Page 1

Publ. No. 2505 B

Feb.1914

instruction

marine

carburetor

bool<

engine

MB

1OA

Page 2

FOREWORD

you

Before

read

and

service

The

dependabi

extent

the instructions

Volvo Penta

with

Always

and

also

We

are

outstanding

such as this

with

start using

instruction

this

your

engine

lity

on how

specially trained

fully

lonq

a

has built

contact

you rsqLrile

when

convinced

performance

will

period

these units

included

your

be

of

GUARANTEE

Each

engine is

purchaser

guarantee

caref

u I ly.

This certificate

boatbu

i lder.

guarantee

lf our

checking

engine

and its equipment

instructions

authorized

accompanied

guarantee

to a

is

shown in the

contains

is

procedures

in this

dealer.

ln all correspondence

state the type

front

of

designation

engine).

your

new

Volvo

book

carefully. lt

in

the best

and the lifetime

given

are

ln

this

book.

a world wide

personnel

nearest Volvo Penta

se'vice or

that

you

more

than

faithf

ul

your

at

the

demands concerning

have

satisfied and that

service.

by a warranty

concerning

warranty

report

forms

valid,

to be

in the

book. when

with

we make one

maintenance

are

always looked

in

your

dealer and

and serial number

Penta

marine

contains

possible

your

of

service and

service organization

service.

pdrts.

every right

all the instructions

way.

engine

and equipment

maintenance.

representative

to make

your

certificate

both materials

card

and we recommend

which

are filled

absolute condition

scheme are

after

doubt,

please

always

also

when ordering

of

the engine

engine,

including

should

good

on

Volvo

we

Always

running

high

a

Penta

which entitles

and Iabour.

in

by the

carried out

in accordance

contact

and reverse

recommend

you

depend

service workshops

you

quallty

will

you

need

to

to a

closely fol

need

advice

economy

product

provide you

run

great

low

and

the first

The extent

you

dealer and/or

and that is that the

and

a Volvo

spare

to

that

with

parts,

gear

of

read

penta

always

the

this

your

the

(see

to

CONTENTS

Presentation

Running

I nstru mentation and

GENERAL

Fuel

R un ni

Recommended

Precautions to

RUNNING

Procedure

Starti

Stopping

the unit

INSTRUCTIONS

lubricating

and

ng-i n

beforestartinS

ng

controls

oil

engine

speed

taken in case

be

recommendations

of frost

. . . .

4

4

4

.

5

5

5

o

Technical description

Engine unit . .

Lubricating system

Fuel

system

Cooling system

Electrical

Wiring diagram

Reverse and

system

reduction

gear

.

7

1

7

8

a

I

10

Servicing

Maintenancescheme

Periodical

General

Technical Data

servicing

servicing

instructions

......

.11

12-16

17-24

25-26

Tracing

faults in case

of running

interruptions

..27

Page 3

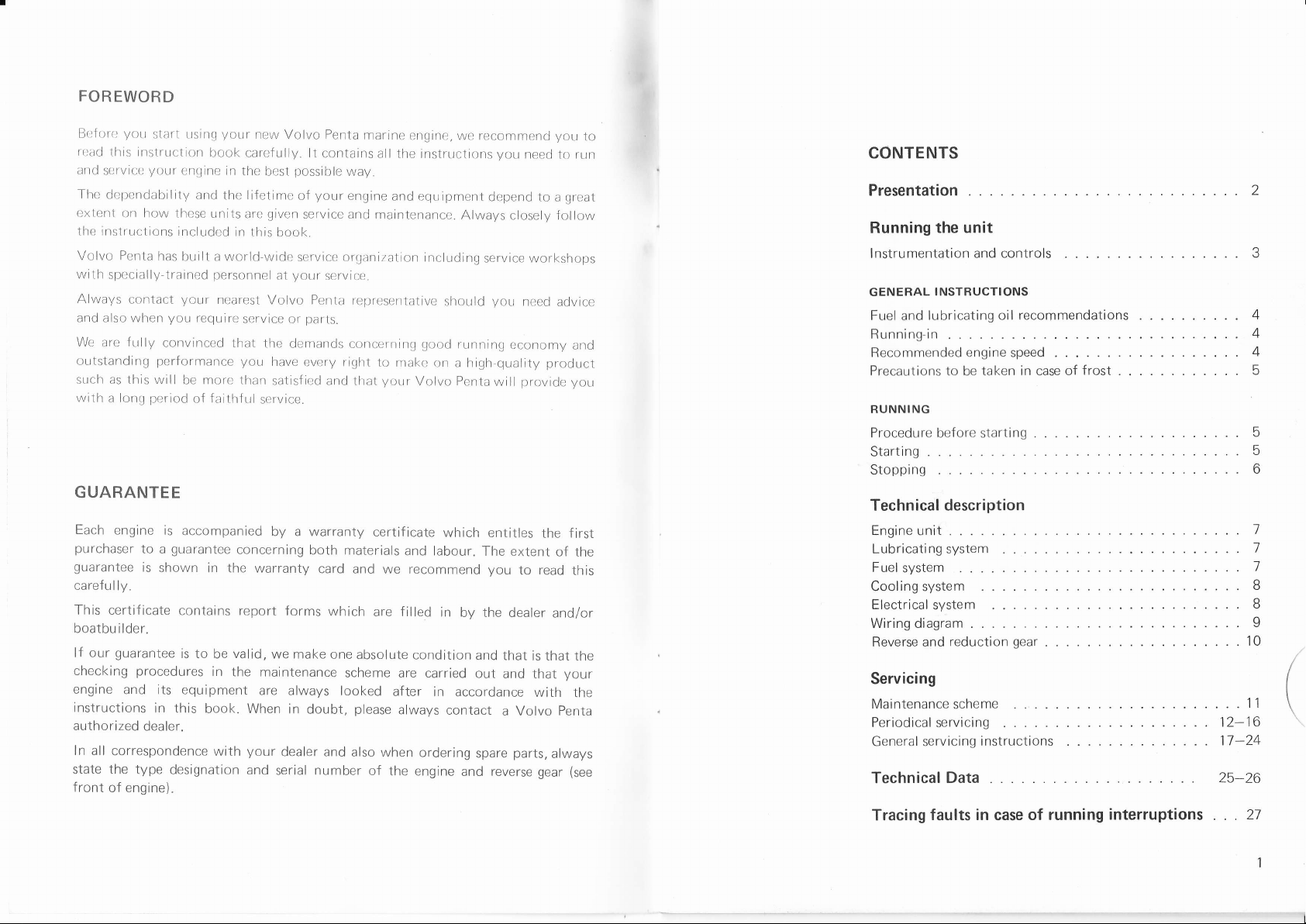

PRESENTATION

RUNNING

THE UNIT

MBlOA

2-cvl.

Fig.

1.

15 h.p.

-

MB10A, with

starboard

side

MS reverse- and

reduction

gear,

1. Distributor

2. Spark

3.

4.

5. Carburetor

6.

plug

Oilfilter

Oil

(Later

pressure

sender

with

flame

arrester

Water-cooled ex-

haust manifold

7. Rocker arm cover

gear

l\,4S. ratio

1

I

pump

primer

gear

1

gear

pump

MS,

with

engine

B. Sea-water

Oil dipstick, rever-

9.

se

1 0. Reduction/reverse

gear

1.91 : 1

1 1.

Starter-generator

1 2. Lifting eyelet

1 3. Thermostat and

water distributing

housing

14. lgnition coil

Reverse

1 5.

ratio

16. Control arm for

reverse

Fuel

17.

hand

18. Oil dipstick,

prod.)

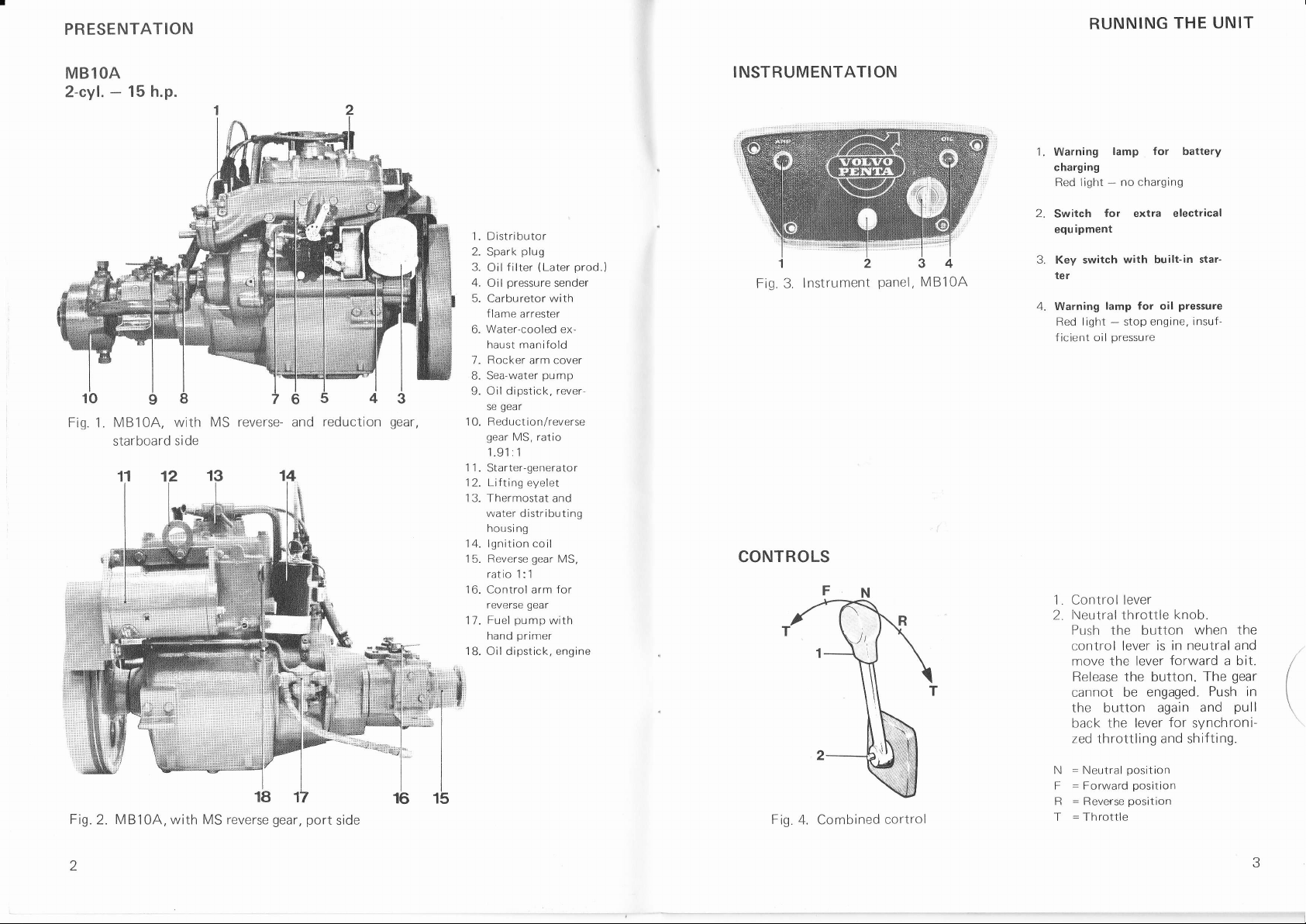

INSTRUMENTATION

Fig.3.

lnstrument

CONTROLS

panel,

MB10A

1. Warning

charging

light

Red

2.

Switch

equ

for extra electrical

ipment

3. Key switch

ter

4. Warning

Red light - stop

ficient

lamp for oil

oil

1. Control Iever

l\eutral

2.

Push

control lever is

move the lever

Release the

cannot be

the button

back the

zed

throttling

lamp f

or

charging

no

-

with built-in star-

engine, insuf-

pressure

throttle

knob.

the button

in neutral and

forward

button.

engaged.

again and

for

lever

and shifting.

battery

pressure

when

The

Push in

synchroni-

a

the

bit.

gear

pull

Fig.

2

MB10A,

2.

with MS

reverse

gear, port

side

Fig

4. Combined

cortrol

N

F

R

T

Neutral

=

Forward

-

Reverse

=

Throttle

=

position

posltion

position

.J

Page 4

RUNNING

THE UNIT

RUNNING

THE

UNIT

GENERAL

FUEL AND LUBRICATING

NOTE.

I u bricating

quality

Fuel

The engine is intended to

(Research

ROT

Lubricating

Only

Multigrade

be used

ensure

of operations.

guarantee

Our

recommendations

oi I

Method).

oil

only applies on condition

be

quality

oil SAE 1O

for

lubricating

maximum lifetime for

the engine and reverse

run on

W30

the engine

RUNNING.IN

your

When

amount of care

subject the engine to full

period

this

marine engine

during the first

that

the moving

is new, we recommend

loading for more

parts

Oil changes

During

changed more frequently

oil

the running-in

filter

after 20 hours of operation, see also under

RECOMMENDED

your

lf

propeller

the

loaded

boat. See under

NOTE.

engine

When the

speed can decrease if there is marine

therefore

regular

intervals.

1)

Previous

get

are

to

is

anti-fouling bottom

designation

period,

ENGINE

the very best

selected so

"Technical

has

boat

"For

the engine

than

that maximum engine

been in

paint.

Service

INSTRUCTIONS

OIL RECOMMENDATIONS

that the following fuel

are f ol lowed :

petrol

with

an octane

quality

with

and

designation

gear.

This oil contains additives

gear

reverse

that

20 hours of operation.

than

brief

wear in together.

reverse

and

usual. Change the engine oil, reverse

"Servicing",

SPEED

performance

Data".

the

water

growth

Check and clean the

MS".

from

for

your

speed

some

on

rating of minimum

"For

Service SE"1)

under different conditions

you

run

During this

periods,

gear

considerable time, maximum

the bottom of the boat. Use

because

lubricating oilshould be

points

boat, it is important that

reached

is

bottom of the boat at

and

is to

which

it with a

certain

time, never

is

it

during

gear

oil and the

4.

3 and

with a normally

B0

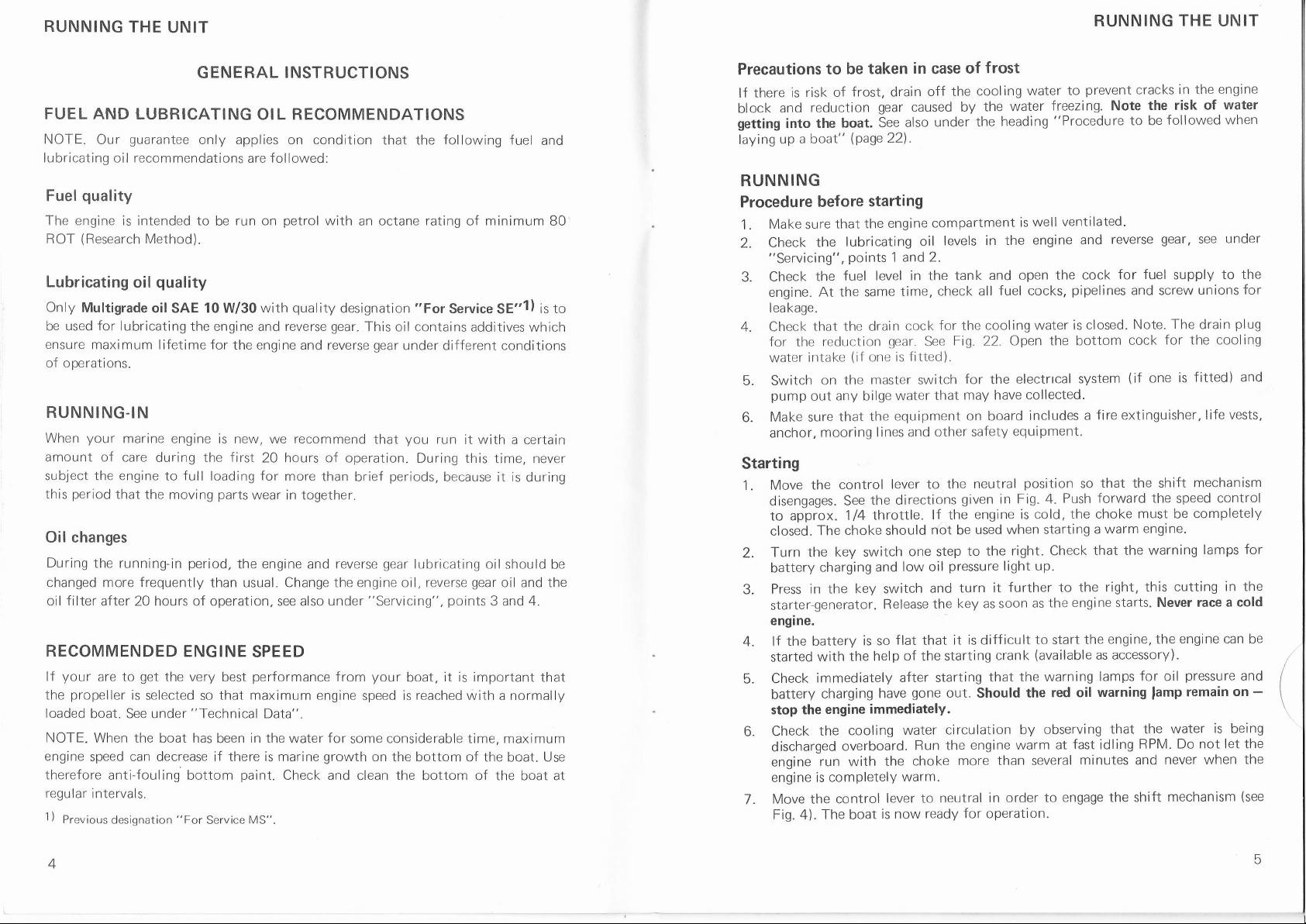

Precautions

risk of

lf there

block

getting

laying

is

and

into

up

a boat"

reduction

the boat.

RUNNING

Procedu

1 .

2.

3.

4.

re bef ore

Make

sure

the

check

"Servicing",

the

Check

engine-

leakage.

Check

At the same

that the drain

for the

intake

water

5. Switch

pump

out

Make sure

6.

anchor,

Starting

the control

Move

1.

disengages.

approx.

to

2.

3.

4. lf

5.

6.

1.

The

closed.

Turn the

battery

Press

starter-generator.

engine.

charging and

in the key switch

the battery

with

started

immediately

Check

battery

stop the

Check

discharged

engine

engine is completely

the

run with

Move the

Fig. 4).

taken

to be

frost, drain

(Page22).

starting

that the

lubricating

points

fuel level

reduction

(if

one is

on the

mooring

master

any

bilge

the

that

the directions

See

1/4

choke should

key

switch

is so

the

charging

engine

immediatelY.

cooling

overboard.

control

The

boat

in

case

of

off the

gear

See

engine

1 and

caused

also

by

under

compartment

levels in

oil

2.

in the tank

check all

time,

for the

cock

gear.

Fig. 22. Open

See

fitted).

for

switch

that may

water

equipment on board

to the

lever

not

one step

low oil

and

flat that

other safety

given

lf the

be

to the

pressure

turn it

key as soon

the

it is difficult

starting

lines and

throttle.

Release

help of the

after starting

gone

water

Run the

choke

warm.

out.

circulation by

more than several

for operation.

have

the

lever to neutral

is now ready

frost

cooling

the

neutral

engine is cold,

used when starting

Should

engine warm

water to

well

is

engine and

the

freezing. Note

"Procedure

ventilated'

the cock

the water

heading

and open

fuel cocks,

cooling water is

the bottom

electrrcal

the

have collected.

includes

equipment.

position

Push

Fig.

in

4.

right. Check

light up.

further to

the

as

to

start

(available

crank

the warning

that

red oil warning

the

observing

at

in order

to engage the

the choke

prevent

cracks in the

the risk

followed

to be

fuel

for

and screw

Note.

cock

(if

one

gear,

supply to

The

for the cooling

reverse

pipelines

closed.

system

fire extinguisher,

a

that the shift

so

forward the

must

be

a warm

engine.

that the warning

starts.

engine,

lamps

that the

idling

shift

this cutting

Never race

the

for oil

lamp

water

RPM.

mechanlsm

the right,

engine

the

as accessory).

fast

minutes and never

engine

of water

when

under

see

the

for

unions

plug

drain

fitted) and

is

life vests,

mechanism

control

speed

completely

lamps for

in the

a

cold

engine can

pressure

remain

Do not let the

and

on

is

being

when the

(see

be

-

4

Page 5

RUNNING THE UNIT

Stopping

idle

position

position

and let the engine

when the engine has

off before the engine has completely

(if

fitted)

and close

for

some considerable time.

for

more than two weeks,

(see

under

Move the control

1.

at idling

Turn the key

2.

The

stopped.

3. Switch

cocks if the unit is to remain idle

lf

4.

measures must be taken with the engine

remain idle").

speed before stopping it.

master switch must never be switched

off

the unit is

lever to neutral

switch

master

the

to remain

to neutral

switch

lf the engine has electrical equipment, this equipment

regularly

with

f luid which

protects

agalnst corrosion and moisture.

fuel

the

"Procedure

run

stopped.

and

special

some

cooling

inhibiting

if

unit is to

minutes

NOTE.

water

should be sprayed

TECHNICAL

DESCRIPTION

TECHNICAL DESCRIPTION

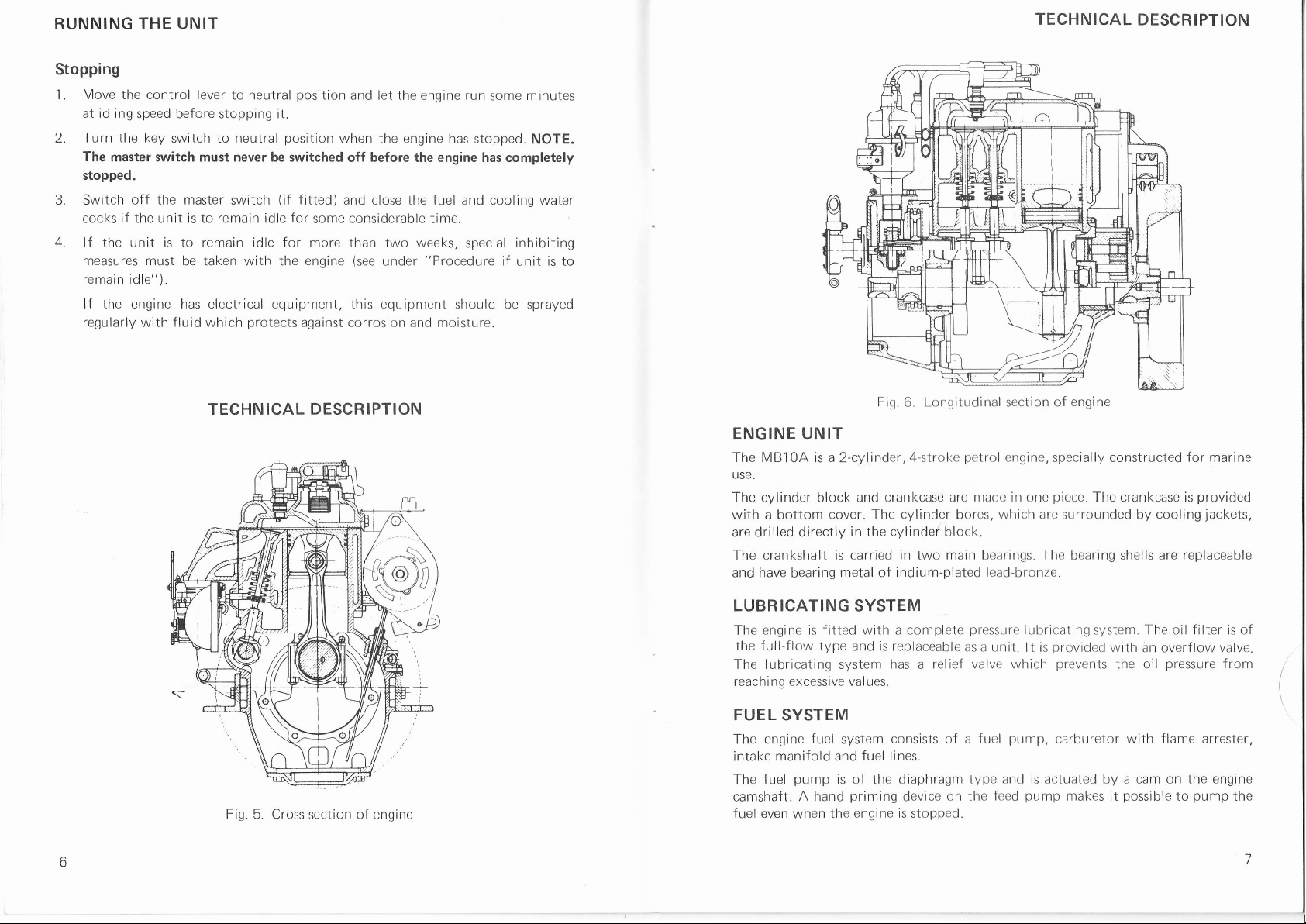

Fig.

5. Cross-section

of

engine

ENGINE UNIT

The MBl0A is a

use.

The

cylinder block

with a bottom

are drilled directly

The crankshaft is

and have

bearing

LUBRICATING

The engine is

the full-flow

2-cylinder,4-stroke

and crankcase are made in one

cover. The cylinder

in the

carried in

metal of

SYSTEM

fitted

with a complete

type and is replaceable

The lubricating system

g

reachi n

excessive val ues.

FUEL SYSTEM

The engine

intake manifold and

The fuel

camshaft. A hand

fuel even when

fuel

system

fuel lines.

pump

is of the diaphragm

priming

the engine is stopped.

Fig.

Longitudinal section of

6.

petrol

engine,

which are

bores,

cylinder

indium-plated lead-bronze.

has

consists of a

block.

main

two

relief valve which

a

bearings.

pressure

as a unit.

pump,

fuel

type and is actuated

device

on the

feed

engine

specially constructed

piece.

The

surrounded

The

bearing shells are

lubricating

lt is

system.

provided

prevents

carburetor

with an overf low valve.

the oil

by

pump

makes it

for

marine

crankcase is

by cooling

The oil filter is of

with

a cam on the engine

possible

provided

replaceable

pressure

flame

pump

to

jackets,

from

arrester,

the

Page 6

TECHNICAL DESCRIPTION

TECHNICAL

DESCRIPTION

COOLING

engine and

The

thermoitat

is taken

The

of

the

the

On

thermostat.

manifold

thermostat

on to

conveyed

i nsta I led.

The

causes

cooling

the

irrespective

care of by

pump

neoprene

sea through

exhaust

top of

are

the water-cooled

cooling water

the thermostat

channels before

cooling water

SYSTEM

reduction

controls

which

is

driven

rubber

means

from the

and

the

manifold

engine

the

When the

filled with

is closed,

overboard,

circulation

size

of the

gear

are sea-water

temperature

the

of

sea-water

a

camshaft

operates

water intake.

ing

cool

there

engine

iackets

is a water

is cold,

cooling water

the surplus

exhaust

depending

engine

in the

to open

it enters

so

engine

of the

cooled

of the

pump

through

cam.

The

and

a

water

fi

lls

is then

the

against

distributing

the cooling

which

passes

water

elbow

where

whether

on

cooling channels

force the

and

exhaust

the

that

the

load.

engine always

the system

and

engine"

mounted

flange.

a

The

Cooling

on

The

pumpsucks cooling water

forced under

water

engine

housing

channels

is

through

in the

rapidly

the distributing

it mixes with

a wet or dry

rapidly

is

cooling

water to

water circulation

timing

the

pump

pressure

channels.

provided

engine and

heated up.

exhaust

the

exhaust line

heated up and

elbow. Thethermostat

the right

has

fitted with a

is

gear

housing.

ler is made

impel

through

exhaust

when the

housing

gases

has been

pass

the

thus regulates

temperature

from

with

and

or

this

engine

Warning!

following

The

Never break the circuit between the alternator and

is running. To

Do not

a

is

under

Wiring diagram,

Cable marking

switch off

"Servicing",

Mark Colour sq.mm.

Black i.5

Black 2.5

lvory i.5

lvory 6

Red 2.5

Red

6

Red 16

Brown 1.5

Green 1.5

Blue 1-5

to

applies

engine fitted

an

with alternator and master

battery while

this would be to ruin the charging regulator immediately.

do

the master switch until the engine has

point

16.

stopped. See

MB10A

I N5IRUMENI

IN5TRUiltNT

AWG

15

13

15

o

13

I

5

15

t5

4E

switch:

the engine

also

Fig.

7. Setting

The

A

= Setting

B

Setting

=

ELECTRICAL

electrical

The

USC.

engine is

The

starter

equipped with a starter-generator,

motor are combined

I

A

the two-way

can be

cock

with

SYSTEM

system

locked in

with drY

wet

voltage

has a

and

for outgoing

cock

the

exhaust

exhaust

of 12

are driven

desired

line

line

volts and

by

cooling water

position

is

which

vee-belts

B

a screw, see

with

designed

means

from the engine

specially

that

the

arrows

for marine

generator

f

lywheel.

and

Components

1. Key switch

2. Warning lamp f or

3. Battery

charging warning lamp

4. Switch {extra)

5. Connection terminal

6. Connection

terminal

l. Battery

"low

oil

pressure'

Fiq.8.

Wiring diagram,

BA starter

Sl

8.

9.

10.

11.

12.

13.

14.

generator.

Master

switch

Starter-generator

Charging

Fuse

pressure

Oil

lgnition coil

Distributor

MBl0Awith

regulator

sensor

I

Page 7

TECHNICAL

DESCRIPTION

PERIODICAL SERVICING

Fig

Wiring diagrams,

1.

9.

Key

ter co

starter

switch

ntact

generator

with star-

2. Extra switch

3.

Battery

4. Oil

5.

ning lamp

pressure

lamp

Connector

charging

warning

6. Connector

gear,

Reverse

The Volvo

alternative,

type Mono

Penta reverse

reduction

a

integrally built with

Power is transmitted

For manoeuvering

clutch

The

with increased

is used. With

Very

little

engaging

transmission

force

is

power

torque. The

throttling.

7. Oil

lgnitlon

8.

with Bosch

pressure

sender

coil

MB10A

9. Distributor

war

1 0.

1 1. Cable

12.

13. Charging

Starter

Fuse

generator

harness

regulator

14. Battery

15.

Shift

gear,

gear

the reverse

f rom

"Forward"

engine to reverse

the

(MS)

type Mono Shift, has a

wlth reduction ratio

gear.

"Reverse",

and

gear

the

6

through a

ratio of

1.91:1.

The

rubber f

Volvo Penta

reduction

patented

switch

Master

this type of clutch, engagement is both smooth and

required

to operate the

of the cone clutch

greater

the torque, the stiffer will be the clutch

gear.

reverse

is influenced by the size of

and, as

i:1

gear

lange.

quiet.

power

the

engagement

cone

MAINTENANCE

numbers of the servicing

The

following

the

knowledge and

out

carried

See

point

2

.t- Change oil

4.

5. Clean oil strainer

6.

1. Check vee-belts

8.

9.

'1

0. Check battery

11

12.

13. lgnition timing and distributor

14. Adjust

i5. Cooling system

i6.

11

.

is

18.

1

Or

)

2) Daily bef ore starting

Every other

3)

4) Change

by

PERIODICAL

Check oil

Check oil level in reverse

Chanqe oil in reverse

Clean air cleaner

Check valve clearances

Check and clean fuel filter

Check

GENERAL SERVICING

Check-tighten cylinder

Electrical

Check

Procedure if unit

i nhi biti ng

once each

year

the oil

SCHEME

procedures

pages.

Some

of these

the use of special

an authorized service

Operation

SERVICING

level

in engine

gear

in engine and change oil filter

and reduction

plugs

spark

head

reduction

is

remain idle and

to

level

INSTRUCTIONS

electrolyte

chanqe

and

carburetor

system

reverse and

should this occur

season

operations require specialized

tools. For this

workshop.

qear

bolts

gear

first

for f irst time

or when engine is

filter

after every 100 hours running or once each season

taken

out of boat

refer to the detailed descriptions

below

reason,

these

Every

14

days

azl

azl

o

To be carried out

according

given

vals

points

tive

necessary

operations

)

Afterl

50 hours

ru nni ng

.4)

a

a

a

a

to the inter-

under

or when

mechanical

should

Afterl)

1

hours

0O

runni

ng

3)

o

o

respect-

on

be

10

11

Page 8

PERIODICAL

SERVICING

PERIODICAL

SERVICING

1.

Checking

Check

located

is

level

above

Remove

and

Fig. 10. Checking

Fig. 10. Checking

oil

the oil

the

on

must never be

upper

the

the dipstick

viscosity, see

2.

Checking

The

level daily

located

max. min. marks

the

quality

oil

oil level

MS reverse anh

before starting

the starboard

on

level). When necessary,

oil

and

in engine

level

in the engine

level

port

side

allowed

mark since

plug

point

3.

engine oil level

engine oil level

in reverse and

reduction

on the dipstick

viscosity, see

of the

to

this

(see

for the

side of

point

daily before

engine

go

down

result in abnormally

can

Fig. 12\ to

I

reduction

gear

has a

first time

reverse

the

(which

top up

4.

starting

has upper and

and

the

below

fill

with

Fig. 11.

gear

separate oil

must

with

gear.

not

the

The

be Screwed

with new oil

for the

lower

f

irst time.

lower

mark and

markings.

high oil

oil. Concerning

Checking

1.

2.

compartment.

help of the dipstick

oil

(see

reverse

f illing

Oil

Dipstick

level should

down when

Fig. 11). Concerning

1,

The

dipstick

The oil

should

not

it

consumptlon.

quality

oil

the

gear

oil

Check the

which

between

be

measuring

level

the

the

be

oil

Change

changed.

changed

The oil

Unscrew

loosened,

screwdriver

Make sure that

filter

contact

the oil

filter is changed

rubber

with the

Tighten

idling speed

Always check

Quality

Service SEl

Previous designation

1)

Gl--

tt

æ;,"-,!'

is

filter after every

ln the case of

for the

fi

rst time after

the old

filter

use

special tensioning

a

can be used

that

the contact surface

gasket

contact surface

{ilter a further

the

checking to

while

the oil

)

a new or

fol lows:

as

(see

oil and screw

with

level

after

Viscosity

Multigrade oil

SAE 1OW/30 approx.

Service

\

I

s

(

100 hours

reconditioned

hours running

20

Fig

12bl .lf

tool or

as a lever.

against

of the

half turn but

make sure

changing

MS

$m

:&

F

å

,lk-"

::

;

running

remains firmly in

it

pierce

Remember that

the

on the

engine block.

no

there is

the oll

capacity,

Oil

Excl. oil

at the same

engine, the

"Running-in

(see

the outer

oil can spill

engine

block

fi lter

more.

by

Start

hand

no leakage at the

filter or changing

litres

filter

(1

1 .5

.3

1 .6) 1.75

=

time as the

oil filter should also be

the engine").

position

part

and cannot

the

of

out.

clean. Smear the

is

just

until it

engine and

the

filter.

engine oil.

the

(lmp.

qts.

=

filter

lncl.

I

1.85)

oil is

filter

with

comes into

run it at

qts.)

US

(1

=

55

be

a

new

3.

Changing

Change

During

Run

with the

srick

enqine

Concerning

12

the

lubricating oil

the

running-in

the

the engine warm

help

hole. The scavenging

afterremoval

the

engine oil and

after every

period

before

of a scavenging

pump

plug

of the

quality

oil

and

oil filter

50 hours

the oil should

changing

pump,

through

viscosity, see

oil.

the tube of

is supplied

which the dipstick

running

changed after 20

be

or at

The oil issucked

which

inserted

rs

with the tool

the table.

hours of

each

season.

operation.

least once

upfromthe'crankcase

see

the dip-

to

Fig. 12a.

through

kit.

is tnserted,

Oil

is added

the

Fig.

Hole for oil fi lling

12a.

Fi

g.

1 2b. Oi

I f ilter

13

Page 9

PERIODICAL

SERVICING

PERIODICAL

SERVICING

4.

reverse

Changing

Change

running or at

During

The

of an oil scavenging

to the upper

oil in

lubricating oil

the

least once

running-in

the

is drained through the

oil

pump

mark on the oil dipstick, see

each

period

oil

quality

Service SE1

Previous

1)

5.

Cleaning

An oil strainer

cleaned in white spirit

the

boat.

designation

the

oil strainer

a new

Use

is

with oil.

6.

Cleaning

The air cleaner should be

once

1.

Clean the

2.

Allow

3.

the air cleaner

each

season.

Release the lock screw

cleaner in white spirit and soak

air

engine

the

7.

Checking

Check the

due to wear or

the

vee-belts

vee-belttension afterevery 50 hours

grease.

Multigrade oil

)

SAE 1OW/30

built

at least

gasket

to run off and

oil

gear

in the reverse

season.

the oil

through

Viscosity

"Service

into the

for the

removed and cleaned

reduction

and

gear

should

reverse

gear

the hole

table below.

MS"

engine

bottom

every other

bottom

with a screwdriver

re-fit the cleaner.

gear

gear

and reduction

changed after

be

hole or is

drain

for

the dipstick.

(lmp.

litres

gear

red.

excl.

min. I

0.35

(0.31

0.37

rna*.

0.45

(0.40

=

0.48)

)

cover.

year

or when

cover and

Oil capacity

check

after every 50

20 hours of

sucked

When adding oil,

qts.

US

=

incl. red.

I

lmin. I

0.50

(o.44

=

0.53)

The oil strainer should be

the engine

for leakage after

after every 100 hours

and remove the cleaner. See

The

oil.

belts

it in engine

running.

hours

operation.

up with the help

f ill up

qts.)

gear

max.

0.60

(0.53

0.64)

is

taken

=

out of

=

filling

running,

Fig.

13.

can

start slipping

or

I

tension

Fig. 13. Cleaning

shows

Test the belt

tor and

under

an alternator

lf

possible

fa n.

lf the belt

the alternator

at

outwards and

tensioning by

flywheel. lt should

normal

thumb

get

the

to

is insufficiently

re-tigh.ten

air cleaner, arrow

lock

is

pulley

)

screwl

pressing

pressure,

fitted, the vee-belt

to slip by

tensioned,

attaching

the screws.

possible

be

Fig.

see

points.

Fig. 14. Checking

the belts

in

14.

turning with

loosen the tensioner

Tension

midway between

press

to

tension

one

the belt by

them in

should be

finger a wing on

belt

the starter-genera-

about 3-4

so hard that

well as

arm as

(1/8")

mm

is

it

the alternator

the

bolts

moving the alternator

just

8.

clearances

Ghecking

Check

each

adjustment

should

valve

the

season.

carried

be

valve clearances

engine

Concerning

wlll involve

out

valve

grinding

an authorized

by

every 100

after

clearances, see

valve stem

ends

Volvo

under

and

Penta

hours running

"Technical

and

seats

workshop'

service

or at

Data".

for this

least once

Any valve

reason

this

9.

filter

filter

that

fuel

cleaned

pump

fuel

re-fit

and

Pump

gasket

the

so that the

with clanrp

every 50 hours

after

clean and

it, with the

forward

does

fuel

remove the

fuel

with

leak. lf the

not

pump

at least once

running

pins

the hand

drive

or

cover and

facing upwards. Check

primer

pumping

cam

alters

its

filter,

fuel

carefully

and

effect is

position.

each

see

the

poor,

lf an

Checking

I

ll

The fuel

season.

Wash the outside

Fig.

packing

check

turn

1) Late

and cleaning

filter should be

Clean the

15.

and re-fit

make

to

prod.

engine a bit

type

over the

of the

the cover.

sure

provided

14

15

Page 10

PERIODICAL

SERVICING

SERVICING

extra fuel filter

should

Qrain

element

10.

be

cock in the

should

with water separator is fitted

checked for

Cleaning fuel f

any water in

bottom of the filter

changed

be

at

ilter

Checking electrolyte level

Check

between 5 and 10 mm

whenever

and cause corrosion

match

11.

Checking

Check the

electrode

type

replaced

that

also that

battery

the

necessary.

gas

since

and

spark

gap

should

gauge.

lf

the

immediately. lf

you

always

plugs

the

electrolyte level

(1

14

Never add

damage. Never check the electrolyte

formed

in

the battery cells is

changing

plug

gap

and

be 0.7

electrodes are

necessary,

get

the right

are tightened

the spark

fuel.

the

container.

least

once each

Fis.

in battery

at

and 112"1 over

much

too

plugs

wear at least

(0.028")

mm

burnt

or

clean the

type of

spark

to the correct

(Fig.

15), the

The

water can

Look out for fuel

season.

15.

fuel filter

Extra

tor

least

every 14

the

since the electrolyte

highly

after every

and this must

the insulation

plugs

plugs

torque.

days.

plates.

cell

explosive.

50 hours

be checked

damaged, the

with

with the

(See

transparent container

be removed

The level

Add

can then

level

through

splash. The filter

',*

Itlkail

with

water separa-

should

distilled water

splash out

using a lighted

by

of operation. The

by using a wire

plugs

wire

a

brush. Make

correct heat range

Technical

Data.)

the

æ., \,

\

must be

sure

and

be

GENERAL SERVICING

12.

Check-tightening

With a new

bolts

should

Concerning

Fig.

16.

13.

lgnition

All

adjusting

workshop with

is one

leads

serious

The ignition

IGNITION TIMING

The ignition

specified

flywheel

the

engine or when

should be

also be

Tightening

cylinder head bolts

re-tightened after

carried out

tightening

timing

work

the

of the most sensitive

to decreased

engine damage.

timing and the distributor

timing

the Technical

in

timing marks,

cylinder

torque, see

sequence

head bolts

the cylinder

20 hours

each

once

"Technical

for

head has

running.

season

and distributor

on the engine ignition system

equipment

special

engine

is checked

parts

output, high fuel consumption

Data On

see

required

the engine and interference

of

should be checked

only with the help of a stroboscope

pump

Fig.

the oil

'1

7.

INSTRUCTIONS

been removed, the

Check-tightening

and always

Data".

@

with

o@

o

should be

for

this

housing there

carried out by a service

purpose.

and, in the

once

cylinder head

of the bolts

torque

a

The ignition system

here immediately

each

is a notch and on

wrench.

worst cases,

season.

at the speeds

to

11

Page 11

SERVICING

SERVICING

DISTRIBUTOR

Check the contact

lock

Turn

gap,

A

correctly located vertically

are

screw

surfaces.

breaker

contacts

each other. The

the

Lubricate the

lubricating wick

the

distributor.

lnspect the distributor cap

that the center

Check

breaker

engine

the

in Fig.

gap

can be adjusted

for

the attaching

distributor

(i)

under

contact

18, which should

points

which must not

until the

over

plate

with a

rotor. Lubricate

the

for

cracks and clean all contact

stud

breaker

so

turning the

by

has

been slackened.

few

drops of

is

loose

not

0.4 mm

be

that the faces

also with oil the lubricator

and

-)

be burned on the contact

points

are

(0.016").

fixed

engine

is

not

fully

open

Make

are completely

contact

(2,

oil in the

surfaces thoroughly.

worn. See

and check the

sure that the

opposite

Fig.18),

drive shaft

(3)

under

Fig.

19.

after

14.

Adjusting

The

service

Adjusting the idling speed

1.

2.

the carburetor

carburetor should

workshop.

when the throttle

Check

of the control cable

sleeve

each

side

and

lever

Run the

Adjust

unevenly,

make sure

clearance

the

of

partly

with the control

engine warm and check

idling

the

adjust the air screw

that

according

"dice".

the connection sleeve

be checked

control

has a clearance

Adiustments

(1,

screw

point

to

1.

and adjusted

is in neutral

can be

lever.

idling

the

Fig.

(2)

when necessary.

20)

even

until

for

authorized

by an

position

of

mm

1.5

made

speed, see

\1

partly

under

116"1

running is obtained.

the control

cable has the

Penta

Volvo

that the connecting

(A,

Fig.20)

the carburetor

with

"Technical

the engine

lf

Data".

runs

Check to

proper

on

1B

Fig. 17.

Timinq

marks

Fig. 19. Distributor,

Fig. 18. Distributor, adjusting breaker

contacts

checklng contact surfaces

15.

Cooling system

cooling

The

system

The thermostat

removed.

slroLrld

can be

clrrtckr:d

lxt

insJ-rcclt:d

regularly

aftt:r thc

Fig. 20. Carburetor, Solex 26VBN2

'1

ld ling screw

.

2. Air screw

1.5 mm

housing

(1/16")

etc.

has been

A

=

for leakage, deposits,

water distributor

19

Page 12

SERVICING

SERVICING

REPLACING

pump

The

of water

pump

Close the

1.

risk

shaft

reach the

protection

Pull

2.

new impeller.

3. Fit the cover

a

Fig.21

16.

Electrical

CHECKING THE

The

state of charge of

is done by using a

this varying

CABLES AND CABLE TERMINALS

At regular

none

STARTE

All work on the

an authorized

engine

THE SEA.WATER

impeller

deficiency

impeller is changed

is made

caused by, for example,

as

bottom cock.

of water

with the

the impeller off

getting

pump

retaining

bolt

under the

into

impeller

screwdrivers in order

the shaft. Clean the inside

with its original

spare impeller on board.

Removing

.

Arrow

lock bolt

impeller.

points

to impeller

system

STATE OF CHARGE

the battery

hydrometer which

with the state of charge.

intervals check that all

of the

R-GENERATOR

given

is

is

cables

damaged.

starter-generator

service

qeneral

a

workshop.

overhaul.

PUMP IMPELLER

of neoprene rubber

fol

Remove the

the impeller.

lows:

the boat.

out of the

and this

blocking

cover

With the

housing as far

See Fig

from

can be damaged

of the

the

sea-water

help of two

as

NOTE. Place

21.

not to damage

pump

of the

gasket

which has the right

Open the bottom

OF THE BATTERY

should be checked at least once each

shows the specific

(See

cable terminals are

(and

alternator

lnspection and control

under

cock.

"Technical

fitted)

lf

thickness. Always

gravity

Data".)

properly

should be carried out by

should be done when the

in the case

sea-water inlet. The

pump.

Note the

in

some

and

season.

pullthe

order

kind

housing.

fit

have

This

screwdrivers

necessary

the impeller

housing

of the electrolyte,

tightened and that

the

NOTE. This is

The battery

grease

or

WARNING!

lf the alternator

to

of

important

Never break

1.

running. The

ru ined.

The master switch

stopped.

Never confuse

2.

stamped

earthed to

be

Use only

3.

generator.

ln the case

4.

Let

battery

englne starts

ordinary batlery.

Never use a

5.

Always disconnect

6.

alternator

electric

7. lf

disconnect

Check

8.

particularly

poles

and

vaseline.

and its regulator are

that the

following instructions

the circuit between

result will be a short-circuit

with a

the engine block.

Volvo

of

starting

ordinary battery

the

to the

disconnect

rapid charger while

equipment.

welding work

the charging

vee-belt tension and

important when

cable clamps should be

must never

the battery

plus

and a

Penta double

be switched

poles

minus sign

diode

using a spare

by

remain

ordinary battery,

the spare

the alternator

battery

both

is to be carried

regulator

cable

the engine is

well tightened and smeared

function

to

are followed:

the alternator and

in the

off before

one another.

with

respectively.

kits when charging

battery,

connected

plus

cables before

cables at

connections at

to

battery

out

plus

but never

on the engine

the alternator

fitted with an alternator.

perfectly,

battery

while the engine

regulatorwhich

the engine

poles

The

The minus

two

batteries

this should

in circuit.

minus to

and

is connected

carrying

be done

Connect

break

to

out any

the circuit to

or installation units,

and insulate.

regular intervals.

it is extremely

is immediately

has completely

generally

are

pole

must always

from one

follows:

as

the

minus. When

the battery.

work on

with

is

spare

the

the

the

17.

remote

the lock

gear

checked regularly

that there

gear.

When

control should be

nut

and turning

for

oil leakage,

no

is

gear

reverse

completely off-

the cable

constant

enga-

is

"dice".

Ghecking

reverse

The

abnormal

remote

When

pressure

ged

loaded.

on the control

"Forward"

for

Adjust if

reverse

the

gear

noise or excessive

control

gear

reduction

and

is connected,

components

"Reverse",

or

necessary by loosening

reduction

and

gear

should be

operatinq temperature.

it must be so designed

of the reverse

the

20

21

Page 13

SERVICING

SERVICING

18.

Procedure

IDLE PERIOD WITH BOAT AFLOAT

ln

case

should be

damage to

lf

the engine is to remain

should be inhibited,

Protect

spraying unpainted

protection

We also recommencl

the case

PROCEDURE

Before the boat is taken

service

compression test on the

PREPARE THE

WATEB AS

1. Run the engine

and

Fill

2.

if

unit is to remain idle

of

an idle

started and

the internal

the engine

spray.

period

see

and equipment from external

surfaces and electrical

that the

of

longer intervals of

BEFORE LAYING UP

workshop

reverse

up the engine

test the engine

ENGINE

FOLLOWS:

gear

warm,

with the

of

less than one

run

warm

parts

of

idle

"Procedure

under

cylinders are

idleness.

up on land for

engine.

FOR LAYING UP BEFORE

stop it and

help

reverse

and

dlpstick. Suitable inhibiting

corresponding oils of

another make.

3. Run the engine off-load for

after

at least every

the engine.

for

a longer

laying up, it

and reverse

pump

of

the

gear

with

oils are Esso

about

5 minutes.

with the

month

period

than one month,

before laying up"

corrosion

components with corrosion

sprayed through the

is advisable to let an

gear.

lt is also

THE BOAT IS

all the lubricating oil

scavening

pump.

inhibiting

Rust Ban

boat afloat, the engine

prevent

14 days

to

damage by regularly

spark

advisable to carry out a

LIFTED

oil to the lowest mark

623, Shell

corrosion

then

engine

the

and moisture

plug

holes in

authorized

OUT OF THE

out of the engine

on the

Ensis

Oil20

c. Disconnect

intake

disconnect the suction line between

intake

lnstead connect a

d.

sufficient

m

ixtu

the

from the

from

to

re.

suction

reduction

Lhe

reach down to the bottom

e. lnsert the connected suction

let it run at idling until the

forming a

this

protective

let the engine run dry since

Then

connect

the coolinct water

f. Drain all cooling

Fig.

22. The rustproofing mixture does not

engine is fitted with a wet exhaust line, this should also be

lf the

frost.

drained of water. When a

cooling water through the

the cooling water

Drain

S.

impeller

shaft

Remove the

over the

or

(see

remain in

spark

engine

under

position

plug

several

line

pump.

When a

112"

from

water

pump

"Servicing",

and

and spray

turns before

between

gear.

rubber

the cooling water

the

gear

reduction

reduction

hose, the

is

length of which

of the containerwith

hose into the container. Start

water has been

sucked

oil film in all the cooling channels.

this can damage the cooling water impeller.

hose.

engine

the

by opening the drain cock, see

protect

reduction

plug

re-f it the

gear

fitted, this

is

in the bottom of the reduction

removing the

by

point

each cylinder with inhibiting

re-fitting

15)

cover.

the spark

forwinter

pump

and bottom

f

itted to

gear

the reverse

and

the

rustproofing

the engine and

out of the contatner,

NOTE. Never

the engine against

should be drained

gear.

pump

cover. Take

storage.

Let

oil. Then turn

plugs.

gear,

bottom

should

out the

the drive

be

of

AFTER

PROCEDURE:

1.

THE

lnhibit

Drain off all cool

a.

opening the

by opening the

Mix rustproofing

b.

lmp.

should

Donax C or

NOTE. Always add the oil to the water and never the other way

22

BOAT HAS BEEN LIFTED

the cooling

system

as follows:

ing water

(on

cock

drain

plug,

drain

agent in a container filled

galls.

4112 US

-

be of the emulsifying type, for example, Esso

similar.

galls.)

Add

ASHORE,

from

the

starboard side) and from

Fig.

see

of fresh

rustproofing

20 %

CARRV OUT THE FOLLOWING

engine

the

Then

22.

water. The

close the cock and

oil to the water and stir well.

and exhaust manifold

the reduction

drain

with at least 20 litres

rustproofing

agent used

Cutwell 40,

gear

plug.

(3

1/2

Shell

around.

by

Fig.22.

1.

Dr,rin,.ock

Drain

2.

Drain cock

pluq

for oooling water, reduction

for

cooling water,

(

fr'r

ooling water, engine

engine

gear

LJ

Page 14

SERVICING

TECHNICAL DATA

J-

Clean the outside of the engine

paintwork.

them with

battery and

be

put

kept in

good

the rustproofing

3 and 4.

reverse

and

impeller in

connect all hoses and check-tighten

gear

the cooling water

4.

touch up

system by

Bemove

damaged

spraying

the

intervals if it ls to

PROCEDURE WHEN LAUNCHING

Pump

1.

2.

3.

4.

out

all

"Servicing",

points

Fill the engine

points

Fit

point

Clean the outside of the engine

3

the

15, and

and 4.

pump

the operating controls.

Take a

5.

NOTE.

The

Grease in the

Remove the

6.

generator

tops of the

"Technical

CIose the drain cock

gear.

Launch the

8.

pump

tank,

leakage.

Start

9.

5*6. Run the

there is

fully

charged

battery

Be careful not to confuse the

negative battery

battery

spark

pole

cable

plugs

should be

clamps with

and

turn over the engine

in order to blow out any rustproofing

pistons.

Data"

NOTE.

for

Open the bottom cock

and fill the fuel tank. Clean

boat

forward fuel with the help of

lines,

connections and cocks to be

the engine and follow carefully the

engine

no leakage

of

Prevent

their tightening torque.

for

the cooling system. Note. The

for

warm with the reverse

fuel,

water, oil, air or exhaust

it immediately. Check the bolts and nuts

10.

Contact an authorized Volvo Penta

gear

engine and

reverse

carried out as specified in the maintenance scheme.

reverse

and

Protect

corrosion and moisture

it into

gear

with white

all

unpainted

parts

protective

storage. lt must be

spirit

and the electrical

spray.

re-charged

condition.

oil from

with

the engine

and

lubricating oil,

pump,

reverse

see under

see under

gear,

the hose clamps.

and

on

reverse

board

earthed

gear

of rustproofing

and connect up the

(see

cables

grease

under

to

the engine.

or vaseline

several turns with the

battery cables.

"Servicing", point

before tightening.

oil which may be on

plugs,

spark

plug

for

(see

Check thoroughly the

that

given

lf there is,

the

oil

splash.

cooling

the hand

Re-fit the

water intake.

fuel filter

the

primer.

absolutely sure

running

for

service workshop and have servicing of the

instructions

gear

engaged. Check

gases.

tightness.

or

similar

regular

at

see unCer

"Servicing",

"Servicing",

oil and

adjust

starter-

see

reduction

the

point

9) and

there is no

on

to make

attend to

and

16).

the

under

pages

sure

General

Type desingation

Max. output,

Max. speed,

Number

Type of operation

Displacement,

Bore mm

Stroke,

Compression

Compression

ldling

Total

Max.

Valves

Valve clearances,

lnlet

Exhaust valve,

Valve

lnlet valve,

Exhaust

Reverse

Type designa

Ratio

Ralio with auxiliarV

h.p.

r.p.m.

of cylinders

(cu.

cc

(in.)

mm

speed,

weight, approx.

inclination of

valve, mm

clearances,

"Forward"

{in.)

ratio

pressure

r.p.m

mm

valve, mm

gear

t ion

. .

warm

mm

cold

and

Lubricating system

Engine

quality

Oil

V iscosity

capacity,

Oil

excl.

incl.

Oil

Reverse

Oil

Oil

Oilcapacity

1

)

Adjustment

2)

Previous

engine, litres

filter

filter

pressure,

quality/Viscosity

capacity.

warm engine,

gear

litrer

with auxiliary

is carriåd

desiqnation

in.

)

({ully

open throttle), speed,

(lb.),

kg

enqine in boat

enginel

{in.)

(in.)

i

enginel

(in.)

(in.)

"Reverse

gear

(lmp.

idling speed,

at full speed,

(lmp.

qt.

out

bv

"service

engine

underway

)

qts.

US

=

gear,

grinding

MS"

+

=

qt.)

litre

reverse

qts.),

US

tp/cm2

kp/cm2

. . .

(lmp.

valve stem

gear

approx.

qt.

kp/cm2

(p.s.i.)

{p.s.i.)

USqt.)

=

ends and

(p.s.i.)

seats

. . .

.

MBiOA

15

2000

in-line

2

Side-valve,

carburetor

1018

88.9

82

6.5:1

7.5

600

1 15

1Bo

0.30 {0.012)

o.35

0.35

0.45

Volvo Penta MS

1.1

1 91:'1

l\/lultigrade

Service SE2)

SAE

1.5

1.75

1-2

4

Same

0.4

0.55

(3.23\

1101\

(253)

(1.3

l51l

(0.35

{62.1 )

(3.50)

(0.014)

(0.014)

(0.018)

1OW/30

=

(1.55

r4-28)

as engine

=

(o.48

4-stroke

engine

oll

1.6)

=

0.42)

=

1.85)

O.5B)

14

25

Page 15

SERVICING

Fuel system

pressure,

feed

ROT,

system

Bosch type

(in.)

(in.)

(in.)

type

min.

. .

ing,

.

.

Carburetor, Solex

jet

Main

ldling

iet

Float valve

pump

Fuel

grade

Petrol

rating

Octane

lgnition

Cylinder

Spark

Early

Distributor, Bosch type

Late

Distributor, Bosch type

marking

plugs,

mm

Gap,

prod.

Basic setting

Stroboscope sett

Gap, mm

Cam angle

prod.

Basic setting

Stroboscope setting,

Gap, mm

Cam angle

Electrical system

Voltage, volts

capacity, Ah max.

Battery

capacity, Ah max.

Battery

electrolyte specif

Battery

Fully charged battery,

to be re-charged

Battery

Starter-generator,

type

Generatoroutput,W

output, h.p.

motor

starter

Starter-generator,

Generator output, W

Starter

Tightening

Cylinder bolts,

plugs,

Spark

Flywheel

Connecting

type

motor output,

torques

(lb.ft.)

kpm

kpm

{lb.ft.)

kpm

(lb.ft.)

(nut),

rod nuts, kpm

26 VBN2

102.5

45

1.2

o.2

80

1 nearest f lywheel

W175T35

correspondi ng

spark

other

0.7

kplcm2

(p.s.i.)

.

JF20231 109 014

30 after

1200

12OO

r.p.m

r.p.m.

oao

0.4

600

JF2O231 109 015

20

1 10

0.4

600

12

(SIBA

(BOSCH

gravity:

ic

9/cm3

at

iba

S

,..

STARTER

STARTER GENERATOR)

GENERATOR)

. .

g/cm3

.,.....

34

60

1.275*1 .285

1.230

DS418

60

0.8

Bosch LA/Ej

. . .

h.p.

(lb.ft.)

135

1

8.3

3.8

38

5.5

(3)

plug

make)

(0.028)

T-D.C.

(0.016)

t

30

(before

(0.016)

a

30

90/2900

max.

(60)

127.51

12151

(40)

(alt.

of

T.D.C.)

9O kont

TRACING

fault-tracing scheme

The

operation.

to trace most

nearest Volvo

Follow the

FAULTS IN CASE OF RUNNING

With the help

of the causes

Penta

service

instructions in the

reliability.

(L

o

o

Hs

o

o

c

o

.;

o

o

o

c

.E

'a

qD

uJ

u.l

X

x

X Fuel

X X X

X X

X

X

9rE

-o

os

(:€

6=

0q

OE

6F

c13

'FE

uJ

ii

X X

X

X

X X

å>

oG

=F

or

LO

øc

E-O

JO

oo

,86

På

llt

>

X

includes only the

below

of the instructions

mentioned

workshop.

servicing scheme

G

o

o

o

o

tr

'6,

ur

X

FAULT TRACING

Master

discharged

tank

fLrel f ilter blocked

Water

Faulty spark

Burnt breaker

distributor

ldling speed

Boat abnormally

Marine

Propeller damaged

Blocked cooling

or cooling

pump

INTERRUPTIONS

more usual

given

in this book

below. ln case of doubt

ensures the best

this

-

not' on: battery

switch

or broken electric cable

empty, fuel

or impurities in

plugs

points,

and ignition cables See

not

growth

iackets,

impeller or thermostat

cock closed,

fuel See

moisture in

properly

loaded See

boat bottom See

on

adjusted

water intake

defective

reasons for faulty

it is usually

possible

always contact

running

Remarks

pages

See

-21

page

See

page

page

See

page

page

See

page

page

pages

See

20

the

15

1

17

4

4

16

1

20

6

9

1

9,

,/6

27

Loading...

Loading...