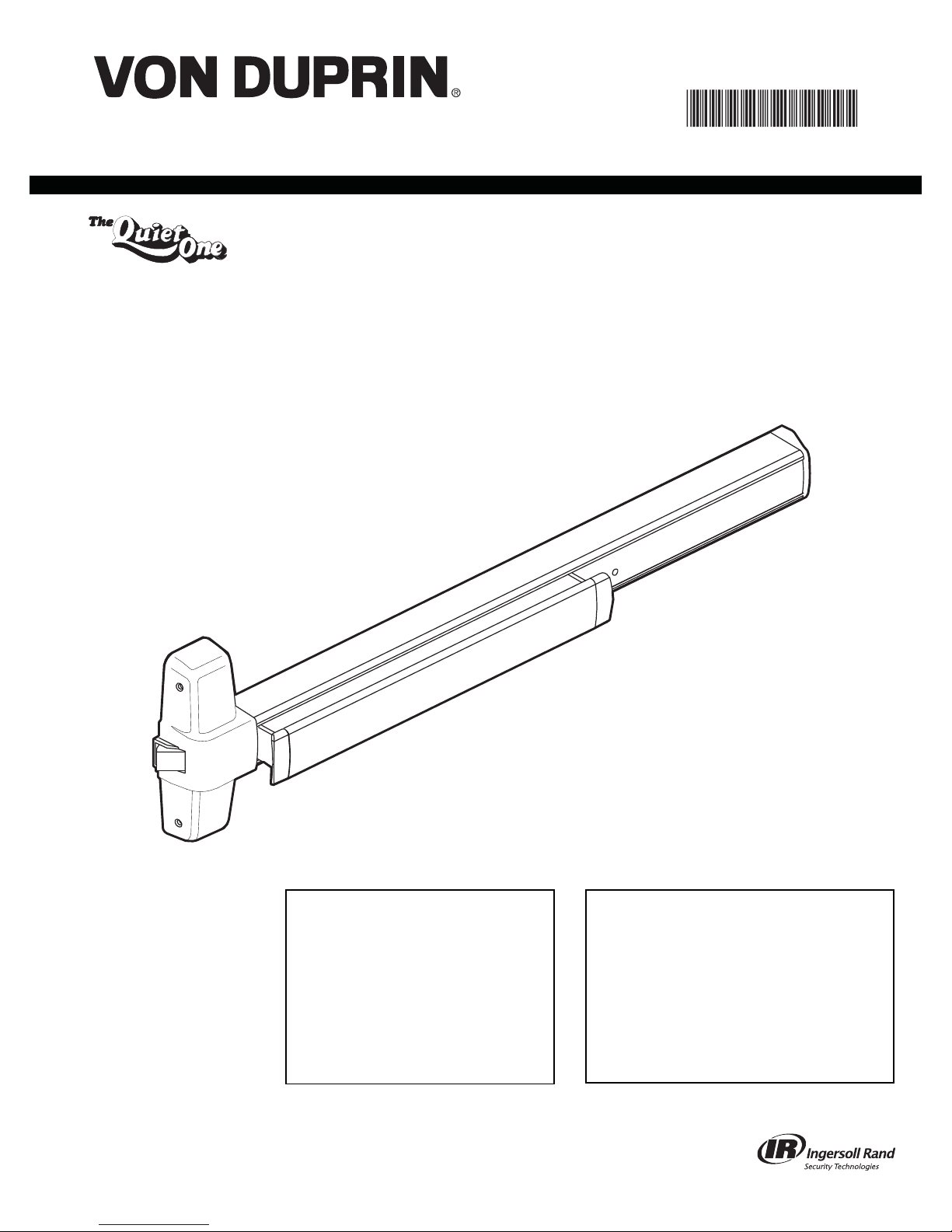

Von Duprin 99, CD98, 98-F, 99-F, CD99 Installation Instructions Manual

...

Installation Instructions

®

98/99

CD98/CD99 (Cylinder Dogging) Rim Exit Device

98-2/99-2 (Double Cylinder) Rim Exit Device

EL98/EL99 (Electric Latch Retraction) Rim Exit Device

Series Rim Exit Device

Devices covered by these instructions:

98/99 Rim Exit Device

98/99-F (Fire) Rim Exit Device

911373-00

Please give these instructions to building owner after device is installed

Special tools needed:

5/64” hex wrench

#10-24 tap

5/8” spade drill (

Drill bits: #25, 1/8”, 1/4”,

99-F wood door

5/16”, 3/8”, 13/32”

s Screw chart ............................. 2

s Preparation chart .................... 3

s Device installation ............... 4-5

)

s Optional equipment ............ 6-7

s Cut device .............................. 8

s 499F strike installation ............ 8

© 2011 Ingersoll-Rand Company

1-877-671-7011

911373_00 Rev. 3/11_c

Index:

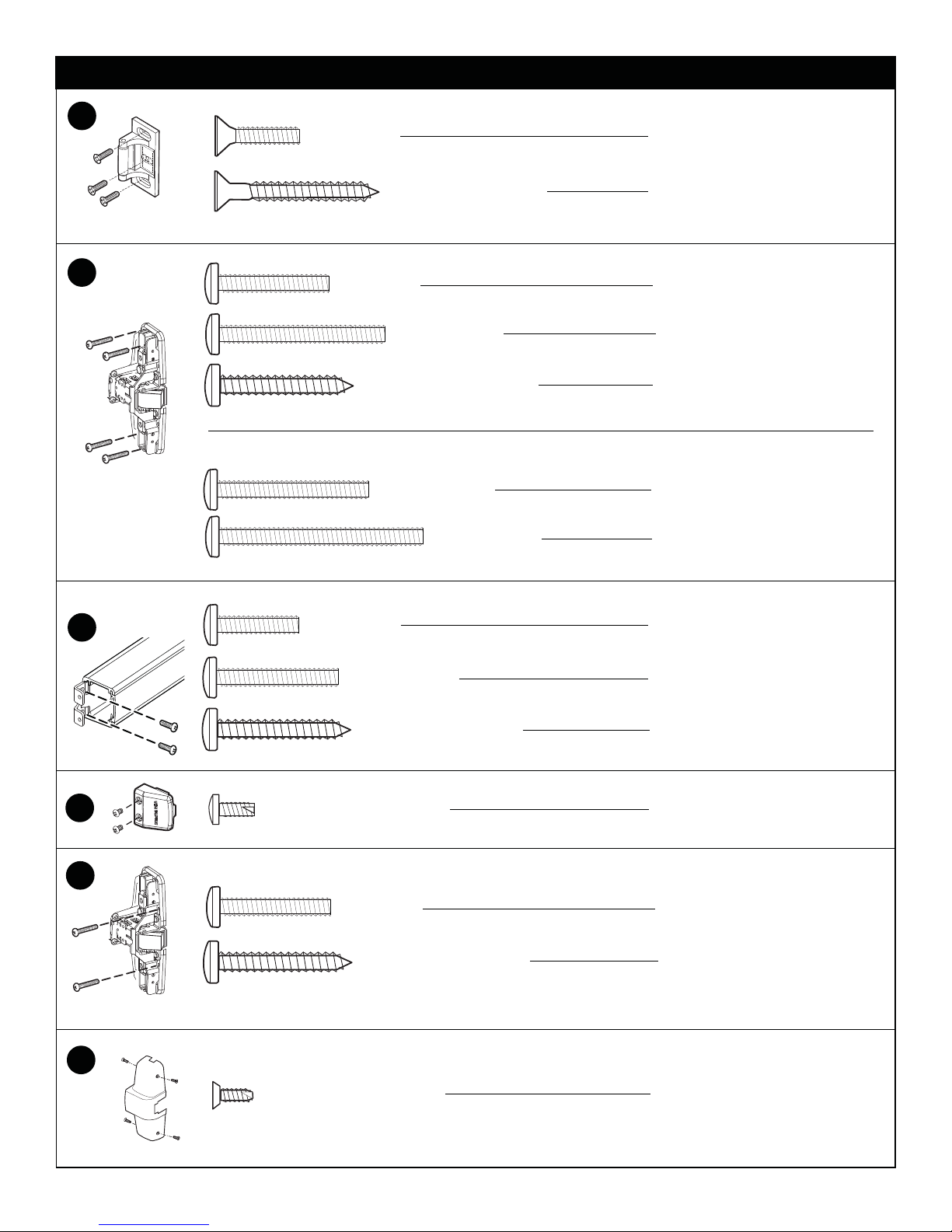

A

#10-24 X 3/4”

SCREW CHART

Metal frame

B

C

- Packaged with trim -

#10-24 X 3/4”

#10 X 1-1/2” Wood screw

#10-24 X 1”

#10-24 X 1-1/2”

#10 X 1-1/4” Wood screw

#10-24 X 1-3/8”

#10-24 X 1-7/8”

Wood frame

Surface mount or

Sex bolts (1-3/4” door)

Sex bolts (2-1/4” door)

Surface mount (wood)

990 Trims (1-3/4” door)

990 Trims (2-1/4” door)

Surface mount or

Sex bolts (1-3/4” door)

D

E

F

#10-24 X 1-1/8”

#10 X 1-1/4” Wood screw

#10-16 X 3/8” Thread cutting

#10-24 X 1”

#10 X 1-1/4” Wood screw

#8-18 X 3/8” Thread cutting

Sex bolts (2-1/4” door)

Surface mount (wood)

End cap screw

Surface mount (metal)

Surface mount (wood)

Cover screw

2

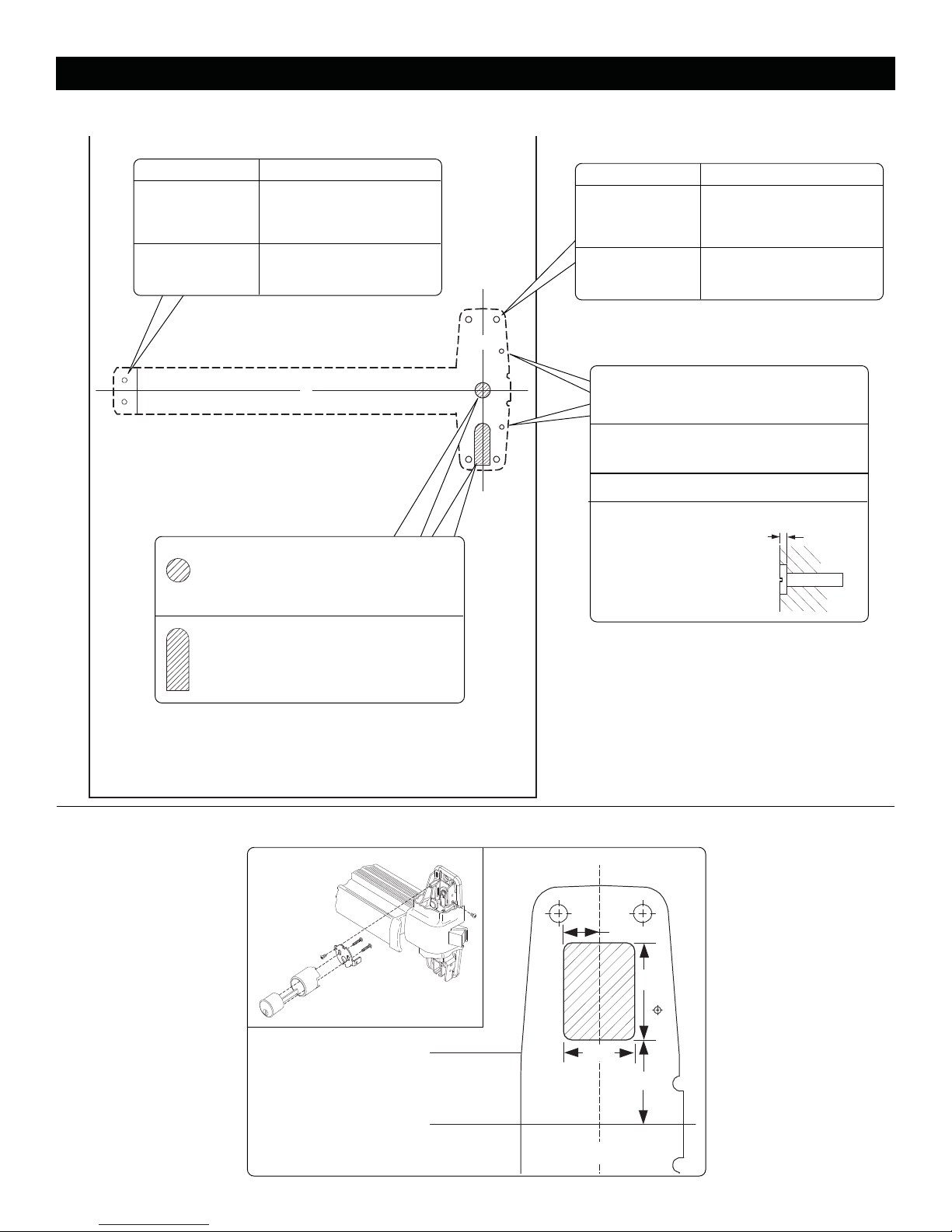

PREPARATION CHART

Go to instructions on next page before using preparation chart

*End cap bracket - 2 holes

Surface mount Sex bolts

#25 Drill

Metal

#10-24 tap

1/8” Drill

pilot 1” deep

Wood

*Prepare holes after lock side of device

is mounted and hinge side is leveled

1/4” Drill (device side)

Metal

13/32” Drill (trim side)

13/32”

C

L

Drill thru

RHR shown

(LHR opposite)

Wood

Door cut-outs

Outside cylinder applications:

Mark with template and cut-out:

Metal door (cut device side)

Wood door (cut thru)

X

C

X

Center case - 4 holes

Surface mount Sex bolts or 990 trims

#25 Drill

Metal

#10-24 tap

1/8” Drill

pilot 1” deep

Wood

L

Center case - 2 support holes

#25 Drill #10-24 tap

Metal

1/8” Drill pilot 1” deep

Wood

For 98-F/99-F (fire) wood door

#825 Sex bolts (2) required

3/8” Drill thru

5/8” Spade drill

Wood or

composite

1/16” Deep outside

1/4” Drill (device side)

Metal

13/32” Drill (trim side)

13/32”

Wood

Drill thru

1/16”

For trim applications with working

lever, thumbpiece, or knob:

Mark with template and cut out:

(cut device side only)

CUT-OUT FOR 99-2 “DOUBLE CYLINDER” OPTION

11/16”

1-3/4”

1-1/4”

1-3/8”

Device and strike

C

L

C

L

3

Loading...

Loading...