Vorsis AirAura User Manual

Digital Spectral Processor

Quick Start Guide

and

Short Form Manual

First Printing – May 2010

600 Industrial Drive, New Bern, North Carolina, USA 28562

This Page Intentionally Left Blank

3

Subject Page Number

Welcome to AirAura 4

The Vorsis Company Vision 5

General Information - Introduction 6

Processing Structure Overview 7

Installation 8

Rack Mounting Considerations 9

Installation Tips 10

Grounding 10

Surge Protection 10

UPS/Power Conditioning 10

Analog Audio Connections 10

Digital Audio Connections 10

Where to install AirAura 11

Analog Left/Right STL 11

Composite Analog STL 11

Analog ‘phone’ lines 12

Digital STL 12

EAS – US Emergency Alert System 13

PPM – Arbitron People Meter 13

Energizing AirAura 14

Rear Panel Connections 14

Audio Inputs 15

Audio Outputs

FM Audio Outputs 15

HD Audio Outputs 15

Headphones 16

Network Connections 16

Wired Ethernet 16

802.11G Wireless 16

General Purpose I/O 16

User Presets 17

Basic Setup 19

Rack Mounting 19

AC Power 19

Selecting the Active Audio Input 19

Adjusting Input Levels 19

Making Output Connections 20

Setting Output Levels 20

Selecting Presets 21

Using the Front Panel GUI to Adjust FM Sound 22

AGC Depth 22

Compression 22

Density 22

Low/Warm Equalization 23

Mid/High Equalization 23

FM Loudness 23

Using the Front Panel GUI to Adjust HD Sound 23

AGC Depth 22

Compression 22

Density 24

Low/Warm Equalization 24

Mid/High Equalization 24

HD Loudness 25

Saving a Preset 25

Preset Scheduler / Events 26

Setting up AirAura and GUI Lite to ‘talk’ 27

Network/LAN Connection 27

GUI IP Address 27

Hardware IP Address 28

Subnet Mask 28

Gateway 28

AirAura’s Front Panel Network Settings 28

Configuring the Remote GUI 28

Connecting without a LAN (Direct Connection) 29

Wireless Connection 30

AirAura/Internet Security Concerns 30

About DHCP and AirAura 31

AirAura Ports and Network Protocols 31

If UDP Doesn’t Work 31

Using GUI Lite 31

Input Menu 32

Input Source 32

Audio Input Signal Presence Indicators 32

Automatic Input Failover 32

Analog Gain 33

AES3 Digital Gain 33

L/R Balance 33

Pre-Emphasis

Output Menu 33

Analog Output Type 33

FM Digital Output 33

De-Emphasis 33

Pre-Delay 33

HD Digital Output 33

Phase Reverse 33

Left/Right Reverse 33

Diversity Delay 33

Special Analog Output Mode Note 34

Stereo Encoder Menu 34

MPX Process 34

MPX Processor Style 34

Lookahead Limiter 34

Soft Clipper 35

Hard Clipper 35

Stereo Pilot Injection 35

SCA 1 and SCA 2 Inputs 35

TX 1 and TX 2 Outputs 35

Presets Menu 36

Selecting a Preset 36

Saving a Preset 36

Preset Library Functions 37

System Menu 37

System Settings Change with Preset Takes 37

Metering Data over TCP/IP 37

Headphone Source 38

Input 38

Analog Input 38

AES Input 38

HD Output 38

FM Pre-Delay 38

FM Output 38

Headphone Volume Control 38

Status Indicators 39

Temp 39

Analog 39

AES 39

Remote Login 39

Setting System Time 40

Accessing Menu Options 40

View 40

Input 40

Output 40

St Encoder 40

Presets 40

System 40

Sound 40

About 40

Hardware 40

Devices 40

On-Line Mode 40

Event Scheduler 40

Login Password 40

Version 40

Update 40

Presets 41

Take 41

Save 41

Library 41

Analysis Menu 41

FFT Introduction 41

O-scope Introduction 41

E vs. F Introduction 41

3-D Plot Introduction 41

SDR Introduction 41

A-Clip Introduction 41

Using and interpreting the FFT 42

Using the O-Scope 42

Using and interpreting the E vs. F Display 42

Using and interpreting the 3-D Plot 43

Using and interpreting the SDR Display 43

Using interpreting the A-Clip Display 43

Appendix A

Default Wired Ethernet Configuration / Changing the Configuration

Appendix B

Default Wireless Ethernet Configuration / Changing the Configuration

Appendix C

General Specifications

Appendix D

Wireless Module Configuration, Approvals, and Miscellaneous Data

Appendix E

General Purpose Input/Output - GPIO

- Welcome to AirAura -

The Audio Processing ‘Game Changer’

In the fall of 2007 we set an aggressive goal to design a new FM peak clipper.

Our goal was to find ways to better handle the challenges posed by competitive

loudness and the FM pre-emphasis curve without the audible aliasing, unnatural

high frequency loss, and intermodulation distortion side effects encountered with

conventional clippers. Little did we know that we would be working on our new

FM peak clipper for almost three years before our lofty goals were met to our

satisfaction.

Our new clipper (project code name “AirAura”) is a completely new approach to

FM audio peak control. AirAura clipper’s algorithm has the resolution required to

be able to tell the difference between distortion and audio, and mitigate only the

audible distortion. Music or speech, our new clipper makes it effortless to be

competitively loud and clean at the same time.

The new clipper turned out to be powerful, but it also required enhanced DSP

hardware in order to run it. Therefore we decided to make an entirely new

hardware product around it, and the AirAura on-air processor was born. While we

were under the hood we also tweaked up our Vorsis Bass Management System

algorithm (creating VBMS-II), and also improved our well regarded Sweet Spot

Technology (SST).

VBMS-II effortlessly reveals and controls very deep and natural bass in program

material that contains such bass. However, VBMS is not a bass creator. Rather,

it’s an algorithm that artistically manages bass in a way that keeps it and the rest

of the audio spectrum clean and natural. To enhance the bass experience even

further, we outfitted VBMS-II with a new Bass Texture algorithm which allows

customization of the bass experience when listening on receivers with smaller,

bass-shy speakers.

Our SST algorithm has been well received by Vorsis customers in the broadcast

industry … even Public Radio stations. SST invisibly manages the behavior of

the five-band AGC as the incoming program density changes. Transitions

between today’s heavily mastered hits and material mastered in a more gentle

time are no longer ‘on-air speed bumps’. SST manages program density as

content changes to provide the listener with a smooth, consistent, easy to listen

to sound.

SST is so effective at invisibly managing the audio that Vorsis products

incorporating this feature have been installed in facilities playing everything from

the most blaring modern rock to the quiet solitude of public radio stations with

much more conservative material.

4

The Vorsis Vision

The Vorsis Audio Processing division of Wheatstone was created in 2005, and

for a single purpose — to “competently design new audio processing tools for the

broadcast industry that truly improve the sound of broadcasting.”

Wheatstone founder and owner Gary Snow had noticed how harsh and distorted

radio stations had become over the years as they chased each other in the

loudness game with existing audio processing products. Frustrated with that

sound and how it was destroying the listening enjoyment originally intended for

radio, he set a goal for Wheatstone as a company:

“Design new technology

that truly improve the sound of radio,

not further destroy it.”

Today the Vorsis development team is comprised of experts in digital signal

processing, professional audio, and product design. The team is led by broadcast

engineering veteran and audio processing expert Jeff Keith (who’s been

interested in audio processing for the better part of 40 years). As well as

designing new DSP algorithms and clever and easy to use user interfaces, he

guides the Vorsis team as they design new and revolutionary audio processing

products.

All of the design, manufacturing and testing of Vorsis audio processing products

is accomplished at Wheatstone’s Corporate Headquarters in New Bern, North

Carolina, USA. In its large, state of the art design and manufacturing facility

Wheatstone maintains 100% control over the quality of their product design and

its manufacturing. True to their goal of making only the highest quality products

Wheatstone utilizes no ‘contract’ or ‘offshore’ manufacturing.

Wheatstone’s obsessive control over the design and manufacturing of their

products ensures that every

same admired product quality that Wheatstone has delivered to its customers for

over thirty years.

Wheatstone’s line of competently designed and feature-rich Vorsis audio

processing products offers the broadcast industry high-quality products with the

superior audio performance and product reliability that Wheatstone is famous for.

Built to Wheatstone’s exacting product and audio quality standards Vorsis audio

processors are a perfect match for those who truly care about how their station

sounds.

customer receives the highest quality gear of the

audio processors

5

General Information

Introduction

The Vorsis AirAura is designed to exceed the expectations of customers who

want more loudness on the radio dial without incurring the usual artifacts that

usually accompany competitive loudness. This third generation full-featured and

top-of-the-line Vorsis audio processor expands on technologies previously

invented by the Vorsis design team as well as incorporating new ones.

The Vorsis design team approaches audio processing with an attitude of ‘quality

first’ and the processing algorithms in the AirAura processor are designed to

push the limits of what can be accomplished in an on-air processor into

completely new territory. Every algorithm is carefully analyzed though hundreds

of hours of critical listening with a wide range of program material to ensure that it

does exactly what it was designed to do - no more and no less.

Equipped with the tools necessary to create the on-air sound you’ve been

yearning for, AirAura’s audio clarity, on-the-dial power and presence, and the

accuracy of its sound are not found in any other audio processing product.

Period. Music sounds like it was meant to sound. Voices are rich and full with no

hint of unnatural coloration or distortion. Transitions between various program

elements are deftly handled with no trace of “processing” while corrections are

being made.

Further, instead of a customer being saddled with the inescapable sound

signature engrained in other brands of audio processors by their designers,

Vorsis products, including the new AirAura, have no

their own. The customer is completely free to use the pallet of tools in the AirAura

to create whatever on air sound he can dream of, from no hint of processing at

all, to wall of sound.

With an internal base sampling rate of 192 kHz (some sections operate as high

as 1½ megahertz!) and its 144dB internal dynamic range AirAura processes a

station’s audio with extreme precision. Twin front panel LCD screens and touchpad allow control of all system and processing setup parameters. Equipped with

the Vorsis GUI Lite right on the front panel, the sound of the AirAura’s Factory

Presets can be quickly customized as desired.

For even more control over processing parameters an optional full-control GUI

designed for processing experts and sporting every possible control can be

obtained by registering for it at http://www.VorsisProGUI.com

users can download a full-control GUI having all processing adjustment controls

available.

fixed sound coloration of

. Once registered,

6

Processing Structure Overview

The AirAura digital audio processor is designed to separately process the audio

for both conventional analog FM and digital HD radio signals. Sharing the fourband fully parametric equalizer and highly intelligent five-band AGC, the FM and

HD paths each have their own 31-band limiter sections followed by separate final

limiters of different styles optimized for their intended mediums.

Each 31-band limiter section operates much like the high-resolution filter banks

used in perceptual codecs that rely on critical band masking to hide their

operation from the human ear. Because of this technology, and unlike other

limiters with fewer bands, human psychoacoustics makes the operation of each

31-band limiter section essentially invisible to the ear.

The FM signal path is equipped with the new AirAura clipper as well as a lookahead limiter — useful for less aggressive program formats. A digitally perfect

stereo generator provides two multiplex composite stereo outputs and two SCA

inputs. The input connector for SCA-2 can be internally switched to convert it into

a 19 kHz stereo pilot Sync output for RDS applications requiring a separate 19

kHz synchronization signal.

The HD signal path is equipped with a smart look-ahead final limiter with

adjustable operating parameters that allow program density and peak control to

be adjusted as desired. The HD path’s digital and analog outputs may be

swapped left for right as well as phase reversed to accommodate a known bug in

HD radio hardware.

A collection of Factory presets makes a wide range of on air sounds available to

the user. These presets, in combination with the front panel’s GUI Lite controls,

allow the end user to create literally millions of different on-air sounds that are

completely different from what the factory presets provide.

A fully routable headphone monitoring path allows the audio in various parts of

the processing chain to be auditioned.

The System Menu of all GUI’s provides access to a flexible preset scheduling

utility that, along with having daily events, also has a long-form schedule. This

feature allows preset changes to occur on a particular date and time in the future.

This feature is useful for changing presets weeks or months after a preset was

prepared for a special event without having to edit the regular daily schedule to

accommodate the special preset.

GPI (General Purpose Inputs) provide easy access to preset changes via

external events such as contact closures and automation control. In addition the

AirAura is equipped with our ACI protocol which allows complete control of the

processor by a program automation system beyond just preset changes.

7

Installation

We know that you’re probably in a hurry to get on the air with your new AirAura. If

you have little technical expertise with audio processor fundamentals, the

following pages will get you up and running as quickly as possible without having

to know a lot of techie stuff.

If during installation or setup you find that you need assistance or advice, please

feel free to contact our technical support folks at (252) 638-7000 or write to

techsupport@vorsis.com.

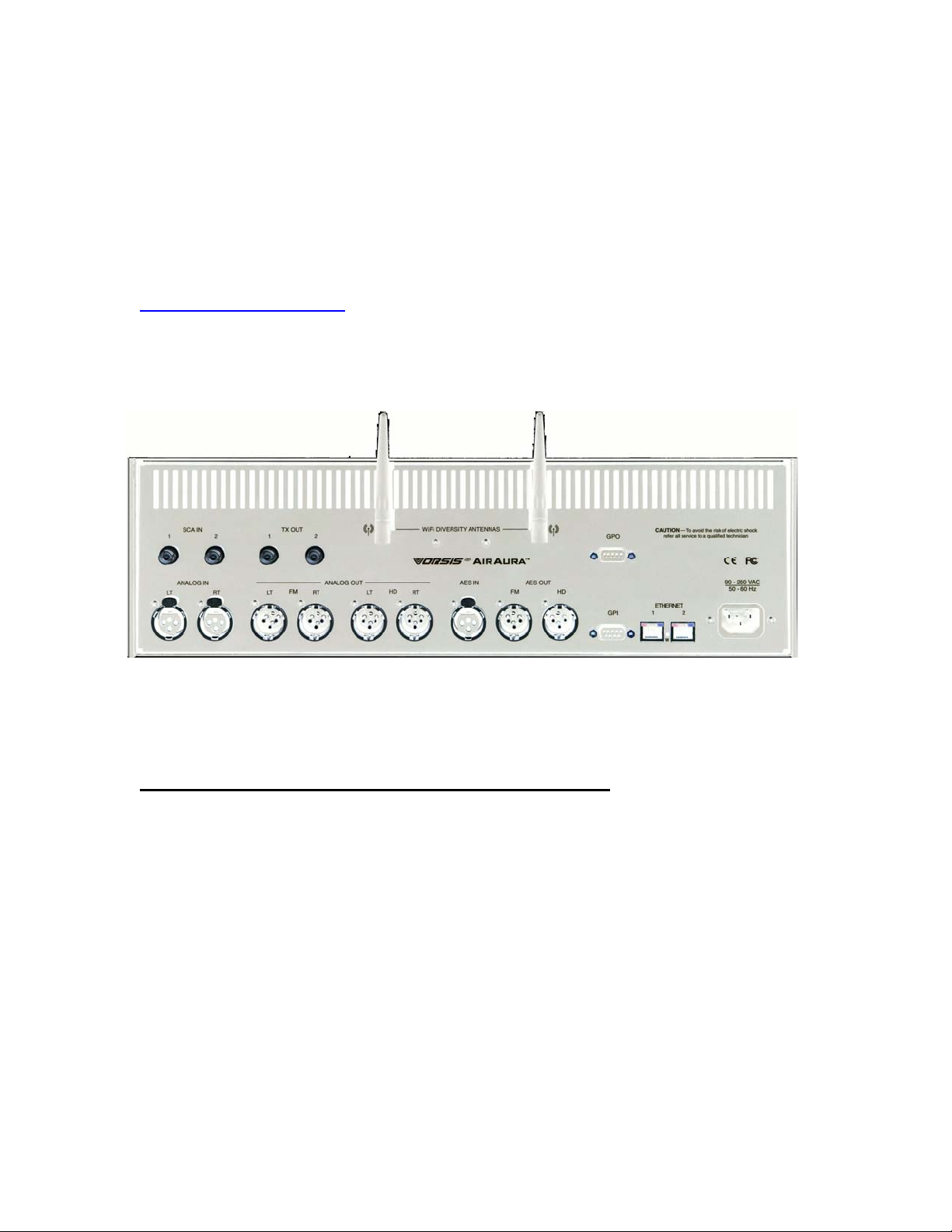

The image below (colors reversed to save on laser printer toner!) shows the rear

panel of the AirAura and the location of the various connectors associated with

an installation:

AirAura Rear Panel Connections

AirAura’s rear panel connectors from left to right are:

Bottom Row Top Row

Analog Left channel In SCA-1 Input

Analog Right Channel In SCA-2 Input

Analog Left Channel Out TX-1 Out

Analog Right Channel Out TX-2 Out

HD Analog Left Channel Out WiFi Antenna 1

HD Analog Right Channel Out WiFi Antenna 2

AES Digital Input GPO Output

FM AES Digital Out

HD AES Digital Out

GPI Input

Ethernet 1

Ethernet 2

AC Power Input

8

Rack Mounting

AirAura is designed to be mounted into an industry standard 19” equipment rack

and requires three rack units (5.25 inches / 13.335cm) of vertical space. If using

only two rack screws always use the bottom two to prevent twisting and other

undue forces from harming the processor.

AirAura does not have top or bottom cover vent holes. Rather, cooler air is drawn

into the unit through vertical slots positioned lower in the side panels, forcing

latent heat, which rises by natural convection, out through slots in the top of the

rear panel.

There is one small fan internal to the unit whose purpose is to stir air inside the

enclosure to even out the temperatures and prevent hot spots. The fan does not

‘remove’ heat and therefore failure of the 80,000 hour-rated fan, in the unlikely

event it should occur, will not compromise the operation of the AirAura as long as

AirAura is being operated in a reasonable environment (below 104F or 40C).

AirAura may be mounted between other devices in the equipment rack; however,

in accordance with good engineering practice it should not be mounted directly

above devices that generate significant amounts of heat such as power

amplifiers or power supplies. If such a location is unavoidable, then it is advisable

to utilize an extra 1RU blank rack panel between the AirAura and devices

immediately above and/or below it.

WARNING!

The AirAura enclosure normally does not need to be opened in the field.

Please be advised that the unit contains high voltage power supply circuits

that are hazardous and potentially deadly if accidentally contacted.

Because there are no user-serviceable parts inside the unit, it should be

returned to Wheatstone Corporation if repair becomes necessary.

9

AirAura Installation Tips:

• Grounding: Establish a lo w impedance common ground in your facility and try

to route all grounds to that point. AirAura’s ground reference (its chassis) should

be connected to the station ground. This is especially important in a high RF

environment.

• Surge protection: Place surge protection circuits as close as possible to the

AirAura being protected. Surge currents should be steered to power ground

instead of station ground if possible.

• UPS/Power Conditioning: Choose the best power conditioning/UPS units that

you can afford, focusing on the most important features and options that you

need. The better UPS products can prevent equipment damage and some even

come with an external equipment damage warranty.

• Analog Audio Connections: Balanced audio sources should be connected to

AirAura using shielded audio cable. Unbalanced audio connections, if they are

necessary, should be made with shielded two conductor cable such as Belden

8451 or 9451 as if connecting a balanced source. At the unbalanced source’s

output connect its “+ Output” to AirAura’s “Hi” (XLR pin2) input and connect the

unbalanced source’s shield wire to AirAura’s “Lo” (XLR pin-3) input wire. If the

cable shield is used (recommended) connect it to the AirAura end only (XLR pin

1) to prevent ground loops.

• Digital Audio Connections: For digital audio connections always use a good

quality digital audio cable with a characteristic impedance of 110 ohms. The

AES/EBU specification with its broad impedance tolerance allows for cables with

impedances from 88 ohms to 132 ohms - 110 ohms is ideal. Twisted pair cable

should be shielded, and in the case of multi-pair cable, each pair should be

individually shielded. Foil shielding is recommended for permanent installations.

Cable with a foil shield plus an overall braid should be used in applications where

frequent flexing of the cables may occur. Each cable pair is capable of carrying

two channels of AES3 digital audio.

Generic “audio” cable such as Belden 8451 and 9451 can be used for

interconnecting AES3 digital audio devices, but the wire length should be

minimized. The actual cable length that will work is primarily determined by the

error correction and jitter tolerance of the AES3 receiver device and the specific

cable used and its length.

The impedance of most ‘analog’ audio cables ranges from 40 ohms to 70 ohms

and represents a fairly large impedance mismatch from the nominal 110 ohms

required by the AES3 standard. Such impedance mismatch will result in signal

reflections which can cause bit errors and audio dropouts at the AES3 receiver.

10

The higher capacitance of generic analog cables slows down the rise time of the

digital data signals which can impair the ability of the AES3 receiver to accurately

detect digital signal transitions. This results in increased jitter, or at the extreme,

no audio at all.

Where to Install AirAura

The best location for installing AirAura, or any other “on-air” processor, is at the

transmitter site. However this requires that a discrete Left/Right STL, either

analog or digital, be involved in the signal path. The benefit of a transmitter site

installation is that it enables the use of AirAura’s built-in lab-grade stereo encoder

allowing more precise control of modulation peaks.

The transmitter site location also allows the operation of AirAura’s highly

oversampled composite clipper to be used to create an additional loudness

advantage. The Vorsis composite clipper algorithm is more forgiving than those

found in other products, and in combination with our pilot and SCA protection

filters can create additional loudness without the usual audio and spectral grunge

that composite clippers typically create.

We recommend that the processor (any processor) be interfaced to the

transmitter using the exciter’s composite stereo multiplex input. The exciter’s

AES3 digital input may be ‘clean’, but it also precludes the ability to gain

additional loudness through the use of AirAura’s intelligent oversampled

composite clipping. Depending on the sample rates being used the exciter’s AES

digital input can also exhibit somewhat inferior peak control than the composite

input.

If AirAura is located at the studio and an STL is used to send the program

material to the transmitter there are several issues that need to be considered.

Analog Left/Right STL:

Older analog discrete left/right STL’s can suffer from an inability to control audio

peaks because of inadequate bandwidth in their IF circuits or poor low frequency

performance. Individual STL’s rarely have identical audio group delay in both

channels which affects stereo separation when the signal is converted to the

multiplex composite domain. Such STL’s also usually suffer from AFC bounce

when handling processed low frequency material and that can rob modulation

capability.

Composite Analog STL;

An analog composite STL has several advantages over the analog left/right STL

just described. These STL’s typically have better audio performance than an

analog discrete STL, and most have the capability to piggyback subcarriers on

the composite audio. This means that most SCA and RDS generators can be

located at the studio end of the STL along with the audio processor. If nothing

11

else, this is at least a convenient setup. When a modern composite STL is used it

can be nearly as transparent audio-wise as a digital STL.

Analog Phone Lines:

We don’t recommend discrete left/right analog ‘phone line’ STL’s because of the

inability of many service providers to guarantee flat frequency response and

proper phase matching between the two circuits. Furthermore, in many countries

wideband analog circuits are unavailable or their cost is prohibitive.

On the other hand if the STL is a dedicated (and equalized if necessary) pair of

circuits under the station’s control then they may be acceptable.

Digital STL:

When using a Digital STL that employs audio compression, it is highly

recommended that the AirAura be placed at the transmitter site which puts it after

the codec. The reason for this placement is that the codec will usually sound

better when presented with unprocessed studio audio than when handling the

highly processed and pre-emphasized audio present at the processor’s output.

Further, the encoding schemes used in such STL’s will not accurately pass the

well-defined peak levels created by AirAura which will create a modulation

(loudness) disadvantage.

AirAura can also be installed at the studio end of a compressed STL with at least

two caveats:

- The stereo generator and composite clipper in AirAura are not available. Most

digital exciters offer a composite clipper function, but they are usually quite crude

in their implementation compared to AirAura’s exceptional clipper. “Exciter

hosted” composite clippers are never the optimum choice when the station’s

ultimate sound quality is important.

- Compressed (data reduced) STL’s do not perform well when presented with

competitively processed audio. This is because codecs work by examining the

audio for opportunities to remove something that shouldn’t be audible to the

human ear.

When dense audio is presented to a codec there are fewer ‘opportunities’ to

remove redundant audio information and mask it from our hearing. Under these

conditions codec operation can be much more obvious — even objectionable —

than when the processing is located after the codec where the masked artifacts

are only occasionally unmasked.

TIP: If using AirAura at the studio be certain that any clippers in the stereo

generator at the transmitter site are properly set up to complement the settings in

AirAura. This will prevent gross distortion and potentially large modulation

overshoots.

12

Also, pre-emphasis should always be applied by the audio processing, not the

exciter. Modern FM audio processors have special and quite complicated but

efficient circuits to deal with the challenges presented by the FM pre-emphasis

curve and can provide very tight modulation control with low perceived distortion.

FM exciters do not have this technology!

EAS – United States Emergency Alert System

If the EAS generator is placed before the AirAura, the levels of the signaling

tones and FSK data can be disturbed if the processing (any processing, not just

AirAura) is very aggressive. Therefore in this situation it is recommended that the

EAS encoder be placed after the processing.

If the EAS unit needs to be installed prior to AirAura and AirAura is operated

aggressively, AirAura may need to be configured so that when the EAS tones are

being sent AirAura is switched to a bypass mode or a less aggressive preset.

This can easily be accomplished by using AirAura’s GPI interface and by

assigning a special preset to the EAS function that has internal processing

defeated and audio levels calibrated to provide proper modulation levels during

EAS transmissions.

Arbitron People Meter (PPM)

Reports from the field indicate that AirAura favorably passes the data

watermarking scheme used in the Arbitron People Meter rating service

technology, regardless of the aggressiveness of the audio processing performed.

13

Energizing

Assuming AirAura is correctly rack mounted you may now energize it, noting that,

for long-term reliability reasons there is no power switch.

The AC line input voltage may be between 90 and 260 VAC, 50 or 60Hz. Power

consumption is under 100VA.

Aggressive AC input filtering is utilized at AirAura’s AC power input; however it is

always advisable to use some form of competent external surge protection

and/or an uninterruptible power supply (UPS), especially where AC power quality

is questionable, such as at a remote transmitter site.

Power conditioning, surge suppression, and even power backup devices are

wise investments when using sensitive modern electronic devices that, like

AirAura, use some type of internal computer.

The use of a UPS (uninterruptible power supply) is usually recommended and

will protect AirAura from short duration power interruptions which may otherwise

signal it to reboot when it sees the power glitch. When this happens there will be

a loss of audio for approximately 20 seconds.

Rear Panel Connections

All audio input and output, control, Ethernet, and power supply connections are

made via various connectors mounted on AirAura’s rear panel.

• Nine XLR connectors are provided for analog and digital audio

input and output connections.

• Four BNC connectors are provided for SCA in and TX (transmitter)

out connections.

• Two RJ-45 connectors are provided for Ethernet connections.

Either of these connectors can be used to connect a Windows® PC

running the Vorsis AirAura GUI.

• Two DB-9 connectors provide 8 GPI inputs (for selecting the first 8

presets) and four GPO outputs. The pin-out drawings in Appendix E

summarize wiring connections for these features.

14

Audio Inputs

Input audio can be applied to either the analog left/right inputs or to the AES3

digital input as appropriate. The AES3 input accepts sample rates between 32

kHz and 96 kHz.

Automatic audio failover from one input to the other is a user selectable option.

Automatic failover from AES3 to analog is instantaneous and based on invalid or

missing bits in the AES3 stream, or after 30 seconds of “silence” (level below 48dBFS).

Automatic failover from analog to AES3 is based on the same silence sense

algorithm responding to audio below -48dBFS for more than 30 seconds.

Audio Outputs

FM Audio Outputs

Output audio for the FM path is available as:

• Analog balanced left/right stereo.

• Analog balanced left/right stereo and de-emphasized according to

any pre-emphasis used.

• AES3 digital, either pre or post diversity delay, and/or deemphasized according to any pre-emphasis used.

• Balanced line level composite stereo.

• Unbalanced composite stereo on two rear panel BNC female

connectors.

HD Audio Outputs

Output audio for the HD path is available as:

• Balanced left/right analog.

• AES3 digital.

15

Loading...

Loading...