DP/N: 4GP020-015 - v1.1 05/30/06

1650 Pacific Avenue, Channel Islands CA 93033-9901 • Phone: 805 247-0226

Fax: 805 247-0669 • www.vortechsuperchargers.com • M-F 8:00AM - 4:30PM (PST)

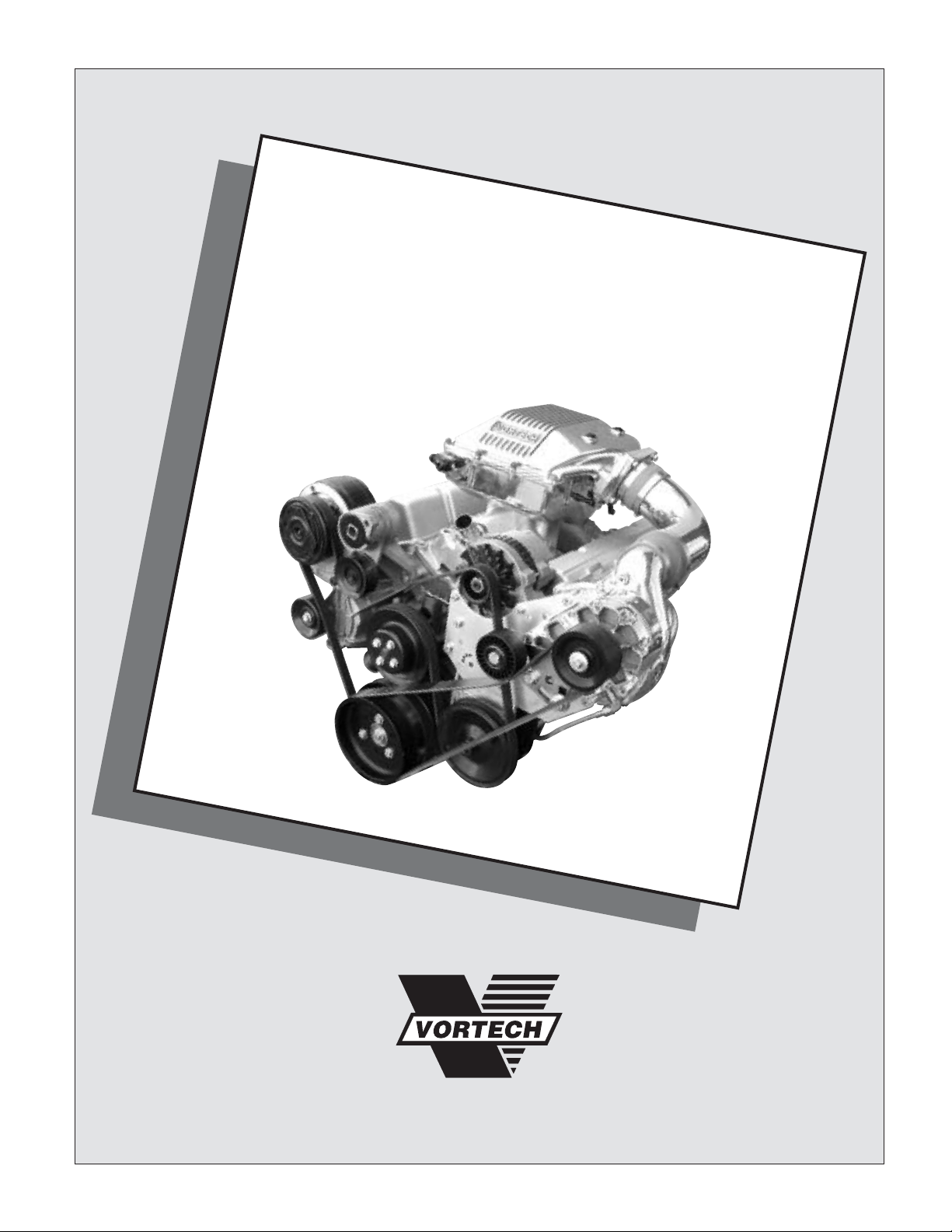

ENGINEERING, LLC

Universal Small

Block Chevy-Carbureted

Supercharger System

Installation Instructions

*Legal in California only for racing vehicles which may never be used upon a highway.

®

P/N: 4GP020-015

©2006 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

30MAY06 SmallBlockChev(4GP..015v1.1)

ii

Proper installation of this system requires general automotive mechanic knowledge and experience. Please browse through each step of this instruction

manual prior to beginning the installation to determine if you should refer the

job to a professional installer/technician. Please call Vortech Engineering for

installers in your area.

FOREWORD

© 2006 VOR TECH ENGINEERING, LLC

All rights reserved. No part of this publication may be reproduced, transmitted, transcribed,

or translated into another language in any form, by any means without written permission

of Vortech Engineering, LLC

Important Installation Notes:

• This system was designed to fit on engines equipped with a “long” water pump.

and OEM V-belt drives or serpentine accessory dr ives (OEM TPI/TBI) applications, 1990-1995 and GM Perfor mance Parts accessor y drive system #’s

12497697, 12497698 and 12497869). For correct belt alignment, the proper

accessory drive crank pulley and accessory bracketry must be used.These

components are not supplied in this kit. Earlier models equipped with short

water pumps will require a long water pump to be installed.

• This kit can be used on engines with and without power steering. For engines

equipped with power steering and V-belt accessory drives, a Saginaw type

pump will be required as well as an optional Vortech power steering pulley

assembly. This assembly includes all required hardware, tensioner assembly

and anodized billet aluminum pulley. Depending on the vehicle, power steering

lines may require fabrication.

— Optional Vortech power steering pulley and hardware assembly: 4GP110-051

The following carbureted system support parts are not included as part

of the system but are available from Vortech:

1. Supercharger pulleys and retainer assembly: contact techical department for proper

application match.

• Vortech #2A031-250: Ø2.50", 10-rib driven pulley

• Vortech #2A031-275: Ø2.75", 10-rib driven pulley

• Vortech #2A031-295: Ø2.95", 10-rib driven pulley

• Vortech #2A031-312: Ø3.12", 10-rib driven pulley

• Vortech #4MA018-051: Ø7.00", 10-rib drive (crank) pulley

2. Compressor bypass valve and flange: (Contact the technical department to deter-

mine the proper valve selection for the application)

• Vortech #4GP012-031: Ø3" aluminum discharge duct w/attached flange for

Vortech race bypass valve. Simple attachment to supplied silicone discharge

elbow contained in #4GP218-030/-038

• Vortech #8D204-001: Race Bypass Valve

• Vortech #8D004-052: Race Bypass weld-on flange (aluminum)

• Vortech #8D103-001: Mondo Bypass Valve

• Vortech #8D003-052: Mondo Race Bypass weld-on flange (aluminum)

• Vortech #8D205-003: BV57 Bypass Valve

• Vortech #8D005-051: BV57 Bypass weld-on flange (aluminum)

3. Custom fuel line/fitting kits for carburetor, stainless steel (designed specifically for

Vortech carburetor enclosure)

• Vortech #8M110-020: Holley 4150 series (w/dual metering blocks), SS fuel line kit

• Vortech #8M110-030: Demon series, SS fuel line kit

4. Aftermarket ignition amplifier (not required, but recommended)

• Vortech #5A001-008: Crane HI-6 ignition amplifier box w/rev-limiter

• Power steering pulley and hardware assembly as described above

• Vortech #4GP110-051

5. Carburetor air diffuser. Straightens airflow into the carburetor for improved

response/driveability

• Vortech #8M011-001: Ø5.75" x 2.50" tall carburetor air-diffuser, stainless steel

P/N: 4GP020-015

©2006 Vor tech Engineer ing, LLC

All Rights Reserved, Intl. Copr. Secured

30MAY06 SmallBlockChev(4GP..015v1.1)

iii

TABLE OF CONTENTS

FOREWORD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ii

TABLE OF CONTENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iii

TOOL AND SUPPLY REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iv

PARTS LIST (Universal Small Block Chevy Carbureted - V2 S-Trim) . . . . . . . . . . . . . .v

PARTS LIST (Universal Small Block Chevy Carbureted - V1 T-Trim) . . . . . . . . . . . . . .vi

PARTS LIST (Universal Small Block Chevy Carbureted - V7 YSI-Trim) . . . . . . . . . . . .vii

1. PREPARATION/REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

2. OIL FEED INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

3. OIL DRAIN INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

4.1 MAIN BRACKET/SUPERCHARGER INSTALLATION (Serpentine) . . . . . . . . . . .3

4.2 MAIN BRACKET/SUPERCHARGER INSTALLATION (V-Belt) . . . . . . . . . . . . . . .4

5. CRANK PULLEY AND SUPERCHARGER DRIVE PULLEY INSTALLATION . . . .6

6. DISCHARGE DUCTING/CARBURETOR ENCLOSURE . . . . . . . . . . . . . . . . . . . .8

7. FINAL REASSEMBLY AND CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

P/N: 4GP020-015

©2006 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

30MAY06 SmallBlockChev(4GP..015v1.1)

iv

INSTALLATION INSTRUCTIONS

Universal Small Block Chevrolet

Carbureted System

PLEASE READ CAREFULLY

This kit should only be installed by qualified mechanics. It is imperative

that the correct air/fuel mixture be maintained at all times.This Universal

Kit is to be supplied to competent engine tuners for their completion by

the addition of, and tuning of, an appropriate carburetor unit and fuel

pump.

This product is intended for use on healthy, well maintained engines.

Installation on a worn-out or damaged engine is not recommended and

may result in failure of the engine.

Vortech Engineering is not responsible for engine damage.Installation on

new engines will not harm or adversely affect the break-in period so long

as factory break-in procedures are followed.

For best performance and continued durability, please take note of the following

key points:

1. Use only premium grade fuel 91 octane or higher (R+M/2).

2. The engine must have stock or lower than stock compression ratio.

3. If the engine has been modified in any way, check with Vortech prior to using this

product.

4. Always listen for any sign of detonation (pinging) and discontinue hard use (no

boost) until problem is resolved.

5. Perfor m an oil and filter change upon completion of this installation and pr ior to

operating the vehicle.Thereafter, always use a high grade SF rated engine oil or a

high quality synthetic, and change the oil and filter every 3000 miles.

6. Before beginning installation, replace all spark plugs with one to two step colder

heat range and reset timing to no more than 26°-28° total.(Always follow the procedures indicated in the factory repair manual.)

TOOL AND SUPPLY REQUIREMENTS:

• Factor y Repair Manual

• 3/8" Drive and Socket Set: SAE and Metric

• 1/2" Drive and Socket Set: SAE and Metric

• Adjustable Wrench

• Open End Wrenches: SAE and Metric

• Center Punch

• SF Rated Quality Engine Oil

• Loctite Sealer #RC-609

• Oil Filter, and Wrench

• Heavy Grease

• Silicone Sealer

• Teflon Paste Sealant

• TAP, 3/8-18 NPT

®

ENGINEERING, LLC

P/N: 4GP020-015

©2006 Vor tech Engineer ing, LLC

All Rights Reserved, Intl. Copr.Secured

30MAY06 SmallBlockChev(4GP..015v1.1)

v

Universal Small Block Chevy Carbureted

V2 S-TRIM

Part No. 4GP218-030SQ/038SQ

ENGINEERING, LLC

PART NO. DESCRIPTION

QTY PART NO. DESCRIPTION

QTY

IMPORTANT: Before beginning installation, verify that all parts are included in the kit. Report any shortages or damaged parts

immediately.

2E128-040 S/C CHEV UNIV CARB, GEN2 V2 1

2A032-333 S/C DRIVE PLY, 3.33" 10-GRV 1

8R101-003 PULLEY RETAINED ASY, 10-RIB 1

7U100-071 KEY, 3/16"SQ x 1-1/8" LONG 1

2A040-011 PULLEY RETAINER S/C 1

7B375-150 3/8-24 x1-1/2" GR8 HX 1

7K375-040 3/8"AN960 FLAT WASHER, PLATED 1

8M001-060 CABLE, THROTTLE 1

8M010-170 BRKT, CHVY THROTTLE CABLE 1

8M205-012 CARB ENCLOSURE ASY 1

007051 CARB ENCL ASY, UNIV SAT, G2 L 1

7A312-078 5/16-18 x 3/4" SHCS, S'STL 16

7A312-253 STUD, 5/16" x 2-1/2" CARB ENCLOSURE 4

7C011-050 10-32 PLUG SCREW 1

7F312-024 5/16-24 JAM NUT 4

7J312-000 5/16" FLAT WASHER, SAE 4

7J375-024 3/8" COPPER WASHER 4

7K312-030 5/16"AN WASHER, SS 12

7P187-102 -3 BULKHEAD FITTING TO 1/4" HOSE 1

7P187-103 PLUG, -3 O-RING PORT 3

7P250-120 1/4"NPT PIPE PLUG 1

7P375-104 PLUG, 3/8-16, BRASS SHORT 4

7PP500-087 PLUG, AN-8 O-RING PORT 3

7U100-003 O-RING 3 - 903 4

7U100-008 O-RING 3 - 908 3

7U100-020 10-32 GASKET 1

8M001-018 GASKET, 90mm THROTTLE BODY 1

8M003-051 MACH, MONDO COOLER COVER2 1

8M010-025 MORSE CABLE BRKT, CARB ENC 1

8M105-012 ENCL, STD. MACH ASY SAT. 1

8M110-010 ASY, THROTTLE LINK, CARB ENCLOSURE 1

8M001-017 HOLLEY 4-BARREL BASE GASKET 2

4GP111-031 MTG BRKT ASY, SBC GEN2 1

4GP017-021 GM THROTTLE CABLE 1

4GP010-035 MOUNT PLATE, SBC UNIV, GEN2 1

2A017-751-05 SPACER, .750"OD x .360" LONG 2

2A041-594 BELT, K100594-GATES 1

7A375-500 3/8-16 x 5" HXHD GRADE-8 2

7A375-400 3/8-16 x 4" BOLT HXHD GR8 3

7A375-100 3/8-16 x 1" G5 HHCS, PLT 5

7A375-126 3/8-16 x 1.25" HHCS, GR8, PLT 4

4GB011-021 MOUNTING BRKT-MACH 1

7K375-040 3/8"AN960 FLAT WASHER, PLATED 14

7A375-475 3/8-16 x 4.75" HXHD GR8 PLTD 2

7A375-375 3/8-16 x 3-3/4" HXHD 3

7A375-112 3/8-16 x 1.125" FLT HD ALN 2

7A375-077 3/8-16 x 3/4" GR8 FLAT HD ZNC 1

7C080-030 M8 x 1.25" x 30 HXHD CL10.9 1

7C080-070 M8 x 1.25" x 70 HXHD ZINC 1

7F008-023 NUT, M8 x 1.25" x 70 HXHD ZINC 1

7J008-001 3/8" FLAT WASHER 2

PARTS LIST

4GP111-041 ASY, MAN TENS. SBC GEN2 1

4MA116-160 IDLER ASY, MARINE GEN2 1

4FA011-032 BELT TENSIONER PLATE STD 1

4GP017-051 SPACER, 10-RIB MAN TENS. SBC 1

7A437-300 7/16-14 x 3.00" SHCS GR8 1

7C012-020 M12 x 1.75 x 20mm HXHD CL8.8 3

7J012-092 12mm WASHER, FLAT 3

7J438-072 7/16" WASHER, .94"OD x .109" THK 1

7J437-081 7/16"SAE WASHER PLATED 1

4GB130-026 OIL FEED LINE ASY 1

70000 INSPECTOR NUMBER 0

7P125-026 1/8"NPT x #4 SAE FLARE, 90° 1

7P250-036 -4 SAE FLARE TO 1/4"NPT 1

7P250-066 -4 45° FEM SWIVEL x 1/4"NPT 2

7P250-080 1/4"NPT FEM. ELBOW, 90° 1

7P250-123 1/4"NPT x 1-1/2" PIPE NIPPLE 1

7P525-067 .525" CRIMP FERRULES 2

7U030-026 1/4" OIL FEED HOSE 3

7U100-055 TIE-WRAP, 7.5" NYLON 4

4GP130-036 OIL DRAIN ASY 1

7U030-036 1/2" OIL DRAIN HOSE 3

7P375-017 3/8"NPT x 1/2" BEADED HOSE BARB 1

7P375-033 3/8"NPT x 3/8"NPT SRT EL 2

7R001-008 #8 STNLS HOSE CLAMP 2

70000 INSPECTION NUMBER 0

7T640-011 PUNCH, OIL PAN FTG 1

4GP112-010 INLET ASY, S.B. CHEVY CARB. 1

8H040-050 AIR FILTER 3.5" FLG. 7"L 1

4FA012-011 INTAKE TUBE, 180° w/o BOSSES 1

7S350-200 SLEEVE, 3-1/2" x 2" BLUE 1

7R002-056 #56 SAE TYPE “F” SS HOSE CLAMP 3

7R002-044 #44 SAE TYPE “F” SS HOSE CLAMP 1

75375-200 SLEEVE, Ø3.75" x 2.00" 1

75350-004 SLEEVE, Ø3.5" x 1" 1

7R002-060 #60 SAE TYPE “F” SS HOSE CLAMP 1

4GP112-040 DISCHARGE ASY, SBC GEN2 SAT 1

8M003-041 MACHINE, Ø3.5" FLANGE, SATIN 1

7S350-276 ELBOW, SIL Ø3.5" x 2.75" CHEVY CARB 1

7R002-056 #56 SAE TYPE “F” SS HOSE CLAMP 1

7R002-044 #44 SAE TYPE “F” HOSE CLAMP 1

4GP116-041 6" CRANK PLY ASY, SBC UNIV GEN2 1

4GP017-031 SPACER, SBC CRANK PULLEY, SERP 1

4MA018-041 6" CRANK PULLEY, UNIVERSAL 1

7B375-500 3/8-24 x 5.0" HXHD GR8 3

7B437-600 7/16-20 x 6.0" HXHD GR8 1

7J375-044 3/8"SAE WASHER, PLTD 3

7J438-081 7/16"SAE WASHER, PLATED 1

4GP017-041 SPACER, SBC CRANK PULLEY, V-BELT 1

7B375-475 3/8-24 x 4-3/4" HXHD GR8 3

4GP020-015 INSTR. MANUAL, UNIV. SBC GEN2 KIT 1

008443 S/C RACE INFO. PKG ASY, VORTECH 1

008130 LICENSE PLATE FRAME, VORTECH 1

008110 SMALL SILVER DIE-CUT DECAL 2

®

P/N: 4GP020-015

©2006 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

30MAY06 SmallBlockChev(4GP..015v1.1)

vi

Universal Small Block Chevy Carbureted

V1 T-Trim

Part No. 4GP218-030T/038T

ENGINEERING, LLC

PART NO.

DESCRIPTION QTY PART NO. DESCRIPTION QTY

IMPORTANT: Before beginning installation, verify that all parts are included in the kit. Report any shortages or damaged parts

immediately.

2A138-040 S/C CHEV UNIV CARB, GEN2 V1 1

2A032-333 S/C DRIVE PLY, 3.33" 10-GRV 1

8R101-003 PULLEY RETAINED ASY, 10-RIB 1

7U100-071 KEY, 3/16"SQ x 1-1/8" LONG 1

2A040-011 PULLEY RETAINER S/C 1

7B375-150 3/8-24 x 1-1/2" GR8 HX 1

7K375-040 3/8"AN960 FLAT WASHER, PLATED 1

8M001-060 CABLE, THROTTLE 1

8M010-170 BRKT, CHVY THROTTLE CABLE 1

8M205-012 CARB ENCLOSURE ASY 1

007051 CARB ENCL ASY, UNIV SAT, G2 L 1

7A312-078 5/16-18 x 3/4" SHCS, S'STL 16

7A312-253 STUD, 5/16" x 2-1/2" CARB ENCLOSURE 4

7C011-050 10-32 PLUG SCREW 1

7F312-024 5/16-24 JAM NUT 4

7J312-000 5/16" FLAT WASHER, SAE 4

7J375-024 3/8" COPPER WASHER 4

7K312-030 5/16"AN WASHER, SS 12

7P187-102 -3 BULKHEAD FITTING TO 1/4" HOSE 1

7P187-103 PLUG, -3 O-RING PORT 3

7P250-120 1/4"NPT PIPE PLUG 1

7P375-104 PLUG, 3/8-16, BRASS SHORT 4

7PP500-087 PLUG, AN-8 O-RING PORT 3

7U100-003 O-RING 3 - 903 4

7U100-008 O-RING 3 - 908 3

7U100-020 10-32 GASKET 1

8M001-018 GASKET, 90mm THROTTLE BODY 1

8M003-051 MACH, MONDO COOLER COVER2 1

8M010-025 MORSE CABLE BRKT, CARB ENC 1

8M105-012 ENCL, STD. MACH ASY SAT. 1

8M110-010 ASY, THROTTLE LINK, CARB ENCLOSURE 1

8M001-017 HOLLEY 4-BARREL BASE GASKET 2

4GP111-031 MTG BRKT ASY, SBC GEN2 1

4GP017-021 GM THROTTLE CABLE 1

4GP010-035 MOUNT PLATE, SBC UNIV, GEN2 1

2A017-751-05 SPACER, .750"OD x .360" LONG 2

2A041-594 BELT, K100594-GATES 1

7A375-500 3/8-16 x 5" HXHD GRADE-8 2

7A375-400 3/8-16 x 4" BOLT HXHD GR8 3

7A375-100 3/8-16 x 1" G5 HHCS, PLT 5

7A375-126 3/8-16 x 1.25" HHCS, GR8, PLT 4

4GB011-021 MOUNTING BRKT-MACH 1

7K375-040 3/8"AN960 FLAT WASHER, PLATED 14

7A375-475 3/8-16 x 4.75" HXHD GR8 PLTD 2

7A375-375 3/8-16 x 3-3/4" HXHD 3

7A375-112 3/8-16 x 1.125" FLT HD ALN 2

7A375-077 3/8-16 x 3/4" GR8 FLAT HD ZNC 1

7C080-030 M8 x 1.25" x 30 HXHD CL10.9 1

7C080-070 M8 x 1.25" x 70 HXHD ZINC 1

7F008-023 NUT, M8 x 1.25" x 70 HXHD ZINC 1

7J008-001 3/8" FLAT WASHER 2

PARTS LIST

4GP111-041 ASY, MAN TENS. SBC GEN2 1

4MA116-160 IDLER ASY, MARINE GEN2 1

4FA011-032 BELT TENSIONER PLATE STD 1

4GP017-051 SPACER, 10-RIB MAN TENS. SBC 1

7A437-300 7/16-14 x 3.00" SHCS GR8 1

7C012-020 M12 x 1.75 x 20mm HXHD CL8.8 3

7J012-092 12mm WASHER, FLAT 3

7J438-072 7/16" WASHER, .94"OD x .109" THK 1

7J437-081 7/16"SAE WASHER PLATED 1

4GB130-026 OIL FEED LINE ASY 1

70000 INSPECTOR NUMBER 0

7P125-026 1/8"NPT x #4 SAE FLARE, 90° 1

7P250-036 -4 SAE FLARE TO 1/4"NPT 1

7P250-066 -4 45° FEM SWIVEL x 1/4"NPT 2

7P250-080 1/4"NPT FEM. ELBOW, 90° 1

7P250-123 1/4"NPT x 1-1/2" PIPE NIPPLE 1

7P525-067 .525" CRIMP FERRULES 2

7U030-026 1/4" OIL FEED HOSE 3

7U100-055 TIE-WRAP, 7.5" NYLON 4

4GP130-036 OIL DRAIN ASY 1

7U030-036 1/2" OIL DRAIN HOSE 3

7P375-017 3/8"NPT x 1/2" BEADED HOSE BARB 1

7P375-033 3/8"NPT x 3/8"NPT SRT EL 2

7R001-008 #8 STNLS HOSE CLAMP 2

70000 INSPECTION NUMBER 0

7T640-011 PUNCH, OIL PAN FTG 1

4GP112-010 INLET ASY, S.B. CHEVY CARB. 1

8H040-050 AIR FILTER 3.5" FLG. 7"L 1

4FA012-011 INTAKE TUBE, 180° w/o BOSSES 1

7S350-200 SLEEVE, 3-1/2" x 2" BLUE 1

7R002-056 #56 SAE TYPE “F” SS HOSE CLAMP 3

7R002-044 #44 SAE TYPE “F” SS HOSE CLAMP 1

75375-200 SLEEVE, Ø3.75" x 2.00" 1

75350-004 SLEEVE, Ø3.5" x 1" 1

7R002-060 #60 SAE TYPE “F” SS HOSE CLAMP 1

4GP112-040 DISCHARGE ASY, SBC GEN2 SAT 1

8M003-041 MACHINE, Ø3.5" FLANGE, SATIN 1

7S350-276 ELBOW, SIL Ø3.5" x 2.75" CHEVY CARB 1

7R002-056 #56 SAE TYPE “F” SS HOSE CLAMP 1

7R002-044 #44 SAE TYPE “F” HOSE CLAMP 1

4GP116-041 6" CRANK PLY ASY, SBC UNIV GEN2 1

4GP017-031 SPACER, SBC CRANK PULLEY, SERP 1

4MA018-041 6" CRANK PULLEY, UNIVERSAL 1

7B375-500 3/8-24 x 5.0" HXHD GR8 3

7B437-600 7/16-20 x 6.0" HXHD GR8 1

7J375-044 3/8"SAE WASHER, PLTD 3

7J438-081 7/16"SAE WASHER, PLATED 1

4GP017-041 SPACER, SBC CRANK PULLEY, V-BELT 1

7B375-475 3/8-24 x 4-3/4" HXHD GR8 3

4GP020-015 INSTR. MANUAL, UNIV. SBC GEN2 KIT 1

008443 S/C RACE INFO. PKG ASY, VORTECH 1

008130 LICENSE PLATE FRAME, VORTECH 1

008110 SMALL SILVER DIE-CUT DECAL 2

®

P/N: 4GP020-015

©2006 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

30MAY06 SmallBlockChev(4GP..015v1.1)

vii

Universal Small Block Chevy Carbureted

V7 YSI-Trim

Part No. 4GP218-030YSI/038YSI

ENGINEERING, LLC

PART NO.

DESCRIPTION QTY PART NO. DESCRIPTION QTY

IMPORTANT: Before beginning installation, verify that all parts are included in the kit. Report any shortages or damaged parts

immediately.

2A158-070 S/C CHEV UNIV CARB, GEN2 V7 1

2A032-333 S/C DRIVE PLY, 3.33" 10-GRV 1

8R101-003 PULLEY RETAINED ASY, 10-RIB 1

7U100-071 KEY, 3/16"SQ x 1-1/8" LONG 1

2A040-011 PULLEY RETAINER S/C 1

7B375-150 3/8-24 x 1-1/2" GR8 HX 1

7K375-040 3/8"AN960 FLAT WASHER, PLATED 1

8M001-060 CABLE, THROTTLE 1

8M010-170 BRKT, CHVY THROTTLE CABLE 1

8M205-012 CARB ENCLOSURE ASY 1

007051 CARB ENCL ASY, UNIV SAT, G2 L 1

7A312-078 5/16-18 x 3/4" SHCS, S'STL 16

7A312-253 STUD, 5/16" x 2-1/2" CARB ENCLOSURE 4

7C011-050 10-32 PLUG SCREW 1

7F312-024 5/16-24 JAM NUT 4

7J312-000 5/16" FLAT WASHER, SAE 4

7J375-024 3/8" COPPER WASHER 4

7K312-030 5/16"AN WASHER, SS 12

7P187-102 -3 BULKHEAD FITTING TO 1/4" HOSE 1

7P187-103 PLUG, -3 O-RING PORT 3

7P250-120 1/4"NPT PIPE PLUG 1

7P375-104 PLUG, 3/8-16, BRASS SHORT 4

7PP500-087 PLUG, AN-8 O-RING PORT 3

7U100-003 O-RING 3 - 903 4

7U100-008 O-RING 3 - 908 3

7U100-020 10-32 GASKET 1

8M001-018 GASKET, 90mm THROTTLE BODY 1

8M003-051 MACH, MONDO COOLER COVER2 1

8M010-025 MORSE CABLE BRKT, CARB ENC 1

8M105-012 ENCL, STD. MACH ASY SAT. 1

8M110-010 ASY, THROTTLE LINK, CARB ENCLOSURE 1

8M001-017 HOLLEY 4-BARREL BASE GASKET 2

4GP111-031 MTG BRKT ASY, SBC GEN2 1

4GP017-021 GM THROTTLE CABLE 1

4GP010-035 MOUNT PLATE, SBC UNIV, GEN2 1

2A017-751-05 SPACER, .750"OD x .360" LONG 2

2A041-594 BELT, K100594-GATES 1

7A375-500 3/8-16 x 5" HXHD GRADE-8 2

7A375-400 3/8-16 x 4" BOLT HXHD GR8 3

7A375-100 3/8-16 x 1" G5 HHCS, PLT 5

7A375-126 3/8-16 x 1.25" HHCS, GR8, PLT 4

4GB011-021 MOUNTING BRKT-MACH 1

7K375-040 3/8"AN960 FLAT WASHER, PLATED 14

7A375-475 3/8-16 x 4.75" HXHD GR8 PLTD 2

7A375-375 3/8-16 x 3-3/4" HXHD 3

7A375-112 3/8-16 x 1.125" FLT HD ALN 2

7A375-077 3/8-16 x 3/4" GR8 FLAT HD ZNC 1

7C080-030 M8 x 1.25" x 30 HXHD CL10.9 1

7C080-070 M8 x 1.25" x 70 HXHD ZINC 1

7F008-023 NUT, M8 x 1.25" x 70 HXHD ZINC 1

7J008-001 3/8" FLAT WASHER 2

PARTS LIST

4GP111-041 ASY, MAN TENS. SBC GEN2 1

4MA116-160 IDLER ASY, MARINE GEN2 1

4FA011-032 BELT TENSIONER PLATE STD 1

4GP017-051 SPACER, 10-RIB MAN TENS. SBC 1

7A437-300 7/16-14 x 3.00" SHCS GR8 1

7C012-020 M12 x 1.75 x 20mm HXHD CL8.8 3

7J012-092 12mm WASHER, FLAT 3

7J438-072 7/16" WASHER, .94"OD x .109" THK 1

7J437-081 7/16"SAE WASHER PLATED 1

4GB130-026 OIL FEED LINE ASY 1

70000 INSPECTOR NUMBER 0

7P125-026 1/8"NPT x #4 SAE FLARE, 90° 1

7P250-036 -4 SAE FLARE TO 1/4"NPT 1

7P250-066 -4 45° FEM SWIVEL x 1/4"NPT 2

7P250-080 1/4"NPT FEM. ELBOW, 90° 1

7P250-123 1/4"NPT x 1-1/2" PIPE NIPPLE 1

7P525-067 .525" CRIMP FERRULES 2

7U030-026 1/4" OIL FEED HOSE 3

7U100-055 TIE-WRAP, 7.5" NYLON 4

4GP130-036 OIL DRAIN ASY 1

7U030-036 1/2" OIL DRAIN HOSE 3

7P375-017 3/8"NPT x 1/2" BEADED HOSE BARB 1

7P375-033 3/8"NPT x 3/8"NPT SRT EL 2

7R001-008 #8 STNLS HOSE CLAMP 2

70000 INSPECTION NUMBER 0

7T640-011 PUNCH, OIL PAN FTG 1

4GP112-010 INLET ASY, S.B. CHEVY CARB. 1

8H040-050 AIR FILTER 3.5" FLG. 7"L 1

4FA012-011 INTAKE TUBE, 180° w/o BOSSES 1

7S350-200 SLEEVE, 3-1/2" x 2" BLUE 1

7R002-056 #56 SAE TYPE “F” SS HOSE CLAMP 3

7R002-044 #44 SAE TYPE “F” SS HOSE CLAMP 1

75375-200 SLEEVE, Ø3.75" x 2.00" 1

75350-004 SLEEVE, Ø3.5" x 1" 1

7R002-060 #60 SAE TYPE “F” SS HOSE CLAMP 1

4GP112-040 DISCHARGE ASY, SBC GEN2 SAT 1

8M003-041 MACHINE, Ø3.5" FLANGE, SATIN 1

7S350-276 ELBOW, SIL Ø3.5" x 2.75" CHEVY CARB 1

7R002-056 #56 SAE TYPE “F” SS HOSE CLAMP 1

7R002-044 #44 SAE TYPE “F” HOSE CLAMP 1

4GP116-041 6" CRANK PLY ASY, SBC UNIV GEN2 1

4GP017-031 SPACER, SBC CRANK PULLEY, SERP 1

4MA018-041 6" CRANK PULLEY, UNIVERSAL 1

7B375-500 3/8-24 x 5.0" HXHD GR8 3

7B437-600 7/16-20 x 6.0" HXHD GR8 1

7J375-044 3/8"SAE WASHER, PLTD 3

7J438-081 7/16"SAE WASHER, PLATED 1

4GP017-041 SPACER, SBC CRANK PULLEY, V-BELT 1

7B375-475 3/8-24 x 4-3/4" HXHD GR8 3

4GP020-015 INSTR. MANUAL, UNIV. SBC GEN2 KIT 1

008443 S/C RACE INFO. PKG ASY, VORTECH 1

008130 LICENSE PLATE FRAME, VORTECH 1

008110 SMALL SILVER DIE-CUT DECAL 2

7S400-350 REDUCER, 4" - 3.5" 1

7R002-064 #64 SAE TYPE “F” SS HOSE CLAMP 1

®

P/N: 4GP020-015

©2006 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

30MAY06 SmallBlockChev(4GP..015v1.1)

viii

This Page Left Intentionally Blank

P/N: 4GP020-015

©2006 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

30MAY06 SmallBlockChev(4GP..015v1.1)

1

Fig. 2-a

A. Disconnect the negative lead to the bat-

tery.

B. Remove the fan and shroud to aid in

installation. It may also be necessary to

install a fan spacer at a later time.

C. (V-Belt) Loosen all nuts and bolts that

are used to tension the alternator and

power steering pump V-belts. Remove

the factory belts.

D. (Serpentine) Loosen tension on the ten-

sioner and remove the factory drive belt.

E. (Serpentine) If so equipped, loosen the

two screws securing the alternator to the

cast factory bracket on the driver’s side.

Remove any other electrical connections

to the alternator. Remove the alternator

from the bracket and set aside.

C. Connect the supplied feed line to the flare fit-

ting and route it up to the front of the driver’s

side cylinder head. Secure the hose with tiewraps away from exhaust heat, chaffing

and/or sharp objects.Temporarily cover the

open end from debris until the connection is

made to the supercharger.

(See Fig. 2-a.)

A. The supercharger uses engine oil for lubrica-

tion and must have an oil feed line connected

to a filtered oil access point on the engine.

B. Remove the 1/4"NPT plug located on the

engine block just above the oil filter boss.

Replace the plug with the supplied 1/4"NPT x

90° elbow and 1/4"NPT x -4 flare fitting.

1. PREPARATION/REMOVAL

2. OIL FEED INSTALLATION

V-BELT NOTE: This kit is designed to work

with later model V-belt power

steering pumps. The power steering pulley shaft should be Ø3/4"

and is not threaded at the end.

NOTE: Use clean engine oil on the pipe threads.

Teflon tape and sealant is not recommended as it might loosen and cause

blockage of the small oil feed orifice

resulting in supercharger failure.

F. (Serpentine) Remove the power steer-

ing pulley from the power steering

pump.Loosen the screws securing the

pump and remove the pump from the

factory bracket.Temporarily lay the

pump in the engine compartment.

G. (Serpentine) Remove the factory cast

bracket from the driver’s side of the

motor.

H. (V-Belt) Remove the factory power

steering pump from the motor.

TO SUPERCHARGER

OIL

FILTER

P/N: 4GP020-015

©2006 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

30MAY06 SmallBlockChev(4GP..015v1.1)

2

Fig. 3-a

3. OIL DRAIN INSTALLATION

A. To provide an oil drain for the supercharger, it

is necessary to make a hole in the oil pan.

Locate and mark the hole location. (See Fig.

3-a.) It is best to punch the hole rather than

drill.

B. Remove any paint from around the hole area.

C. Use a small center punch to perforate the

pan and expand the hole, switch to a larger

diameter punch and expand the hole further

to approximately Ø9/16". Most punches are

made from hexagon material and may be

placed in a socket with an extension to make

this procedure easier.Use caution so that the

hole is not enlarged too much and that the

punch does NOT contact the crankshaft.

D. Tap the hole with a 3/8"NPT tap approximate-

ly 1/4" deep.Pack the flutes of the tap with

heavy grease to hold the chips.Use a small

magnet to check for any stray chips.

E. Thoroughly clean the threaded area. Apply a

small amount of silicone sealer to the new

threads. Apply more sealer to the supplied

3/8"NPT x 90° elbow and secure in the previously threaded hole. Make sure a seal is

formed all around the fitting. Rotate the fitting

so that the oil drain hose can be easily routed

to it. Apply sealer to the supplied 3/8"NPT x

1/2" beaded hose barb fitting and install in

the previously installed 90° elbow.

F. Drain the engine oil, install a new filter and

refill with fresh oil.

NOTE: Removal of the oil pan may ease oil

drain fitting installation on some applications.

NOTE: This method of rolling over the lip of the

hole and tapping works well if carefully

done and should cause no problems.

DOWN 2"

1"

IN-LINE

FOURTH BOLT

OIL PAN

PUNCH HOLE THROUGH

OIL FILTER

P/N: 4GP020-015

©2006 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

30MAY06 SmallBlockChev(4GP..015v1.1)

3

Fig. 4.1-a

NOTE: Some applications (depending on intake

manifold height) may require the reclocking

of the supercharger volute. If reclocking is

required for your application, loosen and

remove the six 1/4-20 cap screws and retaining plates that hold the compressor housing

(volute) to the gearcase. If the compressor

housing does not rotate freely relative to the

gearcase, DO NOT FORCE IT. SERIOUS

SUPERCHARGER DAMAGE MAY OCCUR.

The machined mating surfaces are designed

to prevent pressurized air from escaping and

have minimal tolerances. If the housing will

not move or is very tight, contact Vortech

Engineering immediately at 805 247-0226

and ask our service department for further

assistance.

4.1 MAIN BRACKET/SUPERCHARGER INSTALLATION (Serpentine)

A. Locate the supplied cast bracket, L-shaped

spacer, and two .360" thick spacers.

B. Use the 3/8-16 x 4" screws and washers to

mount the cast bracket to the cylinder head

using the .360" L-shaped spacer between the

bracket and cylinder head.Use the 3/8-16 x

5" hardware to mount the lower section of the

cast bracket to the block with the two .360"

spacers. (See Fig. 4.1-a.)

C. Locate the supplied supercharger mounting

plate. Secure the plate to the mounting bracket with the supplied 3/8-16 x 1.25" screws

and washers. (See Fig. 4.1-b.)

D. Mount the power steering pump (if equipped)

to the back side of the cast bracket using the

supplied 3/8-16 flat-head screws.Reinstall

the power steering pulley. (See Figs. 4.2-b,

4.2-c.)

E. Mount the alter nator to the mounting plate

with the supplied 8mm hardware. (See Fig.

4.1-c.)

Fig. 4.1-b

3/8-16 x 4"

HARDWARE

.360" SPACERS

BETWEEN CAST

BRACKET AND

BLOCK

ALTERNATOR

MOUNT

.360" L-SHAPED SPACER

BETWEEN CAST BRACKET

AND CYLINDER HEAD

3/8-16 x1.25"

SCREWS AND

WASHERS

3/8-16 x 5"

HARDWARE

SUPERCHARGER

MOUNTING PLATE

FRONT VIEW

P/N: 4GP020-015

©2006 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

30MAY06 SmallBlockChev(4GP..015v1.1)

4

NOTE: Due to the many possible configu-

rations of accessory drives in

Small Block Chevy applications,

the accessory drive crank pulley

spacer may be modified to mate

with the supplied supercharger

drive crank pulley and the vehiicle’s existing accessory drive

crank pulley.

4.2 MAIN BRACKET/SUPERCHARGER INSTALLATION (V-Belt)

A. Locate the supplied cast bracket.(See Fig.

4.2-a.)

B. (Non-power steering only, P/S models

proceed to 4.2-C.) Using the 3/8-16 x

3.75" screws and washers, mount the cast

bracket to the cylinder head.Use the 3/8-16

x 4.75" screws and washers to secure the

lower section of the cast bracket to the

engine block.

C. (Power steering models only.) Locate the

optional 4GP110-051 P/S pump support

assembly. Using the 3/8-16 x 3.75" screws

and washers, mount the cast bracket to the

cylinder head. Install the 3/8-16 x 6.75"

screws and washers through the power

steering tensioner bracket, .915" long spacers, cast bracket, and into the engine block.

(See Fig. 4.2-a.)

1. Locate the supplied P/S belt tensioner

pulley. Install the 3/8-16 x 1.75" screw

and washer through the tensioner

bracket.Place the pulley/pilot assembly

onto the previously installed 3/8-16 x

1.75" screw and loosely secure using

the 3/8" washer and NYLOC

Fig. 4.2-a

(Power Steering Equipped Models Only)

4.1 MAIN BRACKET/SUPERCHARGER INSTALLATION (Serpentine), cont’d

Fig. 4.1-c

F. Attach the oil drain hose to the 1/2" barbed

fitting on the bottom of the supercharger.

Secure the hose with the supplied hose

clamp.

G. Using the supplied 3/8-16 x 1.25" screws

secure the supercharger to the mounting

plate. (See Fig. 4.1-b.)

.915" LONG

SPACERS BETWEEN

TENSIONER BRACKET

AND CAST BRACKET

3/8-16 x 6.75"

w/POWER

STEERING,

3/8-16 x 4.75"

w/o POWER

STEERING

CAST BRACKET

POWER

STEERING TENSIONER

BRACKET

FRONT VIEW

P/N: 4GP020-015

©2006 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

30MAY06 SmallBlockChev(4GP..015v1.1)

5

Fig. 4.2-c

NOTE: The end of the pump shaft

should be flush with the end of

the drive flange when fully

installed.

2. Mount the power steering pump to the

back side of the cast bracket using the

supplied 3/8-16 flat-head screws.Locate

the power steering pump drive flange.

Using the appropriate GM power steering

pulley installer, install the dr ive flange as

you would a normal power steering pulley.

(See Fig. 4.2-b.)

3. Using the six 1/4-20 x .75" screws and

washers, attach the supplied power steering pulley. (Blue loc-tite on the threads is

recommended.) (See Figs. 4.2-b, 4.2-c.)

Fig. 4.2-b

(Power Steering Equipped Models Only)

POWER STEERING

TENSIONER

POWER STEERING PUMP

DRIVE FLANGE

POWER STEERING

PUMP

TENSIONER IDLER

D. Locate the supplied supercharger mounting

plate. Secure the plate to the mounting bracket with the supplied 3/8-16 x 1.25" screws

and washers. (See Fig. 4.1-b on previous

page.)

E. Attach the oil drain hose to the 1/2" barbed

fitting on the bottom of the supercharger.

Secure the hose with the supplied hose

clamp.

F. Using the supplied 3/8-16 x 1.0" screws and

washers secure the supercharger to the

mounting plate. (See Fig. 4.2-c.)

3/8-16 x

1.0" SCREWS

P/S PUMP

3/8-16 FLAT-HEAD

SCREWS

SIX 1/4-20 x .75"

SCREWS

AND WASHERS

(V-BELT ONLY)

FRONT VIEW

P/N: 4GP020-015

©2006 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

30MAY06 SmallBlockChev(4GP..015v1.1)

6

A. Locate the supercharger drive assembly

(4GP116-041). Using the 7/16-20 x 6" screw

and washer, loosely install the appropriate

spacer for your application to the front of the

factory crank pulley.

B. Rotate the previously installed spacer to align

the three mounting holes. Install the supplied

10-rib crank pulley and secure using the supplied hardware.(3/8-24 x 5" for Serpentine and

3/8-24 x 4.75" for V-belt applications.) Torque

center bolt to 35 ft.lbs.and the three pulley

retainers to 25 ft.lbs.

E. Locate the manual tensioner assembly

(4GP111-041). Install the 7/16-20 screw

through the 7/16" “thick” washer, tensioner

pulley, pulley spacer and tensioner plate.

Secure using the 7/16"SAE washer (thinner

one) and Nyloc nut provided.

F. Loosely install the belt tensioner assembly

onto the supercharger using the M12 hardware provided. Locate the supplied 10-Rib

supercharger drive belt and install between

the crank pulley and supercharger pulley.

Using a 1/2" ratchet, apply tension to the

supercharger drive belt and secure the three

M12 screws previously installed.(See

Fig. 5-b.)

5. CRANK PULLEY AND SUPERCHARGER DRIVE PULLEY INSTALLATION

NOTE: If the supercharger drive pulley will not

slide onto the shaft DO NOT FORCE IT.

Light heating of the supercharger drive

pulley with a propane torch will aid in

installation.

NOTE: Take care to ensure that all pulleys and

spacer are piloting correctly and seated

flat against their mounting faces.

NOTE: Two crank pulley spacers are provided in this

system. 4GP017-031 (3.695" long) is to be

used for serpentine drive systems. The

4GP017-041 (3.293" long) is to be used for

V-belt applications.

NOTE: The bearing retaining ring on the pulley

should be facing the pulley spacer to properly clear the “thick” retaining washer.

(See Fig. 6-d.)

C. Install all applicable accessory belts at this time

and tension using the appropriate belt tensioner for your application.

D. Lightly grease the supercharger input shaft

and/or the supercharger drive pulley bore.

Install the pulley onto the supercharger input

shaft and rotate the pulley to align the keyways.

Slide the square key into the keyway. Install the

pulley retainer assembly into the input shaft

and hand tighten.

P/N: 4GP020-015

©2006 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

30MAY06 SmallBlockChev(4GP..015v1.1)

7

Fig. 5-b

TENSIONER PULLEY

TENSIONER PLATE

7/16 -14 x 3"

THREE M12 x 1.75" x 20mm

SCREWS AND WASHERS

P/N: 4GP020-015

©2006 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

30MAY06 SmallBlockChev(4GP..015v1.1)

8

Fig. 6-a (Optional)

Fig. 6-b (Optional)

A. Install Vortech carburetor enclosure (if not

already completed) assembly #8M205-012

included in this kit. Instructions are included

in the enclosure assembly.

B. Locate the 4GP112-040 discharge assembly.

Using the supplied gasket and 5/16-18 x 3/4"

socket-head screws from the carburetor

enclosure assembly, secure the 3/5" aluminum flange to the carburetor enclosure lid.

C. Install the 3/5" x 2.75" 90° elbow (7S350-276)

between the supercharger discharge and the

3.5" aluminum flange previously installed.

Trim the ends if necessary for best fit. Secure

using a #44 and #56 hose clamp.

6. DISCHARGE DUCTING/CARBURETOR ENCLOSURE

NOTE: OPTIONAL: Due to the many possible con-

figurations of intake manifolds (with regard

to carburetor flange height) a carburetor

spacer may be required to obtain the necessary height for proper supercharger and discharge duct alignment. As an option, the

carburetor enclosure cover may be turned

around so that the inlet is facing the passenger side of the vehicle. This may be desirable on some vehicle applications with tall

intake manifolds or for vehicles with other

clearance issues. (See Figs. 6-a, 6-b for

more detail.)

1. This optional discharge arrangement

requires the supercharger to be sent into

Vortech for a volute exchange to a straight

discharge unit (a curved volute is originally

supplied on the supercharger).

2. An extended discharge elbow must be purchased from Vortech (#4GA012-021).

3. Also a discharge elbow must be purchased

from Vortech (#8M012-012).

4. Routing of the fuel line inlet to the rear of

the enclosure must also be performed.

NOTE: The 7S350-276 is made to be trimmed in

order to fit, allowing for various intake

manifold heights.

4GA012-021

8M012-012

P/N: 4GP020-015

©2006 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

30MAY06 SmallBlockChev(4GP..015v1.1)

9

A. Refit the upper fan shroud.

B. Reconnect the battery.

C. If your vehicle has gone over 15,000 miles

since its last spark plug change, you will need

to change the spark plugs now before test

driving the vehicle.

D. Check all fittings, nuts, bolts and clamps for

tightness. Pay particular attention to oil and

fuel lines around moving parts, sharp edges

and exhaust system parts. Make sure all

wires and lines are properly secured with

clamps or tie-wraps.

E. Check all fluid levels, making sure that your

tank(s) is filled with 91 octane or higher fuel

before commencing test drive.

F. Start engine and allow to idle a few minutes,

then shut off.

G. Recheck to be sure that no hoses, wires, etc.

are near exhaust headers or moving parts

and for signs of any fluid leakage.Re-jet the

carburetor as required. Install a boost referenced high-performance mechanical fuel

pump or high performance electric fuel pump

with boost referenced fuel regulator. Use a

wide band O2 sensor to verify a proper

air/fuel ratio (Vor tech suggests 11.0:1 for 91

octane pump fuel).

H. Check ignition timing to make sure it is prop-

erly set before commencing test drive.

I. PLEASE TAKE SPECIAL NOTE: Operating

the vehicle without all sub assemblies completely and properly installed and working

may cause FAILURE OF MAJOR ENGINE

COMPONENTS.

J. Test drive the vehicle.

K. Read the Street Supercharger System

Owner's Manual and RETURN THE

WARRANTY REGISTRATION FORM within

thirty (30) days of purchasing your supercharger system to qualify.

7. FINAL REASSEMBLY AND CHECK

WARNING: Do not attempt to operate the vehicle

until all components are installed and all

operations are completed including final

check.

DP/N: 4GP020-015 - v1.1 05/30/06

®

1650 Pacific Avenue, Channel Islands CA 93033-9901 • Phone: 805 247-0226

Fax: 805 247-0669 • www.vortechsuperchargers.com • M-F 8:00AM - 4:30PM (PST)

ENGINEERING, LLC

Loading...

Loading...