Page 1

Maxflow® Fuel Pressure Optimizer 86-95 Mustang

®

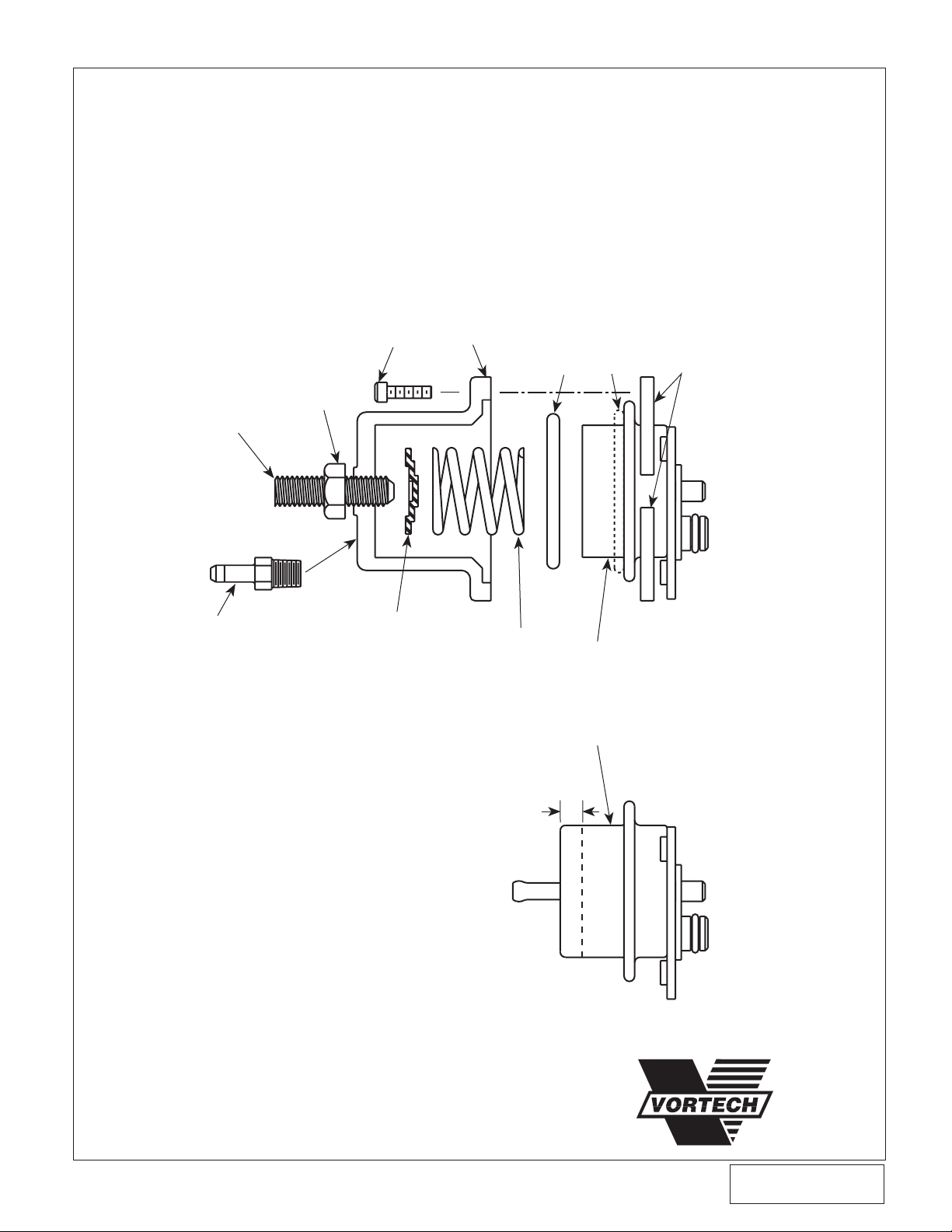

Installation Instructions

Before beginning installation of the Maxflow Fuel Pressure Optimizer, it is imperative to ensure that the

vehicle's engine is cold/cool to the touch, and the fuel pressure has been properly relieved. Refer to a service

manual for the proper technique.

A. Component Removal/Preparation

1. Disconnect the negative cable from the battery

negative terminal.

WARNING: Do not smoke while working on the

2. Disconnect the vacuum line from the regulator.

Remove the screws securing the fuel regulator to

the fuel rail.

NOTE: Inspect the fuel regulator O-ring for

3. Referring to the graphic assembly diagram, measure down 1/4" from the top of the fuel regulator

and mark the location. Cut the upper portion of

the fuel regulator top off and discard.

fuel system. Keep open flame

away from your work area!

cracks and tears. Replace if necessary.

NOTE: Be sure not to cut into or puncture the

4. Install the O-ring onto the factory fuel regulator

and seat onto the lip. Install the Vortech

optimizer as shown in

fuel regulator diaphram. Remove any

burrs and sharp edges.

®

fuel

Fig. 1

. The adjustment

screw should be unscrewed as far as possible to

ease installation. Using a 7/64" hex key, tighten

the four supplied 6-32 x 1/2" stainless steel

screws evenly, using a criss-cross pattern.

is no need to tighten screws excessively

There

. A small

amount of blue loctite 247 is recommended on

each of the four previously mentioned screws.

5. Reinstall the fuel regulator using the previously

removed hardware and tighten to the vehicle

manufacturers torque specifications.

6. Reconnect the vacuum line to the regulator. Reconnect the negative battery cable to the battery

terminal.

7. Turn the ignition switch on, but do not operate the

starter. After the fuel pump has run for approximately two seconds, the fuel pressure in the fuel

line will rise. Repeat this two or three times, then

check for any possible fuel leaks.

8. Adjust the fuel pressure to the desired setting

(turn clockwise to raise fuel pressure) using a

5/32" hex key and secure this setting, tightening

the jam nut against the regulator cover.

TOOLS REQUIRED:

• Metric and standard hex key set (Allen wrenches)

• Pneumatic cutoff wheel or fine tooth hacksaw

• 1/2" wrench

TOOLS RECOMMENDED:

• Blue loctite 247

• High quality/high pressure fuel pressure gauge

P/N: 007067

©2001 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

19DEC01 V1.0

(7067 V1.0)

ENGINEERING, LLC

1

Page 2

INSTALLATION INSTRUCTIONS

5/16-18 NUT

5/16-18 x 1.25 SET SCREW

6-32 x 1.5" SOCKET HEAD

COVER

O-RING

SPRING RETAINER

1/8 NPT - 5/32 HOSE BARB

SPRING

COVER RETAINERS

FUEL REGULATOR

CUT OFF TOP PORTION

AND DISCARD

1/4”

O-RING SEATS HERE

WHEN INSTALLED

®

Fig. 1

ENGINEERING, LLC

©2001 Vortech Engineering, LLC

2

All Rights Reserved, Intl. Copr. Secured

19DEC01 V1.0

P/N: 007067

(7067 V1.0)

Loading...

Loading...