Honda S2000

Supercharger System

Installation Instructions

2000-2003 50 STATE SMOG LEGAL PER CARB EO #D-213-21

2000-2004 Model Years

*2004 Models

*Legal in California only for racing vehicles which may never be used upon a highway.

®

ENGINEERING, LLC

1650 PACIFIC AVENUE • CHANNEL ISLANDS, CA 93033-9901 • (805) 247-0226

FAX (805) 247-0669 • www.vortechsuperchargers.com • M-F 8:00 AM - 4:30 PM PST

4HS020-010 v2.0 07/27/04

FOREWORD

Proper installation of this supercharger kit requires general automotive

mechanic knowledge and experience. Please browse through each step of

this instruction manual

should refer the job to a professional installer/technician. Please call Vortech

Engineering for installers in your area.

Due to the horsepower and torque that your vehicle will

produce after installation of this supercharger system,

it is strongly suggested that the factory clutch be replaced with a high-capacity aftermarket unit.

prior

to beginning the installation to determine if you

NOTE:

All rights reserved. No part of this publication may be reproduced, transmitted, transcribed,

or translated into another language in any form, by any means without written permission

P/N: 4HS020-010

©2004 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

27JUL04 v2.0 S2000 (4HSv2.0)

©

2003 VORTECH ENGINEERING, LLC

of Vortech Engineering, LLC.

ii

TABLE OF CONTENTS

FOREWORD.....................................................................................................................................ii

TABLE OF CONTENTS....................................................................................................................iii

TOOL & SUPPLY REQUIREMENTS ................................................................................................iv

PARTS LIST - HONDA S2000 ..........................................................................................................v

1. PREPARATION/REMOVAL ..................................................................................................1

2. OIL FEED.............................................................................................................................3

3. OIL DRAIN ...........................................................................................................................4

4. CRANK DAMPER PULLEY INSTALLATION........................................................................5

5. FUEL MANAGEMENT UNIT................................................................................................7

6. FUEL PUMP REPLACEMENT.............................................................................................10

7. FUEL RAIL/ REGULATOR MODIFICATIONS (2004 Models Only)......................................11

8. SUPERCHARGER MOUNTING BRACKET/PLATE INSTALLATION...................................12

9. SUPPLEMENTARY FUEL INJECTOR INSTALLATION (2004 Models Only).......................24

10. SUPERCHARGER BELT TENSIONER ADJUSTMENT ......................................................25

11. AIR PUMP INLET HOSE MODIFICATION...........................................................................25

12. CHARGE AIR COOLER INSTALLATION.............................................................................26

13. AIR INLET DUCT INSTALLATION .......................................................................................30

14. HOSE ATTACHMENTS/EXTENSIONS................................................................................31

15. ELECTRONIC CONTROL BOX INSTALLATION .................................................................32

16. FINAL CHECK .....................................................................................................................35

©2004 Vortech Engineering, LLC

iii

All Rights Reserved, Intl. Copr. Secured

P/N: 4HS020-010

27JUL04 v2.0 S2000 (4HSv2.0)

2000-2004

HONDA S2000

Installation Instructions

Congratulations on selecting the best performing and best backed automotive

supercharger available today... the VORTECH® Supercharger!

Before beginning this installation, please read through this entire instruction booklet and the Street

Supercharger System Owner's Manual which includes the Automotive Limited Warranties Program

and the Warranty Registration form.

Vortech supercharger systems are performance improving devices. In most cases, increases in torque of

30-35% and horsepower of 35-45% can be expected with the boost levels specified by Vortech Engineering.

This product is intended for use on healthy, well maintained engines. Installation on a worn-out or damaged

engine is not recommended and may result in failure of the engine as well as the supercharger. Vortech

Engineering is not responsible for engine damage.

Installation on new vehicles will not harm or adversely affect the break-in period so long as factory break-in

procedures are followed.

For best performance and continued durability, please take note of the following key points:

1. Use only premium grade fuel 91 octane or higher (R+M/2).

2. The engine must have stock compression ratio.

3. If the engine has been modified in any way, check with Vortech prior to using this product.

4. Always listen for any sign of detonation (pinging) and discontinue hard use (no boost) until problem is

resolved.

5. Perform an oil and filter change upon completion of this installation and prior to test driving your vehicle.

Thereafter, always use a high grade SF rated engine oil or a high quality synthetic, and change the oil

and filter every 3,000 miles or less. Never attempt to extend the oil change interval beyond 3,000

miles, regardless of oil manufacturer's claims as potential damage to the supercharger may

result.

6. Before beginning installation, replace all spark plugs that are older than 2 years or 20,000 miles with

original heat range plugs as specified by the manufacturer and retard timing from factory specifications

(follow the procedures indicated within the factory repair manual and/or as indicated on the factory

underhood emissions tag). Do not use platinum spark plugs unless they are original equipment.

Change spark plugs every at least 15,000 miles and spark plug wires at least every 50,000 miles.

TOOL & SUPPLY REQUIREMENTS:

• Factory Repair Manual

• 3/8" Socket and Drive Set: SAE & Metric

• 3/8” Swivel Head Ratchet

• 1/2" Socket and Drive Set: SAE & Metric

• 3/8" NPT Tap and Handle

• Adjustable Wrench

• Open End Wrenches: SAE & Metric

• Center Punch

•5 Quarts SH/CF Rated Quality Engine Oil

• Oil Filter and Wrench

• Flat #2 Screwdriver

• Phillips #2 Screwdriver

• Heavy Grease

• Silicone Sealer

• Drill Motor

• 1/8", 3/16" Drill Bits

• Hex Key Wrench Set

•Wire Strippers and Crimpers

• Utility Knife

• Hand Held Grinder

• Blue Loctite

• 07JAB-001020A (Damper Tool) Available at Honda Dealer

• 07NAB-001040A (Damper Tool) Available at Honda Dealer

• Honda Bond (Sealer) Available at Honda Dealer

If your vehicle has in excess of 10,000 miles since its last spark plug change, then you will also need:

• Spark Plug Socket

• New Spark Plugs

P/N: 4HS020-010

©2004 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

27JUL04 v2.0 S2000 (4HSv2.0)

iv

®

ENGINEERING, LLC

2000-2003 HONDA S2000

Part No. 4HS218-010SQ/-018SQ

PARTS LIST

IMPORTANT: Before beginning installation, verify that all parts are included in the kit. Report any shortages or

damaged parts immediately.

PART # DESCRIPTION QTY PART # DESCRIPTION QTY

2E229-180 SUPERCHARGER ASSY 1

4HS111-021 MOUNTING BRACKET ASSY 1

4HS010-011 MTG. PLATE BLOCK 1

4HS010-021 LOWER S/C PLATE SPACER 1

4HS010-034 UPPER S/C SUPPORT PLATE 1

4HS010-044 S/C MOUNTING PLATE 1

4HS010-051 LATERAL S/C MOUNTING PLATE SUPPORT 1

7A250-075 1/4-20 x .75 SHCS 2

4PFA010-031 TENSIONER ADJ. SCREW LOCATOR 1

7PA375-500 TENSIONER SCREW 1

7B500-325 TENSIONER ARBOR 1

4HS017-051 TENSIONER SPACER 1

4HS017-011 RIBBED IDLER SPACER 1

4HS017-031 UPPER S/C PLATE SPACER 4

4HS017-021 12mm S/C BOSS SPACER 1

4HS017-041 S/C PLATE SPACER (TO STOCK IDLER) 1

7F375-028 3/8-24 PRESS NUTS 4

7B375-350 3/8-24 x 3.50 4

7C010-115 M10 X 1.25 x 115 BOLT 1

7J010-002 M10 WASHER (.080 THK.) 2

7C060-622 M6 x 1.00 x 158 STUD 2

7C010-049 M10 x 1.25 x 50 BOLT 1

7C060-080 M6 x 1.00 x 80 BOLT 3

7C012-050 M12 x 1.75 x 50 BOLT 1

7A375-124 3/8-16 x 1.25 7

7A375-350 3/8-16 x 3.50 1

7K375-040 3/8 AN WASHER 12

7J006-093 M6 WASHER 5

7F006-093 M6 NUTS 2

7J012-092 M12 WASHER 2

7F500-030 1/2-20 JAM LOCK NUT 1

2A017-016 3/8 ID BEARING PILOT (6203 BRG) 1

4GF016-160 RIBBED 3" IDLER 1

4FH016-150 SMOOTH 3" IDLER 1

4HS040-050 V-TECH SOLENOID GASKET 1

7C080-046 M8 x 1.25 x 45 SHCS 2

7A312-100 5/16-18 x 1.0 HXHD 2

7K312-001 5/16 AN WASHER 2

4HS116-011 S/C DRIVE ASSEMBLY 1

4HS016-011 CRANK PULLEY 1

7C010-050 10-24 x .50 SHCS GR8 6

4HS016-021 MODIFIED DAMPER PULLEY 1

2A046-510 S/C DRIVE BELT 1

4HS238-068 FMU assembly 1

6Z110-144 FMU ASSY 1

7U030-016 1/4 FUEL HOSE-FMU “IN” 34"

7U030-016 1/4 FUEL HOSE-FMU “OUT” 28"

7R001-004 #4 HOSE CLAMP 2

7U030-046 5/32" VACUUM HOSE 28"

7P156-082 5/32 TEE 1

7R004-003 14.5 STEPLESS CLAMP 2

4HS130-036 OIL DRAIN ASSEMBLY 1

7U030-036 OIL DRAIN HOSE 18"

7R001-008 #8 CLAMP 2

7P375-004 3/8" NPTF x -8 SAE FLARE FITTING 1

7P500-050 FTG,-8 JIC TUBE x 90° W/BARB 1

7T560-001 CUTTER, 9/16" ROTABROACH 1

7T560-002 ARBOR, 9/16" ROTABROACH 1

7P375-041 3/8" NPT x 1.5" HEX NIPPLE 1

4HS130-026 OIL FEED ASSEMBLY 1

7U250-000-360 OIL FEED HOSE 1

7P125-004 #4 JIC x 90 x 1/8 NPT FTG 1

7P125-101 #4 JIC x 45 x 1/8 NPT FTG 1

7P125-125 1/8 NPT FEM x 1/8 BSPT 1

7P125-034 1/8 STREET TEE 1

7U100-055 6" ZIP-TIE 4

4HS112-010 AIR INLET ASSEMBLY 1

8H040-022 3/4" BREATHER FITTING 1

8H040-040 3.5" AIR FILTER 1

7S350-200 3.5 x 2" SLEEVE 1

7R002-056 #56 CLAMPS 2

7R002-052 #52 CLAMP 2

7U030-016 1/4" COOLANT HOSE 16"

4HS013-010 AIR BOX 1

7A250-050 1/4-20 x .5 SHCS 8

7U035-001 3.5" FLEX HOSE 5"

7U030-036 OIL DRAIN HOSE 36"

4HS110-060 AIR FILTER MOUNTING FLANGE ASSY 1

4HS012-011 3.5" PLASTIC INLET ELBOW 1

7P375-017 3/8" NPT x 1/2" BEADED HOSE BARB 1

7E010-049 #10 SHEETMETAL SCREW 2

7C060-020 M6 x 1.0 x 20 HXHD 1

4HS010-110 AIR BOX MOUNTING TAB, UPPER 1

4HS010-120 AIR BOX MOUNTING TAB, LOWER 1

8N401-010 POWERCOOLER/DISCH. ASSY 1

7A250-050 1/4-20 x .5 SHCS 2

8H040-175 RACE BYPASS FILTER 1

8N055-050 SURGE TANK CAP 1

7S275-200 2.75 SLEEVE x 2 SLEEVE 1

7S275-300 2.75 SLEEVE x 3 SLEEVE 1

7R002-044 #44 CLAMP 4

7P500-026 3/4 HOSE BARB x 1/2 NPT x 90 FTGS 2

7U030-046 5/32" VACUUM HOSE 24"

7P156-082 5/32 TEE 1

7U030-030 1/4" VACUUM HOSE 36"

7P250-033 5/32 - 1/4 REDUCER 1

008341 POWERCOOLER DECAL 1

8N301-140 WELDED COOLER CORE ASSY 1

8N106-110 WATER COOLER ASSY 1

4HS010-080 WATER RESERVOIR MNTG BRKT 1

4HS010-090 WATER COOLER MNTG BRKT, UPPER 1

4HS010-100 WATER COOLER MNTG BRKT, LOWER 2

5W001-002 FUSE TAP 1

5W001-009 SLIDE CONNECTOR - 18GA MALE 1

5W001-011 16-14 GA EYELET 2

5W001-014 FUSE HOLDER 10 GA 1

5W001-015 FUSE, BLADE TYPE 20A 1

5W001-017 12GA RING TERMINAL 1

5W001-019 12GA SOLDERLESS CONNECTOR 1

©2004 Vortech Engineering, LLC

v

All Rights Reserved, Intl. Copr. Secured

P/N: 4HS020-010

27JUL04 v2.0 S2000 (4HSv2.0)

®

ENGINEERING, LLC

2000-2003 HONDA S2000

Part No. 4HS218-010SQ/-018SQ

PARTS LIST,

cont’d

IMPORTANT: Before beginning installation, verify that all parts are included in the kit. Report any shortages or

damaged parts immediately.

PART # DESCRIPTION QTY

7A250-050 1/4-20 x .50" SHCS 2

7A250-075 1/4-20 x 3/4 SHCS PLTD 3

7E010-049 #10 x 3/4 HXHD SLF TAPNG ST MTL 9

7F250-021 1/4-20 NYLOCK NUT ZINC PLTD 3

7J250-001 1/4 SAE WASHER, PLTD 10

7P375-075 3/4" HOSE UNION 1

7P500-026 1/2NPT-3/4 BARB 90° 3

7P500-078 1/2NPT x 3/4 HOSE FIT STRT 1

7R003-015 ADEL CLAMP, 15/16".406 EYELET 1

7R007-001 NYLON CLAMP 1-1/8" 10

7U038-000 3/4" HEATER HOSE 12

7U038-012 HOSE, Ø3/4" 90°, 4 x 12" 2

8F001-402 PUMP, WATER 2

8F101-310 RELAY ASSY, HONDA 1

8N006-010 WATER COOLER 1

8N055-030 TANK, LT1 AFTERCOOLER 1

5A201-001 ELECTRONICS UPGRADE ASSY

4HS010-070 BRKT, FTC MNTG S2K 2

5A001-051 TIMING CONTROL BOX 1

5A101-020 MAP CLAMP 1

5W001-009 16-14GA MALE SLIDE INSULATED 11

5W001-010 16-14GA FEMALE SLIDE INSULATED 8

5W001-022 T-TAP CONN,14-16 AWG 3

7C008-050 8-32 x 1/2 SHCS 2

7E010-049 #10 SHEET METAL SCREW 2

7F008-032 8-32 NYLOCK NUT 2

7P156-082 5/32" TEE, BRASS 1

7P157-219 REDUCER UNION, 5/32" TO 7/32" 1

7U030-046 5/32" VACCUM LINE 4'

7U100-055 TIE WRAP, 6" NYLON 8

7U375-001 VELCRO-HOOK 1" BLACK .166 YD

7U375-002 VELCRO-LATCH 1"BLACK .166 YD

8F001-342 Fuel pump assy. 1

8D204-011 Race blowoff valve 1

4HS020-010 Instruction manual 1

008110 Decals 2

008444 S/C owners packet 1

008130 Lic. plate frame, Vortech 1

P/N: 4HS020-010

©2004 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

27JUL04 v2.0 S2000 (4HSv2.0)

vi

®

ENGINEERING, LLC

2004 HONDA S2000

Part No. 4HS218-020/028SQ

PARTS LIST

IMPORTANT: Before beginning installation, verify that all parts are included in the kit. Report any shortages or

damaged parts immediately.

PART # DESCRIPTION QTY PART # DESCRIPTION QTY

2E229-210 V2SQ S/C SC-TRM CCW HONDA S2000 1

2A036-450 S/C PULLEY 4.50" 6-GRV 1

4HS111-021 MOUNTING BRACKET ASSY S2000 1

2A017-016 PILOT, 6203/5 BRG, 3/8 SCREW 1

4FH016-150 IDLR PULLEY, 6-RIB 3" FLANGED 1

4GF016-160 PULLEY, 3" IDLER-RIBBED 1

4HS010-011 MTG BLOCK, SUPPORT PLT S2000 1

4HS010-021 SUPPORT, LWR MTG PLT S2000 1

4HS010-034 S/C SUPPORT PLT, REAR S2000 1

4HS010-044 S/C MOUNTING PLT, S2000 1

4HS010-051 SUPPORT, NTG PLT, LATERAL S2000 1

4HS017-011 RIBBED LIDLER SPACER, S2000 1

4HS017-021 SPACER, S/C BOSS S2000 1

4HS017-031 SPACER, UPPER S/C PLT S2000 4

4HS017-041 SPACER, LOWER S/C PLT S2000 1

4HS017-051 SPACER, TENSNR PULLEY S2000 1

4HS040-050 GASKET, VTEC SOLENOID S2000 1

4PFA010-031 BRACKT, IDLER ADJUST SCREW 1

7A250-075 1/4-20 x 3/4 SHCS PLTD 2

7A312-100 5/16-18 x 1 HXCS GR5P 2

7A375-124 3/8-16 x 1-1/4 HXHD G5 PLATED 7

7A375-350 3/8-16 x 3-1/2 HXHD 1

7B375-350 3/8-24 x 3-1/2" HXHD GR8 4

7B500-325 ARBOR, S/C TENS PLY, S2000 1

7C010-049 M10 x 1.25 x 50 HCHD CL10.9 1

7C010-115 M10 x 1.25 x 115 HXHD CL10.9 P 1

7C012-050 M12 x 1.75 x 50mm HXHD BOLT 1

7C060-080 M6 x 1.00 x 80 SHCS CL 8.8 3

7C060-622 M6 x 1.0 x 6.22" S2000 STUD 2

7C080-046 M8 x 1.25 x 45 SHCS CL8.8 2

7F006-093 6mm NYLOCK NUT 2

7F375-028 PRESS NUT, 3/8-24 x .50 4

7F500-030 1/2-20 HEX JAM LOCK NUT ZINC 1

7J006-093 6mm WASHER, PLATED 5

7J010-002 10mm WASHER, ZINC PLATED 2

7J012-092 12mm WASHER, FLAT 2

7K312-001 5/16 AN WASHER, PLATED 2

7K372-040 3/8 AN960 FLAT WASHER, PLATED 12

7PA375-500 SCREW, IDLER ADJUST, 5.00" 1

4HS116-021 S/C DRIVE ASSY 04’ S2000 1

2A046-500 BELT, K060500-GATES 1

4HS016-011 S/C CRANK PULLEY, 6" S2000 1

4HS016-021 MODIFIED DAMPER PLY S2000 1

7C010-050 10-24 x .50 SHCS GR8 PLT 6

4HS238-048 FMU ASSY, w/LINES 4:1, S2000 1

6Z110-150 FMU, 4:1 1/4 BARB w/SPRING 1

6Z050-151 FMU WASHER, 4:1/38LB. PLATED 1

6Z070-020 FMU 4:1 RING SPACER 1

6Z090-010 SPRING, FMU GM 4.3 1

7C010-050 10-24 x .50 SHCS GR8 PLT 6

7C010-075 10-24 x 3/4 SHCS GR5 ZINC 4

7C024-025 10-24 x 1/4 PHILL HD 3

7E010-046 #8 x 3/4 SHEET METAL 2

7P125-025 1/8 NPT x 5/32 HOSE 90 1

7P125-036 1/8 NPT-STRT 1/4 BARB 1

7P125-037 1/8 NPT-90° TO 1/4 BARB 1

7U100-030 O-RING, FMU 1

7U030-016 1/4" EFI HP FUEL LINE 2

7U030-016 1/4" EFI HP FUEL LINE 2

7R001-004 #4 HOSE CLAMP 2

7U030-046 5/32" VACUUM LINE 2

7P156-082 5/32" TEE 1

7R004-003 STEPLESS CLAMP, 14.5-70 2

4HS130-026 OIL FEED ASSY S2000 1

7U250-000-360 OIL FEED HOSE, 36" -4 STRT 1

7P125-004 1/8 NPT 90° x -4 JIC FTG STL 1

7P125-101 1/8 NPT 45° x -4 JIC FTG STL 1

7P125-125 FTG, 1/8 NPT FEM x 1/8 SPT MALE 1

7P125-034 1/8 NPT x 1/8 NPT STRT T 1

7U100-055 TIE-WRAP, 7.5" NYLON 6

4HS130-036 OIL DRAIN ASSY S2000 1

7P375-004 3/8 NPT x 1/2 SAE MALE FLARE 1

7P375-041 3/8 NPT HEX NIPPLE x 1.5" 1

7P500-050 FTG, -8 JIC TUBE x 90° w/BARB 1

7R001-008 #8 STNLS HOSE CLAMP 2

7T560-001 CUTTER, 9/16" ROTABROACH 1

7T560-002 ARBOR, ROTABROACH 1

7U030-036 1/2" OIL DRAIN HOSE 1

8F001-342 FUEL PUMP w/SCREEN, GSS 342 1

5A101-021 ENGINE MNGMNT ASSY 04’ S2000 1

4HS010-070 BRKT, FTC MNTG S2000 2

5A001-121 TIMING BOX, 04’ HONDA S2000, PROG 1

5W001-009 16-14GA MALE SLIDE INSULATED 11

5W001-010 16-14GA FEMALE SLIDE INSULATED 8

5W001-022 T-TAP CONN. 14-16 AWG 3

7C008-050 #8-32 x 1/2" SHCS, ZINC 2

7E010-049 #10 x 3/4 HXHD SLF DRL SHT MTL 2

7F008-032 8-32 HEX LOCK NUT 2

7P156-082 5/32 TEE 1

7P157-219 REDUCER UNION, 5/32" TO 7/32" 1

7U030-046 5/32" VACUUM LINE 4'

7U100-055 TIE-WRAP, 7.5" NYLON 8

7U375-001 VELCRO-HOOK 1" BLACK .16YD

7U375-002 VELCRO-LATCH 1" BLACK .16YD

4HS112-010 AIR INLET ASSY S2000 1

4HS010-110 MNTG BRKT, UPR, S2000 AIRBOX 1

4HS010-120 MNTG BRKT, LWR, S2000 AIRBOX 1

4HS012-011 INLET ELBOW, 3.5" MOD. S2000 1

4HS013-010 AIRBOX, S2000 1

4HS110-060 FLANGE ASSY, AIRBOX S2000 1

7A250-050 1/4-20 x .50 SHCS ZINC PLTD 8

7C060-020 M6 x 1.0 x 20mm HHCS 1

7E010-049 #10 x HXHD SLF DRL SHT MTL 2

7P375-017 3/8 NPT x 1/2 BEADED HSE BRB 1

7R002-052 #52 SAE TYPE F SS HOSE CLAMP 2

7R002-056 #56 SAE TYPE F SS HOSE CLAMP 2

7S350-200 3-1/2 x 2 SLEEVE, BLUE 1

7U030-016 1/4" EFI HP FUEL LINE 1

7U030-036 1/2" OIL DRAIN HOSE 3

7U035-001 3-1/2" FLEX HOSE .41'

8H040-022 3/4" BREATHER 1

8H040-040 AIR FILTER, 3.5" FLG x 5.52" 1

vii

©2004 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

P/N: 4HS020-010

27JUL04 v2.0 S2000 (4HSv2.0)

®

ENGINEERING, LLC

2004 HONDA S2000

Part No. 4HS218-020SQ

PARTS LIST,

cont’d

IMPORTANT: Before beginning installation, verify that all parts are included in the kit. Report any shortages or

damaged parts immediately.

PART # DESCRIPTION QTY PART # DESCRIPTION QTY

8N401-040 PWR COOLR ASSY, 04' HONDA S2000 1

008341 VORTECH CHARGE COOLER DECAL 1

7A250-050 1/4-20 x .50 SHCS ZINC PLTD 2

7P156-082 5/32 TEE 1

7P250-033 1/4 x 5/32 RED.UNION 1

7P500-026 1/2 NPT x 3/4 BARB 90° BRASS 2

7R002-044 #44 SAE TYPE F SS HOSE CLAMP 4

7S275-200 SLEEVE, BLUE, 2.75" D x 2.00" L 1

7S275-300 2-3/4" x 3", BLUE 1

7U030-030 1/4" VACUUM HOSE 3

7U030-046 5/32" VACUUM LINE 2

8H040-175 FILTER, 1-3/4" I.D., RACE BYP 1

8N055-050 PLASTIC CAP, SURGE TANK 1

8N301-240 PWR COOLR CORE ASSY, 04' S2000 1

8N106-110 WATER PUMP/COOLR ASY S2000 1

4HS010-080 MNTG BRKT, H20 TANK, S2000 1

4HS010-090 H20 COOLR MNTG BRKT, UPR S2000 1

4HS010-100 H20 COOLR MNTG BRKT, LWR S2000 1

5W001-002 FUSE TAP 1

5W001-009 16-14GA MALE SLIDE INSULATED 1

5W001-011 16-14GA RING TERM. .26" HOLE 2

5W001-014 FUSE HOLDER 10GA WIRE 1

5W001-015 FUSE, BLADE TYPE 20 AMP 1

5W001-017 12-10GA x 3/8" RING TERMINAL 1

5W001-019 10-12GA BUTT CONN INSULATED 1

7A250-050 1/4-20 x .50 SHCS ZINC PLTD 2

7A250-075 1/4-20 x 3/4 SHCS PLTD 3

7E010-049 #10 x 3/4 HXHD SLF DRL SHT MTL 10

7F250-021 1/4-20 NYLOCK NUT ZINC PLATED 3

7J250-001 1/4 WASHER, SAE, PLTD 10

7P375-075 3/4" HOSE BARB UNION, BRASS 1

7P500-026 1/2 NPT x 1/4 BARB 90° BRASS 3

7P500-078 1/2 NPT x 3/4 HOSE FIT STRT 1

7R003-027 ADEL CLAMP, 1-11/16" 1

7R007-001 NYLON RATCHET CLAMP 1-1/8" 10

7U038-000 3/4" HEATER HOSE 12

7U038-012 HOSE, Ø3/4" 90° 4 x 12 LEGS 2

8F001-402 PUMP, WATER, PIERBURG 1

8F101-310 FUEL PUMP RELAY ASSY, HONDA 1

8N006-010 WATER COOLR, SETRAB SINGLE PAS 1

8N055-030 TANK, WATER, TRIANGLE SHAPE 1

8D204-011 RACE BLOWOFF VALVE-SATIN 1

7A250-074 1/4-20 x .75 HHCS PLTD 2

7A312-126 5/16-18 x 1.25 SET SCRW OVAL P 1

7F312-022 5/16-18 JAM NUT, STAINLESS 1

7J006-093 6mm WASHER, PLATED 2

7P125-109 FTG, 1/8 NPT - 1/4 BARB, AL 1

7U100-086 SNAP RING, COMPACT BYPASS 1

8D003-080 RATAINER, SPRING 1

8D004-023 COVER, RACE BYPASS-BLUE 1

8D004-053 GASKET, MTG FLNG, M.F. RACE BYPASS 1

8D004-083 SPRING, MFRB, 12" HG 1

8D104-042 MFRB BODY ASSY SATIN 1

7C011-200 10-32 SHCS x 2" ZINC PLATE 1

7F010-030 10-32 THIN NYLOCK NUT SST 1

7P125-020 BREATHER, SFMU 1

7U100-049 O-RING, COMP.BYPASS 1

8D004-031 VALVE, COMPACT BYPASS ANODIZED 1

8D004-061 PISTON, COMPACT BYPASS MACHINED 1

8D004-091 DIAPHRAM, COMPACT BYPASS 1

8D004-141 SLEEVE, COMPACT BYPASS MACHINED 1

8D104-042R MINI BYPASS GUIDE ASSY 1

4HS020-010 INSTRUCT MANUAL, HONDA S2000 1

P/N: 4HS020-010

©2004 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

27JUL04 v2.0 S2000 (4HSv2.0)

viii

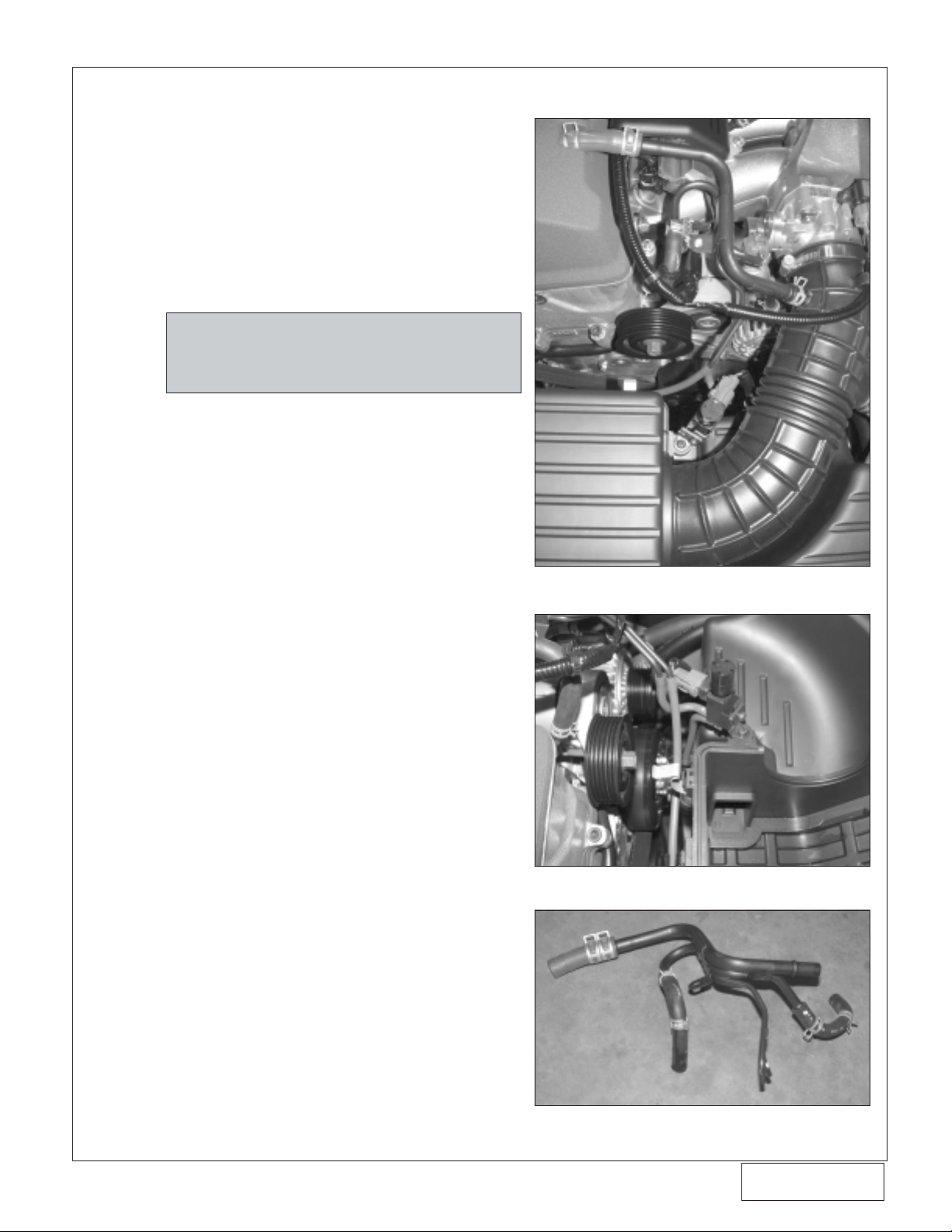

1. PREPARATION/REMOVAL

A. Disconnect the negative battery cable.

B. Remove the factory engine air filter enclosure

cover.

C. Disconnect the crankcase ventilation tube and

the air pump inlet hose attached to the rubber

inlet duct leading to the throttle body.

D. Remove the vacuum/coolant tubing junction from

the vehicle. Tag and label the vacuum hoses for

ease of reassembly in later steps. (See

1-a,1-b,1-c.

)

Figs

NOTE: Make sure that the rubber hoses that are

shown in Fig. 1-c are also removed from

the vehicle along with the tubing junction.

E. Detach the pressure solenoid from the plastic air

filter enclosure (single phillips head screw). (See

Fig. 1-b.

)

F. Separate the rubber vacuum hoses and wiring

from the air filter enclosure.

G. Remove the rubber inlet duct from the throttle

body and the air filter.

H. Remove the air filter and enclosure from the

vehicle.

I. Remove the screw securing the plastic vacuum

canister to the backside of the front crossmember

(located in front of the engine). Set aside for

reinstallation at a later time.

J. Remove the accessory belt and crank damper

pulley from the engine. Removal of the crank

damper pulley bolt may require Honda sourced

tools (07JAB-001020A handle and 07JAA001020A damper socket). Set aside the damper

screw for reinstallation at a later time.

K. Remove the factory idler (smooth) pulley and

hardware and set aside temporarily. (See

)

1-d.

Fig.

L. Remove the two factory M8 x 1.25 screws that

attach the front corner of the cylinder head to the

engine front cover (see

Fig. 1-e

).

M. Disconnect the wiring from the VTEC solenoid

assembly. Remove the three screws attaching

the solenoid assembly to the side of the cylinder

head. (See

Figs. 1-f,1-g.

) Set the VTEC solenoid

assembly aside for mounting in a later step.

Make sure that the o-ring sealing gasket does not

get lost or damaged, because it will be re-used in

a later step.

Fig. 1-a

Fig. 1-b

Fig. 1-c

©2004 Vortech Engineering, LLC

1

All Rights Reserved, Intl. Copr. Secured

P/N: 4HS020-010

27JUL04 v2.0 S2000 (4HSv2.0)

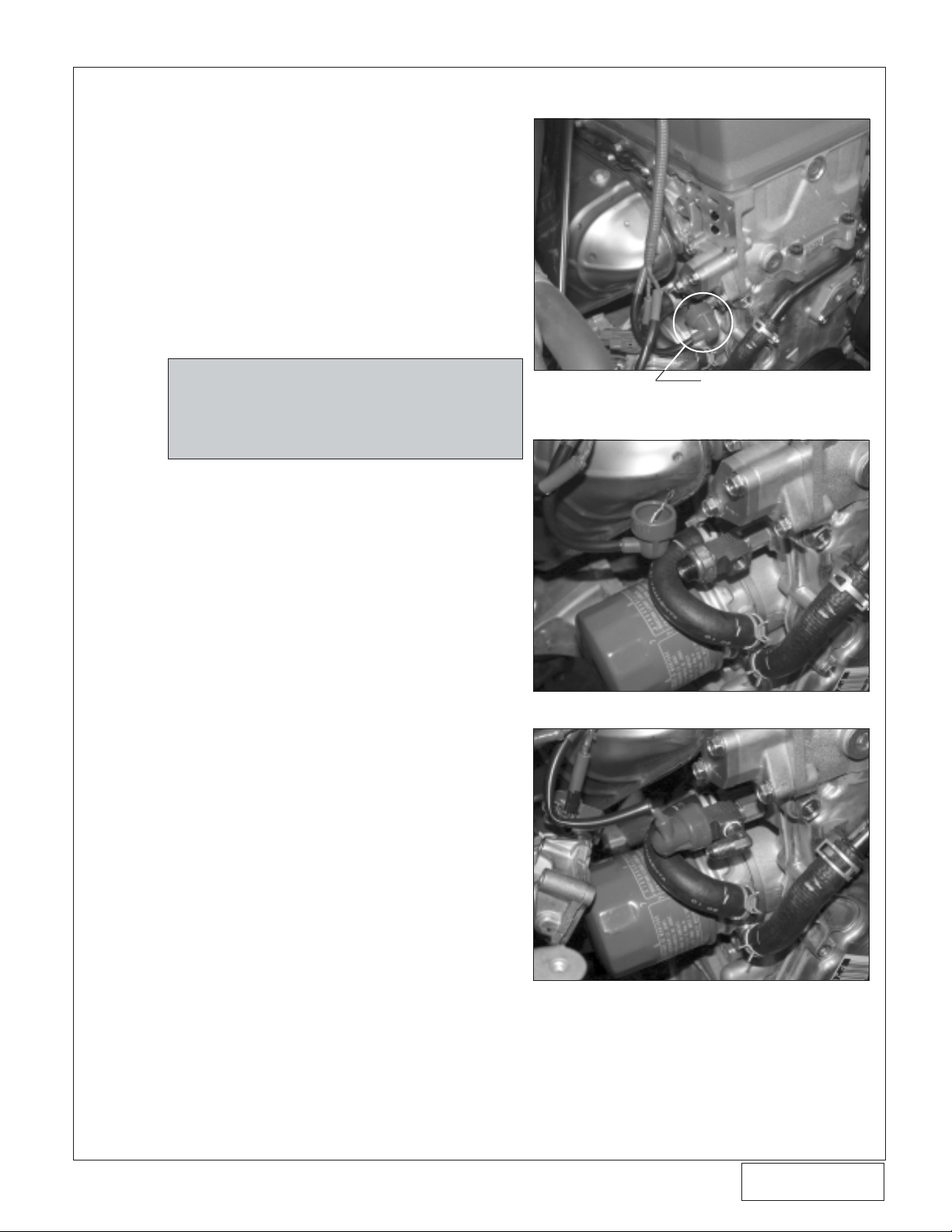

1. PREPARATION/REMOVAL, cont’d.

Fig. 1-d

REMOVE SCREWS

Fig. 1-e

Fig. 1-f

P/N: 4HS020-010

©2004 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

27JUL04 v2.0 S2000 (4HSv2.0)

Fig. 1-g

2

2. OIL FEED

A. The supercharger uses engine oil for lubrication

and must have an oil feed line connected to a

filtered oil access on the engine.

B. Locate the oil pressure sending unit on the pas-

senger side of the engine, toward the front (see

Fig. 2-a

wire from the sending unit. Using a 15/16 socket,

remove the sending unit from the engine.

C. Install the supplied 1/8" BSP adapter into the

block. Install the supplied 1/8" NPT street TEE

into the BSP adapter. Thread the stock sending

unit into the tee as shown in

the stock signal wire and nut to the sending unit.

). Using a 7mm socket, remove the signal

Fig. 2-b

. Reattach

NOTE: Use only clean engine oil on the pipe

threads. Teflon tape or pipe sealant is not

recommended as it might loosen and cause

blockage of the small oil feed orifice resulting in possible supercharger failure.

D. Install the supplied 90° x 1/8" NPT x #4 flare fitting

into the previously installed TEE. (See

Fig. 2-c.

Make sure that the fitting is tightened and clocked

as shown.

E. Temporarily cover the open fitting hole to keep

out debris until the connection is made to the

supercharger hose in step 12.

OIL PRESSURE SENDING UNIT

Fig. 2-a

)

Fig. 2-b

Fig. 2-c

©2004 Vortech Engineering, LLC

3

All Rights Reserved, Intl. Copr. Secured

P/N: 4HS020-010

27JUL04 v2.0 S2000 (4HSv2.0)

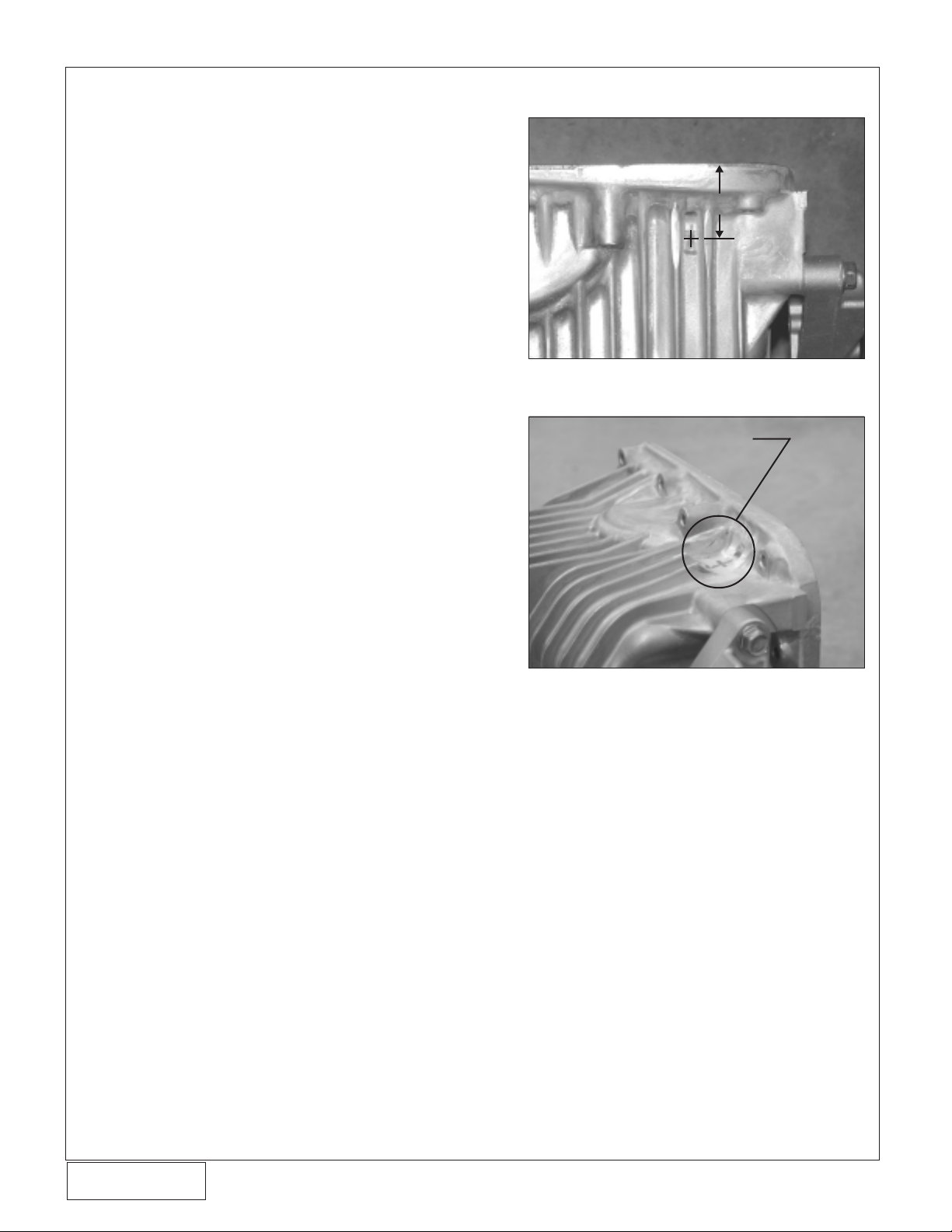

3. OIL DRAIN

A. Drain the engine oil and change the filter.

B. To provide an oil drain for the supercharger, it is

necessary to make a hole in the pan.

C. Remove (6 screws) the tubular chassis

crossmember located beneath the rear of the

engine.

D. Remove the oil pan bumper that is attached to

the vehicle frame in front of the oil pan.

E. Remove the two screws that attach the oil pan to

the transmission bellhousing.

F. Remove the two lower A/C compressor pump

mounting bolts that attach to the oil pan mounting

bracket. Leave the small aluminum mounting

bracket attached to the pan.

G. Remove the remaining oil pan screws around the

perimeter of the pan and carefully remove the

pan.

H. Locate and mark the drain hole location on the oil

pan as per

Figs. 3-a, 3-b

between the two fins as shown, and down from

the sealing surface of the pan 1.25". Grind down

the fins on the oil pan as shown.

I. Using the supplied 9/16" rota-broach cutter and

arbor, carefully machine a through hole into the

pan in the location specified.

J. From the outside of the pan, tap the hole with a

3/8" NPT tap approximately 1/4" deep. Pack the

flutes of the tap with heavy grease to hold the

chips. Thoroughly clean the threads and hole

with acetone or lacquer thinner.

K. Using a small amount of silicone sealer, install

the 3/8 NPT x 1.5" hex nipple into the oil pan.

Thread the supplied 3/8" NPT female x -8 flare

fitting onto the hex nipple. Temporarily cap the

fitting until the drain hose is connected in step 12.

L. Thoroughly clean the mating surface of the oil

pan flange and the bottom of the engine block.

The surfaces must be free from oil so that a

proper seal can be achieved when the pan is

reinstalled.

M. Apply a small amount of Hondabond sealer (avail-

able at the local Honda dealership) to the oil pan

mating flange.

N. Reattach the pan to the engine. Reinstall all of

the factory hardware.

O. Reinstall the two A/C compressor screws, fac-

tory oil pan bumper and chassis crossmember.

P. Re-fill engine with factory specified weight oil.

Vortech recommends the use of synthetic oil.

. The hole location is

1.25”

Fig. 3-a

GRIND FINS AS SHOWN

Fig. 3-b

P/N: 4HS020-010

©2004 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

27JUL04 v2.0 S2000 (4HSv2.0)

4

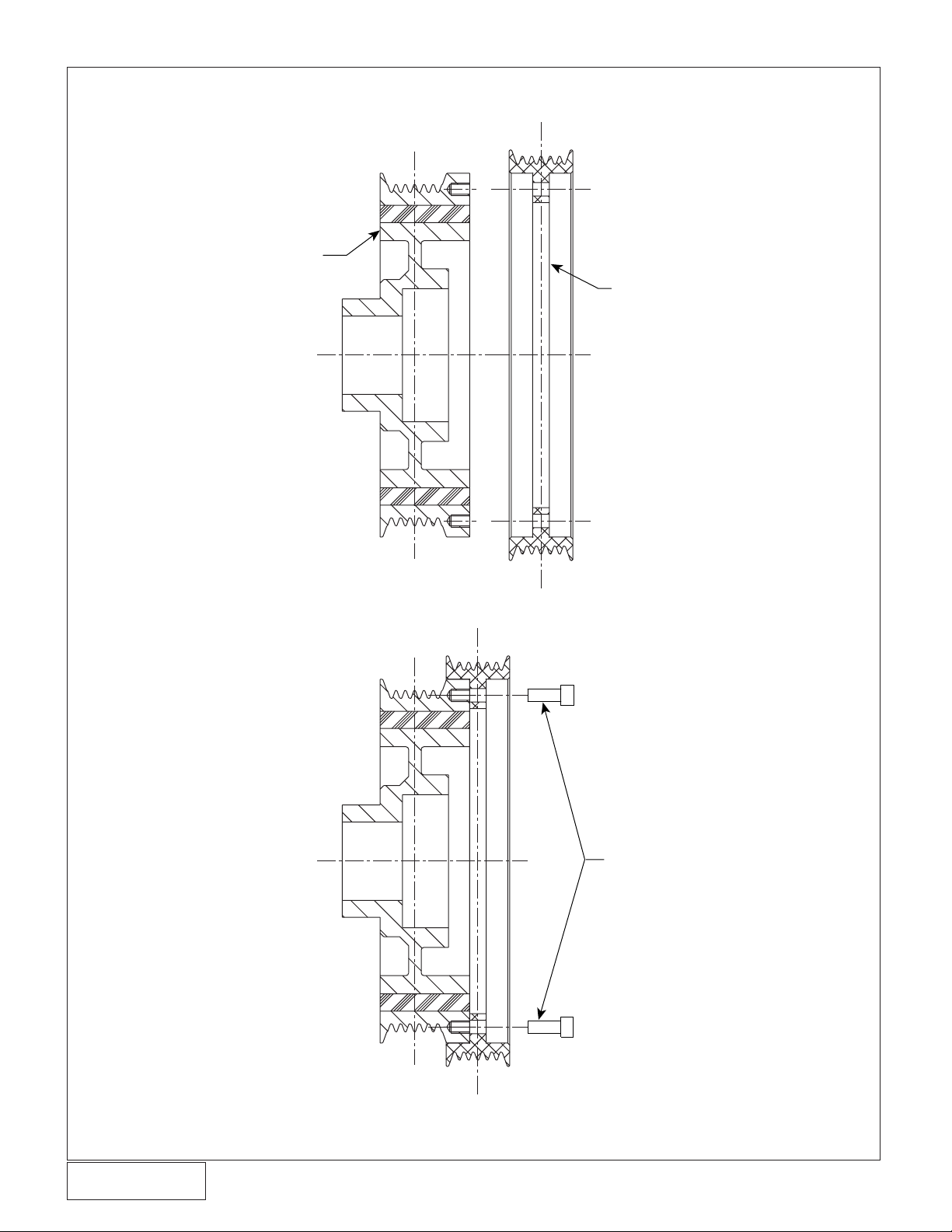

4. CRANK DAMPER PULLEY INSTALLATION

A. Locate the supplied damper pulley and billet

aluminum supercharger crank pulley.

B. The aluminum supercharger crank pulley is to be

installed over the new damper pulley as shown in

Fig. 4-a

that the holes properly line up with the corresponding threaded holes in the damper. Ensure

that the damper is smooth and clean where the

aluminum pulley is to be seated.

C. Carefully lower the aluminum pulley down onto

the damper. Make sure that the aluminum pulley

is completely seated onto the damper. Do not

hammer or pry the pulley into place. If necessary, the aluminum pulley may be lightly heated

to allow for an easier fit onto the damper pulley

D. Secure the pulley and damper together using the

six supplied 10-24 x .50 socket head screws.

Use a drop of blue Loctite on the threads on each

of the screws. Torque the screws to 50 in/lbs (4-5

ft/lbs.)

E. Clean the damper pulley screw and washer that

were removed in step 1. Using a small amount of

engine oil, lubricate the screw threads and the

bottom side of the screw head (area that mates

to the washer). Install the new crank pulley

assembly onto the engine. Torque the screw to

181 lb/ft. Do not use an impact wrench. In order

to achieve the correct torque on the screw,

Honda sourced tools may be required (07JAB001020A handle and 07JAA-001020A damper

socket) to keep the assembly from rotating.

. Be sure to rotate the aluminum pulley so

©2004 Vortech Engineering, LLC

5

All Rights Reserved, Intl. Copr. Secured

P/N: 4HS020-010

27JUL04 v2.0 S2000 (4HSv2.0)

4. CRANK DAMPER PULLEY INSTALLATION, cont’d.

VORTECH SUPPLIED

CRANK DAMPER

PULLEY

6.0” ALUMINUM

SUPERCHARGER CRANK

PULLEY

P/N: 4HS020-010

©2004 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

27JUL04 v2.0 S2000 (4HSv2.0)

6 x 10-24 x .50

SCREWS (TORQUE

EVENLY TO 50 IN/LBS)

Fig. 4-a

6

5. FUEL MANAGEMENT UNIT

A. Disconnect and discard the factory rubber fuel

return line running from the fuel pressure regulator outlet to the steel return line located under the

vehicle.

B. Remove the relay from the factory bracket/tab

near underhood fuse box. (See

Remove the bracket/tab from the vehicle and

discard. Move the relay toward the underhood

fuse box to make space for mounting of the

Vortech FMU.

C. Position the FMU onto the driver side inner

fender as shown in

Figs. 5-c, 5-d

holes and secure the FMU with the supplied

sheet metal screws.

D. Route the supplied 34” hose as shown in

Connect the FMU inlet hose (the hose that goes

to the 90° fitting on the side of the FMU) to the

return side of the factory fuel regulator. Trim

hose length if needed. Secure the fuel line away

from abrasion and exhaust with the tie wraps

provided. Make sure the hose end is securely

clamped onto the regulator outlet using one of

the supplied #4 clamps.

E. Route the supplied 28” hose as shown in the

diagram. Connect the FMU outlet hose (attaches

to the center fitting on the bottom of the unit) to

the steel return line running to the tank (see

). Trim hose length if needed. Secure the fuel

5-e

lines away from abrasion and exhaust with the tie

wraps provided. Make sure the hose end is

securely clamped onto the return line using one

of the supplied #4 clamps.

F. Attach the supplied 28” length of 5/32” vacuum

hose to the fitting on top of the FMU. Splice the

opposite end of the hose into the factory fuel

regulator vacuum connection using the 5/32”

TEE provided. Trim hose length as necessary.

Figs 5-a, 5-b

. Mark and drill

Fig. 5-f

Fig.

.)

RELOCATED RELAY

.

Fig. 5-a

Fig. 5-b

FMU MOUNTING HOLES

Fig. 5-c

©2004 Vortech Engineering, LLC

7

All Rights Reserved, Intl. Copr. Secured

P/N: 4HS020-010

27JUL04 v2.0 S2000 (4HSv2.0)

5. FUEL MANAGEMENT UNIT, cont’d.

Fig. 5-d

FACTORY RETURN

LINE INTO TANK

Fig. 5-e

P/N: 4HS020-010

©2004 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

27JUL04 v2.0 S2000 (4HSv2.0)

8

5. FUEL MANAGEMENT UNIT, cont’d.

ATTACH TO MANIFOLD VACUUM

FMU/FUEL LINE DIAGRAM

FUEL PRESSURE

REGULATOR

SUPPLIED 34” FMU

INLET HOSE —

SECURE BOTH

ENDS WITH CLAMPS

SUPPLIED 28” FMU

OUTLET HOSE —

SECURE BOTH

ENDS WITH CLAMPS

FMU OUTLET

FMU INLET

VEHICLE’S STOCK

RETURN LINE

(TO TANK)

Fig. 5-f

9

©2004 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

P/N: 4HS020-010

27JUL04 v2.0 S2000 (4HSv2.0)

6. FUEL PUMP REPLACEMENT

A. Remove the spare tire from inside the vehicle’s

trunk.

B. Remove the holding tray for the convertible top,

located behind the seats. Remove all of the

pushpins securing the holding tray. (Refer to

page 20-71 of the factory service manual for the

location of all the pushpins) Slide the tray out by

way of the trunk. (See

Fig. 6a.

)

NOTE: Pressing in on the center of the black plas-

tic removable rivets with a small screwdriver

will cause them to release.

C. Remove the three- (3) screws securing the cover

of the fuel tank.

D. Disconnect the fuel feed and return lines from the

top of the tank along with the electrical connectors.

E. Remove the eight- (8) screws securing the top of

the fuel pump module to the gas tank. Carefully

remove the fuel pump module using care not to

damage the fuel level sender. (See

Fig. 6-b.

)

F. Disconnect the electrical connector connecting

to the fuel pump.

G. Unsnap the white plastic retaining clip next to the

fuel filter. (See

Fig. 6-c.

)

H. Using a pair of pliers, slide the spring clamp on

the short fuel hose down and remove the fuel

pump from the module. (See

Fig. 6-d.

)

I. Carefully remove the small retaining clip secur-

ing the fuel filter to the bottom of the fuel pump.

Remove the fuel filter and attach it to the provided

replacement fuel pump and secure it with the

small retaining clip previously removed.

J. Remove the short fuel line from the discharge of

the fuel pump and install onto the new fuel pump.

K. Reinstall the removed components in reverse

order.

Fig. 6-a

Fig. 6-b

P/N: 4HS020-010

©2004 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

27JUL04 v2.0 S2000 (4HSv2.0)

Fig. 6-c

Fig. 6-d

10

7. FUEL RAIL/REGULATOR MODIFICATIONS (2004 Models Only)

4.10"

.60"

DRILL WITH AN ‘R’ DRILL

AND TAP 1/8 NPT

2004 FUEL RAIL

MODIFICATIONS

Fig. 7-a

A. Disconnect the fuel feed line running to the

middle of the factory fuel rail.

B. Remove the hose connected to the return side of

the fuel regulator.

C. Loosen the factory screws securing the fuel rail

and remove the fuel rail from the vehicle.

D. Using

Figs. 7-a, 7-b

, mark the location to be

drilled. Keeping the drill perpendicular to the fuel

rail, drill a .339" (R drill bit) hole into the top of the

fuel rail.

E. With a 1/8 NPT tap, thread the newly drilled hole

until the tap is 1/3 of the way inside the hole or the

supplied 1/8 NPT x -4 fitting can be started.

Thoroughly clean all debris from the fuel rail.

F. Using a thread sealant, install the 1/8 NPT end of

the supplied fitting into the fuel rail until the fitting

is snug.

G. Reinstall the fuel rail back into the vehicle. Re-

connect the fuel feed line and secure all the

factory hardware.

RETURN HOSE

FUEL FEED LINE

SUPPLIED -4 x 1/8NPT FITTING

Fig. 7-b

FUEL PRESSURE

REGULATOR

NOTE: At this time, leave the fuel return line dis-

connected from the fuel regulator.

H. Remove the two screws securing the fuel pres-

sure regulator to the fuel rail.

I. Following

Fig. 7-c

, drill a .078" hole in the rear of

the regulator. (This allows the regulator to bypass more fuel due to increased static fuel pressure.)

NOTE: This step is also recommended for 2001-

2003 model years.

J. Clean all debris and reinstall the fuel pressure

regulator back onto the fuel rail, verifying alignment of the O-ring.

K. Reconnect the fuel return line to the bottom barb

on the fuel pressure regulator.

11

Fig. 7-c

DRILL .078" HOLE

©2004 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

P/N: 4HS020-010

27JUL04 v2.0 S2000 (4HSv2.0)

8. SUPERCHARGER MOUNTING BRACKET/PLATE INSTALLATION

A. Detach the factory wiring harness from the rear of

the front crossmember for mounting bracket clearance. Push the harness down toward the steering rack.

B. Remove the two factory M6 x 1.0 screws from the

passenger side front of the engine near the crank

pulley at the location shown in

Fig. 8-a

C. Locate the lower supercharger plate spacer.

This is a .75" thick aluminum spacer that is 2.9"

wide x 4.05" tall with two 1/2" round protrusions

machined into one end. Slide the two supplied 10

mm studs through the holes in the lower plate

spacer. With the studs located loosely through

the lower plate spacer, thread the two studs into

the front cover as shown in

Figs. 8-b, 8-n, 8-o

This step must be done as described because of

the limited space available in the engine compartment. Use a drop of blue Loctite on the

threads of the studs before threading them into

the engine. Tighten the studs into the front of the

engine by using a stud wrench, or by temporarily

threading two nuts on the end of each stud and

torquing. Remove the nuts from the ends of the

studs.

D. Attach the supplied 6 grooved idler pulley to the

main supercharger mounting plate as shown in

Figs. 8-c, 8-d, 8-e, 8-f

. Slide one of the supplied

3/8-24 x 3.5" screws through the machined bearing pilot, 6 groove idler pulley and steel idler

spacer (1.772" effective length x Ø.406" through

hole). Attach the complete assembly to the aluminum mounting plate by threading the 3/8-24 x

3.5" screw through the plate and into the threaded

steel insert that is pressed into the plate.

E. Attach the belt tensioner adjustment screw,

tensioner arbor and adjustment screw locator

block to the supercharger mounting plate as

shown in

Figs. 8-e, 8-f, 8-g, 8-h, 8-i

assembly to the plate by threading the two 1/4-20

x .75" socket head screws through the plate and

into the adjustment screw locator block as shown.

Make sure the locator block is positioned as

shown in

Fig. 8-h

or you will experience oil feed

line clearance issues.

F. Slide the supplied smooth idler pulley and steel

idler spacer (1.772" effective length x Ø.515"

through hole) over the tensioner arbor that was

previously installed onto the mounting plate.

Install the 12 mm washer and 1/2-20 jam lock nut

over the idler and arbor. Do not tighten the nut at

this time. (See

Fig. 8-f.

)

G. Remove the blue plastic dust cap located on the

1/2" oil drain fitting on the bottom of the supercharger. Attach the supplied 1/2" x 18" fabric

braided oil drain hose to the supercharger drain

.

. Secure the

.

Fig. 8-a

Fig. 8-b

Fig. 8-c

P/N: 4HS020-010

©2004 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

27JUL04 v2.0 S2000 (4HSv2.0)

Fig. 8-d

12

8. SUPERCHARGER MOUNTING BRACKET/PLATE INSTALLATION, cont’d.

REMOVE FACTORY

SCREWS

DO NOT INSTALL HARDWARE

IN THIS HOLE AT THIS STEP

M12 x 1.75 x 50mm SCREW WITH

WASHER INSTALLED THROUGH

SUPPORT PLATE AND Ø1.0 x .549

SPACER AND INTO SUPERCHARGER

BOSS (SPACER SANDWICHED

BETWEEN CENTER SUPERCHARGER

BOSS AND SUPPORT PLATE)

3/8-16 x 1.25 SCREW

WITH AN WASHER

BELT TENSIONER

ADJUSTMENT SCREW

AND LOCATOR BLOCK

(LOCATED ON OPPOSITE

SIDE OF PLATE) ATTACHED

WITH TWO 1/4-20 x .75

SH SCREWS THREADED

IN FROM THIS SIDE

OF MAIN PLATE

MAIN SUPERCHARGER

MOUNTING PLATE

MAIN SUPERCHARGER MOUNTING PLATE

VIEW FROM BACKSIDE

(DASHED LINES REVEAL HIDDEN VIEWS)

1/2-20 BELT TENSIONER

ARBOR SCREW

INSTALLED (FROM

OTHER SIDE)

THROUGH MAIN

PLATE IDLER SPACER

SMOOTH IDLER - M12

x 10" THICK WASHER

AND 1/2-20 JAM LOCK

NUT (SEE SIDE VIEW)

3/8-24 x 3.5" SCREW/

BEARING PILOT

INSTALLED THROUGH

RIBBED IDLER AND

SPACER AND INTO

THE NUT INSTALLED

IN THE MAIN PLATE

(SEE SIDE VIEW)

Fig. 8-e

13

©2004 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

P/N: 4HS020-010

27JUL04 v2.0 S2000 (4HSv2.0)

8. SUPERCHARGER MOUNTING BRACKET/PLATE INSTALLATION, cont’d.

SMOOTH IDLER

PULLEY - Ø3.0

M12 x .10” THICK WASHER

SMOOTH IDLER

SPACER - Ø.515

INSIDE DIAMETER

1/2-20 JAM LOCKNUT

(DO NOT TIGHTEN

UNTIL LAST STEP)

3/8-24 x 3.5"

SCREW

BEARING PILOT - Ø.386

INSIDE DIAMETER

RIBBED IDLER

PULLEY - Ø3.0

1.772

1.772

RIBBED IDLER

SPACER Ø.406

INSIDE DIAMETER

MAIN SUPERCHARGER MOUNTING PLATE

VIEW FROM PASSENGER SIDE

BELT

TENSIONER

ARBOR

PRE-INSTALLED

3/8-24 “PRESS

NUT” INSERT

MAIN SUPERCHARGER

MOUNTING PLATE

P/N: 4HS020-010

©2004 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

27JUL04 v2.0 S2000 (4HSv2.0)

Fig. 8-f

14

8. SUPERCHARGER MOUNTING BRACKET/PLATE INSTALLATION, cont’d.

BELT TENSIONER

ARBOR SCREW

Fig. 8-g

BELT TENSIONER

ADJUSTMENT SCREW

ADJUSTMENT SCREW

LOCATOR BLOCK

Fig. 8-h

Fig. 8-i

15

©2004 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

P/N: 4HS020-010

27JUL04 v2.0 S2000 (4HSv2.0)

8. SUPERCHARGER MOUNTING BRACKET/PLATE INSTALLATION, cont’d.

fitting. Secure with a #8 hose clamp. Make sure

that the hose clamp housing is clocked down

toward the supercharger so that it will not cause

interference with the supercharger mounting plate

that is to be installed. (See

Fig. 8-j

H. Remove the blue plastic dust cap located on the

brass oil feed nozzle on the side of the supercharger. Thread the supplied steel 1/8" NPT x

45° x –4JIC fitting into the supercharger oil feed

nozzle. Carefully tighten and clock the 45° fitting

as shown in

Figs. 8-j, 8-k

. Use caution when

tightening the oil feed fitting, as the brass nozzle

may be broken if care is not exercised. Connect

the supplied oil feed line to the flare fitting.

Temporarily cover the open end from debris until

the connection is made to the engine in step 12.

.)

Fig. 8-J

NOTE: Use only clean engine oil on the pipe

threads. Teflon tape or pipe sealant is not

recommended as it might loosen and cause

blockage of the small oil feed orifice resulting in possible supercharger failure.

I. Attach the supercharger unit to the mounting

plate as shown using the five supplied 3/8-16 x

1.25" screws with AN washers. The sixth supercharger mounting hole should remain empty at

this time. (Refer back to

Fig. 8-e, and Fig. 8-k

J. Using two of the supplied 3/8-16 x 1.25" screws

with AN washers, attach the upper supercharger

support plate to the supercharger mounting block

as shown in

Figs. 8-l, 8-m

. Thread the screws

down until the heads almost touch the plate/

washers. Do not tighten the screws at this time.

NOTE: When directed, it is important to follow the

suggestion: “Do not tighten the screws”.

Failure to follow this direction will result in

bracket misalignment and the possibility of

the VTEC solenoid not maintaining a proper

seal. Thread the applicable screws and nuts

in until the head almost touches down (.01.02" clearance). This will allow the bracket

to properly align itself to the engine and

other components in the assembly during

installation.

.)

NO FASTENER HERE AT THIS TIME

Fig. 8-K

K. From the back side, slide the supplied 3/8-16 x

3.5" screw and AN washer through the top hole

(refer to

and into one of the supplied Ø.875 O.D. x 1.858"

long spacers. Loosely mount the support plate

assembly with spacer onto the supercharger and

previously assembled main supercharger plate.

P/N: 4HS020-010

©2004 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

27JUL04 v2.0 S2000 (4HSv2.0)

Figs. 8-n, 8-o

) of the upper support plate

3/8-16 x 1.25

SCREWS WITH AN

WASHERS (DO NOT

TIGHTEN)

Fig. 8-l

16

8. SUPERCHARGER MOUNTING BRACKET/PLATE INSTALLATION, cont’d.

3/8-16 x 1.25 SCREWS WITH

AN WASHERS (DO NOT

TIGHTEN SCREWS UNTIL

ENTIRE BRACKET

ASSEMBLY IS MOUNTED

ONTO ENGINE)

SUPERCHARGER PLATE

MOUNTING BLOCK

(SANDWICHED BETWEEN

VTEC SOLENOID AND

CYLINDER HEAD)

HOLE FOR M12 x 1.75 x

50mm SCREW (INSTALLED

FROM BACKSIDE)

SUPERCHARGER

SUPPORT PLATE

PRE-INSTALLED 3/8

-24 “PRESS NUT”

INSERT (LOCATED

ON BACKSIDE OF

PLATE)

SUPERCHARGER SUPPORT PLATE

VIEW FROM FRONT (BEFORE

JOINING TO MAIN PLATE

ASSEMBLY)

Fig. 8-m

17

©2004 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

P/N: 4HS020-010

27JUL04 v2.0 S2000 (4HSv2.0)

8. SUPERCHARGER MOUNTING BRACKET/PLATE INSTALLATION, cont’d.

3/8-16 x 3/5” SCREW/AN WASHER INSTALLED

FROM THE BACKSIDE THROUGH SUPPORT

PLATE AND Ø.875 x 1.858 SPACER AND INTO

SUPERCHARGER (SPACER SANDWICHED

BETWEEN MAIN PLATE AND SUPPORT PLATE)

SUPERCHARGER PLATE MOUNTING

BLOCK (SANDWICHED BETWEEN

VTEC SOLENOID AND CYLINDER HEAD)

M12 x 1.75 x 50mm SCREW WITH

WASHER INSTALLED FROM THE

BACKSIDE - THROUGH SUPPORT

PLATE AND Ø1.0 x .549 SPACER

AND INTO SUPERCHARGER

(SPACER SANDWICHED BETWEEN

CENTER SUPERCHARGER BOSS

AND SUPPORT PLATE)

3/8-24 x 3.5” SCREWS/AN

WASHERS INSTALLED

FROM THE FRONT -

THROUGH MAIN PLATE

AND Ø.875 x 1.858

SPACERS AND INTO

SUPPORT PLATE (SPACERS

SANDWICHED BETWEEN

MAIN PLATE AND SUPPORT

Ø3.0” SUPERCHARGER

TENSIONER PULLEY

BELT TENSIONER ARBOR

BELT TENSIONER ADJUSTMENT SCREW

ADJUSTMENT SCREW AND LOCATOR

BLOCK ATTACHED WITH TWO 1/4-20 x .75

SH SCREWS THREADED IN FROM THE

PLATE)

(SMOOTH)

BACK SIDE OF MAIN PLATE

5/16-18 x 1.0 SCREWS

WITH AN WASHERS

THROUGH MAIN PLATE

INTO LATERAL SUPPORT

PLATE

FACTORY

SPRING

TENSIONER

M10 x 1.25 x 115 SCREW

WITH WASHER THROUGH

MAIN PLATE - Ø1.0 x

Ø2.726 SPACER, FACTORY

IDLER AND INTO FACTORY

THREADED IDLER

MOUNTING HOLE

ON FRONT COVER

FACTORY FIXED

IDLER

FACTORY

BELT

FACTORY

BOSSES

LOCATED ON

ENGINE FRONT

COVER

3/8-24 x 3.5 SCREW/BEARING PILOT INSTALLED

FROM THE BACKSIDE THROUGH RIBBED

IDLER AND SPACER AND INTO “PRESSED NUT”

P/N: 4HS020-010

©2004 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

27JUL04 v2.0 S2000 (4HSv2.0)

INSERT INSTALLED IN MAIN PLATE

M6 x 1.0 NUTS WITH WASHERS INSTALLED

ONTO STUDS PREVIOUSLY THREADED INTO

FRONT OF ENGINE (REMOVE FACTORY

LOWER SUPERCHARGER PLATE SPACER (ROUND

PROTRUSIONS TO BE INSTALLED AGAINST THE

HARDWARE)

SUPERCHARGER DRIVE BELT

(DASHED LINES REVEAL HIDDEN VIEWS)

CRANK

PULLEY

FRONT COVER)

OIL PAN FLANGE

FRONT VIEW OF ENGINE

Fig. 8-n

18

8. SUPERCHARGER MOUNTING BRACKET/PLATE INSTALLATION, cont’d.

3/8-16 x 3.5” SCREW / AN WASHER

INSTALLED FROM THE BACKSIDE

THROUGH SUPPORT PLATE AND

Ø.875 x 1.858 SPACER AND INTO

UPPER SUPERCHARGER MOUNTING

BOSS (SPACER SANDWICHED BETWEEN

MAIN PLATE AND SUPPORT PLATE)

M6 1.0 x 80mm SCREWS

THROUGH VTEC SOLENOID

(NOT SHOWN), SUPERCHARGER

PLATE MOUNTING BLOCK

AND INTO CYLINDER HEAD)

SUPERCHARGER PLATE

MOUNTING BLOCK

M10 x 1.25 x 50mm SCREW

WITH WASHER THROUGH

SUPERCHARGER PLATE MOUNTING

BLOCK AND INTO CYLINDER HEAD

M12 x 1.75 x 50 SCREW

CYLINDER HEAD

“PRESS NUT” INSERT (3 PLACES)

M12 WASHER

Ø1.0” x .549 SPACER

PRE-INSTALLED 3/8-24

.549

1.858

2.726

3/8"

WASHER

CENTER M12

SUPERCHARGER BOSS

3/8-24 x 3.5’ SCREWS

INSTALLED FROM THE

FRONT THROUGH MAIN

PLATE AND Ø.875 x 1.858

SPACERS AND INTO

SUPPORT PLATE, SPACERS

SANDWICHED BETWEEN

MAIN PLATE AND SUPPORT

PLATE — 3 PLACES)

FACTORY FIXED IDLER

M10

WASHER

SUPERCHARGER

SUPPORT PLATE

FRONT FACE OF

Ø1.0" x 2.726

STEEL SPACER

M6 x 1.0 NUTS WITH WASHERS INSTALLED

ONTO STUDS PREVIOUSLY THREADED

INTO FRONT OF ENGINE

ENGINE BLOCK

SUPERCHARGER

MOUNTING PLATE

LOWER SUPERCHARGER PLATE SPACER

(ROUND PROTRUSIONS TO BE INSTALLED

AGAINST THE FRONT COVER)

SUPERCHARGER BRACKET ASSEMBLY VIEW FROM PASSENGER SIDE —

VORTECH IDLERS AND SOME FASTENERS NOT SHOWN FOR CLARITY

(DASHED LINES REVEAL HIDDEN VIEWS)

Fig. 8-o

M6 x 1.25 x 1.15 SCREW

THROUGH MAIN PLATE.

Ø1.0 x 2.726 SPACER

FACTORY IDLER AND

INTO FACTORY

THREADED IDLER

MOUNTING HOLE

ON FRONT COVER

19

©2004 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

P/N: 4HS020-010

27JUL04 v2.0 S2000 (4HSv2.0)

8. SUPERCHARGER MOUNTING BRACKET/PLATE INSTALLATION, cont’d.

The 3/8-16 x 3.5" screw is to be threaded through

the main supercharger plate and into the remaining 3/8" threaded mounting hole on the supercharger unit. (See

Fig. 8-p

.) Thread the screw

down until the head almost touches the plate/

washer. Do not tighten the screw at this time.

L. Mount the remaining three Ø.875 O.D. x 1.858"

long spacers between the main supercharger

mounting plate and the upper support plate as

shown in

Figs. 8-P, 8-q

. From the front side, slide

the three supplied 3/8-24 x 3.5" screws and AN

washers through the main mounting plate, through

the three Ø.875 O.D. x 1.858" long spacers and

into the threaded steel inserts that are pressed

into the back side of the support plate. (See

8-n, 8-o

.) Thread the screws down until the

Figs.

heads almost touch the plate/washers. Do not

tighten the screws at this time.

M. From the back side, slide the supplied M12 x 1.75

x 50 screw and M12 washer through the remaining hole in the upper support plate (refer to

8-o, 8-q.

) and into the supplied Ø1.0 O.D. x .549"

Figs.

long spacer. The spacer is to be sandwiched

between the front side of the upper support plate

and the center 12 mm boss located on the

supercharger cover. Thread the screw down

until the head almost touches the plate/washer.

Do not tighten the screw at this time.

N. From the front side, slide the supplied M10 x 1.25

x 115 screw and M10 washer through the remaining hole in the mounting plate and into the

supplied Ø1.0 O.D. x 2.726" long steel spacer.

Figs. 8-r, 8-s

(See

.)

O. Insert the new supplied VTEC o-ring gasket seal

into grooves in the Vortech supercharger plate

mounting block. as shown in

Fig. 8-t

. Make sure

that the gasket remains in the block grooves

during bracket installation on the engine. Apply a

light amount of oil to the gasket.

P. Place the factory idler (removed in step one)

back onto the original boss on the front of the

engine (without hardware, washer or dust shield).

Q. Loosely route the factory accessory belt onto the

engine. The belt should be routed around the

crank pulley and fixed idler pulley per the factory

method. Do not attempt route the belt around the

spring tensioner at this time.

R. Loosely route the supplied supercharger drive

belt onto the engine. Following

Fig. 8-n

, loosely

attach the supercharger with bracket assembly

onto the engine. Line up the two Ø1/4" holes in

the main bracket with the lower spacer and two

M6 studs (previously installed). Move the bracket

assembly over the studs. Thread the supplied

M6 nuts with washers over the ends of the studs

until the nuts almost touch the washers. Do not

tighten the nuts at this time.

Ø.875 x 1.858 SPACERS (4x)

3/8-16 x 3.5 SCREW

INTO SUPERCHARGER

Fig. 8-p

M12 x 1.75 x 50

SCREW/WASHER

Fig. 8-q

M10 x 1.25 x 115 SCREW

WITH Ø2.726” SPACER

Fig. 8-r

P/N: 4HS020-010

©2004 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

27JUL04 v2.0 S2000 (4HSv2.0)

20

8. SUPERCHARGER MOUNTING BRACKET/PLATE INSTALLATION, cont’d.

SLIDE THE Ø1.0” x 2.726”

SPACER ONTO THE M10

x 1.25 x 115 SCREW

BEFORE ATTACHING

THE MOUNTING PLATE

TO THE ENGINE

Fig. 8-s

Fig. 8-t

21

©2004 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

P/N: 4HS020-010

27JUL04 v2.0 S2000 (4HSv2.0)

8. SUPERCHARGER MOUNTING BRACKET/PLATE INSTALLATION, cont’d.

NOTE: When installing the supercharger with bracket

assembly onto the engine, the belt must be

manipulated so that it is properly routed

around the idler, tensioner, supercharger

pulley and lower supercharger plate spacer.

(Refer back to Fig. 7-n.)

S. Align the M10 x 1.25 x 115 screw (previously

inserted through the front of the main supercharger plate) into the factory idler pulley mount

on the front cover. (See

Fig. 8-u

.) Make sure that

the supplied Ø1.0 O.D. x 2.726" long spacer is

sandwiched between the back of the supercharger mounting plate and the inner bearing

race of the factory idler. Do not tighten any

screws at this time.

T. Insert the three supplied M6 x 1.0 x 80 screws

with washers through the previously removed

VTEC solenoid, the Vortech supercharger plate

mounting block and into the side of the cylinder

head. (See

Figs. 8-v, 8-w

.) Make sure that both

of the VTEC gaskets remain in their proper

locations during bracket installation on the engine. Thread the supplied M10 x 1.25 x 50 screw

with washer into the remaining hole in the supercharger plate mounting block and into the cylinder head. Thread the four screws down until the

heads almost touch the washers. Do not tighten

the screws at this time.

U. Attach the supplied lateral supercharger mount-

ing plate (‘L’ shaped bracket) support to the front

corner of the cylinder head as shown using the

supplied M8 x 1.25 x 45 socket head screws (no

washers are used here). See

Figs. 8-u, 8-x

Thread the screws down until the heads almost

touch the plate. Do not tighten the screws.

V. Align the two threaded holes in the end of the

lateral support with the two holes in the supercharger mounting plate. Slide the two supplied

5/16-18 x 1.0" screws with AN washers through

the remaining two holes in the supercharger

mounting plate and into the lateral support. Thread

the screws down until the heads almost touch the

washers. Do not tighten the screws at this time.

W. Secure the completed mounting bracket assem-

bly to the engine by lightly “snugging” the hardware in the following sequence:

1. Four VTEC solenoid mounting screws.

2. 3/8-16 x 3.5" screw running through the top

hole of the upper support plate, Ø.875 O.D.

x 1.858" long spacer and into the supercharger.

3. M12 x 1.75 x 50 screw running through the

upper support plate, Ø1.0 O.D. x .549"

spacer and into the center 12 mm boss

LATERAL MOUNTING PLATE

Fig. 8-u

.

M10 x 1.25 x 50

Fig. 8-v

Fig. 8-w

P/N: 4HS020-010

©2004 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

27JUL04 v2.0 S2000 (4HSv2.0)

22

8. SUPERCHARGER MOUNTING BRACKET/PLATE INSTALLATION, cont’d.

located on the supercharger cover.

4. Two 3/8-16 x 1.25" screws with AN washers

that attach the supercharger support plate

to the supercharger mounting block.

5. M10 x 1.25 x 115 screw through the front of

the supercharger mounting plate and into

the factory idler pulley mount on the front

cover.

6. Two 5/16-18 x 1.0" screws through the supercharger mounting plate and into the lateral support.

7. Two M8 x 1.25 x 45 socket head screws

through the lateral support mounting plate,

front corner of the cylinder head and into the

front cover.

8. Three 3/8-24 x 3.5" screws running through

the main mounting plate, Ø.875 O.D. x

1.858" long spacers and into the threaded

steel inserts that are pressed into the back

side of the support plate.

9. Two M6 nuts that are threaded onto the two

studs inserted into the front of the engine.

X. Repeat the sequence above with final torquing of

all hardware.

Y. Reconnect the previously removed VTEC wiring

connections.

Z. Reattach the plastic vacuum canister to the back-

side of the front crossmember (located in front of

the engine) using the factory screw that was

removed in step 1. Make sure that there is

enough clearance between the vacuum hose

and the crank pulley.

TWO 5/16-18 x 1"

SCREWS WITH

AN WASHERS

Fig. 8-x

TWO M8 x 1.25 x 45

SOCKET HEAD SCREWS

(NO WASHERS)

23

©2004 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

P/N: 4HS020-010

27JUL04 v2.0 S2000 (4HSv2.0)

9. SUPPLEMENTARY FUEL INJECTOR INSTALLATION (2004 Models Only)

A. Locate the supplied charge cooler. Insert the

supplied 55lb/hr fuel injector into the injector

base welded to the cooler discharge tube so that

the injector plug is facing away from the injector

base. (See

Fig. 9-a

NOTE: Lightly oil the O-rings on the injector for

easier installation.

.)

B. Insert the upper block over the injector. Secure

the upper injector block with the supplied shoulder bolts.

C. Install the 1/8 NPT end of the supplied 90° fitting

into the upper injector block. Orient the fitting so

that it is pointing toward the back of the car.

D. Connect the 90° end of the supplied steel braided

line to the -4 end on the installed straight fitting in

the fuel rail. Run the fuel line toward the front of

the car. Leave the open end of the fuel line

disconnected until the charge cooler has been

installed. (See

Fig. 9-b

NOTE: Thread sealant is recommenced on all fit-

ting ends that have pipe threads.

.)

INSTALLED INJECTOR

Fig. 9-a / TOP VIEW

P/N: 4HS020-010

©2004 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

27JUL04 v2.0 S2000 (4HSv2.0)

Fig. 9-b / TOP VIEW

24

10. SUPERCHARGER BELT TENSIONER ADJUSTMENT

A. Make sure that the 1/2-20 jam lock nut previously

threaded onto the tensioner arbor is threaded

down almost all of the way, but not tight. The belt

is tightened/loosened by rotating the belt tensioner

adjustment screw. Tighten the belt until light

resistance is felt in the belt tensioner adjustment

screw. Proper belt tension is achieved when the

belt can be twisted approximately 1/4 of a turn by

hand. Adjust belt tension as needed. Do not over

tension the belt.

B. From beneath the vehicle, tighten the 1/2-20 jam

lock nut on the belt tensioner arbor.

C. Reinstall the factory accessory belt using the

factory routing.

11. AIR PUMP INLET HOSE MODIFICATION

A. Separate the air pump inlet hose from the factory

hose union that was originally connected to the

engine inlet duct.

B. Insert the supplied 3/4" air pump inlet hose filter

into the pump inlet hose. (See

Figs. 11-a, 11-b

.)

SUPPLIED AIR PUMP

INLET FILTER

SUPPLIED AIR PUMP

INLET FILTER

Fig. 11-a / TOP VIEW

Fig. 11-b / BOTTOM VIEW

25

©2004 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

P/N: 4HS020-010

27JUL04 v2.0 S2000 (4HSv2.0)

12. CHARGE AIR COOLER INSTALLATION

A. Attach the supplied breather/filter to the outlet of

the Vortech race bypass valve. Attach the Vortech

race bypass valve to the charge cooler core

using the supplied 1/4-20 x .50" socket head

bolts and gasket. (See

B. Install the charge cooler between the super-

charger and the throttle body using the supplied

2.75" sleeves and #44 hose clamps. The 3" long

sleeve is to be placed on the throttle body.

C. Remove all of the plastic valance or splash

panels located under the vehicle toward the

front.

D. Install the fittings into the water cooler as shown

Fig. Diag 12-b, and Fig. 12-d

in

fitting is to be pointing toward the front of the

vehicle when the water cooler is mounted.

E. Attach the water cooler mounting bracket #1 to

the upper portion of the cooler using the 1/4"

hardware as shown.

F. Trim one of the supplied Ø 3/4" x 90° hoses so

that one leg measures 3" and the other measures

5”. Attach the short leg of the cut hose to the

straight fitting on the water cooler and secure

with one of the provided nylon ratchet clamps.

Install the Ø 3/4" hose union into the other end

and secure with a clamp.

G. Position the water cooler onto the front of the

vehicle in front of the air conditioning condenser

using the lower mounting brackets as shown in

Fig. 12-c

. Secure the water cooler using the

provided #10 self-tapping screws. Route the

attached cooler hose above the condenser hard

line. The upper mounting bracket attaches to the

hood latch screw. (See

H. Attach the short leg of the Ø 3/4" x 90° hose to the

hose union previously installed and secure with

one of the provided clamps.

I. Cut the electrical connector off of the end of water

pump wiring harness and install one 14–16 Ga.

ring terminal onto the brown (negative) wire and

the 18 Ga. insulated male slide connector onto

the blue/green wire (positive).

J. Mount the water pump to the front of the passen-

ger side core support using the supplied 1-11/16"

Adel clamp and one #10 self-tapping screw.

Attach the ground wire (brown wire with ring

terminal installed) from the water pump to the

clamp. Angle the discharge of the water pump up

as shown. (See

Fig.12-f

The discharge of the water pump must be angled

up. This is REQUIRED for the pump to purge itself

of air.

K. Attach an 18 Ga. insulated female slide connec-

tor to the yellow wire attached to the supplied

relay. Route the yellow wire from the relay to the

power distribution box located in front of the

Fig. 12-a

.)

. Note that the 90°

Fig. 12-e.

)

.)

Fig. 12-a

UPPER BRACKET (#1)

LOWER BRACKETS

Fig. 12-b

Fig. 12c

P/N: 4HS020-010

©2004 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

27JUL04 v2.0 S2000 (4HSv2.0)

26

12. CHARGE AIR COOLER INSTALLATION, cont’d.

(SIDE VIEW)

CORRECT FITTING

ORIENTATION

WATER

RESERVOIR

WATER TANK

MOUNTING

BRACKET

WATER

COOLER

(FRONT VIEW)

MOUNTING BRACKET #2

WATER COOLER

WATER FLOW

CHARGE AIR COOLER

WATER PUMP

FROM SUPERCHARGER

Fig. 12-d

27

©2004 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

P/N: 4HS020-010

27JUL04 v2.0 S2000 (4HSv2.0)

12. CHARGE AIR COOLER INSTALLATION, cont’d.

battery. Following

along the factory wires.

L. Remove the factory heater motor relay located in

the underhood fusebox and modify to accept the

electrical power tap as shown in

install the relay with the power tap. Connect the

yellow wire to the power tap.

M. Attach the black wire from the supplied relay to a

suitable ground.

N. Route the red wire from terminal #87 on the

supplied relay down to the water pump. Install a

female insulated slide connector onto the wire

and connect to the blue/green (positive) wire on

the water pump.

O. Cut the supplied fuse holder wire and install the

12 GA ring terminal on one end and the 12 GA.

solderless connector onto the other. Connect the

#30 wire on the supplied relay to the solderless

connector attached to the fuse holder. Connect

the ring terminal to the positive side of the battery

and install the provided fuse.

P. Cut approximately 40" off of the supplied length

of Ø3/4" hose. Install one end onto the water

pump discharge and the other onto the 90° fitting

on the water cooler, routing it forward toward the

front facia. (See

kinks or sharp bends in the hose. Secure both

ends with the provided clamps.

Use a tape measure to correctly check the proper

length and hose routing between each hose connection prior to actually cutting the hose.

Q. Temporarily install the water tank mounting

bracket onto the water reservoir using the 1/4"

hardware (see

voir up as shown and mark the location on the

vehicles frame (passenger side, outer frame rail)

where the #10 self-tapping screws are to be

located. Remove the 1/4" hardware attaching the

bracket to the reservoir. Secure the bracket to

the vehicle using the self-tapping screws. (See

Fig. 12-k

R. Install the two remaining 90° brass fittings into

the water reservoir using a small amount of

thread sealant. Attach one end of the remaining

Ø 3/4" hose to the top of the water reservoir and

secure with a clamp.

S. Permanently attach the water reservoir to the

mounting bracket using the 1/4" hardware.

T. Route the upper reservoir hose into the engine

compartment (

fan and then up between the radiator fan and the

condenser fan finally connecting it to the passenger side fitting on the charge air cooler. Secure

the hose with one of the provided clamps.

U. Measure between the bottom of the reservoir

water outlet and the pump inlet and cut an

appropriate section of hose and set aside.

P/N: 4HS020-010

©2004 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

27JUL04 v2.0 S2000 (4HSv2.0)

Fig. 12-j

.)

Figs. 12-j, 12-l

Fig. 12-g,

Fig. 12-i

). Mock the water reser-

route the wire up

Fig. 12-h

. Re-

.) Be sure there are no

) under the radiator

28

UPPER WATER COOLER BRACKET

UPPER WATER

COOLER BRACKET

Fig. 12-e

WATER PUMP

OUTLET HOSE

Fig. 12-f

Fig. 12-g

MODIFY HERE

Fig. 12h

12. CHARGE AIR COOLER INSTALLATION, cont’d.

V. A hole approximately Ø1" will have to be made

into the lower front plastic valance for the water

line to pass through. Locate the point where the

hose is to pass through and create a hole using

a hole saw or grinder.

W. Reinstall the lower front valance and attach the

passenger side only, leaving the drivers side

loose. Attach the hose previously cut between

the water reservoir and the water pump inlet and

secure with the provided clamps. (See

Fig. 12-m.

X. Temporarily plug the 90° fitting attached to the

driver side of the charge air cooler that connects

to the water cooler outlet hose. Leave the hose

that comes from the top fitting of the water cooler

open to atmosphere.

Y. Fill the system at the charge air cooler with 1/4 -

1/3 of a gallon of anti-freeze.

Slowly

fill the

remainder with water until it comes out of the

open hose coming from the top of the water

cooler, this will help to purge the system of air.

Connect the hose coming from the top fitting on

the water cooler to the open fitting on the charge

air cooler and secure with the provided clamp.

Continue to fill the system with water until it is full

and install the cap onto the charge air cooler.

Z. With the battery reconnected, key the vehicle to

the ON position. Slowly remove the cap on the

charge air cooler and check the level of the

coolant and make sure the coolant is flowing

through the system. Run the system for a few

minutes to allow any air trapped in the lower part

of the system to escape. Top the system off with

coolant if necessary and reinstall the cap.

)

Fig. 12-k

Fig. 12-i

Fig. 12-j

29

Fig. 12-l

Fig. 12-m

©2004 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

P/N: 4HS020-010

27JUL04 v2.0 S2000 (4HSv2.0)

13. AIR INLET DUCT INSTALLATION

A. When installing this supercharger system on

2002-2004 model year vehicles, the horn mounted

inside the engine compartment on the passenger side fender apron must be disconnected and

removed. The horn may be relocated or removed

completely from the vehicle. The vehicle will still

be equipped with the horn located inside of the

fender.

B. Thread the 3/8" NPT x 1/2" beaded brass hose

fitting into the threaded hole on the supplied

Ø3.5" x 90° plastic inlet elbow.

C. Install the Ø3.5" flange into the air box and

secure with four 1/4-20 x 1/2" SHCS. Install the

air filter onto the flange on the inside of the air

box.

NOTE: Rotate the hose clamp on the air filter such

D. Secure the hose clamp on the air filter.

E. Install the upper and lower mounting brackets

onto the air box and secure with 1/4-20 x 1/2"

SHCS. (See

F. Remove the upper passenger side screw secur-

ing the vehicle’s cooling fan. Install the air box

into the vehicle on the passenger side. (See

13-b.

cooling fan mount using the supplied M6 x 10 x

20mm screw.

G. Secure the lower mounting bracket to the vehicle

using the #10 self-tapping screws.

H. Install the supplied Ø3.5" sleeve and two #56

hose clamps onto the beaded end of the Ø3.5" x

90° plastic elbow.

I. Install the supplied Ø3.5" flex hose and two #52

hose clamps onto the flange on the air box.

Check to make sure that there are no obstructions, foreign objects or debris in the air filter, flex

hose or supercharger inlet. Attach the Ø3.5"

elbow to the supercharger and flex hose. Secure

both ends with the provided hose clamps. (See

Fig. 13-c.

be pointing down when the elbow is installed.

that a screw/nut driver may be inserted

through the hole on the bottom of the air

box to tighten the hose clamp.

Fig. 13-a.

)

) Secure the upper mounting bracket to the

) Note that the 1/2” brass fitting should

Fig. 13-a

Fig.

Fig. 13-b

P/N: 4HS020-010

©2004 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

27JUL04 v2.0 S2000 (4HSv2.0)

Fig. 13-c

30

14. HOSE ATTACHMENTS/EXTENSIONS

A. Connect the lower end of the supercharger oil

drain hose to the previously installed fitting in the

drain pan using the supplied 90° x 1/2" swivel

hose end. Hose routing must be downhill with

smooth bends and must not have kinks, sharp

bends or uphill sections. Trim hose length if

necessary. Secure the drain hose to the oil pan

fitting with a #8 clamp.

B. Connect the supercharger feed line to the previ-

ously installed flare fitting near the oil pressure

sending unit. Make a gentle forward loop around

and beneath the front crossmember. Secure the

hose with the tie wraps provided, routing it away

from chaffing and/or sharp objects.

SUPPLIED 1/4”

HOSE x 16”

NOTE: Use only clean engine oil on the pipe

threads. Teflon tape or pipe sealant is not

recommended as it might loosen and cause

blockage of the small oil feed orifice resulting in possible supercharger failure.

C. Attach the supplied piece of 1/4" x 16" long hose

to the cylinder head coolant port that was previously connected to the factory vacuum/coolant

tubing junction removed in step 1. Attach the

remaining end of the hose to the corresponding

port on the throttle body. Secure both ends with

the previously removed factory clamps. (See

Fig. 14-a, 14-b

.)

D. Install the length of 1/2" x 36" hose to the valve

cover vent barb. Connect the opposite end to the

1/2" brass barb located on the supercharger inlet

elbow. Trim the length if necessary.

E. Attach the length of supplied 1/4" vacuum

hose to the fitting on the cover of the Vortech

compressor bypass valve. Route the hose

over near the fuel rail. Install the supplied 5/32"

-1/4" hose reducer into the end of the 1/4"

hose. Splice one of the supplied 5/32" brass

TEEs into the fuel pressure regulator/FMU

signal hose. Attach the compressor bypass

vacuum hose to the remaining leg of the 5/32

TEE using a short piece of 5/32” vacuum hose.

(See

Fig. 14-b

.)

F. Reconnect the two factory vacuum hoses that

were removed in Step 1. Use the supplied

lengths of 5/32" tubing for extensions if required.

G. Re-attach the pressure solenoid (that was

removed in Step 1) to the harness and vacuum

hoses. Use a tie wrap to secure the unit down

toward the crossmember and away from the

crank pulley. (See

Fig. 14-c.

)

Fig. 14-a

SUPPLIED 1/4” HOSE x 16”

COMPRESSOR BYPASS

VACUUM HOSE

Fig. 14-b

31

Fig. 14-c

©2004 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

P/N: 4HS020-010

27JUL04 v2.0 S2000 (4HSv2.0)

15. ELECTRONIC CONTROL BOX INSTALLATION

NOTE: 2004 models do not require the installation

of a map controller.

A. Unclip the yellow wiring harness near the steer-