Volvo Penta TAD1242GE, TAD1240GE, TAD1241VE, TAD1241GE, TAD1242VE Technical Description

...Page 1

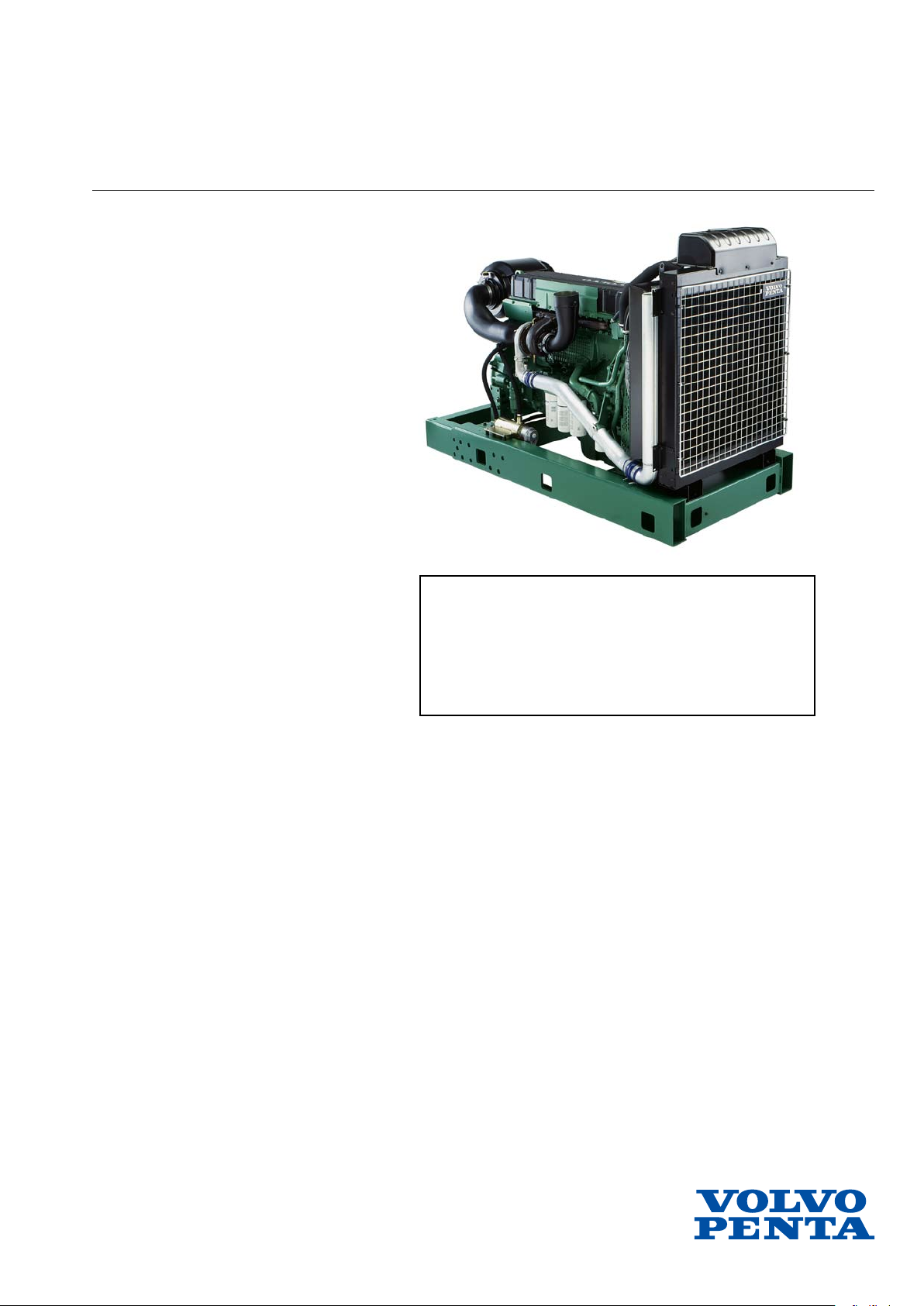

VOLVO PENTA GENSET ENGINE

TAD1242GE

1500 rpm, 387 kW (526 hp) – 1800 rpm, 430 kW (585 hp)

The TAD1242GE is a powerful, reliable

and economical Generating Set Diesel

Engine built on the dependable in-line six

design.

Durability & low noise

Designed for easiest, fastest and most

economical installation. Well-balanced to

produce smooth and vibration-free operation with low noise level.

To maintain a controlled working temperature in cylinders and combustion

chambers, the engine is equipped with

piston cooling. The engine is also fitted

with replaceable cylinder liners and valve

seats/guides to ensure maximum durability and service life of the engine.

Low exhaust emission

The state of the art, high-tech injection

and charging system with low internal

losses contributes to excellent combustion and low fuel consumption.

The TAD1242GE complies with EU

Stage 2 and TA-Luft -50% exhaust emission regulations.

Easy service & maintenance

Easily accessible service and maintenance points contribute to the ease of

service of the engine.

Technical description:

Engine and block

– Optimized cast iron cylinder block with opti-

mum distribution of forces without the block

being unnessarily heavy.

– Wet, replaceable cylinder liners

– Piston cooling for low piston temperature

and reduced ring temperature

– Tapered connecting rods for reduce risk of

piston cracking

– Crankshaft induction hardened bearing

surfaces and fillets with seven bearings for

moderate load on main and high-end bear-

ings

– Case hardened and Nitrocarburized trans-

mission gears for heavy duty operation

– Keystone top compression rings for long

service life

– Viscous type crankshaft vibration dampers to

withstand single bearing alternator torsional

vibrations

– Replaceable valve guides and valve seats

– Over head camshaft and four valves per cyl-

inder

Lubrication system

– Full flow oil cooler

– Full flow disposable spin-on oil filter, for ex-

tra high filtration

– The lubricating oil level can be measured

during operation

– Gear type lubricating oil pump, gear driven

by the transmission

Fuel system

– Non-return fuel valve

– Electronic Unit Injectors

– Fuel prefilter with water separator and water-

in-fuel indicator / alarm

– Gear driven low-pressure fuel pump

– Fine fuel filter with manual feed pump and

fuel pressure switch

– Fuel shut-off valve, electrically operated

Cooling system

– Efficient cooling with accurate coolant con-

trol through a water distribution duct in the

cylinder block. Reliable sleeve thermostat

with minimum pressure drop

Features

– Maintained performance, air temp 40°C

– Cooling system (55°C)

– Fully electronic with Volvo Penta EDC III

– Dual frequency switch (between 1500 rpm and 1800 rpm)

– High power density

– Emission compliant

– Low noise levels

– Gen Pac configuration

– Gear driven, maintenance-free coolant pump

with high degree of efficiency

– Coolant filter as standard

Turbo charger

– Efficient and reliable turbo charger

– Extra oil filter for the turbo charger

Electrical system

– Electronical Diesel Control III (EDCIII), an

electronically controlled processing system

which optimizes engine performance. It also

includes advanced facilities for diagnostics

and fault tracing

– Three different ways for the customer to

connect his controls and instrument to the

engine. CAN SAE J1939 interface, CIU

(Control interface unit) and Stand alone

connections.

– Sensors for oil pressure, oil temp, boost

pressure, boost temp, coolant temp, fuel

temp, water in fuel, fuel pressure and two

speed sensors.

Page 2

TAD1242GE

Technical Data

General

Engine designation ........................................................................ TAD1242GE

No. of cylinders and configuration ........................................................in-line 6

Method of operation ................................................................................4-stroke

Bore, mm (in.) ...................................................................................... 131 (5.16)

Stroke, mm (in.) ...................................................................................150 (5.91)

Displacement, l (in3) ...................................................................12.13 (740.2)

Compression ratio ......................................................................................17.5:1

Dry weight, kg (lb) ......................................................................... 1380 (3036)

With Gen Pac, kg (lb) .................................................................. 1645 (3627)

Wet weight, kg (lb) .........................................................................1455 (3201)

With Gen Pac, kg (lb) .................................................................. 1720 (3792)

Performance

kW (hp) 1500 rpm 1800 rpm

Prime Power 352 (479) 391 (532)

Max Standby Power 387 (526) 430 (585)

Lubrication system

Oil consumption, liter/h (US gal/h) 1500 rpm 1800 rpm

Prime Power 0.12 (0.032) 0.14 (0.037)

Max Standby Power 0.14 (0.037) 0.15 (0.040)

Oil system capacity incl filters, liter ...............................................................35

Oil change intervals at specification

VDS-2, h ........................................................................................................... 600

VDS, ACEA E3, h ............................................................................................400

ACEA E1, E2, API CD, CF, CF-4, CG-4, h ...............................................200

Fuel system

Specific fuel consumption at

Prime Power, g/kWh (lb/hph) 1500 rpm 1800 rpm

25 % 216 (0.350) 231 (0.374)

50 % 199 (0.323) 208 (0.330)

75 % 195 (0.316) 200 (0.324)

100 % 198 (0.321) 202 (0.327)

Max Standby Power, g/kWh (lb/hph) 1500 rpm 1800 rpm

25 % 211 (0.347) 225 (0.365)

50 % 197 (0.319) 203 (0.329)

75 % 195 (0.316) 200 (0.324)

100 % 199 (0.323) 203 (0.329)

Intake and exhaust system

Air consumption at 27°C, m³/min (cfm) 1500 rpm 1800 rpm

Prime Power 23.5 (830) 28.0 (989)

Max Standby Power 25.0 (883) 29.0 (1024)

Max allowable air intake restriction, kPa (In wc) ............................... 5 (20.1)

Heat rejection to exhaust,

kW (BTU/min) 1500 rpm 1800 rpm

Prime Power 250 (14217) 272(15468)

Max Standby Power 276 (15696) 306 (17402)

Exhaust gas temperature after turbine,

°C (°F) 1500 rpm 1800 rpm

Prime Power 490 (914) 465 (869)

Max Standby Power 505 (941) 490 (914)

Max allowable back-pressure in exhaust line, kPa (In wc) ........... 10 (40.2)

Exhaust gas flow, m³/min (cfm) 1500 rpm 1800 rpm

Prime power 58 (2048) 66 (2331)

Max Standby Power 63 (2225) 72 (2543)

Cooling system

Heat rejection radiation from engine,

kW (BTU/min) 1500 rpm 1800 rpm

Prime Power 17 (967) 18 (1024)

Max Standby Power 18 (1024) 20 (1137)

Heat rejection to coolant kW (BTU/min)

Prime Power 123 (6995) 139 (7905)

Max Standby Power 125 (7109) 143 (8132)

Fan power consumption, kW (hp) 9 (12) 15 (20)

Note! Not all models, standard equipment and accessories are available in all countries.

All specifications are subject to change without notice.

The engine illustrated may not be entirely identical to production standard engines.

Power Standards

The engine performance corresponds to ISO 3046, BS

5514 and DIN 6271. The technical data applies to an engine

without cooling fan and operating on a fuel with calorific value

of 42.7 MJ /kg (18360 BTU/lb) and a density of 0.84 kg/liter

(7.01 lb/US gal), also where this involves a deviation from

the standards. Power output guaranteed within 0 to +2% att

rated ambient conditions at delivery. Ratings are based on

ISO 8528. Engine speed governing in accordance with ISO

3046/IV, class A1 and ISO 8528-5 class G3

Exhaust emissions

The engine complies with EU stage 2 emission legislation

according to the Non Road Directive EU 97/68/EEC. The

engine also complies with TA-luft -50% exhaust emission

regulations.

Rating Guidelines

PRIME POWER rating corresponds to ISO Standard Power for

continuous operation. It is applicable for supplying electrical power

at variable load for an unlimited number of hours instead of commercially purchased power. A10 % overload capability for govering

purpose is available for this rating.

MAXIMUM STANDBY POWER rating corresponds to ISO Standard Fuel Stop Power. It is applicable for supplying standby electrical power at variable load in areas with well established electrical

networks in the event of normal utility power failure. No overload

capability is available for this rating.

1 hp = 1 kW x 1.36

Information

For more technical data and information, please look in the Generating Set Engines Sales Guide.

Standard equipment Engine Gen Pac

Engine

Automatic belt tensioner

• •

Lift eyelets • •

Flywheel

Flywheel housing with conn. acc. to SAE 1

• •

Flywheel for 14” flex. plate and flexible coupling • •

Vibration dampers • •

Engine suspension

Fixed front suspension

• •

Lubrication system

Oil dipstick

• •

Full-flow oil filter of spin-on type • •

By-pass oil filter of spin-on type • •

Oil cooler, side mounted • •

Low noise oil sump • •

Fuel system

Fuel filters of disposable type

• •

Electronic unit injectors • •

Pre-filter with water separator • •

Intake and exhaust system

Air filter with replaceable paper insert

• •

Air restriction indicator • •

Air cooled exhaust manifold • •

Connecting flange for exhaust pipe • •

Exhaust flange with v-clamp • •

Turbo charger, low right side • •

Crankcase ventilation • •

Cooling system

Radiator incl intercooler

•¹) •

Gear driven coolant pump • •

Fan hub • •

Thrust fan •¹) •

Fan guard − •

Belt guard − •

Control system

Engine Management System (EMS) with

• •

CAN-bus interface SAE J1939 and stand alone

interface

Alternator

Alternator 60A / 24 V

• •

Starting system

Starter motor, 6.0kW, 24 V

• •

Connection facility for extra starter motor • •

Instruments and senders

Temp.- and oil pressure for automatic

• •

stop/alarm 103°C

Other equipment

Expandable base frame

− •

Engine Packing

Plastic warpping

1)

must be ordered, se order specification - optional equipment

− optional equipment or not applicable

• included in standard specification

• •

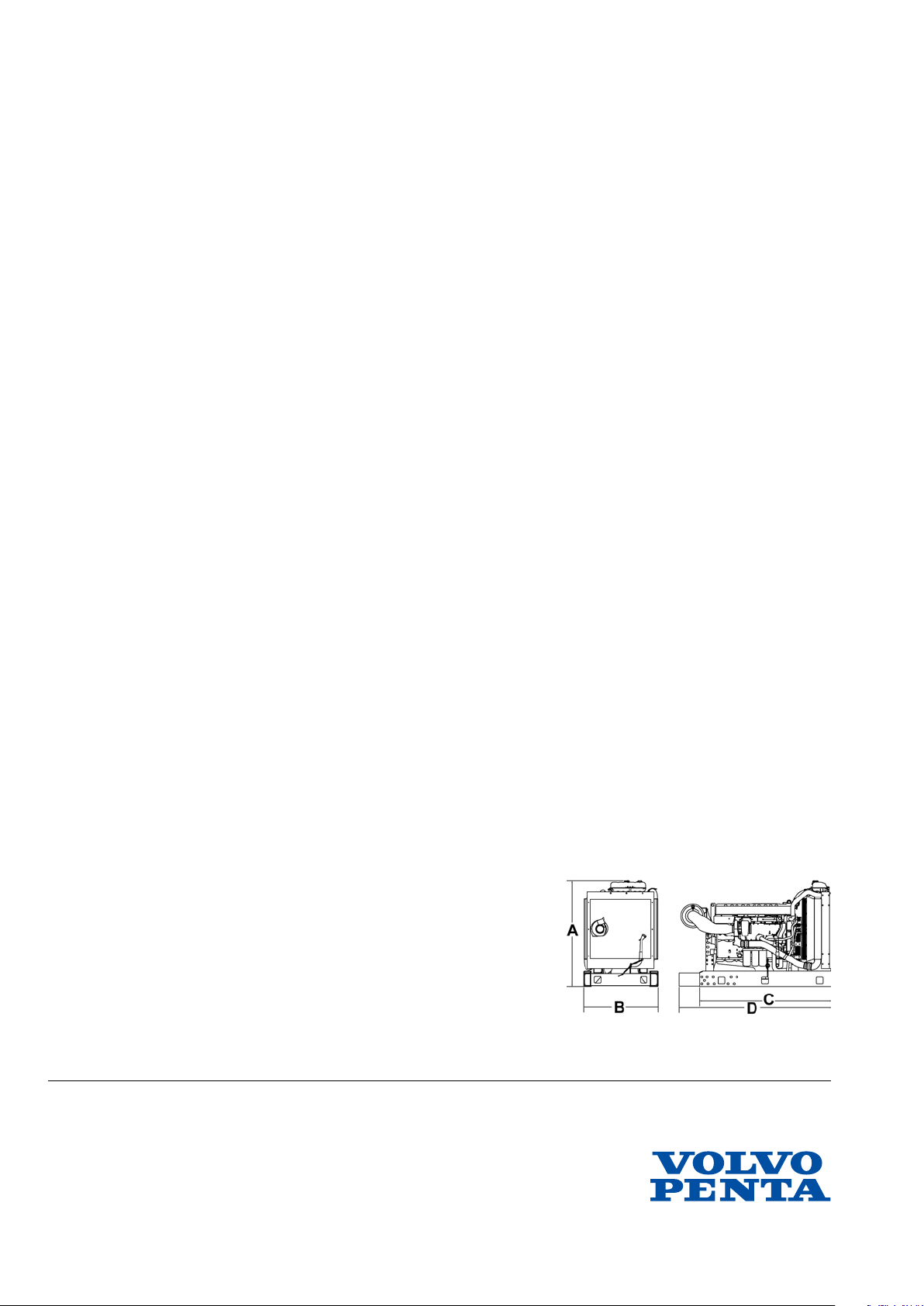

Dimensions TAD1242GE

Not for installation

A* = 1587 mm / 62.5 in

B* = 1120 mm / 44.1 in

C* = 1976 mm / 77.8 in

D = 2296 mm / 90.5 in (During transport)

D = Max 3311 mm / 130.5 in

*Incl. radiator and intercooler

http://www.brizmotors.ru/equipment/ctm/

v400/

English 02 -2009. © 2009 AB Volvo Penta

Page 3

Group 23 EDC III Design and operation

Design and operation

System description EDC III

EDC III, ”Electronic Diesel Control”, is an electronic system with CAN communication for diesel engine management. The system is developed by Volvo Penta and covers fuel management, diagnostic function, etc. The system consists of a control module, six unit injectors, a number of sensors that provide information to the control

module, and a data link connector for diagnostics and functionality checks. The EDC III system also has a ”stand

alone” interface that can be linked directly to the engine control module on the engine. The engine can be linked to

a ”CAN” interface and a ”Control Interface Unit” (CIU), which is an interface to the operator area.

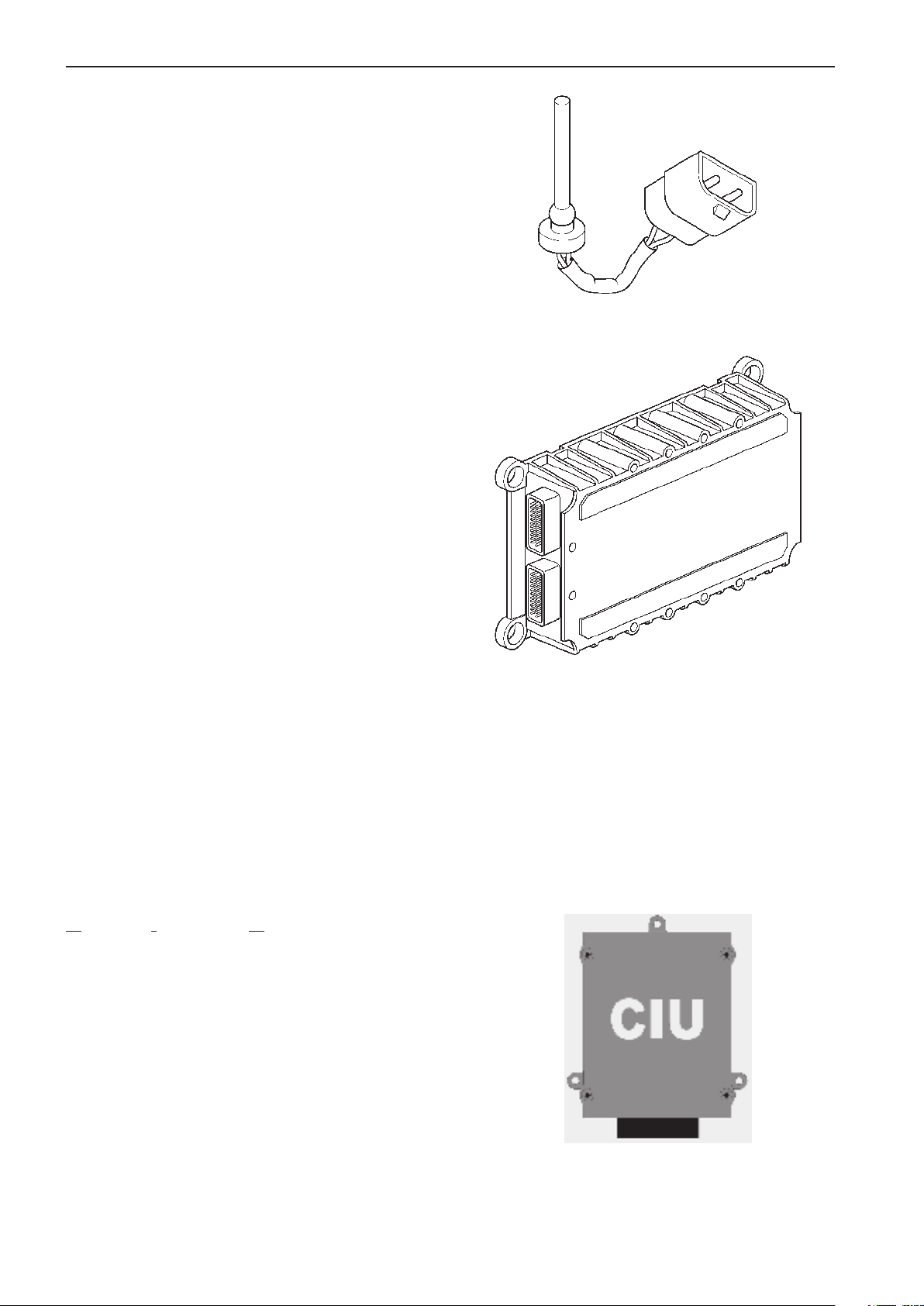

Control module

The EDC III system processor is located in the control module, protected from moisture and vibrations.

The processor continually receives information regarding:

Engine speed

•

Charge air pressure

•

Charge air temperature

•

Coolant temperature

•

Oil pressure

•

Oil temperature

•

Fuel alarm, combined alarm for ”water in fuel” and

•

”fuel pressure”

Coolant level

•

This information is used to make exact determinations

on current operating conditions and allows the processor to calculate the correct amount of fuel, check the

condition of the engine, etc.

Fuel management

The engine’s fuel need is analyzed up to 100 times

per second (depending on engine speed). The quantity

and timing of fuel injection into the engine are controlled completely electronically via fuel valves on the

unit injectors.

This means that the engine always receives the correct amount of fuel under all operating conditions,

providing benefits including improved fuel economy

and minimized exhaust emissions.

The control module checks and controls the unit injectors so that the correct amount of fuel is injected into

each cylinder. It calculates and sets the injection angle. This control is done primarily with the help of the

tachometer sensors and the combined sensor for

charge air pressure/temperature.

The control module actuates the unit injectors via an

electronic signal to the unit injectors’ electromagnetically controlled fuel valve, which can then be opened

or closed.

When the fuel valve is open, fuel streams by, through

the unit injector holes and out through the fuel channel. Fuel is not injected into the cylinder at this stage.

When the fuel valve is closed, pressure is built up by

the mechanically driven pump piston of the unit injector. Once enough pressure is built up, fuel is injected

into the cylinder via the injector portion.

The fuel valve is reopened and pressure in the unit injector sinks while fuel injection to the cylinder ceases.

To determine when the fuel valve should be opened or

closed, the control module has access to signals from

sensors and switches.

12

Page 4

Group 23 EDC III Design and operation

Calculation of fuel quantity

The amount of fuel injected into a cylinder is calculated by the control module. The calculation gives the

amount of time the fuel valve is closed (as fuel is injected into the cylinder when the fuel valve is closed).

The parameters that determine the amount of fuel injected are:

Requested RPM

•

Engine protection functions

•

Temperature

•

Charge air pressure

•

Cylinder balance

When idling, the control module can provide the cylinders with different amounts of fuel. This makes the

engine idle more evenly. At higher RPM, all cylinders

receive an equal amount of fuel.

Diagnostic function

The EDC III system has an internal diagnostic function that makes it possible to detect faults in the engine and sensor.

The role of the diagnostic function is to detect and localize disruptions in the EDC III system, protect the

engine and ensure that the machine remains in working order during serious disturbances.

If a disturbance arises, the diagnostic indicator on the

indicator panel begins blinking. When the diagnosis

button is pressed, an error code is given as guidance

for any fault detection. The diagnostic function can be

read out via the display using the PC diagnostics program.

Idle adjustment (low idle)

Idle can be adjusted to a value between 600 and

1200 RPM.

13

Page 5

Group 23 EDC III Design and operation

Component description

The digits after the headings refer to ”Component diagram and location”.

Water monitor, fuel pre-filter (19)

The monitor is located on the bottom of the fuel prefilter.

Its role is to guard against water in the fuel system.

The monitor consists of two copper pins between

which resistance is measured. When resistance falls

below the limit value, which indicates that there is water in the fuel, a warning signal is sent to the control

module.

Tachometer sensor, camshaft (2)

The tachometer sensor is located on the upper timing

cover. The tachometer sensor, which is linked to the

camshaft, is an inductive sensor. It reads a toothed

wheel with seven pins. The impulses from the camshaft sensor provide the control module information on

which cylinder is next in line for injection and when it

receives it.

Oil pressure/temperature sensor

(10)

Oil pressure and oil temperature are measured by a

combined sensor that is located on the left-hand side

of the engine, next to the control module.

The sensor is mounted in the engine block so that

measurement is taken from the oil system’s main

channel. The sensor consists of a non-linear resistor

whose resistance is dependant on the temperature of

the resistor body. Resistance decreases as temperature increases. The pressure signal is a voltage signal

proportional to the pressure. The reference voltage for

the sensor is 5 Volts.

14

Page 6

Group 23 EDC III Design and operation

Tachometer sensor, flywheel (18)

This sensor is located on the left-hand side of the flywheel housing.

The tachometer sensor on the flywheel is an inductive

sensor. It reads the crankshaft position and engine

speed using grooves in the flywheel. The signal is

sent to the control module, which calculates the injection angle and amount of fuel.

Charge air pressure/temperature

sensor (6)

Charge air pressure and charge air temperature are

measured with a combined sensor located on the intake manifold.

The charge air pressure sensor measures absolute

pressure, which is the sum of the charge air pressure

and atmospheric pressure. The sensor sends a signal

to the control module in the form of voltage that is proportional to the absolute pressure. The sensor receives

a reference voltage of 5 Volts from the control module.

The charge air temperature sensor consists of a nonlinear resistor whose resistance depends on the temperature of the resistor body. Resistance decreases

as temperature increases.

Coolant temperature sensor (15)

The sensor is located on the left-hand rear portion of

the cylinder head.

The sensor reads the temperature of the engine coolant and sends the information to the control module.

It consists of a non-linear resistor whose resistance

depends on the temperature of the resistor body. Resistance decreases as temperature increases.

Fuel pressure monitor (12)

The monitor is located on the left-hand side of the

engine, mounted in the fuel filter bracket.

Its task is to detect if the fuel pressure falls below

29 psi (2 BAR). The monitor is set to shut off when

pressure falls below 29 psi (2 BAR).

15

Page 7

Group 23 EDC III Design and operation

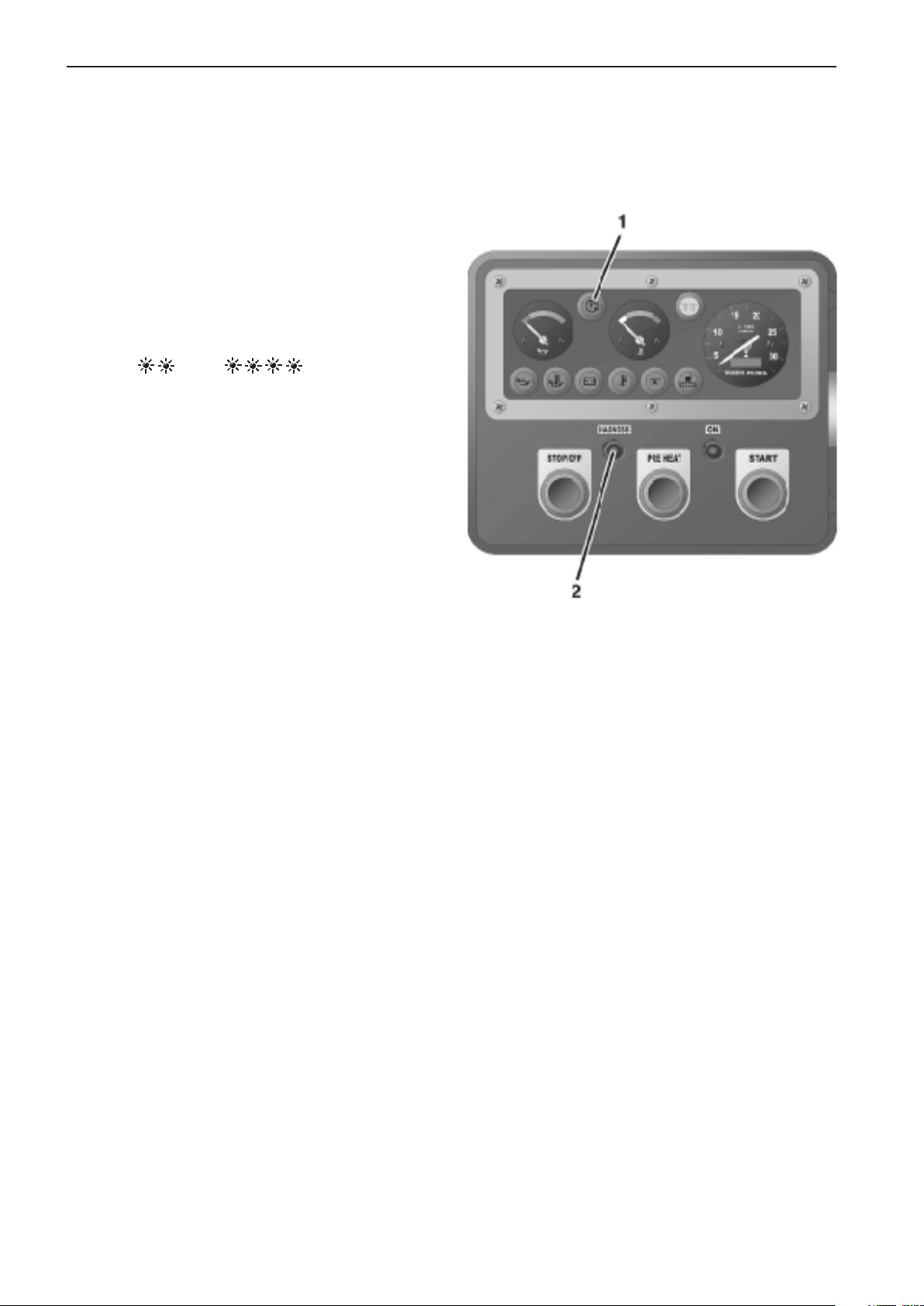

Coolant level monitor (1)

This monitor is located in the expansion tank.

Its task is to detect if the coolant level in the cooling

system (expansion tank) is too low. The monitor consists of a contact that can be actuated magnetically.

A hull located around the monitor actuates the contact

differently depending on the coolant level. An alarm

signal is sent if the coolant level is too low.

Electronic Control Unit (ECU) (11)

The control module (EMS) checks and controls the

unit injectors so that the correct amount of fuel is injected into each cylinder. It calculates and sets the injection angle. This control is done primarily with the

help of the tachometer sensors and the combined

sensor for charge air pressure/temperature.

The EDC III system processor is located in the control unit, protected from moisture and vibrations.

The processor continually receives information regarding:

engine speed

•

charge air pressure

•

charge air temperature

•

coolant temperature

•

oil pressure

•

oil temperature

•

fuel alarm, combined alarm for ”water in fuel” and

•

”fuel pressure”

coolant level

•

This information is used to make exact determinations

on current operating conditions and allows the processor to calculate the correct amount of fuel, check the

condition of the engine, etc.

Control Interface Unit (CIU)

The CIU is a control unit that handles all interaction

with the operator.

It communicates with the engine over two serial communication buses. J1939 is used for controlling and

monitoring the engine. J1587 is used for diagnostics

and backup.

The CIU loads a number of switches and speed requests and forwards them to the engine. It also controls four analogue instruments and up to nine warning

lamps. Using a diagnosis button and diagnostic lamp,

the operator can read out error codes from the system.

16

Page 8

Group 23 EDC III Design and operation

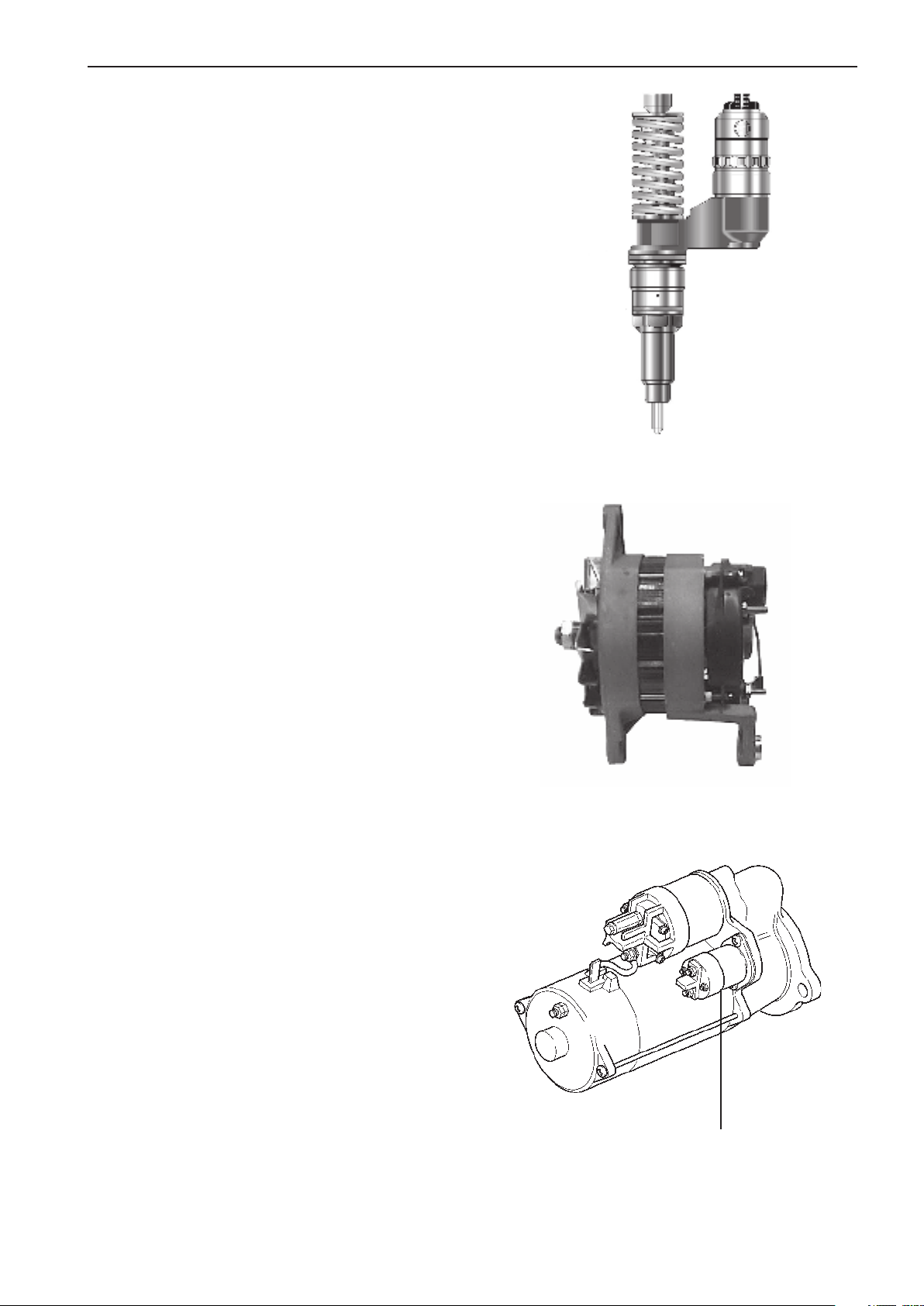

Unit injectors (20)

The unit injectors are located under the valve cover,

mounted in the cylinder head.

The engine’s fuel need is analyzed up to 100 times

per second (depending on engine speed). The quantity

and timing of fuel injection into the engine are controlled completely electronically via the unit injectors’

electromagnetically operated fuel valves. This means

that the engine always receives the correct amount of

fuel under all operating conditions, providing benefits

including improved fuel economy and minimized exhaust emissions.

Generator (8)

The belt-driven generator is located on the left-hand

front edge of the engine.

The voltage regulator of the generator is equipped with

a sensor system. The sensor system compares the

charging voltage between the generator connections,

B+ and B-, with the actual voltage between the positive and negative poles of the batteries. The voltage regulator then compensates for any voltage drop in the

lines between the generator and the battery by increasing the charging voltage from the generator as

needed.

Starter motor (16)

The starter motor is mounted on the flywheel housing

on the right-hand side of the engine.

When the motor is cut in, a gear on the armature shaft

of the starter motor is moved along the axis so that it

meshes with the gear ring of the engine’s flywheel.

The actuator solenoid of the starter motor controls

both the axial movement of the gear and connection

of the starter motor.

In turn, the actuator solenoid of the starter motor is

cut in via the start relay, which is activated when the

ignition key is turned to position III or the start button

is depressed.

The starter motor relay (1) is mounted next to the starter motor solenoid.

1

17

Page 9

Group 23 EDC III Design and operation

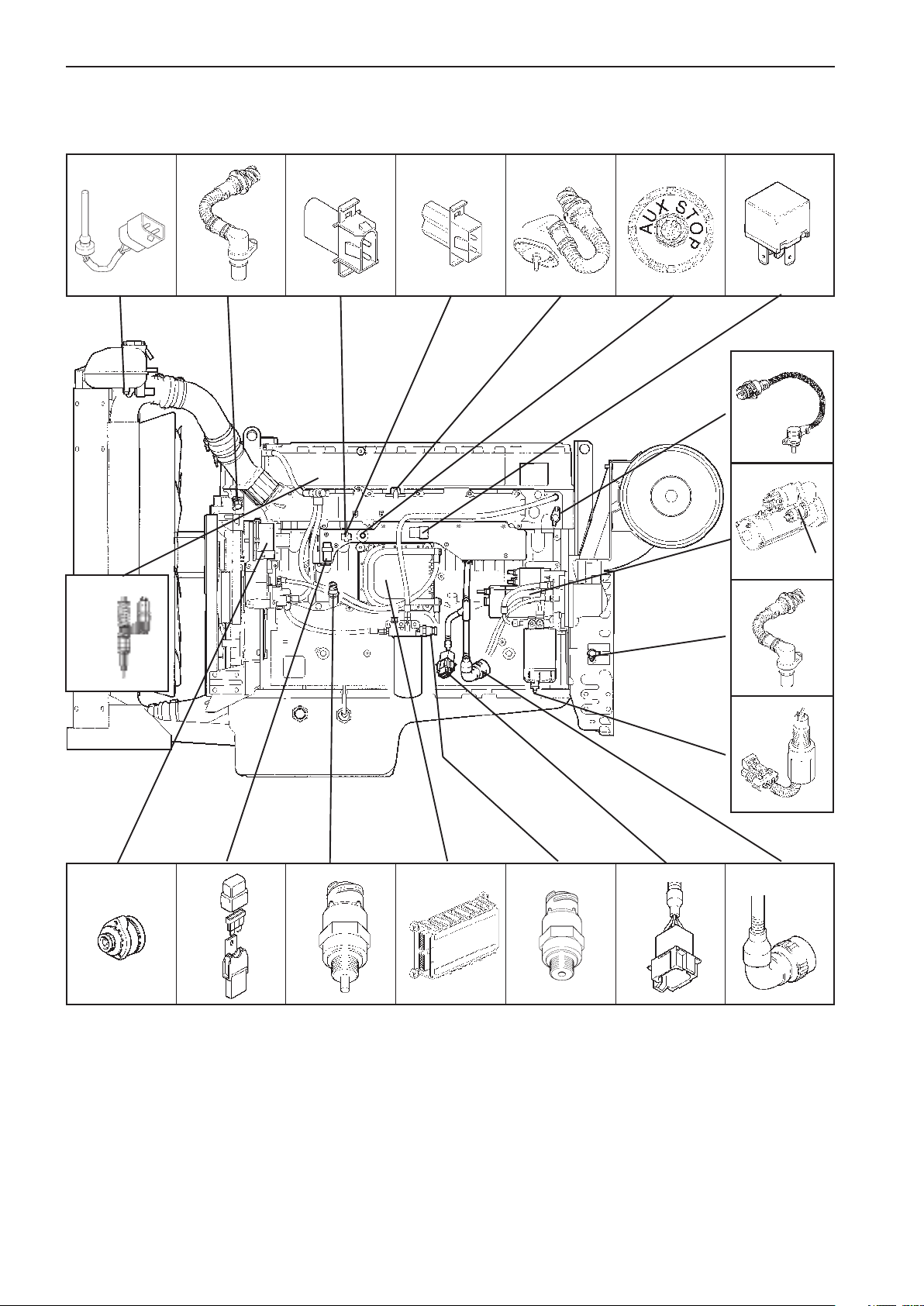

Component diagram and location

20

3

64512

7

15

16

17

18

911128

1. Coolant level monitor

2. Tachometer sensor, camshaft

3. Connection, diagnostic tool*

4. Programming plug*

5. Charge air pressure/temperature sensor

6. Extra stop

7. Main relay*

8. Generator

9. Fuse 10A

10. Oil pressure/temperature sensor

10

13

11. Control unit (ECU)

12. Fuel pressure monitor

13. 8–pin connection (Data bus)

14. 23–pin connection (Stand alone)

15. Coolant temperature sensor

16. Starter motor

17. Starter motor relay

18. Tachometer sensor, flywheel

19. Water monitor, fuel filter

20. Unit injectors (one per cylinder)

19

14

* Inside the Cover

18

Page 10

Group 23 EDC III Limit values

Limit values

Limit values, electronic control unit (ECU) TAD1240GE,

TAD1241-42GE/VE

Alarm values

The maximum permissible values for charge air and coolant temperatures, for example, can be adjusted with the

parameter setting tool and can thus vary within alarm limits.

If the alarm values are exceeded, the system reduces the amount of fuel until the value is once again within the

permissible interval.

This function is a customer parameter that can be completely disengaged.

Alarm limits TAD1240–42GE/VE:

Coolant temperature: Alarm lamp lights Engine is switched off Engine output 50%

Standard value Volvo Penta 98°C / 208°F 100°C / 212°F

Parameter setting (can be set

by the customer) 95–101°C / 203-214°F +2°C / 36°F over the alarm value

NOTE: Engine protection can be switched off.

Coolant level:

Alarm lamp lights when the contact is activated and

the engine is switched off

Alarm switch is activated

NOTE: Engine protection can be switched off.

Charge air temperature:

Standard value Volvo Penta 83°C / 181°F 85°C / 185°F

NOTE: Engine protection can be switched off.

Oil pressure:

Standard value Volvo Penta Idle: 0.7 bar (10,2 psi) For oil pressure 0.3 bar (4,4 psi)

lower than alarm value

>1500 RPM: 2.5 bar For oil pressure 0.3 bar (4,4 psi)

(36,3 psi) lower than alarm value

NOTE: Engine protection can be switched off.

Oil temperature:

Standard value Volvo Penta 125°C / 257°F 127°C / 261°F

Parameter setting (can be set

by customer) 120–130°C / 248-266°F +2°C / 36°F over alarm value

NOTE: Engine protection can be switched off.

Fuel pressure:

Standard value Volvo Penta <2 bar (<29 psi) Engine not switched off

Monitor, water in fuel: Alarm lamp lights

RPM:

Standard value Volvo Penta Max. operational RPM + 20%

Activates upon operational RPM +15%.

Parameter setting (can be set by customer)

Max. operational RPM + 10–20%

NOTE: Engine protection is switched off as standard.

19

Page 11

Group 23 EDC III Gränsvärden

Limit values, electronic control unit (ECU) TWD1240VE

Alarm limits:

Coolant temperature: Alarm lamp lights Engine is switched off Engine output 50%

Standard value Volvo Penta 98°C / 208°F 100°C / 212°F

Parameter setting (can be

set by the customer) 95–101°C / 203-214°F +2°C / 36°F over the alarm value

NOTE: Engine protection can be switched off.

Coolant level: Alarm lamp lights when the contact is activated

and the engine is switched off

NOTE: Engine protection can be switched off.

Charge air temperature:

Standard value Volvo Penta 100°C / 212 °F 102°C / 216°F

NOTE: Engine protection can be switched off.

Oil pressure:

Standard value Volvo Penta Idle: 0.7 bar (10,2 psi) For oil pressure 0.3 bar (4,4 psi)

lower than alarm value

>1500 RPM: 2.5 bar For oil pressure 0.3 bar (4,4 psi)

(36,3 psi) lower than alarm value

* See diagram: ”Oil pressure” below.

NOTE: Engine protection can be switched off.

Oil temperature:

Standard value Volvo Penta 125°C / 257°F 127°C / 261°F

Parameter setting (can be

set by the customer) 120–130°C / 248-266°F +2°C / 36°F over

alarm value

NOTE: Engine protection can be switched off.

Fuel pressure:

Standard value Volvo Penta <2 bar (<29 psi) Engine not switched off

Monitor, water in fuel: Alarm lamp lights

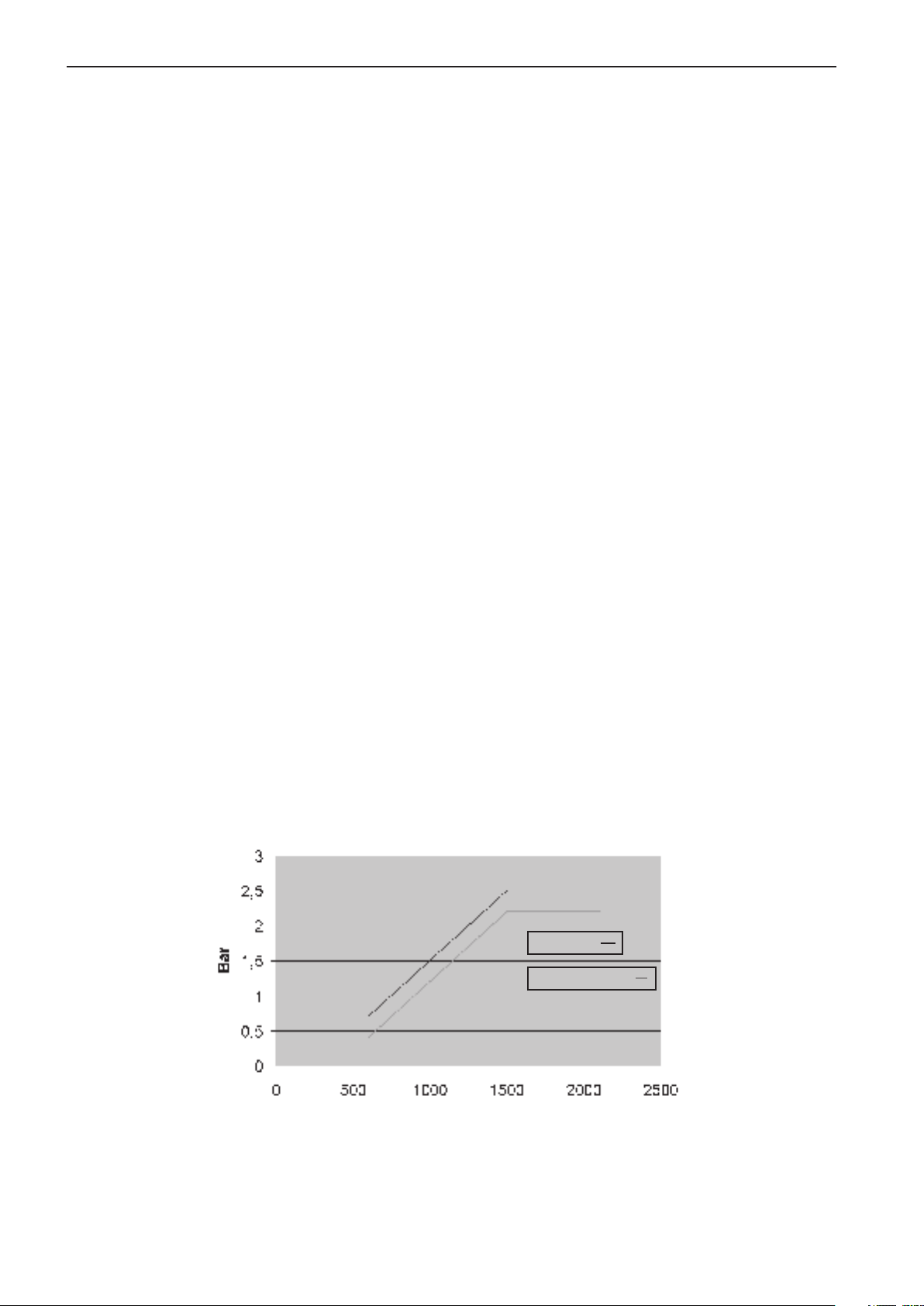

*Oil pressure

Alarm limit

Engine is switched off

20

rpm

Page 12

Group 23 EDC III Limit values

Limp-home values (emergency control

values)

The control unit uses these bases value to be able to

run the engine if a technical error arises in the system

or its peripheral equipment, sensors, etc.

The following values (Limp-home values) are stored

in the control unit:

Charge air temperature +45°C / 113°F

Coolant temperature -15°C / 5°F

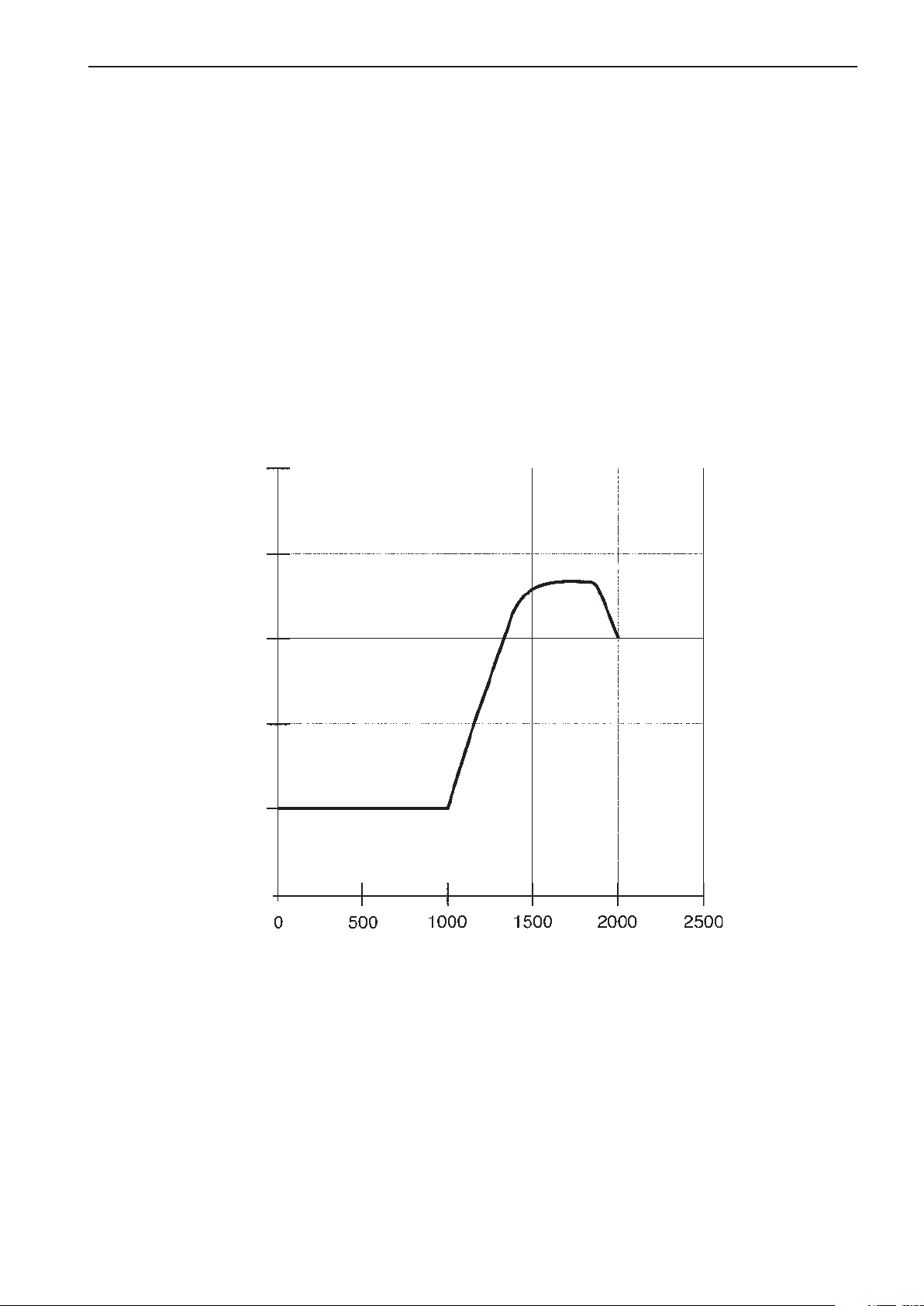

Charge air pressure See diagram below

Engine speed:

TAD1240–42GE/VE RPM frozen

TWD1240VE Idle

3.0

Charge air

pressure

2.5

2.0

bar

1.5

1.0

0

rpm

21

Page 13

Group 23 EDC III Repair instructions

Repair instructions

When working with EDC III

Follow the instructions below so as not to damage the control unit of the EDC system:

Never cut off the main current when the engine is running.

•

Never disconnect battery cables when the engine is running.

•

When quick charging the batteries, the main switch must be turned off or the battery cables must be discon-

•

nected.

During normal maintenance charging, the main switch does not need to be turned off.

Only batteries should be used for jumping. Jumping devices may cause a surge and damage the

•

control unit.

Cut off power to the EDC III system before disconnecting the 2 x 36-pin cable glove from the control unit.

•

If damage to the wiring harness is detected, the cable glove should be disconnected from the control unit.

•

IMPORTANT! The cable glove should be disconnected from the control unit when welding.

When removing a connector from a sensor, be careful not to expose the contact pin to oil or any

•

other fluid.

This could cause a contact problem or, if oil runs down to the pressure sensing membrane, the sensor could

show an incorrect value.

22

Page 14

Group 23 EDC III Repair instructions

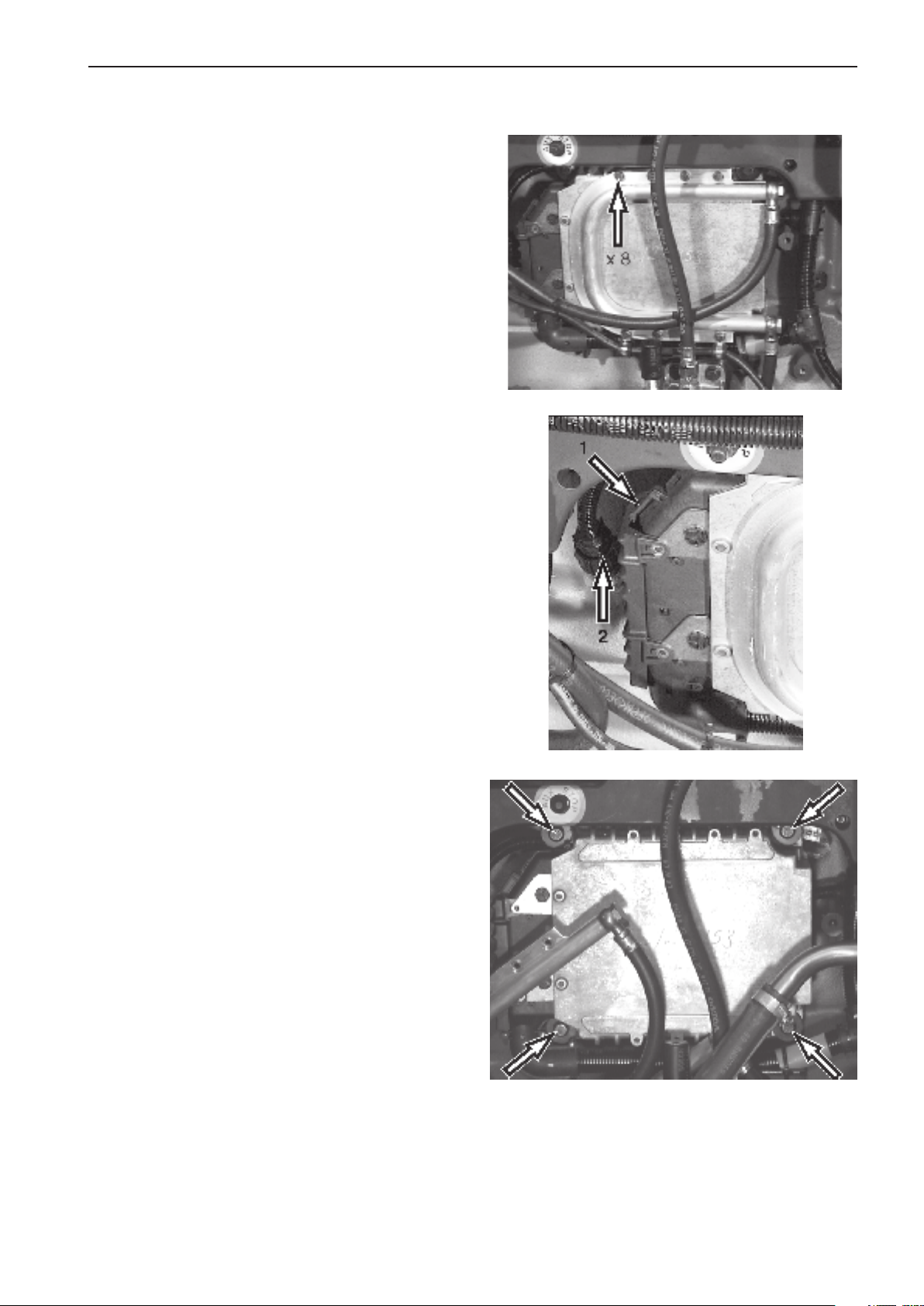

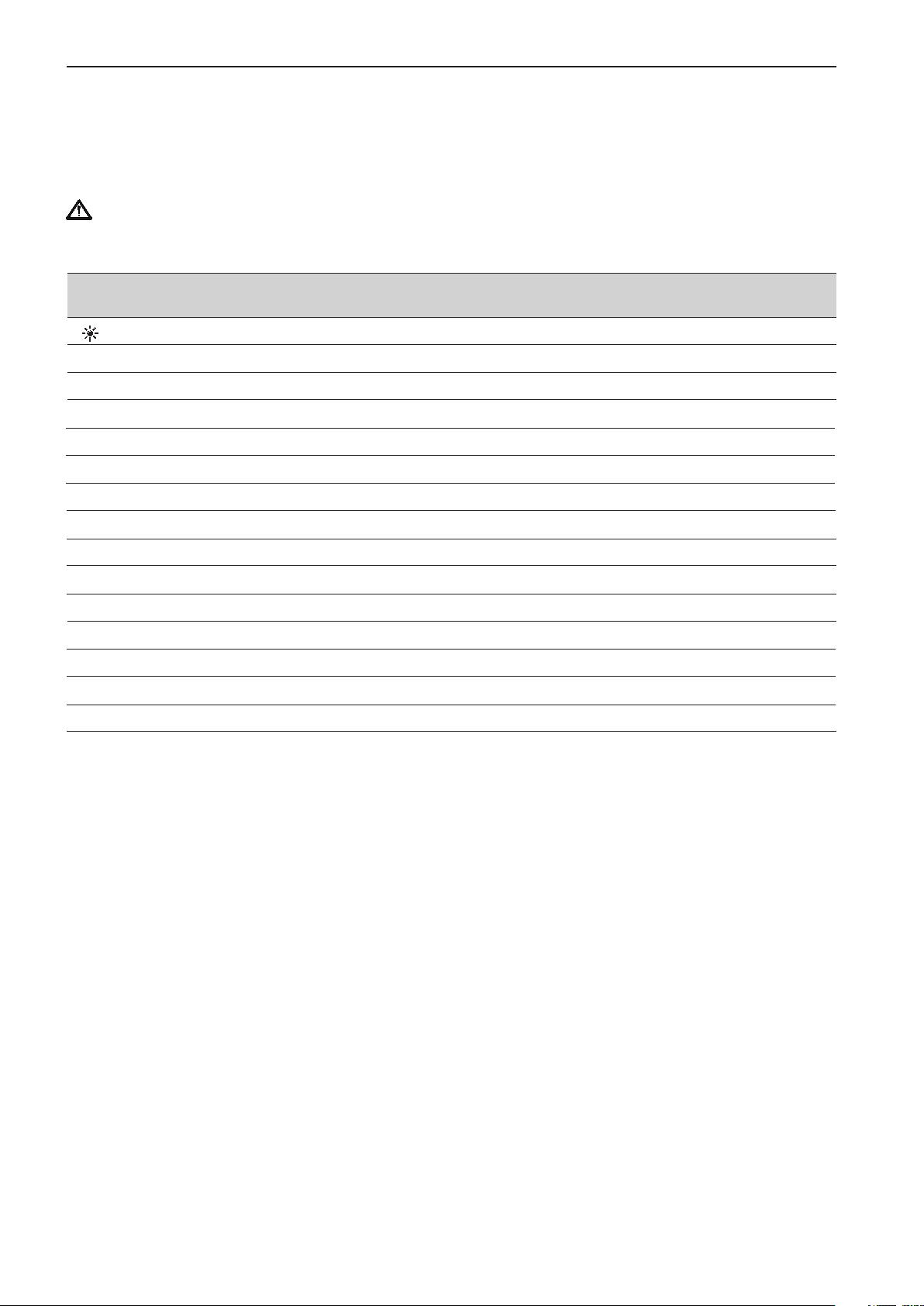

Electronic Control unit (ECU),

replacement

1. Cut off power to the engine.

2. Remove the fuel cooling coil and fuel line clamps

from the control unit.

Bend aside the cooling coil.

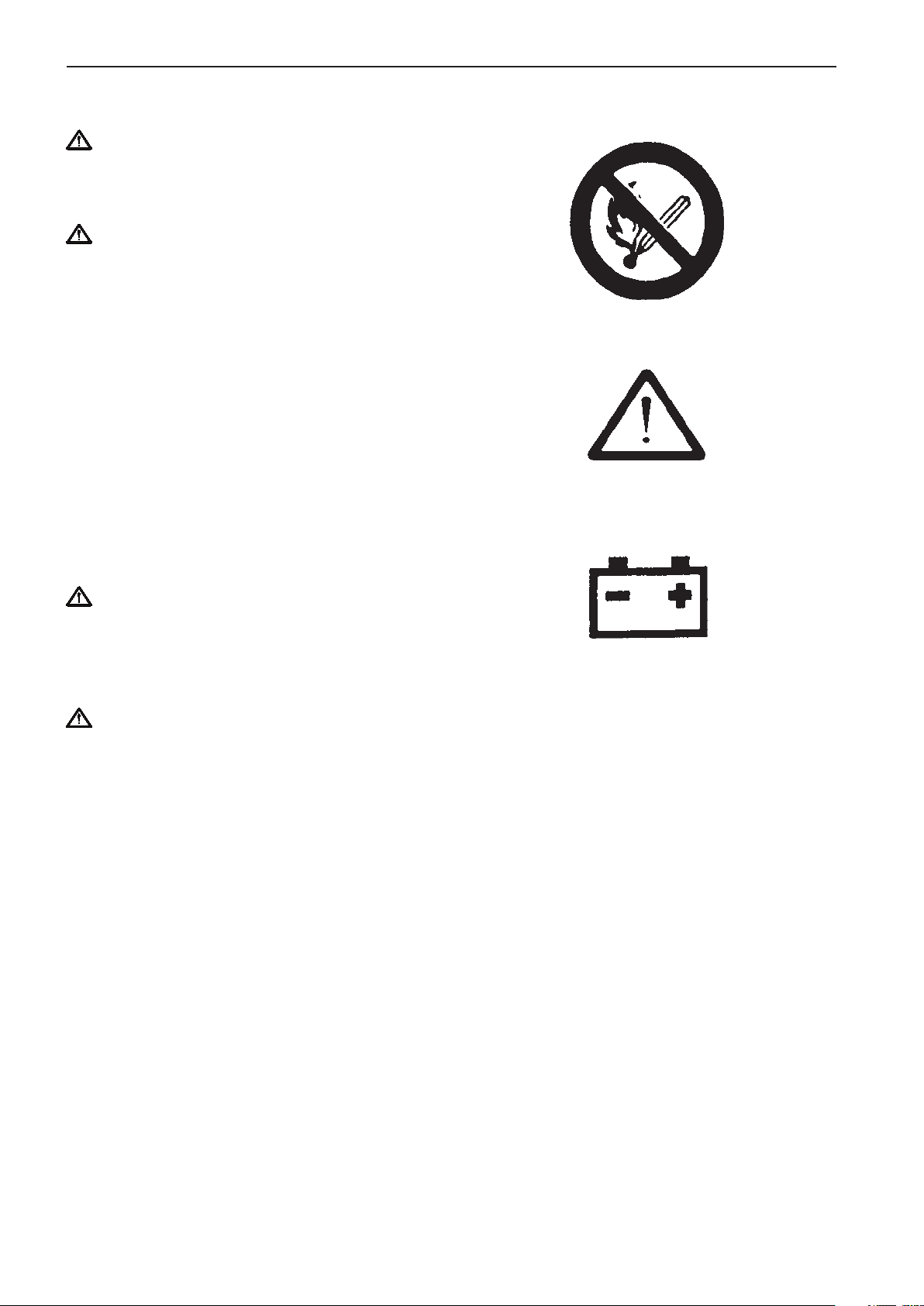

3. Disconnect the cable glove from the control unit.

Press in the catch (1) and push the cable glove (2)

upwards.

4. Remove the control unit.

5. Transfer the rubber cushions to the new control

unit.

6. Fit the new control unit.

7. Connect the cable glove to the control unit.

When connecting the cable glove (2) to the

control unit, make sure that the safety catch (1) is

set.

8. Fit the cooling coil and fuel line clamps to the

control unit.

NOTE: The retaining bolts of the fuel cooling coil are

self-tapping as there are no threads in the control unit.

9. Start the engine and perform leakage and

functionality checks.

23

Page 15

Group 23 EDC III Repair instructions

Start with booster batteries

WARNING! Be sure to have good ventilation.

The batteries build oxyhydrogen gas, which is

very flammable and explosive. A short-circuit,

open flame or spark could cause an explosion.

WARNING! Never confuse the position of the

cables on the battery. Confusing battery poles

when jumpstarting with battery cables causes

short-circuits and sparks, which can cause explosion and greatly damage electrical engine

components.

1. Check that the voltage of the booster battery is

the same as the engine’s system voltage.

2. First connect the red (+) jumper cable to the

positive pole (+) of the discharged batteries and

then to the positive pole (+) of the booster

battery.

3. Then connect the black (-) jumper cable to the

negative pole (-) of the booster battery and a

spot a bit away from the negative pole (-) of the

discharged batteries, such as by the negative

lead’s connection to the starter motor.

WARNING! The black (-) jumper cable must absolutely not come in contact with the positive

lead’s connection to the starter motor.

4. Start the engine and run at high idle about

10 minutes to charge the batteries.

WARNING! Approaching or working on a running

engine is a safety risk.

Beware of rotating parts and hot surfaces.

Do not touch the connections during the start attempt.

Risk of sparks.

Do not lean over any of the batteries.

5. Switch off the engine.

Remove the jumper cables in reverse order from

fitting. One cable at a time!

24

Page 16

Group 23 EDC III Functionality check

Functionality check

PC diagnostics program

This program can read error codes that are stored in the engine control unit, check input and

•

output signals, read current values from engine sensors and then store and print test results.

The program enables service and workshop personnel to quickly localize and remedy errors in the

•

EDC III system.

A data link connector is used to connect to the engine control unit.

•

User information is included in the program.

•

Contact your Volvo Penta dealer to order software.

•

The role of the diagnostic function is to detect and localize disturbances in the EDC III system, protect the

•

engine and ensure that the machine remains in working order during serious disturbances.

If a disturbance arises, the diagnostic indicator on the indicator panel begins blinking.

•

When the diagnosis button is pressed, an error code is given as guidance for any fault detection.

25

Page 17

Group 23 EDC III Fault detection

Fault detection

A number of symptoms and possible causes for engine problems are described in the table below. Always contact

your Volvo Penta dealer if problems occur that you are not able to solve on your own.

WARNING! Read through the safety instructions for maintenance and service work in the chapter ”Safety information” before starting to work.

Symptoms and possible causes

Diagnosis button’s indicator is blinking See the chapter ”Diagnostic function”

The engine cannot be stopped 2, 5

The starter motor does not rotate 1, 2, 3, 4, 5, 6, 7, 8, 25

The starter motor rotates slowly 1, 2

The starter motor rotates normally, but the engine does not start 9, 10, 11, 12, 13

The engine starts, but stops again 9, 10, 11, 12, 14

The engine does not reach the correct operating speed at full throttle 10, 11, 12, 13, 14, 22, 26, 27, 28, 29

The engine runs unevenly 11, 12,13

High fuel consumption 13, 14, 16, 26

Black exhaust smoke 13, 14

Blue or white exhaust smoke 15, 16, 23

Low oil pressure 17

High coolant temperature 18, 19, 20, 21

Low coolant temperature 21

No or poor charging 2, 24

1. Discharged batteries

2. Poor contact/interruption on

electrical line

3. Main switch turned off

4. Fuse on wiring box blown

5. Faulty starter switch

6. Faulty main relay

7. Faulty starter motor relay

8. Faulty starter motor/solenoid

9. Fuel shortage:

– fuel cocks closed

– fuel tank empty/wrong tank

connected

10. Clogged fuel fine filter/pre-filter

(due to contaminates or

paraffin deposits in the fuel at

low temperature)

11. Air in fuel system

12. Water/contaminates in the fuel

13. Faulty unit injectors

14. Insufficient air supply to

engine:

– clogged air filter

– air leak between turbo-

charger and engine’s intake

manifold

– fouled compressor

in turbocharger

– faulty turbocharger

– poor engine compartment

ventilation

15. High coolant temperature

16. Low coolant temperature

17. Low oil level

18. Low coolant level

20. Faulty circulation pump

21. Defective thermostat

22. Clogged intercooler

23. High oil level

24. Generator drive belt is slipping

25. Water in engine

26. Great counterpressure in

27. Interruption, cable ”Pot+” to

28. High oil temperature

29. High charge-air temperature

exhaust system

pedal

26

19. Air in coolant system

Page 18

Group 23 EDC III Diagnostic function

Diagnostic function

Diagnostic function

The diagnostic function checks that the EDC III system is functioning normally.

The diagnostic function performs the following

tasks:

Detects and localizes disturbances

•

Notifies when disturbances are detected

•

Provides guidance for fault detection

•

Protects the engine and ensures that the machine

•

remains in working order when serious disturbances

are detected.

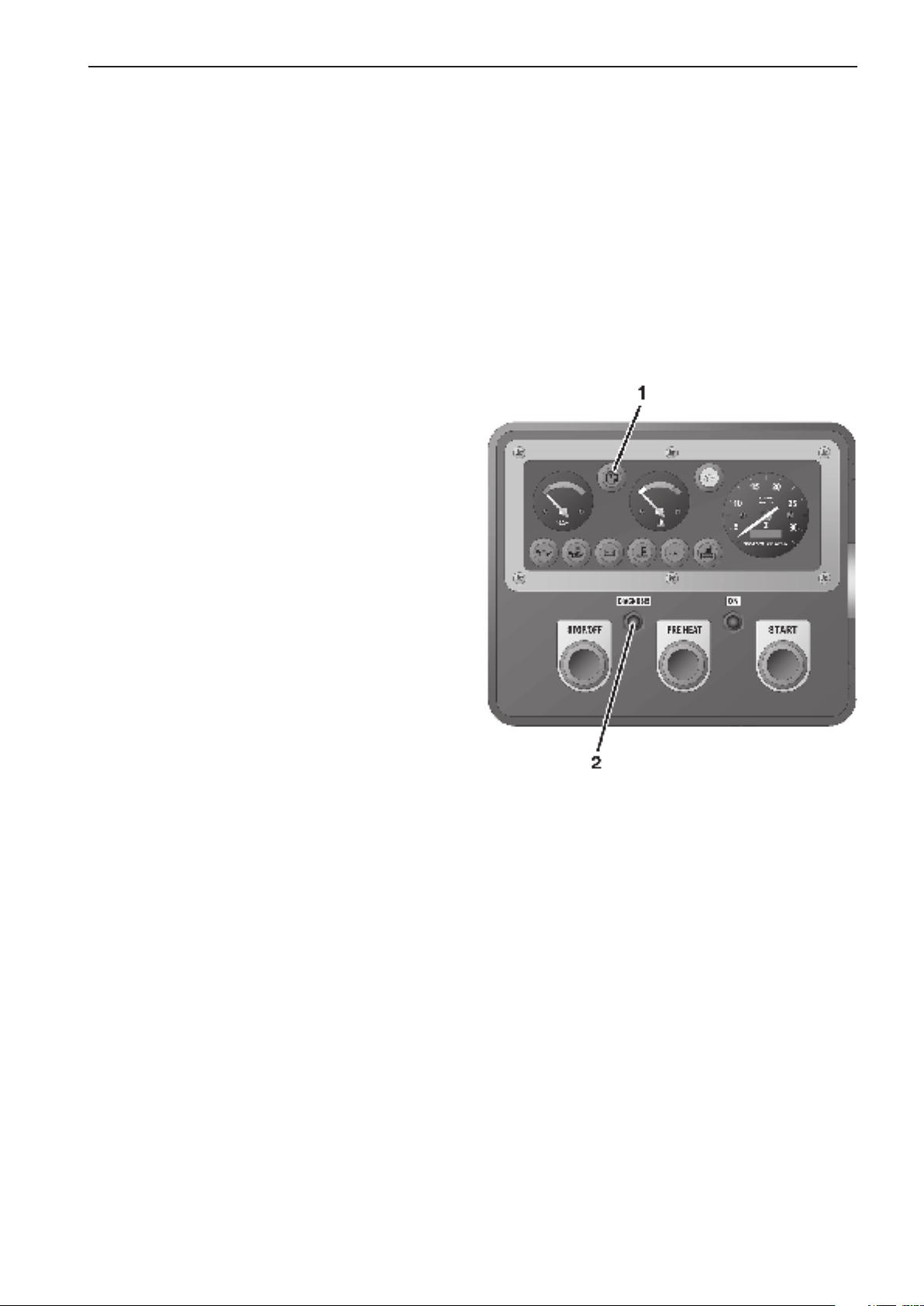

Notification of disturbance If the diagnostic function

detects a disturbance in the EDC III system, the operator is notified by the diagnostic lamp (1), which begins

to blink.

Guidance for fault detection If the diagnosis button

(2) is depressed and then released the diagnostic lamp

(1) blinks out an error code. The code is found in the

error code list, with information on cause, response and

corrective action.

The diagnostic function affects the engine in the

following manner when:

1 The diagnostic function has detected a minor

disturbance that will not damage the engine:

Response: The engine is not affected.

2. The diagnostic function has detected a serious

disturbance that will not immediately damage the

engine:

Response: TAD1240–42GE/VE: Engine is

switched off.

TWD1240VE: Engine is switched off or engine

torque is lowered until the value is normalized.

3. The diagnostic function has detected a serious

disturbance that makes it impossible to control

engine operation:

Response: TAD1240–42GE/VE: RPM maintained.

TWD1240VE: The engine goes to idle. Idle or

freezing of RPM can be set using the Volvo Penta

Parameter Tool.

If the diagnosis button’s

indicator blinks

1. Reduce RPM to idle.

2. Press the diagnosis button (2) to acknowledge the

message.

3. Release the diagnosis button and note the error

code that blinks out. (1) See ”Reading out error

codes”.

4. Look up the error code in the error code list and

follow the recommended course of action.

27

Page 19

Group 23 EDC III Diagnostic function

NOTE: If the warning lamps and other instruments

show normal function and the control is working normally, the operator can choose to continue operating

and remedy the disturbance later. If the engine is switched off, certain error codes could disappear.

Reading out error codes

If the diagnosis button 2 is depressed and then released, an error code blinks out (1).

The error code consists of two groups of blinks separated by a two-second pause. The error code is read

by counting the number of blinks in each group.

Example: pause = Error code 2.4

The error code is stored and can be read as long as

the disturbance remains. The error code list contains

information on cause, response and corrective action.

Read out as follows:

1. Press in the diagnosis button (2)

2. Release the diagnosis button and note the error

code that blinks out (1).

3. Repeat points 1–2. A new error code blinks out if

more codes are stored. Repeat until the first error

code reappears.

NOTE: When the first error code reappears all error

codes have been read out.

Erasing error codes

The error code memory of the diagnostic function is

reset when power to the engine is cut off.

NOTE: The power must be completely disconnected.

When the power is turned on, the diagnostic function

checks to see if there are any disturbances in the

EDC III system. If disturbances are present, new error

codes are set.

This means that:

1. Error codes for disturbances that have been

corrected or that have disappeared are erased

automatically.

2. Error codes for disturbances that have not been

corrected must be acknowledged and read out

every time the power is turned on.

If the diagnosis button is pushed after the error has

been corrected and saved error codes are erased the

code 1.1 (”No errors”) will blink out.

28

Page 20

Group 23 EDC III Diagnostic function

Error codes EDC III

WARNING! Read the safety instructions for maintenance and service work in the chapter ”Safety informa-

tion” before starting to work.

NOTE: The readout of the error codes below, such as 175 Code 2.1, means that 175 is read using the diagnostic tool.

2.1 is the blink code that is shown on the instrument box’s diagnostic lamp. See ”Reading out error codes”.

175 Code 2.1

Cause: Water in the fuel or low fuel pressure.

Response: Alarm lamp lights.

Corrective action:

Check the fuel dehumidification filter (drain the

•

fuel tank).

Check if it is possible to increase the pressure

•

using the hand pump.

Check the fuel filter.

•

Check the fuel pre-filter

•

191 Code 2.2

Cause: Low coolant level.

Response: Engine is switched off (if this protective

feature has not been disabled by the parameter setting tool).

Alarm lamp lights.

Corrective action:

Check the coolant level.

•

Check the function of the coolant level monitor.

•

15 Code 2.4

Cause: Tachometer sensor, flywheel. No signal.

Response: The engine is extremely hard to start and

runs unevenly if it does.

Corrective action:

Check that the sensor connector is fitted correctly.

•

Check that the wiring to the tachometer sensor is

•

not damaged.

Check that the tachometer sensor is correctly fit-

•

ted in the flywheel housing.

Check the function of the tachometer sensor.

•

Check the contact pressure in sleeves 30 and 31

•

in the black cable glove of the engine control unit

(ECU).

18 Code 2.4

Cause: RPM sensor, flywheel. Abnormal frequency.

Response: The engine is extremely hard to start and

runs unevenly if it does.

Corrective action:

Check that the tachometer sensor connector is fit-

•

ted correctly.

Check that the wiring to the tachometer sensor is

•

not damaged.

Check that the tachometer sensor is correctly fit-

•

ted in the flywheel housing.

Check the function of the tachometer sensor.

•

101 Code 2.4

Cause: Tachometer sensor, flywheel. Intermittent signal.

Response: The engine is extremely hard to start and

runs unevenly if it does.

Corrective action:

Check that the tachometer sensor connector is fit-

•

ted correctly.

Check that the wiring to the tachometer sensor is

•

not damaged.

Check that the tachometer sensor is correctly fit-

•

ted in the flywheel housing.

Check the function of the tachometer sensor.

•

Check the contact pressure in sleeves 30 and 31

•

in the black cable glove of the engine control unit

(ECU).

29

Page 21

Group 23 EDC III Diagnostic function

102 Code 2.5

Cause: RPM sensor, camshaft. No signal.

Response: The engine takes longer than normal to

start. The engine runs normally once underway.

Corrective action:

Check that the tachometer sensor connector is fit-

•

ted correctly.

Check that the wiring to the tachometer sensor is

•

not damaged.

Check that the tachometer sensor is correctly fit-

•

ted in the upper timing cover.

Check the function of the tachometer sensor.

•

Check the contact pressure in sleeves 7 and 18

•

in the black cable glove of the engine control unit

(ECU).

103 Code 2.5

Cause: RPM sensor, camshaft. Abnormal frequency.

Response: The engine takes longer than normal to

start. The engine runs normally once underway.

Corrective action:

Check that the tachometer sensor connector is fit-

•

ted correctly.

Check that the wiring to the tachometer sensor is

•

not damaged.

Check that the tachometer sensor is correctly fit-

•

ted in the upper timing cover.

Check the function of the tachometer sensor.

•

23 Code 2.7

Cause: RPM potentiometer connected to engine con-

trol unit (ECU).

Interrupted or shorted to positive (+).

Response: The engine goes to idle. If the pedal is released and then depressed again, the engine can

”limp home” using the idle contact.

Corrective action:

Check the the control’s connector is fitted correctly.

•

Check that the wiring to the sensor is not damaged.

•

Check the function of the sensor.

•

Check that the 23-pin connector is fitted correctly.

•

Check pin C and sleeve C in the 23-pin connector.

•

Check the contact pressure in sleeve 3 in the red

•

cable glove of the engine control unit (ECU).

24 Code 2.7

Cause: RPM potentiometer connected to the engine

control unit (ECU). Short to negative (-).

Response: The engine goes to idle. If the pedal is released and then depressed again, the engine can

”limp home” using the idle contact.

Corrective action:

Check that the potentiometer is connected cor-

•

rectly.

Check that the wiring to the potentiometer is not

•

damaged.

Check the function of the potentiometer.

•

21 Code 2.8

Cause: RPM potentiometer connected to CIU.

Short to negative (-).

Response: The engine goes to idle. If the pedal is released and then depressed again, the engine can

”limp home” using the idle contact.

Corrective action:

Check that the potentiometer is connected cor-

•

rectly.

Check that the wiring to the potentiometer is not

•

damaged.

Check the function of the potentiometer.

•

22 Code 2.8

Cause: RPM potentiometer connected to CIU.

Interrupted or shorted to positive (+).

Response: The engine goes to idle. If the pedal is released and then depressed again, the engine can

”limp home” using the idle contact.

Corrective action:

Check that the potentiometer is connected cor-

•

rectly.

Check that the wiring to the potentiometer is not

•

damaged.

Check the function of the potentiometer.

•

30

Page 22

Group 23 EDC III Diagnostic function

181 Code 3.1

Cause 1: Oil pressure sensor. Short to positive (+).

Response: None.

Corrective action:

Check that the wiring to the oil pressure sensor is

•

not damaged.

Check that the oil pressure sensor is connected

•

correctly.

182 Code 3.1

Cause: Oil pressure sensor. Interrupted or shorted to

negative (-).

Response: None.

Corrective action:

Check that the wiring to the oil pressure sensor is

•

not damaged.

Check that the oil pressure sensor is connected

•

correctly.

Check the contact pressure in sleeve 14 in the

•

black cable glove of the engine control unit

(ECU).

25 Code 3.2

Cause: Charge air temperature sensor. Interrupted or

shorted to positive (+).

Response: None.

Corrective action:

Check that the connector of the charge air tempe-

•

rature sensor is fitted correctly.

Check that the wiring to the charge air temperature

•

sensor is not damaged.

Check that the charge air temperature sensor is

•

fitted correctly.

Check the function of the charge air temperature

•

sensor.

Check the contact pressure in sleeve 2 in the

•

black cable glove of the engine control unit

(ECU).

26 Code 3.2

Cause: Charge air temperature sensor. Short to

negative (-).

Response: None.

Corrective action:

Check that the wiring to the charge air temperatu-

•

re sensor is not damaged.

Check that the charge air temperature sensor is

•

fitted correctly.

Check the function of the charge air temperature

•

sensor.

27 Code 3.3

Cause: Coolant temperature sensor. Interrupted or

shorted to positive (+).

Response: Preheating is activated even if the engine

is warm.

Corrective action:

Check that the connector of the coolant tempera-

•

ture sensor is fitted correctly.

Check that the wiring to the coolant temperature

•

sensor is not damaged.

Check that the coolant temperature sensor is fit-

•

ted correctly.

Check the function of the coolant temperature

•

sensor.

28 Code 3.3

Cause 1: Coolant temperature sensor. Short to negati-

ve (-).

Response: Preheating is activated even if the engine

is warm.

Corrective action:

Check that the wiring to the coolant temperature

•

sensor is not damaged.

Check that the coolant temperature sensor is fit-

•

ted correctly.

Check the function of the coolant temperature

•

sensor.

31

Page 23

Group 23 EDC III Diagnostic function

67 Code 3.4

Cause: Charge air pressure sensor. Short to positive (+).

Response: The engine smokes more than it usually

does when accelerating/under loading.

Corrective action:

Check that the wiring to the charge air pressure

•

sensor is not damaged.

Check the function of the charge air pressure sen-

•

sor.

68 Code 3.4

Cause 1: Charge air pressure sensor. Interrupted or

shorted to negative (-).

Response: The engine smokes more than it usually

does when accelerating/under loading.

Corrective action:

Check that the connector of the charge air pressu-

•

re sensor is fitted correctly.

Check that the wiring to the charge air pressure

•

sensor is not damaged.

Check that the charge air pressure sensor is fitted

•

correctly.

Check the function of the charge air pressure sen-

•

sor.

Check the contact pressure in sleeve 3 in the

•

black cable glove of the engine control unit

(ECU).

184 Code 3.7

185 Code 3.7

Cause: Oil temperature sensor. Short to negative (-).

Response: None.

Corrective action:

Check that the wiring to the oil temperature sen-

•

sor is not damaged.

Check that the oil temperature sensor is correctly

•

connected.

200 Code 4.1

Cause: Oil pressure alarm, circuit interrupted.

Response: Alarm lamp does not work. If the circuit is

interrupted during start-up, diagnostics are deactivated.

Corrective action:

Check the alarm lamp.

•

Check that the wiring to the alarm lamp is not da-

•

maged.

Check sleeve ”L” in the 23-pin connector.

•

Check the contact pressure in sleeve 35 in the

•

red cable glove of the engine control unit (ECU).

201 Code 4.1

Cause: Oil pressure alarm. Short to negative (-).

Response: Alarm lamp lights constantly

Corrective action:

Check that the wiring and connection to the alarm

•

lamp are not damaged.

Cause: Oil temperature sensor. Interrupted or shorted

to positive (+).

Response: None.

Corrective action:

Check that the wiring to the oil temperature sen-

•

sor is not damaged.

Check that the oil temperature sensor is correctly

•

connected.

Check the contact pressure in sleeve 1 in the

•

black cable glove of the engine control unit

(ECU).

202 Code 4.1

Cause: Oil pressure alarm. Short to positive (+).

Response: Alarm lamp does not work. If the circuit is

interrupted during start-up, diagnostics are deactivated.

Corrective action:

Check that the wiring and connection to the alarm

•

lamp are not damaged.

32

Page 24

Group 23 EDC III Diagnostic function

35 Code 4.2

Cause: Alarm for high coolant temp. Linked to Stand

Alone interface. Short to negative (-).

Response: Alarm lamp lights constantly.

Corrective action:

Check that the wiring to the alarm lamp is not

•

damaged.

Check that the alarm lamp is fitted correctly.

•

36 Code 4.2

Cause: Alarm for high coolant temp. Linked to Stand

Alone interface. Short to positive (+).

Response: Alarm lamp does not work. If the circuit is

interrupted during start-up, diagnostics are deactivated.

Corrective action:

Check that the wiring to the alarm lamp is not

•

damaged.

Check that the alarm lamp is fitted correctly.

•

221 Code 4.3

Cause: Lamp to indicate operation. Short to

negative (-).

Response: The indicator lamp shines constantly.

Corrective action:

Check that the wiring and connection to the alarm

•

lamp are not damaged.

222 Code 4.3

Cause: Lamp to indicate operation. Short to

positive (+).

Response: Indicator lamp does not work. If the circuit

is interrupted during start-up, diagnostics are deactivated.

Corrective action:

Check that the wiring and connection to the alarm

•

lamp are not damaged.

223 Code 4.4

226 Code 4.2

Cause: Alarm for high coolant temp. Circuit interrup-

tion.

Response: Alarm lamp does not work. If the circuit is

interrupted during start-up, diagnostics are deactivated.

Corrective action:

Check the alarm lamp for high coolant

•

temperature.

Check that the wiring to the alarm lamp is not

•

damaged.

Check sleeve ”N” in the 23-pin connector.

•

Check the contact pressure in sleeve 33 in the

•

black cable glove of the engine control unit

(ECU).

220 Code 4.3

Cause: Lamp to indicate operation. Interruption

Response: Indicator lamp does not work. If the circuit

is interrupted during start-up, diagnostics are deactivated.

Corrective action:

Check the alarm lamp.

•

Check that the wiring to the alarm lamp is not

•

damaged.

Check sleeve ”N” in the 23-pin connector.

•

Check the contact pressure in sleeve 33 in the

•

black connector of the engine control unit (ECU).

Cause: Overspeed alarm. Circuit interruption.

Response: Alarm lamp does not work. If the circuit is

interrupted during start-up, diagnostics are deactivated.

Corrective action:

Check the alarm lamp.

•

Check that the wiring to the alarm lamp is not da-

•

maged.

Check sleeve ”O” in the 23-pin connector.

•

Check the contact pressure in sleeve 36 in the

•

black cable glove of the engine control unit

(ECU).

224 Code 4.4

Cause: Overspeed alarm. Short to negative (-).

Response: Alarm lamp lights constantly.

Corrective action:

Check that the wiring and connection to the alarm

•

lamp are not damaged.

225 Code 4.4

Cause: Overspeed alarm. Short to positive (+).

Response: Alarm lamp does not work. If the circuit is

interrupted during start-up, diagnostics are deactivated.

Corrective action:

Check that the wiring and connection to the alarm

•

lamp are not damaged.

33

Page 25

Group 23 EDC III Diagnostic function

203 Code 4.5

Cause: Low coolant alarm. Circuit interruption.

Response: Alarm lamp does not work. If the circuit is

interrupted during start-up, diagnostics are deactivated.

Corrective action:

Check the alarm lamp.

•

Check that the wiring to the alarm lamp is not

•

damaged.

Check sleeve ”N” in the 23-pin connector.

•

Checkthe contact pressure in sleeve 33 in the

•

black cable glove of the engine control unit

(ECU).

204 Code 4.5

Cause: Low coolant alarm. Short to

negative (-).

Response: Alarm lamp lights constantly.

Corrective action:

Check that the wiring and connection to the alarm

•

lamp are not damaged.

205 Code 4.5

Cause: Low coolant alarm. Short to positive (+).

Response: Alarm lamp does not work. If the circuit is

interrupted during start-up, diagnostics are deactivated.

Corrective action:

Check that the wiring and connection to the alarm

•

lamp are not damaged.

41 Code 4.6

Cause: Start relay on starter motor.

Short to positive (+).

Response: Engine will not start.

Corrective action:

Check that the wiring to the relay is not damaged.

•

Check the function of the relay.

•

42 Code 4.6

Cause: Start relay on starter motor.

Short to negative (-).

Response: Engine will be started -> The starter motor

engages, but no start request is made when the ignition is switched on.

Engine running -> The starter motor engages, but no

start request is made.

Engine being started -> The starter motor does not disengage once the engine is started.

Corrective action:

Check that the wiring to the relay is not damaged.

•

Check the function of the relay.

•

107 Code 4.6

Cause: Starter motor relay. Circuit interruption.

Response: Engine will not start.

Corrective action:

Check that the cable to the starter motor (yellow/

•

black) is correctly connected.

Check that the cable to the starter motor (yellow/

•

black) is not damaged.

Check that the relay on the starter motor is whole.

•

Check the contact pressure in sleeve 31 in the

•

red cable glove of the engine control unit (ECU).

108 Code 4.7

Cause: Start input, engine control unit (ECU).

Short to negative (-).

Response: Engine will not start.

Corrective action:

Check that the wiring to the ignition key/start but-

•

ton is not damaged.

Check the contact pressure in sleeve ”E” in the

•

23-pin connector.

Check the contact pressure in sleeve 17 in the

•

connector on the engine.

34

Page 26

Group 23 EDC III Diagnostic function

109 Code 4.8

Cause: Stop input engine control unit (ECU).

Short to negative (-).

Response: The engine can only be stopped using

the emergency stop on the engine.

Corrective action:

Check that the wiring to the ignition key/start but-

•

ton is not damaged.

Check the contact pressure in sleeve ”H” in the

•

23-pin connector.

Checkthe contact pressure in sleeve 6 in the con-

•

nector on the engine.

43 Code 5.1

Cause: Main relay. Short to positive (+).

Response: The instrument panel loses power when

the key is twisted to start position. The engine will not

start.

Corrective action:

Check that the wiring to the relay is not damaged.

•

Check the function of the relay.

•

209 Code 5.3

Cause: Stop input on CIU. Short to negative (-).

Response: The engine can only be stopped using the

emergency stop on the engine.

Corrective action:

Check that the connections to the ignition key are

•

not damaged.

Check that the wiring to the ignition key is not

•

damaged.

211 Code 5.3

Cause: Stop input on CIU. Short to positive (+) or ac-

tivated too long.

Response: The engine stops. After 40 seconds an error code is shown. During this time, the engine cannot

be started. When the error code is blinked out on the

diagnostic lamp, the engine can be started but not

stopped.

Corrective action:

Check that the connections to the ignition key are

•

not damaged.

Check that the wiring to the ignition key is not

•

damaged.

208 Code 5.2

Cause: Start input on CIU. Short to negative (-).

Response: The engine cannot be started.

Corrective action:

Check that the connections to the ignition key are

•

not damaged.

Check that the wiring to the ignition key is not

•

damaged.

210 Code 5.2

Cause: Start input on CIU. Short to positive (+)

or activated too long.

Response: The engine starts immediately when the

ignition is turned on.

Corrective action:

Check that the connections to the ignition key are

•

not damaged.

Check that the wiring to the ignition key is not

•

damaged.

214 Code 5.3

Cause: Stop input on CIU. Interrupted or activated too

long.

Response: The engine stops. After 40 seconds an error code is shown. During this time, the engine cannot

be started. When the error code is blinked out on the

diagnostic lamp, the engine can be started but not

stopped.

Corrective action:

Check that the connections to the ignition key are

•

not damaged.

Check that the wiring to the ignition key is not

•

damaged.

35

Page 27

Group 23 EDC III Diagnostic function

74 Code 5.4

Cause: Preheating relay. Connection interruption

Response: Preheating cannot be activated.

Corrective action:

Check that the wiring to the input on the relay is

•

not damaged.

Check the function of the relay.

•

Check the contact pressure in sleeve 36 in the

•

red cable glove of the engine control unit (ECU).

75 Code 5.4

Cause: Preheating relay. Short to negative (-).

Response: Preheating is constantly activated.

Corrective action:

Check that the wiring to the input on the relay is

•

not damaged.

Check the function of the relay.

•

76 Code 5.4

Cause: Preheating relay. Short to positive (+).

Response: Preheating cannot be activated.

Corrective action:

Check that the wiring to the input on the relay is

•

not damaged.

Check the function of the relay.

•

183 Code 5.8

Cause Oil temperature is too high.

Response: Limited engine output (if this protective

feature has not been disabled by the parameter setting tool). Alarm lamp lights.

Corrective action:

Check the oil level.

•

Check the oil temperature.

•

Check the oil system thermostat.

•

Check the function of the oil temperature sensor.

•

31 Code 6.1

Cause: High coolant temperature.

Response: TAD1240–42GE: Limited engine output (if

this protective feature has not been disabled by the

parameter setting tool). Alarm lamp lights.

TWD1240VE: Engine is switched off (if this protective

feature has not been disabled by the parameter setting tool). Alarm indicator lights.

Corrective action:

Check the coolant level.

•

Check the intercooler (cleanness).

•

Check to see if there is air in the coolant system.

•

Check the pressure cap on the expansion tank.

•

Check the function of the coolant temperature

•

sensor.

Check the function of the thermostat.

•

60 Code 6.2

Cause Intake air temperature is too high.

Response: Engine output is limited to 50% (if this

protective feature has not been disabled by the parameter setting tool).

Corrective action:

Check the coolant level.

•

Check the intercooler (cleanness).

•

Check the function of the charge air temperature

•

sensor.

Check the function of the thermostat.

•

213 Code 6.4

Cause Datalink (CAN) error, CIU.

Response: Instruments and alarm lamps stop working.

Corrective action:

Check that the 8-pin connector is not damaged.

•

Check that the wiring between the CIU and the

•

engine control unit (ECU) is not damaged.

Check that sleeves 11 and 12 in the CIU connec-

•

tor are not damaged.

Check the contact pressure in sleeves 1 and 2 in

•

the red cable glove of the engine control unit

(ECU).

36

Page 28

Group 23 EDC III Diagnostic function

38 Code 6.5

Cause Datalink (CAN) error, engine control module

(EMS).

Response: Engine not running: the engine cannot be

started.

Engine running: engine goes to idle and can only be

stopped using the emergency stop.

Corrective action:

Check that the 8-pin connector is not damaged.

•

Check that the wiring between the CIU and the

•

engine control unit (ECU) is not damaged.

Check that sleeves 11 and 12 in the CIU connec-

•

tor are not damaged.

Check the contact pressure in sleeves 1 and 2 in

•

the red cable glove of the engine control unit

(ECU).

105 Code 6.5

Cause: Datalink error (CAN).

Response: Engine not running -> The engine cannot

be started. Engine running -> Engine goes to idle and

can only be stopped with the emergency stop.

Corrective action:

Check that the 8-pin connector is not damaged.

•

Check that the wiring between the CIU and the

•

engine control unit (ECU) is not damaged.

Check that sleeves 11 and 12 in the CIU connec-

•

tor are not damaged.

Check the contact pressure in sleeves 1 and 2 in

•

the red cable glove of the engine control module

(EMS).

106 Code 6.5

Cause: Datalink error (CAN).

Response: Engine not running -> The engine cannot

be started. Engine running -> Engine goes to idle and

can only be stopped with the emergency stop.

Corrective action:

Check that the 8-pin connector is not damaged.

•

Check that the 8-pin cable between the CIU and

•

the engine control unit (ECU) is not damaged.

Check that sleeves 11 and 12 in the CIU connec-

•

tor are not damaged.

Check the contact pressure in sleeves 1 and 2 in

•

the red cable glove of the engine control unit

(ECU).

180 Code 6.6

Cause: Oil pressure is too low.

Response: Engine is switched off (if this protective

feature has not been disabled by the parameter setting tool).

Alarm lamp lights.

Corrective action:

Check the oil level.

•

Check that the oil filter is not clogged.

•

Check the system pressure valves and the safety

•

valve in the oil system.

Check the function of the oil pressure sensor.

•

110 Code 7.1

Cause: Unit injector cylinder #1. Electronic error.

Response: The engine runs on 5 cylinders, sounds

uneven and has decreased performance.

Corrective action:

Check that the wiring to the unit injectors is not

•

damaged.

Check that the connections to the unit injector are

•

not damaged.

37

Page 29

Group 23 EDC III Diagnostic function

111 Code 7.1

Cause: Unit injector cylinder #1. Electronic error.

Response: The engine runs on 5 cylinders, sounds

uneven and has decreased performance.

Corrective action:

Check that the wiring to the unit injectors is not

•

damaged.

Check that the connections to the unit injector are

•

not damaged.

112 Code 7.1

Cause: Unit injector cylinder #1. Electronic error.

Response: The engine runs on 5 cylinders, sounds

uneven and has decreased performance.

Corrective action:

Check that the wiring to the unit injectors is not

•

damaged.

Check that the connections to the unit injector are

•

not damaged.

113 Code 7.1

Cause: Unit injector cylinder #1. Electronic error.

Response: The engine runs on 5 cylinders, sounds

uneven and has decreased performance.

Corrective action:

Check that the wiring to the unit injectors is not

•

damaged.

Check that the connections to the unit injector are

•

not damaged.

114 Code 7.1

Cause: Error in compression or the unit injector on cy-

linder #1.

Response: Cylinder balance is adversely affected ->

Uneven running at low RPM and low load.

Corrective action:

Check the fuel feed pressure.

•

Check the valve clearance.

•

Check that the unit injector and connection cable

•

are not damaged.

Do a compression test and check cylinder #1.

•

115 Code 7.1

Cause: Unit injector cylinder #1. Electronic error.

Response: The engine runs on 5 cylinders, sounds

uneven and has decreased performance.

Corrective action:

Check the contact pressure in sleeve 11 in the

•

black cable glove of the engine control unit

(ECU).

Check that the wiring to the unit injectors is not

•

damaged.

Check that the connections to the unit injector are

•

not damaged.

120 Code 7.2

Cause: Unit injector cylinder #2. Electronic error.

Response: The engine runs on 5 cylinders, sounds

uneven and has decreased performance.

Corrective action:

Check that the wiring to the unit injectors is not

•

damaged.

Check that the connections to the unit injector are

•

not damaged.

121 Code 7.2

Cause: Unit injector cylinder #2. Electronic error.

Response: The engine runs on 5 cylinders, sounds

uneven and has decreased performance.

Corrective action:

Check that the wiring to the unit injectors is not

•

damaged.

Check that the connections to the unit injector are

•

not damaged.

122 Code 7.2

Cause: Unit injector cylinder #2. Electronic error.

Response: The engine runs on 5 cylinders, sounds

uneven and has decreased performance.

Corrective action:

Check that the wiring to the unit injectors is not

•

damaged.

Check that the connections to the unit injector are

•

not damaged.

38

Page 30

Group 23 EDC III Diagnostic function

123 Code 7.2

Cause: Unit injector cylinder #2. Electronic error.

Response: The engine runs on 5 cylinders, sounds

uneven and has decreased performance.

Corrective action:

Check that the wiring to the unit injectors is not

•

damaged.

Check that the connections to the unit injector are

•

not damaged.

124 Code 7.2

Cause: Error in compression or the unit injector on

cylinder #2.

Response: Cylinder balance is adversely affected ->

Uneven running at low RPM and low load.

Corrective action:

Check the fuel feed pressure.

•

Check the valve clearance.

•

Check that the unit injector and connection cable

•

are not damaged.

Do a compression test and check cylinder #2.

•

Check the fuel feed pressure.

•

125 Code 7.2

Cause: Unit injector cylinder #2. Electronic error.

Response: The engine runs on 5 cylinders, sounds

uneven and has decreased performance.

Corrective action:

Check the contact pressure in sleeve 22 in the

•

black cable glove of the engine control unit

(ECU).

Check that the wiring to the unit injectors is not

•

damaged.

Check that the connections to the unit injector are

•

not damaged.

130 Code 7.3

Cause: Unit injector cylinder #3. Electronic error.

Response: The engine runs on 5 cylinders, sounds

uneven and has decreased performance.

Corrective action:

Check that the wiring to the unit injectors is not

•

damaged.

Check that the connections to the unit injector are

•

not damaged.

131 Code 7.3

Cause: Unit injector cylinder #3. Electronic error.

Response: The engine runs on 5 cylinders, sounds

uneven and has decreased performance.

Corrective action:

Check that the wiring to the unit injectors is not

•

damaged.

Check that the connections to the unit injector are

•

not damaged.

132 Code 7.3

Cause: Unit injector cylinder #3. Electronic error.

Response: The engine runs on 5 cylinders, sounds

uneven and has decreased performance.

Corrective action:

Check that the wiring to the unit injectors is not

•

damaged.

Check that the connections to the unit injector are

•

not damaged.

39

Page 31

Group 23 EDC III Diagnostic function

133 Code 7.3

Cause: Unit injector cylinder #3. Electronic error.

Response: The engine runs on 5 cylinders, sounds

uneven and has decreased performance.

Corrective action:

Check that the wiring to the unit injectors is not

•

damaged.

Check that the connections to the unit injector are

•

not damaged.

134 Code 7.3

Cause: Error in compression or the unit injector on cy-

linder #3.

Response: Cylinder balance is adversely affected ->

Uneven running at low RPM and low load.

Corrective action:

Check the fuel feed pressure.

•

Check the valve clearance.

•

Check that the unit injector and connection cable

•

are not damaged.

Do a compression test and check cylinder #3.

•

140 Code 7.4

Cause: Unit injector cylinder #4. Electronic error.

Response: The engine runs on 5 cylinders, sounds

uneven and has decreased performance.

Corrective action:

Check that the wiring to the unit injectors is not

•

damaged.

Check that the connections to the unit injector are

•

not damaged.

141 Code 7.4

Cause: Unit injector cylinder #4. Electronic error.

Response: The engine runs on 5 cylinders, sounds

uneven and has decreased performance.

Corrective action:

Check that the wiring to the unit injectors is not

•

damaged.

Check that the connections to the unit injector are

•

not damaged.

142 Code 7.4

135 Code 7.3

Cause: Unit injector cylinder #3. Electronic error.

Response: The engine runs on 5 cylinders, sounds

uneven and has decreased performance.

Corrective action:

Check the contact pressure in sleeve 23 in the

•

black cable glove of the engine control unit

(ECU).

Check that the wiring to the unit injectors is not

•

damaged.

Check that the connections to the unit injector are

•

not damaged.

Cause: Unit injector cylinder #4. Electronic error.

Response: The engine runs on 5 cylinders, sounds

uneven and has decreased performance.

Corrective action:

Check that the wiring to the unit injectors is not

•

damaged.

Check that the connections to the unit injector are

•

not damaged.

143 Code 7.4

Cause: Unit injector cylinder #4. Electronic error.

Response: The engine runs on 5 cylinders, sounds

uneven and has decreased performance.

Corrective action:

Check that the wiring to the unit injectors is not

•

damaged.

Check that the connections to the unit injector are

•

not damaged.

40

Page 32

Group 23 EDC III Diagnostic function

144 Code 7.4

Cause: Error in compression or the unit injector on cy-

linder #4.

Response: Cylinder balance is adversely affected ->

Uneven running at low RPM and low load.

Corrective action:

Check the fuel feed pressure.

•

Check the valve clearance.

•

Check that the unit injector and connection cable

•

are not damaged.

Do a compression test and check cylinder #4.

•

145 Code 7.4

Cause: Unit injector cylinder #4. Electronic error.

Response: The engine runs on 5 cylinders, sounds

uneven and has decreased performance.

Corrective action:

Check the contact pressure in sleeve 34 in the

•