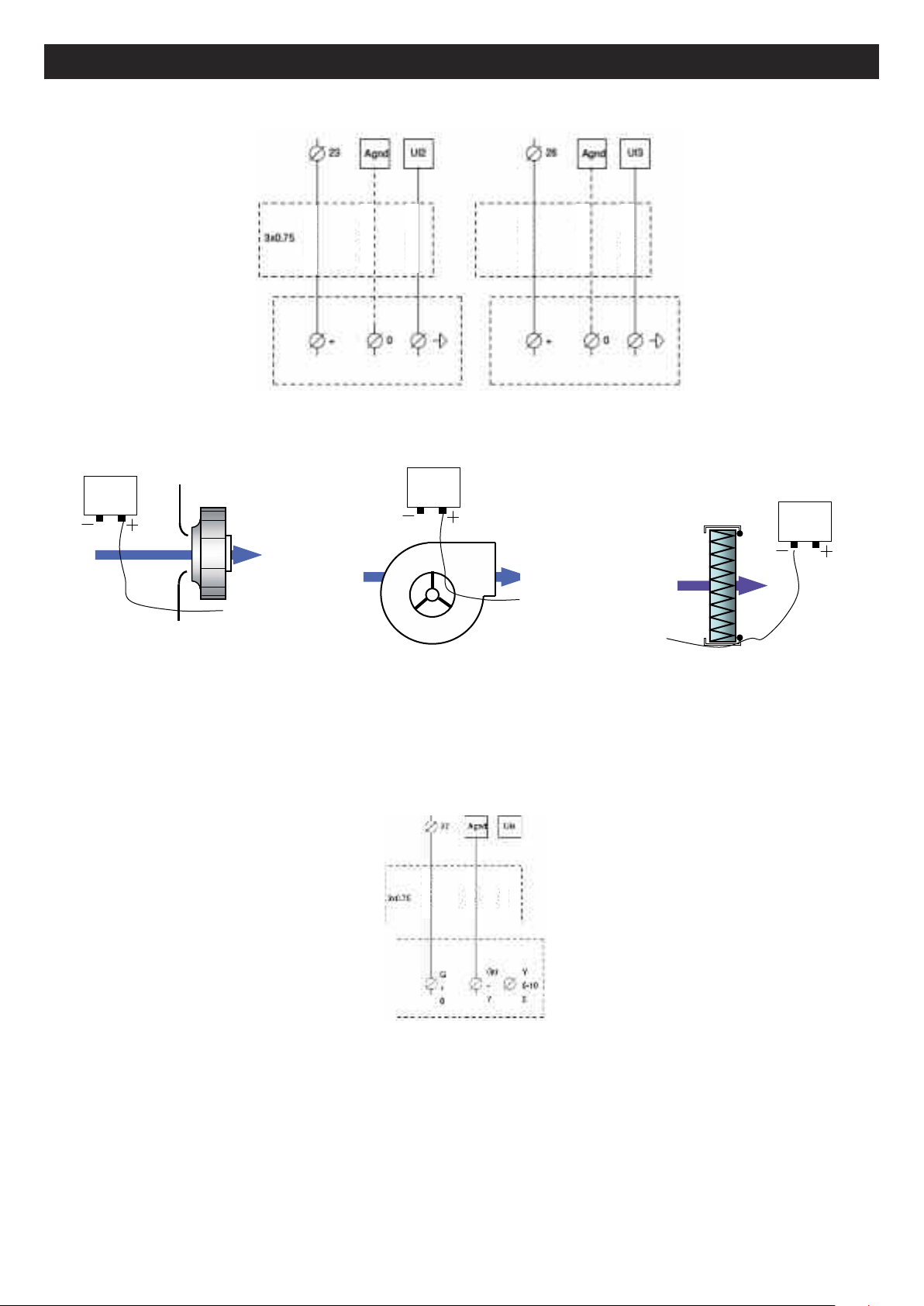

VI.4 CONNECTION TERMINALS - VORT NRG EC FIRST/DIVA/LOBBY

Description Terminals Connection

ADP

(bridge if not used)

DAD (bridge if not used) 3-4 Connect to the DAD fault contact

THA/THS

(bridge if not used)

ED-TOUCH 7-8 + A*-B*

MF PV 9-10 Connect to the NO voltage-free Low Speed Forced Run contact

MF GV 11-12 Connect to the NO voltage-free High Speed Forced Run contact

ARR EST 13-14 Connect to the NO voltage-free External Forced Shutdown contact

BC 15-16-17 BC: Connect to the 3-way valve of the hot water coil (see section IV.12)

BE 18 + DO3** BE: Connect to the static contactor of the electric heater battery (see section IV.14)

Heating pump (PREMIUM

BC)

Cooling pump

(PREMIUM BC)

AL 20 + DO5** 24 V output available if the system is faulty (Caution: max. 24 V 2 A to be connected

DBE 21 + DO6** Connect to the terminals of the contactor for the defrost heater battery (see section

NC (Night cooling)

(LOBBY®)

TRPS (LOBBY®) 23 Agnd* +

DEPS 24 + UI2* Connect to terminals 1 and 3 of the supply DEP (see section IV.8)

1-2 To be connected to the terminals of a firefighter remote shutdown NF contact

5-6 Connect to the NF contact of the THA (PREMIUM CO and INFINITE CO)

Or

Connect to the NF contact of the THA (PREMIUM BE and INFINITE BE)

Connect to the touch screen remote control

(port2)

18 + DO3** Connect to the M/A of the hot water pump (Caution: max. 24 V 2 A to be connected

via relay) (see section IV.12)

19 + DO4** Connect to the M/A of the cold water pump (Caution: max. 24 V 2 A to be

connected via relay)** (see section IV.12)

via relay)

IV.15)

22 + DO7** 24 V output available if the system is configured with the LOBBY EC option for

opening the terminal dampers during Night Cooling operation. (Caution: max. 24 V 2

A to be connected via relay)

Connect to the supply pressure sender (see section IV.9)

UI2*

TRPR (LOBBY®) 25 Agnd* +

UI3*

DEPR 26 + UI3* Connect to terminals 1 and 3 of the return DEP (see section IV.8)

CO2 27 Agnd* UI4* Connect to the CO2 sensor (see section IV.10). For DIVA option.

Connect to the recovery pressure sender (see section IV.9)

59

Page 14

ENGLISH

Description Terminals Connection

BF 28-29-30 BF: Connect to the 3-way valve of the cold water coil (see section IV.12)

DEP FS

DEP FR

RMS 35 + DO1** Connect to terminals 1 and 2 of the motorised supply damper

RMR 36 + DO2** Connect to terminals 1 and 2 of the motorised recovery damper

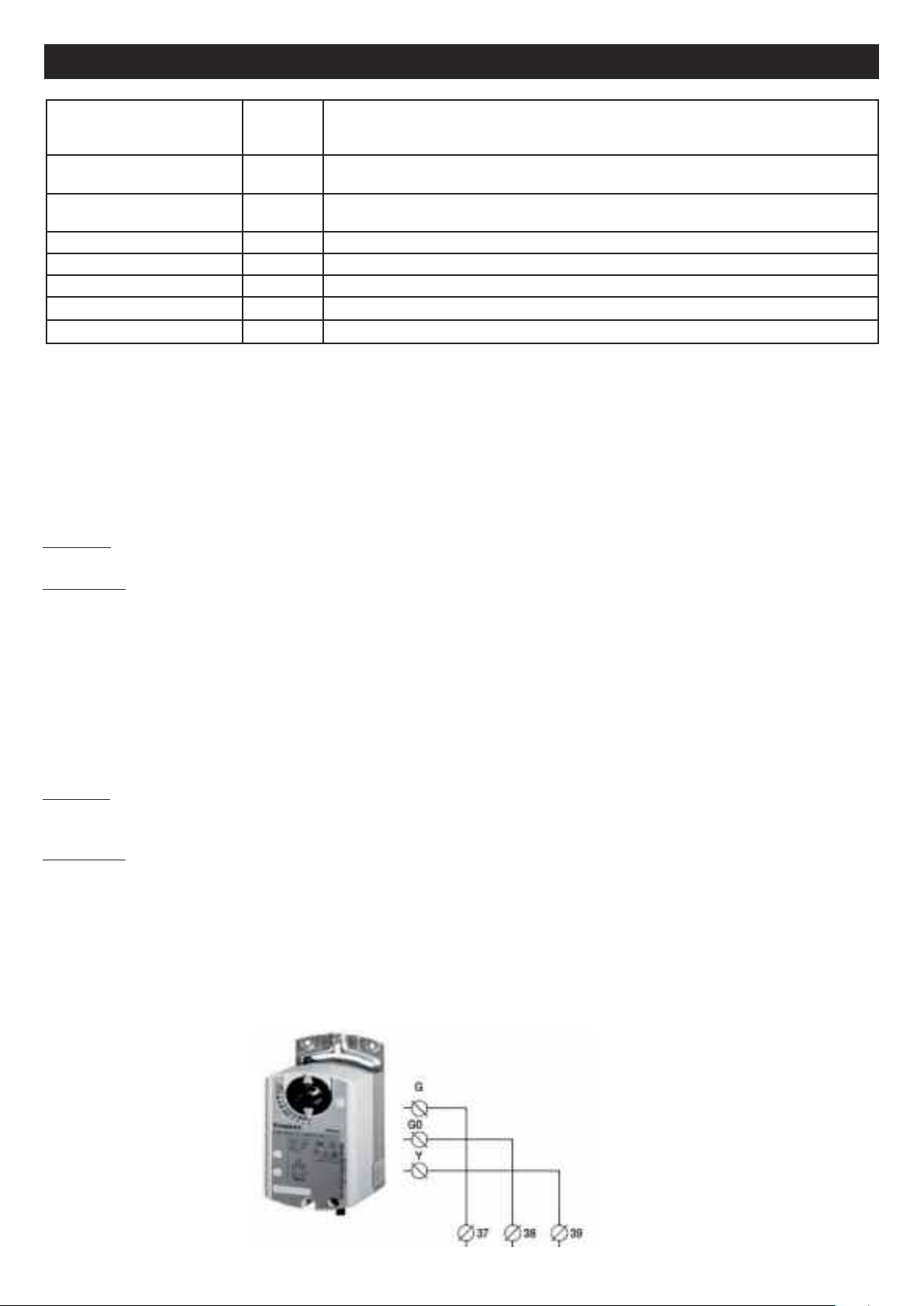

BIM 37-38-39 Connect to the servo of the motorised bypass (see section IV.5.b)

0-10V S 40-41 Connect to the fan or to the supply variator (see sections VIII.2 and 3)

0-10V R 42-43 Connect to the ventilator or the recovery variator (see sections VIII.2 and 3)

31-32

33-34

Connect to terminals 1 and 3 of the DEP Supply Filter (see section IV.7)

Connect to terminals 1 and 3 of the DEP Recovery Filter (see section IV.7)

* Connect directly to the CORRIGO controller

** Connect directly to the CORRIGO controller and to the DO group (max. 8 A)

IV.5. Electrical connection and operation of the plate heat exchanger

IV.5.a. VORT NRG EC version

The heat exchanger bypass is connected in the factory (see diagram in section IV.2)

The automatic operation of the bypass is controlled by two thermostats:

In winter: If the outside temperature is below 18°C (adjustable), the bypass is closed to recover the maximum amount of

heat.

In summer:

COLD RECOVERY : If the outside temperature is greater than 24°C (adjustable) the bypass is closed to recover the

maximum amount of heat.

FREE COOLING: If the temperature is between 24° and 18° (adjustable), the bypass is opened to allow outside air to flow

in directly

IV.5.b. FIRST PREMIUM INFINITE AND SMART version

The heat exchanger bypass is connected in the factory

Its operation is automatically controlled by the CORRIGO controller and the temperature sensors installed as standard in

our VORT NRG EC systems

In winter: When there is a request for a temperature increase, the bypass closes gradually until fully closed to recover the

maximum amount of heat. In cases where this is not sufficient to reach the set temperature, the heater battery will come

into operation.

In summer:

COLD RECOVERY: If the outside temperature is greater than the inside temperature and there is a request to reduce the

temperature, the bypass closes gradually until fully closed to recover the maximum amount of heat.

In cases where this is not sufficient to reach the set temperature, the cooling coil will come into operation.

FREE COOLING : If the outside temperature is below the inside temperature and there is a request to reduce the

temperature, the bypass opens by a suitable amount (until fully open) so as to allow fresh outside air to enter the building.

In cases where this is not sufficient to reach the set temperature, the cooling coil will come into operation.

60

Page 15

3

1

DEPFR

DEP FS

ENGLISH

DEP

DEP

**

1

3

IV.6. Auto defrost

V.6.a. VORT NRG EC version

I

Defrosting is achieved by opening the bypass the moment the defrost temperature (SDG) falls below 5° C (thermostat

nstalled on exhaust duct). The moment the temperature exceeds the threshold value of +5° C, the bypass re-closes.

i

IV.6.b. FIRST PREMIUM INFINITE and VORT NRG EC EH version

his non-modifiable function is automatically controlled by the CORRIGO controller program and by the sensors fitted as

T

standard in all our dual flow systems. Defrosting is achieved by opening the bypass the moment the defrost temperature

(SDG) falls below 5° C (sensor installed on exhaust duct). If opening the bypass is not sufficient to defrost the heat

exchanger (if the outside temperature is below -10° C), the flow rate of the fresh air fan will be modulated to maintain the

temperature at the defrost sensor at 5° C.

For INFINITE BE and INFINITE BC versions: the defrost heater battery is installed next to the fresh air intake, upstream

of the plate heat exchanger. This maintains the temperature at the heat exchanger at –5°C, thereby reducing the risk of

frost forming while keeping the bypass as closed as possible. This ensures that the system operates at maximum

efficiency. If the action of the defrost heater battery is not in itself sufficient to defrost the heat exchanger, first bypass

modulation and then fan modulation will be implemented, as described above.

IV.7. Connection of the filter pressure switches

The fresh air filter pressure switch is installed and wired in the factory.

IV.8. Connection of the fan pressure switches

The fan pressure switches are wired and aeraulically connected in the factory

*To be

connected if the

DEP does not

detect operation

61

Page 16

TRPS

TRPS

TRPS

ENGLISH

IV.9. Connection of pressure senders for LOBBY®

IV.10. Connection of motors

See sections VIII.2 and VIII.3

WHITE

BROWN

GREEN

BROWN

WHITE

GREEN

LOBBY power supply

Connect to the duct

IV.11. CO2 sender connection

The CO2 sender is factory wired (DIVA option)

White

Brown

Green

62

Page 17

ENGLISH

IV.12. Night Cooling

This function is used in summer to cool building interiors at night using outside air. This helps reduce the quantity of cold

ir required during the daytime. The Night Cooling function only operates from 00:00 to 07:00. During Night Cooling, the

a

hot and cold outputs are locked to 0 V. The heat exchanger delivers exclusively fresh air. On termination of the Night

Cooling stage, the heating is locked to 0V for 60 minutes.

Conditions of operation: definable parameters in section V.5.b.2

• The external temperature exceeds 22° C during daytime

• The timers are set to PV and for shutdown between 00:00 and 07:00.

The external temperature is below 18° C during Night Cooling operation

•

• The external temperature exceeds 10° C during Night Cooling operation

• The ambient room temperature exceeds 18° C

During Night Cooling, the fans run at 85% of full speed. This speed is settable (see section V.5.b.2).

For LOBBY versions, a 24 V output (to be connected by relay) is available across terminals 22 and DO7 to force opening

of the area dampers during Night Cooling.

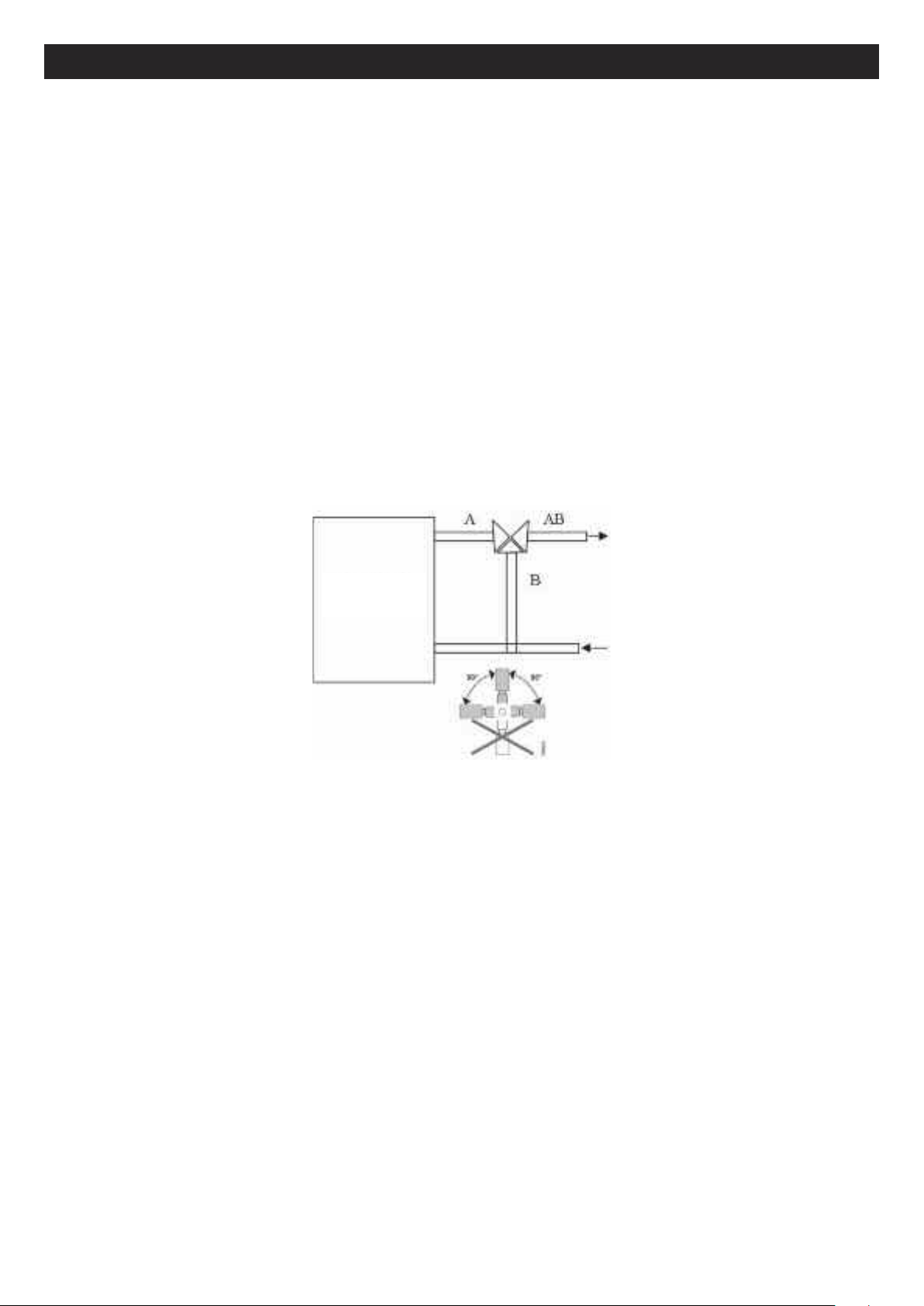

IV.13. Changeover coil

For PREMIUM BC and INFINITE BC systems. Provision must be made for collection of condensate via a siphon.

Be careful not to impede opening of the access doors (with pipes, cables, etc.)

The coil is already installed in the system, the antifreeze thermostat is connected. The 3-way valve must be connected

electrically. If a cooling or changeover battery is used in the duct, move the supply sensor downstream of the coil.

COILS

THE VALVE MUST ONLY BE CONNECTED WHEN THE ELECTRICAL CIRCUIT IS POWERED OFF

Connect the servomotor of the 3-way valve as follows:

Heater battery:

Terminal 15 to +24 V (G) of the valve servomotor

Terminal 16 to 0 V (G0) of the valve servomotor

Terminal 17 to +10 V (Y) of the valve servomotor

Connect the NF contact (C and 2) of the THA (antifreeze thermostat ) to 5 and 6.

Possibility to connect the hot water pump to the system at the terminals DO3 of the controller and connection terminal

18. (Caution: the 24 V output is to be connected via a relay)

Cooling coil:

Terminal 28 to +24 V (G) of the valve servomotor

Terminal 29 to 0 V (G0) of the valve servomotor

Terminal 30 to +10 V (Y) of the valve servomotor

Connect the NF contact (C and 2) of the THA (antifreeze thermostat ) to 5 and 6.

Possibility to connect the cold water pump to the system at the terminals DO4 of the controller and connection

terminal 19. (Caution: the 24 V output is to be connected via a relay)

Changeover coil:

The 3-way plate must be fixed at the water inlet before the bypass.

The 3-way valve and the changeover plate must wired up.

Connect the assembly as follows:

Red wire of the plate (CO) to 10 V (Y) of the valve servomotor

63

Page 18

ENGLISH

Terminal 15 to +24 V (G) of the valve servomotor

Terminal 16 to 0 V (G0) of the valve servomotor

erminal 17 to brown wire of the plate (hot signal)

T

Terminal 30 to black wire of the plate (cold signal)

Connect the NF contact (C and 2) of the THA (antifreeze thermostat ) to 5 and 6.

Possibility to connect the circulator to terminals DO3 of the controller and 18 of the terminal block (higher temperature

required) and to terminals DO4 of the controller and 19 of the terminal block (lower temperature required). (Caution:

the 24 V output is to be connected via a relay)

WARNING: in this case use one relay for each output and wire them in parallel to the M/A of the circulator

IV.14. Direct expansion coil for cooling only or reversible coil

For systems equipped with DX coil, the supplementary module is equipped with a condensate collector. Provision

must be made for collection of condensate via a siphon.

We provide:

• a 24 V output for system heating or cooling requirements

• a 0-10 V hot output and a 0-10 V cold output.

Heating requirement:

• 24 V output: Connect to terminals DO3 of the controller and 18 of the terminal block; allows a startup signal to be

sent to control a DX module (Caution: max. 12 V 2 A to be connected via relay)

• 0-10 V output: Connect to terminals 15 and 16 (15 = 0 V and 16 = 0/10 V)

Cooling requirement:

• 24 V output: Connect to terminals DO4 of the controller and 19 of the terminal block; allows a startup signal to be

sent to control a DX module (Caution: max. 12 V 2 A to be connected via relay)

• 0-10 V output: Connect to terminals 29 and 30 (29 = 0 V and 30 = 0/10 V)

WARNING: If the 24 V outputs are used, use one relay for each output and wire them in parallel to the M/A of the

DX module

WARNING: The 24 V and 0-10 C startup signals do not in any case control the anti-cycle safety function of the

direct expansion coil.

IV.15. Electric heater battery

The electric heater batteries are single-phase units on all the models in the range with the exception of the INFINITE BC

series 2000 and 2500, on which are they are three-phase units.

64

Page 19

ENGLISH

!

!

IV.16. Defrost heater battery

The defrost heater batteries are single-phase units on all the models in the range with the exception of the INFINITE BC

eries 1800 and 2500, on which are they are three-phase units.

s

IV.17. Fire protection function

Refer to parameter settings in section V.6.b.6

There are 2 ways to manage the fire safety function:

• Firefighter shutdown: To be wired between terminals 1 and 2 (volt-free NF contact). Total shutdown of the system

control (plus no selections available).

• Fire alarm: This function allows the supply and recovery fans to be controlled in accordance with the 5 modes

available in the control parameters (this function can be enabled in situ). An alarm appears on the «Fire alarm»

screen

1. “Shutdown”: Total system shutdown

2. “Continuous operation”: Startup or maintenance of the system in HS operation. The fire protection function will

have priority over all other alarms.

3. “Normal operation”: System operation maintained in accordance with parameters defined on site

(Shutdown/PV/GV)

4. “Blower fan only” Startup or maintenance of the blower fan in HS operation (recovery fan stopped)

5. “Recovery fan only” Startup or maintenance of the recovery fan in HS operation (blower fan stopped).

The digital input “Ext shutdown” has priority over the fire protection function.

This function is not suitable for the French market and, in any case, must be approved by an authorised

inspection body.

The digital fire protection input must be connected across terminals DI8 of the controller and 13 of the terminal

block (voltage-free contact mandatory)

IV.18. Dehumidification function

Refer to parameter settings in section V.6.b.7

®

It is possible to associate with the system a COMBIBOX CONCEPT

followed by a heater battery (water, electric or DX heater). In this case the controller will automatically control the heat/cold

ratio required for dehumidification, while maintaining a optimal operating temperature. During a request for cooling,

temperature control has priority over dehumidification.

Function not available in DIVA mode

Connect the coils/batteries as indicated sections IV.12, IV.14

Position the humidity sensor in the ducting at the point of supply or recovery, according to your humidity control mode.

In the case of ambient humidity control for single flow system with recycling, position an ambient humidity sensor in the

building. This must be installed in a neutral position (where it is not affected by external agents)

Connect the humidity sensor as follows:

module: cooling coil (water or cooling-only DX),

65

Page 20

ENGLISH

DEHUMIDIFICATION

HUMIDITY SENDER HR 010

IV.19. MODBUS/WEB/BACNET connection

(refer to parameter settings in section V.6.b)

MODBUS RS485: Use a shielded cable with twin twisted pairs, such as Belden 8723 or equivalent, to connect the BMS

to the controller (connect to port 1 (BANE)/ connect shielding to N and do not connect E)

BACS TCP/IP type BACNET: connect to the TCP/IP port

WEB: connect to the TCP/IP port

BMS: standard

- MODBUS / RS485

- WEB / TCP/IP

- BACNET / TCP/IP

- EXO / TCP/IP

Ext. Disp.

U

O

100 metres

IV.20. Repeater connection

(refer to parameter settings in section V.6.b.2)

A repeater must be used when you connect:

• More than one control panel to the same screen (maximum 6)

• A remote control at a distance of more than 100m

In this case the remote control may be positioned at a maximum distance of 1 km. Connect the repeater and the controller

using a shielded cable with twin twisted pairs, such as Belden 8723 or equivalent. Connect a single-phase 230 V power

supply.

Connect the wires to port 1 as follows:

• B of the repeater to terminal B of the control panel (cable with shielded wire as shown in the diagram below)

• A of the repeater to terminal A of the control panel (cable with shielded wire as shown in the diagram below)

• N of the repeater to terminal N of the control panel (cable with shielded wire as shown in the diagram below)

Single-phase 230 V power supply to provided to the repeater.

66

Page 21

ENGLISH

CONNECTOR

RECOVERY

EARTHEARTH

CONNECTOR

IV.21. LON

(refer to parameter settings in section V.6.b.5). Connect port 2 of the master to port 1 of the LON controller.

BMS: LON

RECOVERY

LON EXTENSION

MASTER

100 metres

Ext. Disp.

V. PARAMETER SETTINGS

V.1. Control (integral or remote control)

The screen has 4 rows of 20 characters. It is backlit. The backlight is not permanently on must it is activated by touch. It

switches off after a period of inactivity.

There are two LEDs on the front of the screen:

Alarm LED with the bell symbol

Write LED with the pencil symbol

- Rapid flashing = the value can be modified

- Slow flashing = a password must be entered in order to modify the value

• The Up, Down, Left and Right arrows keys are used to navigate the menus.

• The Up and Down arrow keys are used to increase or reduce the value of a parameter, while the Right and Left arrow

keys are used to navigate the parameter.

• The OK key is used to enter and confirm a value, while the C key serves to cancel it.

• The alarm key (red) gives access to the predefined list.

• The left arrow is also used to exit the alarms menu and return to the main menu

• The cursors indicate the possible movements and which keys you can press.

%.

!.

67

Page 22

%

!

ENGLISH

Cursor Possibility to scroll up

LARM

A

Arrow

keys for

enu

m

navigation

Possibility to scroll down

V.2. Example parameter settings

• Move the cursor to desired menu

Once you have reached the menu: press OK

and, where required, enter the password.

• Enter the desired value using the arrow keys or the number keypad

• Press OK to confirm and move to the next field.

• Once all the values have been updated, press the left arrow key to return to the initial screen.

V.3. Standard settings (operator menu)

Normal text = read only / Bold text = Can be modified / Bold and underlined text = Can be modified with password

3333 … = not used or not accessible.

WARNING: Do not modify any parameters other than those in bold, otherwise any SAT will not be considered

Analogue input :

Digital input :

Analogue output :

Digital output :

Setting mode

Year:month:day Time

System: function startup or shutdown

SP : T°C Act setpoint : Actual T°C

Operating mode

Temperature

Ventilation control

Humidity control

Schedule setting

Access rights

(10) Language setting (see section V.4.e)

CORRIGO E

Battery/coil type

Control type

PG number

Ventilation

Version :

ID number :

Choose language

Language selection

French (10)

List of main menus that can be accessed

with the password 3333.

The humidity control menu is only available

if the system is configured for humidity

control

68

Page 23

ENGLISH

V.3.a. Operation Mode menu

Operating mode Operating mode

...

Alarm report Alarm log

…

Inputs/Outputs

Operating mode

Auto (7)

Operating period

AS Fan: 00.0 H

Operating period

00.0 H

(Use the down arrow to scroll through the log)

AI

Analogue inputs

AI1: AS T° (supply air)

AI2: Ext T°(external)

AI3: Defrost T°.

AI4: AR T° (recovery air)

DI

Digital inputs

DI1: Al Filter1

DI2: Overheating

or Ext Ant. Prot

DI3: Forced run 1/2

DI4: Forced run 1/1

DI5: Ext stop

(7) Run/Stop setting (see section V.4.d)

UI

Universal inputs

UAI1: Sup. circuit T° (defrost coil)

UAI2: AS press (LOBBY)

UAI3: AR press (LOBBY)

UAI4: CO2 (DIVA)

UDI2: VAS run

UDI3: VAR run

AO

Analogue outputs

AO1: Y1 Heating

AO2: Y2 heat exchanger or M3V

AO3: Y3 Cooling

AO4: VAS Ctrl

AO5: VAR Ctrl

DO1: VAS V freq.

DO2: VAR V. freq

DO3: Electric battery heater or heating

pump

DO4: Cooling pump

DO5: Alarm total

DO6: Sup. control. (DBE)

DO7: Ventilation activated (LOBBY)

69

Page 24

ENGLISH

V.3.b. Temperature control menu

Temperature control

Recovery temperature

Actual :

Sepoint : 21°C (8)

Ext. temp :

Supply temperature

Actual :

Sepoint :

(8) Setting the setpoint temperature (see section V.4.c)

Ref.

Time : 15:54 (1)

Date : 2011-01-25 (1)

Day : Tuesday (1)

Ext. comp. setpoint

-20°C = 25°C (8)

-15°C = 24°C (8)

-10°C = 23°C (8)

Ext. comp. setpoint

-5°C = 23°C (8)

0°C = 22°C (8)

5°C = 20°C (8)

Ext. comp. setpoint

10°C = 18°C (8)

15°C = 18°C (8)

V.3.c. Ventilation control menu

Ventilation control

Frequency control

(ECO or DIVA)

AS manual vent.

Output: 70 (5)

%

or

VAS pressure control

(LOBBY)

Actual : 183Pa (example)

Reference : 180 Pa(5)

Frequency control

(ECO or DIVA)

AS manual vent.

Output: 70 (5)

%

or

VAS pressure control

(LOBBY)

Actual : 183Pa (example)

Reference : 180 Pa(5)

Frequency control

AS manual vent.

Output 1/1 70% (5)

Output 1/2 50% (5)

Frequency control

AS manual vent.

Output 1/1 180Pa (5)

Output 1/2 180Pa (5)

Frequency control

AS manual vent.

Output 1/1 70% (5)

Output 1/2 50% (5)

Frequency control

AS manual vent.

Output 1/1 180Pa (5)

Output 1/2 180Pa (5)

(5) Speed, pressure, flow rate setting (see section V.4.b)

70

Page 25

ENGLISH

V.3.d. Timer setting menu

Schedule setting

Time/Date Time : 15:54 (1)

Normal speed

program

Low speed

program

Date : 2011-01-25 (1)

Day : Tuesday (1)

Normal speed

Monday (2)

Period 1 : 06:00 - 22:00

Period 2 : 00:00 - 00:00

Normal speed

Tuesday (2)

Period 1 : 06:00 - 22:00

Period 2 : 00:00 - 00:00

Etc. to Sunday + vacation

Low speed

Monday (2)

Period 1 : 06:00 - 22:00

Period 2 : 00:00 - 00:00

Normal speed

Monday - Friday (2)

Period 1 : 06:00 - 22:00

Period 2 : 00:00 - 00:00

Low speed

Monday - Friday (2)

Period 1 : 06:00 - 22:00

Period 2 : 00:00 - 00:00

Access rights

Enter

Exit

1. Setting the time and date (see section V.4a)

2. Setting the LS schedule (see section V.4a)

3. Setting the HS schedule (see section V.4a)

4. Setting vacation periods (see section V.4a)

Low speed

Tuesday (2)

Period 1 : 06:00 - 22:00

Period 2 : 00:00 - 00:00

Etc. to Sunday + vacation

Enter password

For the required authorization level :

****

Current lev. :

Leave this access level?

NO or YES

Current lev. :

71

Page 26

ENGLISH

!

V.4. Modification of operator parameters (password 3333 required)

.4.a. Setting different time and date clocks

V

.4.a.1. Date and time o the CORRIGO controller[(1) section V.3.d]

V

Access: Timer/Time Date Setting

he date and time of the controller are pre-set in the CORRIGO. The changeover between the Summer and Winter

T

schedules is managed automatically.

V.4.a.2. Programming system operation times [(2) (3) chapter V.3.d]

ccess:

A

• Normal speed pgr: Times/normal speed program setting

• Low speed pgr: Times/low speed program setting

The system is programmed to operate a normal speed (HS-1/1) 07:00 - 22:00 at low speed (LS-1/2) 22:00 - 06:00 except

for DIVA / LOBBY versions, which permanently operate at low speed (LS-1/2)

As shown in the diagram, it is also possible to modify the periods from Monday to Friday, by pressing the right-hand

button when on the Monday screen

Note: if low speed (LS-1/2) and normal speed (HS1/1) are both active in the same time period, the system will operate in

HS

Operating exceptions:

DIVA: In order for the CO2control function to work, there must be no active time periods in normal speed (HS1/1)

LOBBY: Only the low speed timer (LS-1/2) must be active.

NIGHT COOLING: This function is only active when the system is operating in low speed (LS-1/1)

or stopped between 00:00 and 07:00. (Example: If the system is in low speed (LS-1/2) between 02:00 and 06:00

and in normal speed (HS-1/1) for the rest of the time. In this case, the NIGHT COOLING function will only operate

from 02:00 to 06:00)

V.4.a.3. Vacation period [(4) section V.3.d] (password 3333 required)

Access: Setting Timers/Vacations

The system has no pre-set vacation periods. If you wish to reduce the operating times during vacations, set the operating

periods for vacations as described in section V.3.4), then set the vacation days.

V.4.b. Modifying the speed/pressure for LS and HS operation

V.4.b.1. STANDARD (ECO)/DIVA [(5) section V.3.c]

Access: VAS 1/1 and 1/2 Ventilation control/Frequency control or VAR 1/1 and 1/2 Frequency control

You can change the rotation speed of each fan in the system to LS-1/2 (low speed) and HS-1/1 (high speed) in order to

adjust the air flow rate.

• To adjust the initial flow rate (HS-1/1), set the system to normal speed using the available “Forced HS” terminals

(bridge across terminals 11 and 12).

• To adjust the initial LS flow rate, set the system to low speed using the available “Forced LS” terminals (bridge

across terminals 9 and 10).

V.4.b.2. LOBBY [(5) section V.3.c]

Access: VAS 1/2 ventilation control/pressure control or VAR 1/2 pressure control

You can change the constant system pressure for each fan in order to adjust the flow rate.

To adjust the initial LS flow rate, set the system to normal speed using the available “Forced LS” terminals (bridge across

terminals 9 and 10).

72

Page 27

ENGLISH

!

V.4.c. Modifying the temperature setpoint

[(8) section V.3.b]

Access: Temperature control

The setting is based on the temperature of:

• the supply with external compensation (standard setting). In other words, the setpoint for the temperature changes

ccording to the external temperature. This rule is defined in order to comply with RT 2012

a

• Recovery.

V.4.d. Forced shutdown of control unit or forced LS or HS operation on the remote control

(7)section V.3.a]

[

Access: Operating mode/Operating mode

It is possible to stop (7) (shut down) the system via the CORRIGO command or execute a forced LS (7) (manual speed

1/2) or HS (7) run (manual speed 1/1). As standard, the system operates in Automatic mode controlled by the timers

(7) (Auto)

An alarm will be generated the moment the system is taken out of Auto mode. Note that the manual speed 1/1

and manual speed 1/2 modes are used exclusively for activation and repairs. Any other setting will cause a

system malfunction.

V.4.e. Language selection

[(10) section V.3]

Access: Initial screen/Language selection

V.5. Intermediate settings (function level)

In order to modify the setting type, the Night Cooling parameters and CO2setpoint you need access to the configuration

menu at system level. This requires authorization to access the “Function” level. The procedure is as follows.

Access rights Enter Enter the password 2222

Enter the code 2222 using the arrow keys then press OK to confirm. Press the left arrow key twice to access the menus.

If you make a mistake, press C twice and repeat the operation.

V.5.a. Configuration menu with function level access

Configuration Control function

Ventilation

For the required authorization level :

Current lev. : FUNCTION

Control function

Mode :

Supply + ext. comp (1)

Ventilation active : YES (2)

Ext. temperature activation : 22°C (2)

Night external T°

High 18°C (2)

Low 10°C (2)

Mini ambient temp : 18°C (2)

Speed : 85%

CO2/COV ctrl active :

CO2/VO Ctrl

Run timer yes

Type Fan

Speed 1/2 : 800 ppm (3)

Speed 1/1 : 1000 ppm (3)

Diff : 160 ppm

1. Selection of the setting type (see section V.5.b.1)

2. Modification of Night Cooling parameters (see section V.5.b.2)

3. Modification of CO2setpoints (DIVA and QUATTRO only) (see section V.5.b.3)

73

Page 28

ENGLISH

V.5.b. Modification of function parameters (password 2222 required)

V.5.b.1. System control mode

(1)section V.5.a]

[

Access: Configuration/Control function

The control type is pre-set in the CORRIGO to supply with external compensation It is also possible to switch to recovery

ontrol mode.

c

WARNING: if you wish to set the system according to an ambient temperature, select “Recover Ctrl” mode; any

(

other option will cause a system malfunction)

V.5.b.2. Ventilation parameters

[(2)section V.5.a]

Access: Configuration/Ventilation

The ventilation speed is pre-set to 85%. This value can be modified. It is also possible to modify the temperature for

activation of Night Cooling (daytime external temperature/day, etc.) and deactivate it.

V.5.b.3. CO2 setpoint for DIVA QUATTRO option

[(3)section V.5.a]

Access: Configuration/Ctrl CO2/COV

The CO2 setpoints are pre-set: LS = 800 ppm HS = 1000 ppm. When the CO2level reaches 1000 ppm, the system will

increase the operating speed proportionally up to its maximum speed.

V.6. Administrator settings

Activation of the communication, dehumidification and fire protection functions requires access to the configuration

menu at system level. Authorization for “Admin” level access is required. Proceed as follows:

Access rights Enter Enter the password 1111

Enter the password 1111 using the arrow keys and press OK to confirm. Press the left arrow key twice to access the

menu. In case of error, press C twice and repeat the operation.

For required authorization

Current level: ADMIN

74

Page 29

ENGLISH

V.6.a. Configuration menu with admin level access

Configuration Communication

System

Port 1:

Slave

TCP/IP

Modbus slave

communication

Port 1

Active (1)

Bacnet MSTP

communication Port

1

Active (3)

DHCP: YES (5)

Current Ip:

Bacnet IP

communication

Active (7)

Modbus address: 1 (2)

Speed: 9600 Bps (2)

2 stop bits: Yes (2)

Parity No (2)

Device name: - (4)

Mac: 0 (4)

Low device ID: 2640 (4)

High device ID: 0 (4) (x10000)

Speed: 9,600 Bps (4)

Master max ad.: 127 (4)

IP - (6)

Subnet Mask - (6)

Subnet Mask - (6)

Gateway - (6)

Device name: - (8)

BBMD address: 0 (8)

Low device ID: 2640 (8)

High device ID: 0 (8)

(x10000)

UDP low port N° 7808(8)

UDP high port N° 4(8)

(x10000)

Addresses

PLA: 254 (9)

ELA: 254 (9)

1 and 2 Activation of MODBUS RS485 and settings (see section V.8)

3 and 4 Activation of BACNET MSTP and settings (see section V.8)

5 and 6 ITCP/IP settings (see section V.8)

7 and 8 Activation of BACNET IP and settings (see section V.8)

9 Repeater addressing (see section V.8)

V.7. Modification of function parameters

V.7.a. MODBUS

A simplified MODBUS is presented at the end of the operating and commissioning instruction manual.

Access: Configuration/Communication

MODBUS TCP/IP is activated as standard in DHCP. It is possible to know the DHCP address or set the fixed IP [(5)(6)

section V.6], Modbus port= 502/Device ID = 255

It is necessary to activate the MODBUS RS 485 [(1) section V.6]. Possibility to set speed, parity, stop bits, etc. [(2) section

V.6].

Modbus type

1 = Coil status register (Modbus function 1, 5 and 15)

2 = Input status register (Modbus function 2)

3 = Company register (Modbus function 3, 6 and 16)

4 = Input register (Modbus function 4)

75

Page 30

ENGLISH

Modbus functions supported

Read coils (1)

Read separate input (2)

ead company registers (3)

R

Read input registers (4)

Write single coils (5)

Write single register (6)

Write multiple coils (15)

rite multiple register (16)

W

XOL type

E

R = Real (-3.3E38 – 3.3E38)

I = Integer (-32768 – 32767)

X = Index (0 – 255)

L = Logic (0/1)

Transmission mode

The control unit is set to RTU mode

A maximum of 47 registers can be read in one message.

V.7.a.1. Repeaters and EXO communication

[(3) section V.6]

Access: Configuration/System

The repeater is supplied with an instruction manual for setup and operation If multiple CORRIGO modules are connected

to the same remote control (up to 6 CORRIGO modules), it will be necessary to modify the PLA/ELA on each CORRIGO.

In this case, a different address must be entered in the repeated for each CORRIGO module Follow the instructions given

in the setup and operation instruction manual.

V.7.a.2. WEB communication

It is possible to communicate via TCP/IP WEB in language. In this case, the device is supplied with the Internet page and

the controller set to DHCP.

It is possible to know the DHCP address or set the fixed IP [(5)(6) section V.7], or using the E-tool software

http://www.regin.se

V.8.a.3. BACNET IP communication with BASC type

A simplified BACNET is presented at the end of the operating and commissioning instruction manual.

Access: Configuration/Communication

It is necessary to activate the BACNET IP [(7) section V.6]. It is possible to know the DHCP address or set the fixed IP

[(5)(6) section V.6] It is possible to set the ID / Port N° … [(8) section V.6].

It is necessary to activate the BACNET MSTP (3) section V.6]. Possibility to set speed, ID, address, etc. [(4)section V.6].

Speed = 9600/MAC address = 0/Device ID = 2640/Max master = 127

BACnet type

10XXX = Binary read and write

20XXX = Binary read

10XXX = Analogue read and write

40XXX = Analogue read

30XXX = Multistate read and write

40XXX = Multistate read

(XXX = MODBUS address)

AV = Analogue value

BV = Binary value

MSV = Multistate value

BMMD address: The BBMD address is used to locate devices connected to different BACnet/IP subnetworks and

separated by an IP router. The address is entered as he host; the host can be the host name if DNS is configured. If the

DNS is not configured, it will be necessary to enter the host address in the format xxx.xxx.xxx.xxx followed by the port

number (default setting 47808)

MAC: The MAC address of the device. This must be unique for the sub-network only.

76

Page 31

ENGLISH

Device ID: The ID of a device, used to identify it on the BACnet. This number must not be duplicated anywhere else on

the BACnet and therefore must be unique. To set an ID value of 34600, the low number must be set to 4600 and the high

number to 3

For more information, refer to the CORRIGO images at http://www.regin.se

V.8.a.4. LON communication (if CORRIGO with LON option)

Set the LON function as follows:

In the menu Configuration/Communication/Function port 2 = activate port 2 in the extension unit.

Go to the right and activate the extension unit. 1 in CORRIGO E28 LON

The button for the PIN service is located on the rear of the controller.

The communication table is located at http://www.regincontrols.com

V.8.a.5. Activation of fire protection function

Setting the input parameters

Access: Configuration/Input Output/DI/ DI8

Declare input DI8 as “Fire Al” “NO”

Definition of function parameters

Access: Configuration/Fire protection function

Select the required operating mode to be activated when the fire protection function is activated

“Shutdown”: Total shutdown of the unit

“Continuous operation” Startup or maintenance of unit operation in HS mode.

The fire protection function will have priority over all other alarms.

“Normal operation”: the unit will continue to operate within the parameters selected on site (stop/LS/HS)

“Exhaust fan only”: Start or maintain exhaust fan operation in HS mode (the recovery fan is stopped)

“Recovery fan only”: Start or maintain recovery fan operation in HS mode (the exhaust fan is stopped)

Alarm setting

Access: Configuration/alarm configuration

Enter alarm number “10”, go to the right and enter in priority “C alarm C” “Active”

V.8.a.6. Activation of the dehumidification function

Input settings

Access: Configuration/Input Output/UI/ UI4

Declare input UI4 “Ambient humidity”

Function setting

Access: Configuration/Humidity control

“Select dehumidification”

Reference value setting

Access: Humidity control

Enter the desired setpoint

77

Page 32

ENGLISH

VI. PROBLEM SOLVING

VI.1. Different types of fault

The EASY setting on VORT NRG EC / EC H systems is equipped with alarms. When the red LED flashes, press the alarm

utton (red) to view the fault.

b

he fault will either be class A or class C (see detailed information below)

T

Fault type:

A: The fault causes the ventilation system to shut down. The device will not function until the problem has been resolved

nd the fault eliminated.

a

: The fault does not cause the ventilation system to shut down and the alarm will be reset automatically once the

C

problem has been resolved. To cancel a fault, press the alarm key (red), then “cancel” and “log” the fault using the arrow

keys and press OK. Warning: do not “lock”

Description Cause

The CORRIGO screen does not

switch on

The fan/s does/do not work - The timers are on 0

The remote control does not work

or sends incorrect values

- The system is not receiving sufficient power (P/B LED of the CORRIGO off)

- To illuminate the screen, press a key (backlighting).

- The control fuse is out of service

- No external run command

- External shutdown

- Alarm active

Remote control at distance > 100 m

Repeater not connected correctly.

78

Page 33

ENGLISH

VI.2. Alarms list

N°

Title Description Type Time Cause

1 AS fan fault (UDI2 must be

closed “Fer” if the

fan is in in

operation)

Or

UAI2 should be

over 30 Pa if the

fan is in in

operation)

2 2 AR fan

fault

6 Filter

obstructed

8 External frost

protection

15 High supply

temp.

23 Heater batt.

overheating

27 Ext. temp

sensor error

31 VAS pressure

error

32 VAR

pressure

error

(UDI3 must be

closed (“Fer”) if

the fan is in

operation )

Or

UAI3 should be

over 30 Pa if the

fan is in in

operation)

DI1 should be

open (“Ouv”) in

the absence of

faults

Ext DI3 should be

closed (“Fer”) in

the absence of

faults

Ext AI1 has

exceeded 50° C

Ext DI3 should be

closed (“Fer”) in

the absence of

faults

Check the value

on Ext Al2

Difference of more

than 50 Pa

between the

supply setpoint

and the

temperature

reading on Ext

UAI1

Difference of more

than 50 Pa

between the

supply setpoint

and the

temperature

reading on Ext

UAI2

A 30 s

(120 s

for

LOBBY)

A 30 s

(120 s

for

LOBBY)

C 5 s 1. The filter/s is/are obstructed

C 120 s 1. The THA thermostat is not set to 5° C

A 30 s 1. The supply temperature has exceeded 50° C

A 5 s 1. The THS safety thermostat has tripped. To reset the THS, press the