Vortex BLUEONE BWO 155, BLUEONE BWO 155 ERT, BLUEONE BWO 155 12V, BLUEONE BWO 155 Z Original Operating Instructions

Page 1

90 °C

80 °C

BWO 155 · BWO 155 12V

BWO 155 Z · BWO 155 ERT

Original oper ating

instructions

Deutsche Vortex GmbH & Co. KG

Kästnerstraße 6

71642 Ludwigsburg

Germany

Fon: +49(0)7141.2552-0

E-Mail: info@deutsche-vortex.com

www. deutsche-vortex.com

70 °C

60 °C

50 °C

40 °C

30 °C

20 °C

Page 2

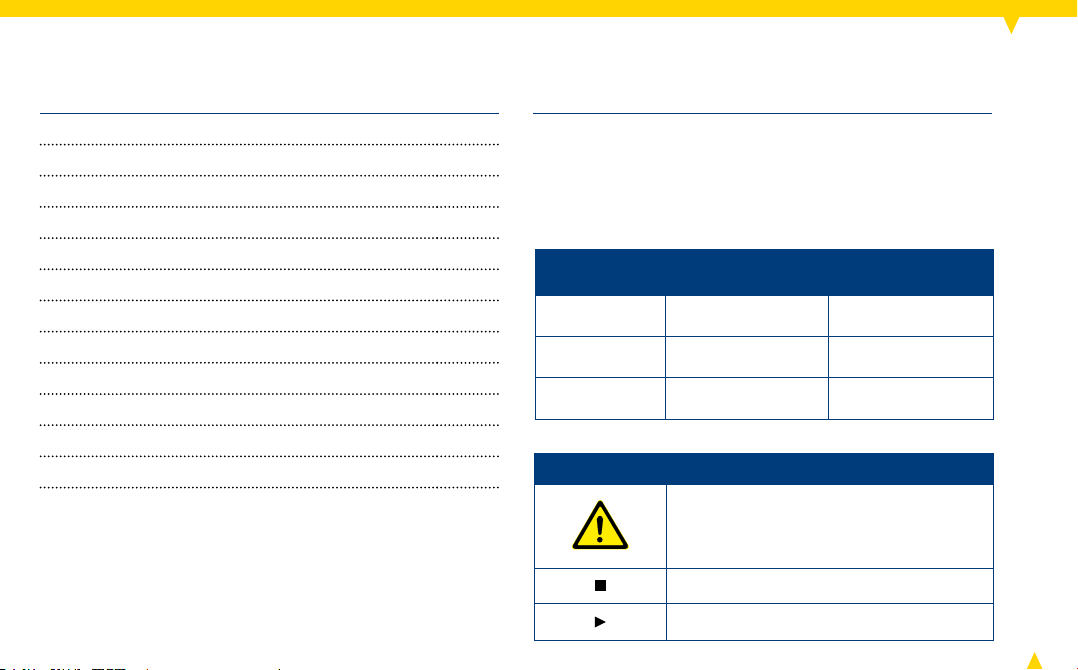

Contents Safety

Safety 2

Product description, declaration of conformity 3

Technical specications 4

Installation 5

Electrical connection 7

Venting 9

Timer 10

Electronic regulating thermostat ERT 12

Speed adjustment 13

Servicing 15

Replacement 17

Faults and remedies 19

These instructions are part of the product, are valid for all

series named and describe how to use the product safely

and correctly during all operating phases.

Warning labels and symbols

Warning label Risk level

Danger!

Warning! potential acute risk

Careful!

Symbol Meaning

immediate acute

risk

potentially hazardous situation

Safety warning sign: Take note of all

information indicated by the safety

warning sign and follow the instructions

to avoid injury or death.

Information

Instruction

Consequences of

non-observance

fatal or serious

injury

fatal or serious

injury

light injury, damage

to device

2

Page 3

Product description

General safety instructions

Installation of the pump may only be performed by quali-

ed personnel.

Keep the operating instructions and other applicable docu-

ments complete, in a legible condition and permanently

accessible.

Read the operating instructions and make sure you under-

stand them before working on the pump.

This circulator is suitable for drinking water only.

Only operate the pump if it is in perfect technical condition;

only use it as intended, staying aware of safety and risks,

and adhering to the instructions in this manual.

Before carrying out any installation or maintenance work,

disconnect motor from power supply and ensure it cannot

be reconnected unintentionally.

This device may only be used, cleaned or maintained

by children aged 8 years and over; persons with limited

physical , sensory or mental faculties; as well as persons

with limited experience or lack of knowledge; under supervision or after they have been instructed for the safe use of

the device and understand the resulting dangers. Children

are not allowed to play with the device.

3

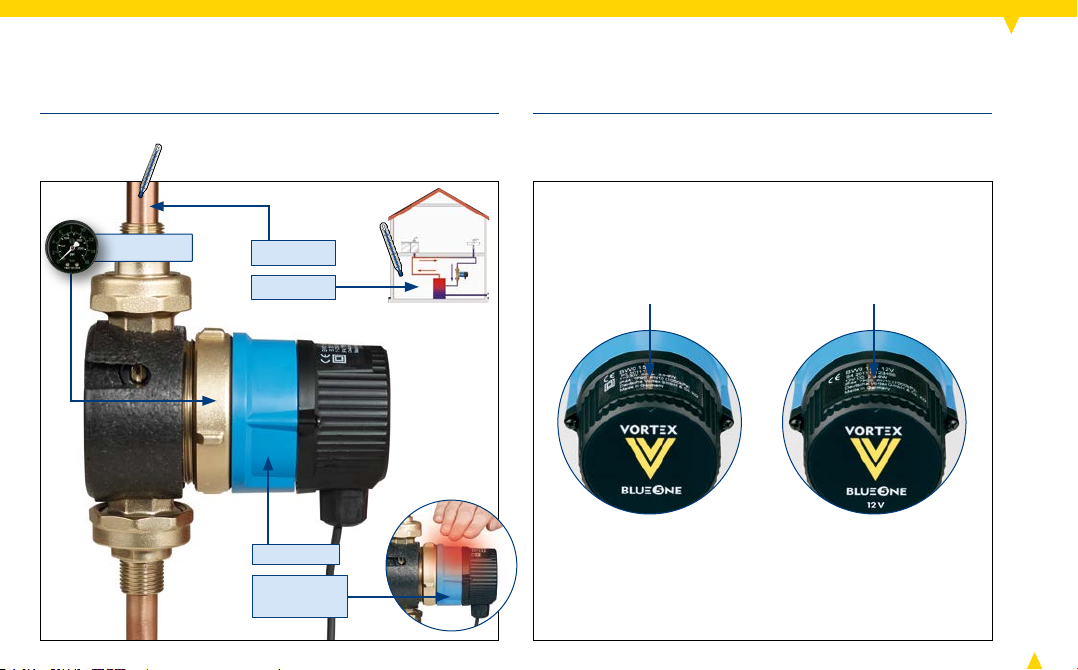

The pump BWO 155 BlueOne is a domestic hot water pump

with a highly-efcient electronically commutated DC motor

as drive source. It is built according to the original VORTEX

spherical motor principle and contains a permanent magnetic

rotor. The speed of the pump BWO 155 is innitely variable.

Scope of delivery

Gaskets and selected union set for pumps with V-type

pump housing

Insulating cover for pump housing

Operating instructions

Declaration of conformity

This product meets the applicable European directives and

the complementary national requirements and standards.

Conformity has been proven. The declaration of conformity can be retrieved under www.deutsche- vortex.com or

directly from Deutsche Vortex GmbH & Co. KG.

Page 4

Technical specications

P

= 10 bar

max

t1 ≤ 95 °C

t2 ≤ 40 °C

~ 43 dB(A)

TF 95

(t1 ≤ 95 °C)

1~115–230 V

50–60 Hz

12 V=

4

Page 5

Installation

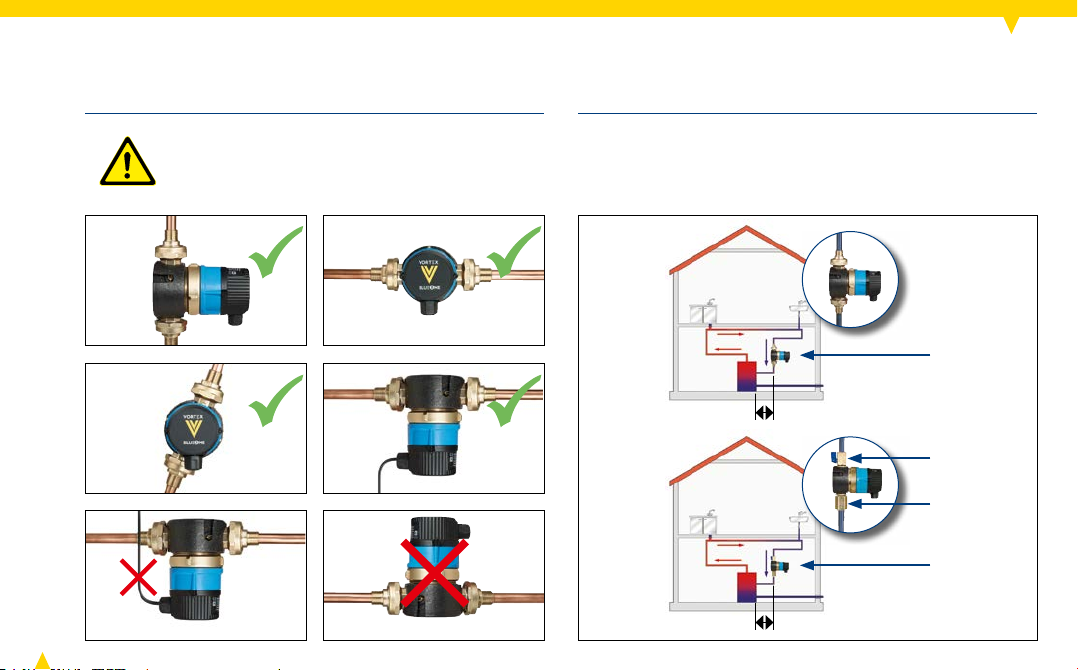

Careful! Damage to device caused by water

intrusion.

► After mounting, ensure that the cable entry

or the cable is pointing downwards (see g.).

5

A shut-off valve and a non-return valve are already built

into V-pumps (1).

► With R 1/2" pumps (2), build in an additional non-return

valve RV 153 and a ball shut-off valve K V 150.

(1)

≥ 50 cm

KV 150

RV 153

(2)

≥ 50 cm

Page 6

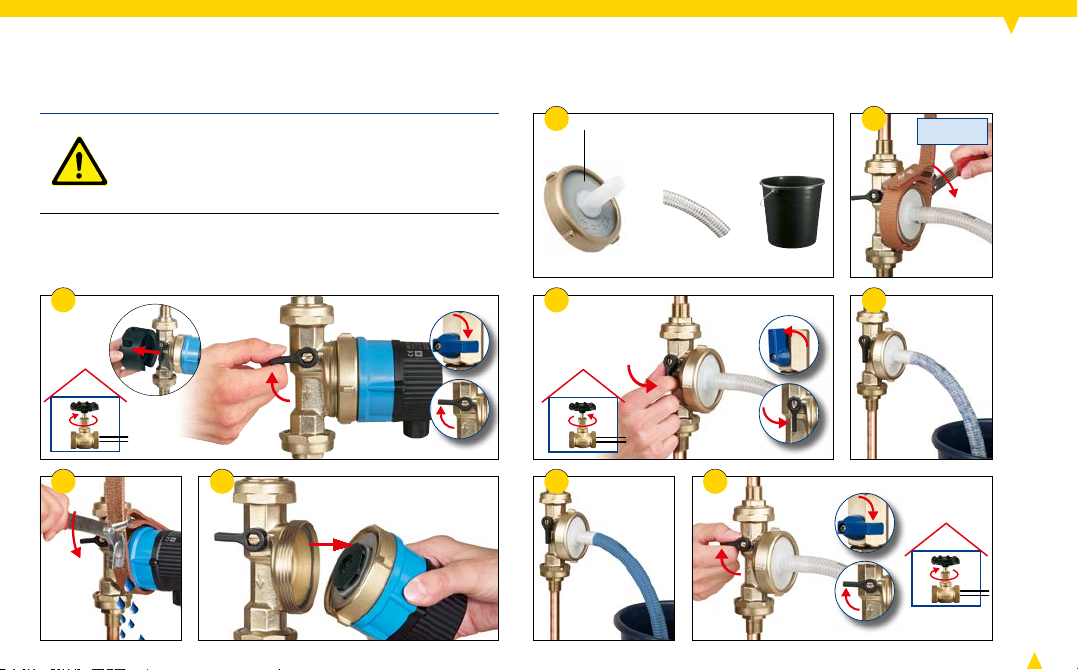

Installation

Careful! Damage to bearings caused by dryrunning.

► Flush pipework thoroughly with water and

bleed (see gs. 1-12).

4 5

VORTEX EF 150

+ +

= 20 Nm

1

2

6 7

983

6

Page 7

7

Installation

10 11 12

Careful! Damage to bearings caused by dry-

running.

► Flood the pump before connecting electric-

ity: Open all stop valves slowly (see g. 13).

13

= 20 Nm

Electrical connection

The drive of the pump is a DC motor. Thus a protective

conductor is not required.

For AC operation a transformer is integrated in the cap.

Danger! Danger of electrocution.

► Have all electrical work carried out by

qualied electricians only.

► Turn off the power supply and safeguard it

against being switched back on (see g. 1).

► Check to make sure the power is turned off.

Warning! Fire hazard due to electrical

ignition.

► Make sure that the pump is only connected

to the power supply specied on the name

plate (see p. 4).

21

Page 8

Electrical connection

3

5

230 V~ 12 V=

► A permanent power supply is possible, alternatively use a mains

plug with IP 44 rating (provide isolator that separates all poles).

► Cable diameter 0.75 – 1.5 mm²

► Round cable with Ø 5 – 8 mm

► Connection with twisted wires, no wire end sleeves, no tinned

ends

Warning! Fire hazard.

► Secure 12 V DC pumps with a 2 A fuse.

4a

4b 4c

230 V~

8,5 - 10 mm

–

+

12 V=

230 V~ 12 V=

6

230 V~

12 V=

7

230 V~

12 V=

8

Page 9

8

230 V~

12 V=

10 11

VentingElectrical connection

9

► Ensure that the return line is air-free (see p. 6).

Then act as follows to bleed the pump until it runs noisefree (alternately):

► Switch the pump on and off several times (see g. 2).

► Open a hot water tap several times (see g. 3).

1 2

Warning! Hot surface on pump housing and

motor. Danger of burns!

► Avoid direct contact with pump housing and

motor.

For pumps with control module:

The BWO 155 Z pump will run continuously.

The BWO 155 ERT pump will run when the preset water

temperature is exceeded.

9

3 4

5x

5

Page 10

Timer

Buttons and LED indicators :

1

5

4

4

10

9

1

Select operating state (clockwise):

2

Continuous

3

Setting mode

4

Operation via time switch

5

Permanent stop

6

Time

7

LED ring of the runtimes (see gure 2, p. 11)

8

Select times (time and runtimes)

9

Pump running (LED lights up) or is off

(LED does not light up)

10

Conrm time/conrm or delete runtimes

When it is connected to the electricity mains for the rst

time, the pump runs continuously (delivered condition –

2, 6

1

2

3

6

7

8

LEDs

Shortest runtime is 30 minutes.

When the power supply is interrupted, the time stops

(no power reserve). The saved runtimes

If the power supply is restored, the pump runs in the

operating state that was last set,

has to be updated.

Setting the time and runtimes:

► Press

► Use

with OK

and 9 light up, see gure 1).

7

are retained.

6

ashes. The time

1

until 3 lights up.

8

to set the red LED to the current time and conrm

10. 9

no longer lights up. The green LED in the

section 0.00 h to 0.30 h ashes.

8

► With

, set the LED to the required runtime and conrm

with OK

Conrm once again with OK

LED ring runs more quickly if

► End setting with

The pump runs according to the set runtimes,

10

. The LED jumps directly to the next runtime.

1

. The saved runtimes are displayed.

10

or skip with 8 (etc.). The

8

is held down.

4

lights

up.

10

Page 11

Timer

Example of a setting (see gure 2):

Current time

6

: for example 9:30 h

(LED in the time window from 9:30 a.m. till 10:00 a.m.)

The pump is not running, LED

Set runtimes

06:00 a.m. - 07:30 a.m.

11:00 a.m. - 01:30 p.m.

7

of the pump:

2

4

9

3

1

11

10 8

9

is off.

03:30 p.m. - 06:30 p.m.

08:00 p.m. - 08:30 p.m.

7

6

4

3

6

1

10 8

09:00 p.m. - 09:30 p. m.

10:00 p.m. - 10:30 p.m.

3

Changing the time:

1

► Press

on the current time

► Conrm with OK

► End setting with

runtimes,

until 3 lights up. Press 8 until the red LED is

6

(see gure 3).

10

.

1

4

. The pump runs according to the set

lights up.

Changing runtimes:

1

► Press

10

until 3 lights up. Conrm current time with OK

(see gure 3). The saved runtimes light up. A runtime

ashes (see gure 4).

► Adding new runtimes: Press

conrm with OK

10

. Repeat process for additional run-

times or end setting with

► Deleting runtimes: Press

to delete ashes, conrm with OK

additional runtimes or end setting with

8

until new runtime ashes,

1

.

8

until the runtime you want

10

. Repeat process for

1

.

Resetting all setting values:

1

► Press

for 5 seconds (see gure 1, p. 10).

Changing the operating state:

1

► Press

(

until the required operating state

2 ,4

or 5) lights up (see gure 1, p. 10).

It is active immediately.

Page 12

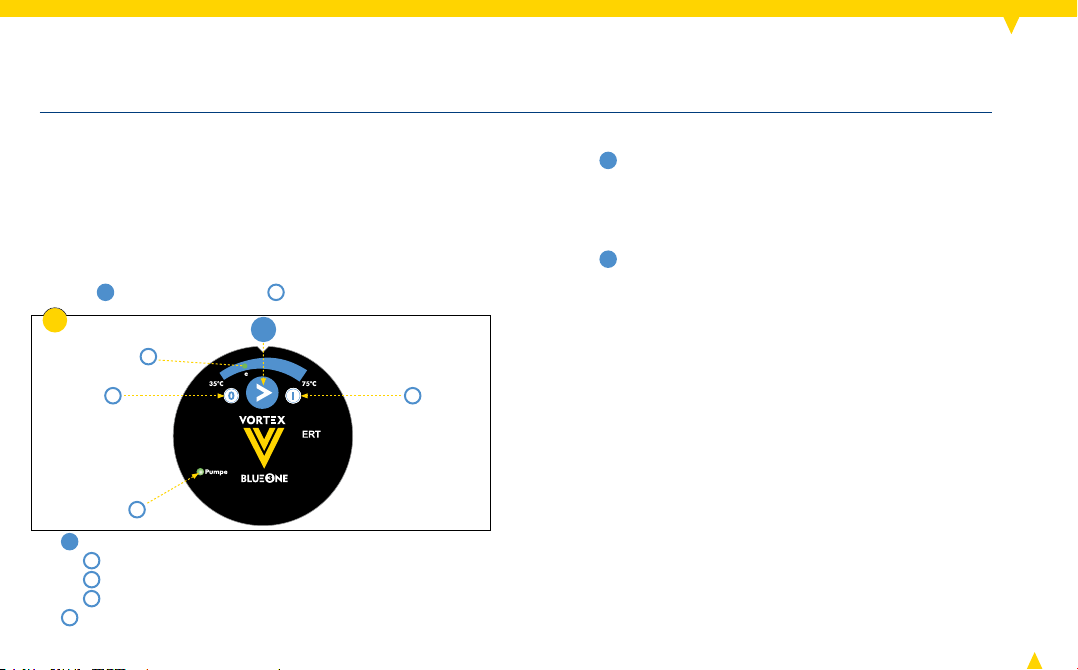

Electronic regulating thermostat ERT

The pump will switch off when the preset temperature is

reached. After the water has cooled down approx. 7°C

the pump will switch back on.

After connection to the electrical power grid 45°C (e) is set

as the switch-off temperature of the pump (see gure 1).

In case of a power outage the preset switch-off tempera-

ture will be conserved.

Button

1

and LED indicators :

1

4

3

5

1

Select the operating mode (clockwise):

2

Continuous pump run

3

Pump stop

4

Switch-off temperature of the pump (e=45°C)

5

Pump is running (LED is illuminated) or switched

2

off (LED not illuminated)

Changing the switch-off temperature:

1

► Press

until the desired switch-off temperature is

illuminated. (9 steps in 5° increments from 35°C to

75°C).

Changing the operating mode:

1

► Press

until the desired operating mode is illuminated.

It will be active immediately.

12

Page 13

0 100 200 300 400 500 600 700

0,2

0,4

0,6

0,8

1,0

1,2

1,4

2

4

6

8

10

12

14

800 900

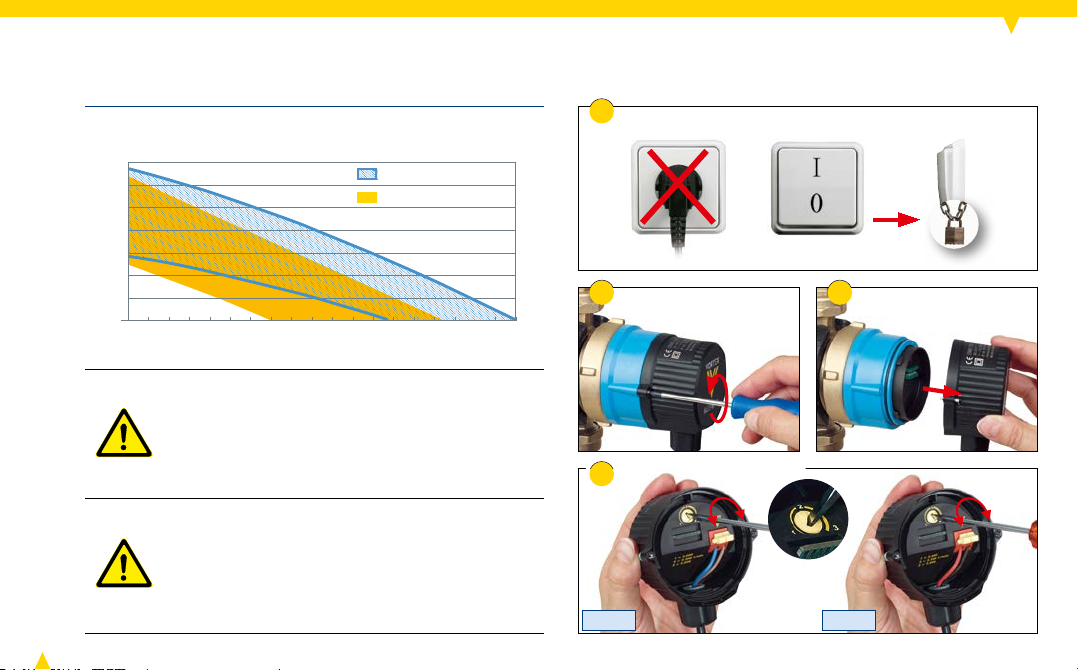

Speed adjustment

8

10

12

14

The speed is innitely variable.

1

BWO 155 R

BWO 155 V

H [mWS]

Q [l / h]

Warning! Hot surface on pump housing and

motor. Danger of burns!

► Avoid direct contact with pump housing and

motor.

13

Danger! Danger of electrocution.

► Before working on the pump, disconnect

power supply and ensure that it cannot be

reconnected unintentionally (see g. 1).

► Check to make sure the power is turned off.

n = 2000 - 3000 1/min

n = 2000 - 3000 1/min

[kPa]

2

4

230 V~ 12 V=

3

Page 14

Speed adjustment

5

7

6

14

Page 15

Servicing

1

3

15

4

Danger! Danger of electrocution.

► Before working on the pump, disconnect

power supply and ensure that it cannot be

reconnected unintentionally (see g. 2).

► Check to make sure the power is turned off.

2

6

5

7 8

Page 16

Servicing

► Every time the motor is opened, replace the sealing

ring (see g. 9).

► Insert the new sealing ring into the groove in the pump

housing and press slightly into place (see g. 10).

9 10

16

5x

17

11

14

12

13

= 20 Nm

15

► Technical support is available from your heating and

sanitary specialist or from Deutsche Vortex.

16

Page 17

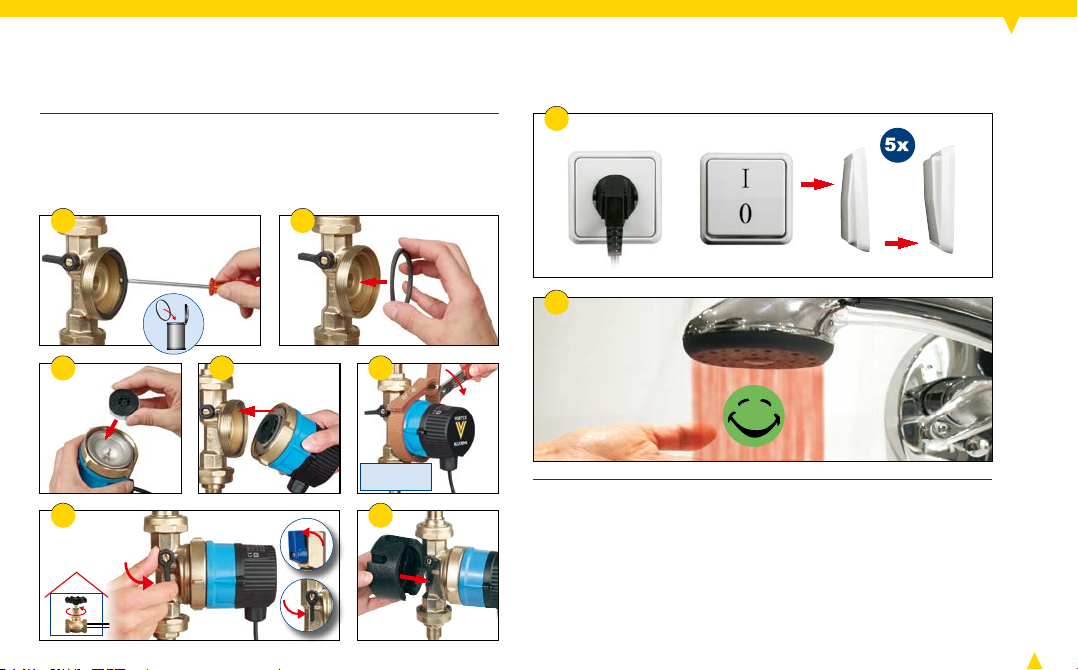

Replacement

Motor (pictured: BWO 155)

Danger! Danger of electrocution.

► Before working on the pump, disconnect

power supply and ensure that it cannot be

reconnected unintentionally (see g. 1).

► Check to make sure the power is turned off.

5 6 7

1 2

3 4

11

8

9 10

= 20 Nm

17

Page 18

Replacement

► Concluding the exchange: See chapters starting at Elec-

trical Connection, p. 7 and fur ther.

2

3

Cap/control module

Danger! Danger of electrocution.

► Have all electrical work carried out by quali-

ed electricians only.

► Disconnect power supply and ensure that it

cannot be reconnected unintentionally

(see g. 1).

► Check to make sure the power is turned off.

1

► Concluding the exchange: See chapters starting at Elec-

trical Connection, p. 7 and fur ther.

18

Page 19

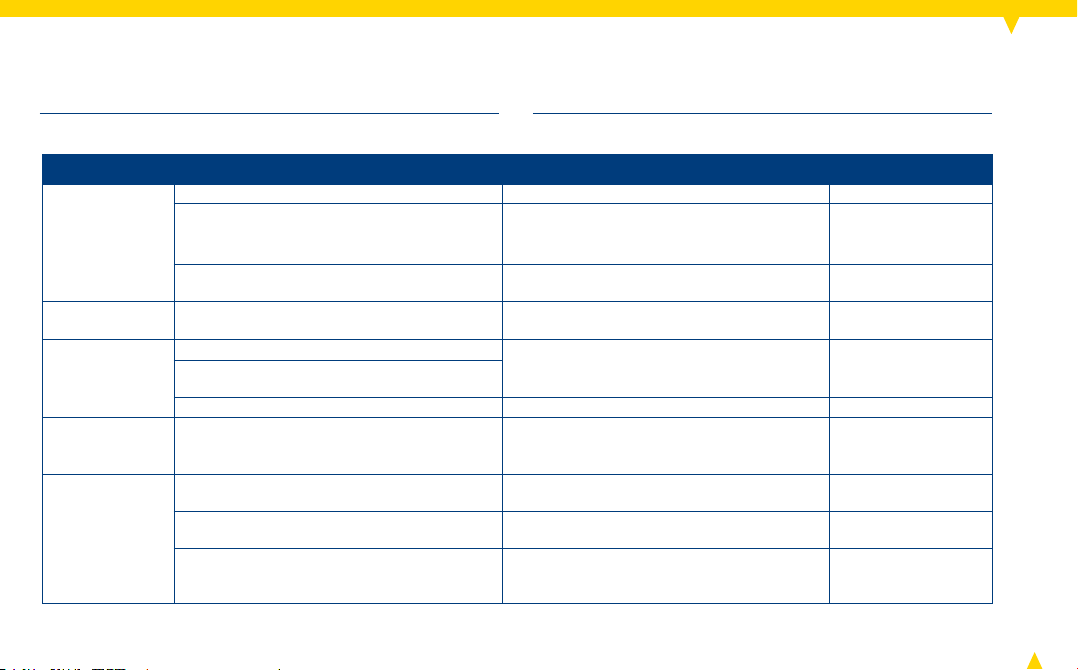

Faults and remedies

► Observe the chapter “Safety” (see p. 3).

Fault Cause Remedy Chapter/page

Pump not running.

"Pump" LED does

not light up*.

"Time" LED

a shes*.

Pump is not

running: LED

"Pumpe" ( pump)

is illuminated.*

Pump stops the

rotor continuousl y.

Pump makes

noise.

*only Pumps BWO 155 Z and/or BWO 155 ERT

Power supply is interrupted. ► Ensure correct power supply.

Time switch function does not start the

pump. (BWO 155 Z)

► Check "Operating state" LED.

► Wait for next pump start.

Timer, p. 11

► Change time setting.

Temperature function does not start the

pump (BWO 155 ERT).

Power supply was interrupted. ► Update time. Timer, p. 11

Motor is defective (electrical/electronics). ► Replace motor.

Rotor is blocked because the rotor bearing is

► Change shutdown temperature or wait for

next pump start.

Electronic regulating

thermostat ERT, p. 12

defective.

Rotor is blocked by debris. ► Clean wetted parts. Maintenance, p. 15

Air in the pump housing, dr y run protection

is active.

Air in the pump housing. ► Bleed the circulation line. Installation, p. 6 and

► Bleed the circulation line. Installation, p. 6 and

Venting, p. 9

Venting, p. 9

Rotor bear ing defective. ► Replace the rotor. If the bearing pin is

Replacement, p. 17

damaged exchange the motor.

Non-return valve is loose. ► E xchange the V-type pump housing or non-

Installation, p. 5

retur n valve installed behind the pump

(e.g. RV 153).

19

Page 20

BWO 155 · BWO 155 12V · BWO 155 Z · BWO 155 ERT

Original operating instructions

Deutsche Vortex GmbH & Co. KG

Kästnerstraße 6

71642 Ludwigsburg · Germany

Fon: +49(0)7141.2552-0

E-Mail: info@deutsche-vortex.com

www.deutsche-vortex.com

199-13 0-265-en · 10/17

20

Loading...

Loading...