Page 1

®

BIG BLOCK CHEVROLET

CARBURETED SYSTEM

(TWIN PLATE)

Installation Instructions*

*Legal in California only for off-road vehicles which may never be used upon a highway.

ENGINEERING, LLC

1650 PACIFIC AVENUE • CHANNEL ISLANDS, CA 93033-9901 • (805) 247-0226

FAX (805) 247-0669 • www.vortechsuperchargers.com • M-F 8:00 AM - 4:30 PM PST

P/N: 4GA020-030

©2008 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

08DEC08 V3.0(BBC LowMount(4GA..030 V3.0))

Page 2

FOREWORD

STOP

his manual provides information on the installation, maintenance and service of the

Vortech supercharger kit expressly designed for this vehicle. All information, illustra-

T

tions and specifications contained herein are based on the latest product information

available at the time of this publication. Changes to the manual may be made at any time

without notice. Contact Vortech Engineering for any additional information regarding this kit

and any of these modifications at (805) 247-0226 8:00am-4:30pm PST M-F..

Take note of the following before proceeding:

1. Proper installation of this supercharger kit requires general

automo tive mechanic knowledge and experience. Please browse

through each step of this instruction manual prior to beginning the

installation to determine if you should refer the job to a professional

installer/technician. Please contact your dealer or Vortech Engineering

for possible installers in your area.

2. This product was designed for use on stock (un-modified, OEM) vehicles. The

PCM (computer), engine, transmission, drive axle ratios and tire O.D. must be stock. If

the vehicle or engine has been modified in any way, check with Vortech prior to installation and use of this product.

3. Use only premium grade fuel with a minimum of 91 octane (R+M/2).

4. Always listen for any sign of detonation (knocking/pinging) and discontinue hard use (no

boost) until the problem is resolved.

5. Vortech is not responsible for any clutch, transmission, drive-line or engine damage.

Exclusions from Vortech warranty coverage considerations include, but

not limited to:

1. Neglect, abuse, lack of maintenance, abnormal operation or improper installation.

2. Continued operation with an impaired vehicle or sub-system.

3. The combined use of Vortech components with other modifications such as, but not limit-

ed to, exhaust headers, aftermarket camshafts, nitrous oxide, third party PCM programming or other such changes.

© 2008 VORTECH ENGINEERING, LLC

All rights reserved. No part of this publication may be reproduced, transmitted, transcribed,

or translated into another language in any form, by any means without written permission

of Vortech Engineering, LLC.

P/N: 4GA020-030

©2008 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

08DEC08 V3.0(BBC LowMount(4GA..030 V3.0))

ii

Page 3

Important Installation Notes:

A. This system was designed to fit on engines equipped with a “long” water

pump. Vortech includes a 3-groove assessory drive crank pulley (for use with

a “short” water pump, a custom accessory drive crank pulley and spacer will

be required).

B. For engines equipped with power steering, a remote reservoir (GM “type 2”)

style pump will be required as well as an optional Vortech power steering

pump bracket and pulley assembly. Depending on the vehicle, power steering

lines may require fabrication.

— Power Steering Pump: OE on 1987 GM Pontiac Sunbird, NAPA #20-874

— Vortech Power Steering bracket/pulley assembly: 4GA110-010

The following carbureted system support parts are not included as

part of the system but are available from Vortech:

1. Optional fuel line/fitting kits for the carburetor. They include custom bent

stainless steel lines, billet-8 bulkhead adapter with fuel pressure port and

plug, -8/-6 junction TEE, aluminum swivel hose ends and USCG

approved fuel hose.

• Vortech #8M110-020 4150 series (w/dual metering blocks), SS fuel line

kit

• Vortech #8M110-030 Demon series, SS fuel line kit

2. Carburetor air diffuser. Straightens airflow into the carburetor for

improved response/driveability

• Vortech #8M011-001 Ø5.75" x 2.50 tall carburetor air diffuser, stainless

steel

3. Compressor bypass valve and flange (required on applications exceed-

ing 5 psig boost) (Contact the technical department to determine the

proper valve selection for the application)

• Vortech #8D204-001 Race Bypass Valve

• Vortech #8D004-052 Race Bypass weld-on flange (aluminum)

• Vortech #8D103-001 Mondo Race Bypass Valve

• Vortech #8D003-052 Mondo Race Bypass weld-on flange (aluminum)

• Vortech #8D205-003 BV57 Bypass Valve weld-on flange

• Vortech #8D005-051 BV57 Bypass Valve weld-on flange (aluminum)

4. Supercharger air inlet ducting (see step 8. in this manual)

5. Vortech power steering bracket/pulley assembly (see notes above):

#4GA110-010

Items to be supplied by installer/end user:

• Carburetor with mechanical secondaries (4150 Holley/Barry Grant MD

style)

• High performance fuel pump (boost referenced)

iii

08DEC08 V3.0(BBC LowMount(4GA..030 V3.0))

©2008 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

P/N: 4GA020-030

Page 4

TABLE OF CONTENTS

FOREWORD ........................................................ ii

TABLE OF CONTENTS ...............................................iv

COPYRIGHT NOTICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

PARTS LIST (Big Block Chevrolet Carbureted System) ......................vi

PARTS LIST (Base Kit, Universal BBC V4 Carb) ...........................viI

TOOL AND SUPPLY REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .viiI

1. PREPARATION/REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2. CRANK PULLEY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

3. SUPERCHARGER OIL FEED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

4. SUPERCHARGER OIL DRAIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

5. SUPERCHARGER MOUNTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

6. ACCESSORY DRIVE BELTS ........................................7

7. SUPERCHARGER DRIVE BELT INSTALLATION ........................ 8

8. SUPERCHARGER MOUNTING RACE (V-4 ONLY) . . . . . . . . . . . . . . . . . . . . . . 10

9. ACCESSORY DRIVE BELTS - V-4 ONLY ..............................11

10. SUPERCHARGER DRIVE BELTS - V-4 ONLY ..........................12

11. AIR INLET SUGGESTIONS .........................................13

12. DISCHARGE DUCTING/CARBURETOR ENCLOSURE ...................14

13. FINAL REASSEMBLY AND CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

P/N: 4GA020-030

©2008 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

08DEC08 V3.0(BBC LowMount(4GA..030 V3.0))

iv

Page 5

NOTICE

This product is protected by state common law, copyright and/or patent. All

legal rights therein are reserved. The design, layout, dimensions, geometry, and engineering features shown in this product are the exclusive property of Vortech Engineering, LLC. This product may not be copied or duplicated in whole or part, abstractly or fundamentally, intentionally or fortuitously, nor shall any design, dimension, or other information be incorporated into any product or apparatus without prior written consent of Vortech

Engineering, LLC.

v

08DEC08 V3.0(BBC LowMount(4GA..030 V3.0))

©2008 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

P/N: 4GA020-030

Page 6

Big Block Chevrolet Carbureted System

®

Part No. 4GA218-030

ENGINEERING, LLC

PARTS LIST

IMPORTANT: Before beginning installation, verify that all parts are included in the kit. Report any shortages or damaged parts imme-

diately.

PART NO. DESCRIPTION QTY. PART NUMBER DESCRIPTION QTY.

2A258-040 SUPERCHARGER ASY 1

4GA111-031 BRKT ASSY, S/C MNT BBC DUAL LO 1

4GA010-051 MTG PLT, BBC LOW MNT DUAL 1

4GA010-061 SPRT PLT, S/C BBC DUAL LOW 1

2A017-049 SPACER A, SBCHEV CARB BRKT 6

4GA010-044 S/C MTG PLT, BBC LOW MOUNT 1

4GA011-021 MACH MTG BRKT, BBC LOW MOUNT 1

7C012-022 M12 X 1.75 X 20MM THIN HD 3

7J012-092 12MM WASHER, FLAT 3

7A375-126 3/8-16 X 1.25 HHCS, GR8, PLT 6

7A375-275 3/8-16 X 2-3/4 HXCSG8P ZINC 4

7A375-300 3/8-16 X 3" HXCSG5P 1

7K375-040 3/8 AN960 FLAT WASHR PLATED 17

7A437-200 7/16-14 X 2" SHCS 2

7A437-425 7/16"-14X4.25" HX HD 1

7J438-081 7/16 SAE WASHER PLATED 1

7F375-017 3/8-16 NYLOCK NUT 2

7A375-201 3/8-16 X 2" S.S. SHCS 2

7A375-426 3/8-16 X 4.25" HX HD GR8 1

7B375-276 3/8-24 X 2.75" HX HD GR8 2

4GA118-011 DRIVE ASY, BBC DUAL 10-RIB 7" 1

4MA018-051 CRANK PLY, 7", UNIVERSAL 1

4MA017-061 SPACER, CRK PLY, GEN2 V-GRV 1

4GA018-011 CRK PLY, ACC, BBC LNG H20 PMP 1

7A375-475 3/8-16 X 4.75" HX HD GR8 PLTD 3

7J375-044 3/8 FLAT WASHR PLATED 3

2A041-618 BELT, 10 RIB X 61.75 EFFECT LENGTH 1

4GA130-036 OIL DRAIN ASSY, BBC LOW MT 1

7U030-036 1/2" OIL DRAIN HOSE 2.5'

7R001-008 #8 STNLS HOSE CLAMP 2

7P375-017 3/8NPT X 1/2 BEADED HSE BRB 1

4MA130-026 OIL FEED ASSY BBC 1

4MA145-020 OIL FEED HOSE ASSY, BBCKIT 1

7P125-026 1/8 NPT X #4 SAE FLARE, 90° 2

7P125-034 1/8NPTX1/8NPT STRT T 1

7P125-103 1/8NPT X 45° -4SAE FLARE 2

7P250-036 -4 SAE FLARE TO 1/4 NPT 1

7P250-120 1/4 NPT PIPE PLUG 1

8M205-012 CARB ENCL ASSY, UNIV SAT, G2 L 1

4GA111-041 TENS. ASSY. BBC DUAL LOW 10-RI 1

7B500-325 ARBOR, S/C TENS PLY, S2000 1

7PA375-500 SCREW, IDLER ADJUST, 5.00" 1

4PFA010-031 BRACKT, IDLER ADJUST SCREW 1

4FP116-030 IDLER W/BRNG ASSY, 36MM COG 1

4GA017-011 SPCR, IDLR,DL. PLT BBC 10-RIB 1

2A017-750-490 SPCR, ARBR,10-RB,DL.PLT BBC 1

7B500-240 ARBOR, S/C TENS PLY, RENEGADE 1

7F500-020 1/2"-20 HEX JAM NUT GR5 ZINC 1

4FD017-011 PILOT, 6203/5 BRG, 1/2 SCREW 1

7A250-100 1/4-20 X 1 FLAT ALLEN 2

4GA112-020 DISCH ASSY, BBC LOW MOUNT 1

4GA012-021 DISCH TUBE, BBC LOW MOUNT 1

7A312-100 5/16-18 X 1 HHCS, GR5, PLATED 4

7K312-001 5/16 AN WASHER, PLATED 4

7R002-048 #48 SAE TYPE F SS HOSE CLAMP 1

7R002-056 #56 SAE TYPE F SS HOSE CLAMP 3

7S350-200 SLEEVE, 3-1/2 X 2, BLUE 1

7S350-301 REDUCER, 3.50-3.00 1

8M012-011 MACH, 90° CARB BOX INLET 1

008110 SMALL SILVER DIE CUT DECAL 2

008444 3 YR S/C STRT INFO PKG ASY VOR 1

008130 LICENSE PLATE FRAME, VORTECH 1

4GA020-030 INSTR MAN, BBC LOW MOUNT KIT 1

P/N: 4GA020-030

©2008 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

08DEC08 V3.0(BBC LowMount(4GA..030 V3.0))

vi

Page 7

Base Kit, Universal BBC V4 Carb

®

Part No. 3GA218-060

ENGINEERING, LLC

PARTS LIST

IMPORTANT: Before beginning installation, verify that all parts are included in the kit. Report any shortages or damaged parts imme-

diately.

PART NO. DESCRIPTION QTY. PART NUMBER DESCRIPTION QTY.

008110 SMALL SILVER DIE CUT DECAL 2

008130 LICENSE PLATE FRAME, VORTECH 1

008443 S/C RACE INFO PKG ASSY VORT 1

4GA020-030 INSTR MAN, BBC LOW MOUNT KIT 1

4GA111-051 TENS. ASSY. COG, BBC DL PLT.LO 1

7G012-175 MACH NUT, COG DRV, SPECIAL 1

4FP017-021 SPACR, IDLR, DUAL PLT 50MM DRV 1

4FP116-020 IDLER W/BRNG ASSY, 50mm 1

4FD017-011 PILOT, 6203/5 BRG, 1/2 SCREW 1

7C012-065 M12 X 1.75 X 65MM HX 1

4GA111-061 BRKT ASSY, S/C MNT V4 BBC 1

4GA010-071 BRACKET,S/C BBC DUAL PLT RACE 1

4GA010-081 BRACKET,SPRT BBC DL. PLT RACE 1

2A017-049 SPACER A, SBCHEV CARB BRKT 8

4GA011-021 MACH MTG BRKT, BBC LOW MOUNT 1

7C012-022 M12 X 1.75 X 20MM THIN HD 3

7A375-126 3/8-16 X 1.25 HHCS, GR8, PLT 9

7A375-275 3/8-16 X 2-3/4 HXCSG8P ZINC 5

7A375-300 3/8-16 X 3" HXCSG5P 3

7K375-040 3/8 AN960 FLAT WASHR PLATED 19

7F375-017 3/8-16 NYLOCK NUT 2

7A437-200 7/16-14 X 2" SHCS 2

7A437-425 7/16"-14X4.25" HX HD 1

7J438-081 7/16 SAE WASHER PLATED 1

7A375-201 3/8-16 X 2" S.S. SHCS 2

7A375-426 3/8-16 X 4.25" HX HD GR8 1

4GA118-031 DRIVE ASY, BBC DUAL LOW COG 1

2A032-032 S/C PULLEY, 32T (50MM) 1

8R101-007 PULLEY RETAINER ASSY 50 MM COG 1

4MA018-080 CRANK PLY, 80T GT 8MM X 2.5W 1

4MA017-061 SPACER, CRK PLY, GEN2 V-GRV 1

4GA018-011 CRK PLY, ACC, BBC LNG H20 PMP 1

2A042-160 BELT, PC GT2 COG 1600X8MX36 1

7A375-475 3/8-16 X 4.75" HXHD GR8 PLTD 3

7K375-040 3/8 AN960 FLAT WASHR PLATED 3

4GA130-036 OIL DRAIN ASSY, BBC LOW MT 1

7U030-036 1/2" OIL DRAIN HOSE 2.5'

7R001-008 #8 STNLS HOSE CLAMP 2

7P375-017 3/8NPT X 1/2 BEADED HSE BRB 1

4MA130-026 OIL FEED ASSY BBC 1

4MA145-020 OIL FEED HOSE ASSY, BBCKIT 1

7P125-026 1/8 NPT X #4 SAE FLARE, 90° 2

7P125-034 1/8NPTX1/8NPT STRT T 1

7P125-103 1/8NPT X 45° -4SAE FLARE 2

7P250-036 -4 SAE FLARE TO 1/4 NPT 1

7P250-120 1/4 NPT PIPE PLUG 1

vii

08DEC08 V3.0(BBC LowMount(4GA..030 V3.0))

©2008 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

P/N: 4GA020-030

Page 8

Big Block Chevrolet

Carbureted System

Installation Instructions

PLEASE READ CAREFULLY

This kit should only be installed by qualified mechanics. It is imperative that

the correct air/fuel mixture be maintained at all times. This kit is to be

supplied to competent engine tuners for their completion by the addition of, and tuning of, an appropriate carburetor unit and fuel pump.

This product is intended for use on healthy, well maintained engines.

Installation on a worn-out or damaged engine is not recommended and

may result in failure of the engine.

Vortech Engineering is not responsible for engine damage. Installation

on new engines will not harm or adversely affect the break-in period so

long as factory break-in procedures are followed.

For best performance and continued durability, please take note of the

following key points:

1. Use only premium grade fuel 91 octane or higher (R+M/2).

2. The engine must have stock or lower than stock compression ratio.

3. If the engine has been modified in any way, check with Vortech prior to

using this product.

4. Always listen for any sign of detonation (pinging) and discontinue hard use

(no boost) until problem is resolved.

5. Perform an oil and filter change upon completion of this installation and prior

to operating the vehicle. Thereafter, always use a high grade SF rated

engine oil or a high quality synthetic, and change the oil and filter every

3000 miles.

6. Before beginning installation, replace all spark plugs with one to two step

colder heat range and reset timing to no more than 26°-28° total. (Always

follow the procedures indicated in the factory repair manual.)

• 3/8" Drive and Socket Set: SAE and Metric

• 1/2" Drive and Socket Set: SAE and Metric

• Adjustable Wrench

• Open End Wrenches: 5/16", 3/8", 7/16", 1/2",

9/16"

• Center Punch

• Drill Press, #7 Drill Bit, 1/4-20 tap

• 6 Quarts SF Rated Quality Engine Oil

• Loctite Sealer #RC-609

• Oil Filter and Wrench

• Flat #2 Screwdriver

• Phillips #2 Screwdriver

• Heavy Grease

• Silicone Sealer

• Drill Motor

• 3/32" Drill Bit

• Teflon Paste Sealant

P/N: 4GA020-030

©2008 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

08DEC08 V3.0(BBC LowMount(4GA..030 V3.0))

viii

Page 9

1. PREPARATION/REMOvAl

A. Disconnect the negative lead of all batteries.

B. Loosen all nuts and bolts that are used to

tension the alternator and power steering

pump V-belts.

C. Remove all of the belts from the accessories.

D. Remove the stock crank pulley and accesso-

ries from the driver’s side of the engine.

NOTE: If you have not changed spark plugs in

the last 15,000 miles do so prior to the

installation of this kit.

1

08DEC08 V3.0(BBC LowMount(4GA..030 V3.0))

©2008 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

P/N: 4GA020-030

Page 10

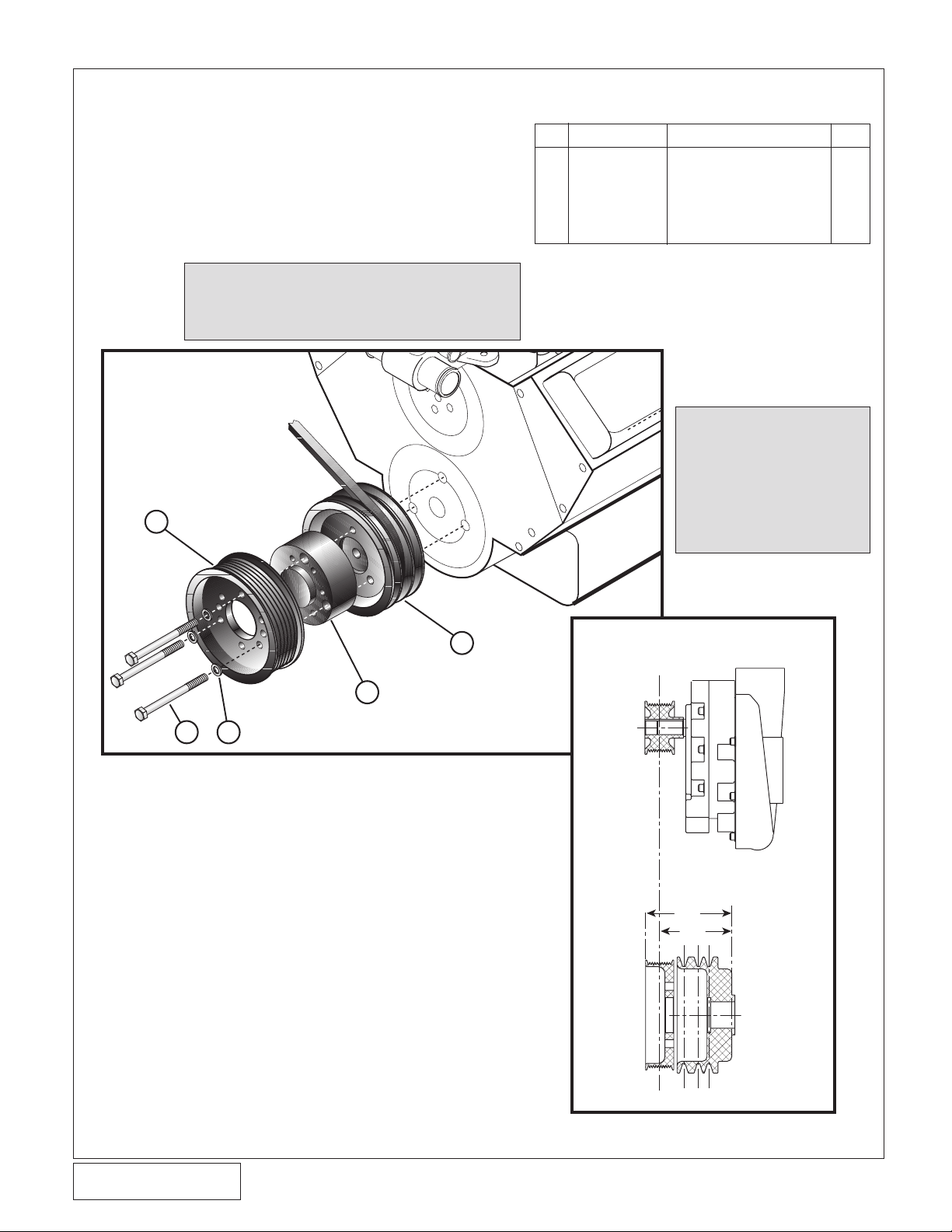

2. CRANK PUllEY

1

2

3

5

4

4.894

4.094

BALANCER FACE

SUPERCHARGER

BELT CENTERLINE

A. Put the supplied crank pulley, spacer and

V-groove pulley together while lining up the

three mounting holes.

B. Using the 3/8-16 x 4.75" hex head bolts and

3/8" washers, mount the crank pulley assembly to the harmonic balancer. Torque bolts to

35 ft./lbs. (See Fig. 2-a.)

CAUTION: Before installing the crank pulley,

make sure the balancer surface is

flat without burrs or other imperfections that would cause the pulley to

run untrue.

NO. PART DESCRIPTION QTY.

1 4MA018-051 Crank Pulley 1

2 7A375-475 3/8-16 x 4.75" HH Bolts 3

3 7J375-044 3/8" Washers 3

4 4GA018-011 V-Groove Pulley 1

5 4MA017-061 Spacer 1

NOTE: If the pulley

configuration on

your engine

requires a special crank and

pulley (short

water pump,

etc.) use Fig.

2-b as a quideline for proper

pulley spacing.

P/N: 4GA020-030

©2008 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

08DEC08 V3.0(BBC LowMount(4GA..030 V3.0))

Fig.2-a

2

Fig.2-b

Page 11

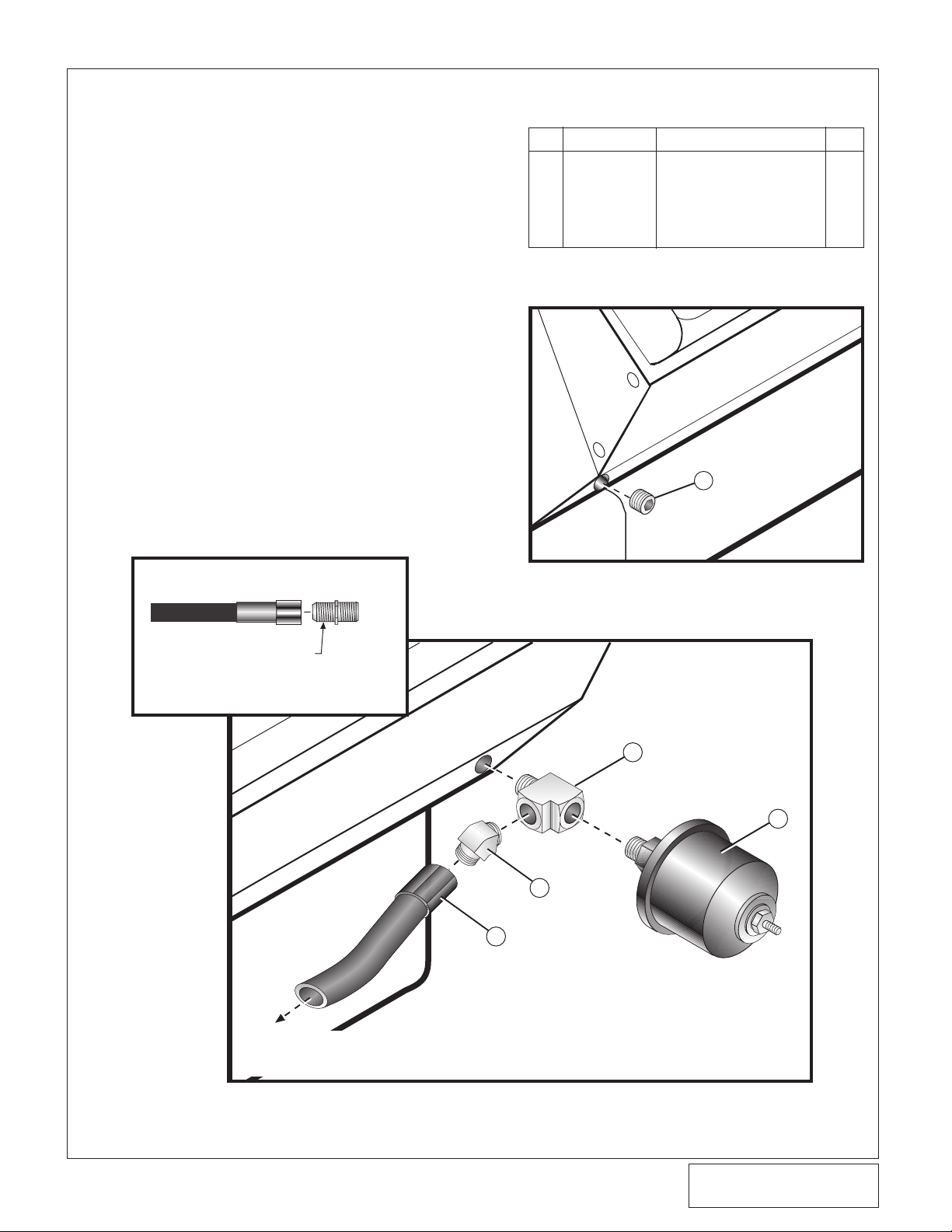

3. SUPERCHARGER OIl FEED

GOES TO

SUPERCHARGER

OIL SUPPLY NOZZLE

3

5

4

2

TYPICAL OIL FITTING ASSEMBLY

• USE ONLY OIL ON FLARE

TYPE FITTINGS. DO NOT

USE TEFLON PASTE OR

TAPE ON FLARE END

1

A. Remove the stock 1/4" hex head pipe plug

from the front left lower portion of the engine

block, if equipped, and replace it with the kit

supplied 1/4" socket head pipe plug.

Replacement of the square head plug allows

for supercharger bracket installation clearance. Apply Teflon paste sparingly to the

plug's threads prior to installation. (See Fig.

3-a.)

B. Remove stock oil pressure transducer, and

install in its place an 1/8" straight "T". Orient

the fitting to allow for suitable installation and

routing of oil supply line. Apply engine oil to

the male thread prior to installation. Next,

install the 1/8"NPT x 45° male elbow into the

side port of the straight "T" (see Fig. 3-b).

Thread one end of the oil feed hose onto the

1/8"NPT x 45° male elbow. Use a small

amount of oil when installing the flare type oil

feed hose assembly. Route the hose towards

the front of the engine; keep the free end

capped to avoid contamination.

NO. PART DESCRIPTION QTY.

1 7P250-120 Socket Head Pipe Plug 1

2 N/A Oil Pressure Transducer 1

3 7P125-034 1/8" Straight “T” 1

4 7P125-103 1/8" NPT x 45° Male Elbow 1

5 4MA145-020 Oil Feed Hose 1

Fig. 3-a

Fig. 3-b

3

08DEC08 V3.0(BBC LowMount(4GA..030 V3.0))

©2008 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

P/N: 4GA020-030

Page 12

4. SUPERCHARGER OIl DRAIN

1”

1”

PUNCH HOLE

THROUGH

A. With this option, it is nec-

essary to make a hole in

the oil pan. (See Fig.

4-a.) It is best to punch the

hole rather than drill.

Remove paint from around

the hole area so that it

does not flake into the pan.

B. Make a mark on the oil

pan on the left side ahead

of the oil filter. The mark

should be 1" below the bolt

flange and forward of the

third bolt by 1". You may

choose a different place, if

necessary. However, take

care not to damage any

internal parts. The drain hose should gradually drop with no dips or kinks and should be

above the oil level.

C. Use a small center punch to perforate the

pan and expand the hole. Switch to a larger

diameter punch and expand the hole further

to approximately Ø9/16" (or use an air hammer with a 9/16" round punch attachment).

Most punches are made from hexagon material and may be placed in a socket with an

extension to make this procedure easier.

D. Tap the hole with a 3/8"NPT tap approximate-

ly 1/4" deep. Pack the flutes of the tap with

heavy grease to catch and hold the chips.

Once the tap is removed, it must be cleaned

and repacked before tapping resumes. Use a

small magnet to check for any stray chips in

the threads after completing the tapping procedure.

E. Thoroughly clean the threaded area with ace-

tone or other solvent. Apply a small amount

of silicone sealer to the new threads. Apply a

small amount of silicone sealer to the threads

of the 3/8"NPT hose fitting and secure in the

hole. Make sure a seal is formed all around

the fitting. Allow the sealer to cure completely.

F. Temporarily cover the end of the hose and

secure out of the way. The return is a gravity

drain and should be routed to provide a gradual drop.

G. Drain and replace the engine oil and change

the filter.

Fig. 4-a

P/N: 4GA020-030

©2008 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

08DEC08 V3.0(BBC LowMount(4GA..030 V3.0))

4

Page 13

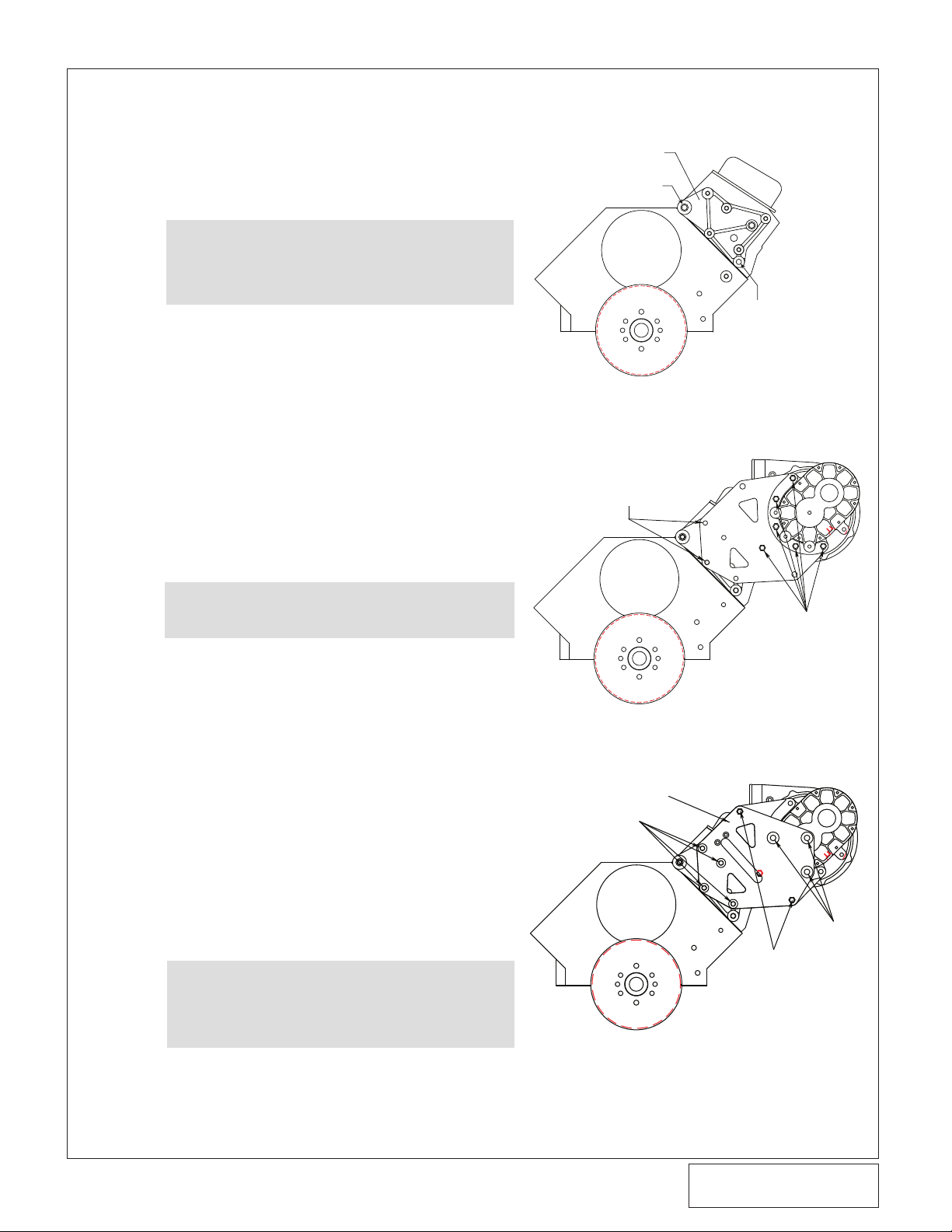

5. SUPERCHARGER MOUNTING (TWIN PlATE v-7 ONlY, v-4 SKIP TO SECTION 8)

TEMPORARILY INSTALL TWO

3/8-16 X 2.75” HEX HEAD SCREWS

3/8-16 X 1.25 HEX

HEAD SCREW AND

WASHER

4GA010-051

3/8-16 X 2.75 HEX HEAD

SCREW AND WASHER

3/8-24 X

2.75” HEX

HEAD

SCREW AND

WASHER

M12 X 1.75 X

20MM HEX

HEAD SCREW

AND WASHER

4GA010-061

7/16-14 X 4.25

HXHD SCREW

VORTECH SUPERCHARGER

MOUNTING BRACKET

2 PLACES 7/16-14 x 2" SH SCREW

A. Mount the supplied aluminum supercharger

mounting bracket onto the front of the driver’s

side cylinder head using the two 7/16-14 x 2"

socket head screws and one 7/16-14 x 4.25"

screw with washer as shown in Fig. 5-a.

NOTE: Some Gen IV and earlier heads (includ-

B. Loosely attach the supplied supercharger

mounting plate (4GA010-051) to the previously installed mounting bracket using one of

the supplied 3/8-16 x 1.25” hex head screw

and washer as shown in fig. 5-b. Temporarily

install two of the supplied 3/8-16 x 2-3/4” hex

head screws through the supercharger

mounting plate as a guide. Tighten the 3/8-16

x 1.25” hex head screw at this time. Remove

the two 3/8-16 x 2-3/4” hex head screws.

C. Remove the blue plastic oil drain cap located

on the fitting at the bottom of the supercharger unit and install the supplied 1/2" (fabric

braided) oil drain hose. Secure with a #8

hose clamp.

ing “GM performance” heads) require

3/8-16 screws and flat washers to be

used in lieu of the 7/16" hardware. Both

sizes have been included in the mounting bracket assembly.

Fig. 5-a

D. Install the supercharger to the mounting

E. Loosely install the supercharger support plate

F. Route the drain hose down to the previously

CAUTION: Clock the clamp screw housing to the

side so that it does not interfere with

the mounting plate during installation.

plate. Secure the unit to the plate with the

five supplied 3/8-16 x 1.25" screws and AN

flat washers.

(4GA010-061) using the four 3/8-16 x 2.75”

screws, washers and four of the Ø.75” x

1.309” long spacers (2A017-049) provided.

Install the two remaining Ø.75” x 1.309” long

spacers (2A017-049) using the two 3/8-24 x

2.75” screws and washer. Finally install the

three M12-1.75 x 20mm thin head screws

with washers as seen in figure 5-e. Tighten

all hardware installed to this point.

installed fitting in the oil pan and secure with

a #8 hose clamp. Trim hose if necessary.

NOTE: Oil drain hose must be routed downhill

with minimal bends and no kinking. The

supercharger relies on a gravity drain for

proper operation. Uphill hose routing will

result in improper drainage and possibly

supercharger failure.

Fig. 5-b

Fig. 5-E

5

08DEC08 V3.0(BBC LowMount(4GA..030 V3.0))

©2008 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

P/N: 4GA020-030

Page 14

5. SUPERCHARGER MOUNTING, CONT'D (TWIN PlATE v-7 ONlY, v-4 SKIP TO

SECTION 8)

G. Install the supplied 1/8"NPT x 90° x #4 fitting

into the supercharger oil feed nozzle. Do not

use teflon tape on the threads or oil feed

blockage may result.

CAUTION: Ensure that the oil supply system is

H. Carefully route the previously installed oil feed

hose up to the supercharger oil feed fitting

taking care not to kink the hose. Carefully

thread the hose end onto the feed fitting.

LIGHTLY LUBRICATE THE FITTING WITH

ENGINE OIL.

free of contamination that might plug

the supercharger oil inlet orifice. Hold

the supercharger oil feed fitting with

wrench while tightening the oil feed

line fitting.

P/N: 4GA020-030

©2008 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

08DEC08 V3.0(BBC LowMount(4GA..030 V3.0))

6

Page 15

6. ACCESSORY DRIvE BElTS (TWIN PlATE v-7 ONlY, v-4 RACE SKIP TO

SECTION 8)

NOTE: Belts are to be sized per each application and

purchased separately and are not included in this

base kit.

A. Install the correct length V-belts onto the

water pump, power steering and crank pulleys.

B. Tighten all bracket hardware that was

“snugged” earlier and adjust/tighten the

V-belts making sure all belts are routed correctly. Make sure all hoses and wiring are

routed correctly and secured, that all coolant

modifications are complete and hose clamps

are properly tightened.

7

08DEC08 V3.0(BBC LowMount(4GA..030 V3.0))

©2008 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

P/N: 4GA020-030

Page 16

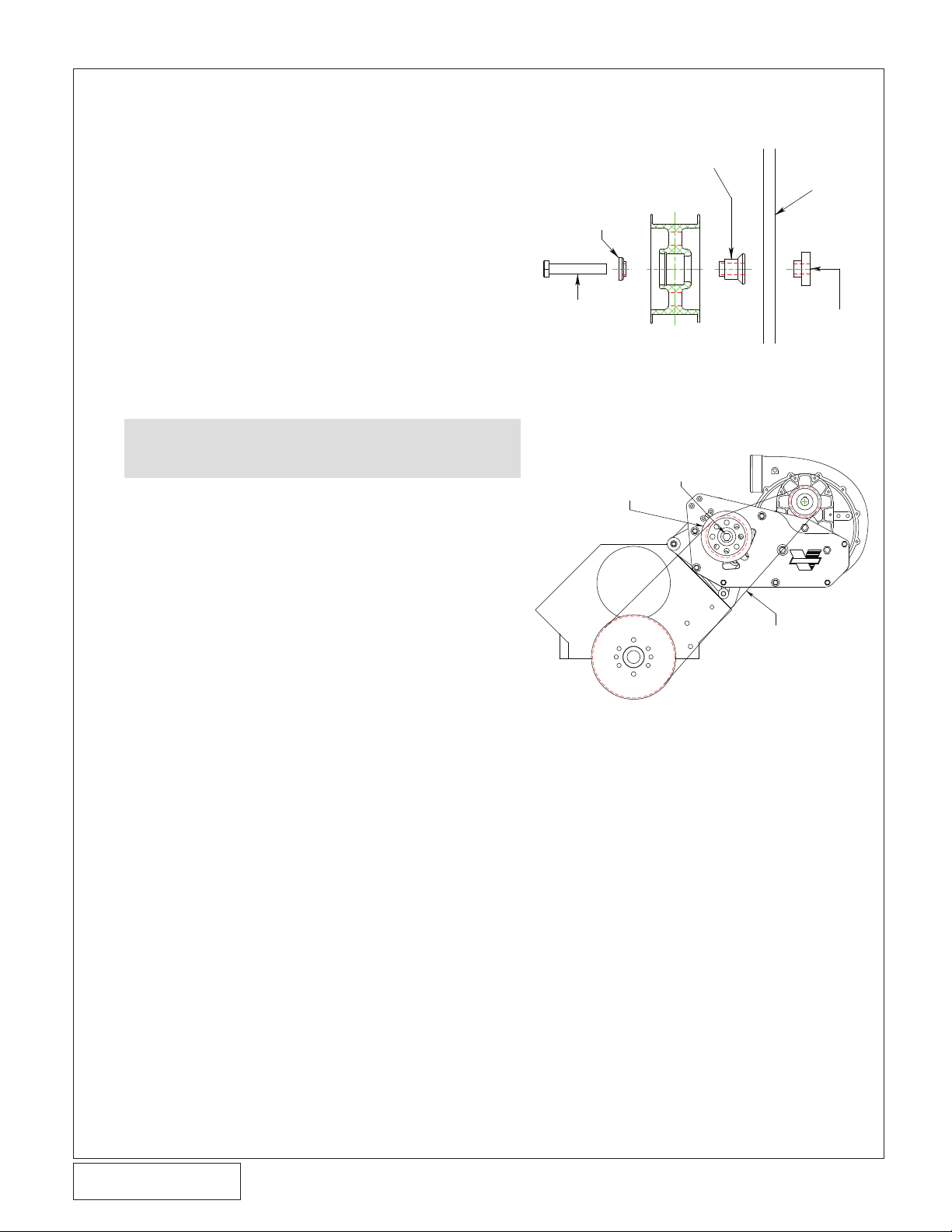

7. SUPERCHARGER DRIvE BElT INSTAllATION

ALUMINUM TENSIONER IDLER

1/2”-20 HEX NUT AND BEARING

PILOT (4DF017-011)

SUPERCHARGER DRIVE

BELT (INSTALLED AFTER

ACCESSORY BELTS)

4GA010-061

1/4-20 X 1” SCREW

ARBOR SPACER

(SLIDES OVER ARBOR)

IDLER

BEARING

PILOT

1/2”-20

HEX NUT

IDLER

SPACER

1/2” MOUNTING PLATE

IDLER

ADJUST

SCREW

BELT TENSIONER ARBOR

IDLER ADJUST

SCREW BRACKET

(TWIN PlATE v-7 ONlY, v-4 RACE SKIP TO SECTION 8)

CAUTION: Cog tensioner assembly does not use the ten-

sioner arbor method. For cog drive applications

skip to 7-e

A. Attach the supplied belt tensioner adjustment

screw, tensioner arbor and adjustment screw

locator block to the supercharger support

plate as show in figure 7-a. Secure the

assembly to the plate by threading the two

1/4-20 x 1” flat head allen screws through the

plate and into the adjustment screw locator

block as shown.

B. Slide the arbor bushing (Ø.75”OD x Ø.530”ID

x .490” long) onto the arbor screw. Verify that

the bushing fits in the arbor slot up against

the arbor screw head. Place the idler spacer

(4GA017-011) and aluminum tensioner idler

onto the arbor screw, secure using the provided bearing pilot (4FD017-011) and supplied 1/2"-20 hex nut.

C. Fit the supercharger drive belt over the new

crank pulley and supercharger pulley.

D. Tension the belt by using a 3/8” socket to

turn the tensioner adjustment screw anticlockwise until the desired tension is

achieved. Secure the tensioner idler by tightening the 1/2"-20 hex nut previously installed.

Fig. 7-a (10-Rib Belt Route Only)

P/N: 4GA020-030

©2008 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

08DEC08 V3.0(BBC LowMount(4GA..030 V3.0))

Fig. 7-b (10-Rib Belt Tensioner Assembly - Side View)

8

Page 17

M12 X 1.75 X 65MM BOLT

BEARING

PILOT

IDLER

IDLER

SPACER

MACHINE NUT SPECIAL

(PILOTS IN SLOT)

1/2” MOUNTING PLATE

4GA010-061

7. SUPERCHARGER DRIvE BElT INSTAllATION, CONT'D

(TWIN PlATE v-7 ONlY, v-4 RACE SKIP TO SECTION 8)

E. (Cog drive only) Slide the M12-1.75 X 65mm

screw through the supplied bearing pilot, aluminum idler and idler spacer. Place the

machine nut into the slot in the supercharger

support plate. Loosely attach the previously

assembled idler assembly, do not tighten at

this time. See Fig. 7-c.

F. (Cog drive only) Fit the supercharger drive

belt over the new crank pulley, idler pulley

and supercharger pulley.

G. (Cog drive only) Tension the belt by pulling

up on the tensioner by hand and then tighten

the previously installed M12 hardware. The

belt does not need to be tightened excessively. See Fig. 7-d.

CAUTION: Do not "back-bend" a cog belt to tension.

Fig. 7-c (Cog Belt Tensioner Assembly - Side View)

Fig. 7-d (Cog Belt Route Only)

9

08DEC08 V3.0(BBC LowMount(4GA..030 V3.0))

©2008 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

P/N: 4GA020-030

Page 18

8. SUPERCHARGER MOUNTING RACE (v-4 RACE BRACKETS ONlY. TWIN PlATE

3/8-16 x 1.25”

HEX HEAD

SCREW AND

WASHER

TEMPORARILY INSTALL

TWO 3/8 X 2.75” HEX

HEAD SCREWS

4GA010-071

3/8-16 X 2.75” HEX

HEAD SCREW AND

WASHER

M12 X 1.75 X

20MM HEX

HEAD SCREW

AND WASHER

3/8-16 X 3.0”

HEX HEAD

SCREW AND

WASHER

4GA010-081

®

7/16-14 X 4.25

HXHD SCREW

VORTECH SUPERCHARGER

MOUNTING BRACKET

2 PLACES 7/16-14 x 2" SH SCREW

v-7 SKIP TO SECTION 11)

A. Mount the supplied aluminum supercharger

mounting bracket onto the front of the driver’s

side cylinder head using the two 7/16-14 x 2”

socket head screws and one 7/16-14 x 4.25”

screw with the washer as shown in Fig. 8-a

NOTE: Some Gen IV and earlier heads (includ-

ing “GM performance” heads) require 3/816 screws and flat washers to be used in

lieu of the 7/16” hardware. Both sizes

have been included in the mounting

bracket assembly.

B. Loosely attach the supplied supercharger

mounting plate (4GA010-071) to the previously installed mounting bracket using one of the

supplied 3/8-16 x 1.25” hex head screws and

washer as shown in fig. 8-b. Temporarily

install two of the supplied 3/8-16 x 2-3/4”hex

head screws through the supercharger

mounting plate as a guide. Tighten the 3/8-16

x 1.25” hex head screw at this time. Remove

the two 3/8-16 x 2-3/4” hex heads screw.

C. Secure an oil drain line to the bottom of the

supercharger in a manner that will not interfere with the supercharger support bracket.

NOTE: There is no oil drain line supplied in

the Race bracket kit.

D. Install the supercharger to the mounting plate.

Secure the unit to the plate with the eight supplied 3/8-16 x 1.25” screws and AN flat washers. See Fig. 8-b

E. Loosely install the supercharger support plate

(4GA010-081) using the five 3/8-16 x 2.75”,

three 3/8-16 x 3” screws, eight Ø1.309” long

spacers (2A017-049) and washers provided.

Finally install the three M12-1.75 x 20mm thin

headed screws as seen in figure 8-c. Tighten

all hardware installed to this point.

F. Route the oil drain hose down to your prede-

termined location and secure.

Fig. 8-A

Fig. 8-B

P/N: 4GA020-030

©2008 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

08DEC08 V3.0(BBC LowMount(4GA..030 V3.0))

NOTE: You will need to provide and adequate oil

drain from the supercharger to the oil pan

or oil collection reservoir. The oil path

should maintain a down hill direction and

be free of any dips or kinks. The oil

should enter the pan/reservoir above the

oil level to maintain a free flowing path.

Fig. 8-C

10

Page 19

9. ACCESSORY DRIvE BElTS (v-4 "RACE" ONlY)

NOTE: Belts are to be sized per each application and

purchased separately and are not included in this

base kit.

A. Install the correct length V-belts onto the

water pump, power steering and crank pulleys.

B. Tighten all bracket hardware that was

“snugged” earlier and adjust/tighten the

V-belts making sure all belts are routed correctly. Make sure all hoses and wiring are

routed correctly and secured, that all coolant

modifications are complete and hose clamps

are properly tightened.

11

©2008 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

08DEC08 V3.0(BBC LowMount(4GA..030 V3.0))

P/N: 4GA020-030

Page 20

M12 X 1.75 X 65MM LONG

SCREW BEARING PILOT, SPACER,

AND SPECIAL MACHINED NUT

ALUMINUM TENSIONER IDLER

SUPERCHARGER DRIVE BELT

(INSTALLED AFTER

ACCESSORY BELTS)

M12 X 1.75 X 65MM BOLT

BEARING

PILOT

IDLER

IDLER

SPACER

MACHINE NUT SPECIAL

(PILOTS IN SLOT)

1/2” MOUNTING PLATE

10. SUPERCHARGER DRIvE BElT INSTAllATION (v-4 "RACE" ONlY)

A. (Cog drive only) Slide the M12-1.75 X 65mm

screw through the supplied bearing pilot, aluminum idler and idler spacer. Place the

machine nut into the slot in the supercharger

support plate. Loosely attach the previously

assembled idler assembly, do not tighten at

this time. See Fig. 10-a

B. (Cog drive only) Fit the supercharger drive

belt over the new crank pulley, idler pulley

and supercharger pulley.

C. (Cog drive only) Tension the belt by pulling

up on the tensioner by hand and then tighten

the previously installed M12 hardware. The

belt does not need to be tightened excessively. See Fig. 10-b.

CAUTION: Do not "back-bend" a cog belt to tension.

Fig. 10-a (Cog Belt Tensioner Assembly - Side View)

P/N: 4GA020-030

©2008 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

08DEC08 V3.0(BBC LowMount(4GA..030 V3.0))

Fig. 10-b (Cog Belt Route Only)

12

Page 21

11. AIR INlET SUGGESTIONS

A. As mentioned at the beginning of this manu-

al, no supercharger air inlet components are

included with this kit because of the numerous configurations and different vehicle types

that this kit will be installed on.

B. When “laying out” your supercharger air inlet,

keep in mind that supercharger and engine

performance is greatly increased when a cool

air source is used. Pulling in heated air from

the engine compartment, or from above the

headers will result in lackluster performance

and possible engine detonation.

C. Vortech offers some individual components

that may aid you in your installation (Not

applicable to V-4 "Race" Kit).

• Vortech #7S400-000 Ø4" x 90° cast aluminum

inlet elbow (3.5" CL radius)

• Vortech #7S400-001 Ø4" x 90° rubber inlet

elbow

• Vortech #7S400-200 Ø4" x 2" silicone sleeve

• Vortech #8H040-095 air filter, Ø4" flange x 5"L x

Ø4.5"

• Vortech #8H040-095 air filter, Ø4" flange x 7"L x

Ø5.38"

• Vortech #8H040-095 air filter, Ø4" flange x

7.63"L x Ø5.38"

13

©2008 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

08DEC08 V3.0(BBC LowMount(4GA..030 V3.0))

P/N: 4GA020-030

Page 22

12. DISCHARGE DUCTING/CARBURETOR ENClOSURE

A. Install optional Vortech carburetor enclosure

(if not already completed) assembly #8M205-

012. Instructions are included with the enclosure assembly. The enclosure lid is to be

attached to the base with the inlet facing the

passenger’s side of the vehicle.

B. Attach the short 90° aluminum elbow with

flange to the enclosure inlet using the supplied gasket, 5/16-18 x 1 bolts and washers.

C. Install the long 3-1/2" aluminum elbow in

between the supercharger discharge and the

90° flange elbow using the 3.5” sleeve, #56

clamps, #48 clamp and reducer.

NOTE: Depending on the vehicle application

and hood configuration, minor bottom

side hood modifications may be required.

P/N: 4GA020-030

©2008 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

08DEC08 V3.0(BBC LowMount(4GA..030 V3.0))

14

Page 23

13. FINAl REASSEMBlY AND CHECK

A. Refit the Radiator fan and shroud, if

equipped.

B. Reconnect the battery.

C. If your vehicle has gone over 15,000 miles

since its last spark plug change, you will need

to change the spark plugs now before test

driving the vehicle.

D. Check all fittings, nuts, bolts and clamps for

tightness. Pay particular attention to oil and

fuel lines around moving parts, sharp edges

and exhaust system parts. Make sure all

wires and lines are properly secured with

clamps or tie-wraps.

E. Check all fluid levels, making sure that your

tank(s) is filled with 91 octane or higher fuel

before commencing test drive.

F. Start engine and allow to idle a few minutes,

then shut off.

G. Recheck to be sure that no hoses, wires, etc.

are near exhaust headers or moving parts

and for signs of any fluid leakage. Re-jet the

carburetor as required. Install a boost referenced high-performance mechanical fuel

pump or high performance electric fuel pump

with boost referenced fuel regulator. Check

ignition timing to make sure it is properly set

before commencing test drive.

H. PLEASE TAKE SPECIAL NOTE: Operating

the vehicle without all sub assemblies completely and properly installed and working

may cause FAILURE OF MAJOR ENGINE

COMPONENTS.

I. Test drive the vehicle.

J. Read the Street Supercharger System

Owner's Manual and RETURN THE Warranty

REGISTRATION FORM within thirty (30)

days of purchasing your supercharger system

to qualify.

WARNING: Do not attempt to operate the vehicle

until all components are installed and

all operations are completed including

final check.

NOTE: Vortech strongly recommends the use of

a wide band O2 sensor to monitor the air

fuel ratio in the exhaust when calibrating

the carburator. A safe air/fuel ratio of

11.0:1 is recommenced when using 91

octane fuel.

15

©2008 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

08DEC08 V3.0(BBC LowMount(4GA..030 V3.0))

P/N: 4GA020-030

Page 24

®

ENGINEERING, LLC

1650 PACIFIC AVENUE • CHANNEL ISLANDS, CA 93033-9901 • (805) 247-0226

FAX (805) 247-0669 • www.vortechsuperchargers.com • M-F 8:00 AM - 4:30 PM PST

08DEC08 V3.0(BBC LowMount(4GA..030 V3.0))

©2008 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

P/N: 4GA020-030

Loading...

Loading...