Page 1

Page 2

Models:

CDX2532G

CDX2532G-78

KEEP THIS BOOKLET

Please read and follow carefully before installing, operate, assemble, or maintain this product.

Make sure to observe all safety information to avoid injury of yourself and others. Non compli-

ance with recommended information can result in injury or property damage! Keep this booklet

for future reference.

Description

This plunger pump is capable of

pumping 2-2.5 GPM at 2500-3200 PSI.

Designed to be coupled with a direct drive

gasoline engine with a shaft spinning up

to 3400 RPMs. The three legged design

provides a convenient connection to

most 5hp 7/8” shaft engines. This

hollow shaft pump includes a

thermal relief valve(for protection

from overheating), an adjustable

unloader valve (for changing the

amount of psi for varying applications),

and a soap injection system (for those

really dirt jobs).

Page 3

Limited Warranty

Axial Radial Pumps are warranted for a period of two years to the

original purchaser. This is from the date shipped from factory or U.S.

Warehouse.

Warranty covers manufacturing defects or workmanship; that may

develop under normal use and service in a manner up to the directions

and usage recommended by the manufacturer.

Warranty does not apply to misuse or when pump or accessory is

altered or used in excess of recommended speeds, pressures, tempera-

tures or handling uids not suitable for pump or accessory material

construction. Warranty does not apply to normal wear (such as but not

limited to: seals/packings, valves, plungers and sealing o-rings), freight

damage, freezing damage or damage caused by parts or accessories

not supplied by Vortex Power Products.

Liability of manufacturer for warranty is limited to repair or replacement of parts only at the option of the manufacturer when such products are found to be of original defect or workmanship at the time it

was shipped from factory. This warranty is in lieu of all other warranties,

expressed or implied, including any warranty of merchantability and of

any and all other obligations or liabilities on the part of the manufacturers or equipment.

Page 4

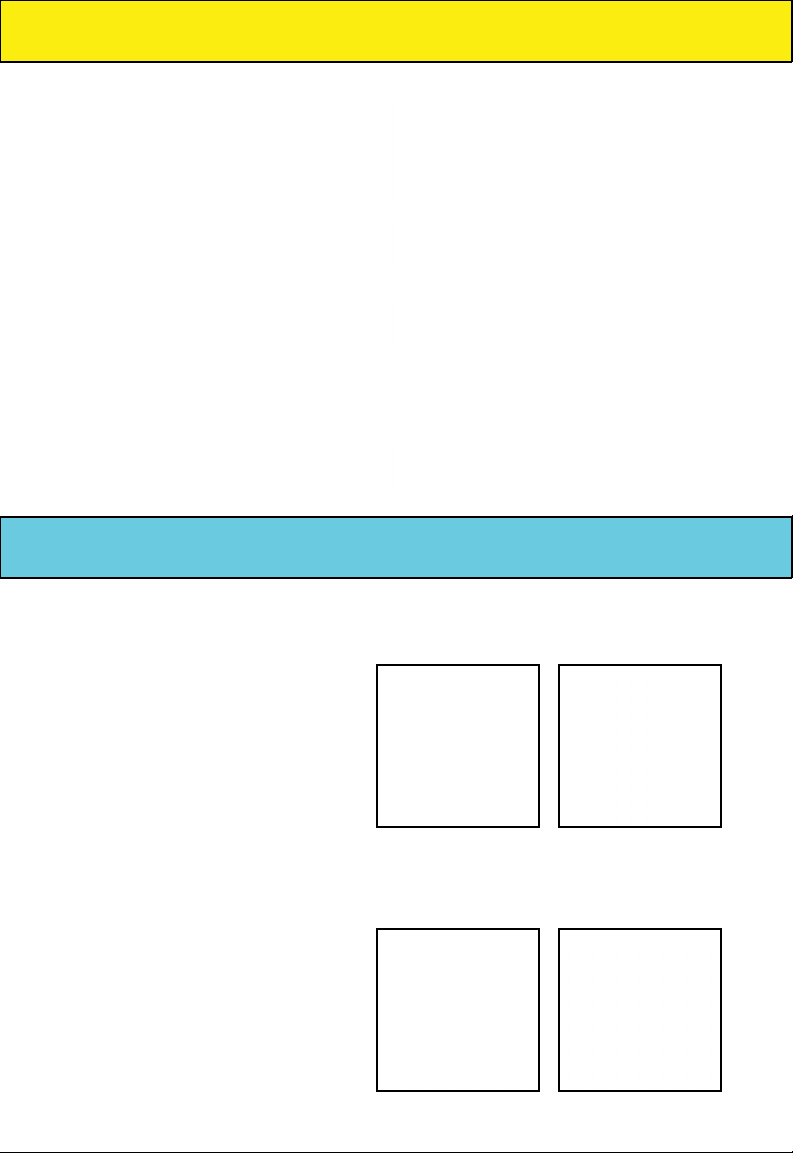

6.12 6.61 7.07 7.25 7.42 7.59 7.75 7.91 8.06 8.22 8.37 8.52 8.66 9.01 9.35 9.68 10.00 10.61 11.18

PSI PSI PSI PSI PSI PSI PSI PSI PSI PSI PSI PSI PSI PSI PSI PSI PSI PSI PSI PSI PSI

1.00 1.12 1.22 1.32 1.41 1.45 1.48 1.52 1.55 1.58 1.61 1.64 1.67 1.70 1.73 1.80 1.87 1.94 2.00 2.12 2.24

1000 1250 1500 1750 2000 2100 2200 2300 2400 2500 2600 2700 2800 2900 3000 3250 3500 3750 4000 4500 5000

2.0

ORIFICE

NOZZLE

NOZZLE SELECTION CHART

1.25 1.40 1.53 1.65 1.77 1.81 1.85 1.90 1.94 1.98 2.02 2.06 2.09 2.13 2.17 2.25 2.34 2.42 2.50 2.65 2.80

2.5

1.50 1.68 1.84 1.98 2.12 2.17 2.22 2.27 2.32 2.37 2.42 2.47 2.51 2.56 2.60 2.70 2.81 2.90 3.00 3.18 3.35

3.0

1.75 1.96 2.14 2.32 2.47 2.54 2.60 2.66 2.71 2.77 2.82 2.88 2.93 2.98 3.03 3.15 3.27 3.39 3.50 3.71 3.91

3.5

2.00 2.24 2.45 2.65 2.83 2.90 2.97 3.04 3.10 3.16 3.22 3.29 3.35 3.41 3.46 3.61 3.74 3.87 4.00 4.24 4.47

4.0

2.25 2.52 2.76 2.98 3.18 3.26 3.34 3.42 3.49 3.56 3.63 3.70 3.76 3.83 3.90 4.06 4.21 4.36 4.50 4.77 5.03

4.5

2.50 2.80 3.06 3.31 3.54 3.63 3.71 3.79 3.87 3.95 4.03 4.11 4.18 4.24 4.33 4.51 4.68 4.84 5.00 5.30 5.59

5.0

2.75 3.07 3.37 3.64 3.89 3.99 4.08 4.17 4.26 4.35 4.43 4.52 4.60 4.68 4.76 4.96 5.14 5.33 5.50 5.83 6.15

5.5

3.00 3.35 3.67 3.97 4.24 4.35 4.45 4.55 4.65 4.74 4.84 4.93 5.02 5.11 5.20 5.41 5.61 5.81 6.00 6.36 6.71

6.0

3.25 3.63 3.98 4.30 4.60 4.71 4.82 4.93 5.03 5.14 5.24 5.34 5.44 5.54 5.63 5.86 6.08 6.29 6.50 6.89 7.27

6.5

3.50 3.91 4.29 4.63 4.95 5.07 5.19 5.31 5.42 5.53 5.64 5.75 5.86 5.96 6.06 6.31 6.55 6.78 7.00 7.42 7.83

7.0

3.75 4.19 4.59 4.96 5.30 5.43 5.56 5.69 5.81 5.93 6.05 6.16 6.27 6.39 6.50 6.76 7.02 7.26 7.50 7.95 8.39

7.5

4.00 4.47 4.90 5.29 5.66 5.80 5.93 6.07 6.20 6.32 6.45 6.57 6.69 6.81 6.93 7.21 7.48 7.75 8.00 8.49 8.94

8.0

4.25 4.75 5.21 5.62 6.01 6.16 6.30 6.44 6.58 6.72 6.85 6.98 7.11 7.24 7.36 7.66 7.95 8.23 8.50 9.02 9.50

8.5

4.50 5.03 5.51 5.95 6.36 6.52 6.67 6.82 6.97 7.12 7.26 7.70 7.53 7.66 7.79 8.11 8.42 8.71 9.00 9.55 10.06

9.0

4.75 5.31 5.82 6.28 6.72 6.89 7.05 7.22 7.36 7.51 7.66 7.81 7.95 8.09 8.23 8.56 8.89 9.20 9.50 10.08 10.62

9.5

5.00 5.59

10.0

5.50 6.15 6.74 7.28 7.78 7.97 8.16 8.34 8.52 8.70 8.87 9.04 9.20 9.37 9.53 9.92 10.29 10.65 11.00 11.67 12.30

11.0

6.00 6.71 7.35 7.94 8.49 8.70 8.90 9.10 9.30 9.49 9.67 9.86 10.04 10.22 10.39 10.82 11.22 11.62 12.00 12.73 13.42

12.0

6.25 6.99 7.65 8.27 8.84 9.06 9.27 9.48 9.68 9.88 10.08 10.27 10.46 10.65 10.83 11.27 11.69 12.10 12.50 13.26 13.98

12.5

6.50 7.27 7.96 8.60 9.19 9.42 9.64 9.86 10.07 10.28 10.48 10.68 10.88 11.07 11.26 11.72 12.16 12.59 13.00 13.79 14.53

13.0

7.50 8.39 9.19 9.92 10.61 10.87 11.12 11.37 11.62 11.86 12.09 12.32 12.55 12.77 12.99 13.52 14.03 14.52 15.00 15.91 16.77

15.0

10.00 11.18 12.25 13.23 14.14 14.49 14.83 15.17 15.49 15.81 16.12 16.43 16.73 17.03 17.32 18.03 18.71 19.36 20.00 21.21 22.36

20.0

GPM

Page 5

General Safety Information

This pump is designed for pumping

non-amable or non-combustible

uids. The pump is intended to

pump clean ltered water.

Modictaions to the manufacturer

design is not recommended.

Do not operate in an enclosed area

or around explosive materials. Always make sure you have adequate

ventillation in your work environment.

Always wear the proper safety

equipment when operating this

pump.

Do not allow children to operate

this pump.

Be careful with where you point the

high-pressure discharge. Never

point it at a person or animals body

or body part.

Do not exceed pumps specications in shaft speed or discharge

pressure.

Maximum temperature of pumped

water should not exceed 140°F.

Winter/Long Term Storage

1. Drain all of the water from the

pump.

2. Screw in bottle of Vortex Pump

Saver to the garden hose inlet and

open up the valve on the cap of the

bottle.

3. Make sure your pressure washer

on off switch is in the off position and

slowly pull on the pull start rope while

squeezing the pump saver bottle to

cycle the contents through the pump.

4. When you see pump saver come

out of the outlet you can stop cycling

the pump. Close the valve on the

bottle cap and remove it from your

pump.

5. Before your next use make sure

you ush the pump by running fresh

water through it.

Page 6

1. Make sure the unit is powered off. Remove the mounting bolts that hold the old

pump to the engine, and remove the old pump. Make certain that the engine shaft is

clean and free of debris before installation of the new pump.

2. Place the shaft key into the key slot on the engine shaft. Hold it in place with your

nger while sliding the pump onto the engine shaft. Make sure that the shaft key

does not slide up the shaft and stays rmly in the key slot or you can risk damaging

the pump hollow shaft when tightening the mounting bolts.

3. After placing the pump onto the shaft with the key in place line up the 4 mounting

bolt holes with the 4 engine mount bolt holes. Slide your pump onto the shaft until

the mounting tabs are ush with the frame. There should be no gap between the

mounting tabs and engine.

Page 7

Installation

4. Once the pump is ush with the frame it’s time to bolt it together. Insert the

mounting bolt with a washer through the mounting tab bolt hole and tighten down

the bolts when you are absolutely positive that the mounting tabs are ush with the

engine or you can break a tab or damage the hollow shaft inside the pump.

5. Once the pump has been mounted to the engine make sure the on off switch is in

the off position and then slowly pull the pull start rope to ensure that the engine shaft

spins freely inside the pump. If it does not spin freely then the shaft key either slid up

the shaft and is binding or the pump isn’t ush to the engine and is binding because

it is tilted at an angle. Remove the pump and reinstall ensuring that each step is done

correctly.

Page 8

Unloader Adjustment

1. The rst step is to reset the

unloader. Turn the adjustment

knob counter clockwise until

there is absolutely no pressure

against the spring inside the

unloader.

2. Connect hoses to your pump

and run water to it. Now you will

need to purge the air from your

hoses by pulling the trigger until

only water comes out.

3. Run your pressure washer

4. With your pressure washer

running hold down the trigger

and slowly turn the adjustment

knob clockwise.

5. When pressure no longer

increases turn the knob counter

clockwise 1/2 turn and release

the trigger. NOTE: If the engine

stalls or acts as if it is still underload then you will need to repeat

steps 4 and 5 again until your

pressure washer goes into bypass mode and there is no load

on the engine.

6. Below the adjustment knob

you will nd a brass stopper

with a set screw. Loosen the set

screw and adjust the stopper

until it is snug against the adjustment knob. Tighten the set

screw to keep it in place

Page 9

Troubleshooting

Symptom Possible Cause Corrective Action

Oil leak between crankcase

and pump section

Frequent or premature

failure of the packing

Pump runs but produces

no ow

Pump fails to prime Air is trapped inside pump Disconnect discharge hose from pump. Flood

Pump loses prime, chattering noise, and/or pressure

uctuates

Low pressure at nozzle 1. Unloader valve is

Pressure gauge uctuates 1. Valves worn or blocked by

Low pressure 1. Worn nozzle 1. Replace with new nozzle of proper size

Pump runs extremely rough,

pressure very low

Worn oil seals around plunger Replace crankcase plunger oil seals

1. Cracked, damaged, or worn

plunger

2. Overpressure to inlet

manifold

3. Material in the uid being

pumped

4. Excessive pressure and/or

temperature of uid being

pumped

5. Running pump dry 5. Do not run pump without water

Pump is not primed Flood suction then restart the engine

1. Air leak in suction hose or

inlet

2. Clogged suction strainer 2. Clean strainer

by-passing

2. Incorrect or worn nozzle 2. Make sure nozzle is matched to the ow

3. Worn packing or valves 3. Replace packing or valves

debris

2. Packing worn 2. Replace packing

2. Air leak in inlet connection 2. Disassemble, reseal, and reassemble

3. Relief valve stuck, partialy

plugged or improperly adjusted valve seat, valve seat worn

4. Worn packing. Abrasive in

pump cavitation. Inadequate

water.

5. Worn inlet, discharge valve

blocked or dirty

1. Inlet restrictions and or air

leak

2. Stuck inlet or discharge

valve

1. Replace plunger

2. Reduce inlet pressure

3. Install lter to pump inlet

4. Check pressure and water inlet tempera-

ture. Be sure they are within specied ranges

suction hose and run the pump until all air

has been evacuated

1. Remove suction line and inspect it for

a loose liner or debris lodged in the hose.

Avoid all unnecessary bends and do not kink

1. Make sure unloader is adjusted properly

and by-pass seat is not leaking

and pressure of the pump. If the nozzle is

worn the replace it with a new one.

1. Clean or replace valves

3. Clean and adjust relief valve and check for

worn or dirty vavle seats

4. Install proper lter at manifold water inlet

5. Replace inlert and discharge valve

1. Clean out foreign material

2. Replace worn valve

Page 10

Troubleshooting

Symptom Possible Cause Corrective Action

Water leakage from under

manifold

Slight leak, oil leaking in the

area of the crankshaft

Water in crankcase 1. Humd air condensing into

Loud knocking noise in

pump

Worn packing or cracked

plunger

1. Worn crankshaft seal or

improperly installed oil seal

2. Bad Bearing 2. Install new bearing

water inside the crankcase

2. Worn packing and/or

cracked plunger

1. Cavitation or sucking air 1. Check that water supply is turned on

2.Broken or worn bearing 2. Replace bearing

Install new packing or plunger

1.Remove oil seal retainer and install new oil

seal

1. Change oil

2. Replace packing and/or plunger

Pump Servicing

Discharge Valve Removal

1. Remove the valve cap and inspect the

o-ring for damage and replace if neccessary.

2. Use a pair of needle nose pliers to remove

the check valve.

3. Use a small probe to move the poppet

up and down inside the valve to insure it is

function properly.

4. Remove any debris lodged between the

spring and poppet or the poppet and seat.

5. Inspect the seat o-ring for damage and

replace if damage is discovered.

Discharge Valve Installation

1. Insert the valve assembly squarely into the

valve port and rmly push it in using your

nger.

Should be quite snug when seated all of the

way.

2. Install the valve cap and torque it to down

221 ft. lbs.

Page 11

Pump Servicing

Inlet Valve Removal

1. Remove the pump head from the body.

Note:

Be careful not to damage parts below so they

can be reused if not worn

2. Remove the rst seal by inserting a screw driver

(or other device for levering) under the lip of the

seal and lift it up.

3. Using a pair of reversible pliers, carfully remove

the seal retainer from the head.

4. Carefully remove the check valve with a pair of

needle nose pliers.

5. Use a small probe to move the poppet up

and down inside the valve to insure it is function

properly.

6. Remove any debris lodged between the spring

and poppet or the poppet and seat.

7. Inspect the seat o-ring for damage and replace

if damage is discovered.

Inlet Valve Installation

1. Insert the valve assembly squarely into the

valve port and rmly push it in using your nger.

Should be quite snug when seated all of the way.

2. Insert the rst water seal (it wil be the thicker

one) and with your nger press it into the valve

port with the at side facing up. Should be a tight

t.

3. Assemble the retainer with the remaining water

seal inplace (at side facing up). Lubricate the retainer o-ring then insert the assembled retainer all

of the way into the valve port. The retainer should

stick out past the head surface.

4.Reinstall head and torque bolts to 221 ft. lbs.

Page 12

Pump Servicing

Easy Start Removal

1. Remove the easy start plug and inspect the

o-ring for damage or wear and replace if necessary.

2. Remove the ball and spring then clean them

and the barb of calcium build-up.

3. Using a coarse wood screw, insert it into the

seat and twist it until the threads catch in the

small hole at the bottom of the seat. When the

treads catch you will be able to pull the seat

out. Inspect the o-ring for damage or wear and

replace if necessary.

Easy Start Installation

1. Insert the seat then use something long and

skinny to push it fully into position inside the

pump head.

2. Place the spring in next making sure that it is

inserted inside the seat.

3. Insert the ball on top of the spring.

4. Install the easy start plug and torque it down

to 221 ft. lbs.

Unloader Valve Removal

1. Remove unloader from the head.

2. Using a hooked pick pull pull out the seat.

It may be stuck tight so you may need to pull

from multiple angles to work it out. Inspect

seat o-ring for damage or wear and replace if

necessary.

Page 13

Pump Servicing

Unloader Valve Installation

1. Insert the seat squarely in the port with the

at side facing up and the concave side facing

down.

2. Press the seat into place with a wide blunt

tool that will allow you to distribute pressure

equally across the seat while pressing it in

place.

3. Reinstall the unloader valve and tighten.

Chemical Injector Removal

1. Remove the hose barb and inspect the o-ring

for damage or wear and replace if necessary.

2. Remove the ball and spring. Then clean them

and the barb of calcium build-up.

Chemical Injector Installation

1. Insert ball into the injector barb followed by

the spring

2. Place the pump so that you can place the

assembled hose barb into the injector port

without the components falling out.

3. Tighten down the injector barb until snug.

Do not overtighten because the barb can easily

break or strip out the threads.

Page 14

Pump Breakdown

H 1002.0409 Easy Start Kit

G 1002.0458 Single Valve Cap

I 1001.3302 Vent Tube

D 1001.3298 Water Seal Kit

C 1001.3300 Check Valve Kit

E 1000.6353 Garden Hose Fitting

F 1001.2150 Thermal Valve

A 1002.0405 Unloader Valve

B 1001.3301 Injector Kit

PART NO. Description Price

Replacement Part Kits

Page 15

Notes

Page 16

Loading...

Loading...