Vortex VRDX13-1 Owner's Manual

WELDING INDUSTRIES

A

DIVISION

OF

WELDING

ACN

Q04

OF

AUSTRALIA

INDUSTRIES

547

4

l1

LTB

Head

Telephone

Office

5

Allan Street, Melrose Park

(08)

8276

and

South

6494

International Sales

Australia,

Facsimile

OWNERS MANUAL

VORTEX DX13

MODEL

VRDXl3-l

06/96

5039

(08)

8276 6327

QUALITY WELDING PRODUCTS,

L

SYSTEMS

AND S&RVlCE

8/

7;;:

Page

2

VORTEX

DX1

3

OWNERS

MANUAL

The information contained in this manual

maintain your new equipment and ensure that you obtain maximum operating efficiency.

Please ensure that this information is kept in a safe place for ready reference when

required at any future time.

When requesting spare parts, please quote the model and serial number of the

machine and part number of the item required. All relevant numbers are shown

contained in this manual. Failure to supply Phis information may result

delays in supplying the correct parts.

is

set out to enable you

to

properly

in

in

unnecessary

lists

SAFETY

Before this equipment

of

back

misuse or improper welding applications.

the manual must be read completely. This will help to avoid possible injury due to

is

put into operation, the

SAFE

PRACTICES

section at the

CONTENTS

Section Page

FIGURES

l

.......................

2..

.....................

3..

.....................

4..

.....................

5

.......................

6..

.....................

7

.......................

8..

.....................

9

.......................

1

Q..

...................

4

.....................

1

12..

...................

Figure Page

...........................

1

2.

..........................

3,.

.........................

4..

.........................

5

...........................

6.

........................

Introduction.

Receiving

Specifications

Power Source Controls..

Connection to Electrical Mains Power Supply

MMAW Welding

GTAW

General Maintenance

Fault

Parts List

Service Information

Safe Practices

Finding,

Power

Connections for

Striking the Arc..

Cable and

Vortex DX1 3 Parts Qiagram

..Vortex DX1 3 Circuit Diagram

.......................................................

...........................................................

....................................................

...................................

................................................

Welding

..................................................

........................................

No

Welding Current

.....................

............................................................

...........................................

...................................................

Source Controls

MMAW

............................................

Hose

Connections for GTAW

..................................

................................

...........................

........................

.......

.3

.4

.4

..5

....

6

.6

8

.9

9

11

.l2

.l3

5

.6

.7

8

10

.l2

L

VORTEX

1.

INTRODUCTION

"AW

Manual Metal Arc Welding is a process where an arc is struck between a flux-coated

consumabtes electrode and the work piece. The arc and the weld pod are both shielded

by gasses generated by the flux coating of the electrode.

DX13

OWNERS

MANUAL

Paae

3

The VORTEX

diameter electrodes. The smaller are used when welding at lower currents, such as sheet

metal applications. Increasing the electrode diameter permits higher welding currents to

be selected.

WIA manufactures a wide range of mild steel and special purpose electrodes which

cater for home workshop, rural, and industrial requirements. Some popular AUSTARC

electrodes are listed below.

conjunction with your new VORTEX

stability of the arc.

Austarc

A

popular general purpose electrode used with ease in all positions, vertical up

or down. The smooth forceful are makes it an ideal electrode for

mild steel applications.

Austarc 13S, Classification

A

smooth running electrode with

sheetmetal and smooth mitre fillet welds.

DX1'3

IZP,

Classification E41

has been designed to be used with 2.Qmm, 2.5mm and 3.2mm

The

correctly selected AUSTARC electrode used in

DX13

E41

will influence the quality of the weld, and the

12.

13.

a

soft

arc, particularly suited to light

all

general

Austarc

Unicord

16TC,

A low hydrogen electrode with good arc stability and out-of-position welding

characteristics. This electrode is ideal for medium carbon steels, or steels of

unknown analysis.

A high tensile (50tsi), chromium nickel electrode specially formulated for joining

all alloy steels and irons, and for tool and die maintenance.

Classification

E4816.

GTAW

Gas Tungsten Arc Welding

non-consumable tungsten electrode and the work piece. A ceramic nozzle surrounds the

tungsten electrode and directs a flow of inert gas, usually Argon, over the electrode and

If

the weld zone.

of the VORTEX

not suitable for welding Aluminium for which an AC machine is required.

filler metal is required, it

DX13

is suitable for welding most ferrous and non-ferrous metals, but is

is

a welding process where the arc is struck between

is

hand fed into the welding arc.

The

DC current

a

L

Page

2.

4

RECEIVING

VORTEX

DX13

OWNERS

MANUAL

Check the equipment received against the shipping invoice to make sure the

shipment is complete and undamaged, If any damage has occurred in transit, please

immediately notify your supplier.

The VORTEX DX1 3 package contains:

Vortex DX13 Inverter Power Source

Shoulder Strap

(This) Owners Manual

Optional additional items for VORTEX DX1 3:

MMAW Welding Lead Kit - 5m

H

150Amp TIG Torch Assembly

E

TIG Torch Adaptor

TIG Torch Twist Lock Connector

E

Work Lead

-

5m

Extension Primary Lead, 15Amp - 1 Om..

Gas Regulator and Flowgauge

3.

SPECIFICATIONS

Primary Voltage

Maximum Primary Demand

Rated Input Current

Electrical Efficiency

Welding Current Range

Rated Output

...................................

Open Circuit Voltage

....................................................

..............................................

...................................................................

..................................................

..........................................................................

................................

.................................................

........................................

............................................................

........................................................................

..............................................................................

...........................................................

130

................................................................

240 Volts AC,

Amps @ 25Volts,

BE-l7V-4M-8

+/-

1

O%,

5

35%

AA53-0/5

CKPCA2-4

DIN25T

AA53-1/5

AM259-0/10

HA801-AR

50/60

23

Hz

Amps

14 Amps

.84%

-

130 Amps

Duty Cycle

.65

Volts

DC

Dimensions

Mass

...................................................................................................

...........................................

H:

195mm

W:

11 1 mm D:

280rnm

4.8Kg

This power source is intended to be connected to a 15Amp mains power outlet.

IMPORTANT

WARRANTY MAY

NOTICE

BE

VOIDED

IF

EQUIPMENT

IS

POWERED FROM

AN

ENGINE

DRIVEN GENERATOR.

This

equipment may be damaged if

it

is powered from a low capacity engine driven

generator. Generators less than l6kva may have inadequate voltage control

application.

in

this

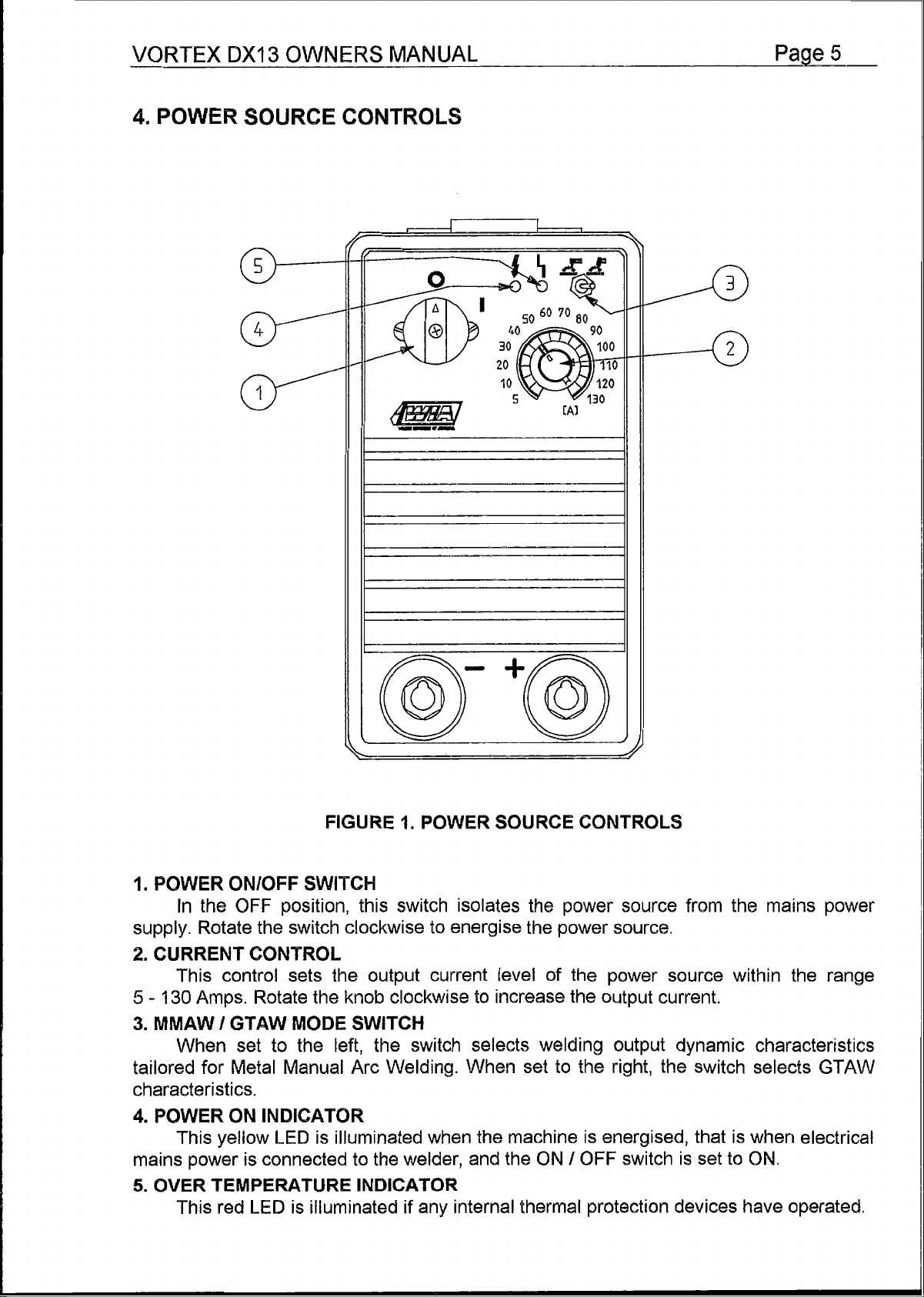

4.

POWER

SOURCE

CONTROLS

FIGURE

l.

POWER

In

supply. Rotate the switch clockwise

2.

CURRENT

This control sets the output current level

5

-

130

3.

MMAW

When set to the teft, the switch selects welding output dynamic characteristics

tailored for Metal Manual Arc Welding. When set to the right, the switch selects GTAW

characteristics.

4.

POWER

This yellow

mains power

5.

OVER

This red

ONlOFF

the

QFF

CONTROL

Amps. Rotate the knob clockwise to increase the output current.

/

GTAW

ON

is

TEMPERATURE

LED

SWITCH

position, this switch isolates the power source

MODE

INDICATOR

LED

connected

is illuminated if any internal thermal protection devices have operated.

SWITCH

is illuminated when the machine is energised, that is when electrical

to

l.

POWER

to

energise the power source.

the welder, and the

INDICATOR

SOURCE

of

ON

CONTROLS

from

the mains power

the power source within the range

/

OFF

switch is set to

ON.

Loading...

Loading...