Page 1

T-100

TORNADO

4-INCH dredge

All information correct as March 2020 and subject to changes without notification.

Dredge Equipment Operations manual.

PATENTED

Page 2

Index

1.

Cover page

2.

Index

3.

Introduction

4.

Introduction continued

5.

Performance and removal rates

6.

User checklist

7.

User checklist continued

8.

Hydraulics

9.

Hydraulic continued

10.

Suction performance graph

11.

Installation

12.

Installation continued

13.

Installation continued

14.

Shipping box

15.

Inventory

16.

Spares

17.

Axial pump repair procedures

18.

Axial pump repair procedures

19.

Trouble shooting

20.

Contacts

Your safety is your responsibility. Please ask if you are unsure about anything.

Page 3

Introduction

The Vortex TORNADO 4-inch is characterized by the following advantages:

• No depth limitations

• Quick mobilization

• Easy operation

The T-100 TORNADO 4-inch dredge Is designed for higher capacity hydraulic supplies that enable a dredge Inlet vacuum up to 29.5

in/hg (100 kpa) at 2800 psi and 78lpm.The Vortex TORNADO ROV 4-inch is designed for Subsea excavation and disposal of seabed

materials up to 99 millimeters in size. It can be mounted to any Work Class ROV and requires no ship deck space and sea fastening. The

Vortex TORNADO 4-inch is very powerful, has no depth limitations and is quick and easy to mobilize and operate, it must NOT be run in

air. Only in water.

The Vortex TORNADO 4-inch equipment can be operated and maintained by the ROV crew.

Vortex has developed a dredge kit with two primary considerations:

First priority is ease of mobilization. The client needs to see rapid deployment of hire gear. The entire kit is shipped in one single box.

Second priority is power. Our TORNADO 4-inch dredge has shown under real world conditions to provide removal rates well in

excess of other 4-inch dredges and has been comparable to 6-inch dredges in performance.

We have included the option of a jetting head kit.

The Vortex TORNADO 4-inch equipment is easy to set up and use. However, if on site support is agreed in the contract, Vortex Personnel

will assist during mobilization and demobilization and or support the project during the entire operation.

Your safety is your responsibility. Please ask if you are unsure about anything.

Page 4

Introduction continued

Operating Limits

The operating limit for the Vortex TORNADO 4-inch, will be the responsibility of the Senior ROV person on-site. The limitation

being the ability to safely deploy and recover the ROV system with the Vortex TORNADO 4-inch attached. Care must be taken whilst

during launch and recovery operations to prevent damage to all components of the dredge system and the ROV.

Risks - Normal Operations

All personnel involved in deck operations shall be aware of the potential risk described hereafter.

• Crane Handling (possible danger of e.g. heavy falling object)

• Launch and recovery of equipment over the side of the vessel

• Personnel working over open sea (typical personnel working with launch and recovery of equipment from vessel

deck or moon pool)

• Object falling down from height (rocks following the equipment when recovering)

• Working with equipment under pressure (hydraulics or water)

• Hydraulic oil spillage

Safety

Personal protection equipment recommended for use when working on ship/platform deck

• Hard Hat

• Safety glasses

• Gloves

• Safety Boots

• Overall

Vortex TORNADO 4-inch Introduction

The Vortex TORNADO 4-inch is designed for Subsea excavation and disposal of sediments and gravel up to 99 millimeters. It is easily

mounted to the ROV and requires no ship deck space and sea fastening. The Vortex TORNADO 4-inch requires no specialist operator or

additional cables between ship and sea floor.

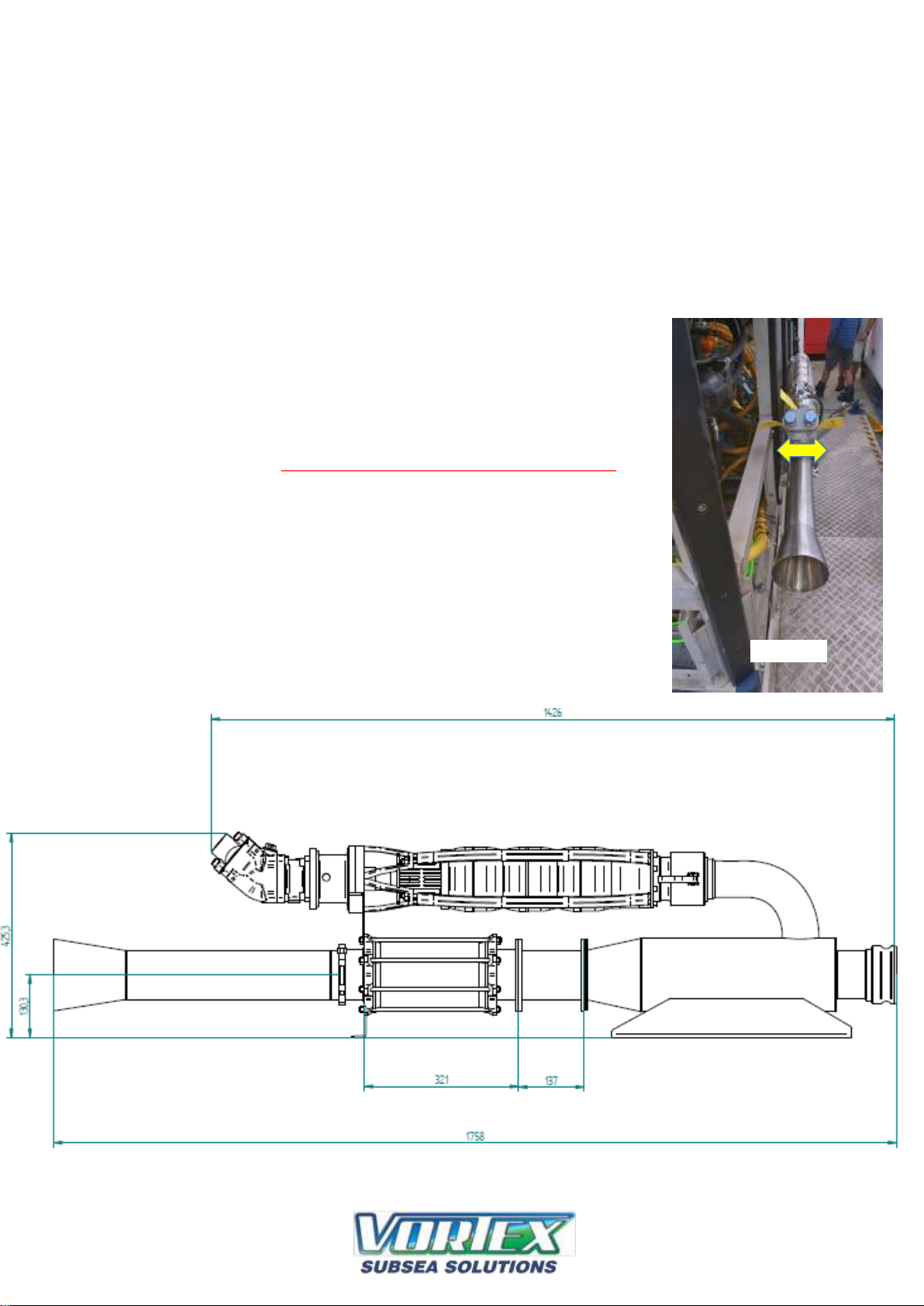

TORNADO 4-INCH ROV DREDGE

EQUIPMENT OPERATIONS MANUAL

Page 5

Vortex TORNADO 4-inch Dredge Capacity

*Based on iron sand and rocks at 2.375 kg per liter

Debris Removal rates (ton/hr) *60 ton per hour plus

Debris removal rates (mtr3/ hr) *27 cubic meter per hour *15% solids by volume

Rated Maximum stone size 100 mm

Actual Maximum stone size 99.5 mm

Inlet suction hose length 3800 mm standard to custom length

Hydraulic flow required 78 lpm minimum (20.6 gpm minimum)

OPTIMUM FLOW IS 80 lpm (21 gpm)

Coupling compensator NO

Hydraulic pressure required 165 bar minimum (2400 psi minimum)

OPTIMUM PRESSURE IS 3000 psi (206 bar) (4500 psi max)

Operating depths Unrestricted

Operate pump in air NO. DO NOT RUN PUMP IN AIR: ALWAYS RUN IN WATER

Available suction at inlet 29.5 in/hg (100 kpa) at 3000 psi and 80 lpm

Main Components Weights and Measures

Pump weight in air 50 kg (complete pump unit)

Pump weight in Seawater 39 kg (complete pump unit)

All items must be accounted for upon return to avoid damage / loss charges.

Performance and removal rates

170mm wide

Page 6

User Checklist Before Dive

To prevent any damage to the equipment this checklist must be followed

Project: ............................................................................................... Dredge No: ...................................................

Item Description Checked Comments Date

1. Ensure ROV can and does supply:

OPTIMUM FLOW IS 80 lpm (21 gpm)

OPTIMUM PRESSURE IS 3000 psi (206 bar)

DO NOT RUN PUMP IN AIR: ALWAYS RUN IN WATER

(4500 psi max) Follow hose directions as shown

2. All fittings are checked for leakage

3. All hose clamps are checked

4. Pumps are fastened, no loose screws

5. Suction hose is fastened

6. Dredge is fastened, no loose ends

7. All hoses are fastened and in proper condition

8. Filter for induction is mounted in clean water

9. No hoses are squeezed or bent

10. Inlet nozzle is mounted correctly

11. Case drain and coupling are filled with clean oil

Comments:

.......................................................................................................................................................................................................................

.......................................................................................................................................................................................................................

..........................................................................................................................................................................................................

Dredge is checked by: ............................................................................................

Date: ............................................................................................

TORNADO 4-INCH ROV DREDGE

EQUIPMENT OPERATIONS MANUAL

Page 7

User Checklist Before Dive

To prevent any damage to the equipment this checklist must be followed

Project: ............................................................................................... Dredge No: ...................................................

Item Description Checked Comments Date

1. Equipment used in the sea must be

DO NOT RUN PUMP IN AIR: ALWAYS RUN IN WATER

properly cleaned with fresh water

2. All fittings are checked for leakage

3. All hose clamps are checked

4. Pumps are fastened, no loose screws

5 Suction hose is fastened

6. Dredge is fastened and in proper condition

7 All hoses are fastened and in proper condition

8. No hoses are squeezed or bent

9. Hydraulic motor and coupling is filled with clean oil

10. Broken parts are reported to vortex

Comments: .................................................................................................................................................................................

...........................................................................................................................................................................................

Dredge is checked by: ............................................................................................

Date: ............................................................................................

What were the positives? ...................................................................................................................................................

What were the negatives? ..................................................................................................................................................

Suggestions to make this kit better for you to use in the field:

............................................................................................................................................................

TORNADO 4-INCH ROV DREDGE

EQUIPMENT OPERATIONS MANUAL

Page 8

Vortex TORNADO 4-inch Hydraulics

DO NOT RUN PUMP IN AIR: ALWAYS RUN IN WATER

Motor / pump Hoses and Connectors

3/4” Pressure Hydraulic Hose -12 JIC Female fittings 4 mtr long

3/4” Return Hydraulic Hose -12 JIC Female fittings 4 mtr long

3/8” Case Drain Hydraulic Hose -6 JIC Female fittings 4 mtr long

Reversal valve actuator hoses and Connectors

1/4” suck Hydraulic Hose -4 JIC Female fittings 3 mtr long

1/4” blow Hydraulic Hose -4 JIC Female fittings 3 mtr long

Hydraulic Motor Requirements

Hydraulic flow / Pressure: 75 lpm minimum (19 gpm minimum)

165 bar minimum (2400 psi minimum)

OPTIMUM FLOW IS 80 lpm (21 gpm)

OPTIMUM PRESSURE IS 3000 psi (206 bar) (4500 psi max)

Reversal valve actuator hose Connectors

Hydraulic flow / Pressure: 10 lpm minimum (2.6 gpm minimum)

68 bar minimum (1000 psi minimum)

Vortex TORNADO 4-inch Pump and Motor

The pump must be mounted on the ROV with ample room for both hydraulic and water hose connections.

Hydraulic connections seen at the top. Fill hydraulic motor with clean oil before start up.

Pump can also be run in air.

Vortex TORNADO 4-inch Pipe Work

Vortex pipe-work with cam locks for suction hose and pressure hose (left) and exhaust tube (right). The pipework is easily fixed to the

ROV using cargo straps or ropes.

Suction Hose and Handle

The suction head comes equipped with a fish-tail style handle for ROV manipulator. Other handle versions can be supplied.

Depth markings supplied for ease of operation.

Page 9

Vortex TORNADO 4-inch Hydraulics

DO NOT RUN PUMP IN AIR: ALWAYS RUN IN WATER

Hydraulic Schematics

Vortex TORNADO 4-inch Hydraulic Hoses

•

Hydraulic hoses for pump/motor connections.

•

Two 4 mtr lengths 3/4’ hoses

•

One 3 mtr length 3/8”

Hydraulic hoses 4 mtr long each.

4250 psi (293 bar) pressure rating.

-12 jic Pressure, -12 jic tank, -6 jic case drain.

Ensure ROV can and does supply 75 lpm minimum

(19 gpm minimum) 165 bar minimum (2400 psi minimum)

before fitting dredge kit.

OPTIMUM FLOW IS 80 lpm (21 gpm)

OPTIMUM PRESSURE IS 3000 psi (206 bar) (4500 psi max)

TORNADO 4-INCH ROV DREDGE

EQUIPMENT OPERATIONS MANUAL

Reversal valve

1000 psi and 10lpm minimum to operate

ROV hydraulic valve

Vortex 4 inch hydraulic connections to ROV.

Water jetter ring valve

200 psi and 12lpm minimum to operate

ROV hydraulic valve

50mm long, -4 jic female

swivel end hoses.

4mtr long, -4 jic female

swivel end hoses.

Case drain to tank

Pressure and tank return

clearly marked.

Page 10

68 psi

82 psi

96 psi

110 psi

124 psi

137 psi

151 psi

165 psi

172 psi

193 psi

206 psi

137 psi

151 psi

165 psi

172 psi

179 psi

186 psi

189 psi

199 psi

206 psi

213 psi

220 psi

227 psi

234 psi

241 psi

248 psi

255 psi

40 KPa

47 KPa

56 KPa

64 KPa

65 KPa

75 KPa

77 KPa

82 KPa

100 KPa100 KPa

40 KPa

42 KPa

46 KPa

48 KPa

52 KPa

55 KPa

58 KPa

60 KPa

63 KPa

67 KPa 67 KPa

72 KPa

75 KPa

42 l/min

46 l/min

50 l/min

58 l/min

62 l/min

63 l/min

65 l/min

68 l/min

75 l/min

78 l/min

64 l/min

67 l/min

70 l/min

73 l/min

75 l/min75 l/min

76 l/min

79 l/min

81 l/min

82 l/min

84 l/min

85 l/min

86 l/min

90 l/min90 l/min

92 l/min

40

60

80

100

120

140

0

50

100

150

200

250

300

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21

Inlet Vacuum (Kpa)

Hydraulic Flow (l/m)

Hydraulic Pressure (psi)

Test No.

Vortex Axial TORNADO 4"

vs competitor

4" Venturi Test Data

Vortex

Hydraulic

Pressure

Competitor

Hydraulic

Pressure

Vortex Inlet

Vacuum

Competitor

Inlet Vacuum

Vortex V4AT-01. March

Vortex T100 suction performance.

Page 11

Installation

Reversal valve actuator and hoses.

Included in kit:, diverter valve, hydraulic hoses, ¾ water

hose goes between water pump and reversal valve..

Connect ¾ inch water hoses to outlet of water pump

and water control inlet of reversal valve.

Opening actuator diverts water from water pump to

reversal valve to actuate urethane bladder which closes

/ blocks flow in reversal valve and changes dredge

direction and go into “blow” mode.

Closing actuator allows bladder to revert to relaxed

state opening flow path allowing dredge to revert to

“suck” mode.

Dredge shown mounted to ROV using supplied

aluminum angle. Drill supplied angle to suit.

Page 12

Installation

Dredge inlet

Ensure pump inlet is clean

and clear of debris.

Water pump outlet to

reversal valve. Blank

off with ¾” plug if not

using reversal valve

Water pump outlet to

optional jetter kit

Reversal valve

8.5mm bleed hole to limit pressure in reversal valve.

Page 13

Installation – Hose Connections

Hydraulic hose fitted with clear markings to facilitate

mobilization times. Pressure and return hoses have identical

pressure rating to

avoid chance of failure through incorrect assembly.

Ensure ROV can and does supply 75 lpm minimum (19 gpm

minimum) 165 bar minimum (2400 psi minimum) before

fitting dredge kit.

OPTIMUM FLOW IS 80 lpm (21 gpm)

OPTIMUM PRESSURE IS 3000 psi (206 bar) (4500 psi max)

Inlet hose with suction head and ROV manipulator handle.

Page 14

Shipping box placement of components.

Suction nozzle and

manipulator handle.

4 inch tube 280mm

long MAXIMUM

length.

4 inch female to hose

tail cam lock.

45 degree

exhaust tail.

Straight exhaust tail 520mm

long overall length.

Spares

boxes.

Reversal valve actuator with

two x 1.5mtr long, ¾” long

water hoses to connect

pump to reversal valve.

Coil all hoses

around edge

of box.

•

157 cm long x 58 cm wide x 74 cm high.

•

165kg weight

Page 15

TORNADO 4-INCH ROV DREDGE

EQUIPMENT OPERATIONS MANUAL

Inventory

• 4 inch dredge unit with integral reversal valve

• Two x 4mtr long -12 Jic female swivel P and T hoses

• One x 4mtr long -6 jic female swivel case drain hose

• One x water reversal valve actuator with two x 3mtr long -4 jic female swivel hyd hoses

• 10 x 75 x 150mm alloy, dredge to ROV mounting plate

• One x 595mm long 4 inch exhaust tail with 4 to 6 inch flare on the end with triclove clamp

• One x 4 inch, 45 degree elbow with 4 to 6 inch flare on the end with triclove clamp

• One x 4 inch female camlock with 4 inch hose tail. For suction hose

• Ove x 4 inch stainless tube, 300mm long with ROV manip handle. For suction hose

• One x generic spares kit as shown below

• One x water pump spares kit as shown below

1 x Mech. seal rotor # 10185

1 x Mech. seal seat # 10180

• One x operations manual

9mm x 75mm x 150mm x 1100mm long

alloy Dredge to ROV mounting plate.

Drill to suit your application.

Page 16

TORNADO 4-INCH ROV DREDGE

EQUIPMENT OPERATIONS MANUAL

Spare Components

Generic spares kit.

•

Ratchet tie.

•

Two x ¾” BSPT blanking plugs.

•

Four M10 x 50 mounting bolts.

•

Two x 112 to 121mm hose clamps.

•

Two x 25 to 27mm hose clamps.

•

Triclove clamp to mount exhaust tail on reversal valve.

•

Two x Triclove gaskets.

Spares kits

Vortex pump spares kit.

Shaft seal.

1 x Mech. seal rotor # 10185

1 x Mech. seal seat # 10180

Spares kits boxes.

Large = CASE ABS MPV1 foam instrument black

Small = CASE ABS MPV2 foam instrument black

Triclove clamp for straight exhaust tail.

Triclove clamp gaskets.

Page 17

Axial pump repair procedures

Mechanical seal replacement:

1. Remove pump suction screen

2. Remove M12 bolts holding aluminium motor adaptor to stainless pump terminal and remove

drive assembly

3. Holding motor in a vise with shaft pointing vertical upwards, unfasten motor capscrews and

remove aluminium adaptor from motor assembly, taking care to avoid contact between seal

stationary seat and shaft surface.

4. Remove circlip and seal seat retainer from motor adaptor. Remove seat and replace with new

item from service kit. Refit retainer in same orientation as when removed and replace circlip.

5. Slide mechanical seal rotor from shaft and fit replacement seal rotor hard back against rear

shoulder of sleeve using light hydraulic oil as a lubricant.

6. Clean both seal face using a lint free cloth and clear gasoline (or equivalent) – lubricate rotor face

with a drop of clean hydraulic oil.

7. Assemble parts in reverse order using torque settings as laid down in torque chart in this

instruction set.

Hydraulic motor replacement:

1. Disassemble unit per steps 1-3 in “Mechanical seal change” instruction

2. Fit plastic protecting sleeve from service kit to shaft spline, holding firmly with vise-grip, and

using a 5mm allen key, remove the shaft retaining capscrew. Using slide hammer with a 12mm

thread remove the shaft from the hydraulic motor.

3. Lubricate the replacement hydraulic motor shaft with a light Moly disulphide paste, refit spacer

and key and slide on the splined stub shaft. If necessary use a hollow drift onto the slide end

shoulder to drive the shaft hard down against the spacer.

4. Clean up the 6mm shaft fastening capscrew and apply a light coating of “BlueMax” or equivalent

silicone sealant to the underside of the head and torque the capscrew to 8 nm.

5. Replace the seal rotor and reassemble the pumpset all per steps 4-6 in the “Mechanical seal

replacement” description.

Torque settings:

M6 – shaft retainer capscrew 8nm

M10 – motor retaining capscrew 12nm

M12 – Adaptor bolts 20nm

Page 18

Axial pump repair procedures

Air test mechanical

seal - 20psi

Apply Blue Max ”

or equivalent

silicone sealant to

underside of cap

screw

Apply grease to spline

fit O ring

into

adaptor

recess

fit O-ring - seat retainer ring and

circlip

fit shaft with hollow drift

Push seal onto shaft

with silicone grease

Lubricate shaft

with light

hydraulic oil as a

lubricant

Remove shaft - using

slide hammer if

necessary

Torque sleeve

fastening cap

screw

Slide joint section

to remove screen

from pump

fit adaptor to motor

fasten motor to

adaptor

Fasten pump

affixing cap screws

Page 19

Trouble Shooting

Symptom: Water pump not operating

Remedy:

1. Ensure that the hydraulic hoses are connected as per manual drawings and match connection labels.

2. Check that 78 lpm minimum (20.6 gpm minimum) 165 bar minimum (2400 psi minimum) can be seen directly at the Vortex

water pump hydraulic motor. OPTIMUM FLOW IS 80 lpm (21 gpm) OPTIMUM PRESSURE IS 3000 psi (206 bar) (4500 psi max).

3. Check any quick connect fittings you may have in the circuit as they can sometimes be faulty.

4. Are your thrusters using most of the available system flow and starving your circuit feeding the Vortex water pump?

5. Ensure the Vortex case drain is connected directly to tank. It is preferable to connect as close as possible to the

reservoir and not run any hoses through quick connects.

Symptom: Debris removal slow

Remedy:

1. Check the caged nozzle of inlet hose is not blocked. Stop hydraulic flow to water pump to allow rocks and

debris to be cleared.

2. Check that all cam locks are fastened and secured correctly.

3. Check all cam lock o-rings are in place and in good condition.

4. Use steady and consistent movements when plunging suction hose inlet into seabed. Try side to side and up and down

movements of suction hose inlet. Differing conditions may require changing methods.

5. Check all hydraulic remedies as seen in “water pump not operating” section of trouble shooting.

6. Check inlet and exhaust hoses are not bent or blocked.

Page 20

Joe Goodin - Managing Director

VORTEX International Ltd, 27 Parrs Road, RD1, New Plymouth, New Zealand

Tel/Fax: +64 (6) 753 8102, Mobile: + 64 (0) 27 688 5372, Email: joe@vortexdredge.com, www.vortexdredge.com

In association with Ashtead Technology:

ABERDEEN

Ashtead Technology Ltd

Ashtead House, Discovery Drive, ArnhallBusiness Park,

Westhill, Aberdeenshire AB32 6FG

Tel: +44 (0)1224 771888,

Email: aberdeen@ashtead-technology.com

SINGAPORE

Ashtead Technology (S.E.A) Pte Ltd

Loyang Offshore Supply Base, 25 Loyang Crescent, Block 302,

Unit 02-12 TOPS Ave 3, PO Box 5157, SINGAPORE 508988

Tel: +65 6545 9350,

Email: singapore@ashtead-technology.com

HOUSTON

Ashtead Technology Offshore Inc

19407 Park Row, Suite 170, Houston, TX 77084, U.S.A

Tel: +1 281 398 9533,

Email: houston@ashtead-technology.com

SCOPE ENGINEERING

(Ashtead Technology Agent)

Scope Engineering (WA) Pty Ltd

35 Stuart Drive, Henderson, Western Australia 6166

T: +61 8 6498 9642 F: +61 8 6498 9584,

Email: Perth@ashtead-technology.com

Innova AS

P.O. Box 390 Forus, 4067 Stavanger

Phone: +47 51 96 17 00

Fax: +47 51 96 17 01

E-mail: post@innova.no

TES Survey Equipment Services LLC

PO Box 128256

Abu Dhabi

UAE

Tel: + 971 2 650 7710

Fax: +971 2 650 7200

E-mail: info@tesme.com

Loading...

Loading...