Page 1

Owner’s Manual &

Installation Instructions

Zone Comfort

hot water air handler

and zoned distribution system

with iStat6 electronic controller for 2 to 4 zones

Vortex Source Systems

45 Cowansview Rd.

Cambridge, Ontario

N1R 7L2

Phone: 888-781-8151

Fax: 888-670-2544

info@vortexsource.com

www.vortexsource.com

Page 2

Table of Contents

CHECKLIST FOR THE INSTALLER .................................................................................................................. 3

TYPICAL PLUMBING CONNECTIONS ............................................................................................................. 4

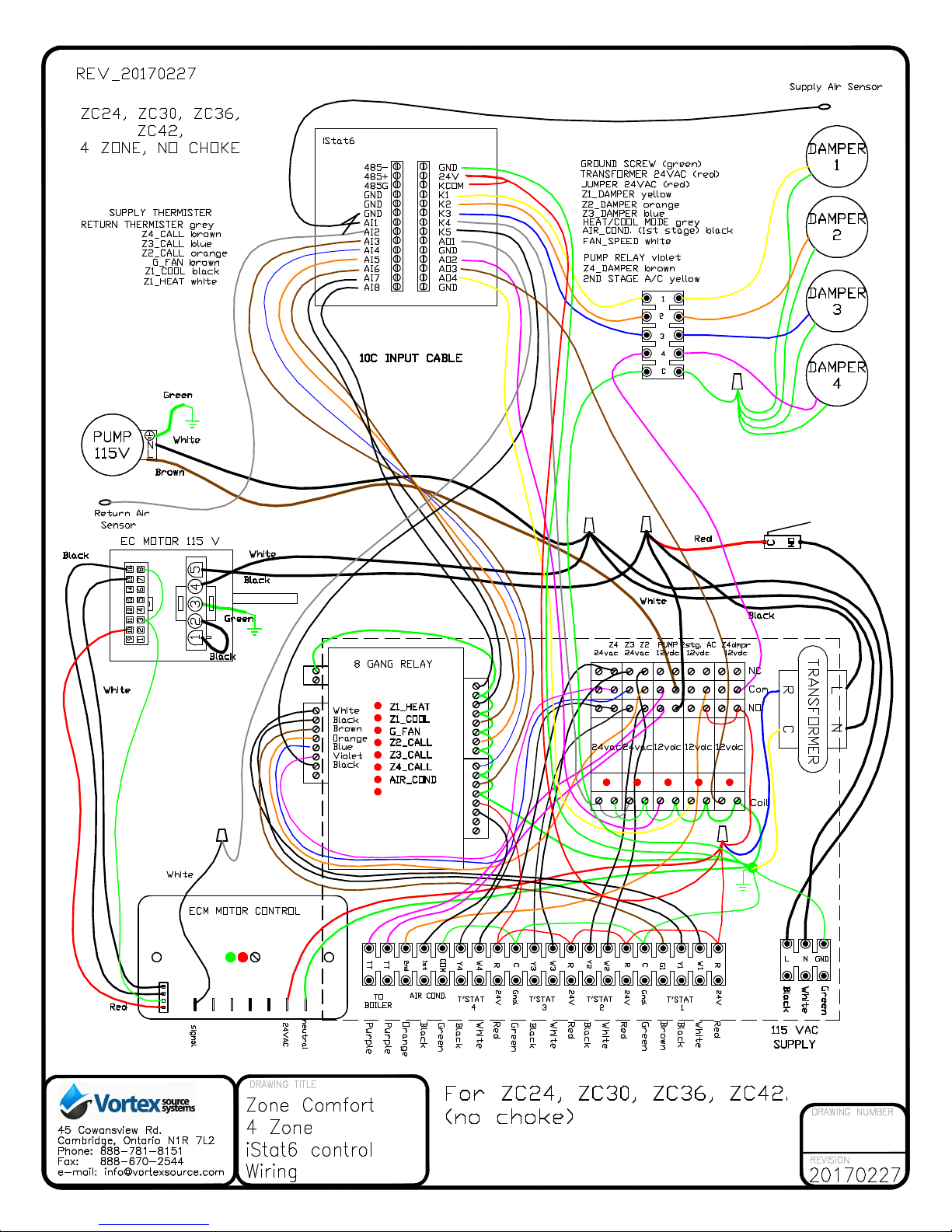

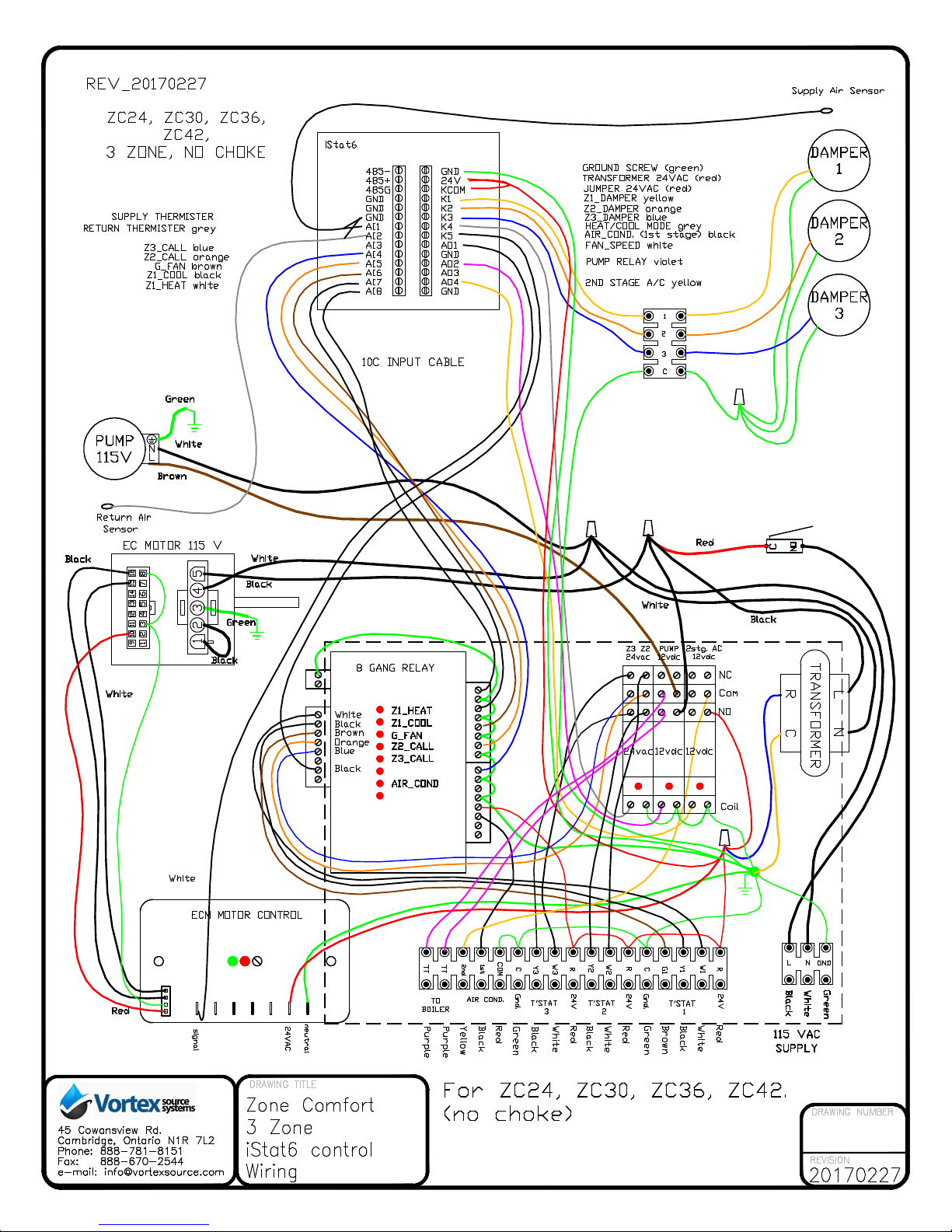

ELECTRICAL WIRING DIAGRAM – 4 ZONE COMPLETE................................................................................. 5

ELECTRICAL WIRING DIAGRAM – 4 ZONE BASE ........................................................................................... 7

EQUIPMENT SPECIFICATIONS AND SIZING TABLES ................................................................................ 8

INTRODUCTION .................................................................................................................................................... 9

HOW IT WORKS..................................................................................................................................................... 9

Zone One ................................................................................................................................................................. 9

Off ......................................................................................................................................................................... 10

Heating .................................................................................................................................................................. 10

Cooling.................................................................................................................................................................. 10

Continuous Fan ..................................................................................................................................................... 10

Features ................................................................................................................................................................. 10

Evaporator Coil Freeze Protection........................................................................................................................ 10

PRODUCT DESCRIPTION .................................................................................................................................. 10

Cabinet .................................................................................................................................................................. 11

Heating coils ......................................................................................................................................................... 11

Fan and Motor ....................................................................................................................................................... 11

Circulating pump .................................................................................................................................................. 11

Check Valve .......................................................................................................................................................... 11

EQUIPMENT SIZING AND SELECTION ......................................................................................................... 12

Procedure .............................................................................................................................................................. 12

Heat Loss / Heat Gain ........................................................................................................................................... 12

Air Handler Selection ........................................................................................................................................... 12

Define Zones ......................................................................................................................................................... 12

INSTALLATION ................................................................................................................................................... 13

Air Handler Mounting .......................................................................................................................................... 13

Ductwork .............................................................................................................................................................. 13

Risk of Freezing .................................................................................................................................................... 14

ELECTRICAL ........................................................................................................................................................ 14

Thermostat ............................................................................................................................................................ 14

Heat Anticipator Setting ....................................................................................................................................... 15

Dehumidistat ......................................................................................................................................................... 15

START-UP PROCEDURE .................................................................................................................................... 16

SERVICE AND MAINTENANCE........................................................................................................................ 16

Filter ...................................................................................................................................................................... 16

Duct cleaning ........................................................................................................................................................ 16

Coils ...................................................................................................................................................................... 16

Air conditioning coil ............................................................................................................................................. 16

Fan and motor ....................................................................................................................................................... 16

Pump ..................................................................................................................................................................... 17

TROUBLESHOOTING ......................................................................................................................................... 17

Page 2 ZC-KI6-VSS1707

Page 3

CHECKLIST FOR THE INSTALLER

A Quick Check List

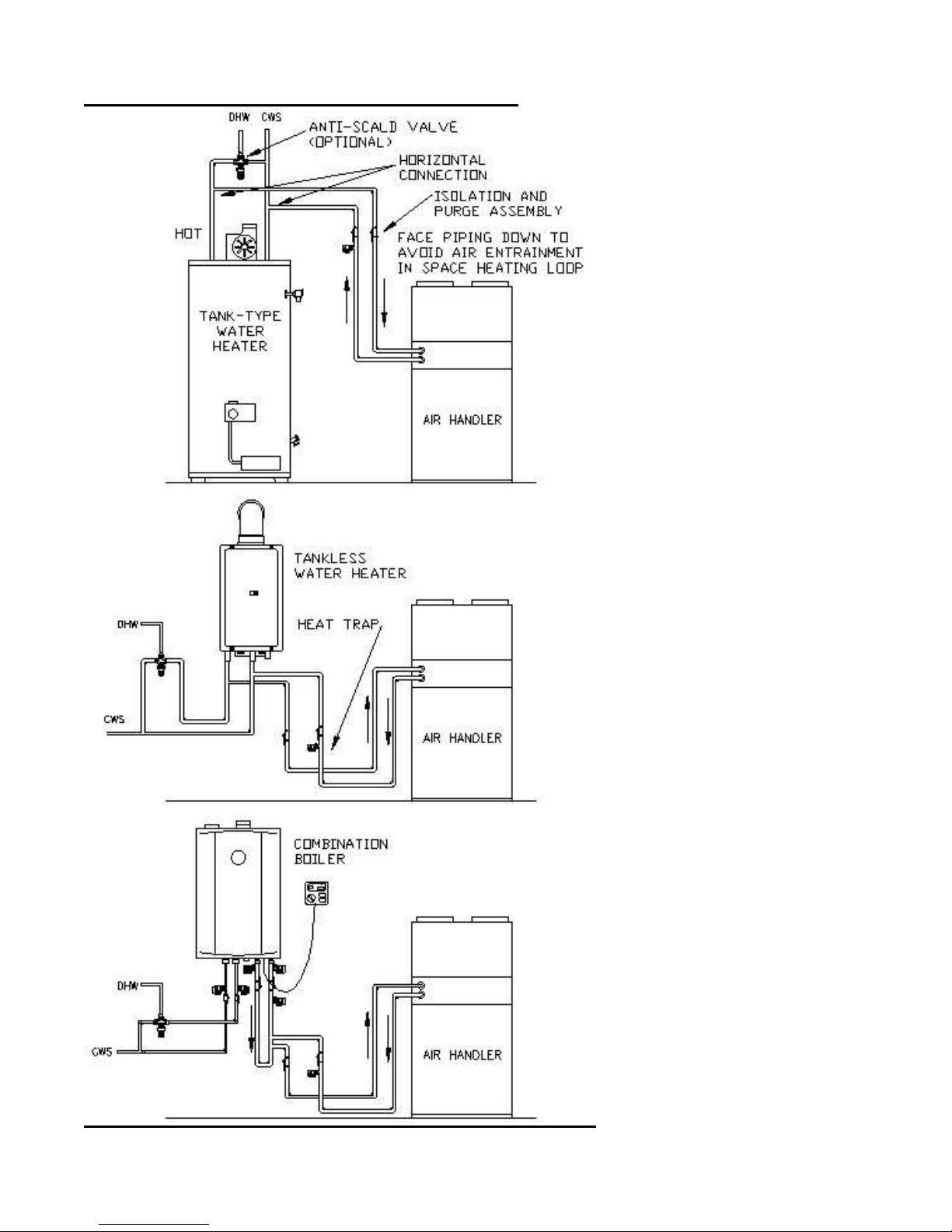

Are the water connections to the water heater oriented in a way to avoid

trapping air in the heating circuit? (see diagram on next page)

Is the purge valve installed on the return water line from the air handler

upstream from the isolation valve?

Is the air handler hung and isolated to avoid transmitting vibration through

framing and duct work?

Are the isolation valves full-port? Restrictive valves will limit performance.

Is outdoor cooling unit contactor wired according to the wiring diagram?

Are Thermostat connections correct, including cooling and continuous run

connections? Do they operate their intended zone?

Have the packing materials been removed from the blower?

Is there an installation manual and controls user manual for the home owner ?

Is the unit accessible? Are there clearances for service and component

replacement?

Is the return duct/drop acoustically lined ? (recommend lining at least 6 ft. of

the return duct/drop)

Is the filter cover in place? Is a clean filter in place?

Has the electronic controller been properly configured as per instructions in the

controls user manual?

Page 3 ZC-KI6-VSS1707

Page 4

TYPICAL PLUMBING CONNECTIONS

Page 4 ZC-KI6-VSS1707

Page 5

Page 6

Page 7

Page 8

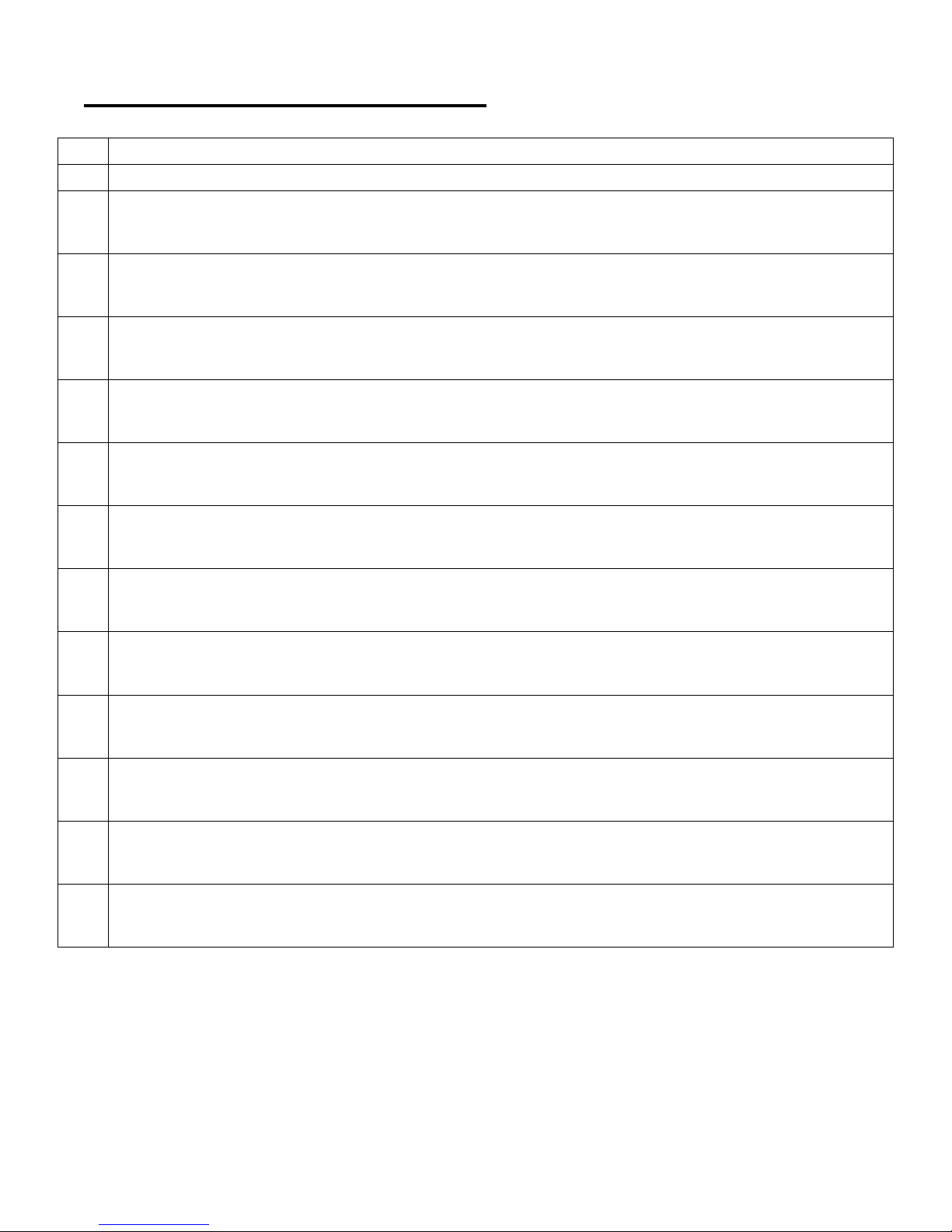

EQUIPMENT SPECIFICATIONS AND SIZING TABLES

REFER TO Small-D design Guide for additional duct sizing options.

TABLE 1 - Air Handler Selection Table

Model

ZC24L

ZCT24L

Min. 4” Branches per Zone 6 8 9 11 12 15 15

Min. 14”x8” Return Air Grilles 5 7 8 8 9 10 11

Heating Capacity1

(Btu/h)@130ºF

Heating Capacity1

(Btu/h)@140ºF

Heating Capacity1

(Btu/h)@160ºF

Heating Capacity1

(Btu/h)@180ºF

Air flow rate at full heating

(cfm)

Max. Ext. Static Pressure (“wc)

50,000 58,000 65,000 65,000 69,000 73,000 91,000

54,000 63,000 70,000 70,000 75,000 80,000

66,000 80,000 90,000 90,000

81,000 99,000 110,000

1000 1200 1400 1400 1600 1800 2000

1.3 0.6 1.1 1.1 1.2 0.7 0.8

ZC30L

ZCT30L

ZC36L

ZCT36L

ZC42L

ZCT42L

110,000 117,000 125,000 164,000

ZC48L

ZCT48L

97,000 103,000 135,000

ZC60L

ZCT60L

ZC100

106,000

USGPM Heating 6 6 6 6 6 6 10

Cooling Capacity

Blower Motor Full Load

(Amps)

2,3

(Tons) 2.0 2.5 3.0 3.5 4.0 5.0 5.0

5.5 5.5 7.7 7.7 9.6 9.6 9.6

Circulator Full Load (Amps) 0.8 0.8 0.8 0.8 0.8 0.8 1.4

Cabinet Width (in.) 22 22 22 22 22 22 22

Cabinet Depth (in.) 25 25 25 25 25 25 25

Cabinet Height (in.)

(Regular ZC)

Cabinet Height (in.)

(Tall ZCT)

44 44 44 44 44 44 65

65 65 65 65 65 65 N/A

Supply Air ( per Zone) 8”Φ 8”Φ 8”Φ 10”Φ 10”Φ 10”Φ 10”Φ

Return air (in.) 18x23 18x23 18x23 18x23 18x23 18x23 18x23

Supply and Return Water

Connections (in.)

Weight-air handler only

(pounds)

1. capacity based on 70ºF return air, high speed and 12.5 feet length per branch at 4”

diameter. Two 3” branches = one 4”, two 4” = one 6”. Do not exceed grille rating. Higher

static pressure/reduced heating capacity available at lower airflow.

3/4 3/4 3/4 3/4 3/4 3/4 1

150 150 155 170 175 175 200

2. Regular ZC requires external cooling coil (extra) in the return air duct.

3. Tall ZCT can use cooling A-coil supplied by others. Cabinet opening is 20W x 24D x 21H.

Page 8 ZC-KI6_VSS1709

Page 9

INTRODUCTION

The Zone Comfort system is a heating

and cooling system that enhances

comfort and improves efficiency by giving

more control over the distribution of

conditioned air. Homeowners enjoy

many benefits such as healthy indoor air,

comfortable basements and cool

summer evenings. Multiple thermostats

provide the means to zone the home by

section or level in order to gain more

control. This will virtually eliminate over

or under conditioned spaces as is

common in a lot of homes today.

The Zone Comfort system is designed

for use in hydronic (boiler) systems or

combination space and water heating

systems (Combo Systems). Combo

heating systems use the home’s water

heater to provide both the space heating

and domestic hot water, eliminating the

need for a furnace. The equipment can

be configured for heating only, heating

and cooling or cooling only applications.

Contact Vortex for Zone Comfort

systems to be connected to a heat pump.

The Zone Comfort duct system can be

much smaller than conventional ducting

making it ideal for retrofit applications or

where a conventional duct system would

result in unsightly bulkheads and wasted

space.

When used as the warm air distributor of

a boiler heating system the Zone

Comfort air system can provide

warmer more comfortable air

temperature than a gas furnace with less

noise and much smaller duct

requirements. This is ideal for large

custom homes where a premium heating

product is required that is quiet,

comfortable and out of sight.

Controls usage and settings are covered

in a separate document.

HOW IT WORKS

The key to the Zone Comfort system is

the level of comfort and efficiency

provided by the unique control system.

Zone dampers in the air handler operate

to increase or decrease the capacity in

each zone of the house as needed.

Heating and cooling air flow for each

zone can be set by the installer to

customize every installation.

Cooling mode uses a fixed or automatic

strategy to maximize homeowner

comfort. In auto mode, blower speed is

carefully controlled to optimize

dehumidification. When cooling demand

is low (determined based on the number

of zones calling or on the measured

supply air temperature) the blower runs a

little slower. The air has more residence

time in the evaporator coil. This results

in removing more moisture from the air,

thus maintaining the humidity in an

optimum range.

Zone One

The primary or master or zone one tells

the air handler whether it is heating

season or cooling season or if

continuous air circulation is desired. Any

zone can be zone one but it is typically

Page 9 ZC-KI6-VSS1709

Page 10

the main area of the building (living

area).

Additional zones act as slaves to the

primary zone. The primary zone must

call for heating or cooling at least

once (a short, 5 second call is

adequate) at the beginning of the

season to tell the Zone Comfort air

handler that it is in heating mode or

cooling mode. The switch on the

primary thermostat is not enough!

Until this happens, a call on zone two,

three or four is ignored.

Off

All zone dampers are open if there is no

call for heating or cooling or power is off.

Heating

When a thermostat calls for heating, the

internal pump starts and the boiler is

activated (if connected to TT). The zone

damper for any zone not requiring heat

closes. The fan will gradually ramp up to

the programmed speed for the given

zone.

Cooling

When a thermostat calls for cooling, the

outdoor air conditioning (AC) condenser

is activated. The zone damper for any

zone not requiring cooling closes. Fan

speed can be controlled based on

number of zones calling and their

programmed cooling loads, or on

measured supply air temperature. Two-

stage air conditioners are strongly

recommended as a means of

improving efficiency, lowering fan

speed for single zone calls and more

closely matching AC output to the

home’s cooling requirements.

Continuous Fan

When the thermostat fan switch for the

primary zone is set to continuous fan, the

fan will run at the set speed for all zones.

When there is a call for heating or

cooling, the normal heating or cooling

speed will over-ride the continuous fan

setting. Zones not requiring heating or

cooling will close. Once the thermostat is

satisfied, continuous fan speed will

resume.

Features

Vortex air handlers offer many unique

features that set them apart from the

competition:

Soft Start is a feature that starts the fan

slowly and quietly rather than a large

“thump” common in some furnaces and

air handlers.

Evaporator Coil Freeze Protection

If the evaporator coil air temperature

drops outside of the expected operating

range this indicates a potential

evaporator coil freeze condition. Coil

freezing can lead to slugging (liquid

refrigerant going back to the compressor)

which will damage the compressor. All

Zone Comforts come equipped with a

sensor and controller which will respond

by shutting off the outdoor cooling unit to

allow the system to warm up. Note that

this freeze condition is not normal and

may indicate blocked ducts, dirty filter or

an over-sized cooling unit.

PRODUCT DESCRIPTION

Page 10 ZC-KI6_VSS1709

Page 11

Cabinet

All cabinets have a tough, durable low

maintenance painted finish.

Cabinet dimensions are designed to

provide maximum installation flexibility.

Refer to installation requirements for

more details.

Heating coils

All heating coils are potable water grade

copper suitable for use in plumbing

systems. No lead solder is used in any

component construction. All coils and

internal piping conform to ASTM B68 or

ASTM B88 standards.

High-density aluminum fins provide

maximum heat transfer for small coil

surface.

Fan and Motor

All fans are wide body dynamically

balanced for extra quiet operation. Multidirectional sleeve bearing motors allow

mounting in any direction for maximum

installation flexibility.

Circulating pump

The circulating pump is matched for

maximum performance. Air handlers

come with internally mounted pumps for

ease of installation. Air handlers can be

special ordered with external, field

installed pumps, when it is desirable to

locate the circulator below the air

handler, such as in attic installations.

Check Valve

Check valves serve two purposes:

• protect against back-flow of water

to avoid short circuiting around the

water heater during domestic

water use.

• protect against thermal siphoning.

Thermal siphoning is flow of water

through the space heating circuit while

the circulating pump is not operating, due

to hot water rising by natural convection.

During summer months this will cause

overheating, interfere with air

conditioning and waste energy.

All Vortex air systems come supplied

with spring-loaded check valves. The

check valve may be integral with the

pump. These check-valves have been

tested and proven to resist thermal

siphoning for installations where the air

handler elevation does not exceed the

distance above the water heater shown

in the table below.

valve size Maximum elevation

1/2”(12mm) 25 feet(8 metres)

3/4”(20mm) 50 feet(15 metres)

Page 11 ZC-KI6-VSS1709

Page 12

EQUIPMENT SIZING AND SELECTION

Procedure

1. Conduct a complete heat loss / heat

gain calculation.

2. Determine inlet water temperature

3. Select Air Handler

4. Determine zones within the space.

Three is typical but it can be 2 or 4.

5. Select # outlets per room

6. Determine Duct Layout

Heat Loss / Heat Gain

Room by room calculations need to be

completed using HRAI, ASHRAE, or

another approved sizing methods.

Air Handler Selection

The selected air handler must be sized

according to the following rules:

a) Heating capacity must be between

100% and 140% of the heat loss.

(110% to 140% for combo systems

130°F water temp)

b) Cooling capacity must be between

75-100% of the heat gain. Note that

slightly under-sizing the cooling

equipment improves efficiency and

provides better humidity control.

Zoning ensures the space will be

comfortable even on the hottest days.

When using a boiler system, select a

boiler with an output that meets or

exceeds the heat loss of the space being

heated. If the boiler is serving additional

loads, size the boiler to meet the total

combined load.

For combo heating systems, use an

approved sizing method such as the

Unified Combo Guidelines published by

HRAI.

Define Zones

The space served by the air handler

should be divided up into zones. Three is

typical. Each of these zones is to be

served by a single main duct by the air

handler. Zones can represent areas such

as the basement, main floor and second

floor. In some applications, it may be

desirable to divide the area into east

facing, west facing and basement zones

depending on solar gain. Zoning based

on usage is also acceptable: office, living

and sleeping areas for example.

Page 12 ZC-KI6-VSS1709

Page 13

INSTALLATION

The installer must adhere strictly to all

local and national code requirements

pertaining to the installation of this

equipment. Detailed instructions are

shipped with all accessory items and

should be followed closely.

Air Handler Mounting

The Zone Control air handler can be

installed in any direction. Some

precautions must be observed for some

of the possible mounting positions. For

installations where the access door faces

up or down, select an air handler with an

external pump to avoid the pump being

mounted with its shaft vertical. The pump

shaft must be mounted horizontally to

avoid premature failure.

The air handler can be hung by securing

straps through any of the existing screw

holes in the cabinet. When the existing

screw is too short for securing a

mounting strap, a longer screw can be

used provided care is taken not to

damage any internal components. When

fastening straps using screws other than

those supplied with the cabinet, special

care should be taken in the vicinity of the

coil to avoid tube puncture.

The cabinet is designed so that the

return air can be located on either side of

the cabinet, through the bottom of the

cabinet, or from the back. Position the

filter rack so that the filter is readily

accessible.

Install the air handler with the door firmly

screwed in place to make sure the

cabinet remains square.

Provide at least 2 feet (0.75 metres) of

service clearance in front of the access

panel of the air handler. Zero clearance

is acceptable on all other faces.

Ductwork

Zone Comfort air handlers are suitable

for conventional ductwork or small D™

systems.

Duct selection for each zone should be

based upon ease of installing ductwork.

Final assignment of zones can be done

by changing zone damper wires on the

terminal strip in the top section of the air

handler. Duct connections at the air

handler should be labeled for future

reference (eg. bsmt, main, upstairs).

Supply trunks may be square or round.

SEAL all joints and seams with metal

tape or sealing compound. Locate outlets

at least 6 inches from outside walls or

window coverings.

For small D™, one 25 ft length of flex

duct will provide two 12.5ft branches.

Use only Class 1 flex duct or duct

connector. All vertical portions of branch

connections (such as to high wall grilles)

must be rigid duct. Flexible duct may only

be used in horizontal portions of the

branch.

Return air plenum should be the same

cross sectional area as the air handler

return air opening. In vertical

installations, a conventional return air

drop and elbow is acceptable.

Ductwork installed in unheated spaces

such as attics must be installed between

the insulation and the heated space.

Page 13 ZC-KI6_VSS1709

Page 14

Provide at least R-12 of insulation above

ducts. If cooling is required, the branch

and trunk lines must be insulated and

sealed with a vapour barrier prior to

applying house insulation.

Risk of Freezing

Steps must be taken to prevent the

hot water coil from freezing. Coils

that have failed due to freezing and

damage caused by frozen coils are

not covered under warranty.

HRV and Fresh air connections

If a fresh air duct is required, make

connection to return air plenum at least

18 inches from filter. Insulate all fresh air

ducts.

Fresh air and HRV connections to

ductwork can pose a risk of dumping

cold air into ductwork during periods of

stand-by or continuous run. Calculate

mixed air stream temperatures and

provide interlock controls to prevent

freezing conditions.

Evaporator coils

The Zone Comfort is designed to provide

acceptable airflow for cooling even if only

one zone is operating in cooling mode.

However, a small, single-zone operating

for a long time or abnormal conditions

such as plugged filter can pose the risk

of freezing. All Zone Comforts with

electronic controls include a temperature

sensor that will detect a near freezing

condition and will interrupt the outdoor air

conditioner until it warms up. (Refer to

Controls User Manual).

Attic and crawl spaces

Air handlers may be located in areas

subject to freezing conditions. It is

necessary to protect the hot water coil

from freezing. Contact Vortex for freeze

protection options.

ELECTRICAL

Warning! - Make sure unit is properly

grounded. Locate air handler on a

separate electric circuit.

All air handlers operate on

115VAC/1ph/60hz line voltage, less than

12 Amps. All control circuits are low

voltage, either 24VAC or 0-10VDC.

Thermostat

The Zone Comfort air handlers are

compatible with most thermostats. Some

electronic thermostats (primarily “power

robbing” types) require the addition of a

resistor between the W & C terminals

and the Y & C terminals. This is usually

covered in the thermostat instruction

manual. A 1,000 ohm, 5 watt resistor on

each of the W and Y terminals will

usually be enough to drain the current

required to power the thermostat. Some

thermostats will need 250 ohm, 10 watt

resistors on each of the W and Y

terminals.

Any zone with cooling will require a

heat/cool thermostat. The Zone

Comfort air handler is compatible with

all standard setback thermostats.

Setback thermostats can be used to

achieve greater energy savings. Twostage thermostats are not required with

two-stage air conditioning. The Zone

Comfort™ will determine when to bring

on second stage cooling based on total

building demand.

Page 14 ZC-KI6_VSS1709

Page 15

Heat Anticipator Setting

For optimum comfort the anticipator

setting should be set to provide

approximately 4 cycles per hour

Typical Heat

Anticipator Setting

0.25 amps

Note: The wires from each thermostat

should be labeled for future reference.

Label suggestions are: 1, 2, 3, 4 or

bsmt., main, upstairs. If labels are not

available, use one, two or three “stripes”

of tape.

Thermostat wires should be connected to

terminal strip inside the air handler.

Each zone has its own terminal for R.

W1, W2, and W3 represent heating for

zone 1, 2, 3, 4. Y1, Y2, Y3, Y4

represents cooling for zone 1, 2, 3, 4.

Only G from the primary thermostat

should be connected to the air handler.

Thermostats with a C terminal should be

connected.

Dehumidistat

Dehumidistats are not necessary, as

dehumidification may be achieved

through Zone Comfort’s automatic

control of cooling speed. Refer to

Controls User Manual for more details.

Zone Selection & Set-up

Zone 1:

Any zone can be the primary zone or

Zone One. However, it is strongly

recommended that this be the main zone

to be heated and cooled. In a home, this

is typically the main living area. This

thermostat is the only one that is used to

select continuous fan operation. It also

plays a critical role in telling the air

handler whether to be in heating mode or

cooling mode.

When initially started or during seasonal

changeover from heating/cooling, this

thermostat must call at least once before

the air handler control will properly

recognize a heating or cooling call from

the other zones.

Other Zones (2,3,4):

These zones are the same and any area

to be heated and/or cooled can be

selected as zone 2, 3 or 4.

Duct/Zone Connections to Air

Handler:

The 6”/8”/10” round duct connections on

top of the air handler are labeled zone 1,

2, 3 and 4. The colours yellow, orange,

blue and violet correspond to the wire

colours connecting them to the air

handler control. NOTE: THESE ARE

FACTORY DEFAULT ZONE

SELECTIONS AND THE

INSTALLATING CONTRACTOR CAN

REASSIGN ANY DUCT CONNECTIONS

ON TOP OF THE AIR HANDLER ZONE

ONE, TWO, THREE OR FOUR.

To change duct connection assignments,

change the wires connected to the

terminal block. The output is as follows:

thermostat #1 = Yellow, #2 = Orange, #3

= Blue, #4 = Violet. The factory default is

for the same coloured wires connected to

the dampers and labeled zones 1, 2, 3

and 4. The colour labels on top of the air

handler correspond to the wire colours to

the damper. For example, to reassign

the blue duct connection to thermostat

#1, and yellow duct connection to

thermostat #3, reverse the yellow and

blue wires on the terminal block.

Page 15 ZC-KI6_VSS1709

Page 16

START-UP PROCEDURE

Do not start the air handler or water

heater until ALL air has been purged!

1. Fill the boiler loop or water heater

with water, but do not start it.

2. Purge all air from the boiler heating or

domestic water system.

3. Purge all air from the space-heating

loop by closing the isolation valve on

the return leg of the loop and open

the drain to purge air. Open the return

leg isolation valve and then close the

drain valve.

4. Start the boiler or water heater

according to the manufacturer’s

instructions. Set the design water

temperature and wait for the system

to shut off. You can check that the

water heater is set properly during the

warm up by running a small amount

of water into a glass in a sink while

the water heater is warming up. Using

a thermometer measure the

temperature of the water as soon as

the water heater burner shuts off. If

the set-point temperature is too low or

is above 140F/60C, reset the tank

control, run water until the burner

starts again and repeat the

measurement.

5. Turn on the power to the air handler

and set up the electronic controller as

per instructions in the Controls User

Manual. This is important to ensure

that the correct airflows are used for

the equipment as installed.

6. Set the room thermostat for heat to

energize the fan and pump. If a

gurgling sound is present, it should

subside within one minute. If noise is

still present after one minute, repeat

step 3 to purge air as necessary.

7. Check pipes for heating to make sure

there is flow and feel the pump motor

to see if it is running hot.

SERVICE AND MAINTENANCE

Filter

The filter should be inspected monthly

and replaced as required.

Duct cleaning

If proper filter maintenance is adhered to,

duct cleaning will not be required for the

life of the equipment.

Coils

Air conditioning and heating coils should

not require cleaning if the filter

maintenance schedule is adhered to. If a

filter is damaged or collapses from

Page 16 ZC-KI6-VSS1709

plugging, dust may foul the coils. If this

happens, replace the filter and carefully

vacuum the heating coil. The fan may

need to be removed to gain access to

the face of the heating coil.

Air conditioning coil

At the start of each cooling season,

check the drain connection to the cooling

coil to ensure it is free of debris. If a

plugged air conditioning coil is

suspected, call a service technician for

testing and cleaning

Fan and motor

Page 17

Check fan for dust once a year. If dirty,

vacuum to remove dust. Keeping the fan

blades clean will reduce noise and

improve the capacity and efficiency of

the heating system.

Pump

The circulating pump is water lubricated

TROUBLESHOOTING

Also refer to the controls

troubleshooting guide.

Thermostat Call Error

Thermostat calls are displayed on the

8_gang relay board. ANY valid heating

call will be illuminated as well as the

pump relay LED. Likewise, ANY valid

cooling call will illuminate as well as

AIR_COND LED.

If both Z1_HEAT and Z2_COOL are on

at the same time, there is a thermostat

error. Check wiring and that the

thermostat is set as a regular heat/cool

and not heat pump mode.

Calls on thermostats two, three and four

are ignored if the air handler system

(through zone one) has not switched

over to the same season. For example,

if zone one is in heating mode, any

cooling call on zones 2, 3 or 4 are

ignored and Z2_CALL, Z3_CALL and

Z4_CALL will not illuminate. If the air

handler does not run when zones two,

three or four are calling, activate the

primary zone briefly ( at least 5 seconds)

to set the air handler in heating or

cooling mode. Note that some

thermostats have a delay (typically five

minutes) before they will start the air

handler in cooling the first time.

and should require no regular

maintenance. A cycle timer feature is

available on the Vortex control to

exercise the pump even during

prolonged periods of no heat to avoid

seizing from long idle periods.

Relay failure – a 24vac DPDT relay acts

as a latching relay for zones 2 and 3 to

prevent incorrect thermostat calls from

reaching the control. A second relay

may be present for zones 4 and 5.

Wrong Zones Operating

Change the damper wires on the

terminal block. Refer to the labels on the

thermostat wires and colour code at the

damper connections.

Pump does not run

The pump is activated by a 12vdc DPDT

relay powered by the control. One side

runs the pump (120vac) and the other

side provides a dry contact (TT) for a

boiler. If the PUMP LED is illuminated

but the pump does not run, the issue is

the pump.

• Seized due to lime build-up; clean

or replace

• Air bound (re-purge)

• Valves closed in error

Second Stage Air Conditioning

Second stage air conditioning is

activated by a 12vdc DPDT relay

powered by the control. Only one set of

contacts is used to provide 24vac to the

air conditioner second stage. First stage

Page 17 ZC-KI6_VSS1709

Page 18

is driven from the control through the 8gang relay.

Insufficient or no heat

• Plugged air filter or coil. Refer to

Maintenance section for filter care

and coil cleaning.

• Air in heating loop; purge system.

• Inlet and outlet connections to air

handler backwards; reverse

connections.

• Water heater supply tube (dip

tube) is restricted or damaged;

check and/or replace.

• Supply water temperature set too

low or not calibrated properly;

check water temperature. In the

case of water heater; If the

temperature has been set low

because of homeowner

preference, it may be necessary

to install an anti-scald valve to

control the faucet temperature and

raise the operating temperature of

the water heater.

• Restrictions in heating loop;

remove restrictions, check valve

stuck, isolation valves too

restrictive, left partially closed after

purging or closed valve.

Cold water at hot faucet

When heat source is a water heater, the

most probable cause is reverse flow

through the heating loop from a stuck

check valve or a faulty single-lever faucet

somewhere in the home; repair or

replace valve.

Fan runs for cooling but not heating

Room thermostat may be connected

improperly. Refer to Electrical section or

wiring schematic on air handler for

proper installation.

Heating during Standby Mode

Probable cause is thermal siphoning.

See check valve description for details;

repair or replace check valve. Check

elevation of air handler above water

heater to see if motorized valve required

for positive shut-off.

Page 18 ZC-KI6_VSS1709

Page 19

ZONE COMFORT ISTAT6 Air Handler Parts & Accessory List

Part No. Description

L,

L

0L,

C24L,

L

L,

L

L,

L,

L,

L

L,

100L

UC20203

UC20203ASS Coil assembly c/w pump-20x20

UCA100

GUPS15-58RU

GUPS26-99BFC

XED008

XED010

XELH620

XELK710

XELK711

XELK715

XELK721

XELK725

XELK740

XELR012DC5L

XELR024DPDT5L Relay 24VAC DPDT, DIN rail + LED S S S S S

XELT002

Hot Water Coil – 20”x20” S S S S

S S S S

Hot Water Coil – Dual 20x20 S

Pump-Grundfos S S S S

Pump-Grundfos c/w check S

8in. motorized damper S S

10in. motorized damper S S S

Wire Harness - power S S S S S

EVO ECM motor speed control S S S S S

Motor speed cable S S S S S

8 Gang Relay Board S S S S S

10k Thermister S S S S S

Remote monitoring gateway O O O O O

iStat6 Programmable control S S S S S

Relay 12vdc DPDT, DIN rail + LED S S S S S

Transformer 24VAC, 40 VA S S S S S

XELD002

XECM03E

XECM04E

XECM06E

XBLF108

XBLF128T

CPVA06

S=Standard, A=Alternate, O=Option

Contact Vortex for blower/control assemblies or cabinet parts.

Door interlock switch S S S S S

EC Blower motor -- -1/3 HP S

EC Blower motor -- -1/2 HP A S S

EC Blower motor -- -3/4 HP S S

Blower – 10x8 DD S S S

Blower – 12x8T DD S S

Valve Assembly – ¾” full port sweat

ball valves plus drain

Page 19 ZC-KI6_VSS1709

O O O O

Page 20

Product Warranty

This product is warranted by Vortex Source Systems to be free from defects in materials and

workmanship that affect product performance under normal use and maintenance within the

applicable periods specified below. Replacements furnished will carry only the un-expired

portion of the original warranty.

Two-Year Parts

Vortex Source Systems will provide replacement parts for ANY part that fail within two years of

purchase, subject to the terms below.

Five-Year Parts

Vortex Source systems will provide replacement parts for any heating coils, cooling coils,

cabinetry and piping that fail within five years of purchase, subject to the terms below.

Terms

Reasonable proof of original purchase date must be provided in order to establish the

effective date of the warranty, failing which, the effective date will be based on the date of

manufacture plus thirty days.

The warranty does not cover failure or damages caused by:

improper installation or operation

accident, abuse or alteration

operation of device at temperatures or pressures outside of the rated capacities

lime or scale deposits

corrosive operating environment

equipment moved from original installation location

Replacements furnished under this warranty will be F.O.B. Vortex Source Systems product

distribution points in the United States and Canada. They will be invoiced at regular prices.

The account will be credited the full amount when the defective part is received by Vortex,

examined and approved as a valid warranty.

Warranty applies to the original purchaser, but may be transferred to another owner

provided the equipment is not moved from the original installation site.

This warranty does not apply to labour, freight or any other cost associated with the service

repair or operation of the product.

Vortex shall not be liable for any direct, special, incidental or consequential damages

caused by the use, misuse, or inability to use this product.

Vortex is under no legal obligations to rectify, including but not limited to, lost profits,

downtime, good will, damages to, or replacement of equipment and property

Purchaser assumes all risk and liability of loss, damage or injury to purchaser and

purchaser’s property and to others and their property arising out of the use, misuse or

inability to use this product.

Page 20 ZC-KI6_VSS1709

Loading...

Loading...