Von Duprin 374-T-BE, 374-T Installation Instructions Manual

*941118-00*

941118-00

Control for Metal Door Applications

374-T & 374-T-BE

Installation Instructions

1. Prepare door for exit device. See exit device

instructions for holes and backset.

2. Transfer center line from inside (exit device side)

of door to outside (control side) of door. Use

extra care if edge of door is beveled. Be sure

center line is parallel to edge of door.

3. Locate and prepare all holes as indicated in

diagrams on other side.

4. Install exit device.

5. Make sure control cam is in position shown

in Figure 1.

6. Install cylinder, if used, in control (Figure 2).

7. Make sure control cylinder plate is correct for

desired function (NL or TL; Figure 3).

8. Disconnect top vertical rod.

9. Apply control and rub plate to door and

secure with screws (Figure 4).

10. Place rod member on top vertical rod so rod

member nger faces door and curved side of

rod member nger faces down (Figure 5).

11. Insert rod member nger into slot in door.

Reconnect top vertical rod.

12. With top latch bolt extended, slide rod

member up rod so rod member nger

touches control cam.

13. Tighten set screws in rod member with 1/8”

wrench.

hex

14. Test key, control, and exit device action.

Surface Vertical Rod Device

Application Schedule

2227

2227-F

9827/9927

9827-F/9927-F

3327/3527

3327A/3527A

3327A-F/3527A-F

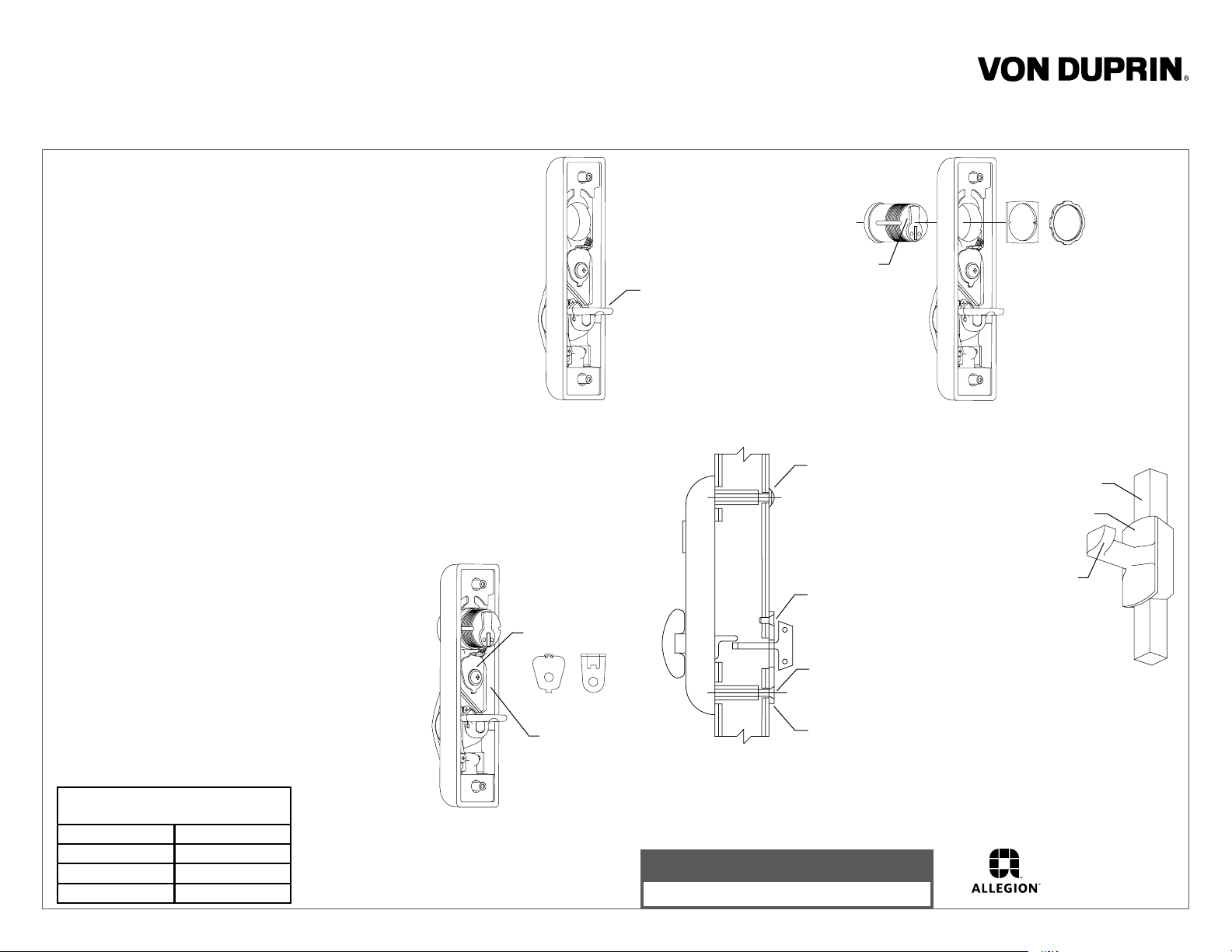

Figure 1. Control cam position.

Cylinder plate

TL

NL

To change

cylinder plate,

remove screw

and washer

Figure 3. Cylinder plate.

Mortise cylinder

Control

cam

cam must be in

position shown with

key removed; if

necessary, remove

cam and install in

correct position

Countersunk

washer with

1/4-20 oval

head screw

1/4-20 x 3/8”

undercut

at head screw

1/4-20 x 7/8”

undercut at

head screw

Rub plate

Figure 4. Control and rub plate

application.

Customer Service

1-877-671-7011 www.allegion.com/us

Mortise

cylinder

Figure 2. Cylinder installation.

Rod member

Curved side of

rod member

nger faces down

Figure 5. Rod member position.

Rod

© Allegion 2014

Printed in U.S.A.

941118-00 Rev. 01/14-b

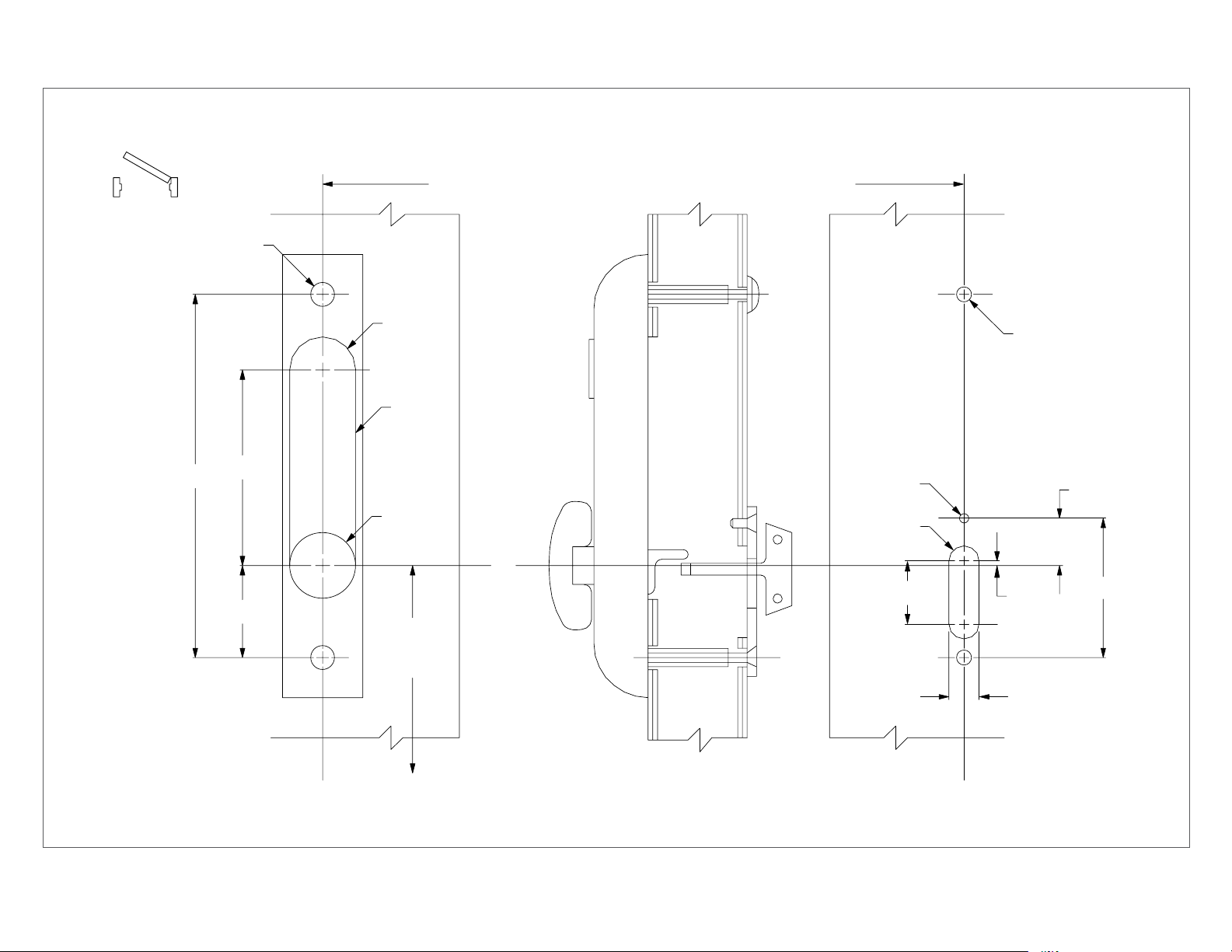

Outside

Inside

LHR shown

RHR opposite

exit device

and latch case

1/2” dia.

2 places

C

exit device

C

L

Center line exit device and latch case corresponds to

center line exit device and latch case on exit device instructions

L

and latch case

6 1/4”

3”

1 7/8”

11/16” R

2 places

Omit

slot

for BE

1-3/8” dia.

BE only

53-1/2”

to nished

oor

C

L

thumbturn

1/4-20 tap

5/16” R

1-1/4”

5/16” dia.

2 places

1/8”

5/8”

1”

2-7/8”

OUTSIDE FACE

OF LOCK STILE

For cutouts on inside face of door, see exit device instructions.

INSIDE FACE

OF LOCK STILE

Loading...

Loading...