Von Duprin 376-T, 376-T-BE Installation Instructions Manual

*941148-00*

941148-00

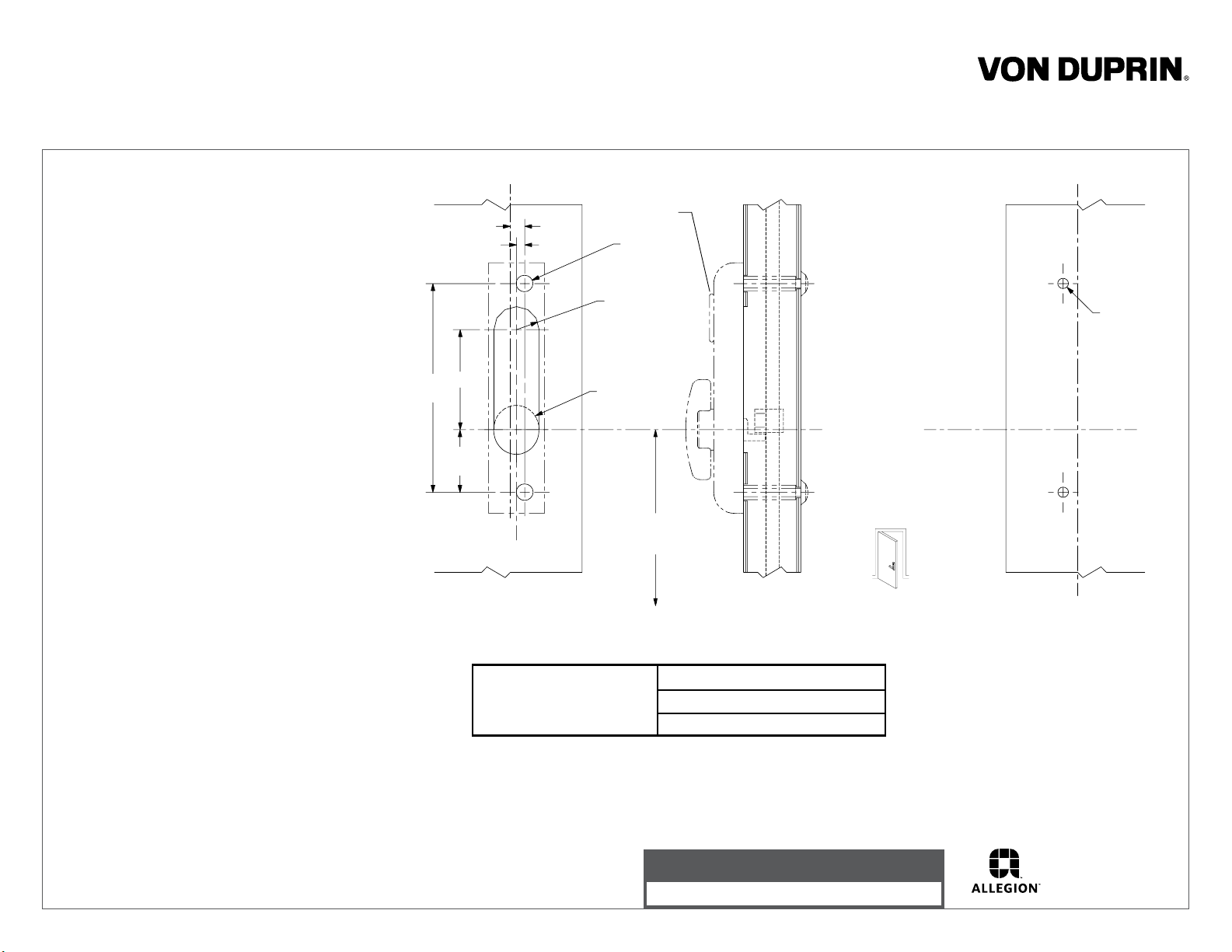

Control for Metal Door Application

376-T, 376-T-BE

Installation Instructions

1. Prepare door for exit device. See exit

device instructions for locations of

holes, backset (line X-X), and center

lines.

2. Prepare door for control:

A. Transfer line X-X from inside (exit

device side) of door to outside

(control side) of door. Use extra

care if edge of door is beveled.

Be sure line X-X is parallel to edge

of door.

B. Locate and prepare holes as

indicated.

3. Reverse cam on back of control if reqd.

(see Figure 1 on backside of sheet).

4. Install rod member (Figure 2):

A. Slip top rod assembly in door until

bottom of rod is visible in control

cutout.

B. Slip rod member on top rod

according to handing of door. Keep

rod member visible in cutout and

lower top rod assembly until latch

release is in position on latch release

reinforcement. Slightly tighten socket

set screws in rod member to

maintain this position.

C. Install and adjust top and bottom rod

assemblies. See installation

instructions for vertical rod device.

D. Adjust member so that the bottom

surface is 1/8” below the centerline

of thumbturn. Secure rod member

by tightening socket set screws.

6-1/4”

of vertical rod

C

L

7/16”

1/4”

3”

1-7/8”

of control

C

L

Outside

face of

lock stile

For cutouts on inside face

of door see instructions in

device carton

Omit cylinder

for BE function

1/2” dia.

2 places

11/16” R, 2 places

(omit for BE)

1-3/8” dia.

(BE only)

53-1/2”

to finished

floor

5547-F Vertical Rod Exit Device

8847-F Vertical Rod Exit Device

C

L

Device Application Schedule

Corresponds to

center line of

Thumbturn

LHR shown

RHR opposite

of vertical rod

C

L

5/16” dia.

2 places

Inside

face of

lock stile

5. Complete the device installation.

6. Install cylinder if required (Figs. 3 & 4).

Insure cylinder cam is set for required

function

and replace if necessary.

7. Retract latch bolts by depressing

device crossbar.

8. Apply control and test key, control,

and device action.

Customer Service

1-877-671-7011 www.allegion.com/us

© Allegion 2014

Printed in U.S.A.

941148-00 Rev. 01/14-b

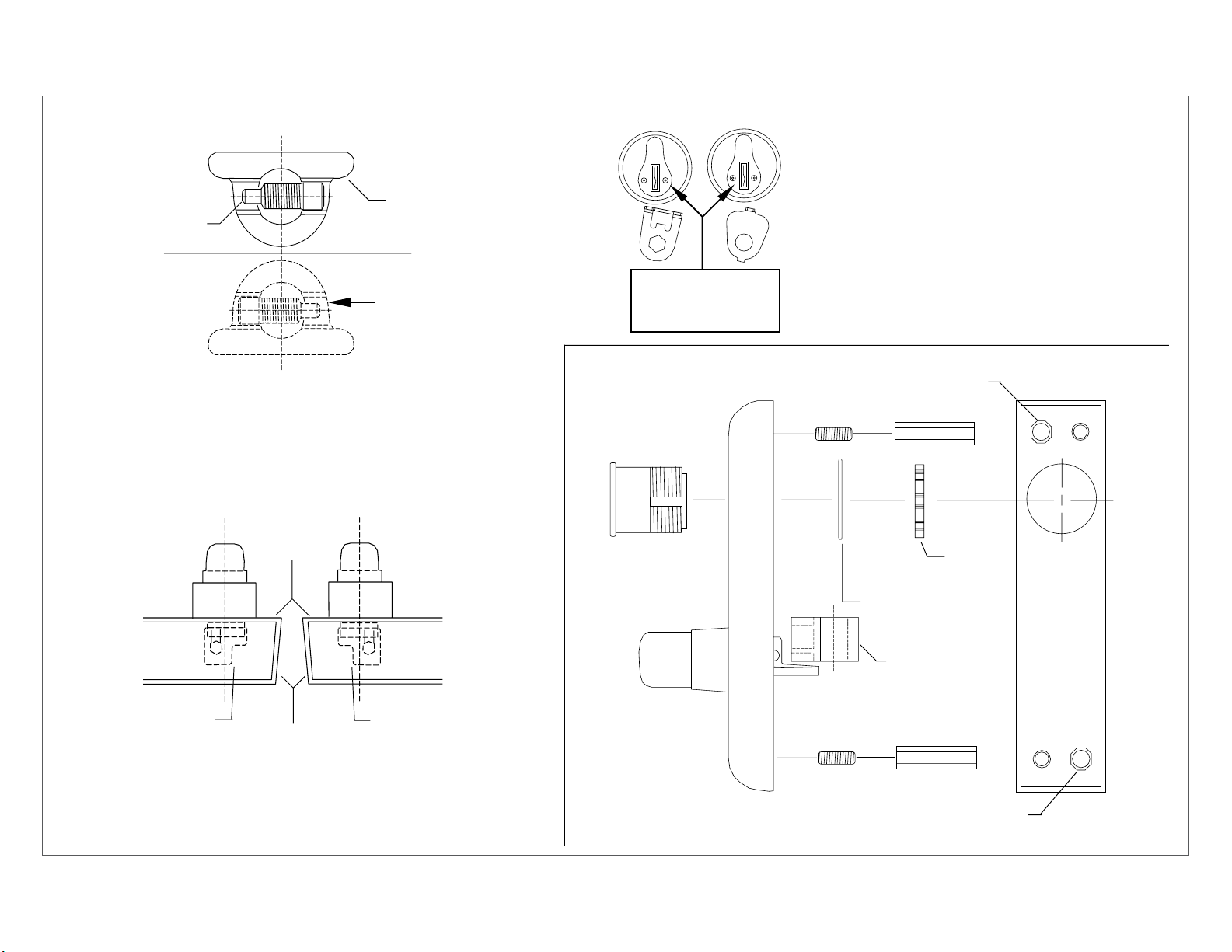

Screw

Control cam

NL

TL

TL Function - Control remains unlocked when

key is removed.

NL Function - Control relocks when key is

removed. Requires use of key to operate.

For NL function replace TL cylinder plate (std.

on all controls) with NL cylinder plate (included

in polybag) replacing screw and washer.

Correct position

for use with

5547-F and

8847-F devices

Control cam reversing procedure if required

Remove screw and rotate control cam 180

degrees to position shown and reinstall screw

Figure 1

Outside face

of door

Install rod member

in this position for

RHR door

Edge of

door

Install rod member

in this position for

LHR door

Cylinder cam in

this position with

key removed

Assemble set screw and mounting extension

Mortise

cylinder

Note: Control must be in locked position when

installing cylinder plate.

Figure 3

in this location for LHR top and bottom

Cylinder

nut

Cylinder locating

washer

Rod member

Hexagon

Socket set

screw

mounting

extension

Figure 2

Figure 4

Assemble set screw and mounting extension

in this location for RHR top and bottom

Loading...

Loading...