Page 1

2007-2009 FORD GT500 OEM POWER PACK UPGRADE

®

Installation Instructions

2007-2009 FORD GT500

P/N: 8E023-265

ENGINEERING, LLC

1650 Pacific Avenue, Channel Islands, CA 93033-9901 • Phone 805 247-0226

Fax: 805 247-0669 • www.vortechsuperchargers.com • M-F 8:00 AM - 4:30 PM (PST)

Page 2

FOREWORD

STOP

This manual provides information on the installation, maintenance and service of the

Vortech supercharger kit expressly designed for this vehicle. All information, illustrations

and specifications contained herein are based on the latest product information available at

the time of this publication. Changes to the manual may be made at any time without

notice. Contact Vortech Engineering for any additional information regarding this kit and

any of these modifications at (805) 247-0226 8:00am-4:30pm PST.

Take note of the following before proceeding:

1. Proper installation of this supercharger kit requires general automo-

tive mechanic knowledge and experience. Please browse through each

step of this instruction manual prior to beginning the installation to determine if you should refer the job to a professional installer/technician.

Please contact your dealer or Vortech Engineering for possible installers

in your area.

2. This product was designed for use on stock (unmodified, OEM)

vehicles. The PCM (computer), engine, transmission, drive axle

ratios and tire O.D. must be stock. If the vehicle or engine has been modi-

fied in any way, check with Vortech prior to installation and use of this product.

3. Use only premium grade fuel with a minimum of 91 octane (R+M/2).

4. Always listen for any sign of detonatlion (knocking/pinging) and discontinue hard

use (no boost) until the problem is resolved.

5. Vortech is not responsible for any clutch, transmission, drive-line or engine damage.

Exclusions from Vortech warranty coverage considerations

include, but not limited to:

1. Neglect, abuse, lack of maintenance, abnormal operation or improper installation.

2. Continued operation with an impaired vehicle or sub-system.

3. The combined use of Vortech components with other modifications such as, but

not limited to, exhaust headers, aftermarket camshafts, nitrous oxide, third party

PCM programming or other such changes.

DP/N: 007125v1.0

© 2010 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured.

27AUG2010 GT500 OEM POWER PACK

©2010 VORTECH ENGINEERING, LLC

All rights reserved. No part of this publication may be reproduced, transmitted, transcribed, or translated into

another language in any form, by any means without written permission of Vortech Engineering, LLC.

ii

Page 3

TABLE OF CONTENTS

FOREWORD ..............................................................i

TABLE OF CONTENTS ....................................................ii

TOOL & SUPPLY REQUIREMENTS ....................................... iii

PARTS LIST OEM POWER PACK (8E023-265) ............................. iv

1. OEM SUPERCHARGER PULLEY REMOVAL .................................1

2. NEW SUPERCHARGER PULLEY INSTALLATION ............................5

3. AUXILIARY IDLER PULLEY INSTALLATION .................................7

4. OEM AIR BOX/AFTERMARKET CAI REMOVAL ..............................9

5. POWER PACK CAI INSTALLATION .......................................12

6. REFLASH COMPUTER .................................................15

7. FINAL CHECK ........................................................20

© 2010 Vortech Engineering, LLC

iiii

All Rights Reserved, Intl. Copr. Secured.

27AUG2010 GT500 OEM POWER PACK

DP/N: 007125v1.0

Page 4

VORTECH OEM POWER PACK UPGRADE

Installation Instructions

2007-2009 FORD GT500

Before beginning this installation,

please read through this entire instruction booklet

The Vortech 2007-2009 FORD GT500 OEM Power Pack upgrade was designed specifically for use on 2007-2009 Ford Mustang Shelby GT500 vehicles equipped with the

OEM supercharger to support applications with increased horsepower over the OEM

design. As with any power enhancing product, this unit is intended for use on healthy,

well-maintained engines. Vortech Engineering is not responsible for engine damage.

Installation on new vehicles will not harm or adversely affect the break-in period so long

as factory break-in procedures are followed.

For best performance and continued durability, please take a note of the following key

points:

1. Use only premium grade fuel 91 octane or higher (R+M/2).

2. Always listen for any sign of detonation (pinging) and discontinue hard use (no

boost) until problem is resolved.

TOOL & SUPPLY REQUIREMENTS:

• 15/16” wench

• 9/16” wrench

• 8mm socket, 1/4” drive

• 10mm socket, 1/4” drive

• 13mm socket, 1/4” drive

• 15/16” socket, 1/2” drive

• 19mm socket, 1/2” drive

• 1/4” drive ratchet

• 1/4” drive, 3” extension

• 3/8” drive breaker bar

• 1/2” drive breaker bar

• 5/32” Allen

• 2.5mm Allen

• 5mm Allen

• 5/16 Nut Driver

• Flat screw driver or upholstery tool

• Moly-based grease

• Utility Knife

DP/N: 007125v1.0

© 2010 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured.

27AUG2010 GT500 OEM POWER PACK

iiiiii

Page 5

2007-2009 FORD GT500

OEM POWER PACK UPGRADE

Part No. 8E023-265

PARTS LIST

IMPORTANT: Before beginning installation, verify that all parts are included in the kit.

Report any shortages or damaged parts immediately.

PART NO. DESCRIPTION QTY

007125 POWER PACK INSTRUCTION MAN 1

2L031-265-02 PULLEY, GT500 2.65" OEM REPL 1

4LFR110-031 AUX IDLER ASSY, 07-09 GT500 1

2A017-753-03 SPACER, PILOT, .750 OD X 1.650 3

4FD017-011 PILOT, 6203/5 BRG, 1/2 SCREW 1

4LFR010-031 PLATE, AUX IDLER, GT500VTS 1

4LFR017-011 SPACER, ADJ IDLER, 07-09 GT500 1

4LFR116-011 IDLER ASSY, SMOOTH, 10-RIB, 3.50 1

7C012-065 M12 X 1.75 X 65MM HX 1

7C060-091 M6 X 1.0 X 90MM SHCS PLT GR12. 3

7G012-175 MACH NUT, COG DRV, SPECIAL 1

7J006-093 6MM WASHER, PLATED 3

4LFR212-020 CAI ACCESSORY KIT, GT500 1

4LFR010-020 HEAT SHIELD, AIR FILTER, GT500 1

4LFR112-020 INTAKE AIR TUBE ASSY, GT500 1

7PS500-300 SLEEVE, Ø5.0 X 3.0, 3-PLY, MAT 2

7R002-080 #80 SAE TYPE F SS HOSE CLAMP 4

7U030-046 5/32" VACUUM LINE 2

8A003-111 MAF HSG, 07-10 GT500, 123MM 1

8H040-600 AIR FILTER, 6" FLANGE X 9" LONG 1

5A003-062 SCT TUNER, GT500 UPGRADE KIT 1

TL0336 TOOL SET, GT500 OEM PULLEY 1

7A375-651 3/8-16 X 6-1/2 HX GR8 2

7C080-031 M8 X 1.25 X 30MM SET SCREW 1

7F625-001 5/8"-18, NYLOC-NUT 1

7J375-044 3/8 SAE WASHER, PLTD 2

7J625-001 5/8", SAE, FLAT WASHER 1

7T001-001 1/2" STEEL PULLER 1

7T001-002 1.250" SOLID SQUARE SUPPORT BL 1

7T625-001 5/8" THRUST BEARING 1

7T625-002 MODIFIED 5/8-18 SCREW EXT THD, 1

© 2010 Vortech Engineering, LLC

iv

All Rights Reserved, Intl. Copr. Secured.

27AUG2010 GT500 OEM POWER PACK

DP/N: 007125v1.0

Page 6

1. OEM SUPERCHARGER PULLEY REMOVAL

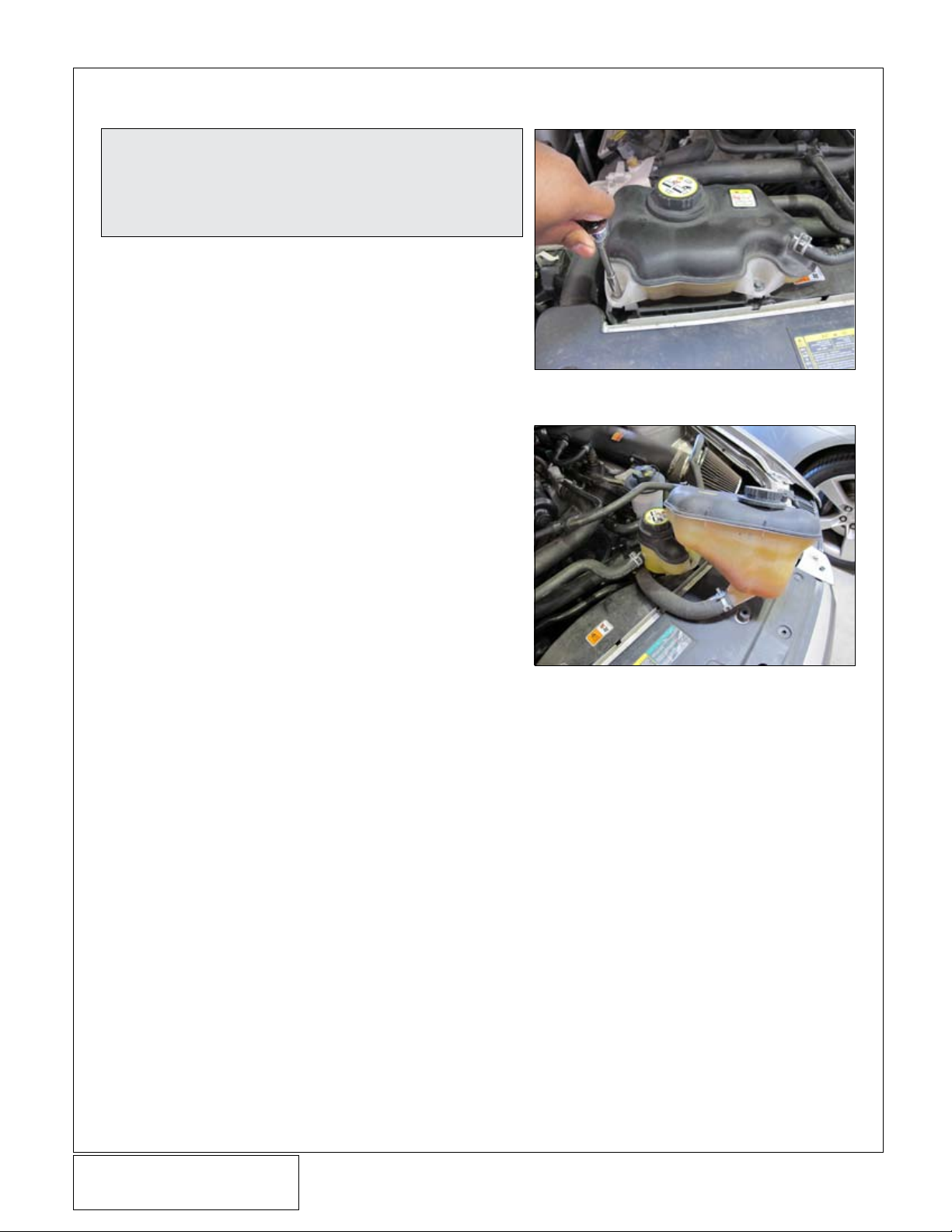

NOTE: It is best to attempt to remove the pulley only

after the vehicle has been allowed to cool down,

preferably overnight. It is also much easier to

remove the pulley in the morning when all the

metals are still cold.

A. Disconnect the negative battery cable.

B. Remove the two screws securing the de-gas bot-

tle to the vehicle with a 10mm socket (See Figure

1-a)

C. Temporarily relocate the de-gas bottle as shown

to gain access to the serpentine belt tensioner

and supercharger pulley. (See Figure 1-b)

Fig. 1-a

Fig. 1-b

DP/N: 007125v1.0

© 2010 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured.

27AUG2010 GT500 OEM POWER PACK

1

Page 7

1. OEM SUPERCHARGER PULLEY REMOVAL, CONT’D

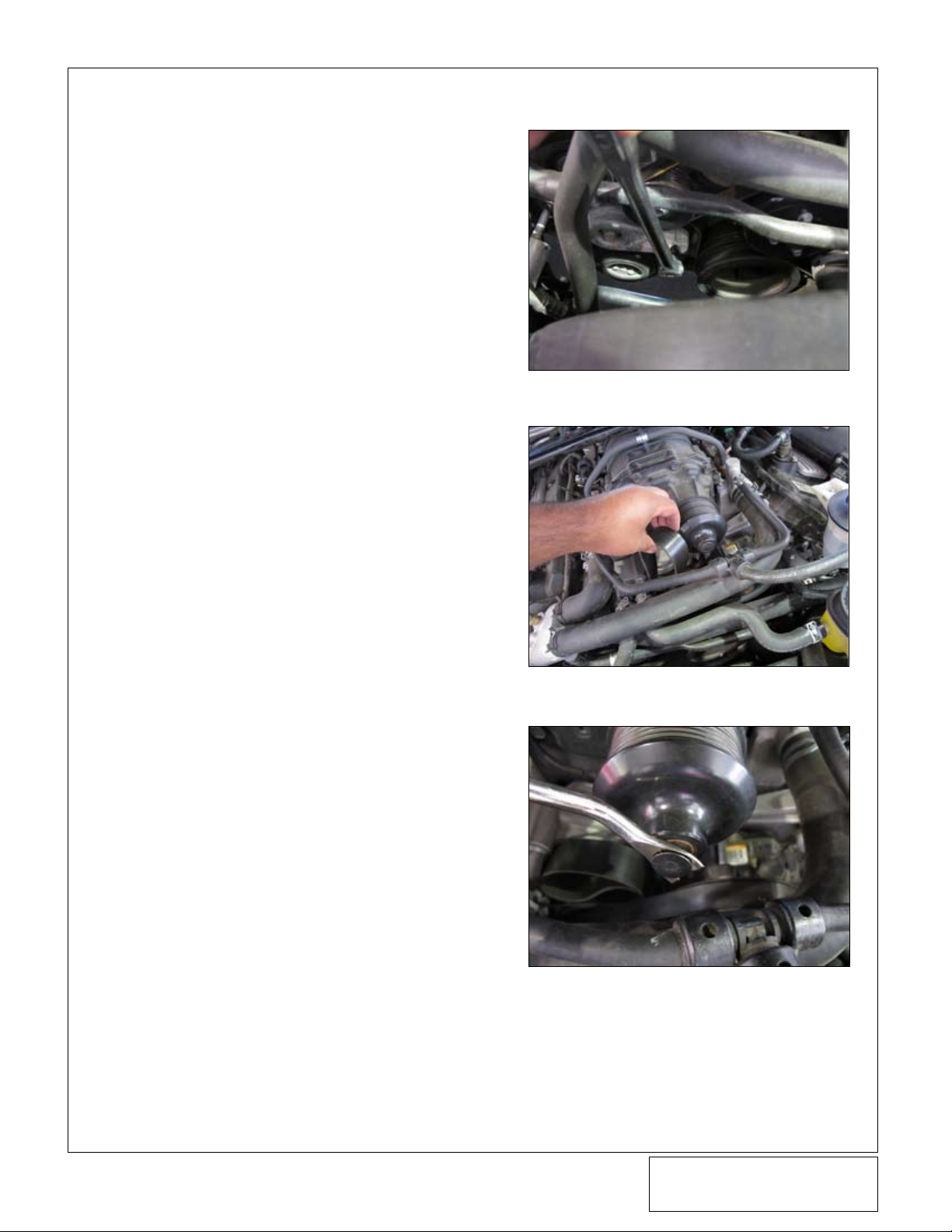

D. Using a 3/8” drive breaker bar on the tensioner,

remove the serpentine belt from the supercharger

pulley. (See Figure 1-c & 1-d)

E. The center plug on the supercharger will need to

be removed so as not to damage it when removing or installing the pulley. Using a flat screw driver

or upholstery tool, pry the plug off the supercharger snout. (See Figure 1-e)

Fig. 1-c

Fig. 1-d

Fig. 1-e

© 2010 Vortech Engineering, LLC

2

All Rights Reserved, Intl. Copr. Secured.

27AUG2010 GT500 OEM POWER PACK

DP/N: 007125v1.0

Page 8

1. OEM SUPERCHARGER PULLEY REMOVAL, CONT’D

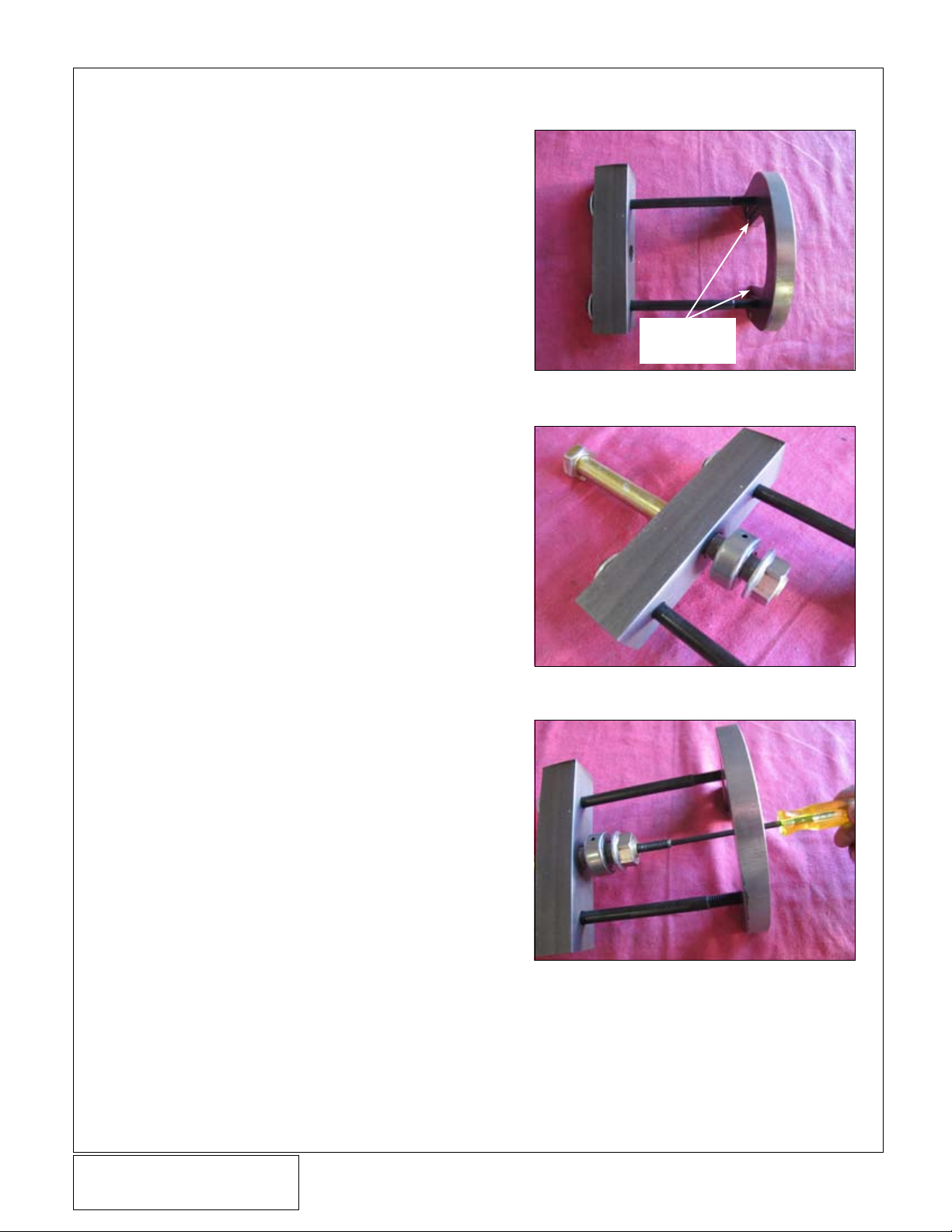

F. Pre-assemble the supplied tool as shown. Insert

the two 3/8”x6-1/2" screws with washers through

the outer holes of the pulley removal bar and

thread them evenly into the pulley removal plate.

Be sure the two 3/8” bolts are exactly flush to the

back of the pulley removal plate. It is very important that the pulley removal plate and the pulley

removal bar are evenly spaced. (See Figure 1-f)

G. At this time you will need to lightly apply anti-sieze

or moly grease to the threads of the 5/8” screw

and light oil into the thrust bearing. Then insert the

screw through the center hole of the pulley removal bar.

H. Assemble the thrust bearing with the free rolling

face towards the pulley removal bar, and install

the supplied 5/8” nut with the flange surface

towards the back of the thrust bearing. (See

Figure 1-g)

I. Apply loctite onto the supplied M8 set screw and

thread it into the center of the 5/8” screw. Tighten

the set screw. This will aid in keeping the tool centered on the supercharger pulley shaft. (See

Figure 1-h)

Step in plate must

face as shown

Fig. 1-f

Fig. 1-g

Fig. 1-h

DP/N: 007125v1.0

© 2010 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured.

27AUG2010 GT500 OEM POWER PACK

3

Page 9

1. OEM SUPERCHARGER PULLEY REMOVAL, CONT’D

J. Install the tool assembly onto the supercharger

pulley, with the back side of the OE pulley nested

into the step in the removal plate. (See Figure 1-i)

NOTE: Instead of an open end wrench, we recommend

installing a boxed end wrench on the flanged nut

to apply the torque more evenly and ensure the

wrench will not round the nut corners. Slide the

box wrench over the nut.

K. Rotate the 5/8" screw clockwise so that the M8

set screw will thread into the end of the supercharger shaft. Snug (do not tighten) the screw into

the supercharger shaft.

L. Using either a 15/16” socket on a breaker bar or a

boxed wrench, hold the end of the 5/8” screw from

turning while using the other wrench to turn the

flanged nut to pull the pulley off.

NOTE: Removing the OEM pulley only after the engine

has been allowed to cool overnight will allow the

pulley to effectively “break loose” from the shaft

and produce a “POP” sound when it becomes

free.

Fig. 1-i

M. Listen for the “POP” to alert you that the pulley

has broken free, it will become easier to turn the

nut at this point and you should see the pulley

coming off. (See Figure 1-j)

Fig. 1-j

© 2010 Vortech Engineering, LLC

4

All Rights Reserved, Intl. Copr. Secured.

27AUG2010 GT500 OEM POWER PACK

DP/N: 007125v1.0

Page 10

2. NEW SUPERCHARGER PULLEY INSTALLATION

A. Once the OEM pulley has been removed, remove

the tool from the pulley and shaft. Reconfigure the

tool as shown to install the new pulley. Ensure

that the free rolling face of the thrust bearing is

facing the flanged nut, and not the pulley and

washer. (See Figure 2-a)

B. If needed, apply more lubricant to the threads of

the 5/8” screw and the bearing.

C. Insert the tool through the new pulley as shown

D. Thread the install tool into the center threaded

hole of the supercharger until the 5/8” screw seats

against the supercharger shaft. (See Figure 2-b &

2-c)

Fig. 2-a

Fig. 2-b

Fig. 2-c (pulley shown installed for clarity)

DP/N: 007125v1.0

© 2010 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured.

27AUG2010 GT500 OEM POWER PACK

5

Page 11

2. NEW SUPERCHARGER PULLEY INSTALLATION, CONT’D

E. Using the 15/16” wrenches/sockets, slowly drive

the new pulley onto the supercharger until the

washer seats the new pulley flush to the supercharger pulley shaft. You will know it is flush when

the new pulley will not go in any further. (See

Figure 2-d)

F. Verify the new pulley is flush to the supercharger

pulley shaft as shown. (See Figure 2-e)

G. Re-insert the plastic cap into the supercharger

pulley shaft.

Fig. 2-d

Fig. 2-e

© 2010 Vortech Engineering, LLC

6

All Rights Reserved, Intl. Copr. Secured.

27AUG2010 GT500 OEM POWER PACK

DP/N: 007125v1.0

Page 12

3. AUXILIARY IDLER PULLEY INSTALLATION

A. Remove the three screws securing the OEM

Charge Air Cooler (CAC) water manifold to the

lower manifold using an 8mm socket (See Figure

3-a)

B. Assemble the supplied Auxiliary Idler Pulley in the

sequence as follows:

1: Install the pilot spacer onto the M12 screw

with the smaller diameter facing away from the

head of the screw as shown (See Figure 3-b)

2: Insert the M12 bolt with pilot spacer through

the idler. Ensure that the snap ring inside the idler

is facing away from the head of the screw. (See

Figure 3-c)

3: Insert the idler spacer with the conical face

into the idler assembly (See Figure 3-c)

4: Insert the custom machined nut into the slot

in the bracket from the counter-bored hole side,

then thread the idler assembly from the opposite

side into the machined nut. DO NOT TIGHTEN

IDLER PULLEY AT THIS TIME. (See Figure 3-d)

5: Install the 1.65” long spacers into the coun-

ter-bored holes on the bracket. (See Figure 3-d)

6: Insert the three M6 screws with washers

through the bracket, from the idler assembly side.

Fig. 3-a

Fig. 3-d

Fig. 3-b

Fig. 3-c

DP/N: 007125v1.0

© 2010 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured.

27AUG2010 GT500 OEM POWER PACK

7

Page 13

3. AUXILIARY IDLER PULLEY INSTALLATION, CONT'D

C. Lower idler assembly below the supercharger

snout and mount onto the previously removed

water manifold screws. Use a 5mm Allen key to

tighten the screws. (See Figure 3-e & 3-f)

D. Have an assistant pry the belt tensioner to install

the belt. While the assistant holds the tensioner,

adjust the idler pulley so that the belt runs parallel

with in ¼” of itself under the supercharger pulley.

Tighten the M12 bolt using a 19mm Socket. (See

Figure 3-g)

Fig. 3-e

Fig. 3-f

Fig. 3-g

© 2010 Vortech Engineering, LLC

8

All Rights Reserved, Intl. Copr. Secured.

27AUG2010 GT500 OEM POWER PACK

DP/N: 007125v1.0

Page 14

4. OEM AIR BOX/AFTERMARKET CAI REMOVAL

A. Remove the four nuts securing the factory

installed strut tower brace using a 13mm socket.

(See Figure 4-a) Remove the factory strut brace

as it will not be reinstalled since it would interfere

with the Power Pack CAI Kit. Re-install the four

nuts and tighten.

B. Using a 5/16” nut driver, loosen the hose clamp at

the throttle body and air box or filter assembly.

(See Figure 4-b & 4-c)

Fig. 4-a

Fig. 4-b

Fig. 4-c

DP/N: 007125v1.0

© 2010 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured.

27AUG2010 GT500 OEM POWER PACK

9

Page 15

4. OEM AIR BOX/AFTERMARKET CAI REMOVAL, CONT'D

C. Disconnect the MAF sensor harness wiring from

the MAF sensor. Pull the red retainer away from

the MAF to unlock the connector, then squeeze

and pull to remove the connector. (See Figure

4-d)

D. Remove the breather hose connection from the

intake tube (See Figure 4-e)

E. Remove the Bypass Valve vacuum hose (See

Figure 4-f)

Fig. 4-d

Fig. 4-e

Fig. 4-f

10

© 2010 Vortech Engineering, LLC

DP/N: 007125v1.0

All Rights Reserved, Intl. Copr. Secured.

27AUG2010 GT500 OEM POWER PACK

Page 16

4. OEM AIR BOX/AFTERMARKET CAI REMOVAL, CONT'D

F. Using a 10mm socket, temporarily remove the

screw securing the ABS brake module and set

aside. This screw will be reused to secure the

Power Pack CAI Heat Shield in a later step. (See

Figure 4-g)

G. Using a 10mm socket, remove the screws secur-

ing the factory air box to the inner fender well. Pull

entire assembly out. (See Figure 4-h)

Fig. 4-g

Fig. 4-h

DP/N: 007125v1.0

© 2010 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured.

27AUG2010 GT500 OEM POWER PACK

11

Page 17

5. POWER PACK CAI INSTALLATION

A. Locate the supplied vacuum hose. Using a utility

knife, cut a slit on one side of the hose the entire

length. A box cutter works best when the blade is

only exposed to cut half the hose diameter. Using

a vise to hold the utility knife in place, while running the hose over it in short lengths works best.

Use the hose parting line to ensure you cut a

straight line.

B. Attach the vacuum hose to the heat shield as

shown. (See Figure 5-a) Trim the excess hose off.

C. Use the remainder hose to attach to the lower

portion of the heat shield as shown. (See Figure

5-e) This will ensure the heat shield does not rub

through the A/C lines below where it will be positioned. (See Figure 5-b)

D. Install the heat shield as shown and secure it with

the hardware from the OEM air box and the hardware used to secure the ABS bracket from a previous step. (See Figure 5-c)

Fig. 5-a

Fig. 5-b

Fig. 5-c

12

© 2010 Vortech Engineering, LLC

DP/N: 007125v1.0

All Rights Reserved, Intl. Copr. Secured.

27AUG2010 GT500 OEM POWER PACK

Page 18

5. POWER PACK CAI INSTALLATION, CONT'D

E. Remove the MAF sensor module from the intake

tube assembly using a 2.5mm allen key. (See

Figure 5-d) Inspect the o-ring for damage or

deformation, replace if necessary.

F. Locate the new MAF sensor housing from the kit

and install the MAF sensor module into the housing, securing it with the factory hardware. (See

Figure 5-e)

G. Install the cone air filter onto the MAF housing.

H. Place filter and MAF housing assembly in the heat

shield area. Be sure the MAF sensor module is

positioned outside the heat shield. (See Figure

5-f)

Fig. 5-d

Fig. 5-e

Fig. 5-f

DP/N: 007125v1.0

© 2010 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured.

27AUG2010 GT500 OEM POWER PACK

13

Page 19

5. POWER PACK CAI INSTALLATION, CONT'D

NOTE: Using a light coat of clean engine oil will help

the couplers slide over the beads.

I. Assemble the carbon fiber intake tube with the

supplied hose couplers. Lubricate the inside of the

coupler on the filter side to aid in sliding over from

the intake tube and onto the MAF housing. This

coupler will need to be installed all the way onto

the carbon fiber intake tube until it is flush. (See

Figure 5-h)

K. Slide the intake tube coupler onto the throttle

body until it seats and tighten both hose clamps.

(See Figure 5-g)

L. With both clamps loose on the filter side, support

the filter with one hand and slide the coupler from

the intake tube over onto the MAF housing.

Re-aligning the housing and intake tube as you

slide the coupler will assist in engaging the coupler to the housing. (See Figure 5-i).

M. Once the entire intake tube assembly is posi-

tioned properly (ensure the MAF is positioned outside heat shield as shown) and with adequate

clearance, then tighten all the hose clamps. (See

Figure 5-j)

N. Connect the MAF wiring harness.

O. Re-attach the breather hose.

P. Re-connect the bypass valve vacuum hose.

Fig. 5-g

Fig. 5-j

Fig. 5-h

Fig. 5-i

14

© 2010 Vortech Engineering, LLC

DP/N: 007125v1.0

All Rights Reserved, Intl. Copr. Secured.

27AUG2010 GT500 OEM POWER PACK

Page 20

6. REFLASH COMPUTER

IMPORTANT! To ensure trouble-free programming of your vehicle's computer:

• Make sure the vehicle's battery is sufficiently charged.

• Turn off all accessories and close doors to prevent unnecessary drain on the battery.

• Do not attempt to program your vehicle while a battery charger is connected.

• Improper battery voltage will result in failure of the programming process.

• Do not disconnect the cable or turn off the ignition during programming.

NOTE: • All vehicles equipped that have aftermarket ste-

ARROW KEYS

reos will experience problems with the ability to

re-program the vehicle’s ECM. It is necessary to

disconnect the aftermarket stereo from the factory wiring harness before continuing with the programming procedure.

CANCEL

SELECT

Fig. 6-a

A. Reconnect the battery if previously dis-

connected.

B. Locate the vehicle’s OBD2 connector

located under the dash on the driver side

of the vehicle. (See Fig 6-b)

C. Attach the OBD2 connector from the

reflash tool that is provided in the kit to

the vehicle’s OBD2 port. Make sure this

connector is seated all the way in the

vehicle’s OBD2 port. Do not allow this

connector to become disconnected during programming or damage may occur

to the vehicle’s ECM. (See Fig 6-c)

• Do not disturb the cable or turn the ignition off

during this time. If the programming is disrupted,

the computer will not start or run your vehicle!

OBD-II

CONNECTOR

Fig 6-b

DP/N: 007125v1.0

© 2010 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured.

27AUG2010 GT500 OEM POWER PACK

Fig 6-c

15

Page 21

6. REFLASH COMPUTER, CONT'D

NOTE: If you have any questions throughout this proce-

dure, please contact our service department for

further assistance.

D. The reflash tool should power up and display

PROGRAM VEHICLE at the top of the screen.

Press the SELECT button. (See Fig 6-d)

E. PREPROGRAMED TUNE will be displayed at

the top of the screen. Press the SELECT button. (See Fig 6-e)

F. Read the disclaimer entirely, then press the

SELECT button if you agree with the terms of

the disclaimer. (See Fig 6-f)

G. At this point you will need to turn the ignition to

the ON position (do not start the vehicle). Set

the parking brake and press the SELECT button to continue. (See Fig 6-g)

Fig 6-d

Fig 6-e

Fig 6-f

Fig 6-g

16

© 2010 Vortech Engineering, LLC

DP/N: 007125v1.0

All Rights Reserved, Intl. Copr. Secured.

27AUG2010 GT500 OEM POWER PACK

Page 22

6. REFLASH COMPUTER, CONT'D

H. The reflash tool will proceed to check the

Operating System (OS) part number of the

vehicles ECU. (See Fig 6-h)

I. PROGRAM VEHICLE will be displayed at the

top of the screen. At this time make sure you

have turned off any additional accessories that

may cause unnecessary draw on the vehicles

battery (headlights, radio, etc.). Press the

SELECT button to proceed with BEGIN

PROGRAM. (See Fig 6-j)

Fig 6-h

NOTE: Once the programming sequence has been start-

ed use care NOT to disturb the cable, or turn the

ignition or any accessories on or off during this

time. Throughout the programming sequence it is

normal for the Reflash tool to AUTOMATICALLY

cycle the vehicles power on and off. If the programming is disrupted, permanent damage to the

vehicles computer may result!

Fig 6-i

Fig 6-j

DP/N: 007125v1.0

© 2010 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured.

27AUG2010 GT500 OEM POWER PACK

Fig 6-k

17

Page 23

6. REFLASH COMPUTER, CONT'D

L. The reflash tool will then automatically proceed

through the following screens during the pro-

gramming process. (See Fig 6-k thru 6-p)

i. Unlock ECU

ii. Upload ECU

iii. Setup Device

iv. Make Adjustments

v. Calculate Checksums

vi. Unlock ECU

vii. Download tune

Fig 6-l

Fig 6-m

Fig 6-n

Fig 6-o

Fig 6-p

18

© 2010 Vortech Engineering, LLC

DP/N: 007125v1.0

All Rights Reserved, Intl. Copr. Secured.

27AUG2010 GT500 OEM POWER PACK

Page 24

6. REFLASH COMPUTER, CONT'D

M. Once the reflash tool has completed the

DOWNLOAD TUNE process the screen should

read "Turn Key Off And Remove key." At this

time remove the key and press the SELECT

button to continue. (See Fig 6-q)

N. Once the tool has successfully completed the

POWER DOWN ECU sequence you will see

"Download Complete" displayed on the screen.

Press the SELECT BUTTON. (See Fig 6-r,

6-s)

O. CONGRATULATIONS! You have successfully

completed reflashing the vehicle's ECU with

the Vortech Supercharger Calibration. You may

now unplug the reflash tool from the vehicle's

OBD2 port.

Fig 6-q

Fig 6-r

Fig 6-s

DP/N: 007125v1.0

© 2010 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured.

27AUG2010 GT500 OEM POWER PACK

19

Page 25

7. FINAL CHECK

WARNING: Do not attempt to operate the vehicle

until ALL components are installed and ALL

operations are completed including the final

check.

A. Reinstall the de-gas bottle and tighten screws.

B. Confirm that all fasteners are properly secured

and tight.

C. Make sure all wires and hoses are routed away

from hot, moving or sharp objects.

D. Test drive the vehicle.

E. Custom calibration will be REQUIRED if the drive

speeds of the supercharger and the boost levels

are changed from the supplied components.

Always listen carefully for engine detonation.

Discontinue heavy throttle usage if detonation is

heard.

20

© 2010 Vortech Engineering, LLC

DP/N: 007125v1.0

All Rights Reserved, Intl. Copr. Secured.

27AUG2010 GT500 OEM POWER PACK

Page 26

®

ENGINEERING, LLC

1650 Pacific Avenue, Channel Islands, CA 93033-9901 • Phone 805 247-0226

Fax: 805 247-0669 • www.vortechsuperchargers.com • M-F 8:00 AM - 4:30 PM (PST)

Loading...

Loading...