Volvo Penta TAD530, TAD420VE, TD520VE, TAD520VE, TAD531 Workshop Manual

...

I

1(0)

Workshop Manual

Technical Data

TD420VE, TAD420VE, TD520GE, TAD520GE, TD520VE

TAD520VE, TAD530/531/532GE, TAD620VE, TAD650VE

TAD660VE, TD720GE TAD720GE, TD720VE, TAD720VE

TAD721GE, TAD721VE, TAD722GE, TAD722VE,

TAD730/731/732/733GE, TAD750VE, TAD760VE

1

General InformationGroup 20

Safety precautions ...............................................2

General information ............................................. 5

Repair instructions ............................................... 6

Location of identification plates

TD/TAD420-620, TD/TAD520-722 .......................9

TAD650/660, TAD750/760 .................................. 10

TD420VE, TAD420VE, TAD620VE, TAD650VE,

TAD660VE

General (420/620)................................................ 11

General (650/660)................................................ 12

Engine block ....................................................... 12

Valve mechanism ...............................................16

Crank mechanism ............................................... 19

Lubricating system .............................................. 22

Fuel system ........................................................ 24

Intake and exhaust system ................................. 32

Cooling system ................................................... 32

Tightening torque ................................................33

TD520GE, TAD520GE, TD520VE, TAD520VE,

TAD530-532GE

General ............................................................... 36

Engine block ....................................................... 37

TD420VE, TAD420VE, TAD620VE, TAD650VE, TAD660VE,

TD520GE, TAD520GE, TD520VE, TAD520VE,

TAD530/531/532GE, TD720GE, TAD720GE, TD720VE,

TAD720VE, TAD721GE, TAD721VE, TAD722GE, TAD722VE,

TAD730/731/732/733GE, TAD750VE, TAD760VE

Valve mechanism ............................................... 40

Crank mechanism ............................................... 43

Lubricating system .............................................. 46

Fuel system ........................................................ 48

Intake and exhaust system ................................. 55

Cooling system ................................................... 56

Tightening torque ................................................57

TD720GE, TAD720GE, TD720VE, TAD720VE,

TAD721GE, TAD721VE, TAD722GE, TAD722VE,

TAD730-733GE, TAD750VE, TAD760VE

General (720-722GE ) ......................................... 59

General (720-722VE) ...........................................60

General (750/760)................................................ 60

Engine block ....................................................... 61

Valve mechanism ............................................... 64

Crank mechanism ............................................... 67

Lubricating system .............................................. 70

Fuel system ........................................................ 72

Intake and exhaust system ................................. 80

Cooling system ................................................... 81

Tightening torque ................................................82

Tightening diagram ............................................. 85

Contents

Technical Data

Industrial Engines

© 2007 AB VOLVO PENTA

All rights to changes or modifications reserved.

Printed on environmentally-friendly paper

2

General Information Group 20

Introduction

Workshop Manuals contains technical specifications,

descriptions, and instructions for the repair of the specified Volvo Penta products or product types. Check

that you have the correct Workshop Manual and the

latest Service Bulletins for your engine.

Before starting work on the engine, read these

sections of the Workshop Manual:

Safety Precautions

General Information

Repair Instructions

Below is a summary of the risks involved and safety precautions you should always observe or

carry out when operating or servicing the engine.

Immobilize the engine by turning off the power

supply to the engine at the main switch (switches) before starting work. Put a warning notice at

the engine control panel.

Generally, all service operations must be carried out with the engine stopped.

However, some work, for example certain adjustments requires that the engine is running when

they are carried out.

Approaching an engine, which is operating, is a

safety risk. Loose clothing or long hair can fasten in rotating parts and cause severe personal

injury.

Take care to avoid contact with hot surfaces

(exhaust pipes, turbocharger, air intake pipe, starter element etc.) and hot liquids in lines and

hoses on an engine that is running or has just

been stopped. Reinstall all protective parts removed during service operations before starting

the engine.

Check that the warning or information labels on

the product are always clearly visible. Replace

labels that have been damaged or painted over.

Never start the engine without installing the air

cleaner filter. Foreign objects entering the intake

ducts can also cause mechanical damage.

Never use ether or similar products when starting the engine. They may cause an explosion in

the inlet manifold and causing personal injuries.

Only start the engine in a well-ventilated area.

If operating the engine in an enclosed area make sure that the exhaust is leading out of the engine compartment and working area.

Avoid opening the coolant filler cap when the engine is hot, when hot steam or coolant might spray out. If the filler cap must be open, slowly release the pressure in the system. Be very careful, it is difficult to anticipate in which direction

hot steam or coolant can spray out.

Safety Precautions

Important

In this book and on the product you will find the following special warning symbols.

WARNING! Possible danger of personal injury,

extensive damage to property or serious mechanical malfunction if the instructions are not followed.

IMPORTANT! Used to draw your attention to something that can cause damage or malfunc-tions on a product or damage to property.

NOTE! Used to draw your attention to important

infor-mation that will facilitate the work or operation in progress.

Warning symbols used in the Workshop Manual are

not in any way comprehensive since it is impossible

to predict every circumstance under which service work or repairs may be carried out.

AB Volvo Penta can only indicate the risks considered likely to occur as a result of incorrect working

methods in a well-equipped workshop using working

methods and tools tested by AB Volvo Penta.

3

General InformationGroup 20

Stop the engine before carrying out operations

on the engine cooling system.

Always use protective glasses or goggles, when

carrying out work where there is a risk of splinters, grinding sparks and acid splashes or when

other chemicals are in use. The eyes are extremely sensitive and an injury could result in blindness!

Avoid getting hot oil on your skin, it might cause

severe burns. Ensure that the lubrication system is not under pressure before carrying out any

work. Never start or operate the engine with the

oil filler cap removed, otherwise oil could be ejected.

Exposure to oil over a long period or repeatedly

will cause problems such as skin drying out, irritation and toxic eczema. Used oil is in a health

aspect even more dangerous than new oil. Use

protective gloves. Use protection creams, which

will ease up cleaning of the skin and counteract

drying out.

Many chemicals such as oils, glycol, diesel oil

and other chemicals, for example degreasing

agents, paint and solvents are dangerous to your health.

Always follow the safety precautions for the product, for example using protective mask, glasses, gloves etc. Make sure of good ventilation is

provided in the working area. Follow the instructions on the product, when disposing used chemicals.

Follow extreme care when working with/or checking the fuel system. Use eye protection. The

jet from a fuel injector nozzle is under extremely

high pressure and can cause severe personal

injury.

WARNING! Use new delivery pipes every time.

Be careful, delivery pipes should under no circumstances be bent.

All fuels and many chemical substances are flammable. Do not allow naked flame or sparks in

the working area!

Make sure that the working area is well ventilated and take the necessary safety precautions

before starting welding or grinding work.

Make sure that there always are fire extinguishers in the working area.

Ensure that rags soaked in oil or fuel are stored

safely. Rags soaked in oil can spontaneously

ignite. Used fuel filters, oil filters, lubricating oil,

contaminated fuel, solvent and degreasing agents are environmentally dangerous waste and must be deposited at an approved site for dest-ruction.

Never expose a battery to naked flame or electrical sparks. Batteries always produce hydrogen

gas, which mixed with air form an explosive gas

– oxyhydrogengas.

This gas is highly volatile and easily ignited. Incorrect connection of the battery can cause a

single spark that is sufficient to cause an explosion. Be very careful when attempting to ju-mpstart the engine and do not at any time lean over

the batteries.

Always ensure that the Plus (positive) and Minus (negative) battery leads are correctly installed. Incorrect installation can result in severe

damage to the electrical equipment. Refer to the

wiring diagrams.

Always use protective goggles when charging

and handling the batteries. Battery electrolyte

contains sulfuric acid, which is highly caustic.

Should the battery electrolyte come into contact

with unprotected skin wash off immediately using plenty of water and soap and if it is exposed

to the eyes, immediately flush with plenty of water and obtain medical assistance at once.

4

General Information Group 20

WARNING! The components in the electrical system and in the fuel system on Volvo Penta products are designed and manufactured to minimize the risk of fire and explosion.

The engine must not be run in areas where there

are explosive materials.

Always use the fuels recommended by AB Volvo Penta. Refer to the Instruction Book. Use of

fuels that are of a lower quality can damage the

engine. On a diesel engine, poor quality fuel can

cause the control rod to seize, which can result

in an over revving of the engine, risking of damaging to the engine and of personal injuries.

Poor fuel quality can also lead to higher maintenance costs.

Observe the following rules when cleaning with

high-pressure water jets. Never direct the water

jet at seals, rubber hoses, or electrical components. Never use a high-pressure jet when washing the engine.

Turn the engine off and turn off the power at the

main switch/switches before carrying out work

on the electrical system.

Clutch adjustments must be carried out with the

engine stopped.

Use the lifting eyes fitted on the engine when lifting the drive unit. Always check that the lifting

equipment is in good condition and has the correct load capacity to lift the engine (engine weight including gearbox, if fitted, and any extra equipment installed).

To make sure of safe handling and to avoid damage, use a lifting beam to raise the engine.

This lifting beam is installed on the top of the

engine, make sure that all chains and cables should run parallel to each other.

If extra equipment is installed on the engine that

would alter its center of gravity, it is required that the lifting device has to be altered for obtaining the correct balance for safe handling.

Never carry out work on an engine suspended

on a hoist without other supporting equipment

attached.

Never work alone when removing heavy engine

components, even when using lifting devices

such as locking tackle lifts. When using a lifting

device two people are usually required to do the

work, one to take care of the lifting device and

another to ensure that components are lifted clear and not damaged during the lifting operations.

Check before starting work if there is eno-ugh

room to carry out removal work without risk-ing

personal injury or damage to the engine or parts.

5

General InformationGroup 20

About this Workshop Manual

This Workshop Manual contains technical data for the

repair of the following engines in standard format:

TD420VE, TAD420VE, TAD620VE, TAD650VE,

TAD660VE, TD520GE, TAD520GE, TD520VE,

TAD520VE, TAD530-532GE, TD720GE, TAD720GE,

TD720VE, TAD720VE, TAD721GE, TAD721VE,

TAD722GE, TAD722VE, TAD730-733GE, TAD750VE,

TAD760VE

The Engine Designation and Engine Numbers can be

found on the Identification plates. Please always include both the engine designation and the engine

number in all correspondence.

The Workshop Manual is produced primarily for the

use of Volvo Penta workshops and service technicians. For this reason, the manual presupposes a certain basic knowledge and that the user can carry out

the mechanical/electrical work described to a general

standard of engineering competence.

Volvo Penta products are under a continual process of

development and we therefore reserve all rights regarding changes and modifications. All the information in

this manual is based on product specifications available at the time the book was published. Any essential

changes or modifications introduced into production or

updated or revised service methods introduced after

the date of publication will be provided in the form of

Service Bulletins

from AB Volvo Penta.

Power standards

The engine performance corresponds to:

ISO 3046, BS 5514, and DIM 6271.

Prime power rating corresponds to ISO standard power for continues operation. It is applicable for supplying electrical power at variable load for an unlimited

number of hours instead of commercial purchased power. A ten-percent overload capability is available for

this rating.

Standby Power rating corresponds to ISO Standard

Fuel Stop Power. It’s is applicable for supplying

standby electrical power at variable load in areas well

est-ablished electrical networks in event of normal utility power failure. No overload capability is available

for this rating.

NOTE! The technical data applies to an engine without cooling

fan and operating on a fuel with calorific value of 42.7 MJ/kg

(18360 BTU/lb.) and a density of 0.84 kg/liter (7.01 lb./US gal,

8.42 lb./lmp. gal) even when it involves a deviation from

standards.

Spare parts

Spare parts for the electrical and fuel systems are

subject to various national safety requirements. Volvo

Penta Original Spare Parts meet these specifications.

Any type of damage which is the result of using spare

parts that are not original Volvo Penta parts for the

product in question will not be covered under any warranty or guarantee provided by AB Volvo Penta.

Engine certificate

Engine certificates to meet national and regional environmental legislation carry with them an undertaking

from the manufacturer that both new and existing engines in use meet the environmental demands of the

legislation. The product must correspond to the validated example that was granted certification. In order for

AB Volvo Penta as the manufacturer to take responsibility for engines in use, certain requirements regarding service and spare parts must be met by the user

according to the following:

• The Service Intervals and maintenance operations

recommended by Volvo Penta must be followed.

• Only Volvo Penta Original Spare Parts intended

for the engine certificates may be used.

• Service work on the injection pump and injectors

must always be carried out by an authorized Volvo Penta workshop.

• The engine may not be altered or modified in any

way, with the exception of accessories and service kits developed by Volvo Penta for that engine.

• No modifications to the exhaust pipes and air

supply ducts for the engine room (ventilation

ducts) may be undertaken as this may effect exhaust emissions.

• Any seals on the engine may not be broken other

than by authorized persons.

IMPORTANT! If replacement parts are required,

use only AB Volvo Penta Original Parts.

Use of replacement parts other than AB Volvo Penta Original Parts will result in AB Volvo Penta being unable to assume any liability that the engine

corresponds to the engine certificates variant.

AB Volvo Penta excludes any liability for all and any

type of damage or costs caused by the use of replacement parts that are not Volvo Penta Original Parts

for the product in question.

General Information

6

General Information Group 20

Introduction

The working methods described in the Workshop

Manual apply to work carried out in a workshop.

The engine has been removed and is installed in

an engine fixture.

Unless otherwise stated reconditioning work that

can be carried out with the engine in place follows

the same working method.

All operations described in the Workshop Manual for

which there are Volvo Penta Special Tools available

assume that the service technician or person carrying

out the repair uses these tools.

Volvo Penta Special Tools have been specifically developed to ensure as safe and rational working methods as possible.

Person or persons using other than Volvo Penta Special Tools or approved Volvo Penta working methods

(as described in a Workshop Manual or Service Bulletin). Has the responsibility to acquaint themselves of

the risk of personal injury or actual mechanical damage or malfunction.

In some cases special safety precautions and user instructions may be required in order to use the tools

and chemicals mentioned in the Workshop Manual, always follow these precautions, as there are no specific instructions given in the Workshop Manual.

By following these basic recommendations and using

common sense it is possible, to avoid most of the

risks involved in the work. A clean work place and a

clean engine will eliminate many risks of personal injury and engine malfunction.

Above all when working on the fuel system, lubrication

system, intake system, turbocharger, bearings and

seals. It is extremely important to observe the highest

standards of cleanliness and avoid dirt or foreign objects entering the parts or systems, since this can result in reduced service life or malfunctions.

Our joint responsibility

Every engine consists of many systems and components that work together. If one component deviates

from the technical specifications, than this can have

dramatic consequences on the environmental impact,

even if it is otherwise in good running order.

It is therefore critical that the stated wear tolerances

are observed, that systems which can be adjusted are

correctly set up and that only Volvo Penta Original

Parts are used.

The stated service intervals in the Maintenance Schedule must be followed.

Some systems, such as the components in the fuel

system, require special expertise and special testing

equipment for service and maintenance.

Some components are factory sealed for environ-mental and product specific reasons. Don’t under no circumstances attempt to service or repair a sealed component, unless it is done by a authorized service technician.

Bear in mind that most chemical products, incorrectly

used, are hazardous to the environment.

AB Volvo Penta recommends the use of biodegradable degreasing agents for all cleaning of engine components, unless otherwise is stated in the Workshop

Manual.

Pay special attention to make sure that oils and washing residue are handled correctly for destruction, and

not end up in the nature.

Repair instructions

7

General InformationGroup 20

Tightening torque

For the correct tightening torque for critical joints,

which must be tightened using a torque wrench is listed under chapter “Tightening Torque”. For correct

tightening torque, is it important to apply cleaned threads, bolt heads and mating surfaces, with lightly oiled or dry threads. In places where grease, locking or

sealing agents is required for screwed joints, the correct torque is stated in “Tightening Torque”.

When no tightening torque is stated, use the general

tightening torque, according to the table below.

Dimension Tightening torque

Nm (lbf.ft.)

M5 ......................................................... 6 (4.4)

M6 ......................................................... 10 (7.4)

M8 ......................................................... 25 (18.4)

M10 ....................................................... 50 (36.9)

M12 ....................................................... 80 (59.0)

M14 ....................................................... 40 (103.3)

Lock nuts

Do not reuse lock nuts that have been removed during

disassembly operations as these have reduced

service life when reused. Use new nuts when

assembling or reinstalling.

For lock nuts with a plastic insert such as Nylock®

the tightening torque stated in the table is reduced if

the Nylock® nut has the same head height as a standard hexagonal nut without plastic insert.

Reduce the tightening torque by 25% for bolt size M8

or larger.

If Nylock® nuts are higher, or of the same height as a

standard hexagonal nut, the tightening torque’s given

in the table applies.

Tightening torque with

protractor tightening

(angle tightening)

Tightening using both a torque setting and a protractor

angle requires that first the recommended torque is

applied using a torque wrench and then the recommended angle is added according to the protractor

scale. Example: A 90° protractor tightening means

that the joint is tightened a further 1/4 turn in one operation after the stated tightening torque has been applied.

Strength classes

Bolts and nuts are divided up into different classes of

strength, the number on the bolt head indicates the

class. A high number indicates stronger material, for

example a bolt marked 10-9 indicates a higher

strength than one marked 8-8.

It is therefore important that bolts removed during the

disassembly of a bolted joint must be reinstalled in

their original position when assembling the joint.

When replacing a bolt, check in the spare parts catalogue to make sure the correct bolt is used.

8

General Information Group 20

Sealant

It is therefore important that bolts removed during the

disassembly of a bolted joint must be reinstalled in

their original position when assembling the joint. When

replacing a bolt, check in the spare parts catalogue to

make sure the correct bolt is used.

To ensure service work is correctly carried out it is important that the correct sealant and locking fluid type

is used on the joint where the agents are required as

described in the Workshop Manual or the Service Bulletin.

During service operations use the same agent or an

alternative.

Make sure that mating surfaces are dry and free from

oil, grease, paint and anticorrosion agent before applying sealant or locking fluid.

Always follow the manufacturer’s instructions for use

regarding temperature range, curing time and any other instructions for the product.

Two different basic types of agent are used:

RTV agent (Room Temperature Vulcanizing)

Used for gaskets, sealing gasket joints or coating

gaskets. RTV is visible when a part has been

disassembled; old RTV must be removed before

resealing the joint.

Old sealant can be removed using methylated spirits

in all cases.

Anaerobic agents:

These agents cure in an absence of air. They are used when two solid parts, for example cast components,

are installed face-to-face without a gasket. They are

also commonly used to secure plugs, threads in stud

bolts, petcocks, oil pressure switches, and so on.

The cured material is glass like and it is therefore colored to make it visible. Cured anaerobic agents are

extremely resistant to solvents and the old agent cannot be removed. When reinstalling the part is carefully

degreased and then new sealant is applied.

Safety rules for fluorocarbon

rubber

Fluorocarbon rubber is a common material in seal

rings for shafts, and in O-rings.

When fluorocarbon rubber is subjected to high temperatures (above 300°C or 572°F),

hydrofluoric acid

can

be formed, which is highly corrosive.

Skin contact can give severe chemical burns. Splashes in eyes can give severe chemical burns.

Breathing of fumes can be permanently damaged

lungs.

WARNING! Be very careful when working on

engines that have been exposed to high temperatures, e.g. overheating during a seizure or fire.

Seals must never be cut with an oxy-acetylene

torch, or be burned up afterwards in an uncontrolled manner.

Always use gloves made of chloroprene rubber

(gloves for handling chemicals) and protective

goggles.

Handle the removed material like corrosive acid.

All residues, including ash, can be highly corrosive.

Never use compressed air to blow anything clean.

Put the remains in a plastic box which is sealed

and provided with a warning label. Wash the gloves under running water before removing them.

These following seals are probably made out of fluorocarbon rubber:

Seal rings for crankshaft, camshaft, and intermediate shafts.

O-rings irrespective of where they are installed.

O-rings for cylinder liner sealing are usually made

out of fluorocarbon rubber.

9

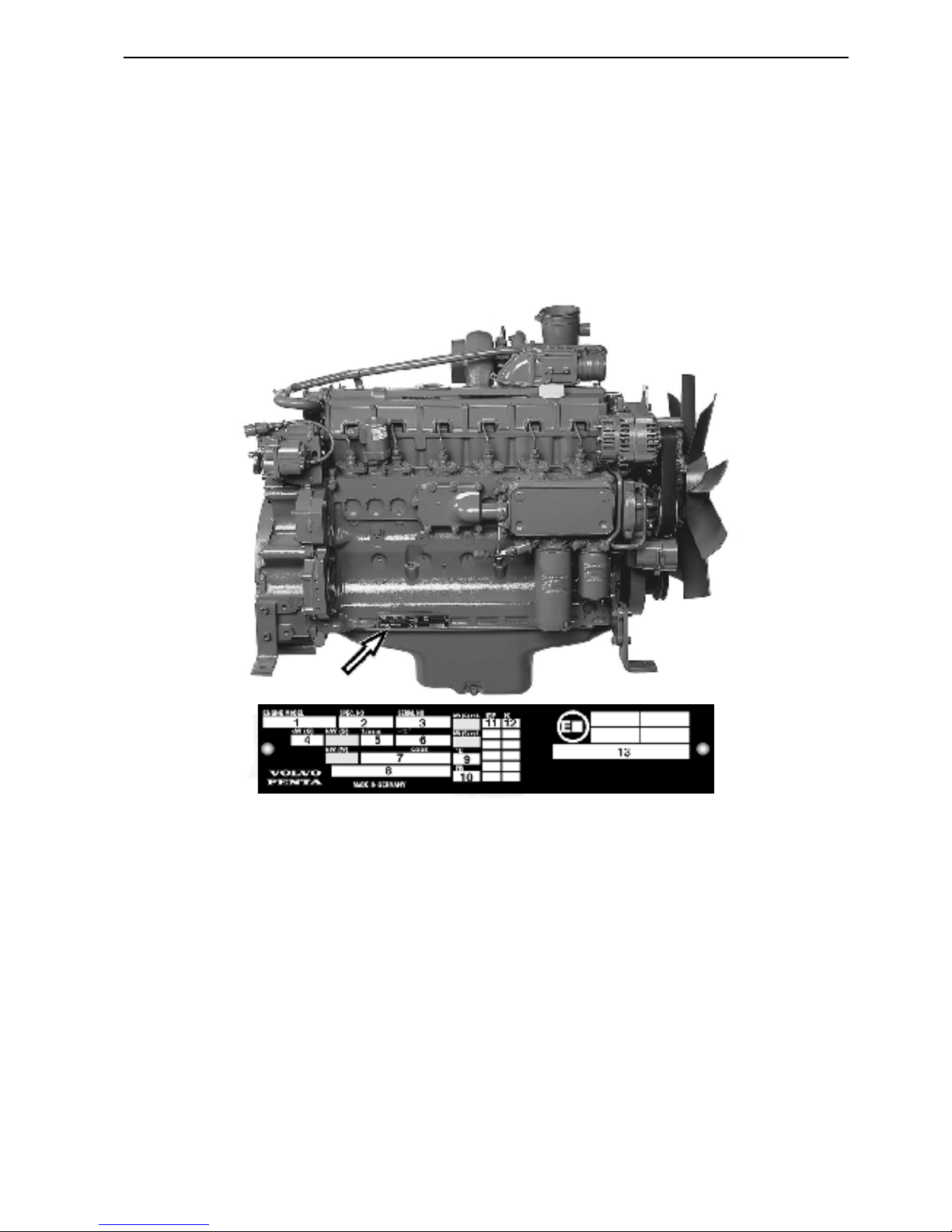

General InformationGroup 20

1. Engine model

2. Engine specification number

3. Engine serial number (10 digits)

4. Engine output without fan

5. Rated engine speed

6. Injection timing and type of camshaft

7. Manufacturers identification code

8. Indication of standard and /or regulation

9. ISO 3046, reference test conditions

10. ISO 3046, reference test conditions

11. Injection pump code (EP code)

12. Piston class

13. Prime output, without fan, at rated speed

Identification plates

Location of identification

plates (420-620, 520-722)

Each engine is supplied with two identical identification plates, of which one is mounted on the right side

of the cylinder block and the other one should be mounted in a suitable location adjacent to the engine.

10

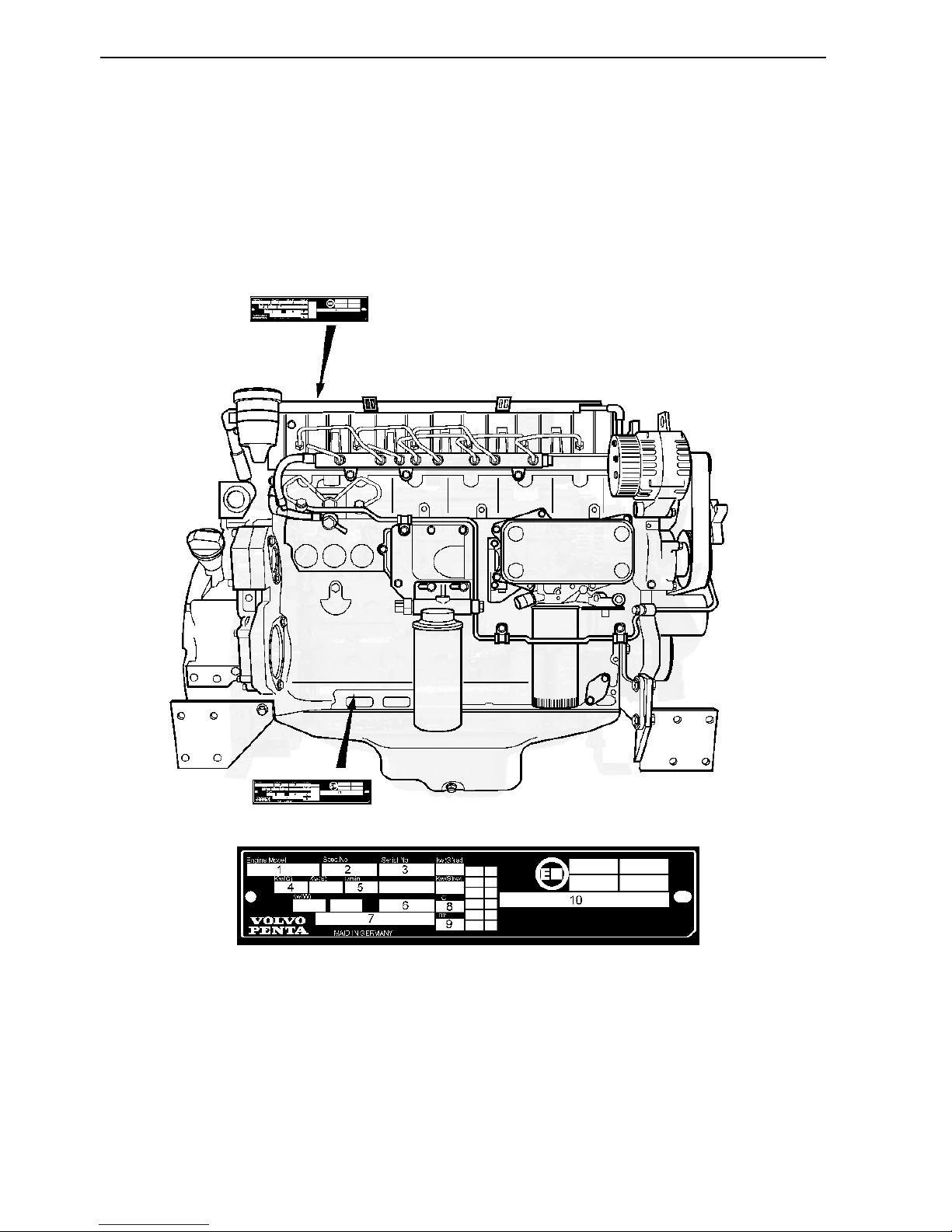

General Information Group 20

1. Engine model

2. Engine specification number

3. Engine serial number (10 digits)

4. Engine output, without fan

5. Rated engine speed

6. Engine code (linked to EPA/EU Tier III approval)

7. Rated power, standard (peak power according to

Tier III)

8. Air temperature in °C (°F), in accordance with

ISO 3046

9. Altitude above mean sea level, in accordance with

ISO 3046

10. EU Tier III approval number

Identification plates

Location of identification

plates (TAD650/660, 750/760)

Each engine is supplied with two identical identification plates, of which one is mounted on the right side

of the cylinder block and the other one is mounted up

on the valve cover.

Technical data: TD/TAD420VE, TAD620VE, TAD650VE, TAD660VE

11

Group 20

General

Type designation .................................................... TD420VE TAD420VE TAD620VE

Rotation direction, facing flywheel: .........................Counterclockwise

Number of cylinders ............................................... 4 4 6

Bore, mm (inch) .....................................................101 (3.97") 101 (3.97") 98 (3.97")

Stroke, mm (inch) .................................................. 126 (4.96") 126 (4.96") 126 (4.96")

Displacement, dm3 (inch3) ....................................... 4.04 (246.5) 4.04 (246.5) 5.7 (347.8)

Number of valves ...................................................8 8 12

Compression ratio:

EPA 1 .................................................................19:1 19:1 18.4:1

COM 2 ................................................................ 19:1 19:1 18.4:1

Firing sequence ..................................................... 1-3-4-2 1-3-4-2 1-5-3-6-2-4

Engine performance at 2500 rpm, kW (hp) ............. 75 (102)

1, 3)

103 (140)

1, 3)

155 (209)

1, 3)

Max torque, Nm (lbf.ft) ........................................... 390 (288)

3)

493 (364)

3)

700 (516)

3)

At speed, rpm ..................................................... 1500 1500 1500

Low idle, rpm ......................................................... 800 800 800

Max, full load speed, rpm .......................................2000 – 25001)2000 – 25001)2000 – 2500

1)

Weight. engine (dry) kg (lb) .................................... 380 (838)

2)

380 (838)

2)

495 (1091)

2)

1)

See identification plate for correct specification

2)

Weight according to DIN 70020-A

3)

See ”General information, Power standards”.

Technical Data

TD420VE, TAD420VE, TAD620VE, TAD650VE, TAD660VE

Technical data: TD/TAD420VE, TAD620VE, TAD650VE, TAD660VE

12

Group 20

General

Type designation .................................................... TAD650VE TAD660VE

Rotation direction, facing flywheel: .........................Counterclockwise Counterclockwise

Number of cylinders ............................................... 6 6

Bore, mm (inch) .....................................................101 (3.97") 98 (3.85")

Stroke, mm (inch) .................................................. 126 (4.96") 126 (4.96")

Displacement, dm3 (inch3) ....................................... 5.7 (347.8) 5.7 (347.8)

Number of valves ...................................................12 12

Compression ratio: ................................................. 18.4:1 18.4:1

Firing sequence ..................................................... 1-5-3-6-2-4 1-5-3-6-2-4

Engine performance at 2300 rpm, kW (hp) ............. 147 (200)

1, 3)

147 (200)

1, 3)

Max torque, Nm (lbf.ft) ........................................... 750 (553)

3)

800 (590)

3)

At speed, rpm ..................................................... 1600 1600

Low idle, rpm.......................................................... 600-800 600-800

Max, full load speed, rpm ....................................... 2400

1)

2400565

Weight. engine (dry) kg (lb) .................................... 565 (1246)

2)

565 (1246)

2)

Weight. engine (wet) kg (lb) ....................................585 (1290)

2)

585 (1290)

2)

1)

See identification plate for correct specification

2)

Weight according to DIN 70020-A

3)

See ”General information, Power standards”.

Engine block

Cylinder head

Type ...................................................................... Common cylinder head

Max surface unevenness ....................................... 0.1 mm (0.0039")

Cylinder head bolts

Thread size ............................................................ M 12

Quantity and length:

TD420VE/TAD420VE .......................................... 13 x 108 mm (13 x 4.3")

TD420VE/TAD420VE .......................................... 5 x 178 mm (5 x 7")

Quantity and length:

TAD620VE, TAD650/660VE ............................... 19 x 108 mm (19 x 4.3")

TAD620VE, TAD650/660VE ............................... 7 x 178 mm (7 x 7")

Technical data: TD/TAD420VE, TAD620VE, TAD650VE, TAD660VE

13

Group 20

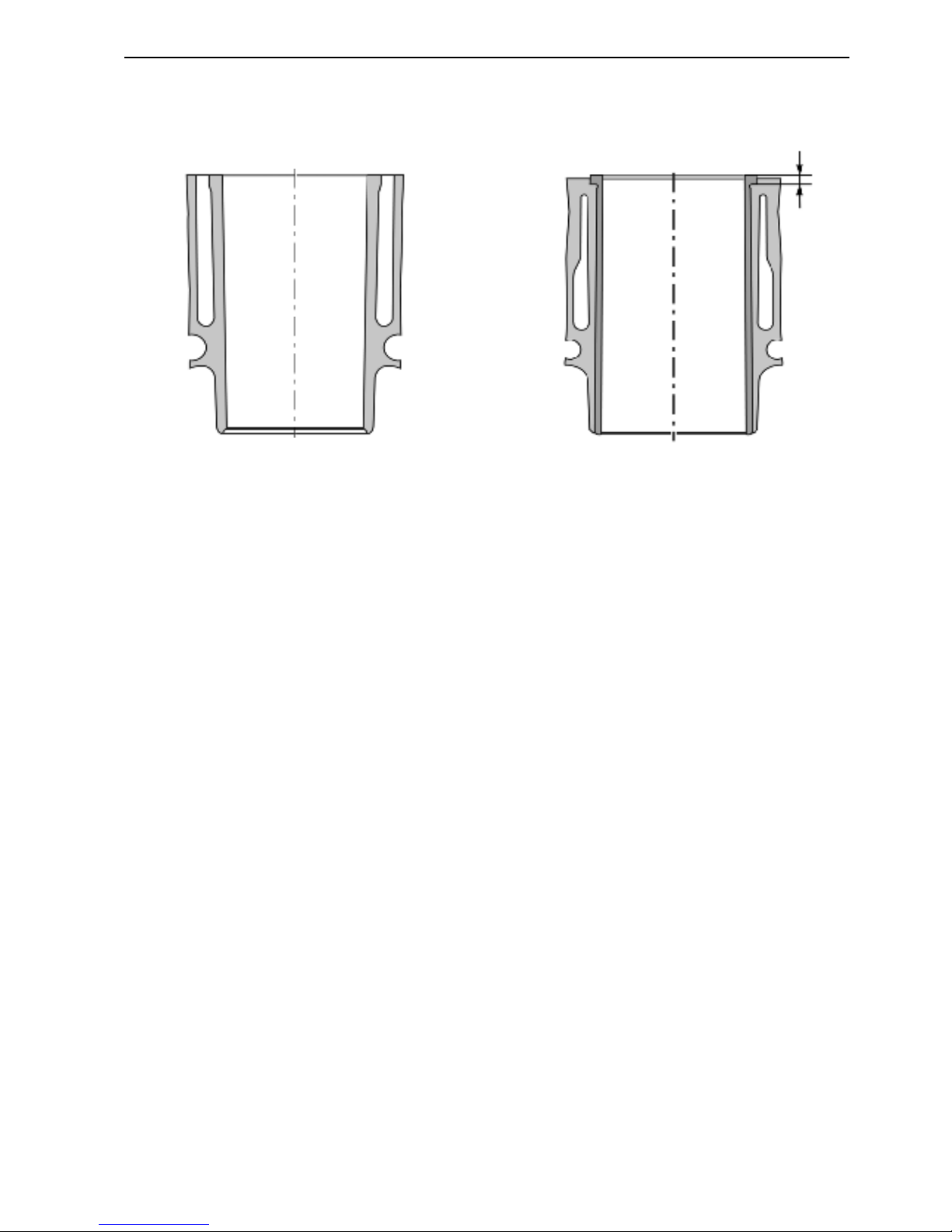

Type:

TD420VE/TAD420VE/TAD650VE ....................... Parent bore

TAD620VE/TAD660VE ....................................... Dry, replaceable

Bore:

TD420VE/TAD420VE/TAD650VE ....................... 101

+0.02

mm (3.976"

+0.00078"

)

TAD620VE/TAD660VE ....................................... 98

+0.02

mm (3.858"

+0.00078"

)

Max bore wear:

TD420VE/TAD420VE/TAD650VE ....................... 101.1 mm (3.98")

TAD620VE .......................................................... 98.1 mm (3.86")

TAD660VE .......................................................... 98.1 mm (3.86")

Sealing surface: Height, see picture (A):

TAD620VE/TAD660VE ....................................... 4.5

-0.02

mm (0.177"

-0.0008"

)

Liner collar seating depth in block:

TAD620VE/TAD660VE ....................................... 4.38

+0.03

mm (0.1724"

+0.0012"

)

Projection of liner above block surface:

TAD620VE/TAD650/TAD660VE .......................... 0.012 – 0.07 mm (0.00047"– 0.0027")

Parent bore

TD420VE, TAD420VE

TAD650VE

Replaceable, dry

TAD620,

TAD660VE

Cylinder liners

A

Technical data: TD/TAD420VE, TAD620VE, TAD650VE, TAD660VE

14

Group 20

• Set the dial gauge in the level of the crankcase surface to ”zero”.

• Position the dial gauge at the measuring points A and B on the top of the piston,

inline with the gudgeon pin.

• Measuring points between A and B on each piston is the distance X.

• Measure all pistons.

• Determine the maximum projection on each piston.

The highest piston projection number, determines the thickness of the cylinder head

gasket. The different head gaskets are identified by the hole identification on each of

the three different thickness available, see picture below.

Measuring points, distance X: ............................. Ø 90 mm (3.5")

Cylinder head gasket

Measuring piston projection

A dial gauge with a fixture (special tool: 999 8678) is needed to measure

the piston projection. The piston is in its TDC above the block surface.

Identification

1 Hole ....................................................................0.33 – 0.55 mm (0.012" – 0.021")

2 Holes .................................................................. 0.56 – 0.65 mm (0.022" – 0.025")

3 Holes .................................................................. 0.66 – 0.76 mm (0.026" – 0.03")

Technical data: TD/TAD420VE, TAD620VE, TAD650VE, TAD660VE

15

Group 20

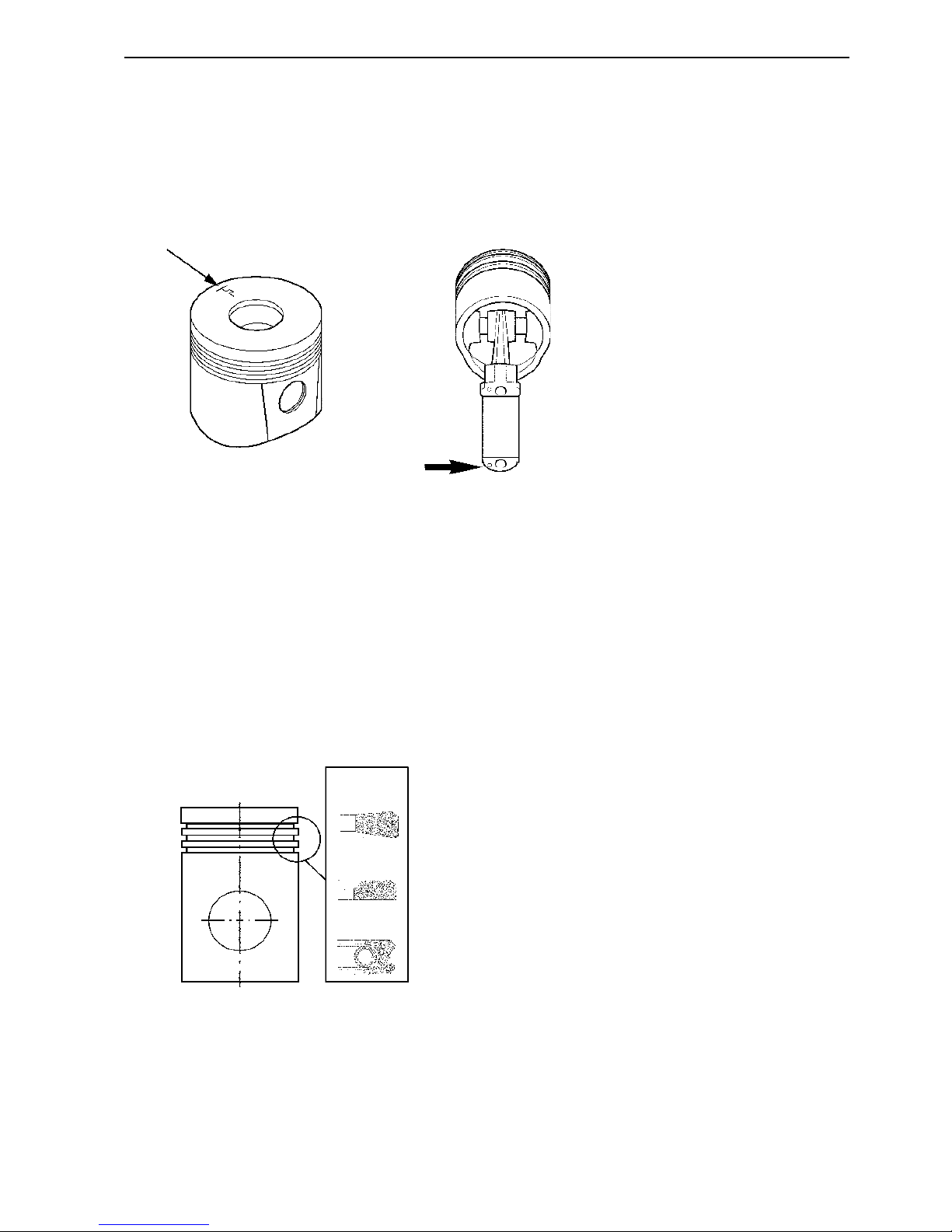

Piston rings

Compression rings

Number of rings ..................................................... 2

Piston ring clearance measured in groove, wear limit:

Upper compression ring (1) ................................. Keystone

Lower compression ring (2) ................................. 0.17 mm (0.067")

Piston ring gap measured in ring opening, wear limit:

Upper compression ring (1) ................................. 0.8 mm (0.03")

Lower compression ring (2) ................................. 2.5 mm (0.0984")

Oilscraper ring (3)

Number: ................................................................. 1

Width, including springcoil: ..................................... 3 mm (0.12")

Piston ring clearance, height: ................................. 0.1 mm (0.0039")

Piston ring gap, wear limit: ..................................... 1.15 mm (0.045”)

Pistons

Number of piston ring grooves ................................ 3

Combustion chamber:

Diameter Ø ......................................................... 61

±0.1

mm (2.402"

±0.0039

”)

Combustion chamber depth:

TD420VE/TAD420VE .......................................... 18

±0.1

mm (0.7087"

±0.0039

”)

TAD620VE, TAD650/TAD660VE ........................ 17.5

±0.1

mm (0.689"

±0.0039

”)

Gudgeon pin diameter Ø ........................................ 38

-0.006

mm (1.496"

-0.0002"

)

Piston front marking, according to picture: Flywheel symbol on the piston top faces the flywheel.

Guiding pins on the connecting rod, must face flywheel symbol on the piston.

1

2

3

Technical data: TD/TAD420VE, TAD620VE, TAD650VE, TAD660VE

16

Group 20

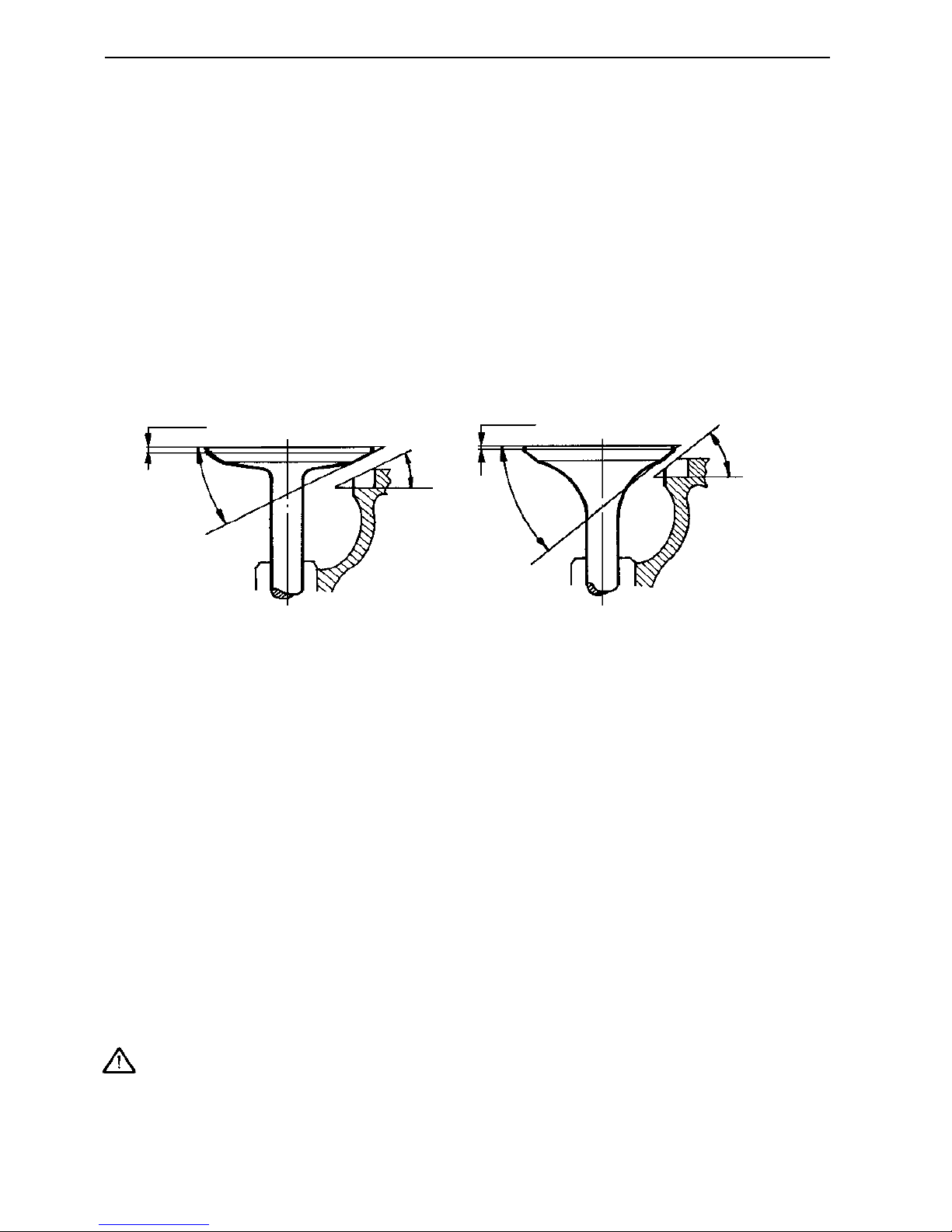

Valve disc edge:

Inlet, min ............................................................. 1.8 mm (0.071")

Exhaust, min ...................................................... 1.1 mm (0.043")

Seat angle, cylinder head:

Inlet .................................................................... 30°

Exhaust .............................................................. 45°

Valve seat width, max:

Inlet, min ............................................................. 2.7 mm (0.106")

Exhaust, min ....................................................... 2.1 mm (0.083")

Valve mechanism

Valves

Disc diameter Ø:

Inlet .................................................................... 41.7

±0.1

mm (1.642"

±0.004"

)

Exhaust .............................................................. 35.9

±0.1

mm (1.413"

±0.004"

)

Stem diameter Ø:

Inlet .................................................................... 7.98

-0.015

mm (0.3142"

-0.0006"

)

Exhaust .............................................................. 7.96

-0.015

mm (0.3134"

-0.0006"

)

Valve seat angle:

Inlet, min ............................................................. 29.5°

Exhaust, min ....................................................... 44.5°

Min 1.8 mm Min 1.1 mm

45°

30°

29.5°

44.5°

Valve clearance (not apply for TAD660VE)

Inlet .................................................................... 0.35

±0.05

mm (0.014"

±0.002"

)

Exhaust .............................................................. 0.55

±0.05

mm (0.022"

±0.002"

)

Important! Control and adjusting of valve clearance is done with an engine oil

temperature between 20 – 80°C (68 – 176°F)

Technical data: TD/TAD420VE, TAD620VE, TAD650VE, TAD660VE

17

Group 20

Diameter Ø (C), standard:

Inlet .................................................................... 42.7

-0.025

mm (1.681"

-0.001"

)

Exhaust .............................................................. 36.9

-0.025

mm (1.453"

-0.001"

)

Depth (D):

Inlet/Exhaust ...................................................... 10+1 mm (0.4"

+0.04"

)

Seat bottom radius (R):

Inlet/Exhaust ...................................................... 1

-0.3

mm (0.04"

-0.0118"

)

Measurement between valve disc and cylinder head face:

Inlet/Exhaust ...................................................... Min 1.4 mm (0.055")

Valve guides

Inner diameter Ø:

Inlet/Exhaust ...................................................... 8.008

+0.0025

mm (0.3153"

0.00098"

)

Wear limit valve stem – guide:

Inlet .................................................................... 0.1 mm (0.0039")

Exhaust .............................................................. 0.13 mm (0.0051")

Valve springs

Type: ..................................................................... Single

Length: Unloaded: .................................................. 59

±1.9

mm (2.323"

±0.075"

)

Wire diameter Ø: .................................................... 4

±0.03

mm (0.16"

±0.001"

)

Ø A

B

Ø C

R

D

Outer diameter Ø (A), standard:

Inlet .................................................................... 42.79

-0.02

mm (1.685"

-0.0008"

)

Exhaust .............................................................. 36.99

-0.02

mm (1.456"

-0.0008"

)

Height (B):

Inlet .................................................................... 6.8

±0.1

mm (0.2677"

±0.004

)

Exhaust .............................................................. 7.5

±0.1

mm (0.2953"

±0.004

)

Valve seats

Valve seat location

Technical data: TD/TAD420VE, TAD620VE, TAD650VE, TAD660VE

18

Group 20

Flywheel

Type of flywheel, standard :

TD/TAD420,620,650,660VE ................................ Clutch 10" or 11.5"

Max, permitted axial runout

Measuring radius 150 mm (5.91") ........................ 0.1 mm (0.004")

Number of teeth on flywheel ................................... 129

Camshaft

Type of camshaft: .................................................. Three different types: K, L or H

Drive ...................................................................... Gear

Number of bearings:

TD420VE/TAD420VE .......................................... 5

TAD620VE, TAD650/TAD660VE ........................ 7

Inner diameter Ø, bearing journals

Standard ............................................................. 63

+0.054

mm (2.48"

+0.0021"

)

Wear limit ........................................................... 63.08 mm (2.483")

Camshaft bearing thickness: max .......................... 1.388

+0.012

mm (0.05465"

+0.0005"

)

Axial clearance ...................................................... 0.1-0.5 mm (0.004-0.02")

Radial clearance .................................................... 0.05-0.124 mm (0.002-0.0049")

Position of bearing bush at flywheel end ................ 3

+0.2

mm (0.118"

+0.008"

)

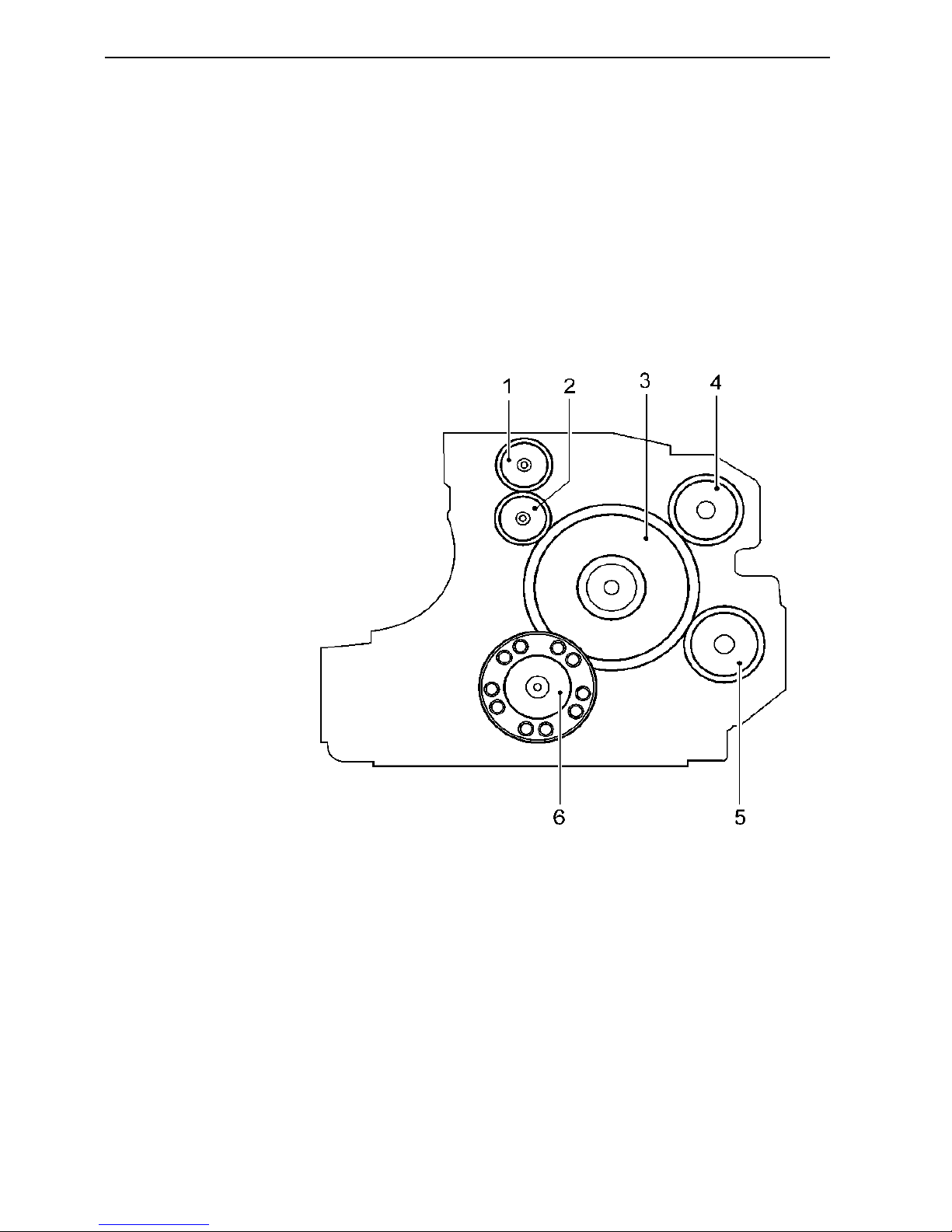

Timing gear

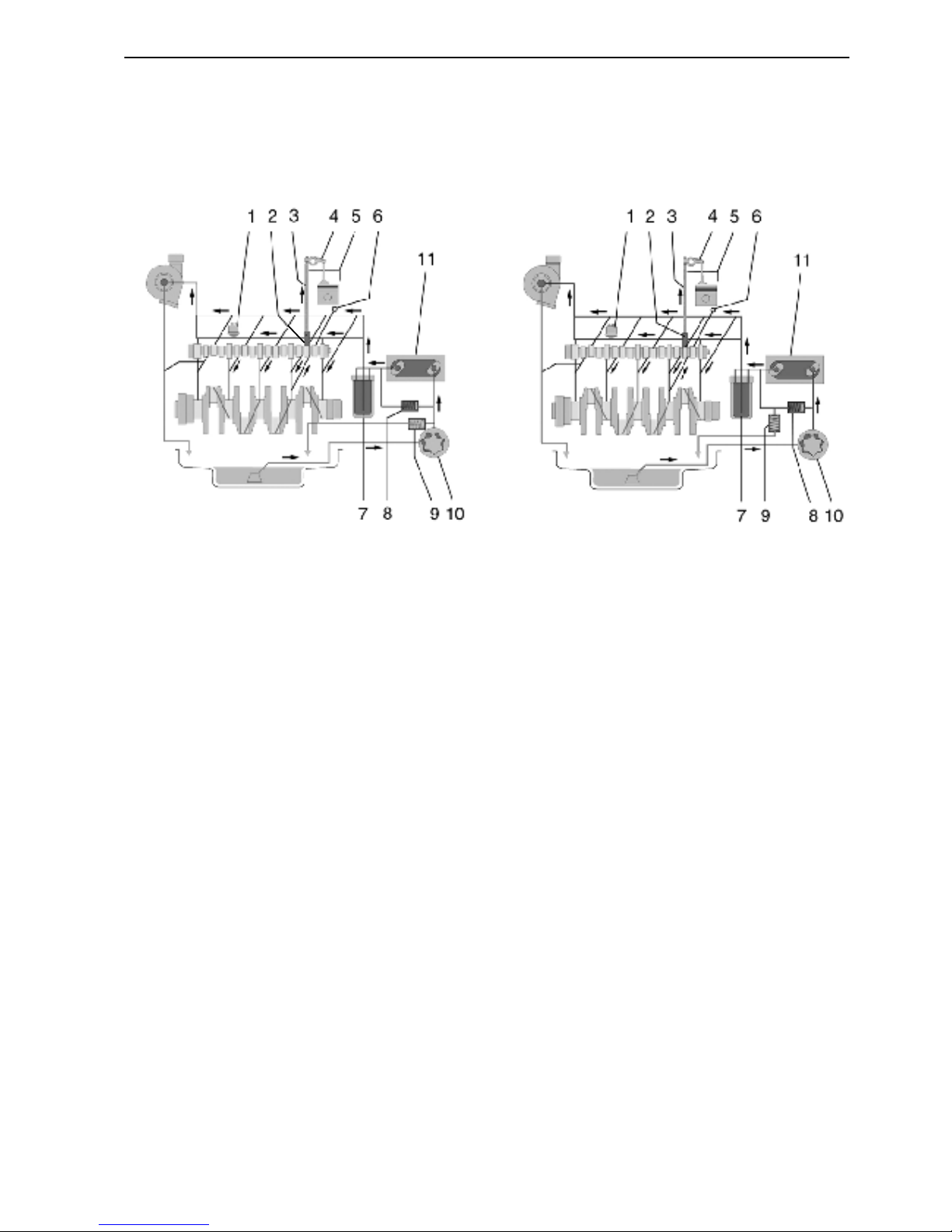

1. Governor drive (not apply for 650/660)

2. Idler gear (not apply for 650/660)

3. Camshaft gear

4. PTO gear B-C (not apply for 650/660)

5. PTO gear A (not apply for 650/660)

6. Crankshaft

Technical data: TD/TAD420VE, TAD620VE, TAD650VE, TAD660VE

19

Group 20

Crank mechanism

Crankshaft length:

TD420VE/TAD420VE .......................................... 618.8 mm (24.36")

TAD620VE, TAD650/TAD660VE ........................ 846.8 mm (33.34")

Crankshaft axial clearance1)................................... 0.1-0.3 mm (0.0039"– 0.0118")

Main bearing radial clearance1)............................... 0.03

+0.062

mm (0.0012"

+0.0024"

)

Max, permissible ovality of main

bearing and crank pins ........................................ 0.01 mm (0.0004")

Max, run-out of center bearing: .............................. 0.1 mm (0.0039"

1)

Important! The dimensions apply to oiled parts

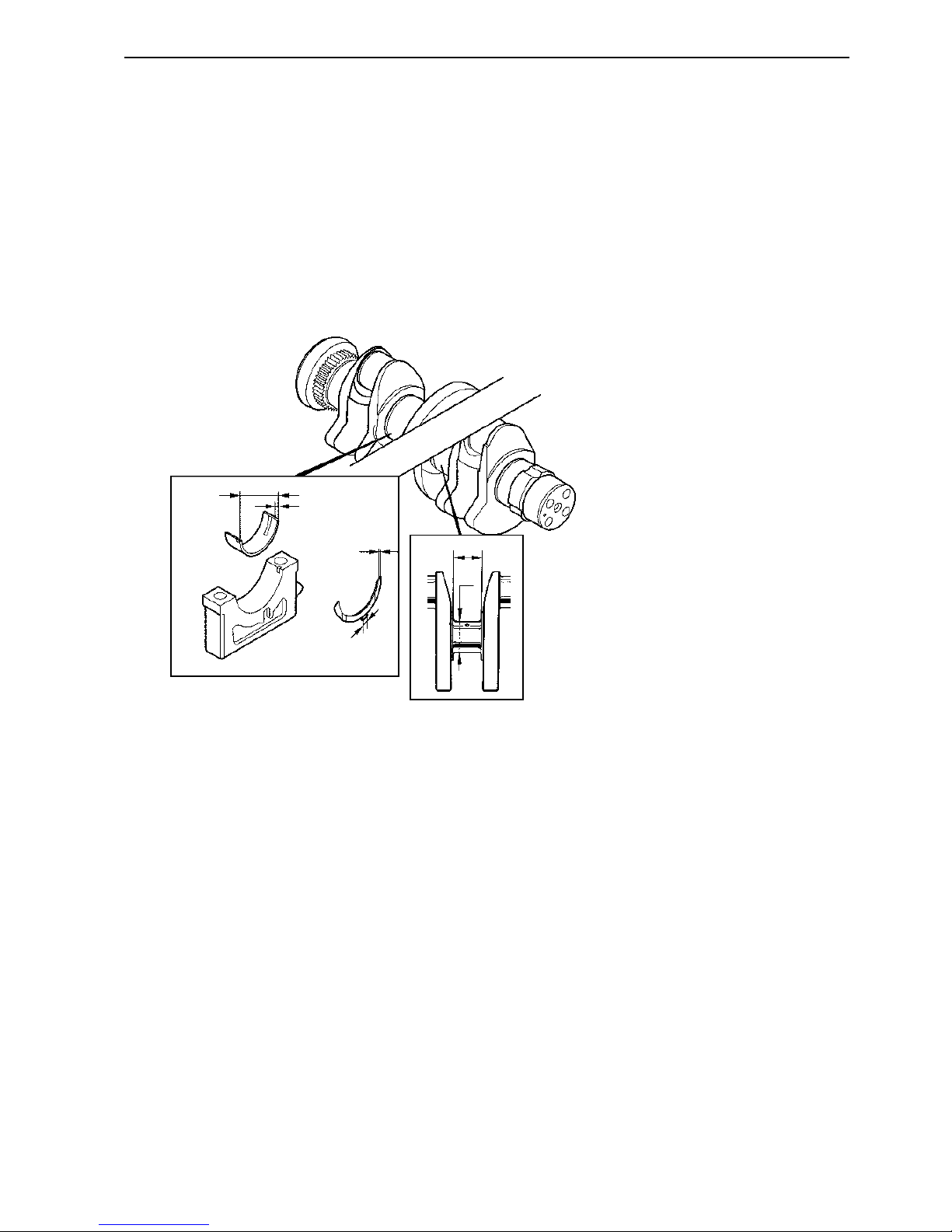

Main bearing journals

Diameter for machining (A): Standard..................... 84

-0.02

mm (2.9134"

-0.0008

)

Undersize:

0.25 mm (0.01") .................................................. 83.75

-0.02

mm (3.2972"

-0.0008

)

Main bearing journals:

Out-of-round: Max. .............................................. 0.01 mm (0.0004")

Taper: Max. ........................................................ 0.01 mm (0.0004")

Width, axial bearing journal (B): Standard ............... 32.2

+0.04

mm (1.1268"

+0.0016"

)

Oversize:

0.4 mm (0.0157") ................................................ 32.6

+0.04

(1.283"

+0.0016"

)

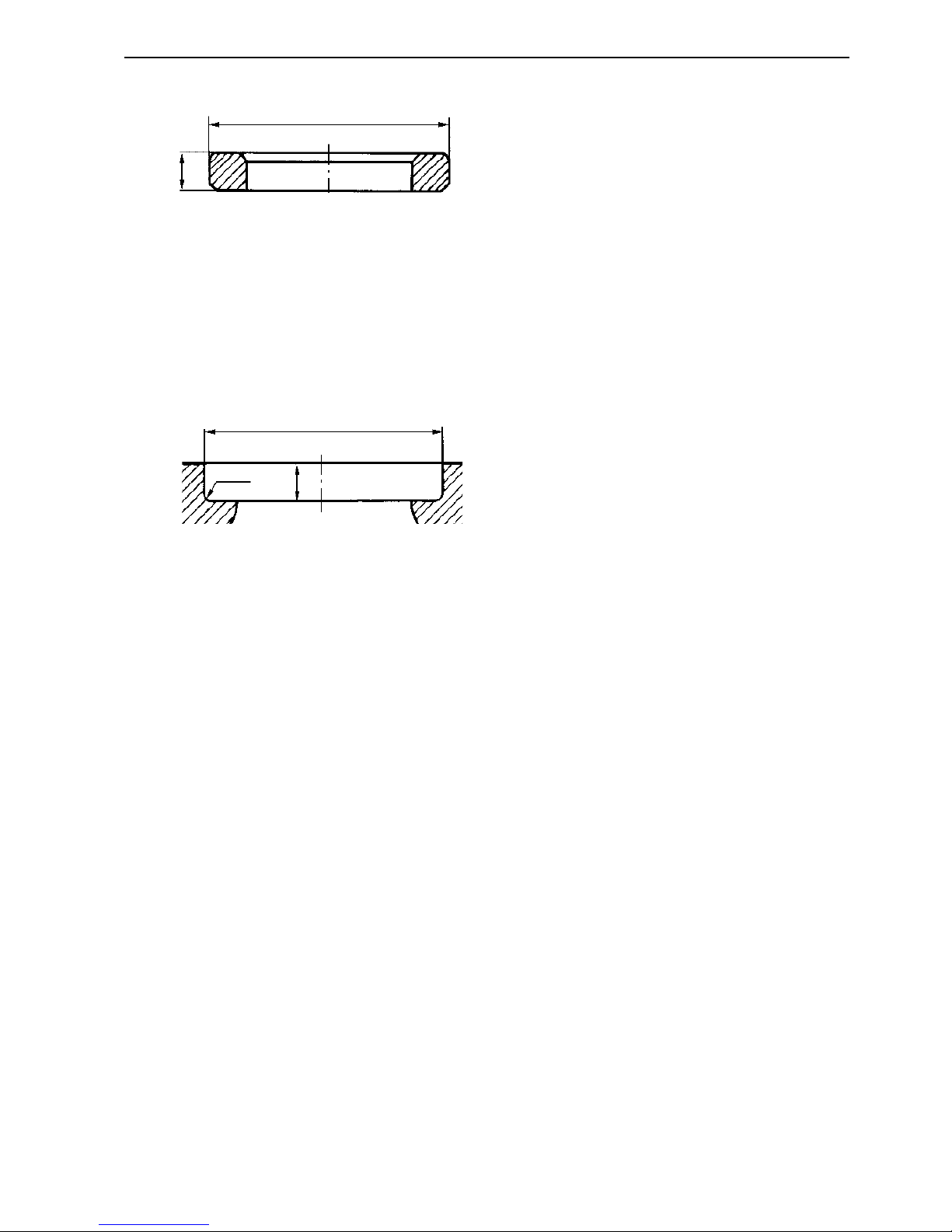

Thrust washers (axial bearing)

Width (C): Standard ................................................ 2

+0.1

mm (0.079"

+0.004"

)

Oversize:

0.2 mm (0.0079") ................................................ 2.2

+0.1

mm (0.087"

+0.004"

)

Width (D):............................................................... 14 mm (0.55")

Main bearing shells

Type: ..................................................................... Replaceable

Inner diameter Ø (E): ............................................. 84.03

+0.042

mm (3.308"

+0.0017"

)

Thickness (F): Standard ......................................... 2.475

+0.01

mm (2.903"-2.903")

Oversize:

0.25 mm (0.01") .................................................. 2.6

+0.01

mm (0.1024"

+0.0004"

)

B

C

D

E

F

A

Technical data: TD/TAD420VE, TAD620VE, TAD650VE, TAD660VE

20

Group 20

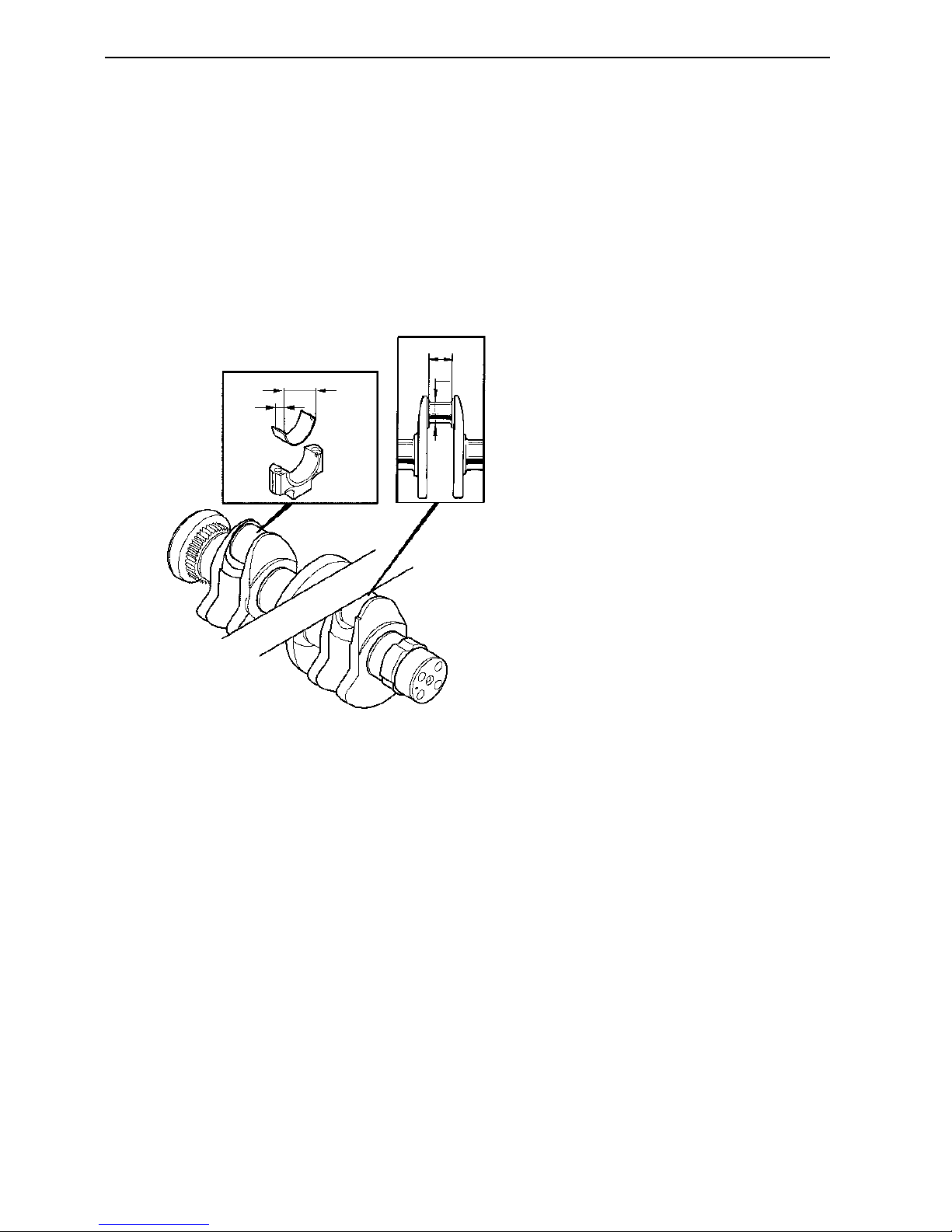

Connecting rod bearing journals

Diameter Ø for machining (G):

Standard ................................................................ 62.994

-0.02

mm (2.48"

-0.0008”

)

Undersize:

0.25 mm (0.01") .................................................. 62.744

-0.02

mm (2.4714"

-0.0008”

)

Width, axial bearing journal (H): ............................. 35.7

±0.02

mm (1.4"

±0.0008"

)

Connecting rod-bearing journals:

Out-of-round: Max. .............................................. 0.01 mm (0.0004")

Taper: Max ......................................................... 0.01 mm (0.0004")

Connecting rod bearing shells

Innerdiameter Ø, bearing (J): .................................. 63.026

+0.039

mm (2.442"

+0.00154”

)

Oversize:

0.25 mm (0.01") .................................................. 62.724

+0.02

mm (2.4716"

+0.00079”

)

Thickness (K): Standard ........................................ 1.777

+0.01

mm (0.06996

+0.0004”

)

Inside bore .......................................................... 66.6

+0.02

mm (2.622"

0.0008"

)

J

K

H

G

Technical data: TD/TAD420VE, TAD620VE, TAD650VE, TAD660VE

21

Group 20

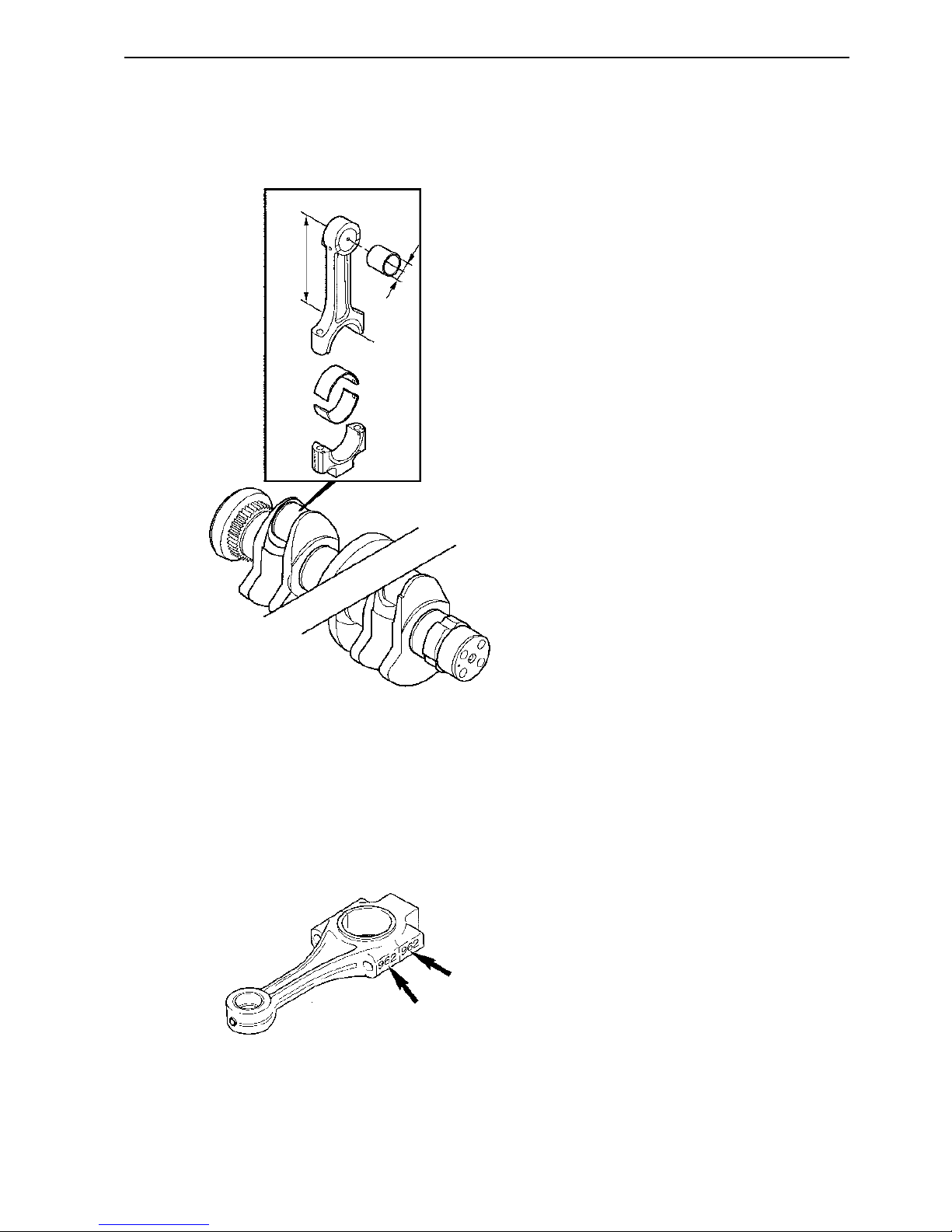

Connecting rods

Length (L): Center – Center .................................... 192

±0.02

mm (7.559"

-0.0008”

)

Connecting rod bushing bore (M): ........................... 38.025

+0.01

mm (1.497"

+0.0004”

)

Wear limit ............................................................ 0.08 mm (0.0031")

Axial clearance, connecting rod – crankshaft1)....... 0.2-0.3 mm (0.00787"-0.0118")

Connecting rod bearing: radial clearance1).............. 0.03-0.09 mm (0.00118"-0.00354")

Parallelism: Tolerans

Over a length of 100 mm..................................... 0.05 mm (0.002")

Squareness: Tolerans

Over a length of 100 mm .................................... 0.05 mm (0.002")

1)

Important! The dimensions apply to oiled parts.

L

M

Connecting rod marking:

Connecting rod and cap number marking must be on one side and identical.

Technical data: TD/TAD420VE, TAD620VE, TAD650VE, TAD660VE

22

Group 20

Viscosity

The viscosity should be selected from the adjacent

table.

NOTE! the temperatures refer to constant outside air

temperature. The tabell above refers to synthetic or

synthetic-based oil.

Fuel sulfur content in percent by weight

Lubricating system

Up to 0.5 % 0.5 – 1 % More than 1 %

1)

Oil change interval: In operation whichever reached first

Oil grade

2)

VDS-3, VDS-2

ACEA: E7, E5, E3 500 hours or 12 months 250 hours or 12 months 125 hours or 12 months

API: CI-4, CH-4, CG-4

1)

If the sulfur content is > 1.0% by weight, use oil with TBN > 15

2)

For markets outside Europe, API: CG-4 and CH-4 can be used instead of ACEA: E3.

NOTE! Mineral based oil, either fully or semi-synthetic, can be used on condition that it complies with the quality

requirements above.

NOTE! For 6 and 7-liter engines equipped with low profile type oil pans, the oil change interval must be halved.

VDS = Volvo Drain Specification

ACEA = Association des Constructeurs Européenne d’Automobiles

API = American Petroleum Institute

Global DHD = Global Diesel Heavy Duty

TBN = Total Base Number

Technical data: TD/TAD420VE, TAD620VE, TAD650VE, TAD660VE

23

Group 20

Engine oil quantity

With oil filter:

TD420VE/TAD420VE .......................................... 10 liter (2.64 US gal)

TAD620VE, TAD650/TAD660VE ........................ 16 liter (4.22 US gal)

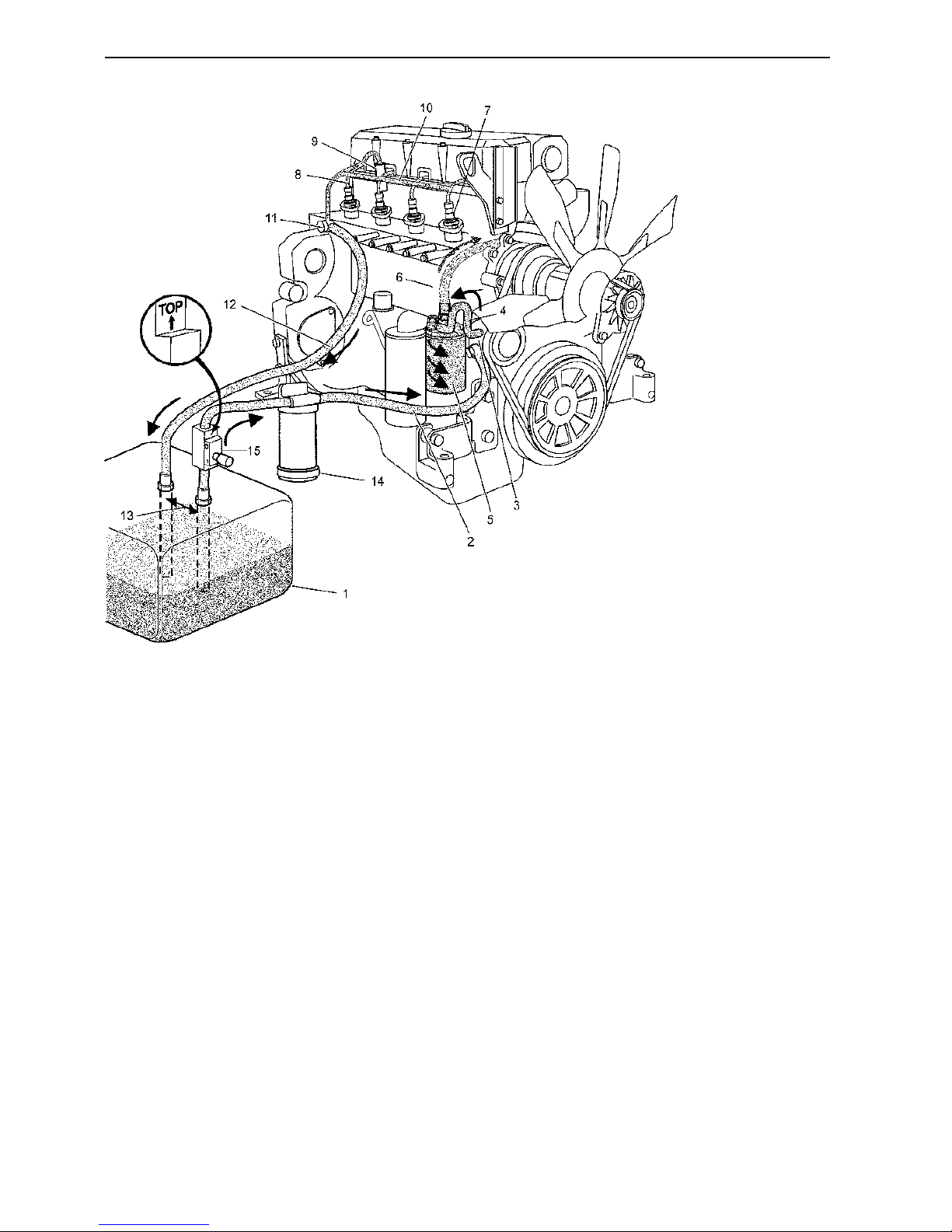

TD420VE/TAD420VE TAD620VE, TAD650VE, TAD660VE

1. Oil pressure sensor

Oil pressure, at operation temperature, min 120°C (248°F)

At rated speed:

TD420VE/TAD420VE .......................................... 400 kPa (58 psi)

TAD620VE, TAD650/TAD660VE ........................ 370 kPa (53.7 psi)

At idle speed (800 rpm), min .................................. 80 kPa (11.6 psi)

Shut down switch, at pressure lower than: ............. 50 kPa (7.2 psi)

2. Tappet with pulse lubrication

3. Pushrod, oil supply for rocker arm lubrication

4. Rocker arm

5. Return line to oil sump

6. Piston cooling .................................................. 2-hole nozzles for each cylinder

7. Oil filter, full-flow

Filtering size ....................................................... 0.012 mm (0.0005")

By-pass valve oil filter

Opening pressure ................................................250

±50

kPa (35±7 psi)

8.By-pass valve oil cooler:

Opening pressure ................................................210

±30

kPa (30.5±4 psi)

9. Safety valve, opening pressure:

TD420VE/TAD420VE .......................................... 600

±75

kPa (87

±10.7

psi)

TD620VE, TAD650/TAD660VE ........................... 400

±40

kPa (58±2 psi)

10. Lube oil pump

Type ...................................................................... Rotary pump driven by the crankshaft

Rotary pump width:

TD420VE/TAD420VE .......................................... 12.3 mm (0.48")

TD620VE, TAD650/TAD660VE ........................... 16.5 mm (0.65")

Oil flow (2500 rpm)

TD420VE/TAD420VE .......................................... 65 l/min (17 US gal/hour)

TD620VE, TAD650/TAD660VE ........................... 90 l/min (24 US gal/hour)

11. Oil cooler

Normal oil temperature: .......................................... 80°C (176°F)

Max oil temperature: ..............................................125°C (257°F)

Technical data: TD/TAD420VE, TAD620VE, TAD650VE, TAD660VE

24

Group 20

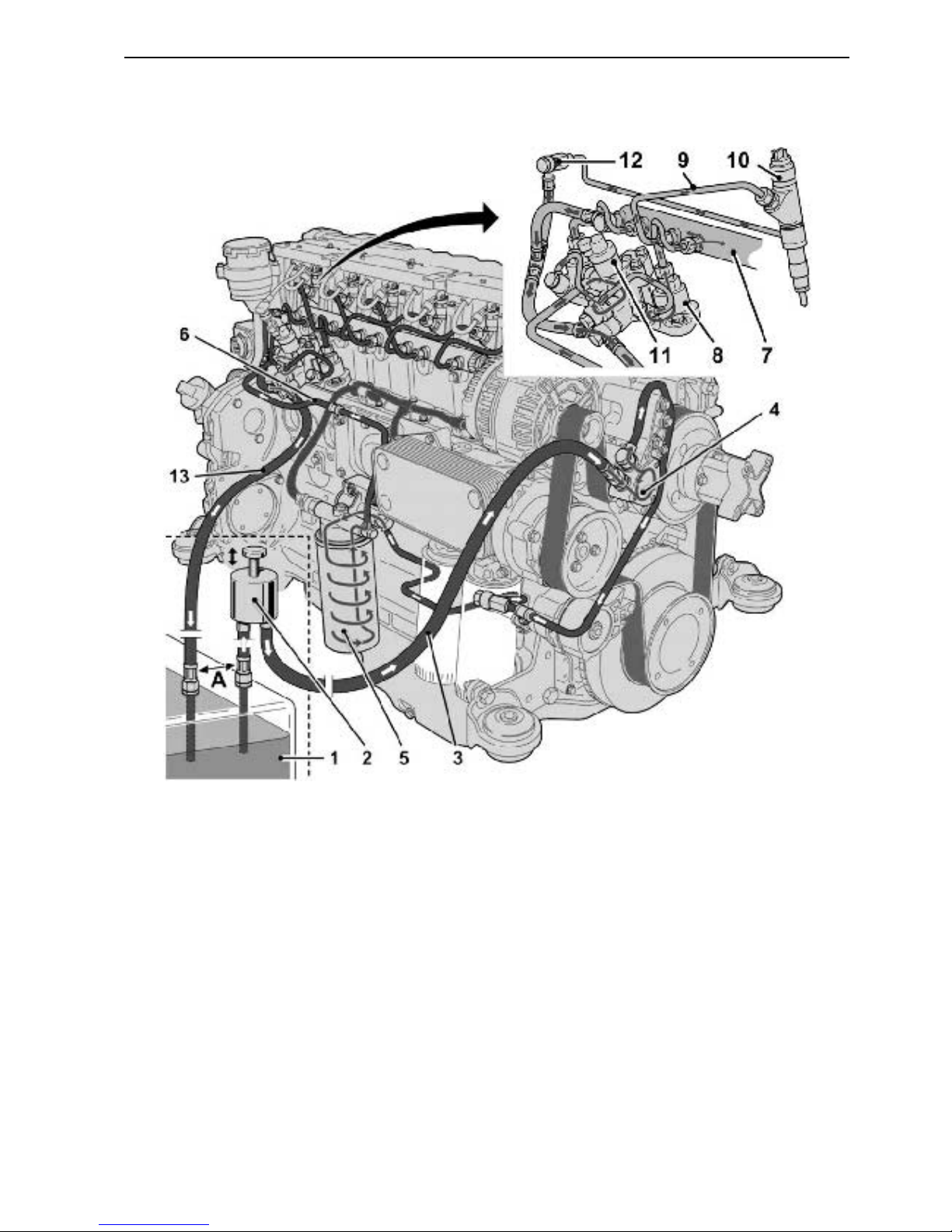

1. Fuel tank.

Max height above fuel pump. 2 meter (6.5 ft)

Max suction height to fuel pump. 1.5 meter (4.9 ft)

2. Fuel line (to pump).

Inside diameter. min 12 mm (0.47")

1)

3. Fuel pump

4. Line to fuel filter.

Inside diameter. min 12 mm (0.47")

1)

5. Fuel filter

6. Fuel line (to fuel duct).

7. Injection pumps, 420/520 (4) 620/720/721 (6)

8. Delivery pipe to injector.

9. Injector

10. Fuel return line

11. Overflow valve

2)

12. Return fuel line to fuel tank.

Inside diameter, min 10 mm (0.39")

1)

13. Fuel pipes, minimum distance 300 mm (11.8")

14. Pre-filter for water separating

15. Hand pump (accessory)

1)

Depending on length of hose.

2)

Used for bleeding.

Fuel system (420, 620)

Technical data: TD/TAD420VE, TAD620VE, TAD650VE, TAD660VE

25

Group 20

1. Fuel tank

2. Hand pump (accessory)

3. Fuel line (to pump)

4. Fuel pump

5. Fuel filter

6. Pipe to highpressure

7. Rail

8. Highpressure pump

9. Fuelpipe, to injector

10. Injector

11. M-prop

12. Pressurevalve

13. Return fuel line, to fuel tank, A = Fuel pipes,

minimum distance 300 mm (11.8")

Fuel system (650, 660)

Technical data: TD/TAD420VE, TAD620VE, TAD650VE, TAD660VE

26

Group 20

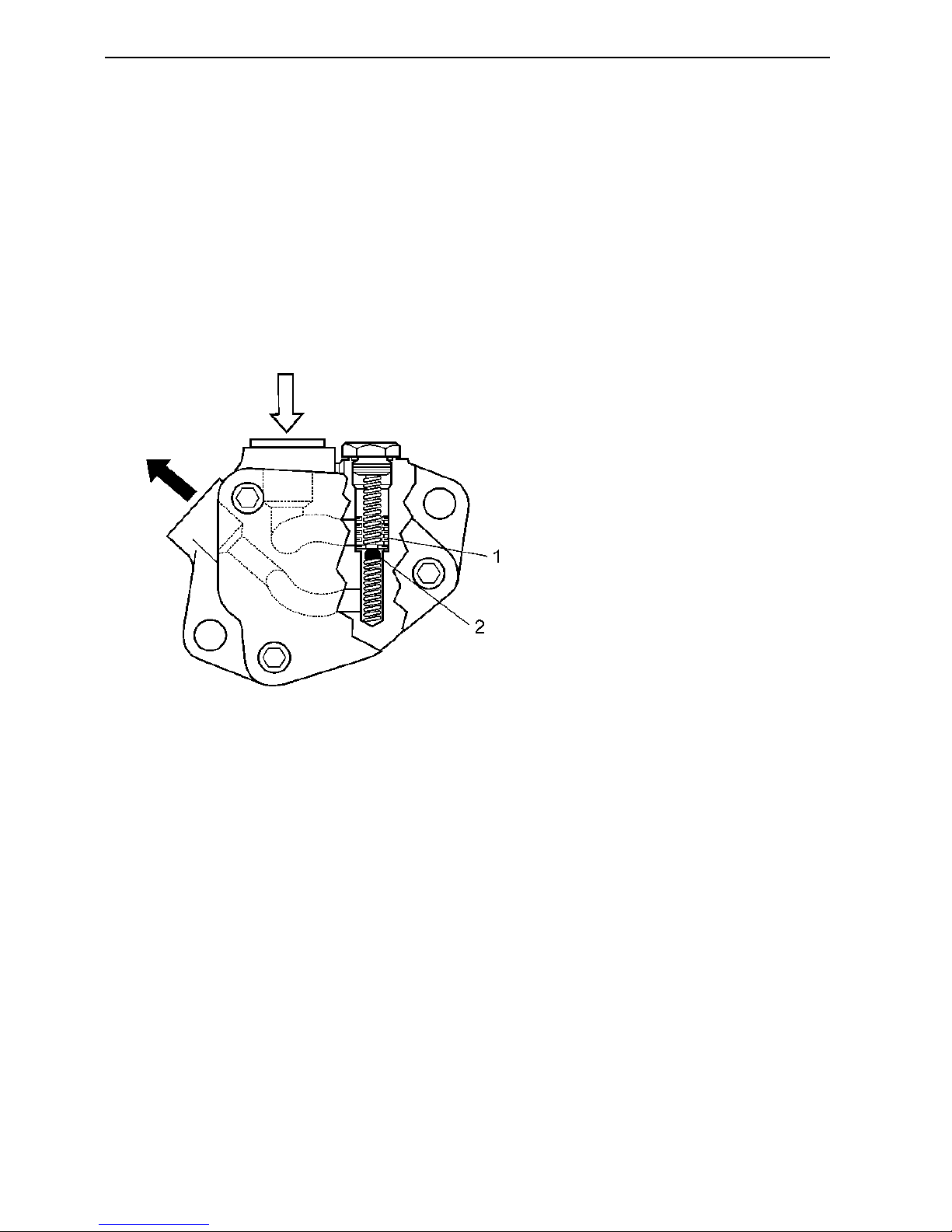

Fuel feed pump

Fuel system figures are corresponding to the picture above.

1. Overpressure relief valve:

Opening pressure ................................................ 0.6

±0.05

MPa (87±7 psi)

1)

2. Bypass valve:

Opening pressure ................................................ 50±5 kPa (7.2

±0.7

psi)

Fuel flow:

Min fuel flow at 1500 rpm. ...................................... 600 l/hour (158.5 gal/hour)

Firing sequence

TD420VE/TAD420VE .......................................... 1-3-4-2

TAD620VE/TAD650VE/TAD660VE ..................... 1-5-3-6-2-4

Feed pressure ........................................................ 0.5 MPa (72.5 psi)

Feed pressure after fuel filter

At 1500 rpm: Min ................................................ 0.28 MPa (40.6 psi)

In

Out

Fuel specification

The fuel must be approved according to national and international standards for commercial fuels for example:

EN 590 (With environmental and sub-zero temperature specifications according to national requirements)

ASTM D 975 No 1-D and 2-D

JIS KK 2204

Sulfur content: According to current legislation in each country.

NOTE! Fuels with extremely low sulfur contents (ex City diesel in Sweden and Finland) can cause a drop in power

output of 5% and an increase in fuel consumption of 2–3%.

Loading...

Loading...