Page 1

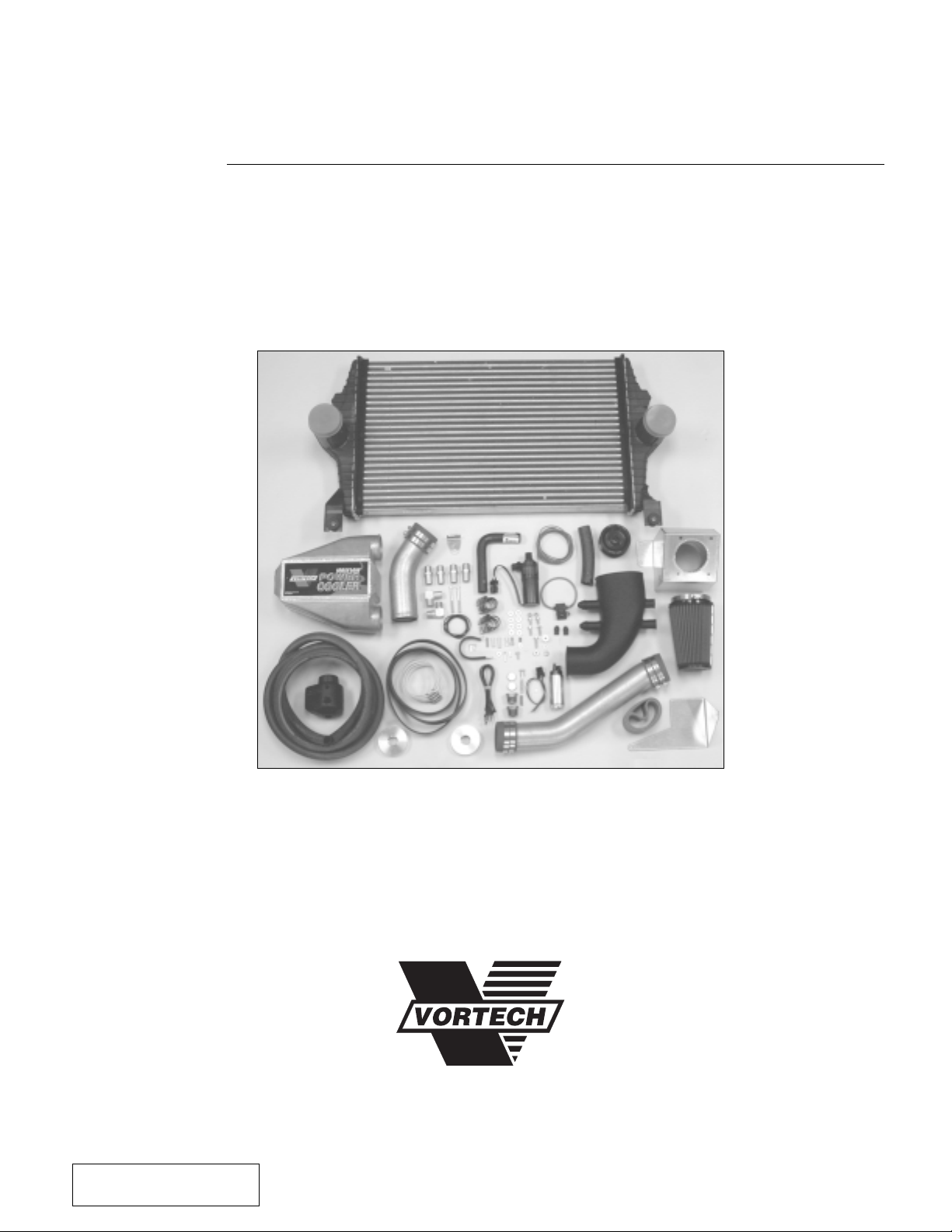

Maxflow® Power Cooler

Installation Instructions

1650 PACIFIC AVENUE • CHANNEL ISLANDS, CA 93033-9901 • (805) 247-0226

FAX (805) 247-0669 • www.vortechsuperchargers.com • M-F 8:00 AM - 4:30 PM PST

P/N: 8N020-100

©2002 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

28MAR02 V1.0

(99-01SDPwrCoolr(8N020-100V1.0)

1999-2001 Ford 6.8L Super Duty

Part #8N301-130/138 CARB E.O. #D-213-15

®

ENGINEERING, LLC

Page 2

FOREWORD

Proper installation of this supercharger kit requires general automotive

mechanic knowledge and experience. Please browse through each step of

prior

this instruction manual

should refer the job to a professional installer/technician. Please call Vortech

Engineering for installers in your area.

to beginning the installation to determine if you

All rights reserved. No parts of this publication may be reproduced, transmitted, transcribed,

or translated into another language in any form, by any means without written permission

P/N: 8N020-100

©2002 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

28MAR02 V1.0

(99-01SDPwrCoolr(8N020-100V1.0)

© 2002 VORTECH ENGINEERING, LLC

of Vortech Engineering, LLC.

ii

Page 3

Table Of Contents

FOREWORD .....................................................................................................................................ii

TABLE OF CONTENTS ....................................................................................................................iii

TOOL & SUPPLY REQUIREMENTS ................................................................................................ iv

PARTS LIST-1999-2001 FORD SUPER DUTY 6.8L-CHARGE COOLER UPGRADE SYSTEM .....v

1. PREPARATION/REMOVAL ..................................................................................................1

2. SUPERCHARGER RECLOCKING ......................................................................................2

3. IN-TANK FUEL PUMP REPLACEMENT..............................................................................3

4. WATER PUMP AND COOLER INSTALLATION...................................................................4

5. AIR INLET ASSEMBLY ........................................................................................................5

6. CHARGE COOLER INSTALLATION.................................................................................... 6

7. HOSE INSTALLATION & FILLING .......................................................................................7

8. REASSEMBLY AND FINAL CHECK ....................................................................................9

APPENDIX ........................................................................................................................................11

A-1 CHARGE COOLER DIAGRAM ..................................................................................12

A-2 WATER HOSE DIAGRAM ..........................................................................................13

©2002 Vortech Engineering, LLC

iii

All Rights Reserved, Intl. Copr. Secured

28MAR02 V1.0

(99-01SDPwrCoolr(8N020-100V1.0)

P/N: 8N020-100

Page 4

Vortech Maxflow® Power Cooler Installation Instructions

1999-2001 Super Duty V-10

Congratulations on selecting the best performing and most efficient

charge cooler... the VORTECH

®

Maxflow® Power Cooler!

Before beginning this installation, please

read through this entire instruction booklet.

This Vortech Maxflow Power Cooler (referred to in general terms as charge cooler) system was

designed as a street/strip oriented charge cooler, specifically for use on 1999 - 2001 Ford V-10

vehicles equipped with a Vortech supercharger producing up to approximately 580 horsepower.

The Maxflow Power Cooler System will fit and work equally well with other brands of centrifugal

superchargers as well as turbochargers, with minor modifications.

As with any power enhancing product, this system is intended for use on healthy, well-maintained engines. Vortech Engineering is not responsible for engine damage. Installation on new

vehicles will not harm or adversely affect the break-in period so long as factory break-in procedures are followed.

For best performance and continued durability, please take a note of the following key points:

1. Use only premium grade fuel 91 octane or higher (R+M/2).

2. Always listen for any sign of detonation (pinging) and discontinue hard use (no

boost) until problem is resolved.

TOOL & SUPPLY REQUIREMENTS:

• Metric and standard - socket set, wrench set

• Ratchet - 1/2” drive

• Extension

• 1/2" drive breaker bar

• Ford spring lock tool 3/8" & 1/2”

• Pliers

• Drill motor

• Ø1/16" and #30, Ø9/32”, and Ø11/16” drill bits

• Test light

• Rubber mallet or dead blow hammer

• Wire cutters and crimping tool

• Standard hex key set (Allen wrenches)

• Alcohol (denatured or rubbing)

• Silicone sealer/RTV

If your vehicle has in excess of 30,000 miles since its last spark plug change, then you will also need:

• Spark Plug Socket

• NEW Spark Plugs

P/N: 8N020-100

©2002 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

28MAR02 V1.0

(99-01SDPwrCoolr(8N020-100V1.0)

iv

Page 5

1999-2001 Ford Super Duty 6.8L

Charge Cooler Upgrade System

®

Part No. 8N301-130/138SQ

ENGINEERING, LLC

PARTS LIST

IMPORTANT: Before beginning installation, verify that all parts are included in the kit. Report any shortages or damaged parts immediately.

Part Number Description Qty Part Number Description Qty

8N101-110 WELDED CORE ASSY. V-10 S.D. 1

4FT112-040 DISCH ASSY PWR COOLR V-10 SD 1

4FT010-060 BRKT, COOLER SUPPORT V-10 S.D. 1

4FT012-040 DUCT, V-10 A.C. TUBE A 1

4FT012-050 DUCT, V-10 A.C. TUBE B 1

4FT012-060 DUCT, V-10 A.C. TUBE C 1

4FT017-080 SPACER, COOLER SUPRT BRKT 1

7C060-025 M6 X 1.0 x 25MM HHCS 1

7F008-020 NUT, M8 x 1.5 1

7J006-094 6MM WASHER S.S. 1

7L312-000 WASHER LOCK 5/16" 1

7R002-044 #44 HOSE CLAMPS 6

7S275-200 2 3/4" x 2" SLEEVE 3

7U034-016 Ø 1.00" G.S. HOSE 6"

8N106-100 WATER COOLER ASSY. V-10 S.D. 1

4FT006-001 WATER COOLER, SUPERDUTY 1

5W018-020 18GA STRD WIRE BLK 3'

7A250-050 1/4-20 x .50" SHCS 2

7A250-075 1/4-20 x 3/4 SHCS PLTD 1

7A250-100 1/4-20 x 1" SHCS 1

7A250-275 1/4-20 x 2.75" SOC HD, ZINC 2

7F250-021 1/4-20 NYLOCK NUT ZINC PLTD. 2

7F250-040 1/4-20 NUT PLATE 2

7J250-001 1/4 SAE WASHER, PLTD 6

7J250-022 1/4" WASHER 2

7P250-020 1/4NPT DRAIN COCK 1

7P500-026 1/2NPT-3/4 BARB 90^ 2

7P500-078 1/2NPT x 3/4 HOSE FIT 4

7R002-052 HOSE CLAMP #52 4

7R007-001 NYLON CLAMP 1-1/8" 8

7S325-200 3.25" x 2.00" SLEEVE 2

7U038-000 3/4" HEATER HOSE 13'

7U100-066 TIE WRAP 11" NYLON 10

8N010-090 MNTG TAB, PLASTIC SURGE TANK 1

8N017-020 ADAPTER, WATER COOLER S.D. 2

8N055-050 CAP, SURGE TANK PLASTIC 1

8N056-060 SURGE TANK

8N107-020 WATER PUMP ASSY. 4.6 1

5W001-011 16-14 GA EYELET 1

5W001-012 SOLDERLESS CONNECTOR 1

5W018-010 18GA STRD WIRE RED 8.25'

5W001-019 SOLDERLESS CONNECTOR 2

5W001-014 FUSE HOLDER 10 GA 1

5W001-015 FUSE, BLADE TYPE 20A 1

5W001-040 12-10GA FEMALE SLIDE 1

5W001-002 FUSE TAP 1

7R003-027 ADEL CLAMP 1-11/16" 1

8F001-402 PUMP, WATER 1

7E010-075 #12 x 3/4" SHEET METAL SCREW 1

7J010-001 #10 FLAT WASHER 1

7U133-060 3/4" x 90° HOSE ELBOW 1

5W001-024 MINI ATC FUSE TAP 1

5W001-025 FEMALE SLIDE, INSULATED, MINI 1

4FT120-020 ECM CHIP PKG ASSY 1

4FT110-030 BRKT ASSY, MAF S.D. GEN II 1

008721 FINISHING PLUGS STEEL 2

2A048-730 BELT 1

2A038-312 8 RIB Ø 3.125 PULLEY 1

8H040-050 AIR FILTER 1

8F101-260 FUEL PMP ASSY, 98+ 4.6,INTANK 1

8F001-260 FUEL PUMP 1

5W001-052 PIGTAIL CONNECTER, FUEL PUMP 1

2A017-048 SPACER, Ø .312 OD / Ø .14 ID 2

5W001-013 14-16AWG, SOLDERLESS CONCTRS 2

7E006-075 #6 x .75 HXHD SHTMTL SCREW 2

4FT011-032 CROWS FOOT, WATER PUMP 1

©2002 Vortech Engineering, LLC

v

All Rights Reserved, Intl. Copr. Secured

28MAR02 V1.0

(99-01SDPwrCoolr(8N020-100V1.0)

P/N: 8N020-100

Page 6

P/N: 8N020-100

©2002 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

28MAR02 V1.0

(99-01SDPwrCoolr(8N020-100V1.0)

xii

Page 7

1. PREPARATION / REMOVAL

A. Remove the supercharger drive belt.

B. Remove the entire air inlet assembly. (MAF

bracket, flex hose and aluminum inlet tube.)

C. Disconnect the flex hose from the MAF (Mass

Air Flow meter) and remove the MAF bracket

from the vehicle with the attached meter.

D. NOTE: If your standard supercharger system

has a Gen. I MAF bracket you will need to

remove the MAF meter from the MAF bracket.

(See

Fig. 1-a

.) It will be installed on the supplied

Gen. II MAF bracket in step 5, air inlet assembly.

E. Remove the aluminum discharge duct.

F. Disconnect the oil feed and oil drain lines from

the supercharger. Cap to prevent debris from

entering the open lines.

G. Remove the supercharger from the mounting

plates.

H. If your vehicle has gone over 30,000 miles since

its last spark plug change you will need to

change the spark plugs.

GEN I MAF

BRACKET

ASSEMBLY

GEN II MAF

BRACKET

ASSEMBLY

Fig. 1-a

©2002 Vortech Engineering, LLC

1

All Rights Reserved, Intl. Copr. Secured

28MAR02 V1.0

(99-01SDPwrCoolr(8N020-100V1.0)

P/N: 8N020-100

Page 8

2. SUPERCHARGER RECLOCKING

A. Loosen and remove the six 1/4-20 cap screws

and retaining plates that hold the compressor

housing to the gearcase.

B. Carefully rotate the compressor housing to the

specified location as shown. (See

Figure 2-a

.)

NOTE: If the compressor housing does not

rotate freely relative to the gearcase,

DO NOT FORCE IT. SERIOUS SUPERCHARGER DAMAGE MAY OCCUR. The machined mating surfaces

are designed to prevent pressurized

air from escaping and have minimal

tolerances. If the housing will not move

or is very tight, contact Vortech Engineering immediately at (805) 247-0226

and ask for our service department for

further assistance.

C. Evenly retighten the four cap screws, torque to

60 in/lbs (5ft/lbs).

D. Remove original Ø3.47” supercharger pulley

from the supercharger and install the supplied

Ø3.125” pulley.

NOTE: Included in this kit is a smaller than

originally supplied supercharger pulley. This new pulley is recommended

to achieve best performance results.

Removal of the factory sealed pulley

will reduce the supercharger warranty

from three years to one year unless

the supercharger unit (with the original pulley still attached) and new pulley are sent into Vortech for removal,

installation and re-sealing. If supercharger warranty is not a concern or if

the supercharger warranty has expired, the pulley may simply be removed and replaced with the new part

supplied. Be aware that hammering/

prying etc. on the supercharger may

damage precision parts.

Fig. 2-a

P/N: 8N020-100

©2002 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

28MAR02 V1.0

(99-01SDPwrCoolr(8N020-100V1.0)

2

Page 9

3. IN-TANK FUEL PUMP REPLACEMENT

NOTE: The following steps are best per-

A. Support the gas tank with a jack and remove the

screws securing the two gas tank straps.

B. Slightly lower the gas tank and disconnect the

top two vents on the gas tank, front and rear.

C. Disconnect the fuel pump/sender wiring har-

ness located in the frame rail and the fuel fill and

overflow lines.

D. Disconnect the fuel feed and return lines using

a springlock tool.

E. Completely lower the gas tank to the ground.

F. Unscrew the outer ring securing the fuel lines

and remove the cover.

G. Depress the two clips securing the plastic fuel

pump enclosure and slide it out of the tank, the

fuel sender float is attached to the fuel pump

enclosure and must be handled with care. Be

careful not to damage the filter.

H. Cut the two fuel pump power wires about 1” from

the fuel pump electrical connector. Noting the

corresponding (+) and (-) connections, splice

the supplied wiring harness into place using two

solderless connectors.

I. Remove the three screws securing the fuel

pump enclosure’s cover using a 3/16” nut driver

and remove the cover. Cut three equally spaced

1/2" long slits in the perimeter of the cover’s fuel

pump locating cylinder (see

lows the larger O.D. pump to fit in the cover.

Some material may need to be removed from

the I.D. of the pump locating cylinder for proper

pump fit.

J. Remove the stock fuel pump from its enclosure.

Separate the rubber pump support and filter

from the pump and install both onto the supplied

pump.

K. Reassemble the new fuel pump assembly and

canister with cap. Install the supplied 1/8” spacers beneath the pump outlet manifold and the

canister cap. (See

manifold mount holes as a template, drill two 1/

16” pilot holes into the enclosure cover. Secure

the outlet manifold to the cap using the two self

tapping #6 screws. Reinstall the fuel tank assembly and reattach the electrical connections.

L. Reinstall the canister assembly into the fuel tank

and screw on the outer ring to secure it.

M. Reinstall the gas tank and reconnect all the fuel

lines and electrical connections.

formed with the gas tank with the

least amount of fuel in it as possible.

Fig. 3-b

Fig. 3-a

.) Using the outlet

). This al-

PLASTIC FUEL

PUMP OUTLET

MANIFOLD

BYPASS

TUBE

CUT THREE 1/2"

LONG SLITS HERE

Fig. 3-a

#6 SCREWS

FUEL OUTLET

SUPPLIED 1/8"

SPACERS

PUMP CANISTER

Fig. 3-b

HOSE

FUEL PUMP OUTLET

©2002 Vortech Engineering, LLC

3

All Rights Reserved, Intl. Copr. Secured

28MAR02 V1.0

(99-01SDPwrCoolr(8N020-100V1.0)

P/N: 8N020-100

Page 10

4. WATER PUMP AND COOLER INSTALLATION

A. Remove the upper shroud, located between the

core support and the grille.

B. Remove the three screws securing the radiator

reservoir and rotate out of the way.

C. Remove jack tools and tray holding brackets.

D. Remove the upper two supports securing the

condenser.

E. Remove the hood latch from the core support

(leaving it attached to the cable) and set out of

the way.

F. Remove the upper core support - secured with

(8-10) screws. (See

G. Following the

Fig. 4-a

Fig 7-b

supplied water fitting adapters onto the heat

exchanger securing with the provided Ø3.25” x

2” sleeves and clamps.

H. Using the diagram as a guide, install the sup-

plied 3/4” NPT brass fittings into the charge

cooler as shown. A small amount of thread

sealant may be used on these threads.

I. Lower the heat exchanger into place between

the vehicle’s condenser and radiator. Rest the

heat exchanger on the pads of the lower core

support. (See

Fig. 4-b

J. Remove the factory nut clips if any, in the core

support and replace with the ones provided.

Secure the heat exchanger to the vehicle using

the supplied 1/4-20 x 2-3/4” cap screws and

washers.

K. Reinstall the upper core support, hood latch and

condenser supports.

L. Using the

Fig. 4-c

as a guide, measure down 20”

from the top of the fan shroud and over 5” and

drill a hole through the fan shroud using a Ø9/

32” drill bit.

M. Using the supplied adel clamp and 1/4” screw,

washers and nylock nut secure the pump to the

fan shroud.

N. Cut the stock connector off of the pump wiring

and install the provided solderless connectors.

Connect the supplied red wire to the green wire

and the supplied black wire to the brown wire

using the previously installed connectors.

O. Reinstall the vehicle’s stock fan, spacer, shroud

and tighten.

P. Connect the black wire to a suitable ground, free

from paint and vehicle undercoating.

Q. Route the red wire to the vehicle’s fuse box

located near the master cylinder. Using the

supplied fuse tap, fuse holder and slide connectors, tap into the #7 mini-fuse. Check that the

fuse only receives power when the key is in the

ON position using a test light.

.)

on page 8, install the

.)

Fig. 4-a

Fig. 4-b

Fig. 4-c

P/N: 8N020-100

©2002 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

28MAR02 V1.0

(99-01SDPwrCoolr(8N020-100V1.0)

4

Page 11

5. AIR INLET ASSEMBLY

A. Attach the MAF meter to the MAF bracket using

the supplied 1/4” hardware. Slide the air filter

onto the tube of the MAF bracket. Using a 5/16”

nut driver or socket, reach in through one of the

Ø5/8” holes and tighten the hose clamp. Cover

the holes with the provided finishing plugs.

B. Install the MAF assembly onto the driver’s side

of the core support using the factory hardware.

(See

Fig. 5-a

.)

?

NOTE: The thick rubber mat may need to be

unsnapped and folded over toward the

radiator to allow proper mounting of

the MAF assembly.

C. Reconnect the MAF wiring connector to the

MAF meter.

D. Reinstall the supercharger and connect the oil

feed and drain lines.

E. Reinstall the Ø3.5” x 2” silicone sleeve and #56

hose clamps onto the supercharger inlet. Install

the cast aluminum inlet duct into the silicone

sleeve and tighten the hose clamps.

F. Connect the cast aluminum duct to the MAF

meter using the supplied Ø3.5" x 15" flex hose

and secure with #52 hose clamps.

G. Install the short end of the Ø5/8" molded elbow

hose onto the Ø5/8" bung on the air inlet.

NOTE: Refer to Fig. A1 in the Appendix.

H. Cut a 90° section from the stock crank case

breather hose and attach to the Ø5/8" molded

elbow hose with the Ø5/8" union. Reconnect the

other end to the crank case breather on the

valve cover. Trim hose length for a proper fit.

Fig. 5-a

©2002 Vortech Engineering, LLC

5

All Rights Reserved, Intl. Copr. Secured

28MAR02 V1.0

(99-01SDPwrCoolr(8N020-100V1.0)

P/N: 8N020-100

Page 12

6. CHARGE COOLER INSTALLATION

A. Remove the coolant line attached to the intake

manifold (see

2” from the bottom of the coolant line (to allow for

clearance of the cooler support bracket) and

reinstall.

B. Cut 4-1/2” off of the supplied piece of foam tape

and the remaining 7-1/2” in half. Thoroughly

clean the top portion of the cooler support bracket

with alcohol and allow it to dry. Following the

diagram (see

the top of the cooler support bracket. Trim the

excess from any over hanging edge.

C. Following the photo (see

supplied cooler support bracket onto the front

passenger’s side of the intake manifold and

secure it using the provided spacer and 6mm

hardware.

NOTE: The spacer is located between the

Secure the lower part of the bracket to the front

cover’s 8mm stud using the 8mm nut and lock

washer provided.

D. Install the provided Ø2-3/4” x 2” sleeves onto

each one of the cooler ducts along with four #44

hose clamps (2 per sleeve).

E. Install the plastic discharge duct onto the throttle

body and secure with the supplied Ø4-1/2”

sleeve and two #72 hose clamps. (See

F. Connect the idle air line and the bypass valve to

the duct as shown (see

using the #16 hose clamps.

G. Connect the bypass valve to the cast air inlet

duct using the supplied Ø1” x 6” hose and

secure using two #16 hose clamps.

H. Slide the Ø3” x Ø2-3/4” reducer sleeve onto the

plastic discharge duct and secure with one #48

hose clamp.

I. Slide one Ø2-3/4" x 2" sleeve and two #44 hose

clamps onto the discharge of the supercharger.

J. Following

the supercharger and discharge duct “B” to the

previously installed plastic duct leading to the

throttle body.

K. Set the charge cooler on top of the cooler

support bracket and connect the discharge ducts

to the charge cooler securing it with the previously installed hose clamps.

Fig. 6-a

Fig. 6-b

cooler support bracket and the top of

the manifold.

Fig. 6-d

). Remove approximately

) attach the foam tape to

Fig. 6-c

Fig. 6-d

) install the

) and secure

, attach discharge duct “A” to

Fig. 6-d

Fig. 6-a

.)

Fig. 6-b

NOTE: Discharge duct “A” must be rotated

P/N: 8N020-100

©2002 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

28MAR02 V1.0

(99-01SDPwrCoolr(8N020-100V1.0)

over enough so that the vehicle’s hood

does not come in contact with the duct.

Fig. 6-c

6

Page 13

6. CHARGE COOLER INSTALLATION , cont’d.

DUCT, TUBE C

DUCT, TUBE A

CHARGE AIR

COOLER

CONNECT TO VALVE COVER

TO IDLE AIR CONTROL

DUCT, TUBE B

MAF BRACKET ASSEMBLY

Ø5/8" HOSE

UNION

ALUMINUM

INLET

DUCT

BYPASS

VALVE

FLEX HOSE

Fig. 6-d / See Appendix A-1 for detail

7. HOSE INSTALLATION & SYSTEM FILLING

A. Attach the surge tank mounting bracket to the

surge tank using the supplied 1/4" hardware.

Using

a template. Drill a Ø9/32" hole in the vehicle’s

evaporator bracket and secure the surge tank

assembly with the 1/4" hardware.

B. Cut an 8" section of the Ø3/4" hose and attach

one end to the driver’s side fitting on the water

cooler and the other end to the inlet of the water

pump. Secure both ends with the provided nylon

clamps. (See

Fig. 7-a

and the surge tank assembly as

Fig. 7-b

.)

Fig. 7-a

©2002 Vortech Engineering, LLC

7

All Rights Reserved, Intl. Copr. Secured

28MAR02 V1.0

(99-01SDPwrCoolr(8N020-100V1.0)

P/N: 8N020-100

Page 14

7. HOSE INSTALLATION & SYSTEM FILLING, cont’d.

C. Cut a 98" section of the Ø3/4" hose and attach

one end to the discharge of the water pump and

secure with a nylon clamp. Route the hose

toward the firewall and the back of the engine.

Connect the hose to the straight fitting on the

charge cooler and secure with a nylon clamp.

Make sure the hose is away from sharp edges

and exhaust system. Ensure that

sharp bends are allowed on any of the hoses.

D. Cut a 23" section of the Ø3/4" hose and connect

between the bottom of the surge tank and the

water cooler. Secure both ends with nylon

clamps.

E. Temporarily plug the hose fitting on the surge

tank that is to connect to the 90° fitting on the

charge cooler.

F. When filling the system, ensure that the

IS OFF

and the drain valve on the water cooler

is OPEN.

G. Pour 3/4 of a gallon of antifreeze into the surge

tank. Fill the system with water until water comes

out of the drain fitting, then close the drain valve

but

do not over tighten

.

H. Continue to fill the system with water until it

pours out of the OPEN fitting on the charge

cooler.

I. Connect the water line from the surge tank to the

charge cooler and secure with the provided

clamps. Top the system off with water and install

the surge tank cap.

NO

kinks or

PUMP

98

"

SURGE TANK TOP VIEW

23"

CONNECTS

TO

BOTTOM

OF

SURGE

TANK

SURGE TANK

SIDE VIEW

8"

CHARGE AIR

COOLER

3/4" NPT

BRASS

FITTING

ADAPTER

Ø3.25" X 2"

AIR FROM

SUPERCHARGER

AIR TO

THROTTLE

BODY

WATER PUMP

WATER COOLER

FRONT OF VEHICLE

Fig. 7-b / See Appendix A-2 for detail

DENOTES

FLOW

DIRECTION

8"

P/N: 8N020-100

©2002 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

28MAR02 V1.0

(99-01SDPwrCoolr(8N020-100V1.0)

8

Page 15

8. REASSEMBLY AND FINAL CHECK

NOTE: Once the ECM is received back from

Vortech with the ECM module installed,

reinstall the ECM into the vehicle. In some

cases, the extra length of the ECM module will not allow the use of the factory holddown bracket unless it is modified. Reconnect the factory harness.

A. Reinstall the stock surge tank and tire iron.

Reinstall the upper radiator hose opposite of the

factory installation (the short leg of the hose

should connect to the radiator). (See

Fig. 8-a

Refill the radiator.

B. Reconnect the battery.

C. Check all fittings, nuts, bolts and clamps for

tightness. Pay particular attention to oil and fuel

lines, especially around moving parts, sharp

edges and exhaust. Make sure all wires and

lines are properly secured with clamps or tie

wraps.

D. Check all fluid levels, making sure that your fuel

tank is filled with 91 octane or higher fuel before

commencing test drive.

E. Start engine and allow to idle a few minutes,

then shut off.

F. Recheck to be sure that no hoses, wires, etc. are

near exhaust headers or moving parts and for

signs of fluid leakage.

.)

Fig. 8-a

WARNING: Operating the vehicle without ALL

the subassemblies completely and

properly installed may cause F AILURE OF MAJOR COMPONENTS.

G. Test drive the vehicle. Listen for any sign of

detonation (pinging) and discontinue hard use

(no boost) until problem is resolved.

Fig. 8-b

©2002 Vortech Engineering, LLC

9

All Rights Reserved, Intl. Copr. Secured

28MAR02 V1.0

(99-01SDPwrCoolr(8N020-100V1.0)

P/N: 8N020-100

Page 16

P/N: 8N020-100

©2002 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

28MAR02 V1.0

(99-01SDPwrCoolr(8N020-100V1.0)

10

Page 17

APPENDIX

11

©2002 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

28MAR02 V1.0

(99-01SDPwrCoolr(8N020-100V1.0)

P/N: 8N020-100

Page 18

APPENDIX A-1

V-10 Inlet And Discharge Diagram

DUCT, TUBE A

CONNECT TO VALVE COVER

DUCT, TUBE C

Ø5/8" HOSE UNION

TO IDLE AIR CONTROL

ALUMINUM

INLET

DUCT

BYPASS

VALVE

CHARGE AIR

COOLER

P/N: 8N020-100

©2002 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

28MAR02 V1.0

(99-01SDPwrCoolr(8N020-100V1.0)

DUCT, TUBE B

MAF BRACKET ASSEMBLY

FLEX HOSE

12

Page 19

DENOTES FLOW

DIRECTION

WATER PUMP

AIR TO THROTTLE BODY

AIR FROM

SUPERCHARGER

ADAPTER

3/4" NPT BRASS FITTING

23"

SURGE TANK

SIDE VIEW

SURGE TANK

TOP VIEW

8"

CHARGE AIR COOLER

98"

Ø3.25" X 2" SLEEVE

CONNECTS TO

BOTTOM OF

SURGE TANK

WATER COOLER

FRONT OF VEHICLE

8"

APPENDIX A-2

Water Hose Diagram

13

©2002 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

28MAR02 V1.0

(99-01SDPwrCoolr(8N020-100V1.0)

P/N: 8N020-100

Page 20

®

ENGINEERING, LLC

1650 PACIFIC AVENUE • CHANNEL ISLANDS, CA 93033-9901 • (805) 247-0226

FAX (805) 247-0669 • www.vortechsuperchargers.com • M-F 8:00 AM - 4:30 PM PST

©2002 Vortech Engineering, LLC

All Rights Reserved, Intl. Copr. Secured

28MAR02 V1.0

(99-01SDPwrCoolr(8N020-100V1.0)

P/N: 8N020-100

Loading...

Loading...