VN2000 Flow Meters

Transmitter

VRX-UM-02233-EN-02 (June 2017)

User Manual

VN2000 Flow Meters, Transmitter

Page ii June 2017VRX-UM-02233-EN-02

User Manual

CONTENTS

Purpose of this Document. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Unpacking and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Product Label. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installing the Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Rotating the Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Analog Version, 4…20 mA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Connecting Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Operating the VN2000 Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Control Panel Keys. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Display Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Programming Mode Level 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Programming Mode Level 2 (A1-SS78MB-C). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Programming Mode Level 3 (A1-SS78MB-S). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Alarm Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Removing VN2000 Transmitter Electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

North American Pipe Schedules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Page iii June 2017 VRX-UM-02233-EN-02

VN2000 Flow Meters, Transmitter

Page iv June 2017VRX-UM-02233-EN-02

Purpose of this Document

PURPOSE OF THIS DOCUMENT

The purpose of this document is to provide instructions the installation, wiring and operation of the VN2000 Transmitter.

MPORTANTI

Read this manual carefully before attempting any installation or operation.

Keep the manual in an accessible location for future reference.

UNPACKING AND INSPECTION

Upon opening the shipping container, visually inspect the product and applicable accessories for any physical damage such

as scratches, loose or broken parts, or any other sign of damage that may have occurred during shipment.

OTE:N If damage is found, request an inspection by the carrier’s agent within 48 hours of delivery and file a claim with the

carrier. A claim for equipment damage in transit is the sole responsibility of the purchaser.

Storage

If the meter is not scheduled for installation soon after delivery and must be stored:

• After inspection, re-pack the meter into its original packing.

• If the meter being stored has been previously installed, remove all process fluids and corrosives.

• Store in a clean, dry site free of mechanical vibration, shock and chemical corrosives.

INTRODUCTION

The VN2000 Transmitter is supplied with all vortex flow meters. It is designed to be located on the head of the meter or

remotely mounted from the meter, for easy viewing and access. Three configurations are available:

• The VN2000 Volumetric Flow Transmitter has a large, easy-to-read LCD indicator that displays flow rate and accumulated

total flow.

• The VN2000 Mass Flow Transmitter also displays temperature compensated flow rate.

• The VN2000 Energy Flow Transmitter also displays compensated flow rate (BTU/hr or kBTU/hr), total flow (total BTU),

operating temperature, and outgoing and returning temperature.

The control panel keys used to program parameters including engineering units, line sizes (insertion only), 4…20 mA span

adjustments and to recalibrate for new flow conditions.

All internal parameters of the flow meter can be read via the VN2000 Transmitter.

The transmitter has a built-in non-volatile memory for setup and calibration data with the ability to field-calibrate. All

transmitters are factory-tested and programmed.

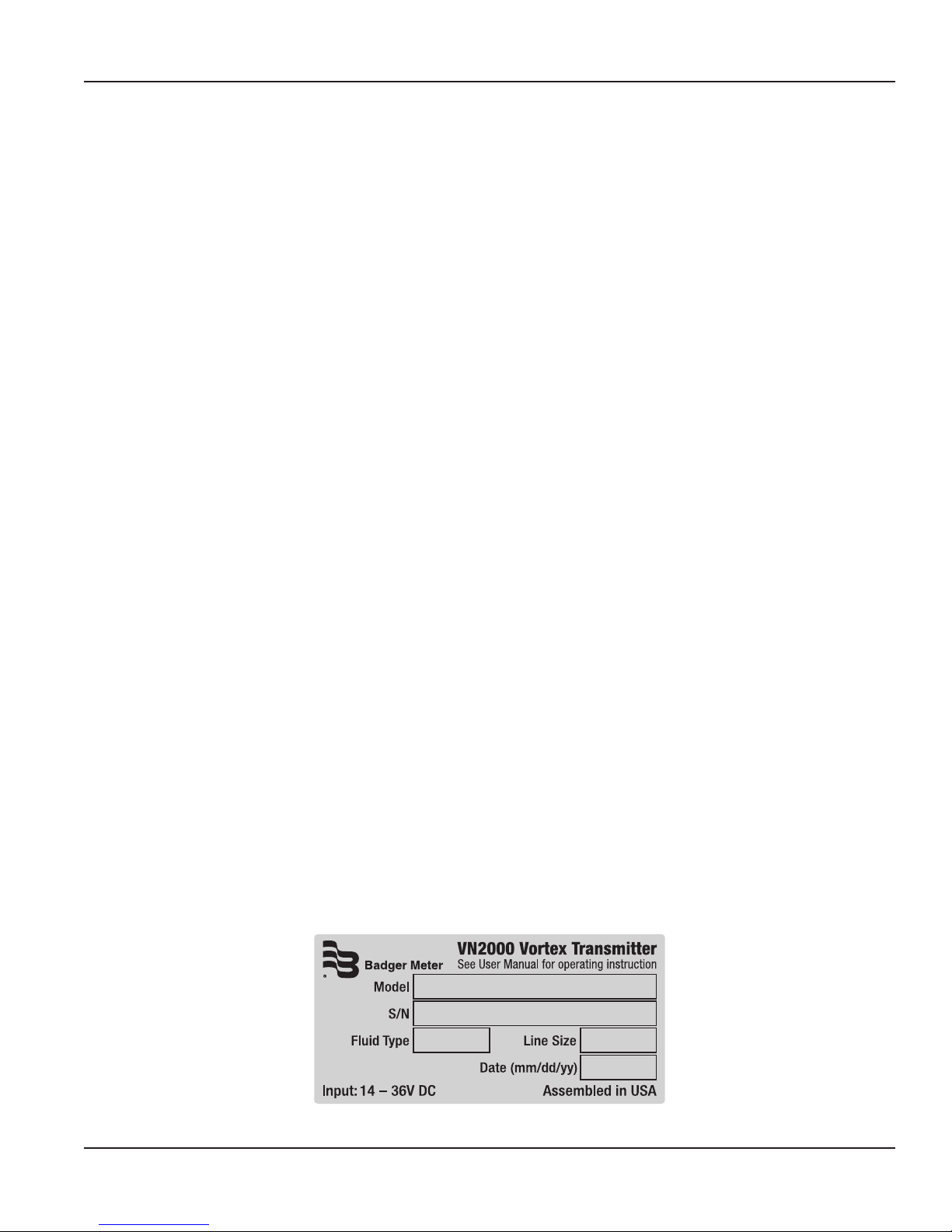

PRODUCT LABEL

Figure 1: VN2000 transmitter label

Page 5 June 2017 VRX-UM-02233-EN-02

Installing the Transmitter

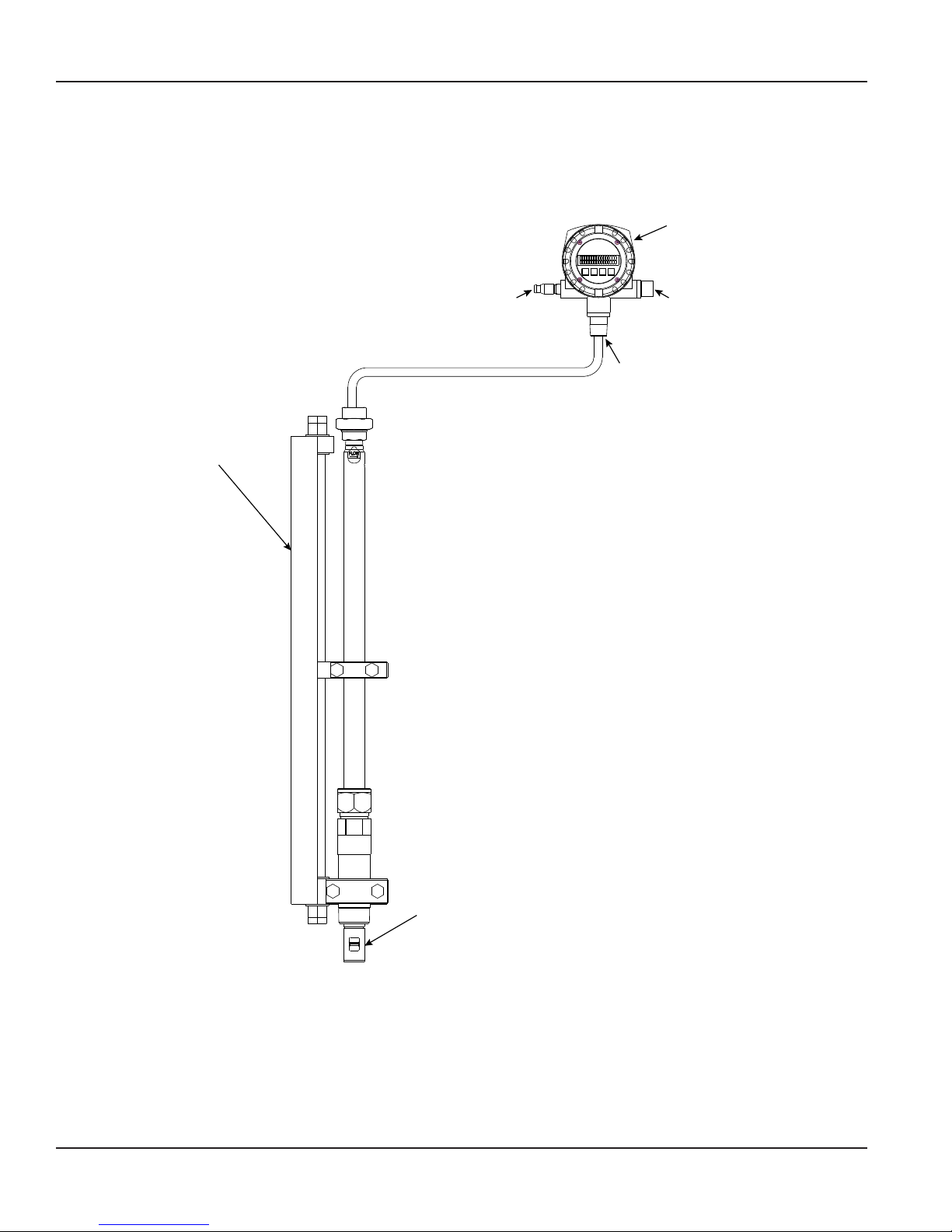

INSTALLING THE TRANSMITTER

The remote transmitter enclosure has a mounting bracket for wall mounting. Locate the enclosure within 30 feet of the

pipeline sensor and at eye level for easy viewing and access to the control panel keys for programming.

Remote

Transmitter

Insertion Tool

To Power

and Outputs

External

RTD Input

(energy

meter only)

To Sensor

(remote only)

Rotating the Display

To adjust the orientation of the display for easier viewing:

1. Unscrew and remove the faceplate cover.

2. Gently lift and turn the faceplate to the desired orientation.

3. Return the faceplate into the enclosure.

4. Replace the faceplate cover.

Page 6 June 2017VRX-UM-02233-EN-02

Sensor Element

Figure 2: Remote installation

Wiring

WIRING

The transmitter ships with a cable that has a connector on one end and flying leads with 4 or 5 wires on the other end. Use

this cable to wire the power and outputs. The transmitter is available with two output options:

• 4…20 mA/pulse output; uses a 4-wire cable

• Modbus RTU; uses a 5-wire output

Display Only (No Output) Black wire 24 VDC

Blue wire Ground

Pulse Output Black wire 24 VDC

Blue wire Ground

Brown wire Pulse DC power

White wire Pulse output

Modbus Output Black wire 24 VDC

Blue wire Ground

Gray wire Data +

Pink wire Data -

White wire Signal Ground (only connect if needed)

4…20 mA Output, Loop Powered Black wire 10…36 VDC

Blue wire 4…20 mA signal

Table 1: Wiring

Grounding

Ground the power supply to DC ground or good earth ground. DO NOT connect to AC ground.

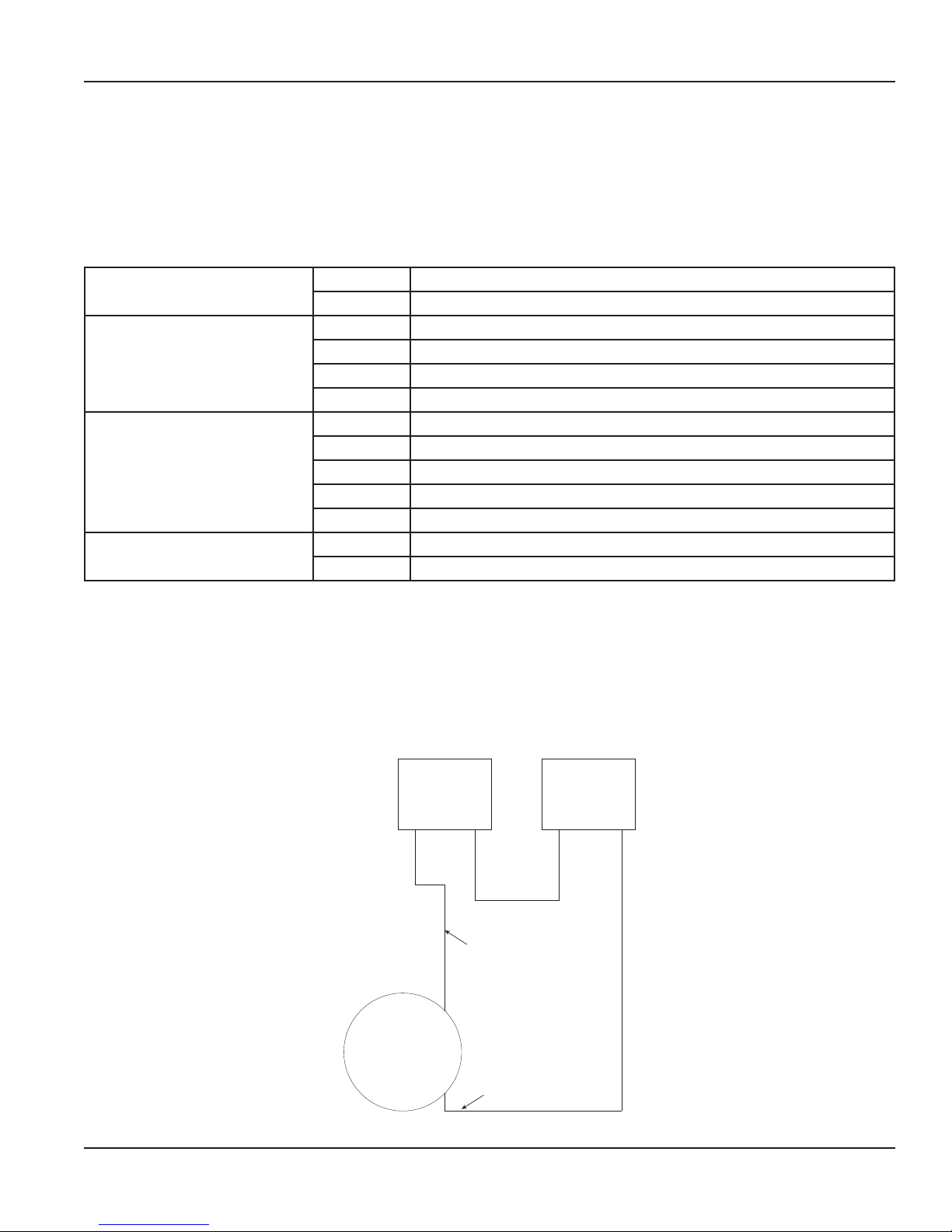

Analog Version, 4…20 mA

To wire for power, use 24 gauge with multi-pin power connector supplied with meter. Do not run the wire over transformers,

motors, or any other magnetic field generating devices. Connect the end of wire to 24V DC for loop powering the device.

Data Logger or PLC

4 . . . 20 mA

Analog Input

Negative/

Common

_ _

Input

Power Supply

Positive Negative

+

Flow Meter

24V DC

_

BLACK Wire (Positive)

+

-

BLUE Wire

Figure 3: Analog version wiring diagram

Page 7 June 2017 VRX-UM-02233-EN-02

Connecting Cables

CONNECTING CABLES

Connecting to the flow meter is easy using our plug-and-play design. No internal wiring is required. All cables are included

with the meter.

Cable Description Replacement

Part Number

Transmitter power, 4…20 mA 4-pin cable, 9 ft (3 m) VNA-CBL-PWR-AA-09

Transmitter power, Modbus RTU 5-pin cable, 9 ft (3 m) VNA-CBL-PWR-MA-09

Transmitter-sensor or external RTD cable, 9 ft (3 m) VNA-CBL-SNR-09

Transmitter-sensor or external RTD cable, 30 ft (9 m) VNA-CBL-SNR-30

Table 2: Transmitter cables

1. Connect the wired end of the cordset to the power supply and outputs.

OTE:N DO NOT USE 110…220V AC without using an optional AC-to-DC power supply, available as an accessory.

2. Connect the other end of the cordset into the remote transmitter. Find the matching keyway between the plug and the

connector in the enclosure. When the key nds the grooved slot, push the plug into the connector.

3. Slowly tighten the threaded connection. Make sure the plug is tightened all the way down into the plug socket.

4. If the transmitter is mounted remotely, use the cordset with connectors on both ends to connect to the sensor.

5. If the meter is an energy meter with an external RTD, use the cordset with connectors on both ends to connect to the

external RTD. The external RTD and remote sensor cable are identical.

6. Apply power to the power supply.

7. The screen displays the version of the operating software.

8. After approximately 5 seconds, the rate and total display (if ow is present).

Page 8 June 2017VRX-UM-02233-EN-02

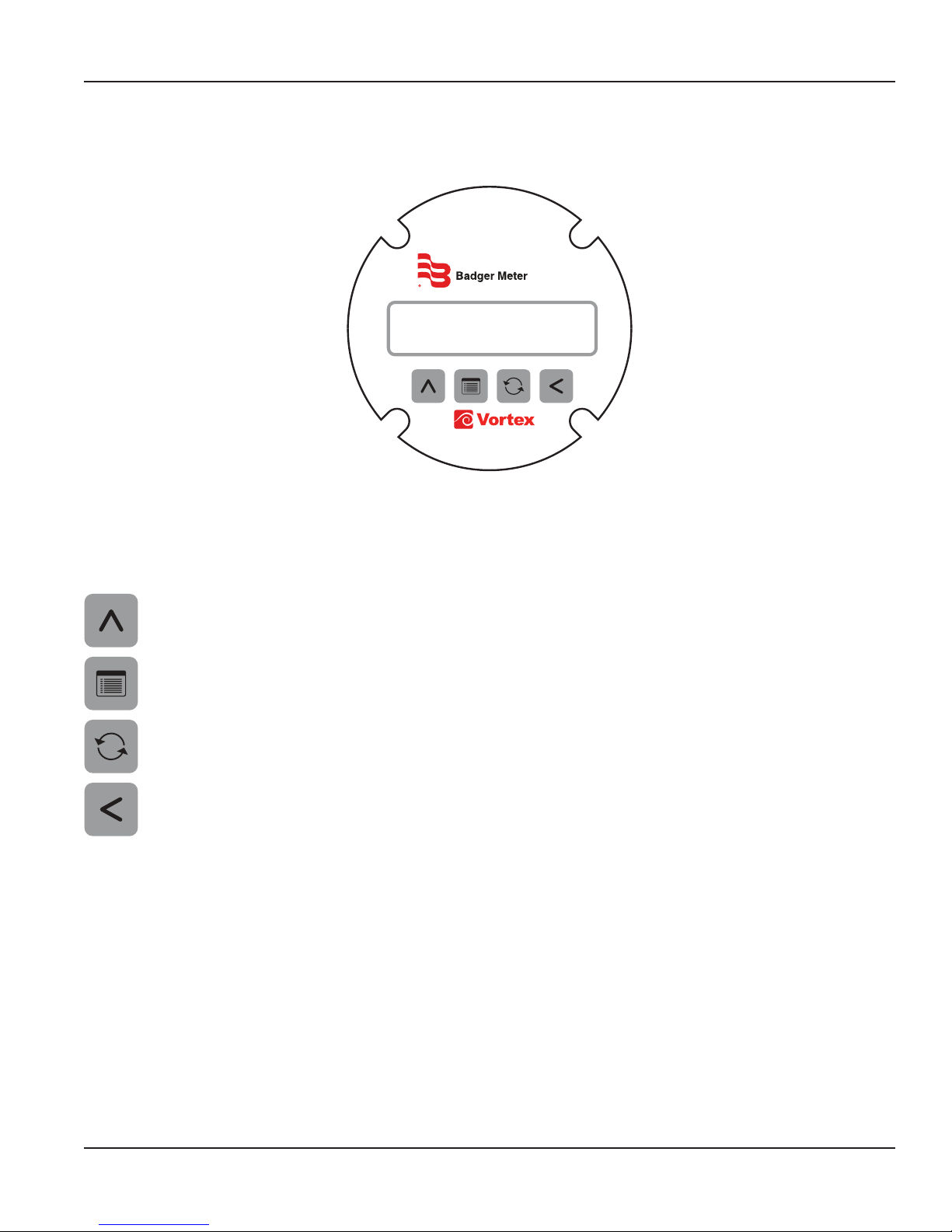

OPERATING THE VN2000 TRANSMITTER

Figure 4: VN2000 transmitter

Operating the VN2000 Transmitter

VN2000

Control Panel Keys

To access the control panel keys, unscrew and remove the faceplate cover.

In Password or Program mode, press the Up Arrow key to increment the selected digit by one.

In an idle state with the temperature adjustment enabled, press to toggle the display between

Totalizer and Temperature.

Press the Menu key to move the control panel keys from an idle state to the Password mode.

Press the Reset key to reset the totalizer.

In Password or Program mode, press the Left Arrow key to move the cursor one digit to the left. If the cursor is

already in the left-most position, press to move the cursor to the right-most position.

Page 9 June 2017 VRX-UM-02233-EN-02

Loading...

Loading...