Volvo Penta MD5A Instruction Book

FOREWORD

Before you start running your new Volvo Penta marine engine, you would be

advised to read through this instruction book carefully. It contains all the

information you need to run and service your engine in the best possible way.

Volvo Penta has built up an extensive service organization with service shops and

specially trained personnel at your service.

Always contact your local Volvo Penta representative for advice and when in need

ot service and parts.

We are convinced that the demands on go od running economy and top

performance, which you have every right to expect of a quality product, will be met

and that your engine will serve you faithfully on many pleasant cruises.

WARRANTY

A warranty certificate is supplied with each engine. It contains the warranty

conditions for the engine and should be studied carefully.

Also included is a report card which is to be completed by the dealer or boat

seller. If our warranty is to apply, however, it is an absolute condition that the

measures given in the “Check and Service Scheme” are carried out and that your

engine and equipment are looked after according to the instructions in this

manual. When in doubt, always get in touch with an authorized Volvo Penta

dealer.

In all correspondence with your dealer and when ordering parts, state the type

designation and serial number of the engine and reverse gear (see starboard side

of engine).

1

Presentation

2

General Information

3 - 4

Running Instructions

5 - 6

Starting the engine

Running instructions

Shutdown procedure

5

6

6

Technical Description

7 - 9

Checks and Service Scheme

10

Checks and Service

11 - 17

Check daily before starting

Check every 14 days

Service every 50 hours of operation

Service every 100 hours of operation

Laying-up and launching

11

11 - 12

12 - 13

13 - 19

20 - 23

Fault Tracing Scheme

24

Technical Data

25 - 26

Wiring Diagram

27

Engine Component Guide

28

Index, alphabetical order

29

CONTENTS

2

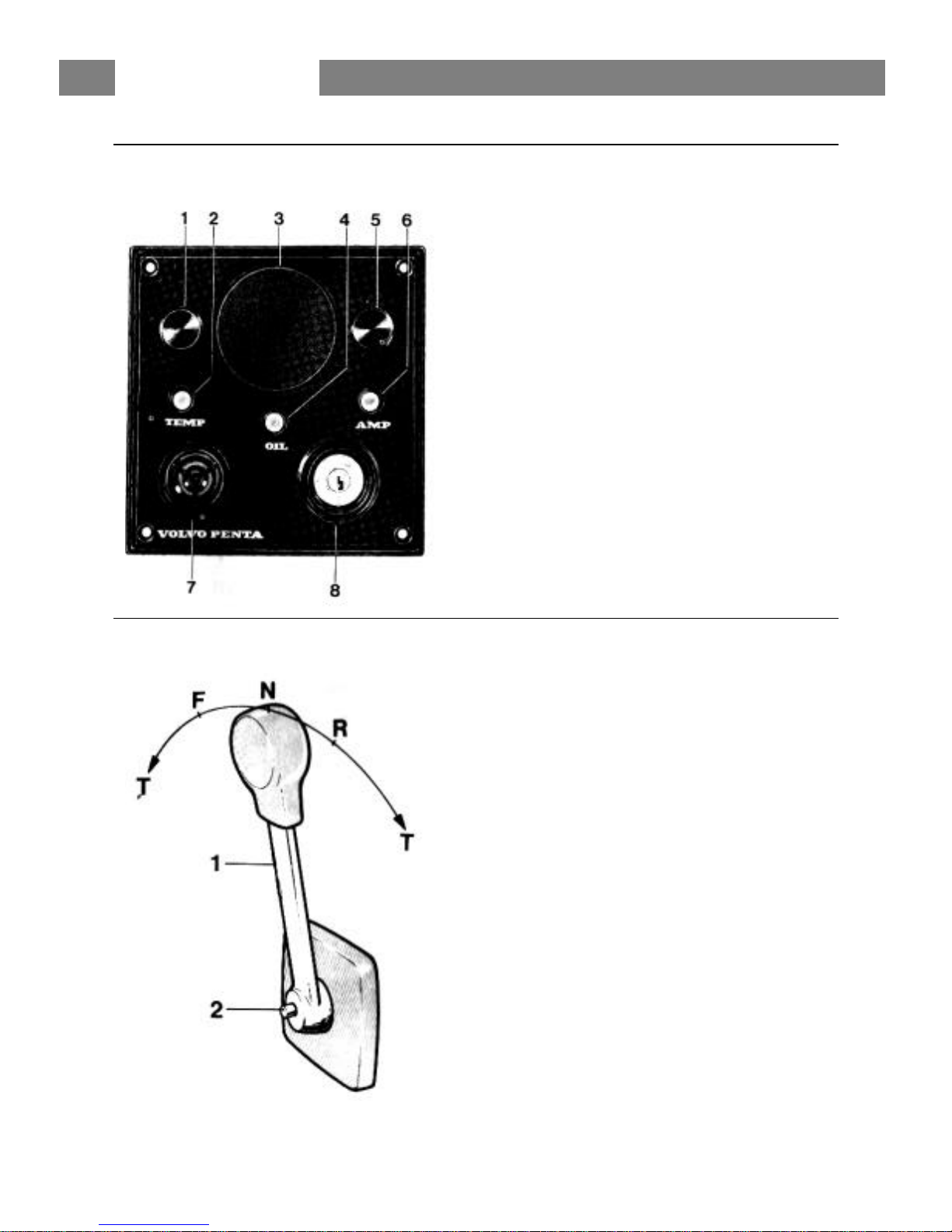

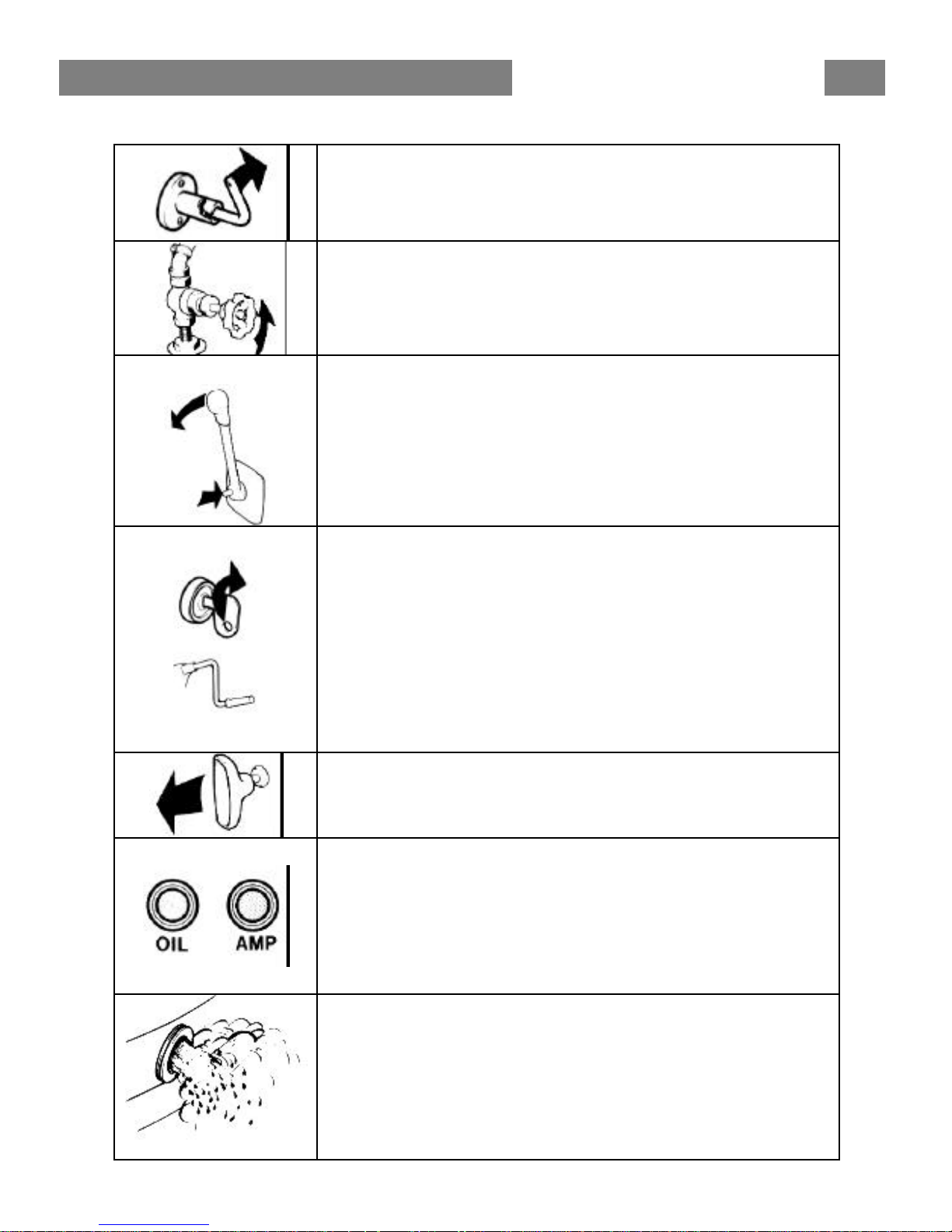

INSTRUMENT PANEL

1. Switch, optional equipment

2. Warning lamp, “Excess temp.”

3. Place for instrument (ø 52 mm opt. equipment)

4. Warning lamp, “No oil pressure”

5. Switch, optional equipment

6. Warning lamp, “No battery charging”

7. Siren, “No oil pressure, excess temp.”

8. Key switch

CONTROL SYSTEM

Volvo Penta Single Control System

For side mounting

1. Control lever

2. Disengaging button

Push in the button when the control lever is in neutral

and move the lever a bit forwards. Release button.

The lever is now used only for engine speed control.

To use the lever for both engine speed control and

gear-changing, push in the button and pull back the

lever to neutral.

N = Neutral

F = Control lever in position for running “Forward”

R = Control lever in position for running “Reverse”

T = Engine speed control

PRESENTATION

3

Important information on the function of your engine:

FUEL

Use diesel fuel oil of quality “Autodiesel”. Poorer fuel quality

can cause interruptions in operation.

LUBRICATING

OIL

Use only oil with quality CD (DS) according to the API system.

Volvo Penta oil for diesel engines can be used with

advantage since it meets these quality demands. See under

“Technical Data” concerning the viscosity.

RUNNING-IN

A new marine engine must be run-in with due care during the

first 20 hours of operation. If full output is taken out during this

time, it should only be done for short periods.

Oil change. Change the engine lubricating oil and the oil filter

after the engine has been run for 20 hours. See further under

“Checks and Service”.

ENGINE SPEED Max. speed: 41.7 rev /sec (2500 rev/mm).

For choice of correct propeller, refer to the Volvo Penta propeller diagram. Check the

engine speed with normal load in the boat. In order to utilize the maximum performance

of the engine, an engine speed as high as possible should be chosen but not, however,

greater than 41.7 rev/sec (2500 rev/mm).

NOTE. When the boat has been in the water for some time, the speed and max. rev/mm

can drop due to marine growth on the hull. Prevent marine growth by painting the bottom

of the boat with ant i-fouling paint. See under “Measures taken when launching”.

GENERAL INFORMATION

4

SAFETY EQUIPMENT

Irrespective of whether the boat is being used for long cruises or short bathing trips, the

boat should be equipped with the safety equipment listed below. It can, of course , be

supplemented further according to personal tastes. Investigate at regular intervals to

ensure that there is safety equipment on board and that it is in working order.

LIFE-JACKETS for all on board.

FIRE EXTINGUISHER, approved, at least one and installed where it is easy to get at.

DISTRESS ROCKETS and matches. Packed watertight.

FIRST-AID BOX

TOOLS suitable for the equipment on board.

ON BOARD KIT containing, e.g. impeller, etc.

ANCHOR with line.

RADAR REFLECTOR

RADIO for listening to, e.g., weather reports.

COMPASS which is deviated.

BOAT HOOK and paddle.

MOORING ROPES

FOG-HORN and whistle.

FLOATING ANCHOR

TORCH

PREPARATIONS BEFORE STARTING

Make sure that:

There is no FUEL LEAKAGE

There is no WATER LEAKAGE from engine and hull

There is no OIL LEAKAGE

There is no SMELL OF LP-GAS in the deep cavities in the boat or elsewhere

The OIL LEVEL is correct

There is enough FUEL for the planned voyage

The proper NAUTICAL CHARTS are on board for the planned voyage

If there are some other persons on board, make sure that some of them is able to

operate the boat.

If there are persons on board who have never been on a boat before, tell them where the

life-jackets are located and where the fire-extinguisher is placed. Also tell them anything

more you think necessary from a safety point of view. Should something unexpected

happen during the voyage, it is very often too late to tell those on board how safety

equipment works.

GENERAL INFORMATION

5

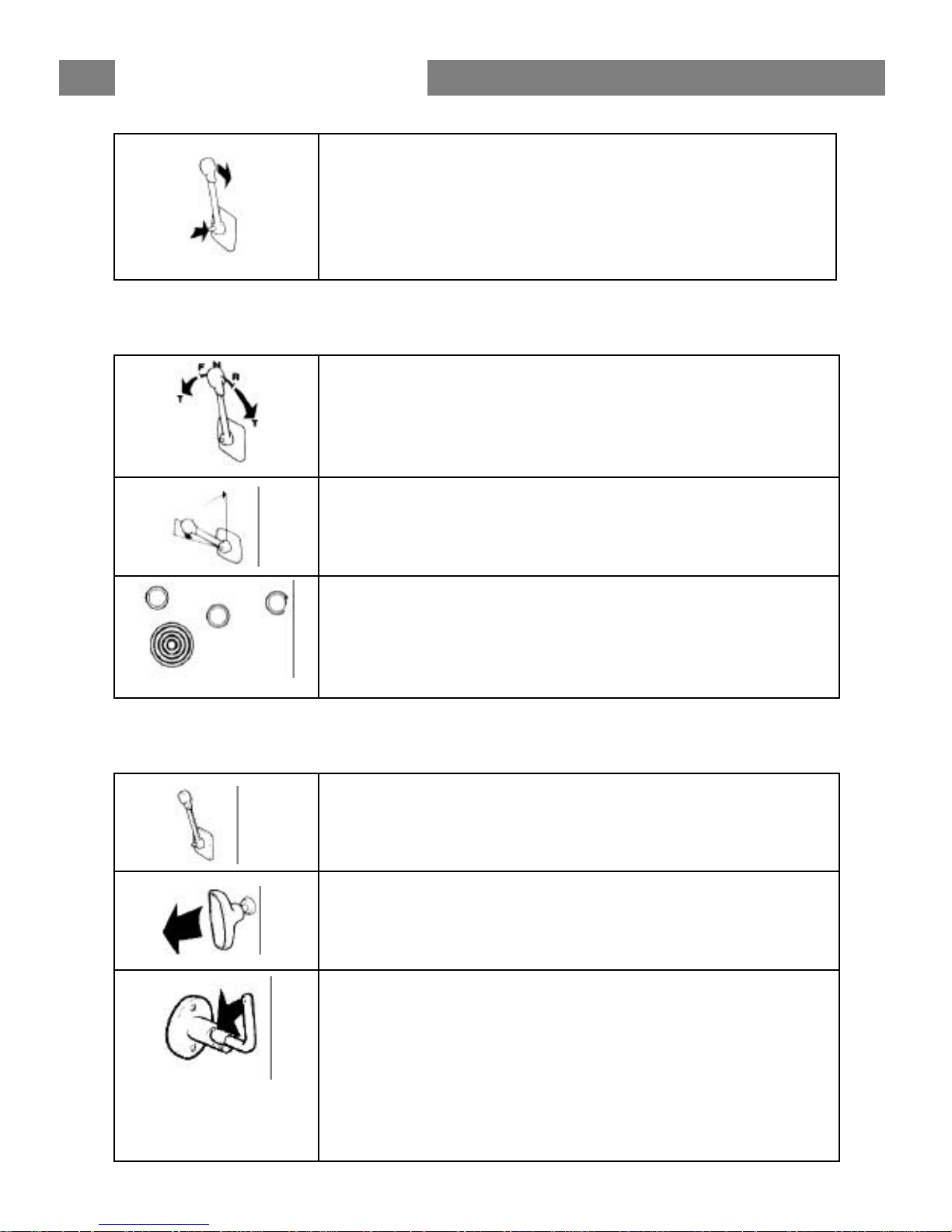

STARTING THE ENGINE

Switch on the main switch. Start the engine room fan (if

fitted) and let it run several minutes before starting the engine.

Open the cock for the cooling water intake.

Disengage the engine speed control from the gearchanging as follows:

Move the control lever to neutral, push in the red disengaging

button, and move the lever slightly forwards. Release the

button. The lever can now only operate the engine speed.

Check to make sure that the stop control is pushed in.

Turn the key switch one stage to the right. The warning

lamps for battery charging and oil press ure should now go on

and the siren should sound. Push in and turn the key further to

the right to start the engine. Release the key when the engine

starts.

Hand starter. If the engine is started with the starting crank,

the decompression handle on the rock er arm cover should first

be folded up. Fold down this handle for running when the

cranking has got the engine up in speed.

Starting in cold weather is facilitated if the cold-start control

is pulled out. Push it in again after a while.

Check immed iately after starting that the warning lamps for

the oil pressure and battery charging are out and that the siren

is quiet. If any of the lamps are on and the siren is

sounding, the engine must be stopped immediately and

an investigation made.

Run the engine warm at rapid idle. Check to make sure that

the cooling water flows out with the exhaust gases.

NOTE. The key switch should always be switched on as

long as the engine is running to ensure that there is

battery charging.

RUNNING INSTRUCTIONS

6

Reduce to idle and check that the engine is running smoothly.

Engage the control lever for gear-changing as follows:

Push in the red disengaging button and pull the lever back to

neutral. Release the button. The control lever can now be

used both for gear-changing and engine speed.

RUNNING

The single lever control has both engine speed and

manoeuvering functions.

F = Forward N = Neutral

R = Reverse T = Engine speed control

To achieve good running economy, the engine should not be

run at max. speed for a longer period.

Make sure that the battery charging warning lamp does not

light when the engine is running The siren will sound and the

respective warning lamp go on if the engine temperature

becomes excessive or the oil pressure too low.

SHUTDOWN PROCEDURE

After shutdown the engine should be allowed to idle for a

couple of minutes or so with the control lever in neutral.

Stop the engine by pulling out the stop control when the

engine is idling. Then turn back the key switch to the initial

position.

Switch off the main switch. NOTE. This switch must never

be switched off until the engine has stopped.

Close the fuel and cooling water cocks if the boat is not going

to be used for some time.

Check for leakage before leaving the beat.

In cold weather and whenever there is risk of icing, the

cooling water should he drained from the engine and reverse

gear. See under “Laying-up and launching”.

RUNNING INSTRUCTIONS

7

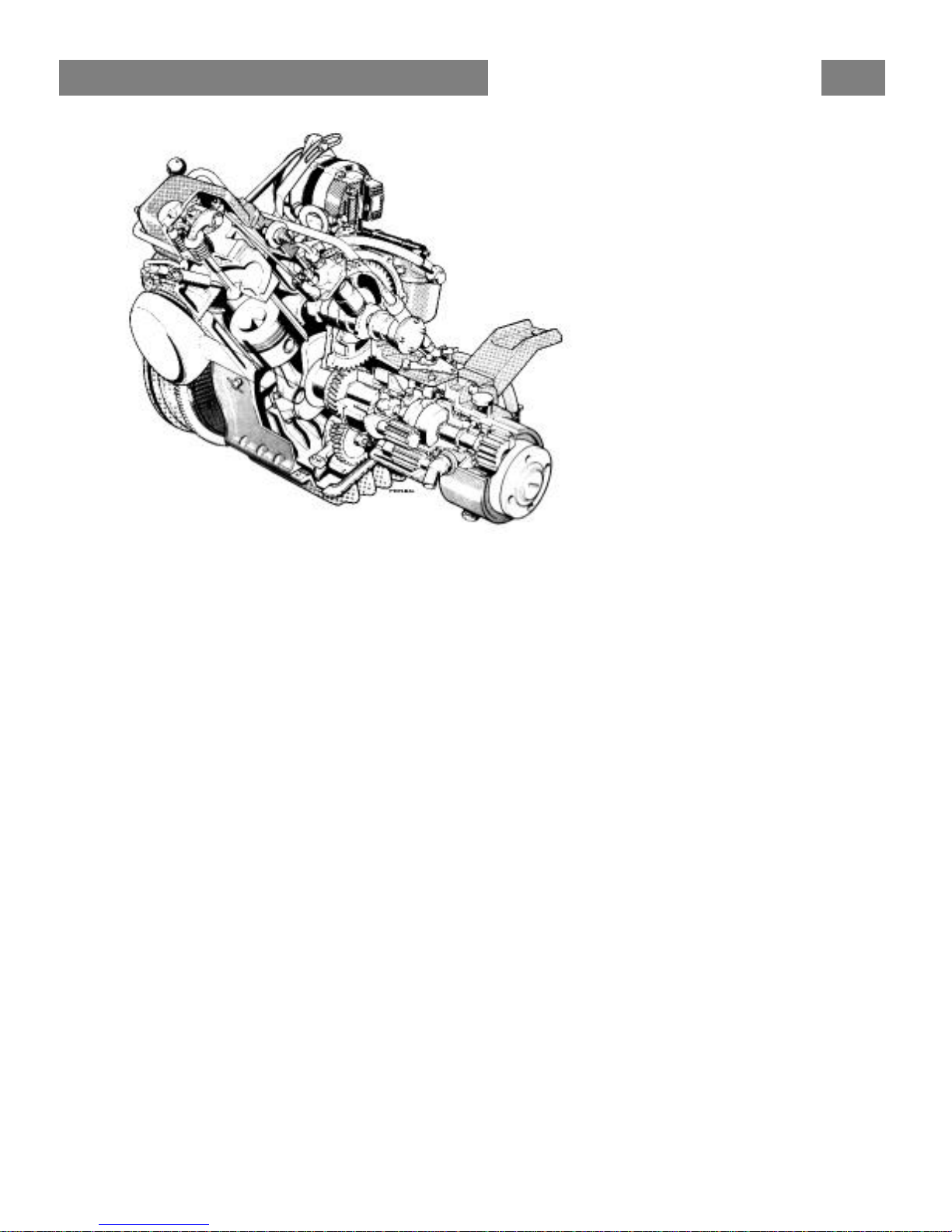

The MD5A is a single-cylinder, 4-stroke, marine diesel engine with direct injection and

sea-water cooling.

ENGINE ASSEMBLY

The engine block and cylinder head are made of cast iron. Cylinder angle 45o. The

cylinder liner is replaceable. The engine has overhead valves.

LUBRICATING SYSTEM

The lubricating system includes a full-flow oil filter which filters all the oil before it reaches

the lubricating points. A relief valve in the oil pump prevents the oil pressure from

becoming excessive.

ELECTRICAL SYSTEM

The engine has a starter motor and alternator with built -in rectifier. Voltage regulation is

taken care of by a transistorized regulator mounted on the alternator. The alternator

makes it possible to charge two battery circuits independent of each other if a charging

distributor (accessory) is fitted on the alternator.

A main fuse, which can easily be re-connected, is fixed to the engine. It protects the

electrical system from damage in the event of overloading. The wiring diagrams for the

engine and instrument panel are shown on page 27.

TECHNICAL DESCRIPTION

Loading...

Loading...