Vonsch Unifrem Series, Unifrem 400, Unifrem 230 M, Unifrem 400 M, Unifrem 500 Configuration And Diagnostics

...

10 May 2017 Page 1 from 180

Configuration and diagnostics

for UNIFREM and QUATROFREM (output side)

frequency converters

UNIFREM v.3.41x

10 May 2017 Page 2 from 180

UNIFREM v.3.41x

10 May 2017 Page 3 from 180

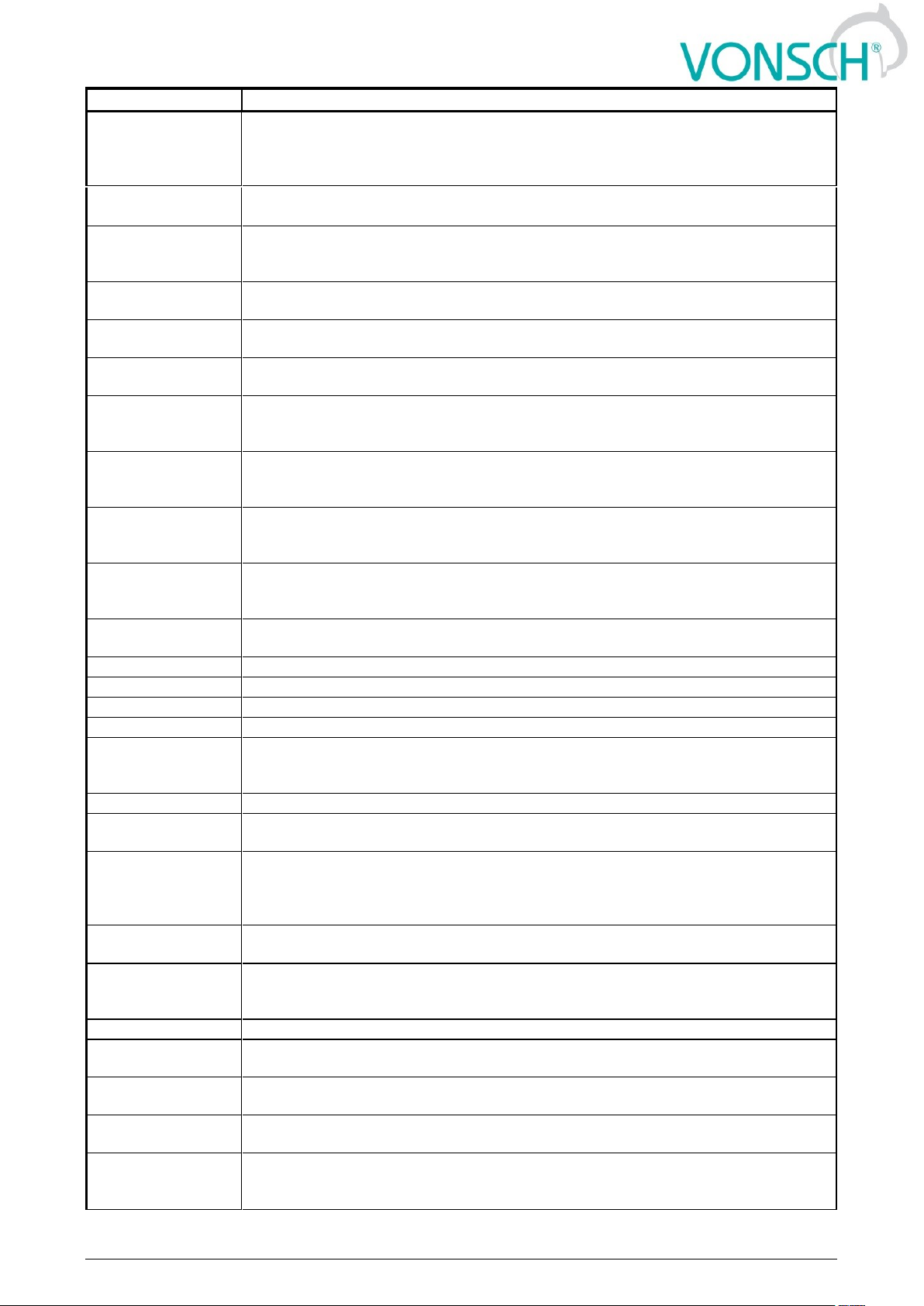

1 Contents

2 Structure and types of parameters in the document .................................................................... 7

2.1 Defining the meaning and type of parameters in part DIAGNOSTICS ................................ 7

2.2 Defining the meaning and type of parameters in part SETTINGS ....................................... 8

2.3 Type of parameters defining in the part SAVE / RESTORE .............................................. 13

3 Range of parameters by product type ........................................................................................ 14

3.1 Undervoltage, overvoltage .................................................................................................. 14

3.2 Temperatures ...................................................................................................................... 14

4 DIAGNOSTICS ........................................................................................................................... 15

4.1 Command ............................................................................................................................ 15

4.2 Control ................................................................................................................................. 15

4.2.1 Power and energy ........................................................................................................ 16

4.2.2 Additional quantities ..................................................................................................... 16

4.2.3 Positioning .................................................................................................................... 17

4.3 Inputs and outputs ............................................................................................................... 17

4.3.1 BIN................................................................................................................................ 17

4.3.2 AIN................................................................................................................................ 17

4.3.3 RELAYS ....................................................................................................................... 18

4.3.4 AOUT ........................................................................................................................... 18

4.3.5 IRC1,IRC2,ARC ........................................................................................................... 19

4.4 Functions ............................................................................................................................. 20

4.4.1 PLC function ................................................................................................................. 20

4.4.2 Limit switches ............................................................................................................... 21

4.4.3 Process controller ........................................................................................................ 21

4.4.4 Optimization ................................................................................................................. 22

4.4.5 Lifting functions ............................................................................................................ 22

4.4.6 Pantograph ................................................................................................................... 22

4.4.7 Ext. thermal protection ................................................................................................. 23

4.4.8 Differential .................................................................................................................... 23

4.5 Converter state .................................................................................................................... 23

4.6 Thermal protections ............................................................................................................. 24

4.7 Communication.................................................................................................................... 25

4.7.1 MODBUS ...................................................................................................................... 25

4.7.2 PROFIBUS ................................................................................................................... 25

4.7.3 RS LINKS ..................................................................................................................... 26

4.8 SW and HW version ............................................................................................................ 26

4.9 Date and Time ..................................................................................................................... 27

5 WARNINGS ................................................................................................................................ 28

6 ERRORS ..................................................................................................................................... 32

7 SETTINGS .................................................................................................................................. 35

7.1 Using the quick setup wizard with VONSCH UNIFREM .................................................... 35

7.1.1 Working with the wizard ............................................................................................... 35

7.1.2 Steps of the quick setup wizard ................................................................................... 36

7.1.3 Setting the motor data, application and command macro ........................................... 37

7.1.4 Application macros ....................................................................................................... 38

7.1.5 Command macros ........................................................................................................ 39

7.1.6 Directions and the encoder .......................................................................................... 40

7.1.7 Control methods, parameter identification, dynamics of the drive .............................. 41

7.2 MOTOR ............................................................................................................................... 42

7.2.1 MOTOR MACROS ....................................................................................................... 43

7.2.2 IDENTIFICATION......................................................................................................... 43

7.2.3 NAMEPLATE MOTOR PARAMETERS....................................................................... 44

7.2.4 SPECIAL PARAMETERS OF THE MOTOR ............................................................... 45

7.3 CONVERTER PARAMETERS ............................................................................................ 47

7.3.1 APPLICATION MACROS ............................................................................................ 47

UNIFREM v.3.41x

10 May 2017 Page 4 from 180

7.3.2 ENERGY CONS........................................................................................................... 48

7.4 COMMANDS ....................................................................................................................... 48

7.4.1 COMMAND MACROS ................................................................................................. 48

7.4.2 START STOP RESET ................................................................................................. 49

7.4.3 FREQUENCY SETPOINT ........................................................................................... 51

7.4.4 TORQUE SETPOINT ................................................................................................... 52

7.4.5 POSITION SETPOINT ................................................................................................. 53

7.4.6 DISCRETE SETPOINTS ............................................................................................. 54

7.4.7 UP/DOWN COMMANDS ............................................................................................. 56

7.4.8 AUTO OFF ................................................................................................................... 56

7.5 CONTROL AND REGULATION ......................................................................................... 57

7.5.1 CONTROL METHOD ................................................................................................... 57

7.5.2 V/f CONTROL .............................................................................................................. 58

7.5.3 VECTOR CONTROL ................................................................................................... 62

7.5.4 FREQUENCY RAMPS ................................................................................................. 69

7.5.5 MAXIMUM CURRENT AND VOLTAGE ...................................................................... 71

7.5.6 FLYING START ........................................................................................................... 71

7.5.7 VOLTAGE CONTROLLER (VC) .................................................................................. 72

7.5.8 BRAKE MODULE......................................................................................................... 73

7.5.9 FLUX BRAKING ........................................................................................................... 74

7.5.10 POWER RESTRICTION .............................................................................................. 74

7.6 INPUTS AND OUTPUTS .................................................................................................... 75

7.6.1 BINARY INPUTS.......................................................................................................... 75

7.6.2 ANALOG INPUTS ........................................................................................................ 76

7.6.3 RELAY OUTPUTS ....................................................................................................... 80

7.6.4 ANALOG OUTPUTS .................................................................................................... 82

7.6.5 IRC1 ............................................................................................................................. 84

7.6.6 IRC2/ARC..................................................................................................................... 85

7.7 FUNCTIONS ........................................................................................................................ 85

7.7.1 PLC FUNCTIONS ........................................................................................................ 85

7.7.2 LIMIT SWITCHES ........................................................................................................ 95

7.7.3 PROCESS CONTROLLER .......................................................................................... 97

7.7.4 OPTIMIZATION .......................................................................................................... 100

7.7.5 MECHANICAL BRAKE .............................................................................................. 102

7.7.6 LIFTING FUNCTIONS ............................................................................................... 102

7.7.7 EXTERNAL THERMAL PROTECTION (ETP) .......................................................... 105

7.7.8 IRC1,2 DIFFERENCE ................................................................................................ 106

7.7.9 DIFFERENTIAL .......................................................................................................... 107

7.8 FAULTS AND WARNINGS ............................................................................................... 107

7.8.1 OPTIONAL FAULTS .................................................................................................. 107

7.8.2 ENC. FAULTS ............................................................................................................ 109

7.8.3 FAULT ACKNOWLEDGEMENT ................................................................................ 109

7.8.4 QUANTITIES TO LOG ............................................................................................... 110

7.8.5 WARNINGS ............................................................................................................... 111

7.9 DISPLAY............................................................................................................................ 112

7.9.1 DISP. QUANT. SETTINGS ........................................................................................ 112

7.9.2 MONITOR SETTING ................................................................................................. 112

7.10 COMMUNICATION ........................................................................................................... 112

7.10.1 MODBUS .................................................................................................................... 113

7.10.2 PROFIBUS ................................................................................................................. 115

7.11 PAR. SETS ........................................................................................................................ 117

7.11.1 SET SWITCH ............................................................................................................. 117

7.11.2 USER SETS ............................................................................................................... 118

8 Converter function configuration manual ................................................................................. 128

8.1 Production (factory) settings ............................................................................................. 128

8.2 Motor parameters – MOTOR MACROS – identification ................................................... 128

8.3 Motor control modes .......................................................................................................... 129

UNIFREM v.3.41x

10 May 2017 Page 5 from 180

8.3.1 V/f control ................................................................................................................... 130

8.3.2 V/f curve ..................................................................................................................... 131

8.3.3 IR compensation ........................................................................................................ 133

8.3.4 Starting Torque Controller (STC) ............................................................................... 134

8.3.5 Slip compensation ...................................................................................................... 135

8.4 Maximal current controller (MCC) ..................................................................................... 136

8.5 Resonance damping ......................................................................................................... 139

8.6 Voltage controller (VC) - Dynamic deceleration (DD) a Kinetic backup (KB). ................. 141

8.7 Flux braking ....................................................................................................................... 143

8.8 Flying start ......................................................................................................................... 144

8.9 Power restriction ................................................................................................................ 145

8.10 Optimization ....................................................................................................................... 146

8.11 External thermal protection (ETP) ..................................................................................... 149

8.12 Overload switch „OPS“ ...................................................................................................... 151

8.13 Dynamic lift (DL) function .................................................................................................. 154

8.14 IRC detuning function ........................................................................................................ 156

8.15 Using the parameter set switching for a special behavior of converter functions ............ 158

9 UNIFREM Frequency converter settings examples ................................................................. 162

9.1 Process controller - PC setting to control the level height in the tank .............................. 162

9.1.1 Situation ..................................................................................................................... 162

9.1.2 Converter connection ................................................................................................. 162

9.1.3 Analog inputs setting .................................................................................................. 162

9.1.4 Process controller setting........................................................................................... 162

9.1.5 Converter output setting............................................................................................. 163

9.1.6 Monitoring................................................................................................................... 163

9.2 Example of logical blocks setting ...................................................................................... 164

10 Control panel – Unipanel user manual ................................................................................. 169

10.1 Buttons............................................................................................................................... 169

10.2 Panel start ......................................................................................................................... 170

10.3 Display ............................................................................................................................... 170

10.4 Converter status ................................................................................................................ 170

10.5 Main menu F1.................................................................................................................... 170

10.6 Monitor, monitor detail ....................................................................................................... 173

10.7 Parameters setting ............................................................................................................ 174

10.8 Graph ................................................................................................................................. 177

10.9 Parameter search .............................................................................................................. 179

10.10 Device selection for control panel ................................................................................. 180

UNIFREM v.3.41x

10 May 2017 Page 6 from 180

WARNING

This manual dedicates to the parameters and options of VONSCH UNIFREM frequency converter

settings and diagnostics.

UNIFREM v.3.41x

10 May 2017 Page 7 from 180

2 Structure and types of parameters in the document

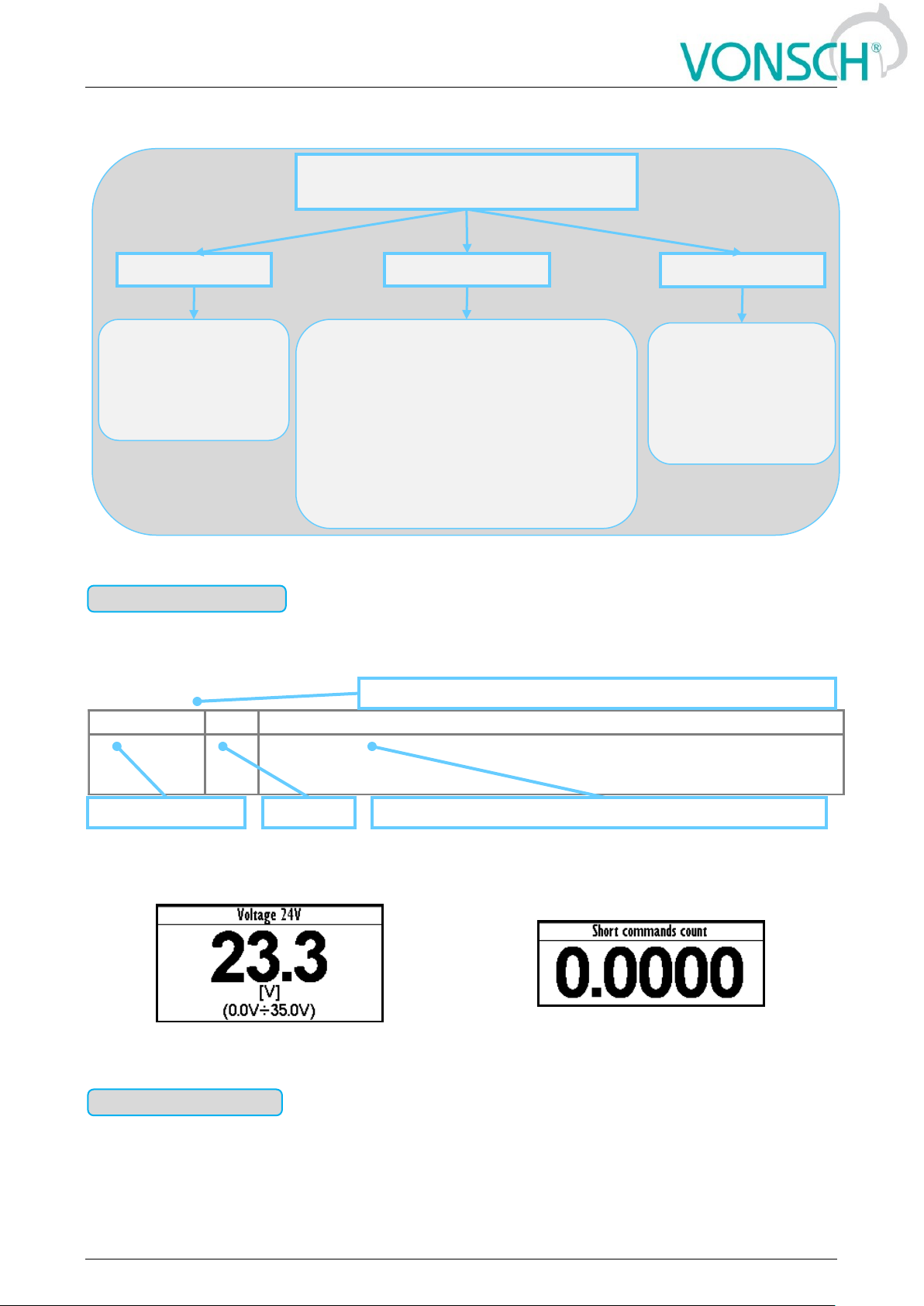

2.1 Defining the meaning and type of parameters in part DIAGNOSTICS

Diagnostic parameter that displays the value of signal in physical units or in relative units or

discrete number of sequences, steps, received data etc.

EXAMPLE:

Value – the value

MENU \ DIAGNOSTICS \ Converter state \

Value – discrete number

MENU \ DIAGNOSTICS \ Functions \ Lifting functions\

Example for value diagnostics – the value display

Example of diagnostic value representing the number

of illegal control drive sequences

Individual word bits status diagnostics. Each bit represents the status of one flag of a specific

function or converter mode.

MENU PARAMETERS

ID – unique identification number

SETTINGS

DIAGNOSTICS

SAVE/RESTORE

-Value–the value,

number

-Word (array of bits)

-Constant

-Date time

-The value

-Calculated parameters

-Selection (1 option selection)

-Multiple selection (multiple options

selection - mask)

-Command (execution of a single action)

-Signal (source of signal and functions

inputs)

-Dynamic value (linked parameter)

-Password

-Path (position in the

structure of

parameters)

-parameters types as

in the part

SETTINGS

Parameter type: VALUE

Name [ID]

Unit

Description

AIN1 Rel.

[41]

%

Value of the signal connected to the analog input terminals + X1:11 and X1:12.Parameters of the analog input can be configured in the parameter group

P[147] AIN1.

MENU \ DIAGNOSTICS \ Inputs / outputs \ AIN \

Value unit

Values ID and name

The basic diagnostics information about the importance of value

Position of the parameter in a tree hierarchical parameters structure

Parameter type: WORD

UNIFREM v.3.41x

10 May 2017 Page 8 from 180

EXAMPLE:

MENU \ DIAGNOSTICS \ Command \

MENU \ DIAGNOSTICS \ Inputs / outputs \ Relay

Converter control signals diagnostics

Output relays status diagnostics

Diagnostic information, which takes a fixed value.

EXAMPLE:

Constant

Diagnostic value of the date or time format.

MENU \ DIAGNOSTICS \

MENU \ DIAGNOSTICS \

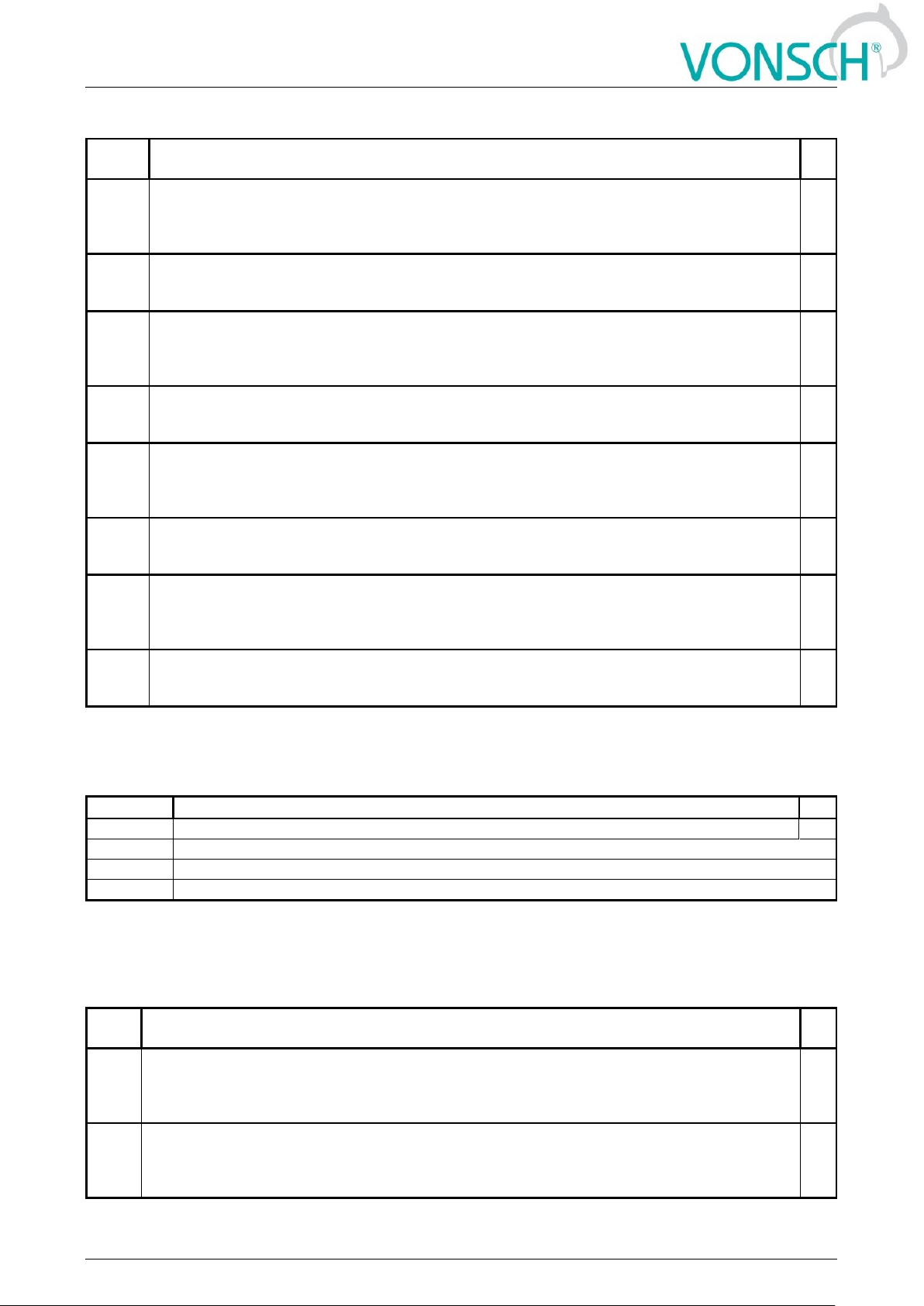

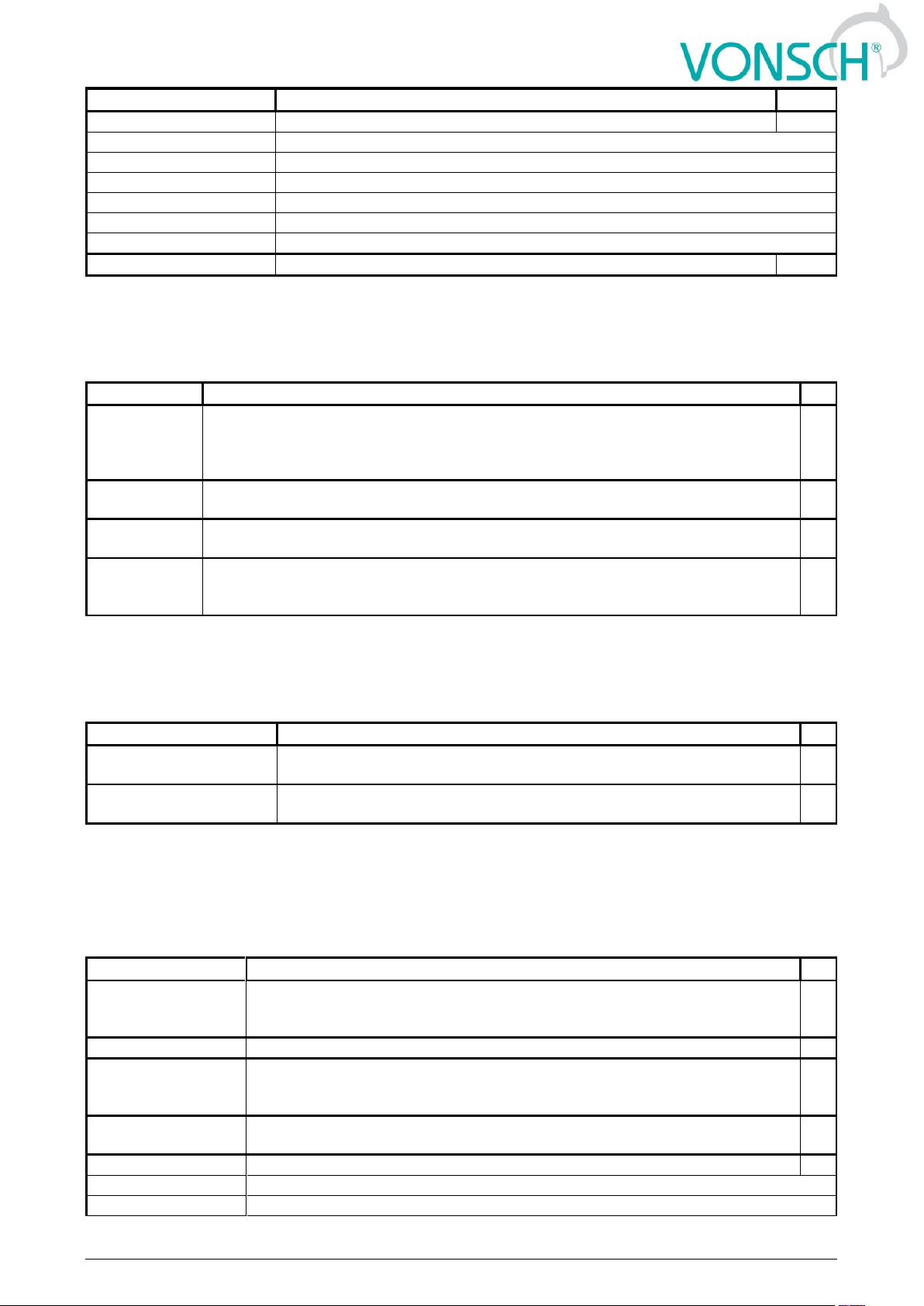

2.2 Defining the meaning and type of parameters in part SETTINGS

Possibility of parameter value setting in absolute or relative units.

Name [ID]

Unit

Description

OPS status [856]

Indicates the status of the OPS switch block.

Reset

RESET signal of the OPS is active.

Detection

Autodetection of the overload limits is running.

Overload

Overload occurred. Operation in the positive direction (up) is blocked.

Tipping

Too many forbidden tipping control commands.

Settling

Drive operates in static mode.

Dynamics

Drive operates in dynamic mode.

MENU \ DIAGNOSTICS \ Functions \ Lifting functions\

The basic diagnostic information about the importance of word

Additional diagnostic information about word bits view, status of

word bits view, respectively meaning of word bits

Individual word bits

description

Parameter type: CONSTANT

Name [ID]

Unit

Description

SW Version [379]

Converter SW version

MENU \ DIAGNOSTICS \ SW and HW version \

Constant description

Parameter type: DATE TIME

Parameter type: THE VALUE

UNIFREM v.3.41x

10 May 2017 Page 9 from 180

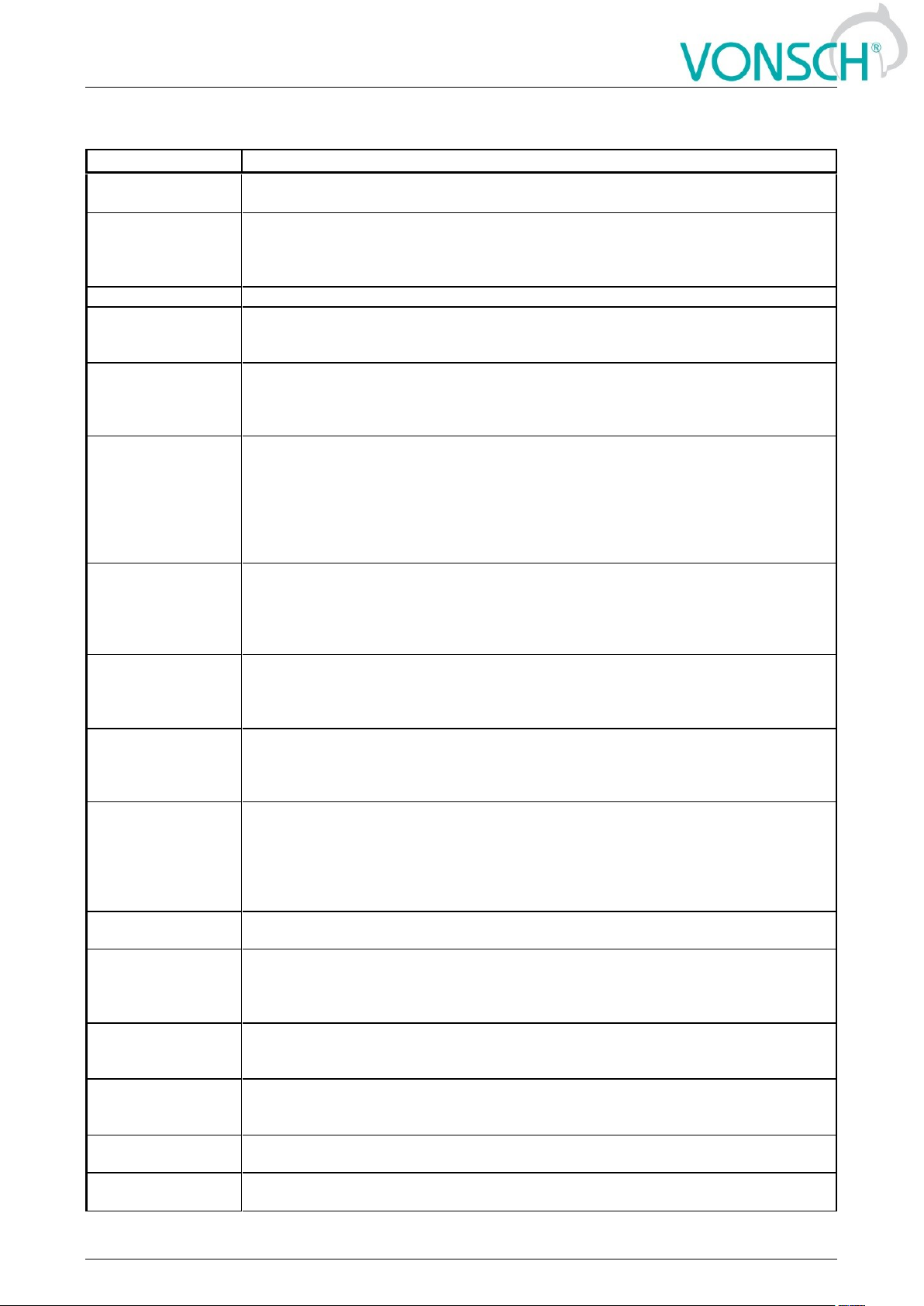

EXAMPLE:

MENU \ SETTINGS \ MOTOR \

Motor current value setting

Nominal motor voltage value setting

Parameter, that is derived by calculation based on the values of other parameters.

EXAMPLE:

MENU \ SETTINGS \ MOTOR \ SPECIAL PARAMETERS \

Example of the calculated parameter

Name [ID]

Description

Def.

Nom. Current

[151]

Nominal motor current, read from the nameplate or catalog data.

2.80 A

0.01 A ÷ 1000.00 A

This parameter determines the value of permanent motor current for motor

overload protection P[27] Motor overloading.

MENU \ SETTINGS \ MOTOR \

Basic information about the importance of the parameter

Range of the value, that

parameter can take Min ÷ Max

Additional information

about the importance of the

parameter

The default value of the parameter –

The value that is set at factory settings

restoration

Parameter type: CALCULATED PARAMETER

Name [ID]

Description

Def.

Nr of motor poles [1049]

Number of motor poles calculated from the nominal rpms and the motor

frequency.

2 ÷ 1000

MENU \ SETTINGS \ MOTOR \ SPECIAL PARAMETERS \

Additional information about derivation of parameter calculation

UNIFREM v.3.41x

10 May 2017 Page 10 from 180

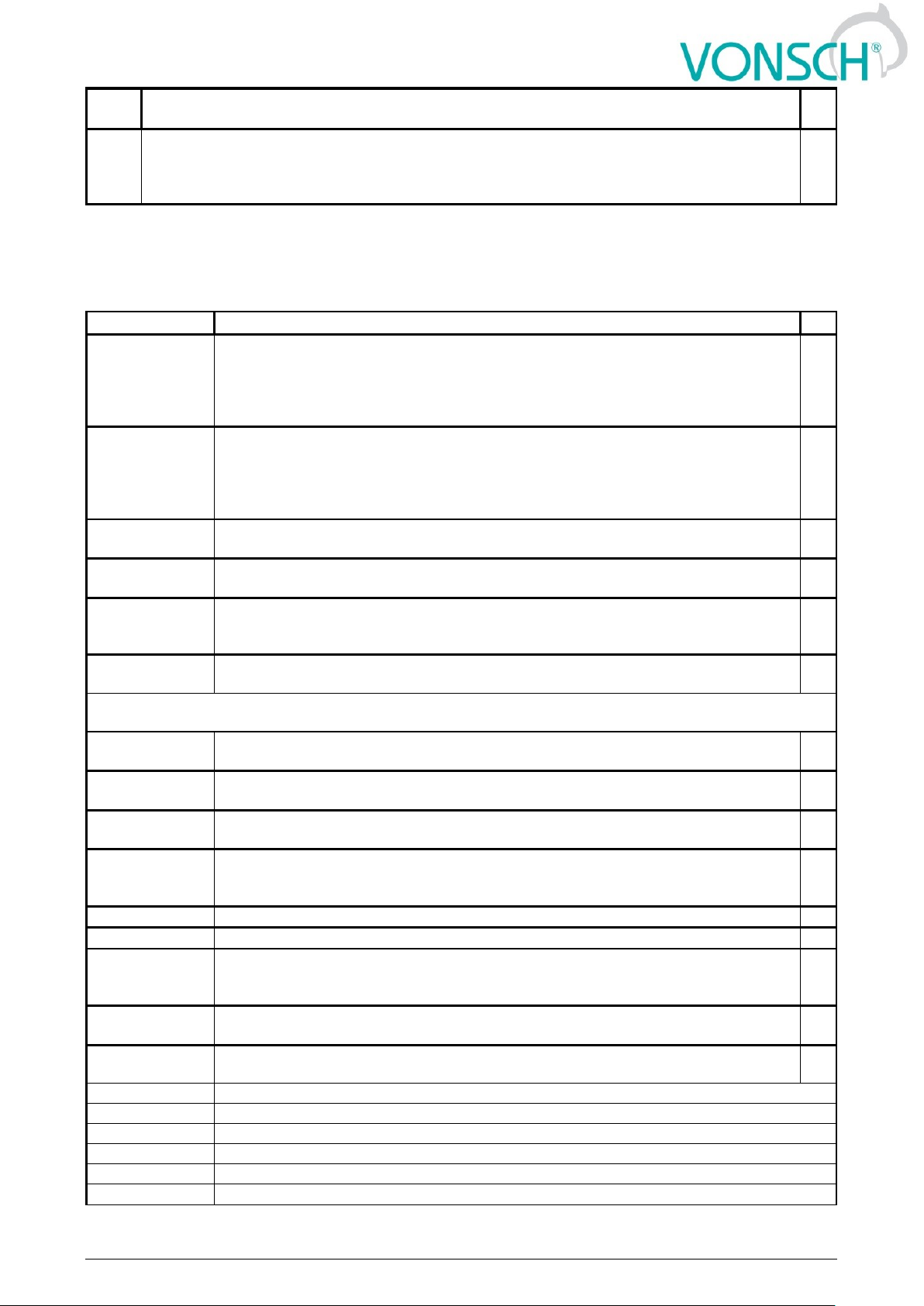

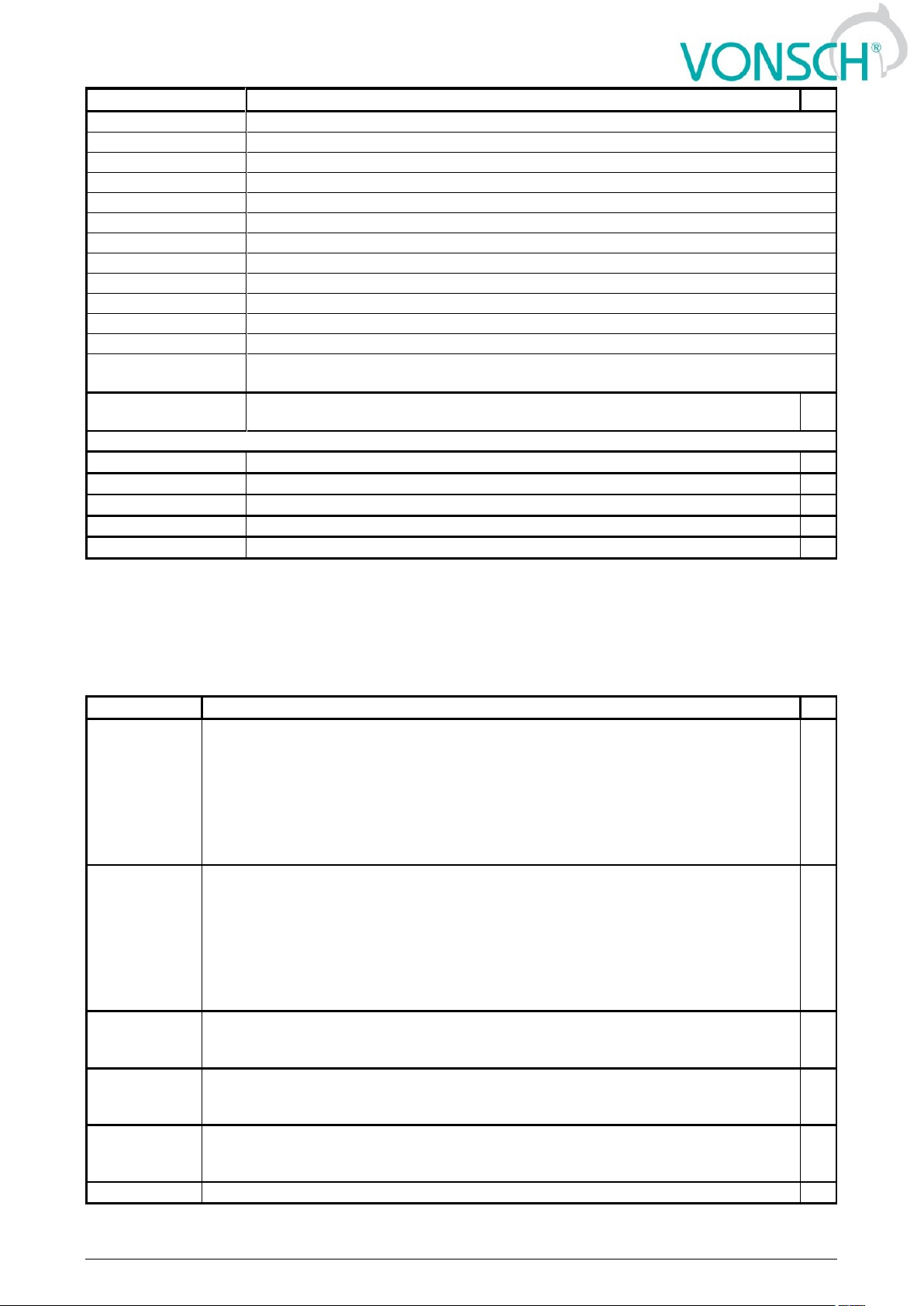

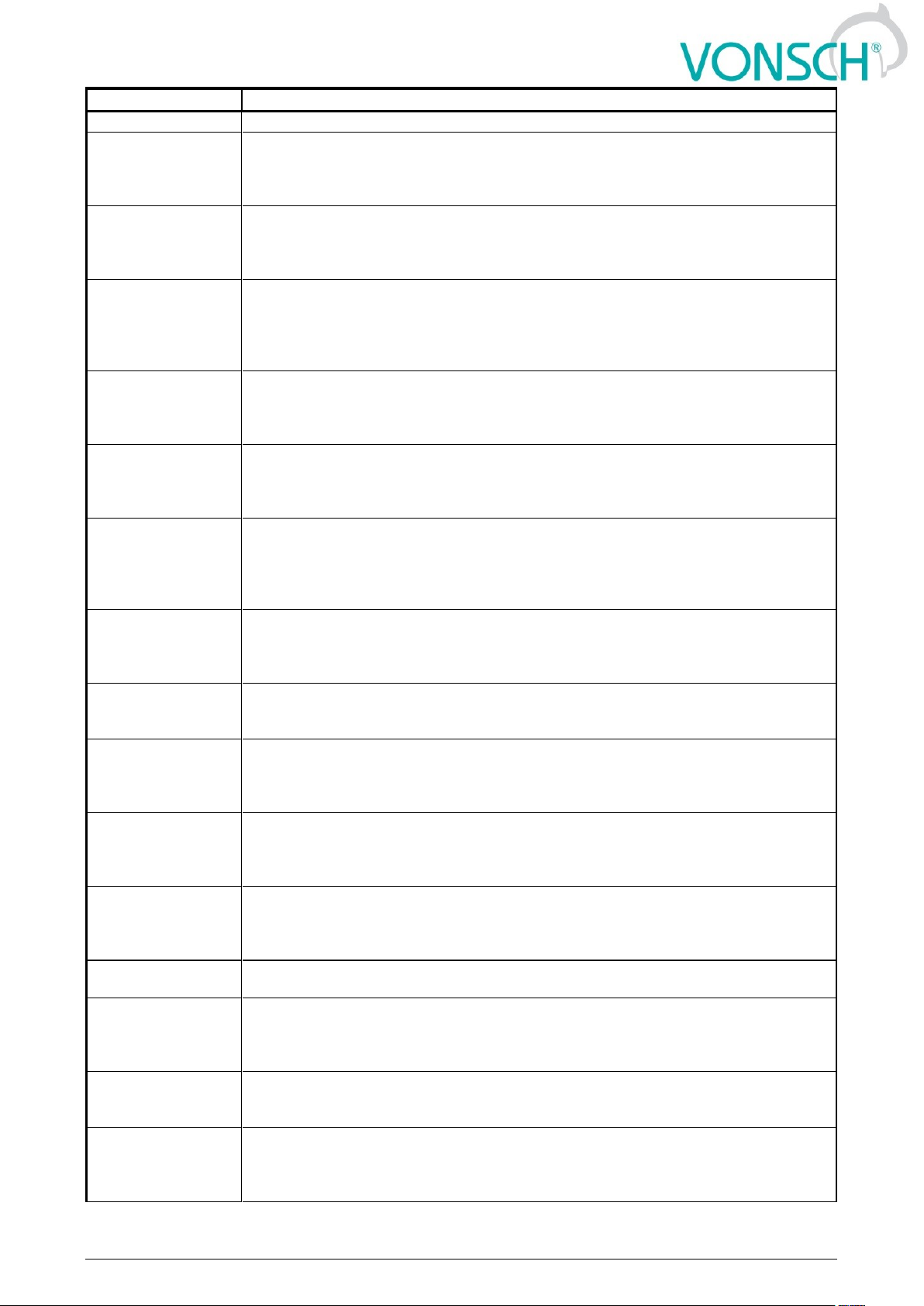

Type of parameter with option to select only one setting option (alternative).

EXAMPLE:

MENU \ SETTINGS \ COMMANDS \ FREQUENCY SETPOINT \

... \ SETTINGS \ FUNCTIONS \ LOGICAL BLOCKS\ LB1 (Fast) \

One setting option selection of selection type parameter examples

Parameter type with a option to select multiple possible value elections, modes, respectively active

bit of parameter.

Parameter type: SELECTION

Name [ID]

Description

Def.

Start source

[194]

Setting the converter start source. The START command generates the desired voltage and frequency

on the U,V,W outputs (or U,V for a single phase load).

BIN1

Control panel

Pressing the green START button on the control panel causes the converter to start. The start is canceled by

pressing the red STOP button.

Permanent

start

The converter starts immediately after the switch on.

BIN1

The converter start after the activation of the 1st binary input.

BIN5

The converter starts after the activation of the 5th binary input.

BIN6

The converter starts after the activation of the 6th binary input.

MODBUS

The converter start is controlled over the serial communication. See the MODBUS serial communication

protocol.

PROFIBUS

The converter start is controlled over the serial communication. See the PROFIBUS serial communication

protocol.

Special

The converter start is controlled by a special preset signal and switching thresholds, see P[987] SPECIAL

START.

MENU \ SETTINGS \ COMMANDS \ START STOP RESET \

Basic information about type of parameter - selection

The name of specific (alternative)

selection of parameter value

Additional information about the meaning

of a specific parameter selection

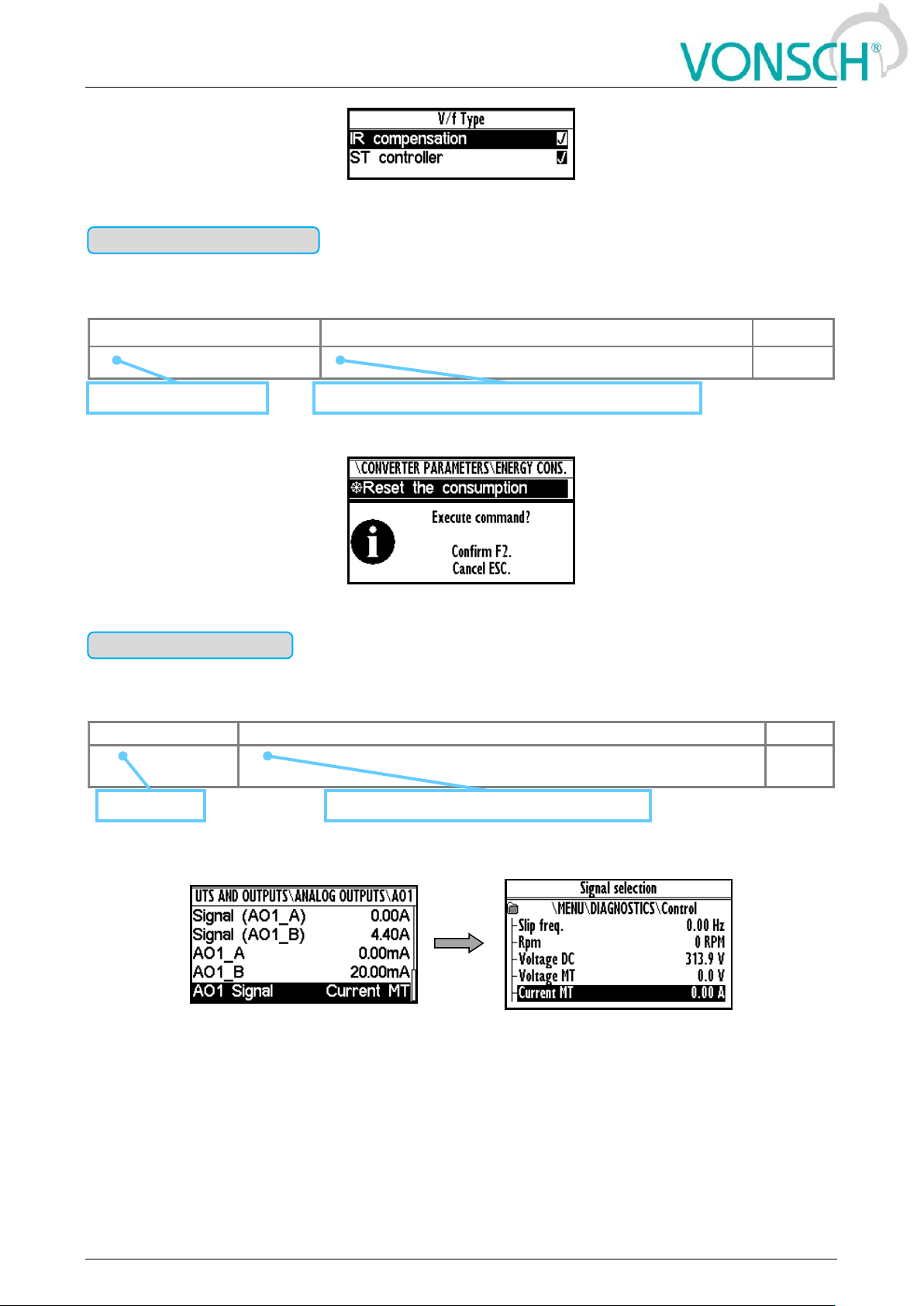

Parameter type: MULTIPLE SELECTION (MASK)

Name [ID]

Description

Def.

V/f Type [347]

V/f Curve type. Selecting the features of the V/f control method operation.

□ IR compensation

Turns on the stator resistance loss compensation P[973] Compensation of IR

(CIR). Requires correct value of the motor parameters and the stator resistance

P[345] Stator resistance.

□ ST controller

Turns on the starting torque controller P[29] ST Controller (STC) to boost starting

torque.

* When the square is black ■ - the default setting is set

MENU \ SETTINGS \ CONTROL AND REGULATION \ V/f CONTROL \ V/f CURVE \

Basic information about the

parameter type - multiple selection

Names of parameter

value elections (modes)

Additional information about the meaning of

individual parameter elections (modes)

UNIFREM v.3.41x

10 May 2017 Page 11 from 180

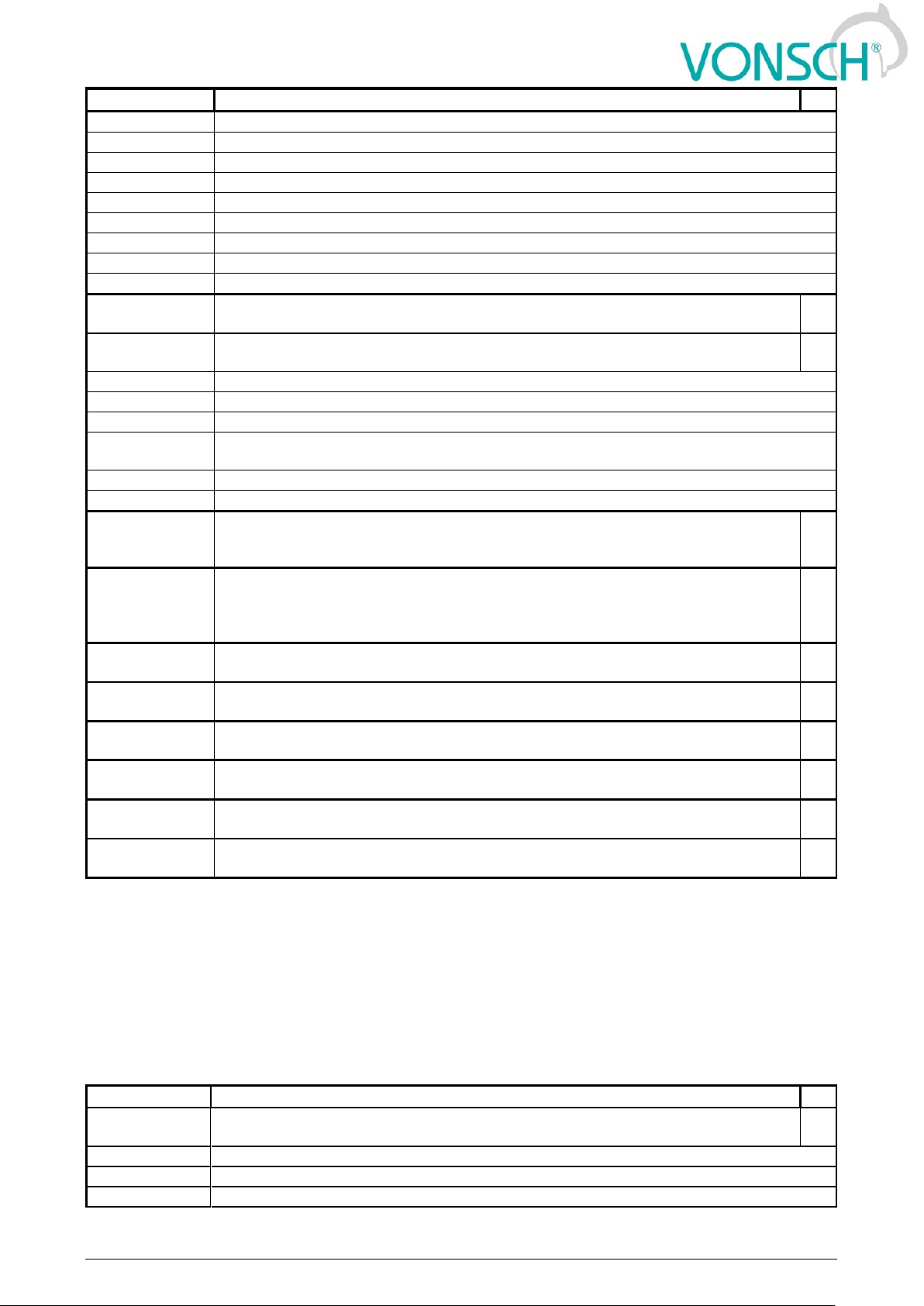

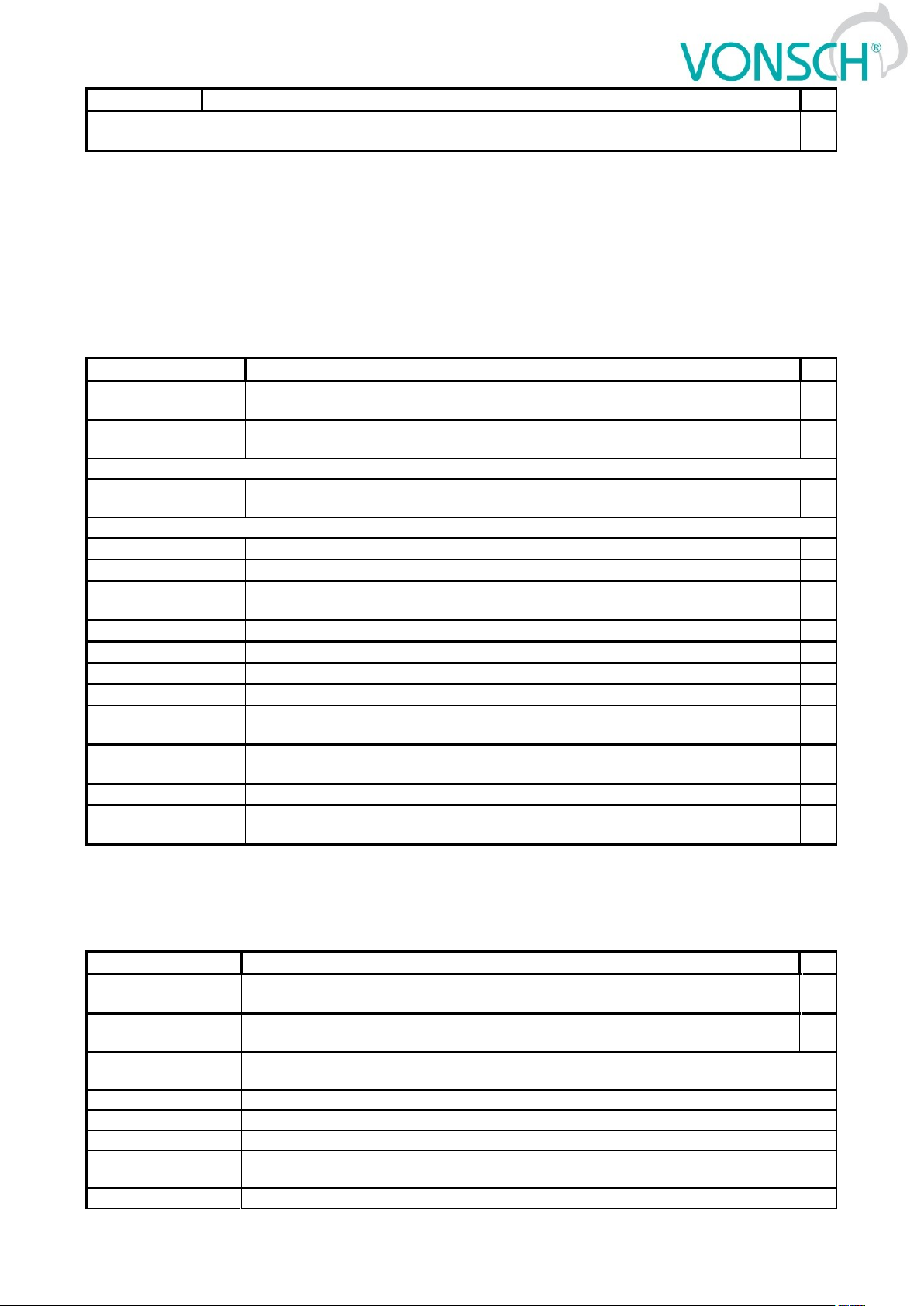

EXAMPLE:

Example: V/f curve operation mode selection

Command to execute a single action or operation on the converter. It is required to confirm the

command before execution in the confirmation window.

EXAMPLE:

This command resets consumed energy counters

Parameter for dynamic ties and any parameter connection, that becomes a value source for a

given function or for input of this function.

EXAMPLE:

MENU \ SETTINGS \ INPUTS AND OUTPUTS \ ANALOG OUTPUTS \ AO1 \

Selection of the signal that will linearly recalculate the analog output AO1

Parameter type: COMMAND

Name [ID]

Description

Def.

Reset the consumption [897]

This command resets the counters of consumed energy.

MENU \ SETTINGS \ CONVERTER PARAMETERS \ Energy consumption \

Function, description and importance of the command

Name and command ID

Parameter type: SIGNAL

Name [ID]

Description

Def.

AIN1 Signal [251]

Selection of the signal that will be linearly recalculated according to the

analog input.

[ - ]

MENU \ SETTINGS \ INPUTS AND OUTPUTS \ ANALOG INPUTS \ AIN1 \ SPECIAL SETTING \

Type of signal selection from the diagnostics

Signal name

UNIFREM v.3.41x

10 May 2017 Page 12 from 180

Parameter is dynamically set to the value that is inherited from another parameter (usually from the

signal type parameter).

EXAMPLE:

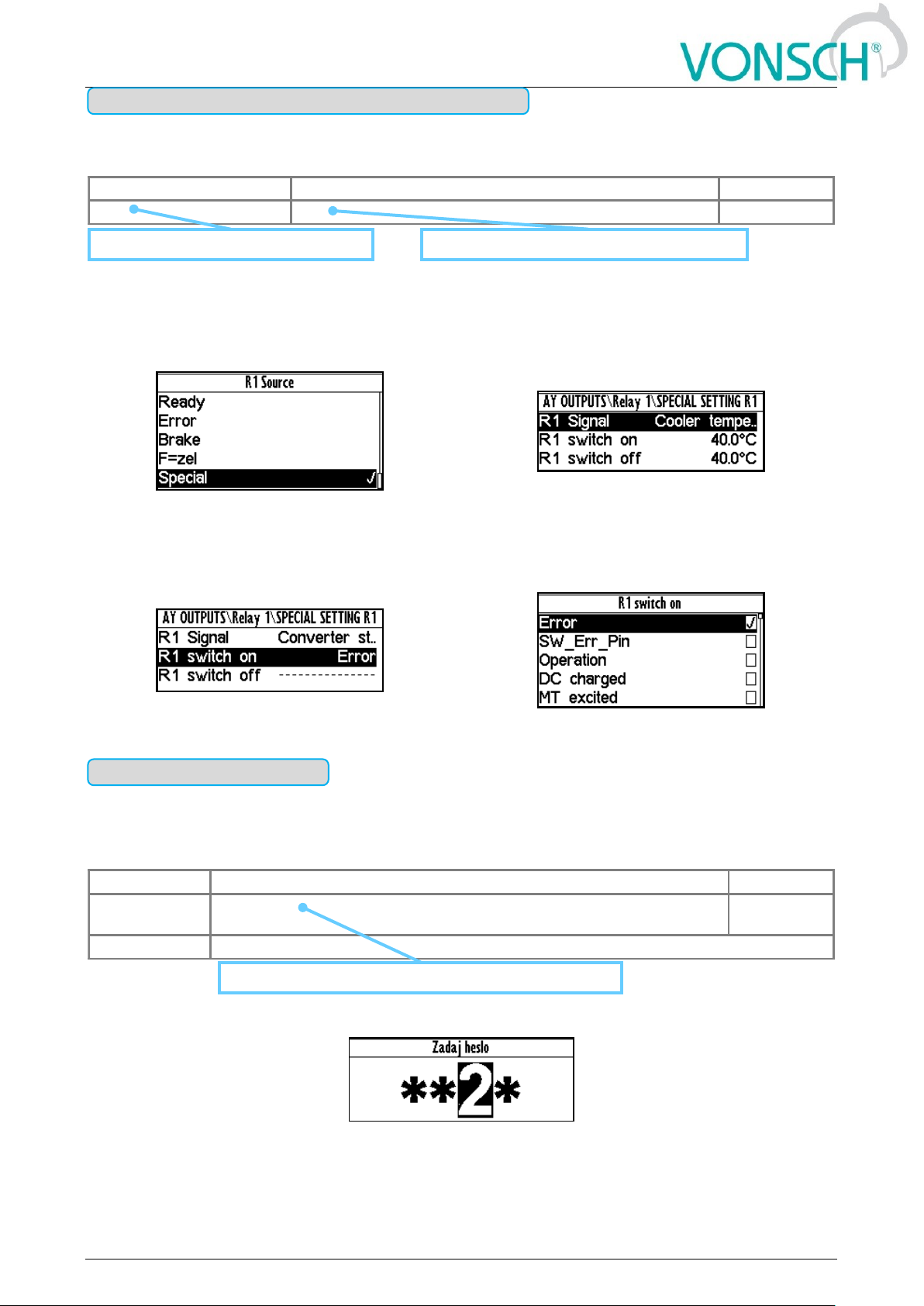

The condition for RELAY switching „R1 switch on [301]“ – If any parameter (e.g. Cooler

temperature [74]) is selected as „R1 Signal [189]“:

MENU \ SETTINGS \ INPUTS AND OUTPUTS \ RELAY

OUTPUTS \ Relay 1 \

MENU \ SETTINGS \ INPUTS AND OUTPUTS \ RELAY

OUTPUTS \ Relay 1 \ SPECIAL SETTING R1 \

Special source of Relay R1 switch setting

Relay R1 switches on when heatsink temperature

exceeds the set level

The condition for RELAY switching „R1 switch on [301]“ – If status word is selected as „R1 Signal

[189]“:

MENU \ SETTINGS \ INPUTS AND OUTPUTS \ RELAY OUTPUTS \ Relay 1 \ SPECIAL SETTING R1 \

Relay R1 switches on at active bite (Failure) of converter status word

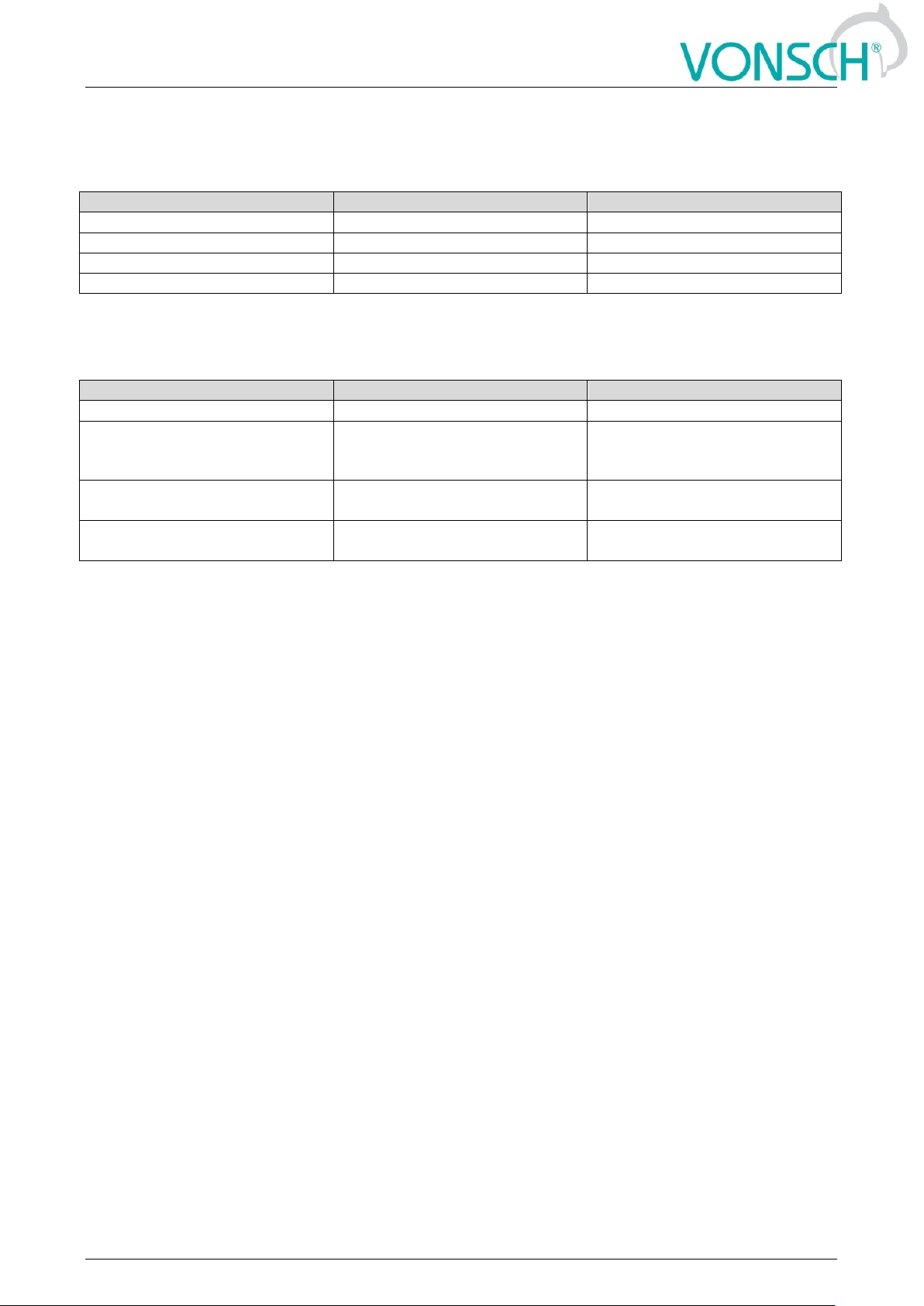

Parameter to enter a password to allow access to the specific levels of converter setting

respectively to unlock some of the modes.

The password characters can be {0..9, A..Z}.

EXAMPLE:

Example of password entry

Parameter type: DYNAMIC VALUE (Linked parameter)

Name [ID]

Description

Def.

R1 switch on [301]

Conditions for R1 switch on.

Run |

MENU \ SETTINGS \ INPUTS AND OUTPUTS \ RELAY OUTPUTS \ Relay 1 \ SPECIAL SETTING \

Name and ID of the dynamic parameter

Default value of the dynamic value parameter

Parameter type: PASSWORD

Name [ID]

Description

Def.

Password

[548]

Setting the user password for access to the device settings. Password

needs to be entered when entering the converter settings.

0 *

0 * ÷ 0 *

Protects the converter settings against reconfiguration by unauthorized persons.

MENU \ SETTINGS \ CONVERTER PARAMETERS \

Basic information about the importance of the parameter

UNIFREM v.3.41x

10 May 2017 Page 13 from 180

UNIPANEL – PASSWORD SETTING

Set the required password character:

Cursor position change:

After setting the password, press ENTER to confirm.

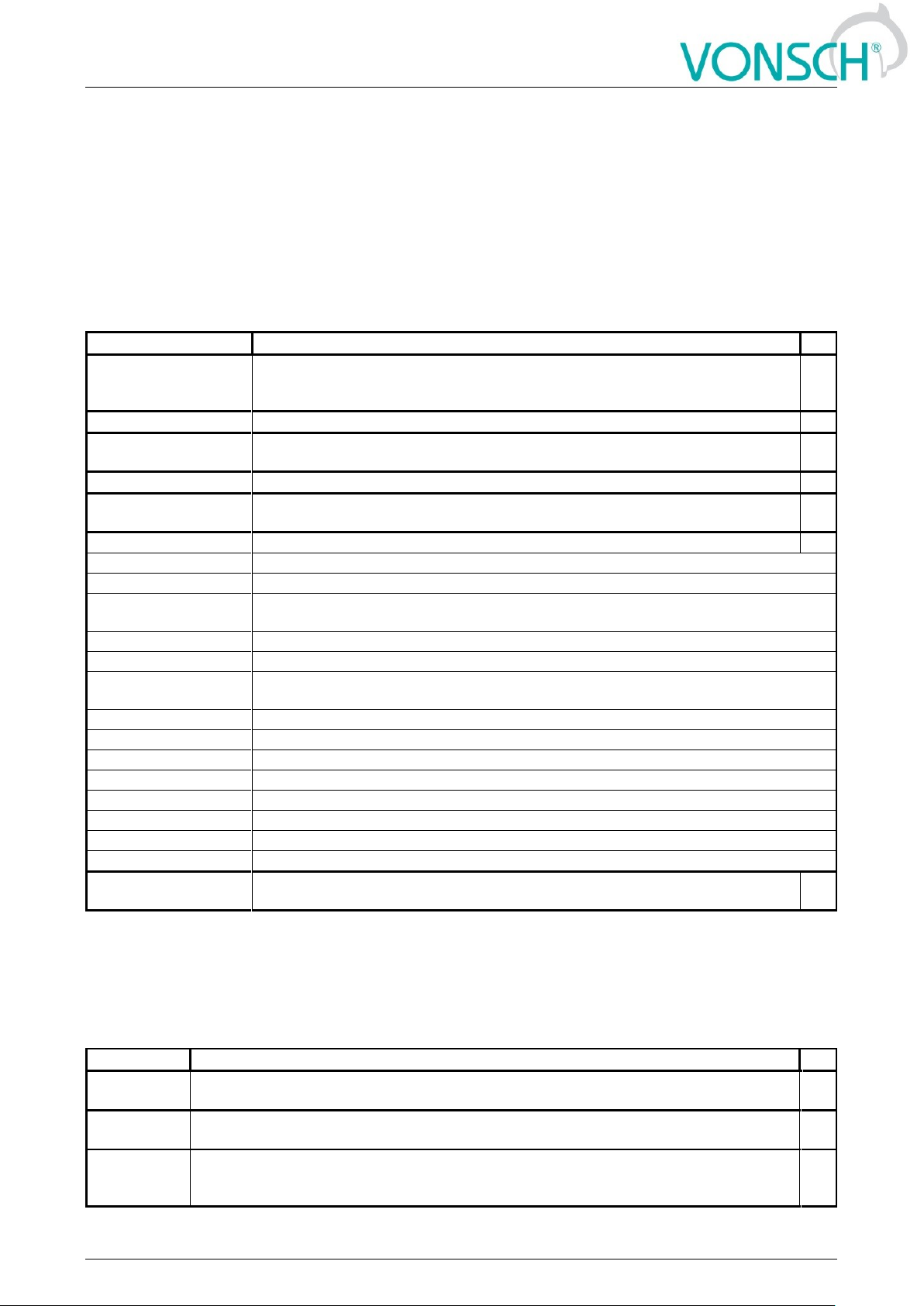

2.3 Type of parameters defining in the part SAVE / RESTORE

Parameter of root parameters directory choice defining.

EXAMPLE:

INPUTS AND OUTPUTS root directory selection for the transfer of parameters from set 1 to set 3

Parameter type: PATH

Name [ID]

Description

Def.

Directory [ - ]

The choice of which part of the parameters will be restored. If nothing

is selected, all will be restored.

INPUTS AND

OUTPUTS

0 * ÷ 0 *

MENU \ SAVE / RESTORE \ Parameters backup \ Parameter transfer \

Basic information about the importance of the parameter

The selected path in the tree hierarchy

UNIFREM v.3.41x

10 May 2017 Page 14 from 180

3 Range of parameters by product type

3.1 Undervoltage, overvoltage

Undervoltage [V]

Overvoltage [V]

Unifrem 230 M

220

420

Unifrem 400, 400 M

425

735

Unifrem 500

350

900

Unifrem 690

730

1 250

3.2 Temperatures

Warning line [°C]

Fault line [°C]

CB temperature [75]

55

70

Cooler temperature [74]

Unifrem 230M, 400 M

Unifrem 400 011 – 400 090

75

90

Cooler temperature [74]

Unifrem 400 110 – 400 200

110

125

Cooler temperature [74]

Unifrem 400 250 – 400 630

94

109

UNIFREM v.3.41x

10 May 2017 Page 15 from 180

4 DIAGNOSTICS

Group of parameters number [2]

Diagnostic information (quantities and states).

4.1 Command

Group of parameters number [758]

Quantities affecting the converter control, inputs and outputs.

MENU \ DIAGNOSTICS \ COMMAND

Name [ID]

Description

Dim.

Freq. setpoint [162]

Frequency setpoint. Represents the value at the input of ramp block, thus the

actual frequency Freq. INV [47] (page 15) is reached after the time ramps

reach the setpoint.

Hz

Torque setpoint [923]

Torque setpoint.

Nm

Panel freq. Setpoint

[161]

Setpoint value from the panel, entered in the monitor window.

Discrete setpoint [10]

Discrete setpoint value [60] (page 54).

Up/down commands

[977]

Output from the Up/Down commands [970] (page 56).

%/s

Control word [77]

Control signals of the converter

□ START

Control command for the motor operation mode (1 - starts the motor).

□ REVERZ F

Control command for the motor rotation direction (1 - reverse operation mode).

□ RESET PWM

Control command for the immediate voltage cut-off on the converter output (active -

turns off PWM).

□ FAULT ACK.

Command for fault acknowledgement.

□ ERR_MASTER

Master fault

□ COMPENSATION

DT

Turn on the dead time compensation mode

□ SCALAR / VECTOR

0 - scalar control 1 - vector control.

□ UNF BOARD TYPE

0 - UNF 400, 1 - UNF 230/400 M.

□ RAMP_F_VSTUP0

Frequency ramp input reset.

□ RAMP_F_VYSTUP0

Frequency ramp output reset.

□ RAMP_F_FREEZE

Frequency ramp stop.

□ QUICK_STOP

Quick emergency drive stop.

□ REVERZ MOM.

Control command for changing the polarity of the torque setpoint.

□ Reserve

ON / OFF time [1577]

Represents the time in AUTO OFF mode to the next automatic start or stop of

the inverter.

4.2 Control

Group of parameters number [759]

Quantities affecting the converter control, values of important control and operating quantities.

MENU \ DIAGNOSTICS \ CONTROL

Name [ID]

Description

Dim.

Freq. INV [47]

Frequency on the converter output. Represents the applied output voltage frequency

behind the ramp block with all corrections taken into account (e.g. [348] (page 60)).

Hz

Freq. RT

[937]

Rotor frequency evaluated by a mathematical model from electric quantities in open

control or from the rotation speed feedback (IRC) in closed control.

Hz

Slip freq.

[938]

Slip frequency evaluated by a mathematical model from electric quantities in open

control or from the rotation speed feedback (IRC) in closed control. In V/f control, for

correction of the stator frequency (slip compensation), [348] (page 60) is used.

Hz

UNIFREM v.3.41x

10 May 2017 Page 16 from 180

Name [ID]

Description

Dim.

Rpm [68]

Motor revolutions per minute. For correct displaying of this parameter, it is neccesary to

set up Nom. revolutions [356] (page 44) correctly, according to the nameplate.

This quantity is not affected by motor slip, it corresponds to the frequency setpoint.

RPM

Voltage DC

[46]

Voltage of the DC link. In a steady-state, the voltage gains its value near 1.41 x supply

voltage RMS, which corresponds with he nominal voltage of the converter. During the

braking, it can rise to the value of BM operating voltage [377] (page 73).

V

Voltage MT

[73]

Voltage on the motor terminals is not exactly measured quantity, it is evaluated from

PWM modulation index and DC link voltage Voltage DC [46] (page 16).

V

Current MT

[42]

RMS value of the motor current.

A

Cos Phi [67]

Motor power factor. Positive values indicate motoric operation and negative values

indicate regenerative motor operation.

Torque [69]

Mechanical torque on the motor shaft. The value of torque is evaluated by the

mathematical motor model; its accuracy is influenced mainly by the parameters Rotor

resistance [439] (page 45), Mutual inductance [441] (page 45) and Nom. revolutions

[356] (page 44). Torque saturation is defined by the parameter Torque setpoint [920]

(page 52).

Nm

Mag. Flux

[71]

Rotor magnetic flux. Defines the level of motor excitation. Unless the field-weakening is

in effect, the value should be close or equal to Magnetic Flux setpoint [452] (page 63).

Wb

Modulation

index [768]

PWM duty cycle of the switching power elements.

%

4.2.1 Power and energy

Group of parameters number [486]

Diagnostic group of quantities dealing with the energy indicators (power, consumption, losses).

MENU \ DIAGNOSTICS \ CONTROL \ POWER AND ENERGY

Name [ID]

Description

Dim.

Input power [70]

Active motor input power of the motor without considering any losses.

W

Power [66]

Active motor power, evaluated from voltage, current and power factor of the motor.

W

kWh

Consumption

[429]

Number of consumed kWh. This value can be reset by the command Reset the

consumption [897] (page 48).

kWh

MWh

Consumption

[430]

Number of consumed MWh. This value can be reset by the command Reset the

consumption [897] (page 48).

MWh

Power restriction

[1092]

Coefficient of power restriction from external effects.

At maximal allowed power or current the value 1 is acquired and when power

restriction is in effect, this value is decreased to 0. Individual conditions of the power

restriction can be selected in Power restriction (PR) [766] (page 74).

4.2.2 Additional quantities

Group of parameters number [534]

Additional and derived quantities for special use.

MENU \ DIAGNOSTICS \ CONTROL \ ADDITIONAL QUANTITIES

Name [ID]

Description

Dim.

Freq. INV ramp

[487]

Frequency on the ramp block output. Represents the speed controller (SC)

reference in the vector control mode.

Hz

Freq. INV abs. [472]

Frequency on the converter output in an absolute value.

Hz

Rpm behind the

transmission [907]

Rotation speed behind the transmission. To display it correctly, it is necessary to

correctly enter the parameter Transmission ratio [888] (page 47).

RPM

Motor rotation

speed [1130]

Rotation speed on the motor shaft. For a correct display, it is necessary to

configure the motor parameters according to the motor nameplate and correctly

identify Stator resistance [345] (page 45) for the slip model.

This value is affected by the actual motor slip and corresponds with the actual

rotor speed.

RPM

UNIFREM v.3.41x

10 May 2017 Page 17 from 180

Name [ID]

Description

Dim.

Max. current [494]

Motor current RMS value limitation on the converter output. During an excessive

converter load, maximal current can drop from the value Max. mot. current [5]

(page 71) to the value Permanent current [24] (page 47).

A

Current MT unfilt.

[49]

RMS value of the non filtered motor current (load).

A

Curr. phase U

[1221]

U-phase current RMS value at the output of frequency converter.

A

Curr. phase V [1222]

V-phase current RMS value at the output of frequency converter.

A

Curr. phase W

[1223]

W-phase current RMS value at the output of frequency converter.

A

Sum of I-AC [831]

Filtrated absolute sum of AC currents for evaluation of leak or current

measurement fault.

A

UL1_rms [1519]

RMS value of L1 phase voltage. This voltage can represent supply or generated

grid voltage, according to connection.

V

UL2_rms [1520]

RMS value of L2 phase voltage. This voltage can represent supply or generated

grid voltage, according to connection.

V

UL3_rms [1521]

RMS value of L3 phase voltage. This voltage can represent supply or generated

grid voltage, according to connection.

V

4.2.3 Positioning

Group of parameters number [1146]

Quantities for position control diagnostics.

MENU \ DIAGNOSTICS \ CONTROL \ POSITIONING

Name [ID]

Description

Dim.

Pos.

setpoint

[1149]

Position

[1147]

Position evaluated from Pos. feedback source [1141] (page 66) signal.

Pos. error

[1148]

Difference between position setpoint Pos. setpoint [1149] (page 17) and actual position

Position [1147] (page 17).

Absolute value of position error. The value is calculated after ramp and S-curve blocks,

so it can be lower than expected in transient state. It can be used as a signal for

switching the limit switches.

4.3 Inputs and outputs

Group of parameters number [859]

Diagnostics of the converter inputs and outputs.

4.3.1 BIN

Group of parameters number [1212]

MENU \ DIAGNOSTICS \ INPUTS AND OUTPUTS \ BIN

Name [ID]

Description

Dim.

Binary inputs [184]

State of the binary inputs. Filled rectangle represents the BINx physical switch-on.

□ BIN1

State of 1st binary input (Terminal 1).

□ BIN2

State of 2nd binary input (Terminal 2).

□ BIN3

State of 3rd binary input (Terminal 3).

□ BIN4

State of 4th binary input (Terminal 4).

□ BIN5

State of 5th binary input (Terminal 5).

□ BIN6

State of 6th binary input (Terminal 6).

4.3.2 AIN

Group of parameters number [82]

Diagnostic group of quantities for the analog inputs of the converter AIN1 to AIN4.

UNIFREM v.3.41x

10 May 2017 Page 18 from 180

Parameters of the analog inputs can be configured in the parameter group [144] (page 76).

MENU \ DIAGNOSTICS \ INPUTS AND OUTPUTS \ AIN

Name

[ID]

Description

Dim.

AIN1

[256]

Value of the signal brought to the analog input terminals X1:11 and - X1:12 in physical units.

Using the parameter AIN1 Signal [251] (page 77) select the quantity that will be changed

according to the analog input level change.

Parameters of the analog input can be configured in the parameter group [147] (page 76).

V

AIN1

Rel.

[41]

Relative value of the signal connected to the analog input terminals + X1:11 and - X1:12.

Parameters of the analog input can be configured in the parameter group [147] (page 76).

%

AIN2

[280]

Value of the signal brought to the analog input terminals X1:13 and - X1:14 in physical units.

Using the parameter AIN2 Signal [259] (page 78) select the quantity that will be changed

according to the analog input level change.

Parameters of the analog input can be configured in the parameter group [149] (page 77).

V

AIN2

Rel.

[43]

Relative value of the signal connected to the analog input terminals + X1:13 and - X1:14.

Parameters of the analog input can be configured in the parameter group [149] (page 77).

%

AIN3

[281]

Value of the signal brought to the analog input terminals X1:15 and - X1:16 in physical units.

Using the parameter AIN3 Signal [269] (page 79) select the quantity that will be changed

according to the analog input level change. Not available for the UNIFREM 400 M converters.

Parameters of the analog input can be configured in the parameter group [148] (page 78).

V

AIN3

Rel.

[44]

Relative value of the signal connected to the analog input terminals + X1:15 and - X1:16. Not

available for the UNIFREM 400 M converters.

Parameters of the analog input can be configured in the parameter group [148] (page 78).

%

AIN4

[282]

Value of the signal brought to the analog input terminals X1:17 and - X1:18 in physical units.

Using the parameter AIN4 Signal [275] (page 80) select the quantity that will be changed

according to the analog input level change. Not available for the UNIFREM 400 M converters.

Parameters of the analog input can be configured in the parameter group [152] (page 79).

V

AIN4

Rel.

[45]

Relative value of the signal connected to the analog input terminals + X1:17 and - X1:18. Not

available for the UNIFREM 400 M converters.

Parameters of the analog input can be configured in the parameter group [152] (page 79).

%

4.3.3 RELAYS

Group of parameters number [217]

MENU \ DIAGNOSTICS \ INPUTS AND OUTPUTS \ RELAYS

Name [ID]

Description

Dim.

Relay [185]

Condition of the output relays. Filled rectangle represents the RELEx physical switch-on.

□ RELAY1

Condition of the 1st output relay.

□ RELAY2

Condition of the 2nd output relay.

□ RELAY3

Condition of the 3rd output relay. Not available for the converters UNIFREM 400 M.

4.3.4 AOUT

Group of parameters number [700]

Diagnostic group of quantities for the analog inputs of the converter AOUT1 to AOUT3.

MENU \ DIAGNOSTICS \ INPUTS AND OUTPUTS \ AOUT

Name

[ID]

Description

Dim.

AO1

[701]

Recalculated value of the signal on the analog input terminals X1:19 and X1:20 (X1:15 and

X1:16 for UNIFREM 400 M). Using the parameter AO1 Signal [359] (page 83), select the

quantity according to which the analog output level is changed.

Parameters of the analog input can be configured in the parameter group [370] (page 82).

A

AO2

[702]

Recalculated value of the signal on the analog input terminals X1:21 and X1:22 (X1:17 and

X1:16 for UNIFREM 400 M). Using the parameter AO2 Signal [364] (page 83), select the

quantity according to which the analog output level is changed.

Parameters of the analog input can be configured in the parameter group [371] (page 83).

A

UNIFREM v.3.41x

10 May 2017 Page 19 from 180

Name

[ID]

Description

Dim.

AO3

[703]

Recalculated signal value on the terminals of the analog output X1:23 and X1:24. Using the

parameter AO3 Signal [365] (page 84), select the quantity according to which the analog

output level is changed. Not available for the UNIFREM 400 M converters.

Parameters of the analog input can be configured in the parameter group [372] (page 83).

A

4.3.5 IRC1,IRC2,ARC

Group of parameters number [1001]

Diagnostic set of quantities for the IRC and ARC speed sensors inputs.

MENU \ DIAGNOSTICS \ INPUTS AND OUTPUTS \ IRC1,IRC2,ARC

Name [ID]

Description

Dim.

Freq. IRC1 [434]

Rotor frequency defined by the rotation speed sensor from the IRC1. It is the

mechanical frequency, its value can be several times lower than electrical frequency.

The ratio between the frequencies is defined by the number of pole couples ( Nr of

motor poles [1049] (page 47)). For correct evaluation of the speed from the IRC

sensor, it is necessary to correctly configure IRC1 pulses [436] (page 84).

Hz

Freq. IRC2/ARC

[803]

Rotor frequency defined by the rotation speed sensor from the IRC2. It is the

mechanical frequency, its value can be several times lower than electrical frequency.

The ratio between the frequencies is defined by the number of pole pairs ( Nr of

motor poles [1049] (page 47)). For correct evaluation of the speed from the IRC

encoder, it is necessary to correctly configure IRC2 pulses [827] (page 85).

Hz

Freq. IRC1 gear

[1540]

Speed from IRC1 sensor at gear output.

Hz

Freq. IRC2/ARC

gear [1541]

Speed from IRC2/ARC position sensor at gear output.

Hz

Freq. IRC1-IRC2

gear [1086]

Frequency difference between IRC1 and IRC2 at gear output.

This quantity is filtered by the first order filter configured by the parameter Filter

dIRC1,2 [1083] (page 107).

Hz

Chyba IRC

[1623]

Status word of IRC fault.

□ ERR output EM | □ Incorrect reverses of IRC1 | □ Incorrect reverses of IRC2 | □ Disconnected / broken

IRC | □ Speed step change

IRC1 position

[1286]

Position from IRC1 sensor in revolutions.

IRC1 position

gear [1535]

Position from IRC1 sensor at gear output in revolutions.

IRC2/ARC

position [1287]

Position from IRC2 or ARC sensor in revolutions.

IRC2/ARC

position gear

[1536]

Position from IRC2 or ARC sensor at gear output in revolutions.

ARC angle [290]

Angle within one revolution evaluated from absolute position sensor in degrees.

Freq. ARC [291]

ARC rotor frequency evaluated by the RM-SERVO extension module.

Hz

Freq.

ARCmaster

[1617]

ARCmaster device rotor frequency evaluated by the RM-SERVO extension module.

Hz

Servo CRC

errors [1542]

CRC error counter of the communication between the converter and RM-SERVO

module.

Servo error

[1608]

Fault of the absolute encoder or RM-SERVO extension module.

□ CRC

Too many CRC errors.

□ Inverter

Module is not receiving valid data from the converter.

□ Eeprom

Memory error of the module.

□ Modbus

Modbus master is not communicating with the module.

□ CAN

CAN timeout.

□ EnDat timeout

EnDat encoder is not communicating with the module.

UNIFREM v.3.41x

10 May 2017 Page 20 from 180

Name [ID]

Description

Dim.

□ EnDat

EnDat encoder is reporting a fault.

□ Reserve

□ Reserve

□ Inverter 2

□ Eeprom 2

□ Modbus 2

□ CAN 2

□ EnDat timeout 2

□ EnDat 2

CRC error rate

[933]

Communication error rate with RM-SERVO. Zero value means reliable transmission.

%

Status RM_ARC

[292]

Status of RM_ARC extension module.

Ok

RM ARC is communicating ok, or there is no module selected.

LOT

Loss of Position Tracking error.

DOS

Degradation of signal (DOS) is detected when any resolver input signal is corrupted.

LOS

Loss of signal (LOS) is detected when any resolver input falls below the fixed threshold.

Most likely the resolver is disconnected.

Parity

Parity check of communication between ARC and the converter failed.

RDVEL

Incorrect value read from ARC module.

IRC1-IRC2

position gear

[1515]

IRC1 and IRC2 sensor position difference at gear output in revolutions.

ARCARCm/IRC1

position gear

[1622]

ARC - master (ARCmaster or IRC1) position at gear output in revolutions.

IRC1 pos. 32b

high [1616]

High 32 bits of IRC1 position at gear output.

hex

IRC1 pos. 32b

low [1539]

Low 32 bits of IRC1 position at gear output.

hex

IRC2/ARC pos.

32b high [1543]

High 32 bits of IRC2/ARC position at gear output.

hex

IRC2/ARC pos.

32b low [1607]

Low 32 bits of IRC2/ARC position at gear output.

hex

ARCmaster pos.

32b high [1288]

High 32 bits of ARCmaster position at gear output.

hex

ARCmaster pos.

32b low [1621]

Low 32 bits of ARCmaster position at gear output.

hex

4.4 Functions

Group of parameters number [760]

Quantities regarding the remaining optional functions of the converter.

4.4.1 PLC function

Group of parameters number [1278]

Numerical and logical blocks output.

MENU \ DIAGNOSTICS \ FUNCTIONS \ PLC FUNCTION

Name [ID]

Description

Dim.

Logical blocks

[8]

Logical operation outputs, first two LB are fast (they respond in 1ms), others are

slower (10ms).

□ LB1

LB1 status

□ LB2

LB2 status

□ LB3

LB3 status

UNIFREM v.3.41x

10 May 2017 Page 21 from 180

Name [ID]

Description

Dim.

□ LB4

LB4 status

□ LB5

LB5 status

□ LB6

LB6 status

□ LB7

LB7 status

□ LB8

LB8 status

Numerical blocks

Group of parameters number [312]

Output of numerical blocks.

MENU \ DIAGNOSTICS \ FUNCTIONS \ PLC FUNCTION \ NUMERICAL BLOCKS

Name [ID]

Description

Dim.

NB1 [1274]

Result of operation of the first numerical block.

NB2 [1275]

Result of operation of the second numerical block.

NB3 [1276]

Result of operation of the third numerical block.

NB4 [1277]

Result of operation of the fourth numerical block.

4.4.2 Limit switches

Group of parameters number [890]

States and tracks of the limit switches.

MENU \ DIAGNOSTICS \ FUNCTIONS \ LIMIT SWITCHES

Name [ID]

Description

Dim.

LS [919]

Limit switch state.

□ LS1

LS1 inactive/active.

□ LS2

LS2 inactive/active.

□ LS3

LS3 inactive/active.

□ LS4

LS4 inactive/active.

□ Slows down F>0

Slow down in effect for positive frequency.

□ Slows down F<0

Slow down in effect for negative frequency.

LS1 Track [891]

Number of meters run during the activated limit switch function.

m

LS1 Track in km [929]

Number of kilometers run during the activated limit switch function.

km

LS2 Track [892]

Number of meters run during the activated limit switch function.

m

LS2 Track in km [930]

Number of kilometers run during the activated limit switch function.

km

LS3 Track [893]

Number of meters run during the activated limit switch function.

m

LS3 Track in km [931]

Number of kilometers run during the activated limit switch function.

km

LS4 Track [894]

Number of meters run during the activated limit switch function.

m

LS4 Track in km [932]

Number of kilometers run during the activated limit switch function.

km

4.4.3 Process controller

Group of parameters number [18]

Diagnostic group of the process controller quantities.

MENU \ DIAGNOSTICS \ FUNCTIONS \ PROCESS CONTROLLER

Name [ID]

Description

Dim.

Setpoint PC [21]

Setpoint value of the process controller.

%

Feedback PC

[409]

Feedback value of the process controller. If the process controller is turned on and

works correctly, the value is near the value Setpoint value [407] (page 98).

%

Error PC [410]

Regulation error of the process controller. In steady-state, it should be close to 0.

%

Output PC [64]

Action value (output) of the process controller.

State PC [820]

Actual state of the process controller.

□ Lower

saturation

Process controller operates at lower saturation.

□ Upper

Process controller operates at upper saturation.

UNIFREM v.3.41x

10 May 2017 Page 22 from 180

Name [ID]

Description

Dim.

saturation

□ Error in the

dead-zone

Process controller error in the dead-zone.

□ Positive error

Process controller error is positive.

□ SP achieved

If error is lower than hysteresis.

□ Parked

Process controller is parked.

□ PC Reset

Active PC RESET - integration term and the output are equal to the value PC Reset value

[1131] (page 99).

4.4.4 Optimization

Group of parameters number [707]

Setting the parameters for the optimization block that is used to search for the extremum of any signal using

the change of a selected entering setpoint signal.

Optimization searches for an output value, at which it reaches the criteria of the selected signal. During the

optimization, if the measurement conditions and the operation condition are met, new output samples are

counted in defined intervals. The found global extremum is stored to the memory. In case the optimization

output should apply, it is necessary to select its output as the source of the setpoint value.

MENU \ DIAGNOSTICS \ FUNCTIONS \ OPTIMIZATION

Name [ID]

Description

Dim.

OPT Output

[423]

Output value of the optimization block. You can watch the status and quality of the

optimization process here. 100% represents the min.-max. range from the setpoint

channel, which is connected to the optimization block (see [65] (page 100)).

Optimization

step [742]

Optimization step represents the difference between two consecutive optimization

algorithm samples. (see [65] (page 100)).

OPT Starting

point [708]

Defines the starting point of the optimization at the optimization start, when scanning

is turned off.

OPT State [709]

Shows the present state the optimization block.

□ Reset

Optimization is in initial or blocked state.

□ Measuring

Measuring of the optimized quantity is running.

□ Scan

Scanning of the whole optimization output range is running.

□ Tuning

State of fine tuning and searching for the optimization point.

4.4.5 Lifting functions

Group of parameters number [853]

Diagnostic group of quantities for the drive OPS switch, load calculation and dynamic lift.

MENU \ DIAGNOSTICS \ FUNCTIONS \ LIFTING FUNCTIONS

Name [ID]

Description

Dim.

Load [854]

Drive load rate evaluated from the signal Load. signal [843] (page 102) related to

100% Load [844] (page 103).

%

Short

commands

count [855]

Number of forbidden short commands. After exceeding the short commands count,

the OPS switch will switch regardless of the drive load. Short commands evaluation

can be turned off by the parameter OPS mode. [842] (page 103).

OPS status [856]

Indicates the status of the OPS switch block.

□ Reset

RESET signal of the OPS is active.

□ Detection

Autodetection of the overload limits is running.

□ Overload

Overload occurred. Operation in the positive direction (up) is blocked.

□ Tipping

Too many forbidden tipping control commands.

□ Settling

Drive operates in static mode.

□ Dynamics

Drive operates in dynamic mode.

4.4.6 Pantograph

Group of parameters number [122]

Diagnostics of the Pantograph outage function.

MENU \ DIAGNOSTICS \ FUNCTIONS \ PANTOGRAPH

UNIFREM v.3.41x

10 May 2017 Page 23 from 180

Name [ID]

Description

Dim.

Pantograph status [112]

Status of the Pantograph outage function.

□ Pantograph fault

Fault " E41-Pantograph outage (page 33)" occurred.

□ Pantograph warning

Warning " W39-Pantograph outage (page 30)" occurred.

□ Turning off CHARGE

The charging contactor switched off during a pantograph outage fault or warning.

□ Motor torque = 0

During the pantograph outage, the motor restricted the motor torque to zero.

□ Enabled

Pantograph functions are enabled.

□ Block warnings

Blocking of warning is enabled.

Pantograph voltage [113]

Voltage of the pantograph of trolley vehicle.

V

4.4.7 Ext. thermal protection

Group of parameters number [868]

Diagnostic group of quantities of the external thermal protection (ETP).

MENU \ DIAGNOSTICS \ FUNCTIONS \ EXT. THERMAL PROTECTION

Name [ID]

Description

Dim.

ETP

Temperature

[869]

Temperature of the ETP sensor. After exceeding the temperature defined in the

parameter ETP Warning [865] (page 105), the converter generates a warning. After

exceeding the temperature defined in the parameter ETP Fault [866] (page 105), the

converter generates the fault " E38-ETP temperature (page 33)".

°C

ETP Current

[870]

Measuring current of the external thermal protection. By rule, it is selected as the

signal source of an analog input, AOUT1 to AOUT3.

mA

ETP Voltage

[867]

Value of measured voltage drop on the ETP sensor.

V

Sensor

resistance

[871]

Resistance value of the ETP sensor.

By multiple sensors connected to a series, it represents the average resistance value

on one of them.

Ω

4.4.8 Differential

Group of parameters number [1243]

Quantities for torque differential diagnostics.

MENU \ DIAGNOSTICS \ FUNCTIONS \ DIFFERENTIAL

Name [ID]

Description

Dim.

Value difference [1244]

Difference between the values of Sig.1 Value [1249] (page 107) and Sig.2

Value [1240] (page 107).

Nm

Freq. setpoint correction

[1245]

Frequency setpoint correction caused by differential operation.

Hz

4.5 Converter state

Group of parameters number [761]

Quantities regarding the overall state of the converter and its components.

MENU \ DIAGNOSTICS \ CONVERTER STATE

Name [ID]

Description

Dim.

Voltage 24V [72]

DC control voltage of 24V. Option for the detection of the supply load caused by

the control inputs and outputs. Converter generates the fault " E16-Supply

overload (page 32)" when the voltage drops under 16 V.

V

Battery voltage [773]

Voltage of the battery that backs up the history logs in the converter.

V

Converter

operational hours

[496]

Converter operational hours. Converter operation time when switched on

(RUN). This value can be reset by authorized technicians only.

h

MT operational

hours [497]

Motor operational hours. Converter operation time. This value can be reset by

the command Reset the motor operation hours MT [1075] (page 45).

h

Converter state [76]

Status word of the converter.

□ Fault

Converter is in fault.

□ SW_Err_Pin

System, internal converter status.

UNIFREM v.3.41x

10 May 2017 Page 24 from 180

Name [ID]

Description

Dim.

□ Run

Converter generates voltage on the outputs.

□ DC charged

DC link is charged.

□ MT excited

Motor is excited.

□ Accel./Decel. F

Inactive - motor accelerates, active - motor decelerates.

□ Fsp > 0

Active - forward (+), inactive - backward (-). It is the polarity of the setpoint frequency.

□ F = Fsp

When active, the setpoint frequency is achieved.

□ Warning

Warning or functional message occurred in the converter.

□ Active

Always active. It can be used as logical 1.

□ Deexciting MT

Motor is still excited, the start is blocked.

□ Ready

Converter is ready for the start command. (READY).

□ Mechanical brake

Mechanical brake relay control. Brake is released when active.

□ Motor/generator

Active - regenerative operation mode, inactive - motoric operation mode.

□ Frot > 0

Rotor frequency polarity. If IRC is not available, then it represents the sign of the

frequency evaluated by the mathematical model.

Status word negated

[547]

Negated status word.

Look choises of parameter's Converter state [76] (page 23)

Warning [250]

State of individual warnings.

Warning2 [424]

State of individual warnings.

Warning3 [1627]

State of individual warnings.

Fault [781]

State of individual faults.

Fault2 [780]

State of individual faults.

4.6 Thermal protections

Group of parameters number [485]

Diagnostic group of quantities regarding the thermal protections and overloads.

MENU \ DIAGNOSTICS \ THERMAL PROTECTIONS

Name [ID]

Description

Dim.

Cooler

temperature

[74]

Temperature of the power elements cooler. Converter generates a warning " W6Cooler temperature (page 28)" after exceeding the temperature set by Cooler

temperature warning [767] (page 111). Converter generates the fault " E1-Cooler

temperature (page 32)" after exceeding the temperature set by service parameter

"Cooler temp. fault". If the temperature falls below minimal limit of sensor, this value is

inaccessible.

If the cooler temperature drops under the minimal measuring range, the displayed

value is inaccessible.

°C

CB

temperature

[75]

Control board (CB) temperature. When the temperature exceeds the parameter CB

temperature warning [204] (page 111) converter generates a warning " W7-CB

temperature (page 28)". After exceeding the critical temperature set by service

parameter "CB temper. fault" converter generates the fault " E22-CB temperature

(page 32)". If the temperature falls below minimal limit of sensor, this value is

inaccessible.

If the temperature drops under the minimal limit of the measurement channel, the

displayed value is inaccessible.

°C

Thermal

integral INV

[31]

Warming rate of the converter. The fault " E8-Converter overload (page 32)" is

generated after exceeding 100% by this value.

%

Thermal

integral INV

[1219]

Time remaining until the end of fault " E8-Converter overload (page 32)".

s

Thermal

integral MT

[33]

Motor warming rate, the " E29-Motor overload (page 33)" fault occurs after exceeding

100%.

%

Thermal

Time remaining until the end of fault " E29-Motor overload (page 33)".

s

UNIFREM v.3.41x

10 May 2017 Page 25 from 180

Name [ID]

Description

Dim.

integral MT

[1220]

4.7 Communication

Group of parameters number [219]

Information regarding serial communications MODBUS, PROFIBUS, RS485, CAN.

4.7.1 MODBUS

Group of parameters number [661]

MODBUS protocol diagnostics on the RS 485 and USB ports.

MENU \ DIAGNOSTICS \ COMMUNICATION \ MODBUS

Name [ID]

Description

Dim.

Modbus setpoint

value [934]

Setpoint value from the Modbus protocol.

%

SW_MODBUS [935]

State word sent over the Modbus communication. For a more detailed

description, see the documentation for MODBUS communication protocol.

Look choises of parameter's SW_PB [804] (page 25)

CW_MODBUS [936]

Command Word sent by the Modbus master. For a more detailed description,

see the documentation for MODBUS communication protocol.

Look choises of parameter's CW_PB [805] (page 26)

Last Addr. [662]

Last received address of the device.

hex

Last Func. [663]

Last received function (may also be another device).

hex

Last register [741]

Last received register (only for this device, it is shown first if there is access to

multiple registers).

hex

Last result [664]

Result of the last received function determined for this device.

hex

Last length [665]

Size (in bytes) of the last received frame over MODBUS.

Last CRC [666]

Last received CRC (it can also be a frame for another device)

hex

Message count [740]

Count of all received messages, including error messages.

hex

CRC error count

[668]

Count of all received CRC error count messages.

hex

Exception count

[800]

Number of messages, which are responded by the error messages.

hex

Slave count [801]

Count of received messages with a valid device address.

hex

No response [802]

Count of received messages with a valid device address, when the device did

not respond.

hex

4.7.2 PROFIBUS

Group of parameters number [817]

PROFIBUS diagnostics.

MENU \ DIAGNOSTICS \ COMMUNICATION \ PROFIBUS

Name [ID]

Description

Dim.

Profibus setpoint

value [809]

Setpoint value received over the Profibus protocol.

%

SW_PB [804]

Status word sent over the Profibus communication. For a more detailed

description, see the documentation for Profibus Extension Module.

□ Ready To Switch

On

Convert Reset, Quick stop are inactive, no faults or initialization are present.

□ Ready To Operate

Converter is ready for the start command.

□ Operation Enabled

Converter generates voltage on the outputs.

□ Fault Present

Converter is in fault.

□ No OFF 2

Inactive - Reset is active, outputs of the converter are blocked, active - Reset is not

active.

□ No OFF 3

Inactive - Quick stop is active, active - Quick stop is inactive.

UNIFREM v.3.41x

10 May 2017 Page 26 from 180

Name [ID]

Description

Dim.

□ Switching On

Inhibited

Reset or Quick stop are active, or an initialization or fault are present.

□ Warning Present

Warning or functional message occurred in the converter.

□ Speed Error within

tolerance

When active, the setpoint frequency is achieved.

□ Control Requested

Inactive - converter does not accept Control Word over communication. Acitve -

converter is controlled by Control Word received over communication.

□ F or n Reached

When active, the setpoint frequency is achieved.

□ Run

Converter generates voltage on the outputs.

□ Set b0

Bit 0 of active set binary combination.

□ Set b1

Bit 1 of active set binary combination.

□ LB3

Status of logical block 3.

□ LB4

Status of logical block 4.

CW_PB [805]

Command word sent by the Profibus master. For a more detailed description,

see the documentation for Profibus Extension Module.

□ ON

Converter is ready to accept the START command.

□ No OFF 2

Inactive - Reset is active, Active - normal converter operation.

□ No OFF 3

Inactive - Quick stop is active, active - normal converter operation.

□ Enable Operation

Start. Converter starts generating voltage on its output terminals.

□ Enable Ramp

Generator

Inactive - ramp input is set to zero, active - normal operation of the ramp input block.

□ Unfreeze Ramp

Inactive - ramp output is frozen, active - ramp is operating normally.

□ Enable Setpoint

Inactive - ramp input is set to zero, active - normal operation of the ramp input block.

□ Fault Acknowledge

Fault acknowledgement (only transition inactive-active). Fault acknowledgement has

to be allowed in Fault acknowledgement source [165] (page 109).

□ Bit 8

Unused

□ Bit 9

Unused

□ Control by PLC

Inactive - converter does not accept Control Word. Active - converter is controlled by

Control Word.

□ Bit 11

Unused

□ Bit 12

Unused

□ Bit 13

Unused

□ Bit 14

Unused

□ Bit 15

Unused

PB-MASTER Error

[819]

Number of communication errors between the Profibus module and the Profibus

master.

hex

PB-INV Error [818]

Number of communication errors between the converter and the Profibus

module.

hex

4.7.3 RS LINKS

Group of parameters number [228]

Serial lines diagnostics.

MENU \ DIAGNOSTICS \ COMMUNICATION \ RS LINKS

Name [ID]

Description

Dim.

FRAME_ERR_USB [232]

USB wrongly received data count. (wrong parity, wrong stop bit,...)

FRAME_ERR_RS485 [229]

RS 485 wrongly received data count. (wrong parity, wrong stop bit,

...)

FRAME_ERR_EXT_MODUL

[233]

RS external module wrongly received data count. (wrong parity,

wrong stop bit,...)

4.8 SW and HW version

Group of parameters number [762]

Information about the converter and its components (Mostly static information).

UNIFREM v.3.41x

10 May 2017 Page 27 from 180

MENU \ DIAGNOSTICS \ SW AND HW VERSION

Name [ID]

Description

Dim.

UNIFREM SW version [379]

UNIFREM converter SW version.

Serial number [35]

First part of the converter unique serial number.

hex

Serial number 2 [36]

Second part of the converter unique serial number.

hex

Parameter date [380]

Parameter generating date.

Parameter time [381]

Parameter generating time.

4.9 Date and Time

Group of parameters number [1213]

MENU \ DIAGNOSTICS \ DATE AND TIME

Name [ID]

Description

Dim.

Date [210]

Current date.

Time [209]

Current time.

Day [1046]

Current day.

□ Monday | □ Tuesday | □ Wednesday | □ Thursday | □ Friday | □ Saturday | □ Sunday

Trial period [1006]

Number of days until the trial period of the converter expires.

d

UNIFREM v.3.41x

10 May 2017 Page 28 from 180

5 WARNINGS

A sample disley

Description

F1-PWM Reset

Converter outputs are blocked. RESET sources can be a binary input or any signal

(see Reset source [704] (page 49)).

W2-DC charging

If this warning is present longer than 30 seconds after the converter start, the charging

relay probably did not switch, which can be caused by incorrect supply parameters, or

damaged charging circuit of the converter. For the duration of the warning, the value

of Voltage DC [46] (page 16) is displayed in FAULTS window.

W3-System problem

Software problem occurred. Please, contact the service.

W4-24V Overload

24V power supply voltage dropped under 22V. 24V supply is probably overloaded.

For the duration of the warning, the value of Voltage 24V [72] (page 23) is displayed

in FAULTS window.

F5-Power restriction

Power restriction after reaching critical temperature or an overload status. Power

restriction function is configured in the parameter Power restriction (PR) [766] (page

74). For the duration of the warning, the value of Power restriction [1092] (page 16) is

displayed in FAULTS window.

W6-Cooler

temperature

High cooler temperature. Cooler temperature Cooler temperature [74] (page 24)

exceeded the value defined by the parameter Cooler temperature warning [767]

(page 111). If the automatic power restriction Power restriction (PR) [766] (page 74)

function is turned on, the converter can restrict power. Life cycle of the device

decreases when the device is overheated excessively and very often. For the duration

of the warning, the value of Cooler temperature [74] (page 24) is displayed in

FAULTS window.

W7-CB temperature

Igh temperature of control board. CB temperature CB temperature [75] (page 24)

exceeded value of parameter CB temperature warning [204] (page 111). Life cycle of

the device decreases when the device is overheated excessively and very often. For

the duration of the warning, the value of CB temperature [75] (page 24) is displayed

in FAULTS window.

W8-DC

Undervoltage

Low voltage of the DC link. The value Voltage DC [46] (page 16) dropped under the

fault limit DC Undervoltage - control and evaluation of other faults is blocked. For the

duration of the warning, the value of Voltage DC [46] (page 16) is displayed in

FAULTS window.

W9- PWM saturation

Converter reached maximum voltage on the output. At actual voltage value of the DC

link, duty cycle of the PWM modulation is at maximum and the current controllers are

saturated. Quality of the regulation decreases. For the duration of the warning, the

value of Modulation index [768] (page 16) is displayed in FAULTS window.

W10-INV Overload

Converter is overloaded - converter integral Thermal integral INV [31] (page 24)

exceeded the 90% value and the fault " E8-Converter overload (page 32)" can occur

shortly, after which the converter is blocked for a longer time! If the automatic power

restriction Power restriction (PR) [766] (page 74) function is turned on, the converter

may restrict power. For the duration of the warning, the value of Thermal integral INV

[31] (page 24) is displayed in FAULTS window.

W11-Fan error

Fans on the converter cooler are damaged or clogged by debris. If the problem is not