Vortec 921 Series, 921-3, 981 Series, 930-8, 930-9 Operation & Safety Instructions

...

TABLE 1: FILTER RECOMMENDATIONS

FILTER AND REPLACEMENT PART ITEM NUMBERS

Vortec Model 5 Micron Air Filter Oil Removal Filter Pressure Regulator .002”, .003” or .004” shims

921-3 701S-24A 701S-48 208R 930-8, 930-9, 930-10

921-6, 981-6 701S-24A 701S-48 208R 930-8, 930-9, 930-10

921-12, 981-12 701S-40A 701S-54 208R 930-8, 930-9, 930-10

921-18, 981-18 701S-40A - 208RX 930-8, 930-9, 930-10

921-24, 981-24 701S-40A - 208RX 930-8, 930-9, 930-10

TABLE 2: DETERMINING COMPRESSED AIR LINE SIZE

1. Calculate total product compressed air consumption (SCFM, SLPM).

2. Determine length of compressed air line required for connection to main supply.

3. Locate pipe length in left column and read to the right to nd the compressed air requirements.

4. Locate pipe size at top of column.

MAXIMUM AIRFLOW (SCFM) THROUGH PIPE AT 5 PSIG PRESSURE DROP (100 PSIG AND 70OF)

Pipe Length

(Feet)

10 29 65 120 254 480 978 1483 2863 4536

20 21 46 85 180 340 692 1049 2024 3208

30 17 37 70 147 277 565 856 1653 2619

40 15 32 60 127 240 489 792 1431 2268

50 13 29 54 114 215 437 663 1280 2029

60 12 26 49 10 4 19 6 399 606 116 9 1852

70 11 25 46 96 18 1 370 561 1082 17 15

80 10 23 43 90 170 346 524 1012 1604

90 10 22 40 85 160 326 494 954 1512

100 9 21 38 80 152 309 469 905 1435

1/4 3/8 1/2 3/4 1 1-1/4 1-1/2 2 2-1/2

Pipe Size (Nominal) - Schedule 40

OPERATION & SAFETY

INSTRUCTIONS

AIR KNIVES &

IONIZING AIR KNIVES

Models 921-X and 981-X

(Includes all BSP versions of models listed above)

MAXIMUM AIRFLOW (SLPM) THROUGH PIPE AT 0.3 BAR PRESSURE DROP (6.9 BAR AND 21OC)

Pipe Length

(Meters)

3 821 1840 3396 7188 13584 27677 42117 81023 128369

6 594 1302 2406 5094 9622 19584 29687 57279 90786

9 481 1047 1981 4160 7839 15990 24225 46780 74188

12 425 906 1698 3594 6792 13839 20999 40497 64184

15 368 821 1528 3226 6085 12367 18763 36224 57421

18 340 736 1387 2943 5547 11292 17150 33083 52412

21 3 11 708 1302 2717 5122 10471 15877 30621 48535

24 283 651 1217 2547 4811 9792 14829 28640 45393

27 269 623 11 3 2 2406 4528 9226 13980 26998 42790

31 255 594 1075 2264 4302 8745 13273 25612 40611

Rubber hose maximum airow rating: 1/2” I.D. rubber hose = 3/8” pipe; 3/4” I.D. rubber hose = 1/2” pipe

LIT0080

1/4 3/8 1/2 3/4 1 1-1/4 1-1/2 2 2-1/2

Pipe Size (Nominal) - Schedule 40

IMPORTANT

Please read all instructions BEFORE

attempting to use this product

10125 Carver Road, Cincinnati, OH 45242

Phone: 513-891-7474 • Fax: 513-891-4092

Toll Free: 800-441-7475

www.vortec.com • techsupport@vortec.com

GENERAL SAFETY CONSIDERATIONS

WARNING: COMPRESSED AIR COULD CAUSE

DEATH, BLINDNESS OR INJURY

1. Do not operate Air Knives at compressed air pressures

above 150 psig (10.3 Bar).

2. Avoid direct contact with compressed air.

3. Do not direct compressed air at any person.

4. When using compressed air, wear safety glasses with side

shields.

INTRODUCTION

Air Knives are airow ampliers that can reduce compressed air

consumption by up to 50% while helping to meet OSHA dead-end

pressure and noise specications. Air Knives produce a high velocity,

highly uniform airow for blow off or surface cooling of moving webs,

sheets, strips and large or small objects and wide surfaces.

Ionizing Air Knives are used for static neutralization and blow off of

moving webs, sheets, strips and large or small objects and wide

surfaces.

COMPRESSED AIR SUPPLY

The compressed air supply must be ltered to remove water and dirt

using a 5 micron or smaller lter. Failure to use a lter may cause

clogging of the compressed air paths inside the Vortec product. Filter

recommendations are given in Table 1.

Filter elements must be changed on a regular basis. Frequency of

change is determined by the condition of the compressed air supply.

Filters should be installed in the compressed air supply line as close as

possible to the Vortec product.

The appropriate size of the compressed air supply line should be

selected to ensure optimal performance of the Vortec product. Please

refer to Table 2 to determine what supply line size is recommended for

your application. Contact Vortec at 1-800-441-7475 for further assistance.

INSTALLATION AND OPERATION

Air Knives can be cycled on and off to match machine cycle times. In

order to vary the volume of airow from the Air Knife, an appropriately

sized pressure regulator can be used to control the compressed

air pressure, (less pressure = less airow). Pressure regulator

recommendations are given in Table 1.

Air Knives have no moving parts, and require only ltered compressed

air for proper operation. Ionizing Air Knives must be connected to a

suitable power supply (Vortec models F167 or D167RY). The power

supplies are capable of operating up to two or four separate Ionizing Air

Knives respectively. The total effective length of all Ionizing Air Knives

connected to one power supply should not exceed 200 inches.

Multiple Air Knives can be installed by connecting to an air manifold or

by directly plumbing to the appropriately-sized, hard piped, compressed

air source that does not exceed 150 psig (10.3 Bar). Air Knives will be

most effective if securely mounted at 18 inches or less from the surface

to be blown off.

MAINTENANCE

It is critical to the performance of the Air Knives that the internal air

passages remain clean. If performance suddenly drops, carefully

disassemble the unit and inspect for debris. If debris is found, it may be

necessary to change the lter element. Clean the debris from the unit

and reassemble. For detailed instructions on cleaning or reassembly

contact your authorized distributor or Vortec.

If uneven airow is present from the Air Knife, it may be partially clogged

with dirt. You may disassemble the Air Knife and clean any debris that

may be blocking airow out of the extremely small air gap. Use a soft

brush and/or pure isopropyl alcohol on a clean cloth to remove stubborn

deposits. Be careful not to damage the thin aluminum shim(s) inside the

unit. When reassembling the Air Knife, use the same thickness shims

that were removed from the unit. Red colored shims are 0.002”, green

are 0.003” and silver are 0.004”. Tighten the cap screws that secure the

two main components together from the center of the unit out to the

ends. Replace the end caps and gaskets.

Ionizing Air Knives

In order for the ionizing system to function, the ionizing high voltage

cable must be kept at least 1/4” (6mm) from any grounded surface. Two

cable supports are provided to help position the cable and keep it in

place away from grounded surfaces. To install the cable supports, push

the plastic bushing out of the metal support. Screw the metal support

into the desired location; then snap the plastic bushing onto the cable

(the bushing is split to allow this) at the desired position. Push the cable

onto the metal support and press the bushing back into the support.

Run the green ground wire from the ionizing bar back to the power

supply. Attach the ground wire ring terminal to the ground stud on the

power supply. Secure the ground wire to the power supply with a locknut.

Keep the green ground wire at least 1/4” away from the high voltage

cable.

Insert the spring loaded connector on the end of the high voltage cable

into one of the high voltage receptacles on the power supply. Finger

tighten the knurled knob on the connector into the receptacle. Be

sure that the power to the power supply is disconnected before

attempting to connect the high voltage power cable.

Verify that all electrical connections are securely attached before

plugging the power supply into the appropriate 115 VAC receptacle. The

receptacle must have a good ground connection for the ground pin on

the plug. If it does not, bolt the power supply to a well grounded metal

machine frame. The Ionizing Air Knife will not operate unless properly

grounded.

If you suspect that your ionizing bar is not functioning properly, you may

test it when the unit is operating. Using an insulated handle screwdriver,

place the metal shaft of the screwdriver on the metal surface of the

ionizing bar. While the metal shaft of the screwdriver is touching one

of the metal sides of the ionizing bar, position the tip of the screwdriver

near one of the sharp emitter points on the bar. A small spark should

jump a 1/16” to 1/8” (1 to 3mm) gap between the emitter point and the

tip of the screwdriver. Continue this test on each emitter point. The

emitter points can be cleaned with a soft brush and small amounts of

isopropyl alcohol. Disconnect power to the power supply when cleaning

the emitter points.

TROUBLESHOOTING

Insufficient airow may be caused by the following:

1. Undersized compressed air line size.

2. Compressed air pressure too low.

3. Partial or complete blockage of internal air path, due to dirt. See

Maintenance section for cleaning instructions; and Compressed Air

Supply section for lter recommendations.

4. Insufficient compressed air volume.

If trouble persists, please contact Vortec at 1-800-441-7475.

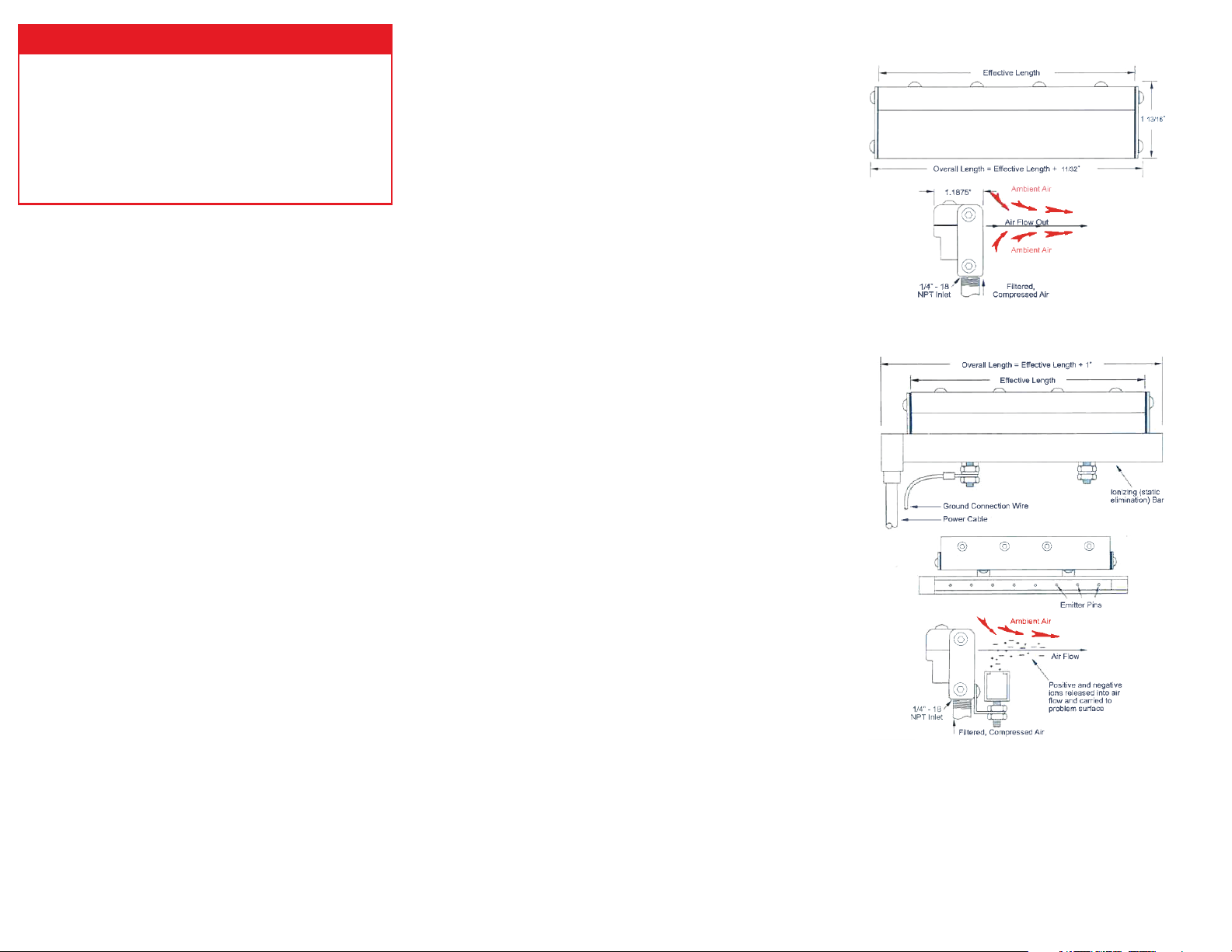

AIR KNIFE DIMENSIONS AND FUNCTIONALITY

IONIZING AIR KNIFE

(Drawings shown above are not to scale)

LIMITED WARRANTY

Vortec compressed air products manufactured by ITW Air Management

will be replaced or repaired if found to be defective due to manufacture

defect within ten years from the date of invoice. Refer to our website

www.vortec.com for full warranty details and limitations. ITW Air

Management makes no specic warranty merchantability or warrant of

tness to a particular purpose.

Loading...

Loading...