Page 1

2013 Scion FR-S and Subaru BRZ

Supercharger System Installation Instructions

2013 MODEL YEAR*

*Legal in California only for racing vehicles which may never be used upon a highway.

1650 Pacific Avenue, Channel Islands, CA., 93033-9901 • Phone: 805 247-0226 • Fax: 805 247-0669 • vortechsuperchargers.com • M-F 7:00AM - 3:30PM (PST)

DP/N: 4TF020-010 - v2.1 05/14/2013

Page 2

FOREWORD

This manual provides information on the installation, maintenance and

service of the Vortech supercharger kit expressly designed for this vehicle.

All information, illustrations and specifications contained herein are based

on the latest product information available at the time of this publication.

Take note of the following before proceeding:

1. Proper installation of this supercharger kit requires general automotive mechanic knowledge and experience.

Please browse through each step of this instruction manual prior to beginning the installation to determine if

you should refer the job to a professional installer/technician. Please contact your dealer or Vortech

Engineering for possible installers in your area.

2. This product was designed for use on stock (un-modified, OEM) vehicles. The PCM (computer), engine, trans-

mission, drive axle ratios and tire O.D. must be stock. If the vehicle or engine has been modified in any way,

check with Vortech prior to installation and use of this product.

3. Use only premium grade fuel with a minimum of 91 octane (R+M/2).

4. Always listen for any sign of detonation (knocking/pinging) and discontinue hard use (no boost) until the

problem is resolved.

5. Vortech is not responsible for any clutch, transmission, drive-line or engine damage.

Exclusions from Vortech warranty coverage considerations include, but not limited to:

Changes to the manual may be made at any time without notice. Contact

Vortech Engineering for any additional information regarding this kit and

any of these modifications at (805) 247-0226 7am-3:30pm PST.

P/N: 4TF020-010 v2.1, 05/14/2013

©2013 Vortech Engineering, Inc

All Rights Reserved, Intl. Copr. Secured

1. Neglect, abuse, lack of maintenance, abnormal operation or improper installation.

2. Continued operation with an impaired vehicle or sub-system.

3. The combined use of Vortech components with other modifications such as, but not limited to, exhaust

headers, aftermarket camshafts, nitrous oxide, third party PCM programming or other such changes.

©2013 VORTECH ENGINEERING, INC

All rights reserved. No part of this publication may be reproduced, transmitted, transcribed, or translated

into another language in any form, by any means without written permission of Vortech Engineering, Inc.

ii

Page 3

TABLE OF CONTENTS

FOREWORD ..........................................................................................................................................................ii

TABLE OF CONTENTS ......................................................................................................................................iii

TOOL & SUPPLY REQUIREMENTS ............................................................................................................... v

PARTS LIST, 4TF218-014L & 4TF218-114L ................................................................................................ vi

1. ECU RE-FLASH (COMPLETE KITS ONLY) ........................................................................................ 1

2. PREPERATION/REMOVAL ......................................................................................................................8

3. MOUNTING BRACKET AND SUPERCHARGER INSTALLATION ............................................. 10

4. CHARGE AIR COOLER INSTALLATION ...........................................................................................18

5. MAF HARNESS EXTENSION ................................................................................................................. 25

6. WINDSHIELD WASHER RESERVOIR INSTALLATION ................................................................27

7. CHARGE AIR COOLER TUBE INSTALLATION ............................................................................... 31

8. COMPRESSOR BYPASS VALVE INSTALLATION ........................................................................... 34

9. PCV VALVE INSTALLATION ..................................................................................................................35

10. AIR INLET INSTALLATION ..................................................................................................................... 36

11. FINAL CHECK ...............................................................................................................................................39

12. APPENDIX ....................................................................................................................................................40

P/N: 4TF020-010 v2.1, 05/14/2013

©2013 Vortech Engineering, Inc

All Rights Reserved, Intl. Copr. Secured

INTERACTIVE PDF

This is an interactive Adobe PDF. Clicking on the table of contents takes you to your

desired page. All photos or drawings contained within link to higher resolution versions

found on our server. You will be told you are being directed to an outside source.

iii

Page 4

COPYRIGHT NOTICE

This product is protected by state common law, copyright and/or patent. All legal rights

therein are reserved. The design, layout, dimensions, geometry and engineering features

shown in this product are the exclusive property of Vortech Engineering, Inc. This product

may not be copied or duplicated in whole or part, abstractly or fundamentally, intentionally

or fortuitously, nor shall any design, dimension, or other information be incorporated into

any product or apparatus without prior written consent of Vortech Engineering, Inc.

P/N: 4TF020-010 v2.1, 05/14/2013

©2013 Vortech Engineering, Inc

All Rights Reserved, Intl. Copr. Secured

iv

Page 5

SCION FR-S AND SUBARU BRZ

®

ENGINEERING, INC.

Installation Instructions

Congratulations on selecting the best performing and best backed automotive supercharger

available today... the VORTECH® Supercharger!

Before beginning this installation, please read through this entire instruction booklet and the Street Supercharger System Owner's Manual which includes the

Automotive Limited Warranties Program and the Warranty Registration form.

Vortech supercharger systems are performance improving devices. In most cases, increases in torque of 30-35% and horsepower of 35-45% can be expected with

the boost levels specified by Vortech Engineering. This product is intended for use on healthy, well maintained engines. Installation on a worn-out or damaged

engine is not recommended and may result in failure of the engine as well as the supercharger. Vortech Engineering is not responsible for engine damage.

Installation on new vehicles will not harm or adversely affect the break-in period so long as factory break-in procedures are followed.

For best performance and continued durability, please take note of the following key points:

1. Use only premium grade fuel 91 octane or higher (R+M/2).

2. The engine must have stock compression ratio.

3. If the engine has been modified in any way, check with Vortech prior to using this product.

4. Always listen for any sign of detonation (pinging) and discontinue hard use (no boost) until problem is resolved.

5. Perform an oil and filter change upon completion of this installation and prior to test driving your vehicle. Thereafter, always use a manufacture-rated, high

grade engine oil or a high quality synthetic, and change the oil and filter every 3,000 miles or less. Never attempt to extend the oil change interval beyond

3,000 miles, regardless of oil manufacturer's claims as potential damage to the supercharger may result.

6. Before beginning installation, replace all spark plugs that are older than 1 year or 30,000 miles with original heat range plugs as specified by the

manufacturer and reset timing to factory specifications (follow the procedures indicated within the factory repair manual and/or as indicated on the factory

underhood emissions tag). Do not use platinum spark plugs unless they are original equipment. Change spark plugs every at least 30,000 miles and spark

plug wires at least every 50,000 miles.

TOOL & SUPPLY REQUIREMENTS

• Factory Repair Manual

• 3/8" Socket and Drive Set: SAE & Metric

• Adjustable Wrench

• Open End Wrenches: SAE & Metric

• Flat #2 Screwdriver

• Phillips #2 Screwdriver

• Drill Motor

• 1/4" Drill Bit

• Tin snips or light-duty grinder

• Wire Strippers and Crimpers

• Utility Knife

• Soldering gun and solde

If your vehicle has in excess of 30,000 miles since its last spark plug change, then you will also need:

• Spark Plug Socket

• NEW Spark Plugs

P/N: 4TF020-010 v2.1, 05/14/2013

©2013 Vortech Engineering, Inc

All Rights Reserved, Intl. Copr. Secured

v

Page 6

2013 SCION FR-S TUNER SYSTEM

Part No. 4TF218-014L / 4TF218-114L

IMPORTANT: Before beginning installation, verify that all parts are included in the kit. Report any shortages or damaged

parts immediately.

PARTS LIST

PART NO. DESCRIPTION ..............................................QTY

008110 SMALL SILVER DIE CUT DECAL ................................. 2

008130 LICENSE PLATE FRAME, VORTECH .......................... 1

008447 1 YR S/C STRT INFO PKG ASY VOR .......................... 1

009035 S/C LUBE, BOTTLED, VORT 3-PACK ......................... 1

2F369-014 S/C ASY, 2013 SCION FR-S .......................................... 1

4TF020-010 INSTR MAN, 2013 SCION FR-S BRZ ........................... 1

4TF110-044 MTG BRKT ASSY, 2013 SCION FR-S .......................... 1

4TF112-010 AIR INLET ASSY, 2013 SCION FR-S ............................ 1

4TF212-030 DISCH ASSY, 2013 SCION FR-S .................................. 1

8N101-354 CHARGE AIR COOLER, SCION FR-S ......................... 1

4TF218-014L ONLY INCLUDES BELOW ITEMS

5A001-130 TUNING KIT ASSEMBLY, ECUTEK .............................. 1

4TF212-030 DISCH ASSY, 2013 SCION FR-S .................................. 1

4TF010-160 TAB, PANL SUPPORT ........................................................................ 2

4TF010-170 BRACKET, TUBE D ............................................................................. 1

4TF010-180 MNT TAB, DISCH TUBE A .................................................................. 1

4TF012-060 DISCH TUBE B .................................................................................. 1

4TF112-030 DISCH TUBE A ASSY ......................................................................... 1

4TF112-040 DISCH TUBE C ASY ........................................................................... 1

4TF112-050 DISCH TUBE D ASSY ......................................................................... 1

5W001-032 1/4" PLASTIC WIRE LOOM ............................................................. 48"

5W001-095 1/8" HT-SHRINK TUBING ................................................................1.5'

5W022-020 22GA STRD WIRE,BLACK .................................................................4'

5W022-030 22GA STRD WIRE, RED ....................................................................4'

5W022-040 22GA STRD WIRE,GREEN ................................................................4'

5W022-060 22GA STRD WIRE, BLUE ...................................................................4'

5W022-250 22GA STRD WRE WH/BLU ................................................................4'

7A250-051 1/4-20 X .50 HHCS ............................................................................ 4

7C040-008 M4-.7X8MM SCHD SS ........................................................................ 2

7C060-013 M6 X 1.0 X 12MM FLG HD ................................................................ 2

7C060-016 M6 X 1.0 X 16 HXHD .......................................................................... 2

7C060-026 M6 X 1.0 X 25MM, FLG HD ................................................................ 4

7E014-075 #14 X .75 HEX HD SHEETMETAL SC ............................................... 4

7F006-093 NUT, M6 X 1.0, NYLOCK .................................................................... 7

7F106-080 NUT PLATE, 2X M6 ............................................................................ 1

7J006-093 6MM WASHER ...................................................................................11

PART NO. DESCRIPTION ..............................................QTY

4TF212-030 DISCH ASSY, 2013 SCION FR-S ......................... cont’d.

7J250-001 1/4 WASHER, SA ................................................................................ 4

7P375-156 3/8"X3/8"X5/32"MALE BARB TEE ...................................................... 1

7P375-378 VALVE, CHECK, 3/8 BARB X 3/8 ...................................................... 1

7PS251-250 SLEEVE, 2.5"D X 2.5"L STRAIGHT .................................................... 3

7PS251-300 SLEEVE, 2.5"D X 3"L BUMP .............................................................. 2

7PS300-250 REDUCER, BLK 3.0-2.50.................................................................... 1

7PS301-175 SLEEVE, 3"D X 1.75"L STRAIGHT ..................................................... 1

7R002-016 #16 SAE TYPE F SS HOSE CLAMP .................................................. 2

7R002-036 #36 SAE TYPE F SS HOSE CLAMP ................................................ 14

7R002-048 #48 SAE TYPE F SS HOSE CLAMP .................................................. 3

7R003-008 ADEL CLAMP, 1/2" ID ......................................................................... 1

7R004-002 STEPLESS CLAMP, 17.0-70 ............................................................... 2

7R009-012 CLAMP, SPRING, .75" ........................................................................ 2

7U030-046 5/32" VACUUM LINE ...........................................................................3'

7U034-016 1" GS HTER HOSE ......................................................................0.208'

7U314-004 LORD MOUNT, RUBBER M6 X 1" OD ............................................... 1

8D001-004 COMPRESS BYPASS VALVE, G2 ...................................................... 1

8H040-075 FILTER, 1" BYPASS VALVE ................................................................ 1

8N010-420 BRKT, CAC UPPER, RIGHT ............................................................... 1

8N010-430 BRKT, CAC UPPER, LEFT ................................................................. 1

7U030-056 3/8" HOSE .......................................................................................... 5"

7P375-156 3/8" X 5/32 TEE ................................................................................... 1

4TF112-010 AIR INLET ASSY, 2013 SCION FR-S .............................................. 1

008358 DECAL, INLET .................................................................................. 1

4TF010-070 BRACKET, LID .................................................................................. 1

4TF010-080 BRKT, AIR BOX MOUNT, LEFT ........................................................ 1

4TF010-090 BRKT, AIR BOX MOUNT, CENTER .................................................. 1

4TF010-121 BRKT, AIRBOX SPPRT ..................................................................... 1

4TF013-010 AIRBOX ............................................................................................. 1

4TF013-020 AIRBOX LID ...................................................................................... 1

4TF110-060 BULKHD ASSY ................................................................................. 1

4TF110-100 BRKT ASY, AIR BOX, RH ................................................................. 1

4TF110-130 ASY, PROP ROD RELOC BRKT ...................................................... 1

7C060-013 M6 X 1.0 X 12MM FLG HD ............................................................... 9

7C060-026 M6 X 1.0 X 25MM, FLG HD .............................................................. 1

P/N: 4TF020-010 v2.1, 05/14/2013

©2013 Vortech Engineering, Inc

All Rights Reserved, Intl. Copr. Secured

vi

Page 7

2013 SCION FR-S TUNER SYSTEM

Part No. 4TF218-014L / 4TF218-114L

IMPORTANT: Before beginning installation, verify that all parts are included in the kit. Report any shortages or damaged

parts immediately.

PART NO. DESCRIPTION ..............................................QTY

4TF112-010 AIR INLET ASSY, 2013 SCION FR-S ......................................cont’d.

7F006-093 NUT, M6 X 1.0, NYLOCK .................................................................. 3

7F106-080 NUT PLATE, 2X M6 .......................................................................... 2

7J006-093 6MM WASHER .................................................................................. 4

7J625-125 SHIM, .625" ID X .13" THK ............................................................... 2

7P500-001 1/2" HOSE UNION ............................................................................ 1

7P500-009 1/2" X 90 HOSE BARB UNION ......................................................... 1

7R002-056 #56 SAE TYPE F SS HOSE CLAMP ................................................ 1

7R002-080 #80 SAE TYPE F SS HOSE CLAMP ................................................ 1

7S500-351 INLET SLEEVE, 5 X 3.5 ................................................................... 1

7U008-010 Q-TURN FASTENER ........................................................................ 2

7U008-012 PLATE, Q-TURN FASTENER ........................................................... 2

7U008-014 RETAINER, Q-TRN FSTNR .............................................................. 2

7U030-050 12MM (1/2") FUEL HOSE ....................................................... 0.762M

7U100-004 RIVET, 3/16 X 3/16, ALUMINUM ...................................................... 2

7U100-006 RIVET, 1/8 X 3/16, ALUMINUM ........................................................ 4

7U100-065 GROMMET, .5"ID, .812"OD, .187" GRV ........................................... 1

7U188-375 TAPE, FOAM, 3/16" X 3/8" W ....................................................... 36"

8H040-050 AIR FILTER 3.5"FLG X 7"L ............................................................... 1

4TF110-044 MNTG BRKT ASSY, 2013 SCION FR-S .......................................... 1

2A017-462 SPACER,IDLER SMOOTH 6RIB ...................................................... 1

2A017-750-016 SPACER .75 OD X .328 ID X .160 ................................................... 2

2A046-975 BELT, K060975 .................................................................................. 1

4FA016-171 DUST COVER (IDLER PULLEY) ...................................................... 1

4FH016-150 IDLER PULY, SMOOTH 6RIB 3" FLG ............................................... 1

4TF010-011 BRKT, ALT TILT ................................................................................. 1

4TF010-021 PLATE, S/C MOUNT ......................................................................... 1

4TF010-031 STAY, MTG BRKT ............................................................................. 1

4TF010-041 MOUNT, BASE .................................................................................. 1

4TF010-050 STIFFENER, MTG PLT ..................................................................... 1

4TF017-011 BUSHING, ALT BRKT ....................................................................... 1

4TF017-021 SPACER, DUAL THRD ..................................................................... 1

4TF017-031 SPACER, MAIN BRKT ...................................................................... 2

PART NO. DESCRIPTION ..............................................QTY

4TF110-044 MNTG BRKT ASSY, 2013 SCION FR-S ................................. cont’d.

4TX016-150 IDLER, 2.75 DIA, SMOOTH, 7 RIB................................................... 1

7A312-124 5/16-18 X 1.25 FLG HD .................................................................... 2

7A312-500 5/16-18 X 5" HX HD .......................................................................... 1

7A375-127 3/8-16 X 1.25 SHCS.......................................................................... 1

7A375-129 3/8-16 X 1.25 FLG HD ...................................................................... 7

7C010-027 M10 X 1.25 X 25 FLG HD ................................................................. 1

7C010-059 M10 X 1.25 X 50 FLG HD ................................................................. 2

7C010-093 M10 X 1.25 X 90 FLG HD ................................................................. 2

7C012-040 M12 X 1.75 X 40 HXHD .................................................................... 1

7C060-020 M6 X 1.0 X 20MM HHCS ................................................................. 2

7C060-026 M6 X 1.0 X 25MM, FLG HD .............................................................. 2

7F312-017 5/16-18 NYLOCK NUT ...................................................................... 1

7J006-093 6MM WASHER, PLATED .................................................................. 4

7J312-875 5/16" WASHER, 7/8" OD, CUSTOM ................................................. 2

7U375-055 5/8" VACUUM CAP FOR .625 NIP ................................................... 1

4TF155-021 WASHER RESERVOIR ASY, SCION FR-S ...................................... 1

4CJ017-021 SPACER, COIL, .625" X .45" LO ...................................................... 1

4TF010-190 BRKT, WASHER RES, UPPER ........................................................ 1

4TF010-200 BRKT, WASHER RES, LOWER ........................................................ 1

4TF014-010 TUBE, 1.25" WASHER FILL PIPE .................................................... 1

4TF055-021 WASHER RES CAP, SCION FR-S ................................................... 1

4TF055-041 WASHER RESERVOIR, SCION FR-S .............................................. 1

7C060-013 M6 X 1.0 X 12MM FLG HD CL10.9+ ................................................ 3

7C060-026 M6 X 1.00 X 25MM FLG HD, PLATE ................................................ 1

7C080-022 M8 X 1.25 X 20 BHCS, PLTD ........................................................... 4

7F006-093 NUT, M6 X 1.0, NYLOCK, PLATED .................................................. 1

7F008-023 NUT, M8 X 1.25 NYLOCK NUT ........................................................ 4

7J250-001 1/4 WASHER, SAE, PLTD ................................................................ 1

7J312-000 5/16 FLAT WASHER-SAE ................................................................. 8

7R002-020 #20 SAE TYPE F SS HOSE CLAMP ................................................ 2

7U034-020 HOSE, 1.25 DIA RUBBER RAD. ...................................................... 4

PARTS LIST

CONTINUED

P/N: 4TF020-010 v2.1, 05/14/2013

©2013 Vortech Engineering, Inc

All Rights Reserved, Intl. Copr. Secured

vii

Page 8

1. SOFTWARE INSTALLATION

AND ECU RE-FLASH

(COMPLETE KITS ONLY. TUNER KITS SKIP AHEAD TO STEP 2)

NOTE: Prior to attempting to install any portion

of the supercharger system and re-flash

the ECU, it is important to confirm that

your vehicles’ ECU is supported by the

EcuTek components included in your kit

and to get any available updates. This will

require that you have a computer with an

internet connection so that you can

download and install the free EcuTek

software. A laptop is suggested, as you will

need to connect the computer to the

vehicles’ OBD2 port using the supplied

cable after the downloads have completed.

Please read through and understand this

step COMPLETELY before proceeding with

anything related to the installation.

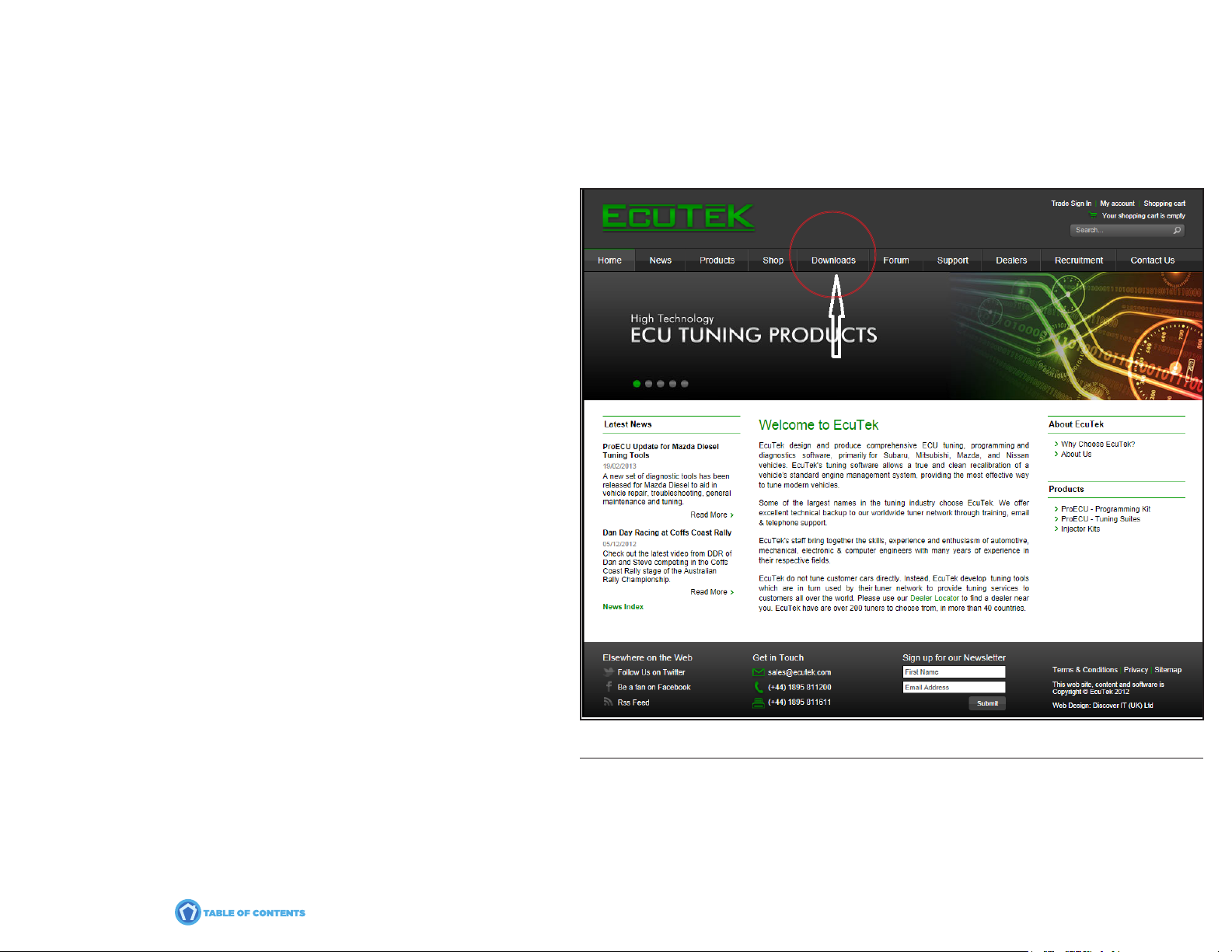

A. Visit the EcuTek Website: www.ecutek.

com. Click on the [Downloads] tab. See

arrow in Fig 1A.

P/N: 4TF020-010 v2.1, 05/14/2013

©2013 Vortech Engineering, Inc

All Rights Reserved, Intl. Copr. Secured

Fig. 1A

1

Page 9

B. After you have selected the [Downloads]

tab, select [EcuTek App Downloader] in

the next window. See arrow in fig 1B.

C. After you have selected [EcuTek App

Downloader], you will be prompted with

a new window. Select [Next] to continue.

Fig 1C.

Fig. 1B

P/N: 4TF020-010 v2.1, 05/14/2013

©2013 Vortech Engineering, Inc

All Rights Reserved, Intl. Copr. Secured

Fig. 1C

2

Page 10

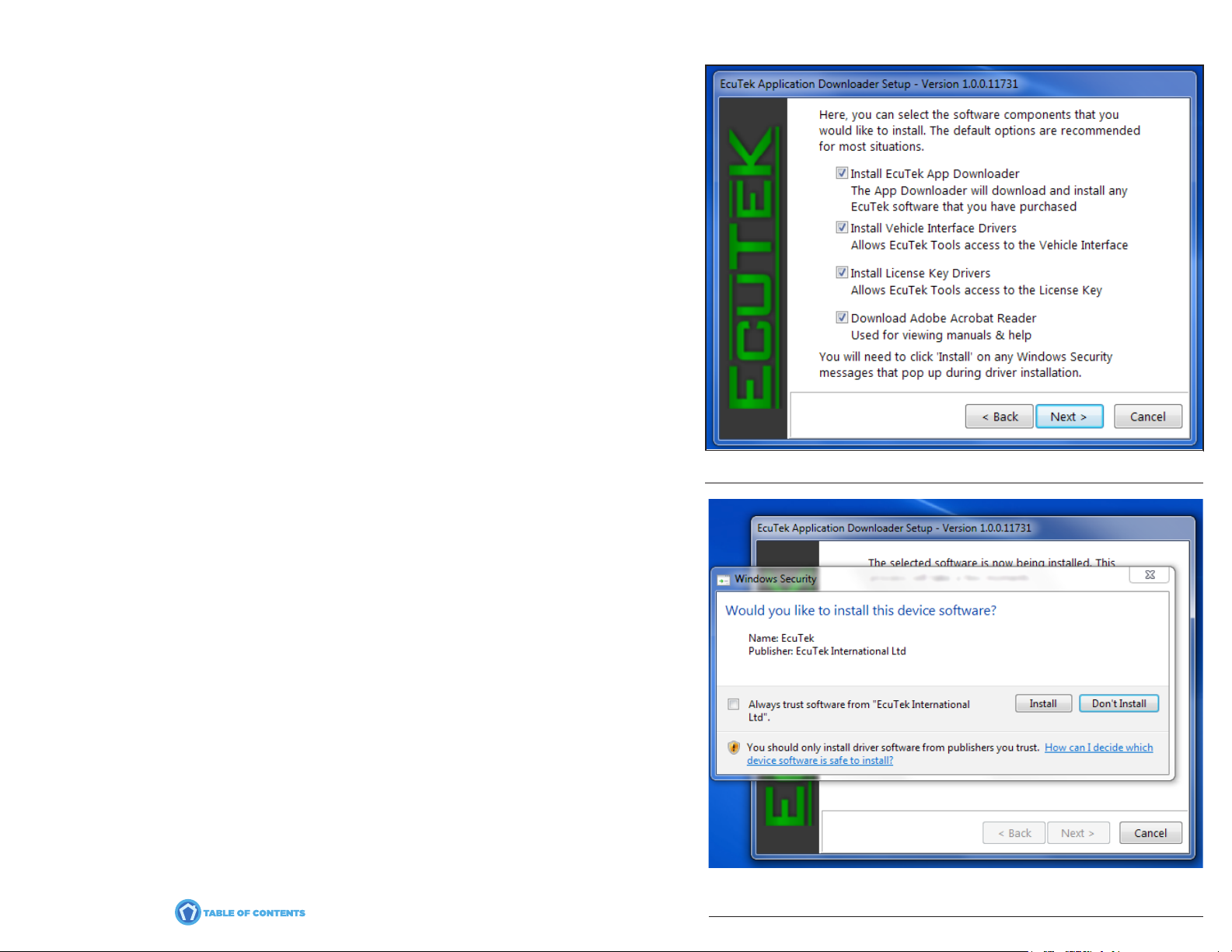

D. Next, you will be prompted to install the

necessary software and drivers. It is

recommended to use the default settings.

If you have Adobe Reader installed, you

can uncheck this part of the installation.

Select [Next] to continue. See Fig 1D.

E. It is recommended that you agree with

Windows security warnings if they appear

as shown below. Select [Install] to

continue. See Fig 1E.

Fig. 1D

P/N: 4TF020-010 v2.1, 05/14/2013

©2013 Vortech Engineering, Inc

All Rights Reserved, Intl. Copr. Secured

Fig. 1E

3

Page 11

F. Once you have installed the EcuTek

application and drivers, you will be

prompted to plug in the vehicle interface

cable. Select [Next] to continue.

See Fig 1F.

G. After selecting [Next], you will be

prompted to insert the license key.

See Fig. 1G

Fig. 1F

P/N: 4TF020-010 v2.1, 05/14/2013

©2013 Vortech Engineering, Inc

All Rights Reserved, Intl. Copr. Secured

Fig. 1G

4

Page 12

H. After the EcuTek license key has been

inserted, select [Next] to continue.

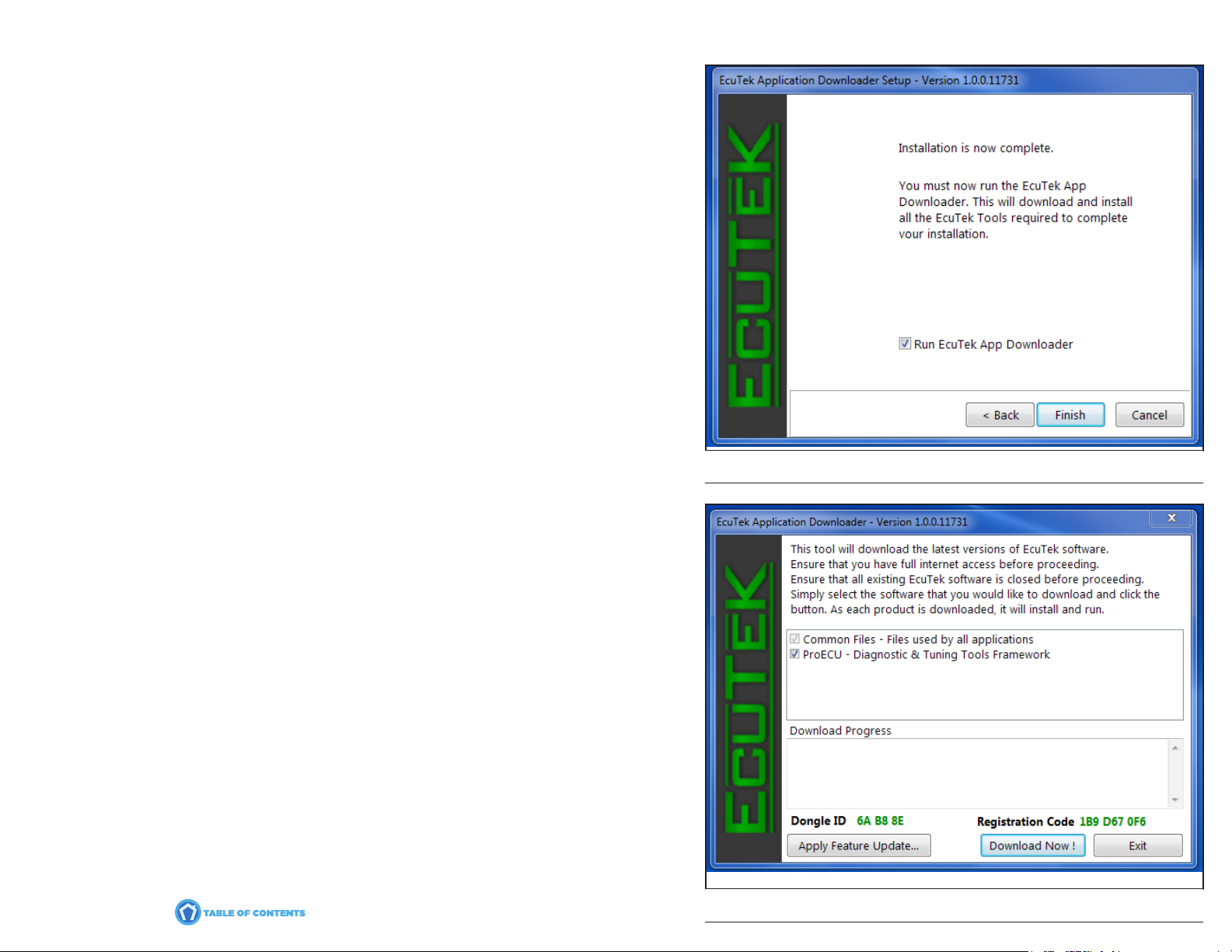

I. You will be prompted with “Installation is

now complete”. Select [Finish] to complete

the process. See Fig. 1I.

J. After selecting [Finish], you will be

prompted by a new window. Make note of

the Dongle ID and the Registration Code

shown on your screen. Keep this

information safe, for future reference.

See Fig. 1J.

Fig. 1I

P/N: 4TF020-010 v2.1, 05/14/2013

©2013 Vortech Engineering, Inc

All Rights Reserved, Intl. Copr. Secured

5

Fig. 1J

Page 13

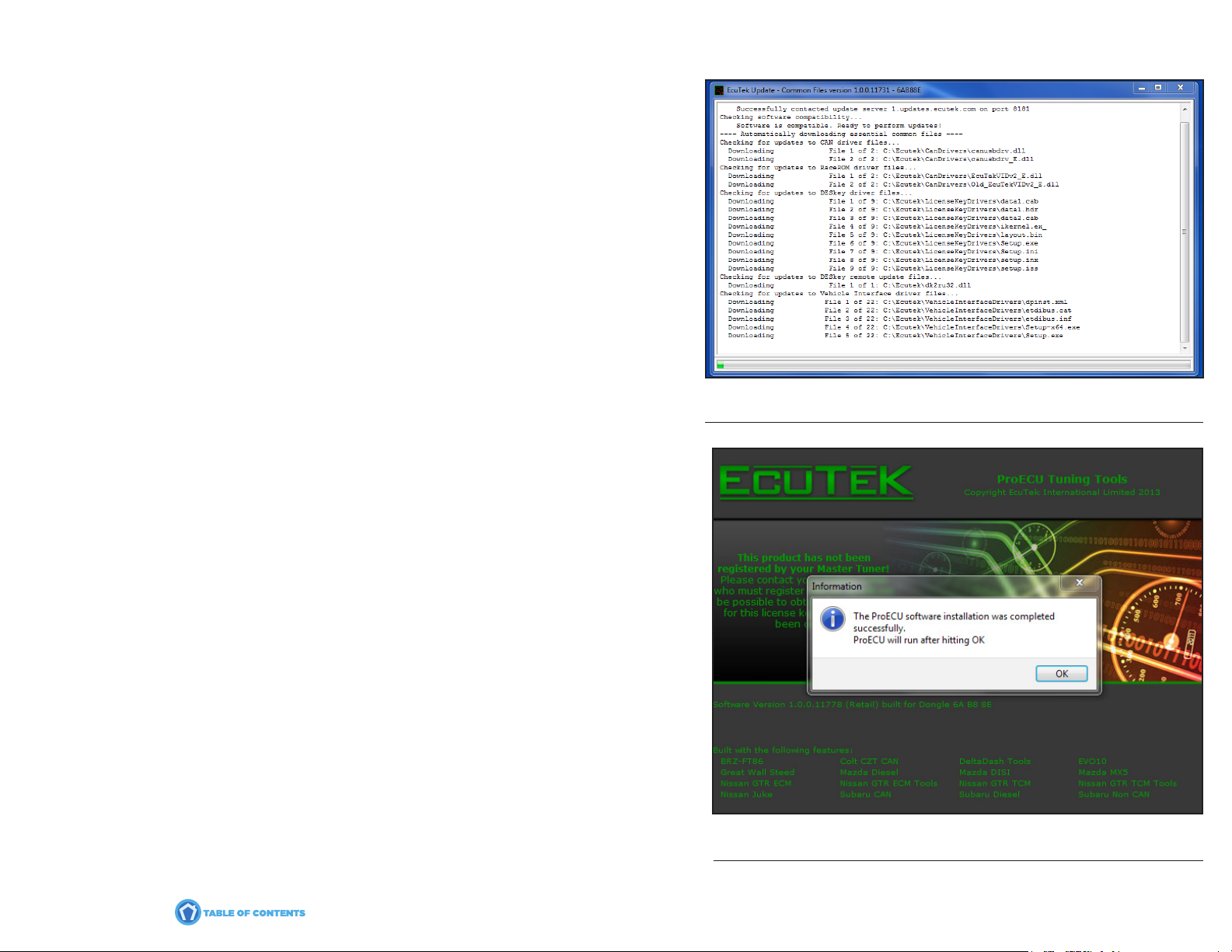

K. Select [Download Now!]. You will see a new window appear

that will show progress and details of what is being

downloaded. This can take a few minutes, so please be

patient. See Fig. 1K.

L. When the download has completed, you will be prompted

with a new window.

M. Select [OK] to continue. Installation of the EcuTek ProECU

software is now complete. See Fig. 1L

ECU re-flash:

NOTE: Programming an ECU is the process of taking a ROM file

and placing it into permanent storage inside the ECU. It is

highly recommended that all non-essential vehicle devices

are switched off before attempting to program an ECU. This

helps to minimize electrical interference to vehicle systems

that may conflict with communication between the EcuTek

components and the ECU. For devices within the car, this

includes: headlights, interior lights, A/C, HVAC fan and any

other powered devices.

Fig. 1K

N. Confirm that your laptop computer is booted up and the

EcuTek ProECU application is running. The laptop must be

plugged into a power source. Do not rely on the laptop

battery power.

O. Insert the supplied USB flash drive inth the laptop computer.

Copy and save the file located on the flash drive onto your

computer in the following folder location:

C:\EcuTek\ProECURomFiles\Subaru\BRZ

P. Plug the EcuTek OBD2 vehicle interface cable into the

vehicles OBD2 diagnostic socket. The socket is located

beneath the lower section of the dashboard just above the

drivers throttle pedal.

Q. Connect the other end of the EcuTek vehicle interface cable

to a USB port on the laptop computer.

R. ‘Key-On’ the vehicle ignition. DO NOT START the engine.

P/N: 4TF020-010 v2.1, 05/14/2013

©2013 Vortech Engineering, Inc

All Rights Reserved, Intl. Copr. Secured

Fig. 1L

6

Page 14

S. In the ProECU software menu bar (at the top of the window):

Select ‘Tools’, then > ‘Detect Vehicle’. A new window will appear

with ‘Program Engine ECU’ highlighted. Select [OK].

T. Select [Program ECU] in the following window. It will take a few

minutes for this process to complete. After programming the

ECU, follow the on-screen instructions to cycle the ignition ON,

OFF etc. It is important that this is done in sequence with the

appropriate time delays as directed.

U. The message ‘Programming Sequence completed’ should appear.

Select [Ok]. The re-flash step is now complete.

NOTE:

It is possible that you will come across an ECU version that

EcuTek has not seen. It will not be possible for you to program

this ECU until EcuTek has been supplied with certain information

about the specific ECU. The ‘Dump Details for EcuTek’ button

saves certain information from this ECU. The information is stored

in a file that will be saved into the ‘C:\EcuTek\RomDumps’ folder.

The name of the file will be displayed as it is saved.

This information should be sent to EcuTek using the Website

Form, together with a clear photograph of the ECU label and

details of the type of car (please include Model Year and Manual

or Auto gearbox) from which the ECU originates. EcuTek will then

supply an updated version of ProECU that will be capable of

programming the ECU. You will then need to send the new file

received from EcuTek over to Vortech with your Dongle ID and

License Key to have the revised calibration completed.

Please note that it is not something that can be done while-you-

wait. Turnaround time is likely to be 3 to 7 days for support of a

new ECU. It is therefore important for the tuner to check that the

ECU version is supported well before the car is scheduled to be

reprogrammed – this will avoid a panic situation for all parties

involved.

Please note that it is not possible to open ROM Dumps in ProECU

until the file has been emailed to EcuTek.

P/N: 4TF020-010 v2.1, 05/14/2013

©2013 Vortech Engineering, Inc

All Rights Reserved, Intl. Copr. Secured

7

Page 15

2. PREPARATION/REMOVAL

A. Place car on vehicle lift.

B. Raise hood and use appropriate fender covers for paint

protection.

C. Unpack the new accessory drive belt to let the “bends” relax. This

is best done in a warm room rather than a cold shop.

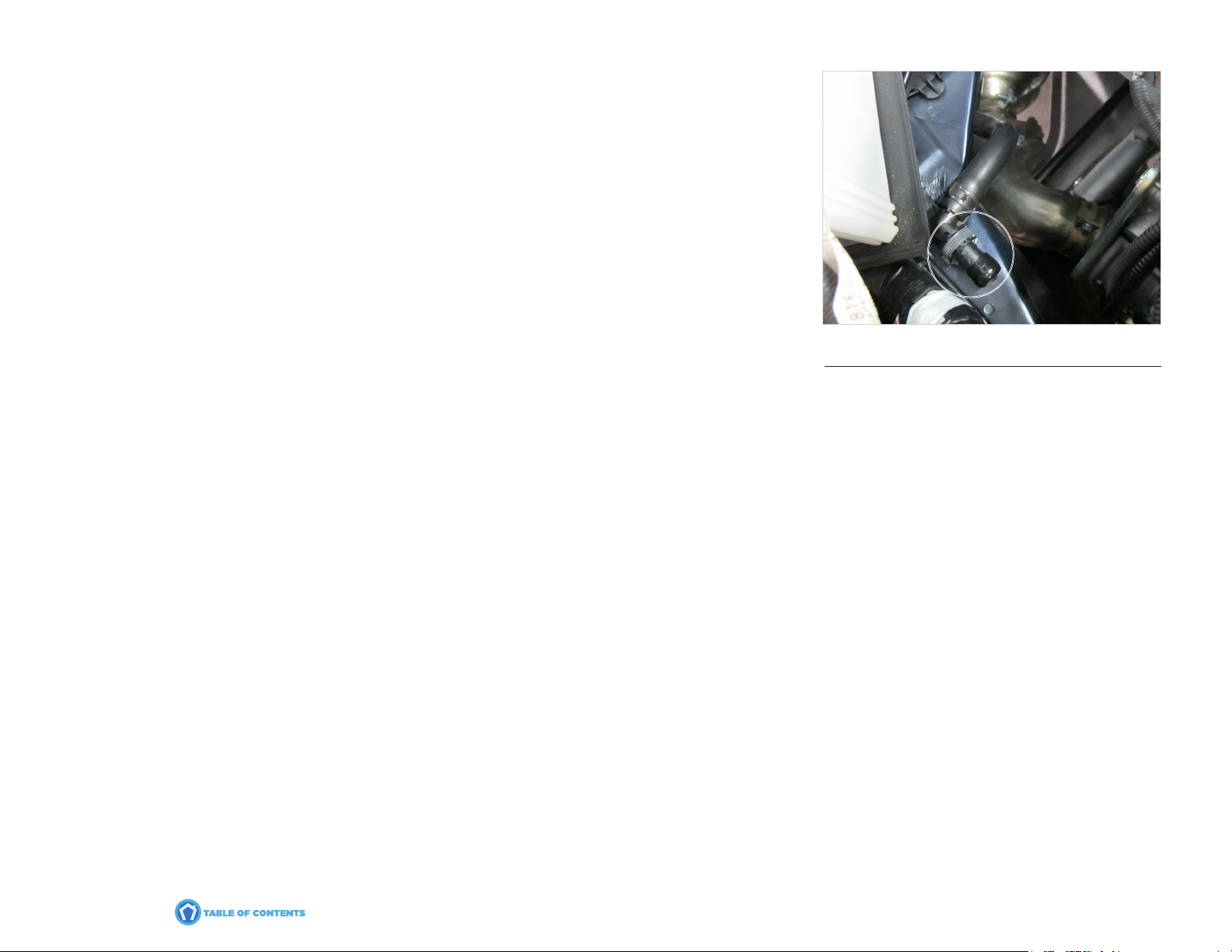

D. Locate the hose coming from the firewall that leads to the air filter

resonator system and disconnect at the first 90° fitting near the

firewall. Cap fitting with supplied 5/8” cap. See Fig. 2A.

E. Disconnect the opposite end at the resonator. Remove the entire

assembly from the vehicle, as it will no longer be used.

F. Disconnect the crankcase breather hose from the 90° plastic

fitting in the rubber air inlet duct.

G. Unplug the Mass Air Flow (MAF) connector from the MAF sensor

located on the air filter lid. Disconnect the rubber inlet duct from

the throttle and remove it with the air filter lid and set aside.

Unfasten the air filter box at the three mounts and remove.

Remove and save the rubber cushion mount assemblies and

hardware for reinstallation in a later step. The duct and other air

filter box components will not be reused.

Fig. 2A

H. Remove the plastic belt covers from both the alternator and the

A/C compressor. Set aside covers and mounting hardware for

re-installation in a future step.

I. De-tension the belt tensioner and remove the accessory drive belt.

The belt will not be used with the supercharger system.

P/N: 4TF020-010 v2.1, 05/14/2013

©2013 Vortech Engineering, Inc

All Rights Reserved, Intl. Copr. Secured

8

Page 16

Scion FR-S models only:

J. This procedure is to make room for the charge cooler ducts

to pass through. The connectors should be secured with

nylon tie-wraps after the modification has been made and

the ducts are in place.

K. Behind each headlight assembly, the main electrical connec-

tor lays in a cradle extending from the assembly.

L. Pull the connector from the assembly and place aside (do

not disconnect the connector).

M. With a one-inch drum grinder [in a drill or Dremel], remove

80-90% of the cradle. See Fig. 2B.

Fig. 2B

P/N: 4TF020-010 v2.1, 05/14/2013

©2013 Vortech Engineering, Inc

All Rights Reserved, Intl. Copr. Secured

9

Page 17

3. MOUNTING BRACKET AND

SUPERCHARGER INSTALLATION

A. Temporarily loosen the shorter mounting bolt on the out-

board side of the alternator. Remove the longer bolt on the

opposite side. Rotate the inboard side of the alternator

upwards. Modify (file or carefully grind) the OEM alternator

bracket boss. See Fig. 3A.

B. Place the supplied alternator tilt bracket into position.

See Fig. 3B.

C. Loosely reinstall the long OEM bolt in the upper position

through the new bracket, then the new 5/16” x 5” bolt with

thick washer provided into the lower position. Insert the supplied bushing into the rear of the lower tilt bracket hole.

Slide the remaining thick washer and nylon lock nut onto the

end of the 5/16” screw. After the alternator has been tilted

and all three bolts are lightly snug, torque the bolts per OEM

specification.

MODIFY BOSS AS SHOWN

Fig. 3A

P/N: 4TF020-010 v2.1, 05/14/2013

©2013 Vortech Engineering, Inc

All Rights Reserved, Intl. Copr. Secured

Fig. 3B

10

Page 18

D. Remove the two lower OEM A/C mount

bolts. Attach the mounting bracket support with the

provided M10 x 50mm bolts and secure as shown.

Note that the spacer is positioned toward the left side

of the support. See Fig. 3C.

E. Remove the grooved (1) and smooth (2) OEM idler

pulleys from the front engine cover and set aside.

See. Figs. 3D, 3E.

P/N: 4TF020-010 v2.1, 05/14/2013

©2013 Vortech Engineering, Inc

All Rights Reserved, Intl. Copr. Secured

Fig. 3C

IDLER PULLEY AND

HARDWARE REMOVED

11

Fig. 3D

IDLER PULLEY AND

HARDWARE REMOVED

Fig. 3E

Page 19

F. Replace the smooth idler located just above the crank

damper pulley with the supplied 2.75” diameter steel

pulley. Secure the pulley with the supplied M10 x 25mm

screw (for clearance purposes, do not re-use the OEM

screw). See Fig. 3F.

G. The supercharger assembly comes mounted to the

supercharger mounting plate with a smooth idler installed

along with a drain hose connected. There is a loose,

captured screw in one of the mounting plate holes as well.

See Figs. 3G, 3H.

REPLACEMENT IDLER AND SCREW

P/N: 4TF020-010 v2.1, 05/14/2013

©2013 Vortech Engineering, Inc

All Rights Reserved, Intl. Copr. Secured

Fig. 3F

M12 x 1.25 x 90 SCREWS

12

Fig. 3G

Fig. 3H

Page 20

H. Check over the supercharger bracket assembly for loose

fasteners and fittings. One of the fasteners will remain

captured, but loose (see previous photo). Place the two of

the previously removed OEM idlers back into their former

positions (smooth pulley below the A/C compressor and

grooved pulley beneath the alternator) without the dust

washers or screws. Temporarily place the two main bracket

spacers with the new M10-1.25x90 fasteners through the

idler pullies and into the mounting bosses loosely.

Temporarily hold the supercharger/plate assembly in front

of the engine and familiarize yourself with the relative

placement of the components. Using the belt routing guide

graphic and photo as a guide, route the belt around the

accessory pulleys as shown, leaving slack for the

supercharger and its attached smooth idler pulley.

See Figs. 3I, 3J.

P/N: 4TF020-010 v2.1, 05/14/2013

©2013 Vortech Engineering, Inc

All Rights Reserved, Intl. Copr. Secured

Fig. 3J

13

Fig. 3I

Page 21

I. Leaving the idler pulleys in place, remove

the main bracket spacers and bolts and

place them in position on the supercharger

mounting plate assembly with the M10 x

90mm bolts. Place the assembly on to the

engine, loosely route the belt around the

supercharger and idler pulleys (not the

alternator) and thread the 10mm bolts into

their pulley supports and lightly snug the

screws. Thread the 3/8 x 1.25” bolt into the

support located beneath the A/C clutch.

Loosely attach the mounting bracket

support onto the alternator tilt bracket with

the two 5/16 x 1.25” fasteners (lightly snug;

do not tighten). Thread the 3/8 x 1.25” bolt

(captured in the supercharger mounting

plate) into the end of the support and

tighten. See Figs. 3K, 3L, 3M.

3/8-16 x 1.25” SCREW

Fig. 3K

5/16-18 x 1.25” SCREWS

P/N: 4TF020-010 v2.1, 05/14/2013

©2013 Vortech Engineering, Inc

All Rights Reserved, Intl. Copr. Secured

14

Fig. 3L

3/8-16 x 1.25” SCREW

Fig. 3M

Page 22

J. Torque all mounting fasteners. Finish

installing the accessory drive belt by fully

retracting the tensioner and correctly

routing per the belt routing diagram. Note:

final installation of the belt is made easiest

by routing over the top of the alternator

pulley LAST. See Fig. 3N.

K. Remove the two OEM screws near the cam

covers as shown. See Fig. 3O.

L. Loosely attach the supplied steel mounting

plate stiffener behind the supercharger

mounting plate with the supplied M6x

25mm screws. Sandwich the supplied .16”

thick aluminum spacers (1 per hole) between

the other side of the stiffener bracket and

the threaded holes near the cam covers

with the M6 x 20mm long fasteners and

washers provided. Tighten hardware. See

Fig. 3P.

Fig. 3N

REMOVE TWO

OEM CAM COVER

SCREWS

Fig. 3O

P/N: 4TF020-010 v2.1, 05/14/2013

©2013 Vortech Engineering, Inc

All Rights Reserved, Intl. Copr. Secured

15

Fig. 3P

Page 23

M. Mount the supplied airbox support bracket

to the tab located on the driver side frame

rail using the supplied M6 x 12 screw. See

Fig. 3Q

N. Locate the supplied hood prop rod

relocation bracket assembly. See Figs. 3R

and 3S for final position. Temporarily locate

the bracket onto the fender mount flange

with the OEM prop rod inserted in the clip.

Using the bracket as a drill template, align

the assembly into the desired position for

best fit and mark where the mounting holes

are to be drilled into the fender mount

flange. Carefully drill two (2) 1⁄4” holes

through the flange. Remove sharp edges

from around the hole edges and mount the

hood prop rod relocation bracket assembly

as shown using the supplied M6 x 12 screws.

O. Locate the plastic OEM belt covers

previously removed from the A/C

compressor and alternator.

Fig. 3Q

P/N: 4TF020-010 v2.1, 05/14/2013

©2013 Vortech Engineering, Inc

All Rights Reserved, Intl. Copr. Secured

16

Fig. 3R

Fig. 3S

Page 24

P. Re-install the alternator cover using the

original hardware. The A/C cover will

require modification so as to clear the

supercharger and belt. Modify the cover and

re-install using the original hardware. See

Fig. 3T

Fig. 3T

P/N: 4TF020-010 v2.1, 05/14/2013

©2013 Vortech Engineering, Inc

All Rights Reserved, Intl. Copr. Secured

17

Page 25

4. CHARGE AIR COOLER

INSTALLATION

A. Raise the car and remove the lower plastic cover panels

from below the engine and front bumper cover. See Fig.

4A.

B. Using a round file, lengthen the three fastener slots in the

panel rearward about 1/8th of an inch (3mm), as the

panel sits in the car. See Fig. 4B.

C. Carefully remove the front bumper cover from the vehi-

cle (retain all hardware and note location of each screw

for future re-installation):

1. Remove four (4) fasteners each side attaching the inner

fender liner to edge of the front bumper cover. Remove

the fasteners securing each fender liner to the bottom

side of the bumper cover.

2. Reach up and un-plug the marker and fog light

connectors from behind the front bumper cover.

Fig. 4A

3. Carefully remove the marker lights (secured with 2

spring clips) from where each side of the fender meets

the bumper cover. Remove the fastener securing the

corner of the bumper cover to the fender.

4. Remove the hardware attaching the top edge of the

front bumper cover to the vehicle.

5. Ensure that all hardware securing the bottom portion

of the front bumper cover has been removed. Carefully

remove the front bumper cover and place it in a safe

location.

D. Remove the windshield washer fluid tank and filler.

P/N: 4TF020-010 v2.1, 05/14/2013

©2013 Vortech Engineering, Inc

All Rights Reserved, Intl. Copr. Secured

Fig. 4B

18

Page 26

E. Temporarily remove the two plastic side

panels from either side of the cooling air

feed cavity. These panels need to be modified to accommodate the CAC ducts. Find

the two (left and right-side) 1:1 paper templates in the back of this manual. Use the

templates to mark the modifications and

then, using heavy-duty shears, modify the

panels per the markups. Set aside. See Figs.

4C, 4D.

Fig. 4C

P/N: 4TF020-010 v2.1, 05/14/2013

©2013 Vortech Engineering, Inc

All Rights Reserved, Intl. Copr. Secured

Fig. 4D

19

Page 27

F. Remove the horn from in front of the A/C

condenser.

G. Flatten the OEM horn locating tab. See Figs.

4E, 4F, 4G.

Fig. 4E

P/N: 4TF020-010 v2.1, 05/14/2013

©2013 Vortech Engineering, Inc

All Rights Reserved, Intl. Copr. Secured

20

Fig. 4F

Fig. 4G

Page 28

H. Remove the OEM fastener as shown

(passenger side), and relocate the horn to

the newly “shared” position. Re-attach

connector. See Figs. 4H, 4I.

Fig. 4H

P/N: 4TF020-010 v2.1, 05/14/2013

©2013 Vortech Engineering, Inc

All Rights Reserved, Intl. Copr. Secured

Fig. 4I

21

Page 29

I. Temporarily remove the lower OEM 6mm

bolt from the center support then loosen

(do not remove) the two bolts at the top of

the support just below the radiator. See Fig.

4J.

J. Attach the supplied charge cooler upper

mounting brackets to the sides of the CAC

using the 1⁄4"-20 x 1⁄2" screws with washers.

Note left and right positions. Do not tighten

the screws at this time. See Figs. 4K, 4L.

Fig. 4J

P/N: 4TF020-010 v2.1, 05/14/2013

©2013 Vortech Engineering, Inc

All Rights Reserved, Intl. Copr. Secured

Fig. 4L Fig. 4K

22

Page 30

K. With the slot mount at the bottom rear of the

charge-cooler, temporarily lift the charge-cooler

into place. Have an assistant pull down on the OEM

support to allow the cooler to fit in place. Place the

slot mount on the CAC over the support upper

flange. Replace the lower bolt on the support. See

Fig. 4M.

L. On the top, outboard corners of the charge-cooler

are the upper mounting brackets. Carefully position

the cooler so as to be centered, and parallel with

the A/C condenser, then adjust the upper mounting

brackets (they are slotted for adjustment).

M. Mark the holes to be drilled for the upper mounts

into the bottom of the OEM bumper beam. Reverse

the process with the center support and remove

the charge-cooler. Center-punch the marks and drill

four 3/16” mounting holes into the OEM bumper

beam.

Fig. 4M

P/N: 4TF020-010 v2.1, 05/14/2013

©2013 Vortech Engineering, Inc

All Rights Reserved, Intl. Copr. Secured

23

Page 31

N. Again, lift the cooler into place and secure

with the four #14 hex-head self-tapping

fasteners provided. Secure the upper

mounting bracket fasteners and center

support. See Figs. 4N, 4O, 4P.

P/N: 4TF020-010 v2.1, 05/14/2013

©2013 Vortech Engineering, Inc

All Rights Reserved, Intl. Copr. Secured

Fig. 4N

24

Fig. 4O

Fig. 4P

Page 32

5. MAF HARNESS EXTENSION

NOTE:

Complete (non-tuner) kits include a

plug-and-play MAF extension harness

(Vortech p/n 5W001-094). Disregard the

following "cut and solder" portion of this

step if you have a MAF extension harness.

Simply plug the extension into the vehicle

harness and route down to the relocated

MAF module. Connect to the MAF module

and secure wires from sharp edges.

A. Locate the Mass Air Flow (MAF) sensor

harness previously attached to the airbox

cover. See Fig. 5A.

B. Carefully remove the electrical tape securing

the plastic split loom and expose the five

wires. See Fig. 5B.

Fig. 5A

C. Cut the five wires just above the shielding of

the white wire (approximately 2" from the

connector). Be sure to leave enough wire to

be stripped and soldered on each end. See

Fig. 5C.

P/N: 4TF020-010 v2.1, 05/14/2013

©2013 Vortech Engineering, Inc

All Rights Reserved, Intl. Copr. Secured

25

Fig. 5B

Fig. 5C

Page 33

D. Using the provided wires, solder wire

extensions onto the harness. Seal solder

joints with heat shrink tubing. See Fig. 5D.

E. Route the modified MAF under the throttle

body and under the intake manifold and

away from the alternator. See Fig. 5E.

F. Continue to route the harness and

connector over to the passenger side

headlight, and down behind the bumper

cover.

G. Secure the harness with nylon ties insuring

that the harness is away from hot or sharp

objects.

Fig. 5D

P/N: 4TF020-010 v2.1, 05/14/2013

©2013 Vortech Engineering, Inc

All Rights Reserved, Intl. Copr. Secured

Fig. 5E

26

Page 34

6. WINDSHIELD WASHER

RESERVOIR INSTALLATION

A. Locate the OEM windshield washer reservoir

assembly removed in a previous step.

B. Separate the filler neck, filler neck grommet,

washer pump and washer pump grommet

from the main tank. The tank will not be

re-used.

C. Cut the excess length from the filler neck.

Remove any plastic burrs from the cut edge.

Discard the portion no longer connected to

the cap end of the tube. See Fig. 6A, 5B.

D. Install the supplied length of Ø1.25” hose

onto the end of the filler neck and secure

with supplied #20 clamp. See. Fig. 6C.

P/N: 4TF020-010 v2.1, 05/14/2013

©2013 Vortech Engineering, Inc

All Rights Reserved, Intl. Copr. Secured

Fig. 6A

27

Fig. 6B

Fig. 6C

Page 35

E. Remove the OEM hood release cable

retainer from the chassis mounting hole.

See Fig. 6C.

F. Attach the modified filler neck and hose

to the vehicle. Use the supplied M6 x 12

screw with washer and nut to secure

the assembly into to the hole previously

occupied by the hood release cable.

Align as shown. See Fig. 6D.

SUBARU BRZ APPLICATIONS ONLY:

• Instead of the M6x12 screw, use

the supplied M6x25 screw and

.45" space between the filler neck

tab and chassis mount. See Fig.

6D-1.

• Use a file to lightly clearance

corner of headline housing as

shown See Fig. 6D-2.

HOOD LATCH

CABLE LOCATION

Fig. 6C

(SUBARU BRZ ONLY) Fig. 6D-1 (SUBARU BRZ ONLY) Fig. 6D-2

P/N: 4TF020-010 v2.1, 05/14/2013

©2013 Vortech Engineering, Inc

All Rights Reserved, Intl. Copr. Secured

Fig. 6D

28

Page 36

G. Insert the OEM filler neck grommet into the

1.43” hole in the supplied tank. Ensure that it

is seated properly. Apply a very small

amount of white grease or similar lube onto

the inside diameter of the grommet. Insert

the non-beaded end of the supplied metal

tube into the grommet just far enough until

the end starts to push through the grommet

on the inside of the tank. See Fig. 6E.

H. Using the supplied M8 screws, nuts and

washers, install the new mounting brackets

to the reservoir. See Fig. 6F.

I. Insert the OEM washer pump grommet into

the 1.37” hole in the supplied tank cap.

Ensure that it is seated properly. Apply a

very small amount of white grease or similar

lube onto the inside diameter of the

grommet. Insert the OEM washer pump into

the grommet until seated. Install the cap/

pump assembly onto the tank. Ensure that

the cap gasket is in place and the cap is

snug. Rotate the pump and orient as shown.

See Fig. 6G.

Fig. 6E

Fig. 6F

P/N: 4TF020-010 v2.1, 05/14/2013

©2013 Vortech Engineering, Inc

All Rights Reserved, Intl. Copr. Secured

29

Fig. 6G

Page 37

J. Drop the remaining #20 hose clamp over the metal tube.

Attach the new tank assembly to the vehicle using two of

the original chassis mount locations and the supplied

M6 x 16 screws. See Figs. [6H, 6I). As the assembly is being

installed, ensure that the metal filler tube is inserted into

the rubber filler hose. Secure the connection with the #20

hose clamp.

K. Re-attach the OEM washer hose and connector to the

washer pump. The pump wiring harness may need to be

separated from the main harness in order to get the

connector to reach the new pump location. Do this by

carefully opening up the plastic harness cover with a razor

blade. Be careful not to cut into any of the wire insulation.

Re-tape and cover the original harness.

L. Fill the reservoir with appropriate washer fluid until

the level can be seen in the filler neck.

Fig. 6H

P/N: 4TF020-010 v2.1, 05/14/2013

©2013 Vortech Engineering, Inc

All Rights Reserved, Intl. Copr. Secured

Fig. 6I

30

Page 38

7. CHARGE AIR COOLER TUBE

INSTALLATION

NOTE: On Subaru BRZ models, the passenger

side headlight must be removed in order

to properly install the charge cooler tubes.

A. Locate the supplied discharge tube 'B'

(simple 90 degree bend) and slide a 2-1/2"

silicone sleeve and pair of #36 clamps on

each end of the tube. Attach the long leg of

the tube to the driver side of the CAC.

Temporarily snug the clamps so the tube

does not fall out, but can still be moved

slightly. See Fig. 7A.

B. Locate the supplied discharge tube 'A' (with

welded 1” boss attached). From the top,

slide discharge tube 'A' behind the left

(driver side) headlight and into the sleeve

on discharge tube 'B'. Attach discharge tube

'A' to the supercharger with the “bump”

sleeve and #36 clamp provided. See Fig. 7B.

Fig. 7A

C. Secure tube 'A' to the previously installed

airbox support bracket using the #36 clamp,

mount tab, M6 screw, washers and nuts. See

Fig. 7C.

P/N: 4TF020-010 v2.1, 05/14/2013

©2013 Vortech Engineering, Inc

All Rights Reserved, Intl. Copr. Secured

Fig. 7B

Fig. 7C

31

Page 39

D. Locate the supplied discharge tube 'C' (MAF flange

attached) and OEM MAF module previously

removed. Ensure that the o-ring is intact on the MAF

module. Insert the MAF sensor module into the

flange and secure with the supplied M4 fasteners.

On the passenger side, connect discharge tube 'C'

to the CAC using the supplied 3” x 2-1/2” reducer

sleeve and clamps. Install a “bump” sleeve onto the

remaining open end of the tube after it is in place.

See Fig. 7D.

E. Attach the supplied mounting tab to the

supercharger mounting bracket using the screws

and nut plate. See Fig. 7E.

F. Thread the supplied rubber mount into tube 'D'. See

fig. 7F.

Fig. 7D

P/N: 4TF020-010 v2.1, 05/14/2013

©2013 Vortech Engineering, Inc

All Rights Reserved, Intl. Copr. Secured

Fig. 7E

Fig. 7F

32

Page 40

G. Install the supplied 3” dia. x 1.75” sleeve and #48

clamps onto the throttle body. Locate the supplied

discharge tube 'D'. Attach the tube between the

throttle body sleeve and the “bump” sleeve. The

stud on the rubber mount will mate with the

previously installed mounting tab. Adjust tube to

ensure adequate clearance to the drive belt. Install

the M6 locknut with washer onto the mount stud.

Tighten all clamps after all tubes have been

aligned and proper clearance adjustments have

been made throughout the charge tube route.

See Fig. 7G.

H. Re-install the two previously modified plastic OEM

side panels from into the cooling air feed cavity

into their OEM positions. Secure the bottom

portion of the panels to the CAC tubes using the

supplied mount tabs, M6 x 16 screws, nuts, washers

and clamps. See Figs. 7H, 7I.

Fig. 7G

I. Connect extended MAF harness connector to MAF

module on tube ‘C’.

J. Reinstall the headlight (if removed), bumper cover

and lower plastic cover panels.

P/N: 4TF020-010 v2.1, 05/14/2013

©2013 Vortech Engineering, Inc

All Rights Reserved, Intl. Copr. Secured

33

Fig. 7H

Fig. 7I

Page 41

8. COMPRESSOR BYPASS VALVE

INSTALLATION

A. Install the supplied compressor bypass valve

onto the 1” nipple on discharge tube A using

the short section of 1” hose provided. Secure

with #16 clamps. Attach 1” filter to open end of

bypass valve and secure. See Fig. 8A.

B. Attach the supplied length of 5/32” hose to the

small port on the bypass valve. Route the hose

over to where the OEM brake booster hose

attaches to the intake manifold.

C. MANUAL TRANSMISSION ONLY - Using the

supplied brass branch tee, splice into the brake

booster hose approximately 2” from where it

attaches to the manifold. Reconnect hose.

Attach 5/32” bypass hose to the open port in

the tee. See Fig. 8B.

D. AUTOMATIC TRANSMISSION ONLY - Remove

the OEM vaccum cap located at the top of the

intake manifold on the driver side. Attach the

supplied 5” length of 3/8” rubber hose to the

open manifold port. Insert one of the 3/8” legs

of the supplied tee into the hose and then cap

the remaining 3/8” leg on the tee with the OEM

cap previously removed. Attach the 5/32”

bypass hose to the open port in the tee. See

Fig. 8C.

Fig. 8A

(Manual transmission models only) Fig. 8B

P/N: 4TF020-010 v2.1, 05/14/2013

©2013 Vortech Engineering, Inc

All Rights Reserved, Intl. Copr. Secured

(Auto transmission models only) Fig. 8C

34

Page 42

9. PCV VALVE & MAP SENSOR

INSTALLATION

A. Locate the OEM breather hose connecting

the top on the intake manifold to the

passenger side of the engine.

B. Splice-in the supplied breather hose check

valve into the OEM hose. NOTE FLOW

DIRECTION on the valve (flow direction is

toward the intake manifold). Secure with

stepless clamps provided.

See Fig. 9A,9B, 9C.

C. COMPLETE (NON-TUNER) SYSTEMS ONLY:

Replace the OEM MAP Sensor with the

supplied unit. See Fig. 9D.

P/N: 4TF020-010 v2.1, 05/14/2013

©2013 Vortech Engineering, Inc

All Rights Reserved, Intl. Copr. Secured

35

Fig. 9A

Fig. 9B

Fig. 9C

Fig. 9D

Page 43

10. AIR INLET INSTALLATION

A. Locate the supplied airbox assembly and two of the rubber

cushion mount spacers and screws originally installed in the

OEM airbox.

B. Temporarily remove the steel inserts from the rubber cushion

mount spacers. Install the cushion mounts into the center of

the two supplied 5⁄8" ID spacers. See Fig. 9A.

C. Insert two of the rubber cushion mounts into the mounting

tabs attached to the supplied airbox assembly. See Fig. 9B.

D. Attach the supplied 5” x 3-1⁄2” rubber coupler to the inlet of

the supercharger. Loosely place one each of the supplied

#80 and #56 clamps onto the sleeve.

Fig. 10A

Fig. 10B

P/N: 4TF020-010 v2.1, 05/14/2013

©2013 Vortech Engineering, Inc

All Rights Reserved, Intl. Copr. Secured

36

Page 44

E. Install the airbox assembly onto the supercharger inlet and

vehicle. Align the airbox to the mounting holes, forward

facing inlet duct and previously installed airbox mounting

bracket. See Figs. 10C, 10D, 10E. Use two (2) of the OEM

screws to secure the airbox to the forward OEM mount

locations. Secure the tab located on the driver side using the

supplied M6 x 20 screw and nut.

F. Tighten hose clamps at supercharger interface.

Fig. 10C

Fig. 10D

P/N: 4TF020-010 v2.1, 05/14/2013

©2013 Vortech Engineering, Inc

All Rights Reserved, Intl. Copr. Secured

37

Fig. 10E

Page 45

G. Insert the supplied 1⁄2" hose union into the

end of the OEM breather hose. Attached

the supplied length of 1⁄2" breather hose

to the 1⁄2" hose union and route the hose

over to the 90° fitting located on the

rear of the airbox. Route the hose away

from sharp edges and moving objects.

Trim hose length if necessary. See Figs.

10F, 10G.

Fig. 10F

P/N: 4TF020-010 v2.1, 05/14/2013

©2013 Vortech Engineering, Inc

All Rights Reserved, Intl. Copr. Secured

Fig. 10G

38

Page 46

11. FINAL CHECK

WARNING: Do not attempt to operate the vehicle

until all components are installed and all operations

are completed including the final check.

A. If your vehicle has gone over 30,000 miles since its

last spark plug change, you will need to change the

spark plugs now before test driving the vehicle.

B. Check all fittings, nuts, bolts and clamps for

tightness. Pay particular attention to oil and fuel lines

around moving parts, sharp edges, and exhaust

system parts. Make sure all wires and lines are

properly secured with clamps or tie-wraps.

C. Check all fluid levels, making sure that your tank is

filled with 91 octane or higher fuel before

commencing test drive.

D. Start the engine and allow to idle a few minutes, then

shut off.

E. Recheck to be sure that no hoses, wires, etc. are near

exhaust headers or moving parts. Look also for any

signs of fluid leakage.

F. PLEASE TAKE SPECIAL NOTE: Operating the vehicle

without ALL of the subassemblies completely and

properly installed may cause FAILURE OF MAJOR

COMPONENTS.

G. Test drive the vehicle.

H. Always listen carefully for engine detonation.

Discontinue heavy throttle usage if detonation is

heard.

For internally lubricated V3 units only

This supercharger has been factory pre-lled with special

Vortech synthetic lubricant. Oil does not need to be added

to a brand new unit, however a uid level check should be

performed.

Prior to operating the supercharger on the vehicle and after

installation onto the vehicle:

Remove the factory installed at-head brass shipping plug

(not the dipstick) from the top of the supercharger case.

Replace the sealed shipping plug with the supplied vented

plug. Do not operate the supercharger without it. Check the

supercharger uid level using the dipstick as follows:

Fluid level checking procedure:

1. Ensure that the .06” copper sealing washer

is located on the dipstick base.

2. Thread the clean dipstick into the unit until

it seats.

3. Once the dipstick has seated, remove the

dipstick from the unit. Fluid should register

in the crosshatched area on the dipstick.

4. DO NOT OVERFILL!!! Drain excess uid from

the unit if it is above the maximum level on

the dipstick.

Check the uid level using the dipstick at least every 2,500

miles.

Initial supercharger uid change must be performed at 2,500

miles. The supercharger uid must be changed every 7,500

miles maximum thereafter.

Drain the uid, rell the unit with 4 oz. of Vortech V3

lubricating uid, and then conrm proper oil level using the

dipstick. DO NOT OVERFILL!!!

I. Read the STREET SUPERCHARGER SYSTEM

OWNER'S MANUAL AND RETURN THE WARRANTY

REGISTRATION FORM within thirty (30) days of

purchasing your supercharger system to qualify.

P/N: 4TF020-010 v2.1, 05/14/2013

©2013 Vortech Engineering, Inc

All Rights Reserved, Intl. Copr. Secured

WARNING: Use of any uid other than the special

Vortech lubricant will void the warranty and may

cause component failure

39

Page 47

12. APPENDIX

P/N: 4TF020-010 v2.1, 05/14/2013

©2013 Vortech Engineering, Inc

All Rights Reserved, Intl. Copr. Secured

40

Page 48

P/N: 4TF020-010 v2.1, 05/14/2013

©2013 Vortech Engineering, Inc

All Rights Reserved, Intl. Copr. Secured

41

Page 49

1650 Pacific Avenue, Channel Islands, CA., 93033-9901 • Phone: 805 247-0226 • Fax: 805 247-0669 • vortechsuperchargers.com • M-F 7:00AM - 3:30PM (PST)

Loading...

Loading...