Von Duprin PS914 Installation Instructions Manual

PS914 Power Supply

44487056

These instructions cover the following parts:

RNING:

WA

!

WARNING:

!

NGER

DA

!

1

F

GER:

DAN

!

Installation

Instructions

!

DANGER:

To avoid risk of electric shock, turn off AC power

before installing or servicing PS914 power supply.

PS914 Power Supply

Pages 1-3

900-KL Keylock

(optional)

Page 2

900-BB Battery Backup

(optional)

Page 3

900-2RS (optional) - Page 4

PS914 Power Supply Specifi cations:

Input 120/240 VAC, 1.4 A, 50/60Hz, High Voltage Class 1 Wiring Required

Output 4 Amp DC @ 12/24 VDC

May be used to power Von Duprin & Falcon EL device at 24VDC, 16A, 300ms

Enclosure 14” H x 12” W x 4” D (8 knockouts, 1/2” or 3/4” )

Temperature Range 32°-120° F (0°- 49° C)

Fuse F1, T6.3A

250 VAC

For protection against risk of fi re, replace fuse with same type and rating

Compliance UL 294, ULC-S318, RoHS, & FCC Part 15, Class 2 Output

Compatible Boards

(Optional, 2 boards maximum)

900-2RS

900-2Q

900-4R

900-4RL

900-8F

900-8P

Fire Alarm Input Board (Optional) 900-FA (Requires one option board above)

Battery Backup Board (Optional) 900-BB

AC Monitor Output Form C Contacts, 30 VDC, 1 Amp, Resistive Load

!

CAUTION:

INST. INSTRUCTIONS - 44487056

INST. INSTRUCTIONS - 44487098

INST. INSTRUCTIONS - 44487106

INST. INSTRUCTIONS - 44487080

INST. INSTRUCTIONS - 44487106

INST. INSTRUCTIONS - 44487106

INST. INSTRUCTIONS - 44487072

INST. INSTRUCTIONS - 44487064

(2 Zone EL Control -

Individual/Sequential)

900-2RS Specifi cations:

Inputs I1,I2 Dry contacts required (Closed = Active)

Connect control contacts between SC (Signal Common) and any input

Outputs O1,O2 • 12/24VDC, 3A (wet) when AC powered • 9.6-13.2VDC or 19.2-26.4VDC when battery powered

• May be used with PS914 to power EL device at 24VDC, 16A, 300ms

• Maximum load cannot exceed power supply ratings or 3A for outputs combined

Board Input Power Board requires 0.1A max. of power supply output current to operate

Temperature Range 32°-120° F (0°- 49° C)

Compliance UL 294, ULC-S318, RoHS, & FCC Part 15

Fire Alarm Input Accepts 900-FA Fire Alarm Board (Optional)

© 2010 Ingersoll-Rand Company

1-877-671-7011

44487056 Rev. 10/10_a

1 of 4

MOUNTING NOTES

The PS914 must be installed in accordance with the article 760 of the National Electrical Code or NFPA 72,

Canadian Electrical Code, or any other applicable codes.

Install the PS914 indoors within the protected premises.

Check national and local codes for additional installation requirements.

Enclosure must be fi rmly mounted to a solid surface using hardware suitable for the surface.

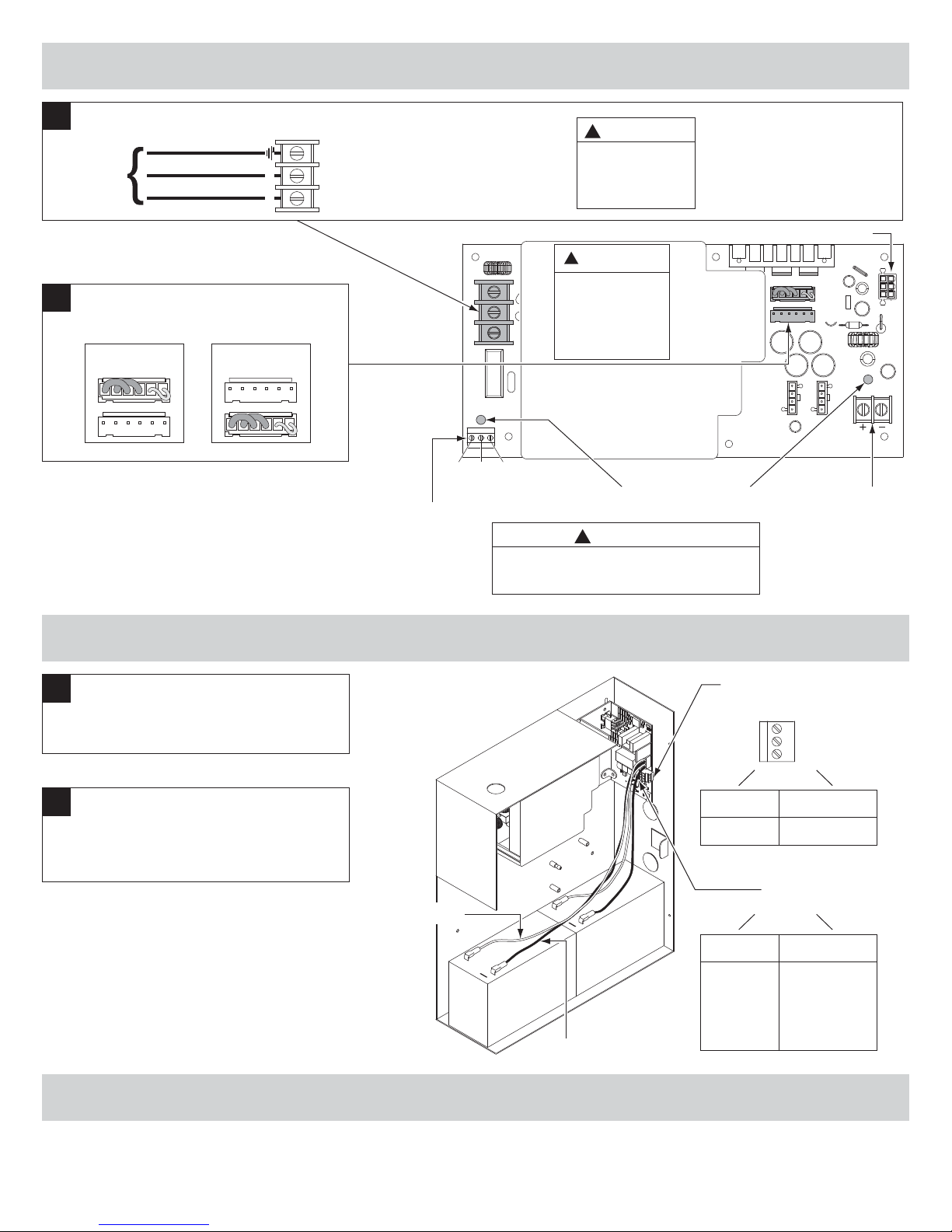

1 MOUNT POWER SUPPLY

1a

Mark 2 Top Holes

2 SECURE ENCLOSURE DOOR

1b

Secure Enclosure with 4 Screws

Board not shown

for clarity

x

x

If No Keylock

Enclosure will be secured with 2 screws

as shown (done as last step)

2 of 4

OR

If Keylock

Remove knockout and insert key cylinder, then slide in clip

a

b

3 PS914 SETUP AND TESTING

3a

Connect AC Wiring

AC (In)

120/240

VAC

3b

Use Jumper to Select Use Jumper to Select

Green (Ground)

White (Neutral)

Black (Hot)

24 VDC or 12 VDC Output

24 VDC

Output Setting

OR

Output Setting

AC Input

NEU

LINE

12 VDC

F1

NC C NO

!

DANGER:

Ensure AC

Breaker is

Turned Off

!

DANGER

High Voltage

If main board must be

removed, turn off AC power

and wait 8 minutes before

removal

Do not remove this cover, no

serviceable parts

900-BB Connector

24

12

Note:

Minimum of 1/4” separation

between AC and DC wiring

as well as power limited and

non-power limited.

AC Monitor

Active when AC

present and F1

fuse not open

(Form C dry

contacts)

If AC LED is off, turn off AC breaker

4 INSTALL 900-BB BATTERY BACKUP (IF INCLUDED)

4a

Place Batteries in Box with

Terminals to the Left

4b

Attach Wires from Battery Board

Red wires = (+)

Black wires = (-)

Red Wires = (+)

AC Input

(Green LED)

!

DANGER:

prior to checking F1 fuse

+

DC Output

(Red LED)

12/24 VDC

Output Terminals

Refer to 900-BB instructions

for additional info

Battery Supervision Terminals

(Form C Dry Contacts)

NO

(Shown

C

AC Off)

NC

Active

AC On

Inactive

AC Off

BB LED

(Amber)

Note: Allow 24 hours for batteries to fully charge

5 TURN ON AC BREAKER TO TEST POWER SUPPLY

• Verify AC LED is On = GREEN

• Verify DC LED is On = RED

• Verify BB LED (if applicable) is On = AMBER

+

Battery 1 Battery 2

Black Wires = (-)

On-Solid

AC On

Batteries

Charging

On-Blinking

AC Off

Batteries

Supplying

Powe r

3 of 4

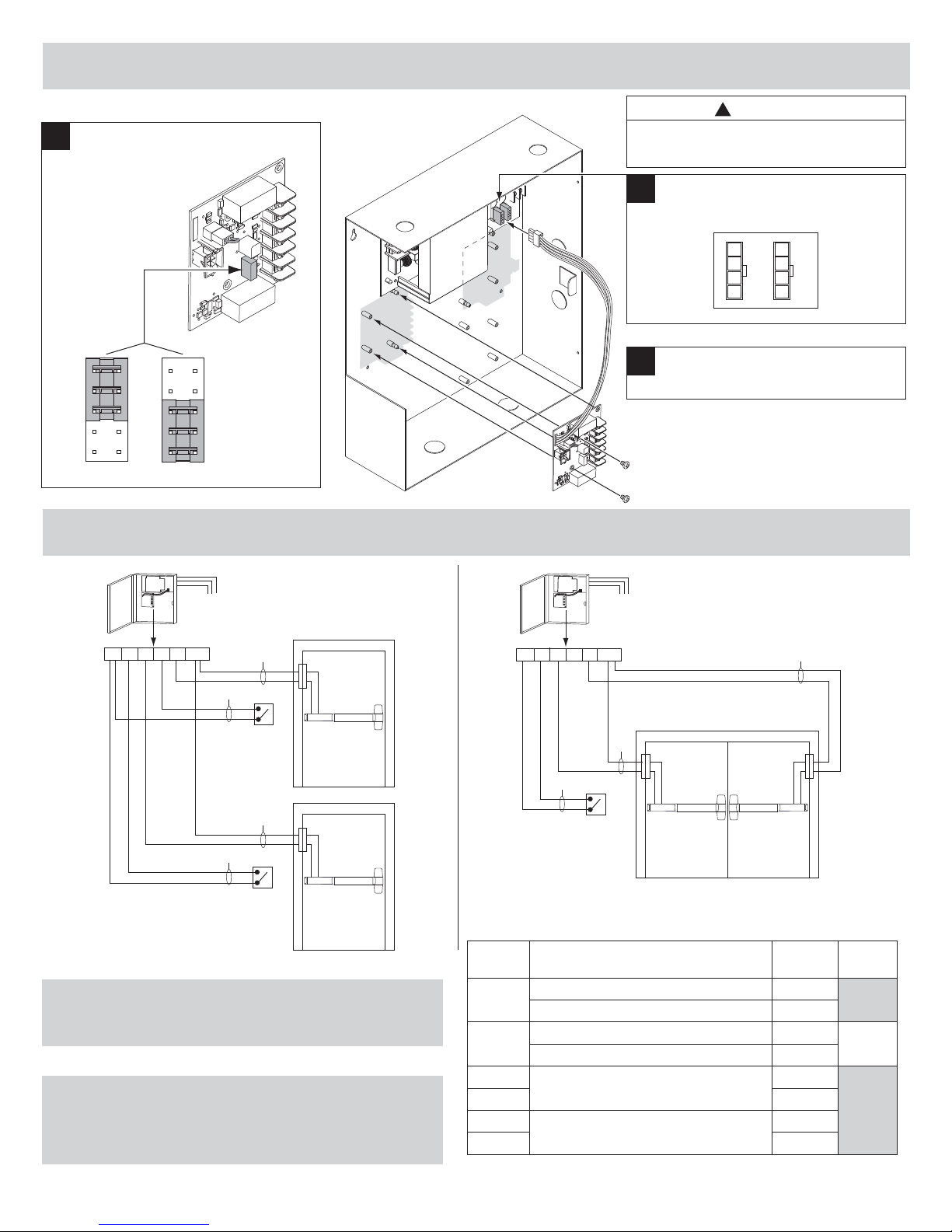

6 INSTALL 900-2RS OPTION BOARD (IF REQUIRED)

6a

Use Jumper to Select Use Jumper to Select

Function

!

DANGER:

Ensure AC breaker is turned off when

installing or wiring option boards

6b

Plug 2RS Cable into any

Available Option Connector

2

1

OR

Sequential Individual

7 CONNECT WIRING TO 900-2RS OPTION BOARD

Individual Mode - Typical Wiring

120/240 VAC

50/60Hz

2RS

SC I1 01 I2 02 GND

Input I1 will activate output 1

Input

I2 will activate output 2

A

B

Access

Control

for Device 2

EPT-2/10

EL Device 2

(not polarized)

6c

120/240 VAC

50/60Hz

2RS

SC I1 01 I2 02 GND

A

B

Option 1

Option 2

Secure Board with Screws

Note: 24VDC output setting required when EL

device connected

If installing board in location 2, rotate board 180˚

Sequential Mode - Typical Wiring

Input I1 will activate both outputs

A

EPT-2/10

EPT-2/10

A

B

Note:

Fail secure output only

allowed if approved

by Authority Having

Jurisdiction

8

IF PS-914 HAS OTHER OPTION BOARDS,

Access

Control

for Device 1

EPT-2/10

EL Device 1

(not polarized)

SEE THEIR INSTRUCTIONS

NOTE: WHEN INSTALLATION IS

COMPLETE, SECURE ENCLOSURE

DOOR WITH SCREWS OR KEYLOCK

4 of 4

Access

Control

for

Devices 1 & 2

Wire table (suggested maximum)

Wire Ga

(AWG)

14 0.3 850

18 0.3 340

12 Using EL device with EPT or Door Loop

14 100

12 Using EL device with Electric Hinge/Pivot

14 75

*Wiring allows for 10% voltage drop at device current at 12 or 24VDC

Max. ft = one way distance between power supply and device

(PS914 required)

(PS914 required)

EL Device 1

(not polarized)

Device Current

(Amps DC)

0.5 500

0.5 200

EL Device 2

(not polarized)

Output*

(max. ft)

200

150

Input

(max. ft)

1200

Installation

44487080

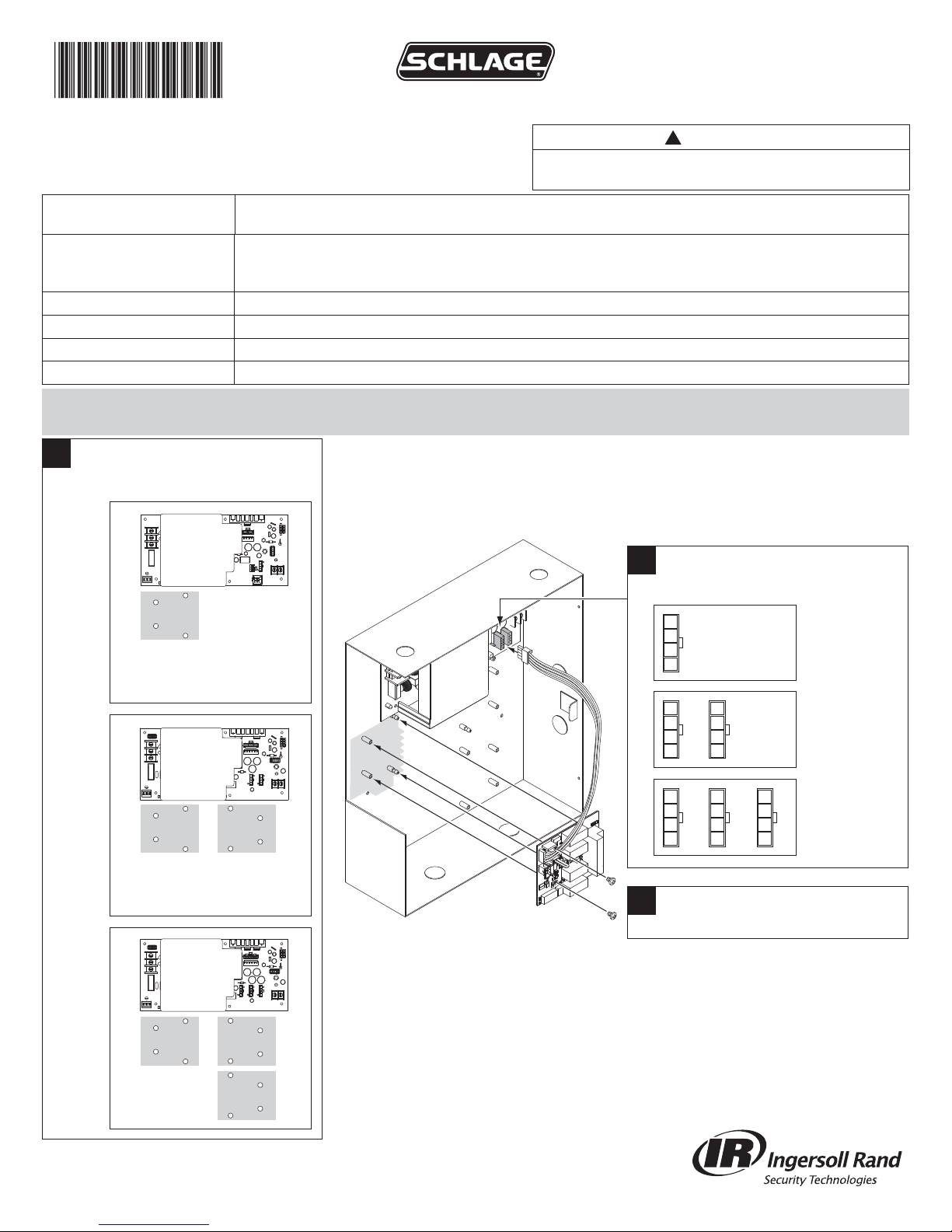

900-4RL Option Board

!

DANGER:

To avoid risk of electric shock, turn off AC power to

900-4RL Specifi cations:

Inputs I1-I4 Dry contacts required (Closed = Active)

Connect control contacts between SC (Signal Common) and any input

Outputs O1-O4 • Form C contacts rated 30VDC, 3A (Dry) • 12/24VDC, 3A (Wet) when AC powered • 9.6-13.2VDC or

19.2-26.4VDC when battery powered • May be used with PS914 to power EL device at 24VDC, 16A,

300ms • Maximum load cannot exceed power supply ratings or 6A for outputs combined

Board Input Power Board requires 0.18A max. of power supply output current to operate

Temperature Range 32°-120°F (0°- 49° C)

Compliance UL 294, ULC-S318, RoHS, & FCC Part 15

Fire Alarm Input Accepts 900-FA Fire Alarm Board (Optional)

power supply before installing or wiring option board

Instructions

1 INSTALL 4RL BOARD(S) INTO POWER SUPPLY

1a

Review Available 900-4RL

Mounting Locations (Gray)

PS902

1

PS904

PS914

12

Refer to installation instructions for compatible supply models - PS902, PS904,

PS906, and PS914.

1b

Plug 4RL Cable into any

Available Option Connector

PS902

Option 1

PS904, 914

Option 2

Secure Board(s) with Screws

Option 1

Option 1

Option 2

PS906

Option 3

1

1c

PS906

1

© 2010 Ingersoll-Rand Company

1-877-671-7011

44487080 Rev. 10/10_a

2

3

Note:

For UL listed installations, use

only UL listed locks and strikes

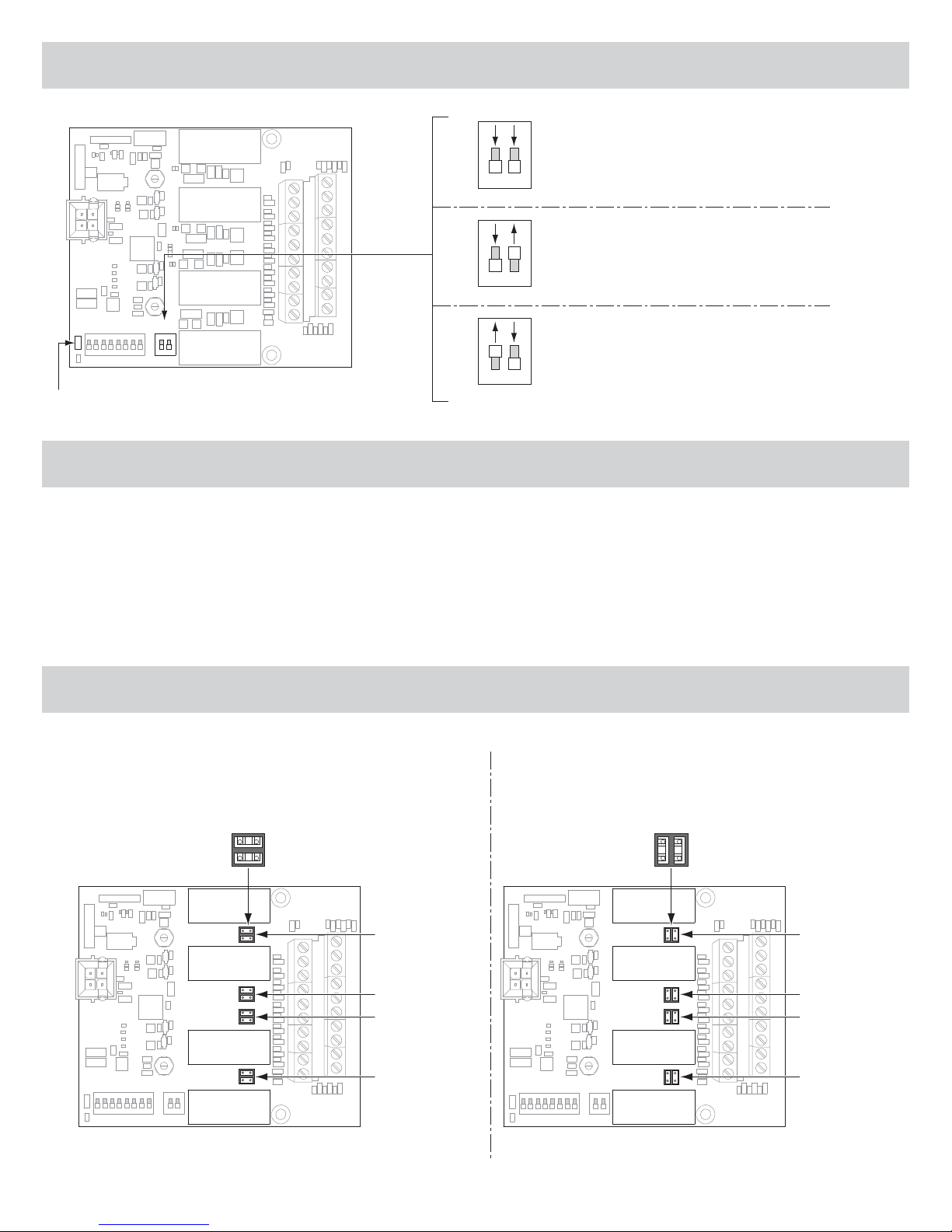

2 CHOOSE FUNCTION OF 900-4RL BOARD BY SETTING SW2 DIP SWITCHES

ON

OFF

4TD

Four Zone Controller Function (4TD):

Controls up to four inputs and four outputs with time delay.

This is the default setting.

Function LED will blink one time every 5 seconds

1 2

ON

OFF

AO

Auto Operator Function (AO):

Coordinates the unlocking of one or two zones with the

signaling of an auto operator.

Function LED will blink two times every 5 seconds

1 2

SW1

Function LED (D17)

SW2

OFF ON

1 2

ON

OFF

1 2

SI

Security Interlock Function (SI):

Controls multi-door interlocks. Two through six door

systems are possible (additional boards required for three

to six doors).

Function LED will blink three times every 5 seconds

3 TO COMPLETE CONFIGURATION AND WIRING, GO TO APPROPRIATE SECTION

For 4TD: Go to pages 3-4

For AO: Go to pages 5-6

For SI: Go to pages 7-8

Basic Troubleshooting: Go to page 8

(OPTIONAL) DRY CONTACT CONFIGURATION

Powered Outputs

(Default)

By default, all outputs provide12/24VDC For dry contact outputs, remove appropriate jumpers and

rotate 90˚, then reinstall (Zone 1 - Zone 4)

Jumpers factory

installed

Zone 2

Zone 4

Zone 3

Output 2

Output 4

Output 3

Dry Contact Outputs

(Optional)

Jumper

rotated 90˚

Zone 2

Zone 4

Zone 3

Output 2

Output 4

Output 3

Zone 1

2

Output 1

Zone 1

Output 1

Loading...

Loading...