Page 1

60 °C

90 °C

80 °C

70 °C

50 °C

40 °C

30 °C

20 °C

BWO 155 SL

30 °C6060

606000 °C°C°C°CCCC

C

0 °C°C°C°C°C°CC

°C°C080

°C°

°C°C°C

40

Original operating

instructions

Deutsche Vortex GmbH & Co. KG

Kästnerstraße 6

71642 Ludwigsburg

Germany

Fon: +49(0)7141.2552-0

E-Mail: info@deutsche-vortex.com

www. deutsche-vortex.com

Page 2

2

DIN EN 60335-1:2010-11; EN 60335-1:2002+ A11+ A1+ A12+ A2+ A13+ A14 :2010

DIN EN 60335-1/A15: 2012-03; EN 60335-1/A15: 2011

DIN EN 60335-2-51:2012-08; EN 60335-2-51: 2003+ A1+A2:2012

DIN EN 62233:2008-11; EN 62233:2008

DIN EN 62233 Ber.1: 2009-04; EN 62233 Ber.1:2008

DIN EN 62233 Ber,1:2009-04; EN 62233 Ber.1:2008

DIN EN 55014-1:2012-05; EN 55014-1:2006+ A1:2009+ A2:2011

DIN EN 61000-3-2:2010- 03; EN 61000-3-2: 2006+ A1:2009+ A2:2009

DIN EN 61000-3-3:2009-06; EN 61000-3-3:2008

DIN EN 55014-2:2009- 06; EN 55014-2:1997+ A1:2001+ A2:2008

(Legally binding signature of

the issuing entity)

(Place, date)

EC-Declaration of conformity

Name of

issuing entity: Deutsche Vortex GmbH & Co. KG

Address: Kästnerstraße 6

71642 Ludwigsburg

Deutschland

Product name: Domestic hot water pump

Type designation: BWO 155 SL

The designated product complies with the provisions of

Directives:

*

2006/95/EG

„Directive 2006/95/EC of the European Parliament and the

Council on the approximation of the laws of the Member

States relating to electrical equipment designed for use

within certain voltage limits“

and

2004/108/EG

„Directive 2004/108/EC of the European Parliament and

of the Council on the approximation of the laws of the

Member States relating to electromagnetic compatibility

and repealing Directive 89/336/EEC“.

* The conformity of the product with the provisions of the

Directives is proven by complete adherence to the

following standards:

Ludwigsburg, 01.01.2012

Page 3

3

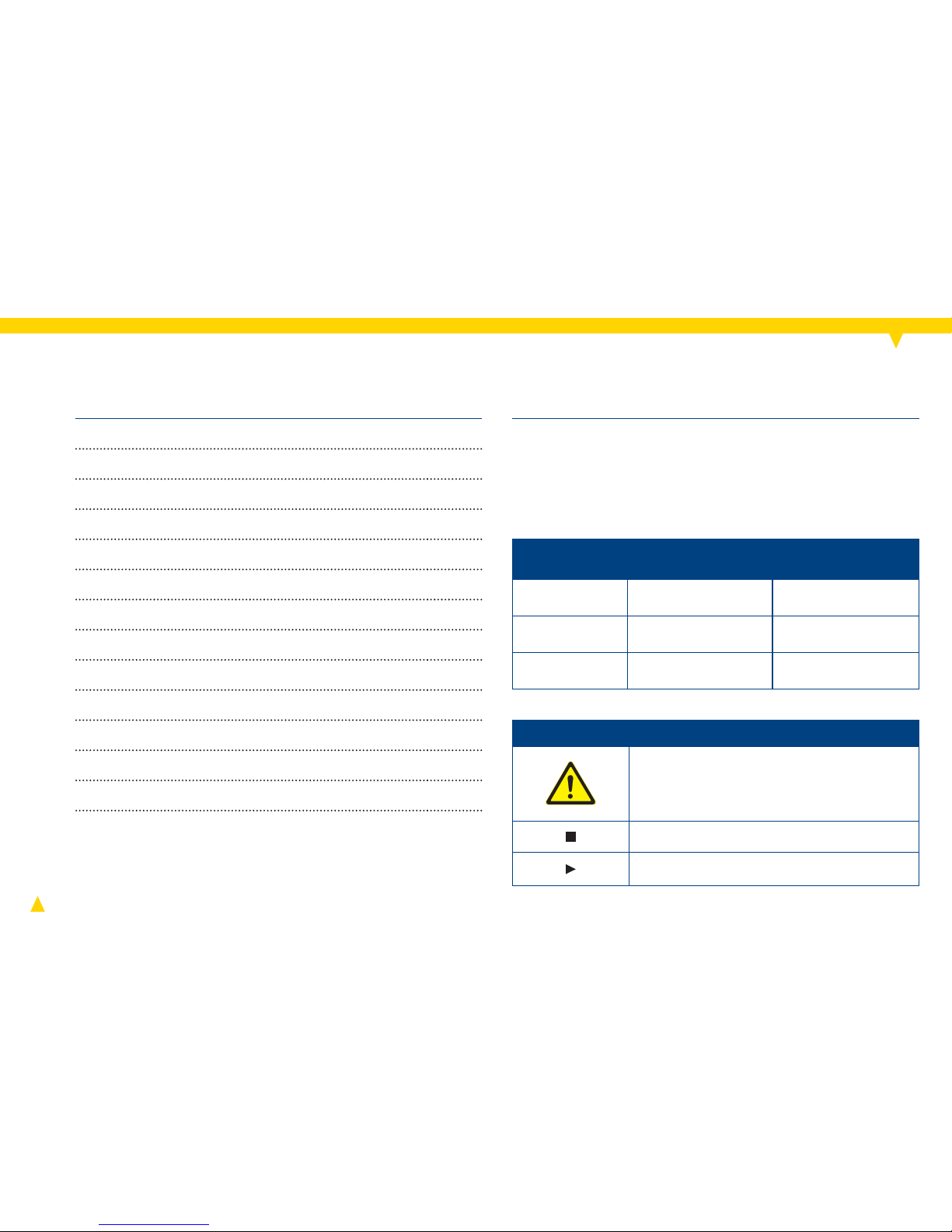

Declaration of conformity 2

Safety, product description 3

Technical specifi cations 5

Installation

* 6

Electrical connection

* 9

Venting

* 11

Speed adjustment

* 11

Mounting cable box 13

Self-learning module 16

Description of functions 17

Servicing

* 18

Replacement

* 20

Faults and remedies 22

These instructions are part of the product, are valid for all

series named and describe how to use the product safely

and correctly during all operating phases.

Danger!

immediate acute

risk

fatal or serious

injury

Warning! potential acute risk

fatal or serious

injury

Careful!

potentially hazardous situation

light injury, damage

to device

Warning labels and symbols

Safety warning sign: Take note of all

information indicated by the safety

warning sign and follow the instructions

to avoid injury or death.

Information

Instruction

Contents

Safety

Chapters marked with * contain illustrations of the pump BWO

155.

Warning label Risk level

Consequences of

non-observance

Symbol Meaning

Page 4

4

automatically identifi es the consumer’s hot water

consumption patterns within a short time. It identifi es

when hot water is needed and provides it proactively.

Using the button controller, the comfort setting can be

adjusted to the specifi c needs. LED indicators display the

current operating status of the pump.

automatically detects deviations from the “standard”

pattern, e.g. weekends, absence and daylight-savings

time.

automatically detects the time for the thermal

disinfection

1

.

switches the pump off as soon as the pump control

detects that hot water is available in the domestic hot

water (DHW) circuit.

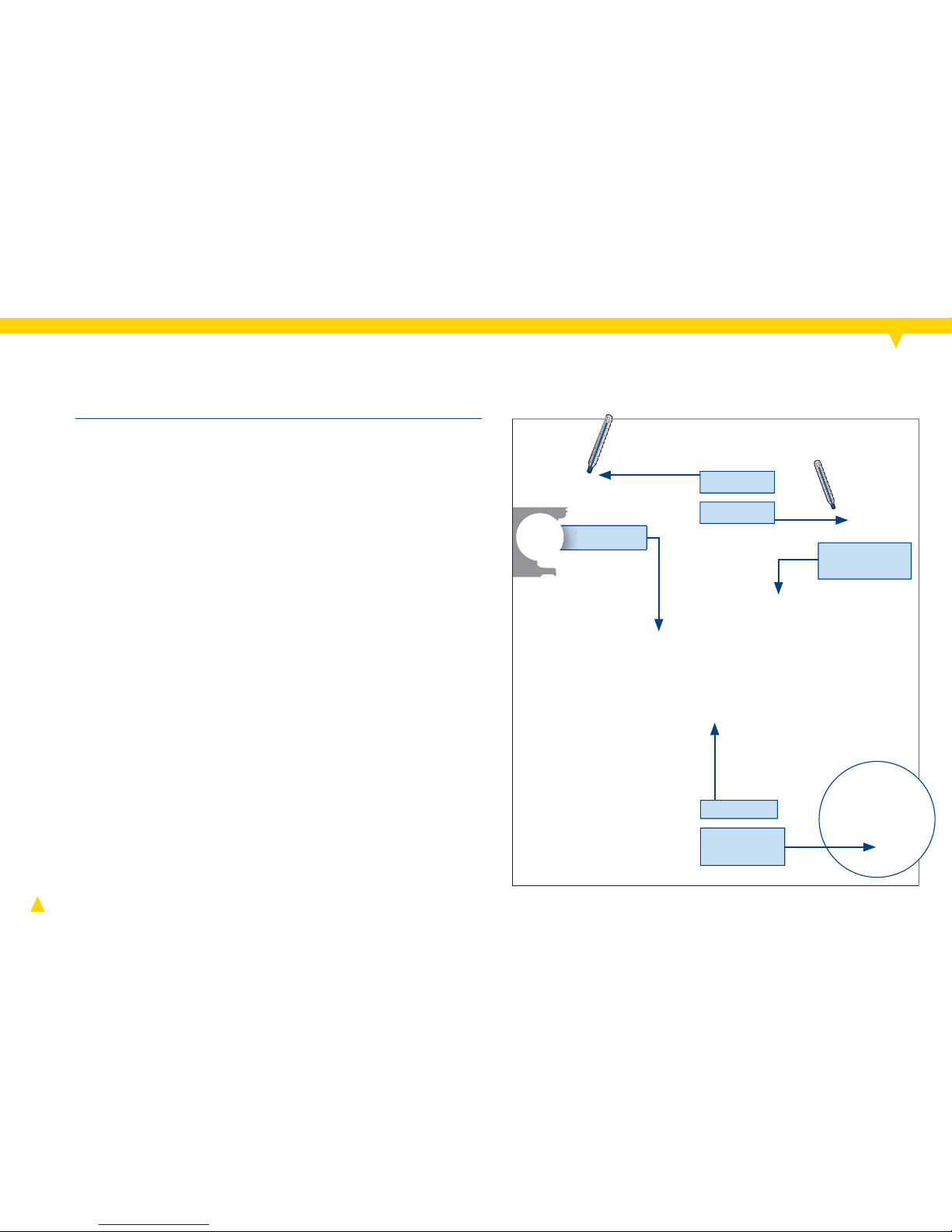

The self-learning module

(also see chapter "Functional description" p. 17)

Product description

The pump BWO 155 SL BlueOne is a domestic hot water

pump with a highly-effi cient electronically commutated DC

motor as drive source. It is built according to the original

VORTEX spherical motor principle and contains a permanent magnetic rotor. The speed of the pump BWO 155 SL is

infi nitely variable.

Installation of the pump may only be performed by quali-

fi ed personnel.

Keep the operating instructions and other applicable docu-

ments complete, in a legible condition and permanently

accessible.

Read the operating instructions and make sure you under-

stand them before working on the pump.

This pump is suitable for drinking water only.

Only operate the pump if it is in perfect technical condition;

only use it as intended, staying aware of safety and risks,

and adhering to the instructions in this manual.

Before carrying out any installation or maintenance work,

disconnect motor from power supply and ensure it cannot

be reconnected unintentionally.

General safety instructions

Page 5

5

P

max

= 10 bar

~ 43 dB(A)

TF 95

(t1 ≤ 95 °C)

t2 ≤ 40 °C

t1 ≤ 95 °C

1~115–230 V

50–60 Hz

Technical specifi cations

In branched pipework without hydraulic balancing, the level

of convenience may be reduced.

The pump run times can be reduced to a minimum with the

BWO 155 SL. This does not contradict DVGW working paper

W 551, since the protection required against the growth of

legionellae is attained through regular thermal disinfection. This is performed automatically by the BWO 155 SL

1

.

Furthermore, if the consumer is absent, regular water

exchange in the pipework is ensured (daily fl ushing).

Scope of delivery

Gaskets and selected union set for pumps with V-type

pump housing

Insulating cover for pump housing

Operating instructions

Cable box with temperature sensor, sensor cable

2

and

detachable cable tie

3 cable ties for attaching the sensor cable

1

Precondition: The hot water boiler has an anti-legionellae function.

2

A 5m long sensor cable is available as an accessory.

Page 6

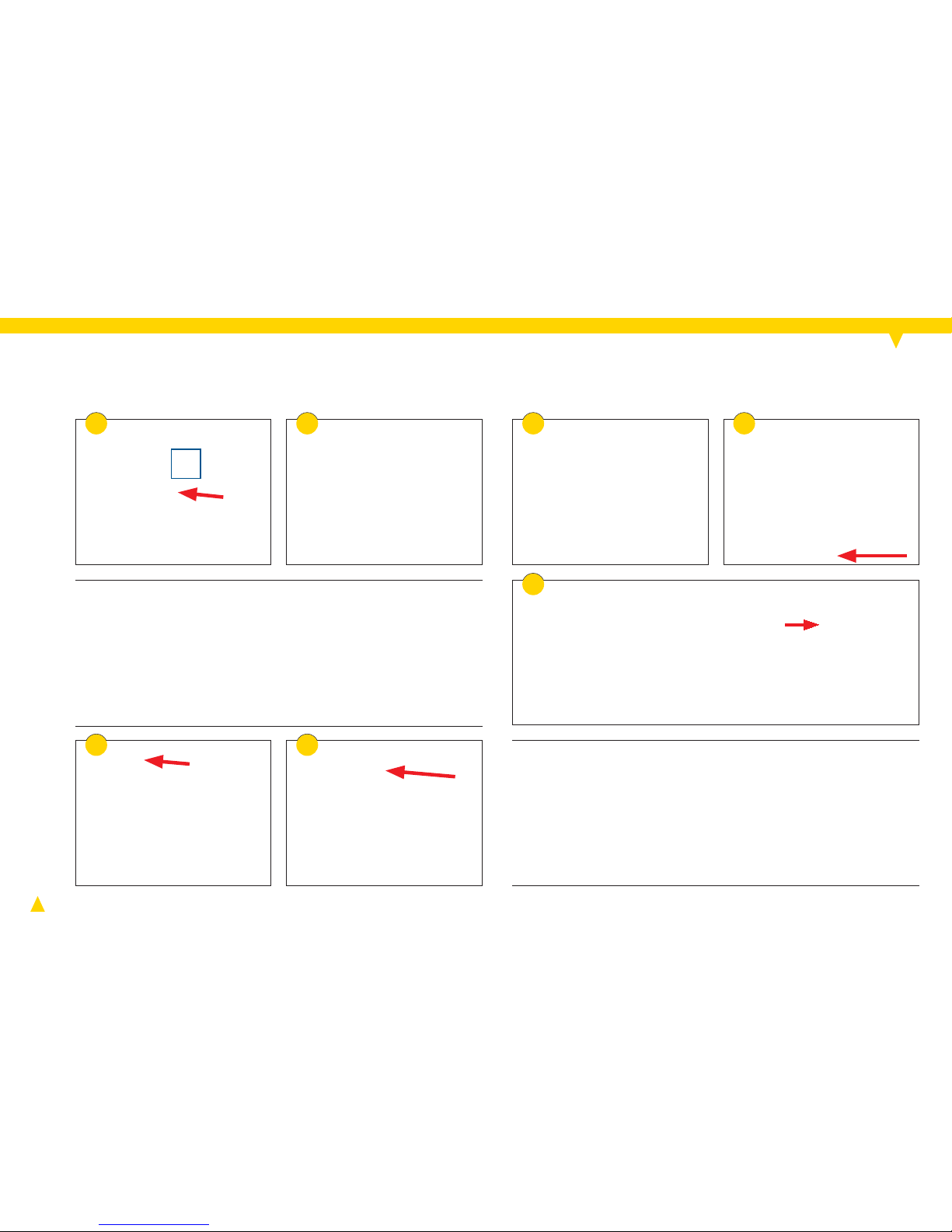

6

≥ 50 cm

KV 150

RV 153

(1)

(2)

≥ 50 cm

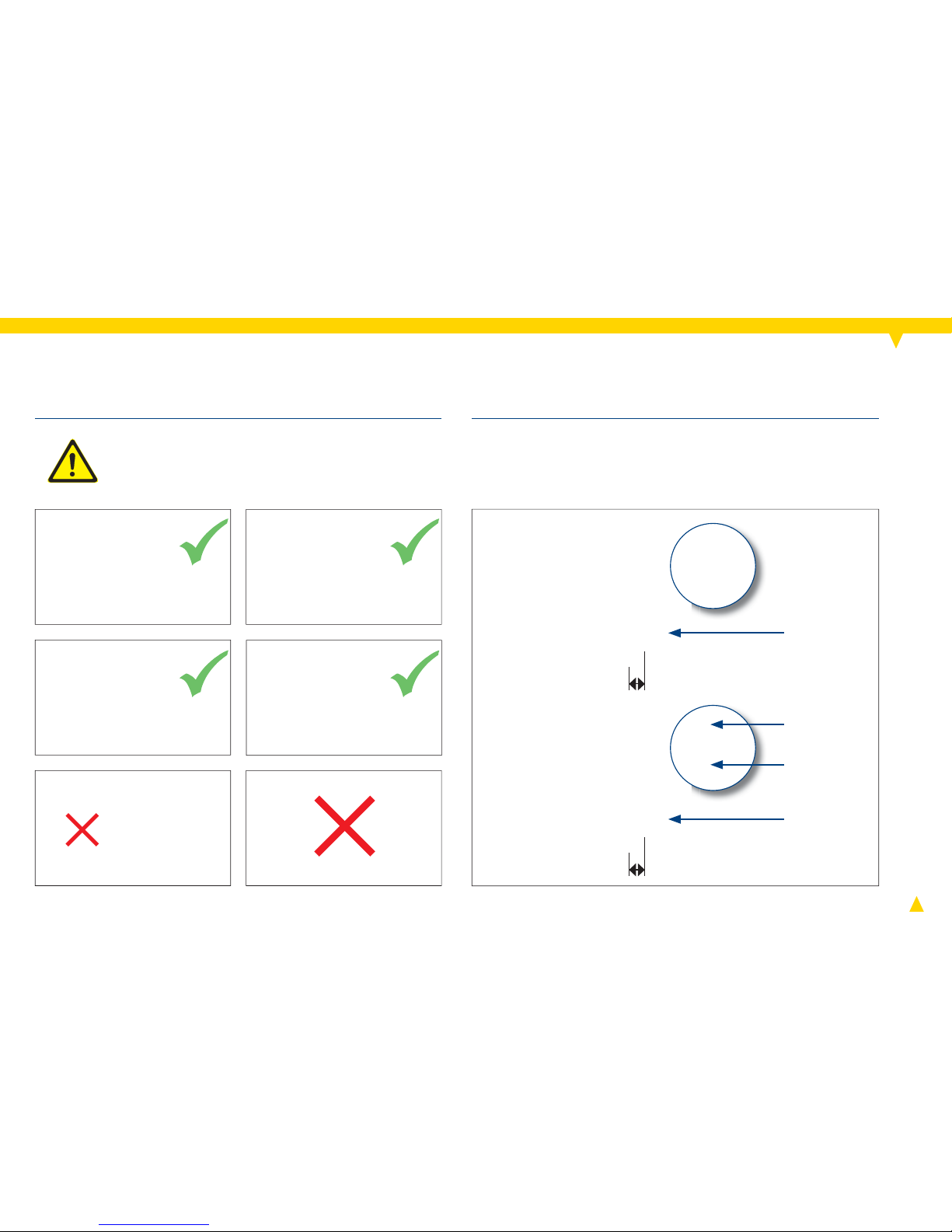

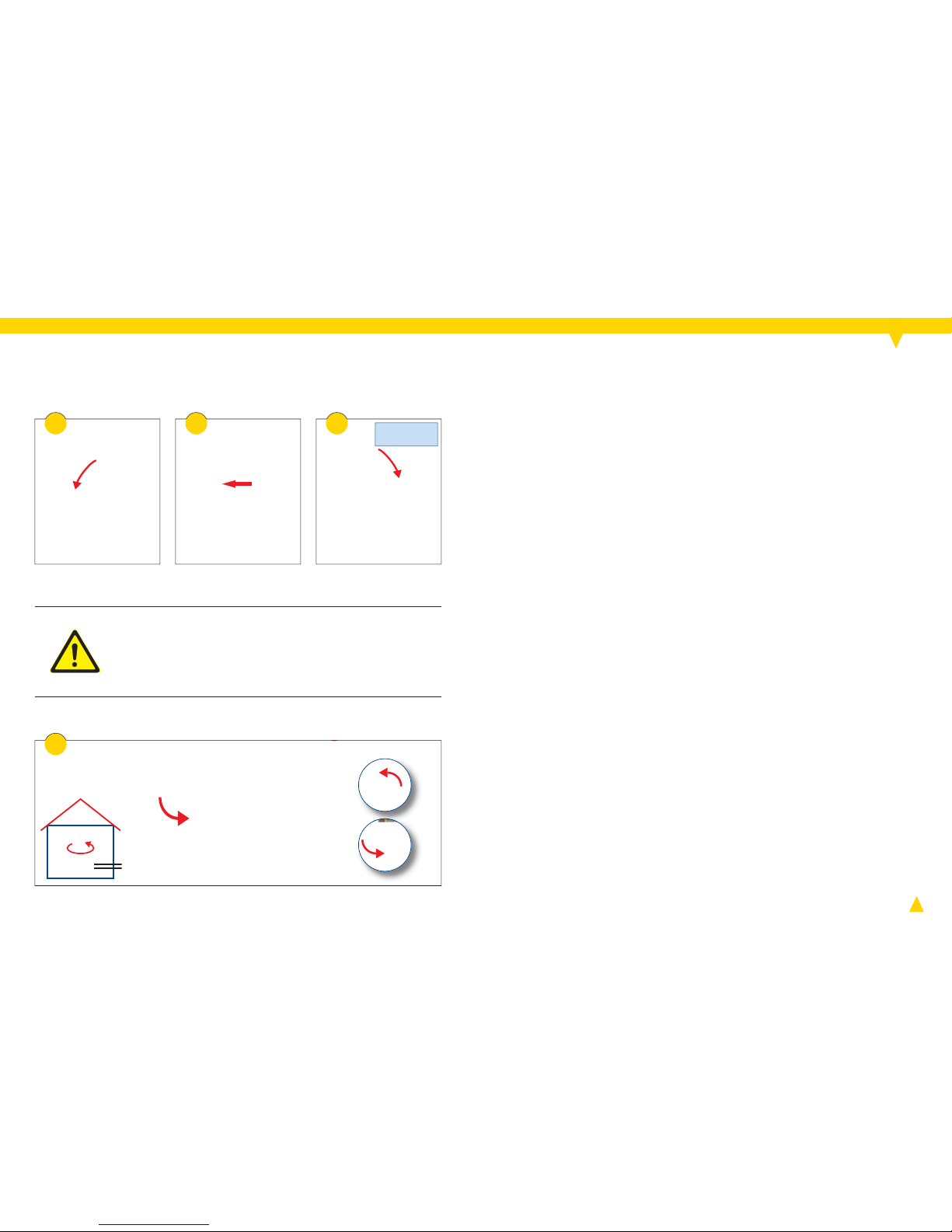

Careful! Damage to device caused by water

intrusion.

► After mounting, ensure that the cable entry

or the cable is pointing downwards (see fi g.).

Installation

A shut-off valve and a non-return valve are already built

into V-pumps (1).

► With R 1/2" pumps (2), build in an additional non-return

valve RV 153 and a ball shut-off valve KV 150.

Page 7

7

++

VORTEX EF 150

= 20 Nm

6 7

98

4 5

3

1

2

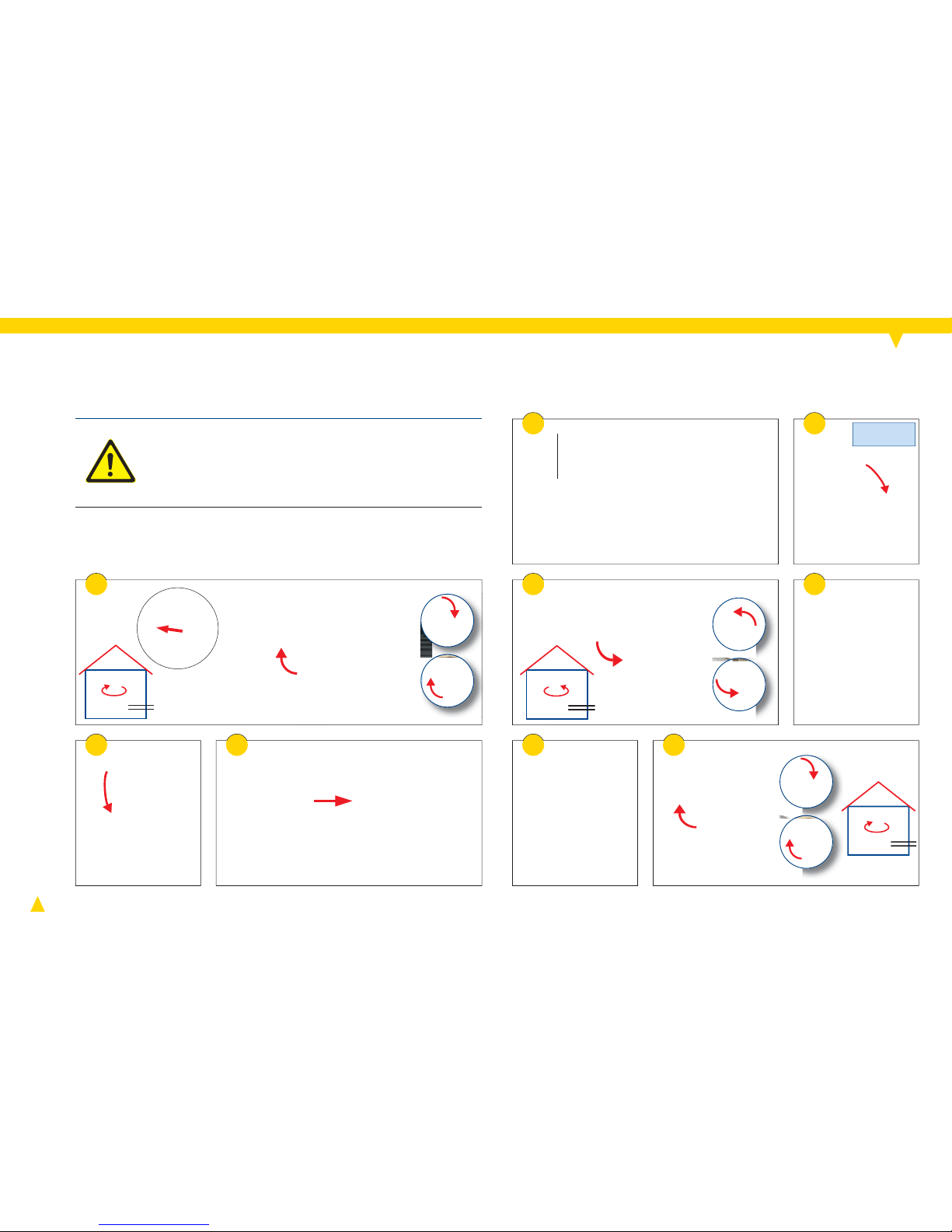

Careful! Damage to bearings caused by dry-

running.

► Flush pipework thoroughly with water and

bleed (see fi gs. 1-12).

Installation

Page 8

8

13

= 20 Nm

10 11 12

Careful! Damage to bearings caused by dry-

running.

► Flood the pump before connecting electric-

ity: Open all stop valves slowly (see fi g. 13).

Installation

Page 9

9

230 V~

8,5 - 10 mm

3a 3b 3c

21

The drive of the pump is a DC motor. Thus a protective

conductor is not required.

For AC operation a transformer is integrated in the cap.

Electrical connection

Danger! Danger of electrocution.

► Have all electrical work carried out by

qualifi ed electricians only.

► Turn off the power supply and safeguard it

against being switched back on (see fi g. 1).

► Check to make sure the power is turned off.

Warning! Fire hazard due to electrical

ignition.

► Make sure that the pump is only connected

to the power supply specifi ed on the name

plate.

Note: The pump deletes all commands for automatic starts

if the power supply is shut off.

► The pump requires an independent electrical power

supply. Do not connect the pump to an additional

controller or timer.

► A permanent power supply is possible, alternatively

use a mains plug with IP 44 rating (provide isolator that

separates all poles).

► Cable diameter 0.75 – 1.5 mm²

► Round cable with Ø 5 – 8 mm

► Connection with twisted wires, no wire end sleeves, no

tinned ends

Page 10

10

10

8 9

230 V~

7

5

4

230 V~ 230 V~

230 V~

6

11

The pump will run continuously as long as the sensor

cable is not connected (see fi g. 11).

Electrical connection

Page 11

11

0 100 200 300 400 500 600 700

0,2

0,4

0,6

0,8

1,0

1,2

1,4

2

4

6

8

10

12

14

800 900

Q [l / h]

H [mWS]

n = 2000 - 3000 1/minBWO 155 V

n = 2000 - 3000 1/minBWO 155 R

[kPa]

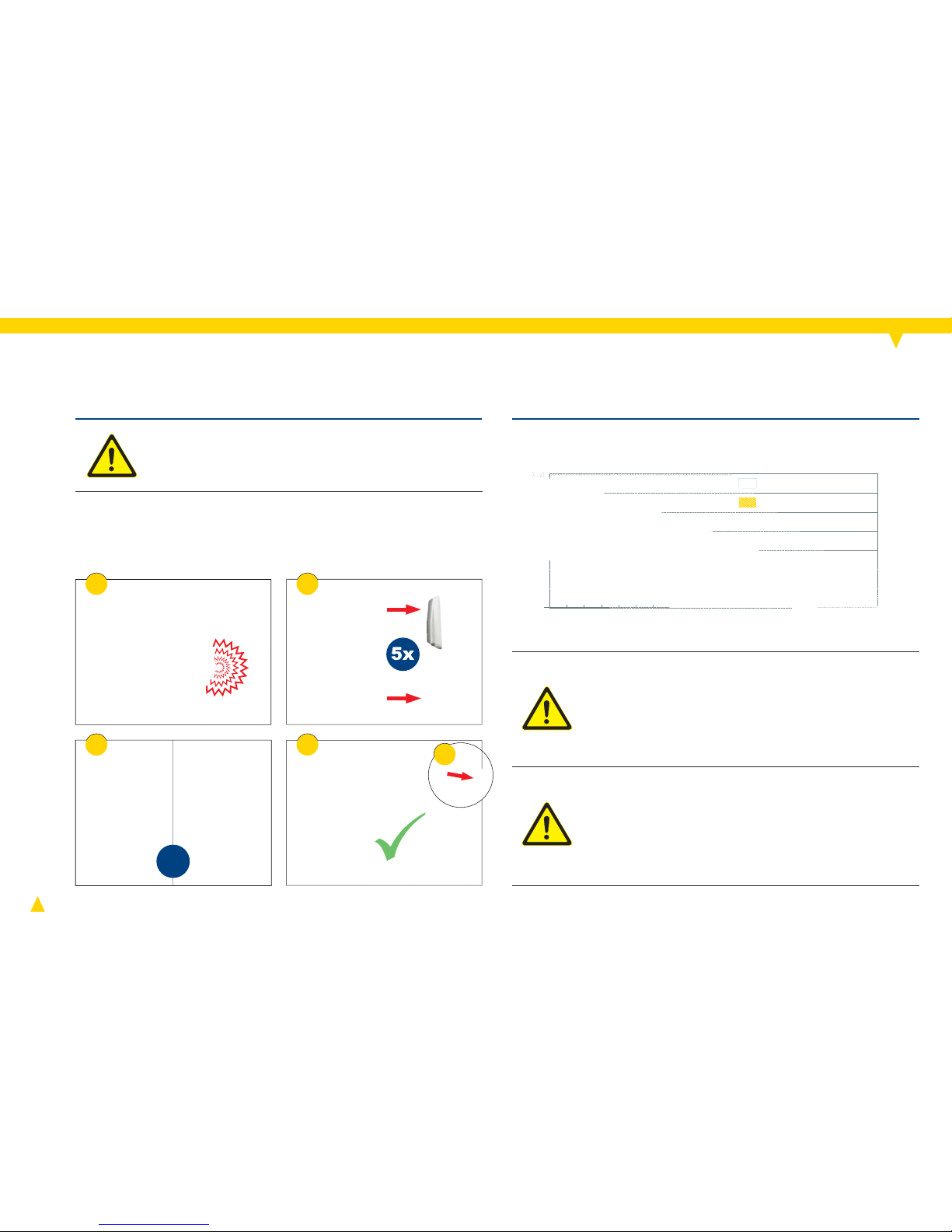

5x

3 4

1 2

5

Venting

Warning! Hot surface on pump housing and

motor. Danger of burns!

► Avoid direct contact with pump housing and

motor.

► Ensure that the return line is air-free (see p. 7). Then

act as follows to bleed the pump until it runs noise-free

(alternately):

► Switch the pump on and off several times (see fi g. 2).

► Open a hot water tap several times (see fi g. 3).

Speed adjustment

Danger! Danger of electrocution.

► Before working on the pump, disconnect

power supply and ensure that it cannot be reconnected unintentionally (see fi g. 1, p. 12).

► Check to make sure the power is turned off.

Warning! Hot surface on pump housing and

motor. Danger of burns!

► Avoid direct contact with pump housing and

motor.

The speed is infi nitely variable.

Page 12

12

3

4

2

230 V~

7

5

6

1

Speed adjustment

Page 13

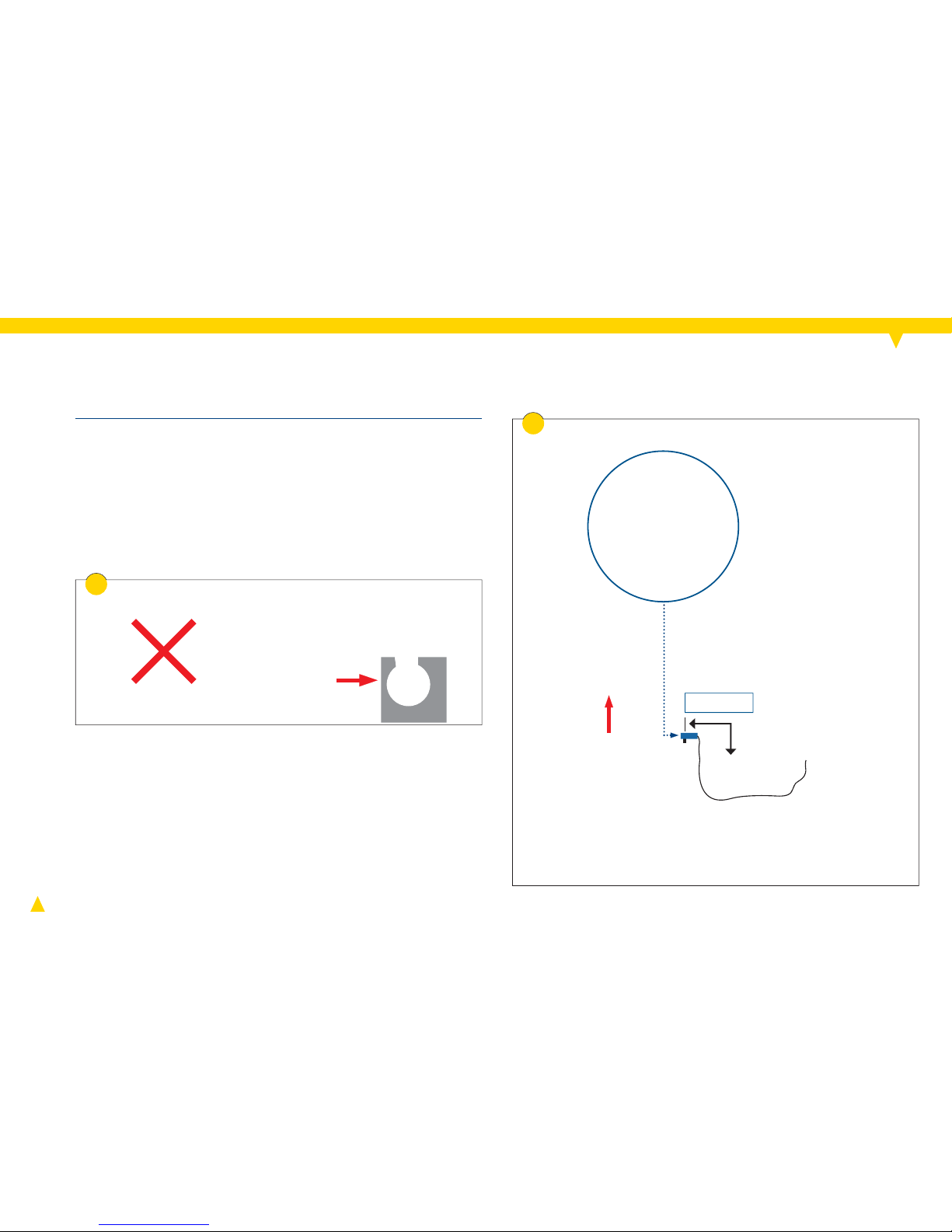

13

20 - 50 cm

2

1

Mounting cable box

Note! Malfunctions of the self-learning module are possible

as a result of incorrect installation.

► Note order of assembly steps (installation sequence).

► Disconnect power supply and ensure that it cannot be

reconnected unintentionally (see fi g. 1).

Installation conditions

The cable box must be mounted onto the supply line (hot

water pipe), independently from the type of hot water

generating system used.

Optimal distance of the cable box to the boiler: 20 to

50 cm.

If a mixer valve is present: The cable box can be installed

before or af ter the mixer valve.

Page 14

14

AB

B

3 4 8

6 7

5

A

Warning! Danger of stumbling by loose sensor

cable.

► Secure the sensor cable with the cable ties

after laying (see fi gs. 6 and 14).

Installation sequence

Measure distance between pump and point of installa-

tion of cable box. Only pull as much sensor cable from

the cable box as required. The maximum length of the

sensor cable is 2.50 m. A 5m long sensor cable is available as an accessory.

The sensor cable can only be wound up or unwound

when plug A is still inside the cable box (see fi g. 4).

Mounting cable box

Page 15

15

9 10

11

12

13 14

A

15

Mounting cable box

► Fix cable box to supply line using the cable tie.

► Ensure there is suffi cient thermal contact between the

sensor and the supply line.

Restart: As soon as the power supply has been restored,

the pump and the self-learning module will be ready for

operation, LED indicator 3 will be illuminated (basic setting), and the learning process will begin.

Page 16

16

4

3

5

6

1

1

2

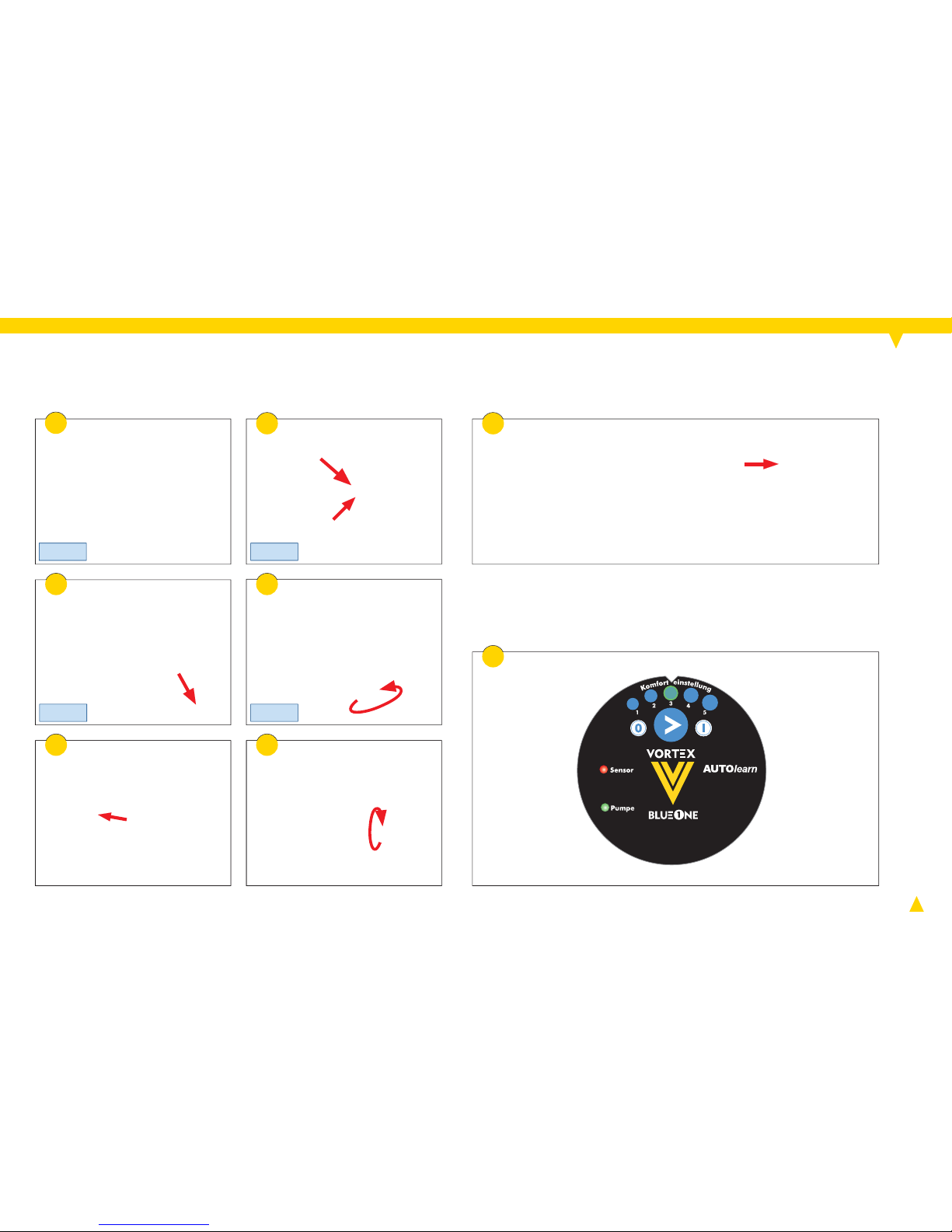

Button and LED indicators :

Legend for fi g. 1:

1

Select the operating mode (clockwise):

2

Comfort setting

3

Continuous pump run

4

Pump stop

5

Pump is running (LED is illuminated green) or it is

switched off (LED is not illuminated)

6

Sensor fault (LED is illuminated red, see p. 23)

Step 1: Maximum energy savings, minimum pump

run times

Step 2: Normal comfor t, short pump run times

Step 3: Basic setting – good comfort, average pump

run times

Step 4: Very high comfort, normal pump run times

Step 5: Maximum comfort, increased pump run times

► Press

1

until the desired operating mode is illuminated.

It will be active immediately.

Changing the operating mode:

Comfort settings:

Press

1

for 5 seconds. All acquired switch-on commands

will be deleted, comfort setting 3 will be set again.

Restoring the factory default settings (reset):

Self-learning module

After establishing a connection to the electric power

grid, the comfort setting 3 will be set (LED 2 is illuminated). This comfort setting is optimal for the majority of

the applications.

► We recommend to wait three weeks before altering the

comfort settings.

► If no hot water is available immediately after opening a

tap, close tap again and wait until circulation has started.

The comfort setting is retained (non-volatile) in case of

power failure.

Page 17

17

How does the pump learn?

A hot water tap is opened. The supply line heats up. This

is detected by the pump through the external temperature

sensor and the point in time of the hot water tap is learned.

For periodic (typical) taps the pump will proactively execute a

pump run (approx. 5 to 15 minutes prior to that point in time).

When does the pump start to run?

For reasons of comfort and independent of DHW drawings,

the pump starts frequently during the fi rst 2 weeks (early

part of the learning phase).

Afterwards, the pump starts in the following cases:

- proactively (at the typical "learned" points in time),

- when hot water is tapped (at not yet learned points in time),

- for a fl ushing or disinfection cycle (see below).

The pump calculates the need for a pump run individually

every single day (Mon to Sun) based on the previous hotwater taps of the last 2 weeks.

How long does the pump run?

The pump will run until the circulation loop is supplied with

warm water (detection through a thermostat in the pump).

The run time depends on the size of the circulation system.

How long does the pump run per day?

The daily runtime depends on the size of the circulation

system, the comfort setting and the tapping behavior of

the consumer. Typically, the pump will run between 1 and 5

hours daily.

Description of functions

How does the disinfection cycle recognition work?

The highest fl ow temperature measured in a given week is

interpreted as the disinfection temperature. At this point in

time, the pump will run for 30 minutes (once per week). If at

any other time of the week a higher supply temperature is

detected, the pump will shift the disinfection cycle to that

point in time.

How is absence detected (vacation detection)?

If no hot water is tapped within 24 hours, the pump will

determine an absence. Proactive pump runs will no longer

occur. A detected disinfection cycle will still be performed

(once per week). Otherwise, the pump will perform a daily

fl ushing cycle (duration: 15 minutes).

How will the return from the absence be recognized?

With 2 hot water tappings within an hour the previously

learned cycle will come into effect again.

How do you delete the learned tappings (reset)?

The self-learning module erases all learned switch-on

commands if the power is interrupted or the button

1

is

pressed for 5 seconds.

Page 18

18

6

4

7 8

3

5

2

1

Danger! Danger of electrocution.

► Before working on the pump, disconnect power

supply and ensure that it cannot be reconnected unintentionally (see fi g. 2).

► Check to make sure the power is turned off.

Note: Damage of sensor cable.

► When removing the motor from the pump housing, pay

attention to the sensor cable (fi xed with cable ties).

Servicing

Page 19

19

5x

16

17

9 10

11

13

14

12

15

= 20 Nm

► Technical support is available from your heating and

sanitary specialist or from Deutsche Vortex.

Servicing

► Ever y time the motor is opened, replace the sealing

ring (see fi g. 9).

► Insert the new sealing ring into the groove in the pump

housing and press slightly into place (see fi g. 10).

Page 20

20

11

5 6 7

8

9 10

= 20 Nm

1 2

3 4

Danger! Danger of electrocution.

► Before working on the pump, disconnect

power supply and ensure that it cannot be

reconnected unintentionally (see fi g. 1).

► Check to make sure the power is turned off.

Motor

Replacement

Page 21

21

1

3

2

► Concluding the exchange: See chapters starting at Elec-

trical Connection, p. 9 and further.

Cap/control module

Danger! Danger of electrocution.

► Have all electrical work carried out by quali-

fi ed electricians only.

► Disconnect power supply and ensure that it

cannot be reconnected unintentionally

(see fi g. 1).

► Check to make sure the power is turned off.

Replacement

► Concluding the exchange: See chapters starting at Elec-

trical Connection, p. 9 and further.

Page 22

22

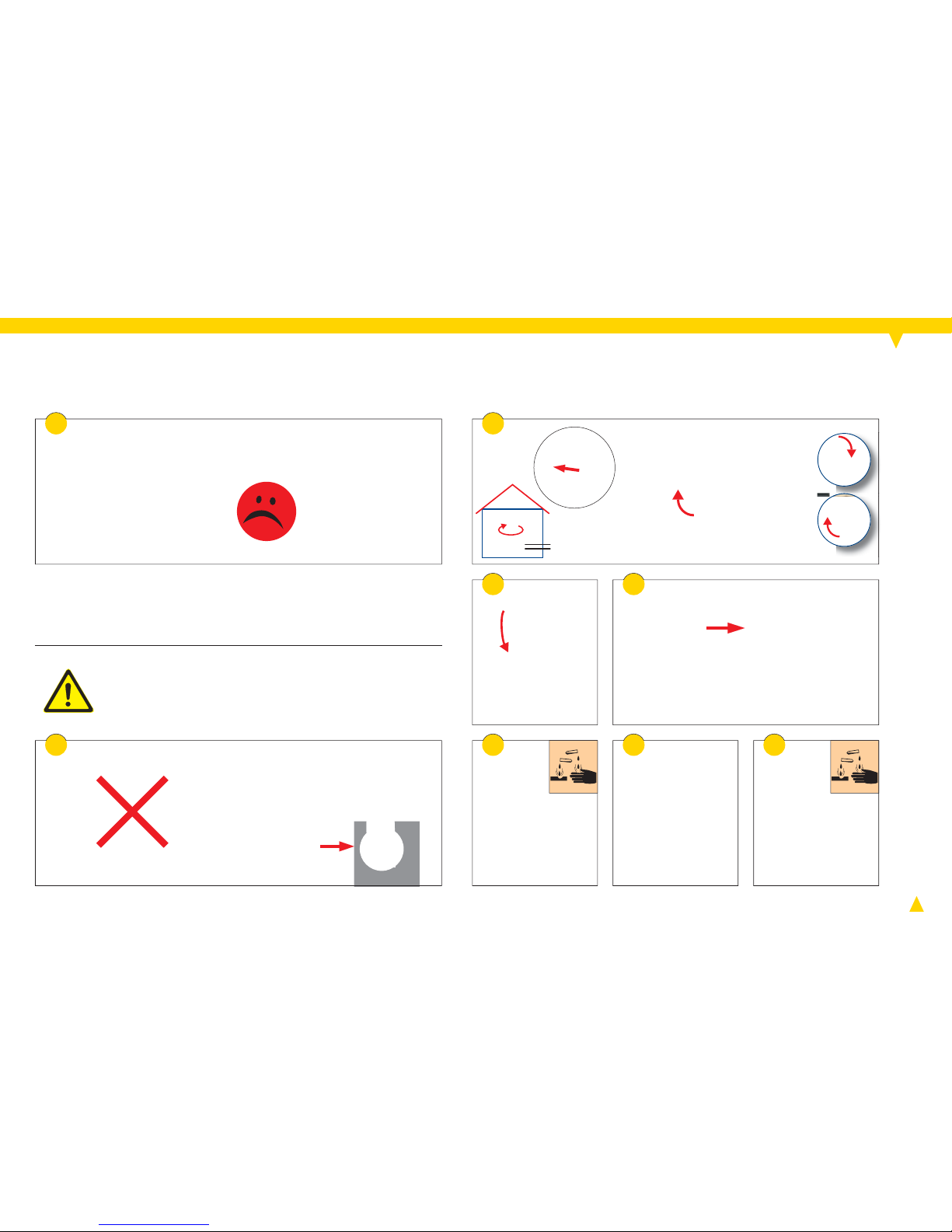

Pump is not

running: LED

"Pumpe" (pump)

is not illuminated.

Power supply is interrupted. ► Make sure that the power supply is establis-

hed correctly.

Electrical connection,

p. 9.

Cooling down, in case of a detected ab-

sence or if there is no current demand.

► Wait for the next pump start or tap hot

water.

Pump is not

running: LED

"Pumpe" (pump)

is illuminated.

Motor is defective (electrical/electronics). ► Replace motor.

Replacement, p. 20.

Rotor is blocked because the rotor bearing is

defective.

Rotor is blocked by debris. ► Clean wetted parts.

Servicing, p. 18.

LED "Sensor" is

illuminated red.

E xternal sensor is defective. ► Replace the cable box. Mounting cable box,

p. 13 and further

Sensor cable connection is interrupted. ► Check electrical connections (contact

of blue plugs) and replace module, if

required.

Mounting cable box,

p. 13 and further

Pump stops the

rotor continuously.

Air in the pump housing, dr y run protection

is active.

► Bleed the circulation line.

Installation, p. 6 and

Venting, p. 11.

Faults and remedies

► Observe the chapter “Safety” (see p. 3).

Fault Cause Remedy Chapter/page

Page 23

23

The pump "is

not learning” /

insuffi cient DHW

provision.

The circulation is blocked. ► Restore the fl ow.

The cable box is not mounted to the supply

line.

► Mount the cable box to the supply line

(avoid mounting on braces, valves etc.).

Mounting cable box,

p. 13 and further

The cable box is mounted on a non-heat

conducting piece of pipework.

► Use heat conducting pipework material

(metal, plastic, composites).

Mounting cable box,

p. 13 and further

Non-return valve is missing or constantly

open (gravity circulation!).

► Install or replace V-pump housing or the

non-return valve RV 153.

Speed is set too low. ► Increase speed. Speed adjustment,

p. 11 and further.

No hydraulic balancing where there are

branches in the pipework.

► Perform hydraulic balancing or install a

different control module (timer or control

thermostat)

Pipework too extensive; pump rate too low. ► Install a larger DHW circulation pump.

Pump makes

noise.

Air in the pump housing. ► Bleed the circulation line.

Installation, p. 6 and

Venting, p. 11.

Rotor bearing defective. ► Replace the rotor. If the bearing pin is

damaged exchange the motor.

Replacement, p. 20.

Non-return valve is loose. ► Exchange the V-type pump housing or non-

return valve installed behind the pump

(e.g. RV 153).

Installation, p. 6.

Faults and remedies

► Observe the chapter “Safety” (see p. 3).

Fault Cause Remedy Chapter/page

Page 24

BWO

BWO

155 SL

155 SL

199-13 0-287-en · 0 5/14

Original operating instructions

Deutsche Vortex GmbH & Co. KG

Kästnerstraße 6

71642 Ludwigsburg · Germany

Fon: +49(0)7141.2552-0

E-Mail: info@deutsche-vortex.com

www.deutsche-vortex.com

Loading...

Loading...