Page 1

OPERATOR’S MANUAL

Volvo Penta IPS

Page 2

This Operator’s Manual may be ordered in a diffe-

rent language free of charge up to 12 months after delivery,

via internet.

http:// manual.volvopenta.com/coupon/

If internet access isn‘t possible, please contact your

Volvo Penta dealer.

Tämä käyttöohjekirja on tilattavissa Internetin kau-

tta veloituksetta eri kielillä 12 kuukauden ajan toimituksen

jälkeen.

http:// manual.volvopenta.com/coupon/

Jos sinulla ei ole Internet-yhteyttä, ota yhteys lähimpään

Volvo Penta jälleenmyyjään.

Diese Betriebsanleitung kann bis zu 12 Monate

nachder Lieferung über Internet kostenlos in einer anderen

Sprache bestellt werden.

http:// manual.volvopenta.com/coupon/

Wenn Sie keinen Internet-Zugriff haben, kontaktieren

Sie bitte Ihren Volvo Penta-Händler.

Ce manuel d‘utilisation peut être commandé gratuitement sur Internet en différentes langues, jusqu‘à 12 mois

après la date de livraison.

http:// manual.volvopenta.com/coupon/

Veuillez contacter votre Distributeur Volvo Penta si vous

avez un problème d‘accès à l‘Internet.

El presente libro de instrucciones puede solicitarse

en otro idioma diferente, libre de cargo, hasta 12 meses

después de la entrega, mediante internet.

http:// manual.volvopenta.com/coupon/

Si no se tiene acceso a internet, contacten al su concesionario Volvo Penta.

Il manuale per l‘operatore può essere ordinato tra-

miteInternet, in varie lingue e per consegna gratuita, entro

12 mesi dalla consegna del prodotto

http:// manual.volvopenta.com/coupon/

Se l‘accesso a Internet risulta impossibile, contattare la concessionaria Volvo Penta.

Este Manual do Operador pode ser encomendad

em idiomas diferentes isento de custos até 12 meses após

entrega, via internet.

http:// manual.volvopenta.com/coupon/

Se não for possível aceder à internet, contacte o seu concessionário Volvo Penta.

To παρόν Βιβλίο Χρήσης μπορεί να παραγγελθεί

δωρεάν σε άλλη γλώσσα μέχρι 12 μήνες μετά την

παράδοση,μέσω διαδικτύου.

http:// manual.volvopenta.com/coupon/

Εάν δεν είναι δυνατή η πρόσβαση στο ιαδίκτυο,παρακαλούμε

επικοινωνήστε με το δικό σας αντιπρόσωπο της Volvo Penta.

Данное руководство по эксплуатации можно

бес-платно заказать на другом языке по Интернету в

течение 12 месяцев после доставки.

http:// manual.volvopenta.com/coupon/

Если доступ к Интернету отсутствует, обратитесь к

своему дилеру компании Volvo Penta.

Bu Kullanım Kılavuzu, teslimden 12 ay sonrasına

kadar İnternet yoluyla ücretsiz olarak farklı bir dilde sipariş

edilebilir.

http:// manual.volvopenta.com/coupon/

İnternet mümkün değilse, lütfen Volvo Penta yetkili

satıcınızla tmasa geçin.

Denna instruktionsbok kan beställas via internet på

ett annat språk gratis i upp till 12 månader efter leverans.

http:// manual.volvopenta.com/coupon/

Kontakta din Volvo Penta-återförsäljare om du inte har tillgång till internet.

购,交付后可免费使用达12 个月。

http:// manual.volvopenta.com/coupon/

如果无法访问互联网,请与沃尔沃遍达经销商联系。

Dit instructieboek kan gratis via internet in een a

dere taal worden besteld tot 12 maanden na aevering.

http:// manual.volvopenta.com/coupon/

Als toegang tot het internet niet mogelijk is, neem dan

contact op met uw Volvo Penta dealer.

em um idioma diferente, gratuitamente, até 12 meses após

a entrega, via internet.

http:// manual.volvopenta.com/coupon/

Caso o acesso à internet não for possível, contatar seu distribuidor Volvo Penta.

Denne instruktionsbog kan bestilles gratis på et an-

det sprog via Internettet i op til 12 måneder efter leveringen.

http:// manual.volvopenta.com/coupon/

Hvis det ikke er muligt at bestille via Internettet, bedes du

kontakte din Volvo Penta forhandler.

CALIFORNIA PROPOSITION 65 WARNING

Engine exhaust, some of its constituents, and a broad range of engine parts are known to the State of California to cause cancer, birth

defects, and other reproductive harm. Additionally, lubricants, fuels, and other uids used in engines – including any waste created

through the wearing of engine parts – contain or produce chemicals known to the State of California to cause cancer and birth defects or

other reproductive harm.

Battery posts, terminals, and related accessories contain lead and lead compounds. Wash your hands after handling. Used engine oil

contains chemicals that have caused cancer in laboratory animals. Always protect your skin by washing thoroughly with soap and water.

後最高12か月間、インターネットより無料で発注可能です。

http:// manual.volvopenta.com/coupon/

インターネットにアクセスできない場合は、担当のボル ボ ペンタ

ディーラーまでご連絡ください。

本操作手册可通过互联网以不同的言进行订

Este Manual de operador pode ser encomendado

このオペレーターズ マニュアルの他言語版が、発行

Page 3

Content

Foreword ...................................................................................................... 2

Safety Information

Introduction ................................................................................................. 8

Instruments and Controls ........................................................................ 10

Optional ..................................................................................................... 36

Starting ...................................................................................................... 56

Operation ................................................................................................... 59

Engine Shutdown ...................................................................................... 64

Fault Handling ........................................................................................... 67

Fault Code Register .................................................................................. 71

In Case of Emergency .............................................................................. 75

Maintenance Schedule ............................................................................. 81

Maintenance .............................................................................................. 84

Storage ..................................................................................................... 116

Calibration and Settings ......................................................................... 120

Technical Data ......................................................................................... 129

Alphabetical index .................................................................................. 135

...................................................................................... 3

47705796 05-2014 © AB VOLVO PENTA 1

Page 4

Foreword

Volvo Penta marine engines are used all over the world. They are used in all possible operating conditions for

professional as well as leisure purposes. This is not a coincidence. After 100 years as an engine manufacturer

the Volvo

long service life. We also believe that this is what you demand and expect of your Volvo Penta engine.

We would like you to read this operator’s manual thoroughly and consider the advice we give on running and

maintenance before your maiden voyage so that you will be ensured of fulfilling your expectations. Please pay

attention to the safety instructions contained in the manual.

As owner of a Volvo Penta marine engine, we would also like to welcome you to a worldwide network of dealers

and service workshops to assist you with technical advice, service requirements and replacement parts. Please

contact your nearest authorized Volvo Penta dealer for assistance.

You will find your closest dealer at our home page on the Internet www.volvopenta.com - amongst other

useful information about your Volvo Penta engine - we invite you to visit!

Penta name has become a symbol of reliability, technical innovation, top of the range performance and

2 47705796 05-2014 © AB VOLVO PENTA

Page 5

Safety Information

!

Read this chapter very carefully. It has to do with your safety. This describes how safety information is presented

in the operator’s manual and on the product. It also gives you an introduction to the basic safety rules for using

and looking after the engine.

Check that you heave received the correct operator’s manual before you read on. If not, please contact

your Volvo Penta dealer.

This symbol is used in the operator’s manual and on the product, to call your attention

to the fact that this is safety information. Always read such information very carefully.

Safety texts in the operator’s manual have the following order of priority:

DANGER!

Indicates a hazardous situation which, if not avoided, will result in death or serious

injury.

WARNING!

Indicates a hazardous situation which, if not avoided, could result in death or serious

personal injury.

CAUTION!

Indicates a

personal injury.

IMPORTANT!

Indicates a situation which, if not avoided, could result in property damage.

NOTICE! Used to draw attention to important information that will facilitate work or

operations.

This symbol is used on our products in some cases and refers to important information

in the operator’s manual. Make sure that warning and information symbols on the

engine are clearly visible and legible. Replace symbols which have been damaged or

painted over.

hazardous situation which, if not avoided, could result in minor or moderate

47705796 05-2014 © AB VOLVO PENTA 3

Page 6

Safety Information

Your new boat

Read the instruction books and other information

carefully, which came with your new boat. Learn to

handle

safe and correct manner.

If this is your first boat, or a type of boat you are not

experienced in using, we recommend that you practice operating the boat in peace and quiet. Get to know

the way the boat reacts to sea and to the controls

under different speed, sea and loading conditions

before you cast off for your first “real” maiden voyage.

Remember that the captain of every boat is required

by law to know and to observe applicable rules for

traffic and safety at sea. Get to know the rules which

apply to you and your waters, by contacting the relevant authority or sea safety organization.

It is a good idea to go on some kind of boat operation

course. We recommend that you contact a regional

boat or sea safety organization to find a suitable

course.

engine, controls and other equipment in a

the

Daily checks

Make it a habit to give the engine and engine bay a

visual check before driving (before starting the

engine) and after operation (when you have stopped

the engine). This helps you to quickly discover

whether any leakage of fuel, coolant, oil or any other

abnormal event has happened, or is about to happen.

Fuel filling

There is always a risk of fire and explosion during fuel

filling. Smoking is not permissible, and the engine

should be stopped.

Never over-fill the tank. Shut the tank cap securely.

Only use the fuel recommended in the instruction

book. The wrong grade of fuel can cause serious malfunctions, power loss or stop the engine.

Do not start the engine

Do not start the engine if you suspect a fuel or LPG

leak in the boat, close to explosive media, or if there

is a spillage of explosive media. An explosive environment entails a risk of fire and/or explosion.

Manoeuvring

Avoid sudden or surprising rudder movements and

gear shifting.

over, or overboard.

A rotating propeller can cause severe injury. Check

that there is nobody in the water before you engage

forward / astern (reverse) drive. Never drive close to

bathers or in areas where you could reasonably

expect that people could be in the water.

There is a risk that passengers could fall

Accidents and near misses

Life saving statistics show that inadequate care of

boats and engines, and deficiencies in safety equipment are frequent causes of accidents and near

misses at sea.

Make sure that your boat and engine are maintained

in accordance with the advice in each instruction

book, and that the necessary safety equipment is on

board, and is in working condition.

4 47705796 05-2014 © AB VOLVO PENTA

Page 7

Carbon monoxide poisoning

P0003073

When a boat moves forwards, an area of low pressure

air forms behind the boat. In adverse conditions, this

low pressure can be so strong that the boat’s own

exhaust fumes are sucked into the cockpit or cabin,

which entails

all aboard.

The problem of low-pressure suction is worst in high,

wide boats with a square transom. But even in other

types of boats, low-pressure suction can be a problem

in some conditions, such as if you drive with the hood

up. Other factors which increase the low-pressure

effect are wind conditions, load distribution, pitching,

trimming, open windows and ventilators etc.

a risk of carbon monoxide poisoning for

Safety Information

Most modern boats are designed so that the problem

of low-pressure suction is very rare, however. If lowpressure suction does occur anyway, do not open

hatches or ventilators in the forward part of the boat.

Strangely enough, this makes the problem worse. Try

changing speed, trimming or load distribution instead.

Also try taking down/opening the hood or modifying it

in some other manner. Ask your boat dealer for advice

about the best solution for your particular boat.

Remember

• Safety equipment: Life jackets for everybody aboard, communication equipment, emergency

•

• Take your chart out and study your planned route. Calculate distance and fuel consumption.

• Tell your friends/relatives about route plans if you undertake a long journey. Remember to

• Inform everybody aboard about where the safety equipment is located, and how it works. Make

This list can be extended, since the need for safety equipment varies with the type of boat, and

where or how it is used etc. We recommend that you ask a regional boat or sea safety organization

for more detailed maritime safety information.

rockets, approved fire extinguisher, first aid kit, life buoy, anchor, paddle, torches etc.

Spare parts and tools: Impeller, fuel filters, fuses, tape, hose clamps, engine oil, propeller and

tools for the jobs you could be expected to have to do.

Listen to weather reports.

notify changed plans or delays.

sure that there is more than one person aboard who can start and operate the boat safely.

47705796 05-2014 © AB VOLVO PENTA 5

Page 8

Safety Information

Preparations

Knowledge

The operator’s manual contains instructions on how

to carry out general maintenance and service opera-

safely

tions

fully before starting work.

Service literature covering more complicated operations is available from your Volvo Penta dealer.

Never carry out any work on the engine if you are

unsure of how it should be done, contact your Volvo

Penta dealer who will be glad to offer assistance.

Stop the engine

Stop the engine before opening or removing engine

hatches. Unless otherwise specified all maintenance

and service must be carried out with the engine stopped.

To prevent accidental start of the boat engine, remove

the ignition key, turn off the power supply to the engine

at the main switches and lock them in the OFF position before starting work. Put up a warning sign in the

control position that work on the engine is being carried out.

Approaching or working on an engine which is running

is a safety risk. Loose clothing, hair, fingers or a dropped tool can be caught in the rotating parts of the

engine and cause serious personal injury. Volvo

Penta recommend that all servicing with the engine

running should be undertaken by an authorized Volvo

Penta workshop.

Lifting the engine

When lifting the engine, use the lifting eyes installed

on the engine. Always check that lifting equipment is

in good condition and has sufficient load capacity to

lift the engine (engine weight including any extra

equipment installed). For safety’s sake lift the engine

using an adjustable lifting beam. All chains and cables

should run parallel to each other and as perpendicular

as possible in relation to the top of the engine. Bear

in mind that extra equipment installed on the engine

may alter its center of gravity. Special lifting equipment may then be required in order to maintain the

correct balance and make the engine safe to handle.

Never carry out work on an engine suspended on a

hoist.

and correctly. Read the instructions care-

Before starting the engine

Reinstall all protective parts removed during service

operations before starting the engine. Check that no

tools or other items have been left on the engine.

Never start a turbocharged engine without installing

the air

Turbocharger unit can cause serious personal injury.

Foreign objects can also be sucked in and cause

mechanical damage to the unit.

cleaner (ACL). The rotating compressor in the

Fire and explosion

Fuel and lubrication oil

All fuel, most lubricants and many chemicals are

inflammable. Read and follow the instructions on the

packaging.

When carrying out work on the fuel system, make sure

the engine is cold. A fuel spill onto a hot surface or

electrical components can cause a fire.

Store fuel soaked rags and other flammable material

so that there is no danger of them catching fire. Fuelsoaked rags can self-ignite under certain conditions.

Do not smoke when filling fuel, oil or in proximity of a

filling station or in the engine room.

Non-original components

Components used in the fuel and electrical systems

on Volvo Penta products are designed and constructed to minimize the risk of fire and explosion.

Using non-original Volvo Penta parts can result in fire

or explosion on board.

Batteries

The batteries contain and emit oxyhydrogen gas,

especially during charging. This gas is easily ignited

and highly volatile.

Do not under any circumstances smoke or use naked

flame or allow sparks in the vicinity of the batteries or

battery compartment.

An incorrect connection of a battery terminal cable or

jump-start cable can cause a spark which in its turn

can be sufficient to cause an explosion.

Start spray

Never use start spray or similar agents to start an

engine equipped with air pre-heating (glow plugs/

starter element). This may cause an explosion in the

inlet manifold. Danger of personal injury.

6 47705796 05-2014 © AB VOLVO PENTA

Page 9

Safety Information

Hot surfaces and fluids

There is always a risk of burns when working with a

hot

engine.

exhaust pipe, turbo unit, oil pan, charge air pipe,

starter element, hot coolant and hot oil in oil lines and

hoses.

Beware of hot surfaces. For example: the

Carbon monoxide poisoning

Only start the engine in a well-ventilated area. If operating the engine in an enclosed space, ensure that

there is proper ventilation in order to remove exhaust

gases and crankcase ventilation emissions from the

working area.

Chemicals

Most chemicals such as anti-freeze, rustproofing

agent, inhibiting oil, degreasing agent etc. are hazardous to health. Read and follow the instructions on

the packaging.

Some chemicals such as inhibiting oil are inflammable

and dangerous if breathed in as well. Ensure good

ventilation and use a protective mask when spraying.

Read and follow the instructions on the packaging.

Store chemicals and other hazardous materials out of

the reach of children. To protect the environment,

please dispose of used or leftover chemicals at a

properly designated disposal site for destruction.

Cooling system

There is a risk of flooding when working on the seawater system. Turn off the engine and close the sea

cock before starting work on the system.

Avoid opening the coolant filler cap when the engine

is hot. Steam or hot coolant can spray out and cause

burns.

Fuel system

Always

uids ejected under pressure can penetrate body tissue and cause serious injury. There is a danger of

blood poisoning.

Always cover the generator if it is located under the

fuel filter. The generator can be damaged by spilled

fuel.

use protective gloves when tracing leaks. Liq-

Steering system

The boat has a advanced steering system. DO NOT

change connectors, wiring or splice of the components.

Service must be done by approved workshops which

have certifed personnel with qualified professional

training.

Electrical system

Cutting off power

Always stop the engine and break the current using

the main switches before working on the electrical

system. Isolate shore current to the engine block

heater, battery charger, or accessories mounted on

the engine.

Batteries

The batteries contain an extremely corrosive electrolyte. Protect your skin and clothes when charging or

handling batteries. Always use protective goggles and

gloves.

If battery electrolyte comes into contact with unprotected skin, wash off immediately using plenty of

water and soap. If battery acid comes into contact with

the eyes, flush immediately with plenty of water and

obtain medical assistance without delay.

If work must be carried out with the engine at operating temperature and the coolant filler cap or a cock

open or a coolant hose disconnected, open the coolant filler cap carefully and slowly to release pressure

before removing the cap completely. Note that the

coolant may still be hot and can cause burns.

Lubrication system

Hot oil can cause burns. Avoid skin contact with hot

oil. Ensure that the lubrication system is not under

pressure before commencing work on it. Never start

or operate the engine with the oil filler cap removed,

oil can spray out.

47705796 05-2014 © AB VOLVO PENTA 7

Page 10

Introduction

This Operator's Manual has been prepared to give you the greatest possible benefit from your Volvo Penta marine

engine. It contains the information you need to be able to operate and maintain the engine safely and correctly.

Please read the Operator's Manual carefully and learn to handle the engine, controls and other equipment in a

safe manner before you cast off on your maiden voyage.

Always have the Operator's Manual available. Store it safely and do not forget to hand it over to the next owner

if you sell your boat.

The Operator’s Manual describes the engine and equipment sold by Volvo Penta. The illustrations in this book

covers several

different controls and instrumentation might occur, in these cases we refer to this products manual.

Warranty

Your new Volvo Penta marine engine is covered by a

limited warranty, under the conditions compiled in the

Warranty Information.

Please note that AB Volvo Penta’s liability is limited to

the specification in the Warranty Information. Read it

carefully, as soon as possible after delivery. It

includes important information about service, maintenance, which it is the responsibility of the owner to

know, check and carry out. If this is not done, AB Volvo

Penta may fully or partly refuse to honour its warranty

undertakings.

Please contact your Volvo Penta dealer if you

have not received the Warranty Information or

Service Book.

Environmental care

All of us want to live in a clean, healthy environment.

Where we can breathe clean air, see healthy trees,

have clean water in lakes and seas, and be able to

enjoy the sunlight without fearing for our health.

Unfortunately, this is not self-evident these days, it is

something all of us must work hard for.

As a manufacturer of marine engines, Volvo Penta

has particular responsibility and for this reason, environmental care is a core value in our product development. Volvo Penta has a wide engine programme

these days, where considerable progress has been

made in reducing exhaust fumes, fuel consumption,

engine noise etc.

We hope that you will be want to preserve these values. Always observe the advice in the Operator's

Manual about fuel grades, operation and maintenance, to avoid unnecessary environmental impact.

Please contact your Volvo Penta dealer if you notice

any changes such as increased fuel consumption or

increased exhaust smoke.

varieties and might differ, the essential information is always correct though. Installations with e.g.

Moderate your speed and distance so that wake and

noise do not disturb or damage animal life, moored

boats, jetties etc. Leave the archipelago and harbours

in the same state you would like to find them. Remember to always hand in drained oil, coolant, paint and

wash residue, used batteries etc. for destruction at a

recycling station.

If we all pull together, we can make a valuable contribution to the environment together.

Running in

The engine must be “run in” during its first 10 hours,

as follows:

Use the engine in normal operation. Full load should

only be applied for short periods. Never run the engine

for a long period of time at constant speed during this

period.

Higher oil consumption is normal during the running

in period. For this reason, check the oil level more

frequently than normally recommended.

After the first period of operation, the specified warranty inspection “First service inspection” can be

done. For more information: Please refer to the Maintenance Schedule.

Fuel and oils

Only use the fuels and oils recommended in the Operator's Manual. Other grades can cause malfunctions,

increased fuel consumption and eventually even

shorten the life of the engine.

Always change the oil, oil filters and fuel filter at the

specified intervals.

8 47705796 05-2014 © AB VOLVO PENTA

Page 11

Introduction

Service and spare parts

Volvo Penta marine engines are designed for high

reliability and long life. They are built to withstand a

marine environment, but also to have the smallest

possible

ice and use of by Volvo Penta approved spare parts,

these qualities are retained.

Volvo Penta’s world-wide network of authorised dealers is at your service. They are Volvo Penta product

specialists, and have the accessories, original spares,

test equipment and special tools needed for high quality service and repair work.

Always observe the maintenance intervals in the

Operator's manual, and remember to note the engine/

transmission identification number when you order

service and spare parts.

environmental

impact. Through regular serv-

Recording engine data

One or more computers in your Volvo Penta engine

can record detailed information. It can include data

such as usage and information of other systems and

modules on the engine. This data can include information such as boat position and usage. Only a limited amount of data can be stored.

AB Volvo Penta will not distribute this stored information without permission. AB Volvo Penta may, however, be forced to provide this information if required

by national legislation. In general, AB Volvo Penta and

authorised workshops may read and use the information.

Certified engines

If you own or operate an emission certified engine it

is important to be aware of the following:

Certification means that an engine type has been

checked and approved by the relevant authority. The

engine manufacturer guarantees that all engines

made of the same type are equivalent to the certified

engine.

This makes special demands on the care and

maintenance you give your engine, as follows:

• Maintenance and service intervals recommended by Volvo Penta must be complied with.

• Only by Volvo Penta approved spares may be

used..

• Service on injection pumps, pump settings and

injectors must always be done by an authorised

Volvo Penta workshop.

• The engine must not be converted or modified,

except for the accessories and service kits

which Volvo Penta has approved for the engine.

• Installation changes to the exhaust pipe and

engine air inlet ducts must not be done.

• No seals may be broken by unauthorised personnel.

The general advice in the Operator's manual about

operation, care and maintenance apply.

Volvo Penta Electronic Vessel Control

system (EVC) Integrity and Modification

The EVC system is a complete vessel control system

for engine, gear and vessel steering control. The complete EVC system is developed, tested and verified to

comply with Volvo Penta’s stringent requirements for

safety and reliability based on approved standard configurations. In order to maintain the EVC system integrity, all interaction with external systems (e.g., autopilot) is performed via Volvo Penta designed interfaces.

After-market interfaces breach system integrity and

may negatively affect vessel performance, safety and

warranty coverage. Volvo Penta does not endorse

any direct or indirect connection with other systems or

components not being fully tested, verified and

approved in writing by Volvo Penta. Volvo Penta

accepts no responsibility for modification of the Volvo

Penta EVC system and/or use of components or interfaces not sold or approved by Volvo Penta.

Late or inadequate maintenance/service or the use of

spare parts not approved by Volvo Penta will invalidate AB Volvo Penta’s responsibility for the engine

specification being in accordance with the certificated

variant.

Volvo Penta accepts no responsibility or liability for

any damage or costs arising due to the above.

47705796 05-2014 © AB VOLVO PENTA 9

Page 12

Instruments and Controls

This chapter describes the instruments, panels and controls Volvo Penta sells for your engine.

If you would like to complement your instrumentation, or if your boat is equipped with instruments not described

here, we ask that you contact your Volvo Penta dealer.

For information about screens from 8” and above, please refer to the separate manual for Volvo Penta Glass

Cockpit.

Ignition Lock

The start keys are supplied with a plate bearing the

start code

the code beyond the reach of unauthorized people.

S = The stop position.

0 = The key can be inserted or removed.

I = Operating position. System power is connected.

II = Not used.

III = Start position. Starter motor is engaged.

There is always a helm station with an ignition lock.

The ignition

helm stations to be used.

Read the starting instructions in the Starting page 56

chapter to make sure you use the correct start procedure.

to be used when ordering spare keys. Keep

must be switched on here in order for other

Control Panels

Volvo Penta panels and gauges can be installed in different combinations. There is always one information

panel per driveline and helm station if no 7" screen is

installed. The control panels can be used together with

the tachometer and other accessory equipment.

10 47705796 05-2014 © AB VOLVO PENTA

Page 13

P0001306

Instruments and Controls

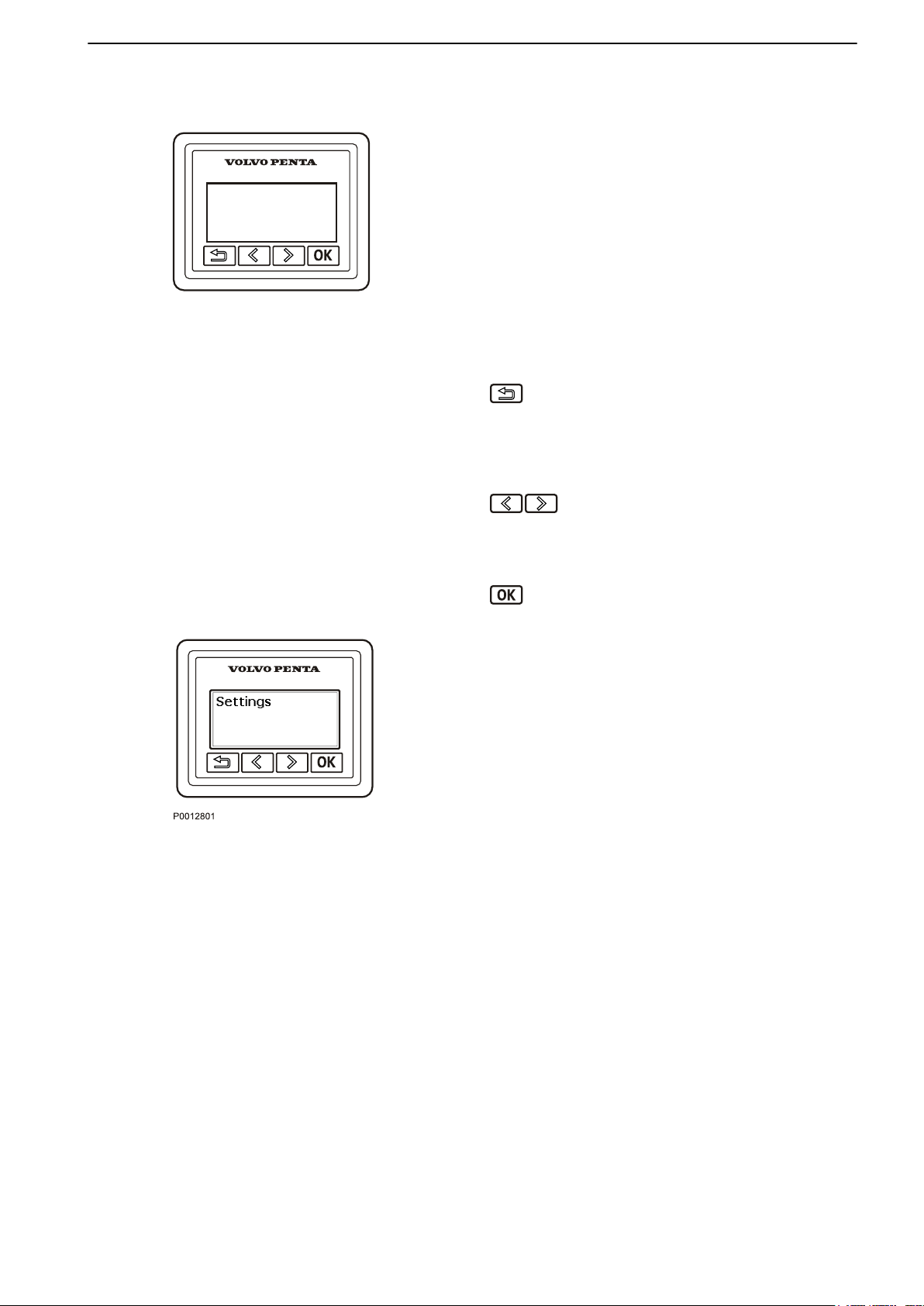

Information Panel

The information panel shows engine and operational

information, messages and alarms.

There is one information panel per driveline and helm

station if no 7" screen is installed.

The information

sonal preferences. Basic settings show:

Engine speed

•

Oil pressure

•

Coolant temp

•

Battery voltage

•

Return to the previous menu by pressing the button.

Hold the

the main menu or browse back to it by pressing the

button repeatedly.

button down for more that 3 seconds to reach

shown can be set up according to per-

Browse backwards and forwards through the information panel menus by pressing the buttons.

Hold down a button to scroll through a menu.

Confirm a selection by pressing the button.

Settings

Browse to the settings menu and press “OK” to proceed to the submenu.

For further information about settings, refer to Settings

Menu page 120.

To adapt information shown in the main menu to suit

your personal preferences, refer to My

View page 120.

47705796 05-2014 © AB VOLVO PENTA 11

Page 14

P0001259

P0002114

Instruments and Controls

Fault messages

If the system discovers a fault, the word Fault is displayed on

detected, press “OK”.

For further information on how to handle fault messages and recommended actions, refer to the Fault

Handling page 67 chapter.

Backlighting

Panel backlighting can be adjusted by pressing

the screen. To see the what faults have been

simultaneously.

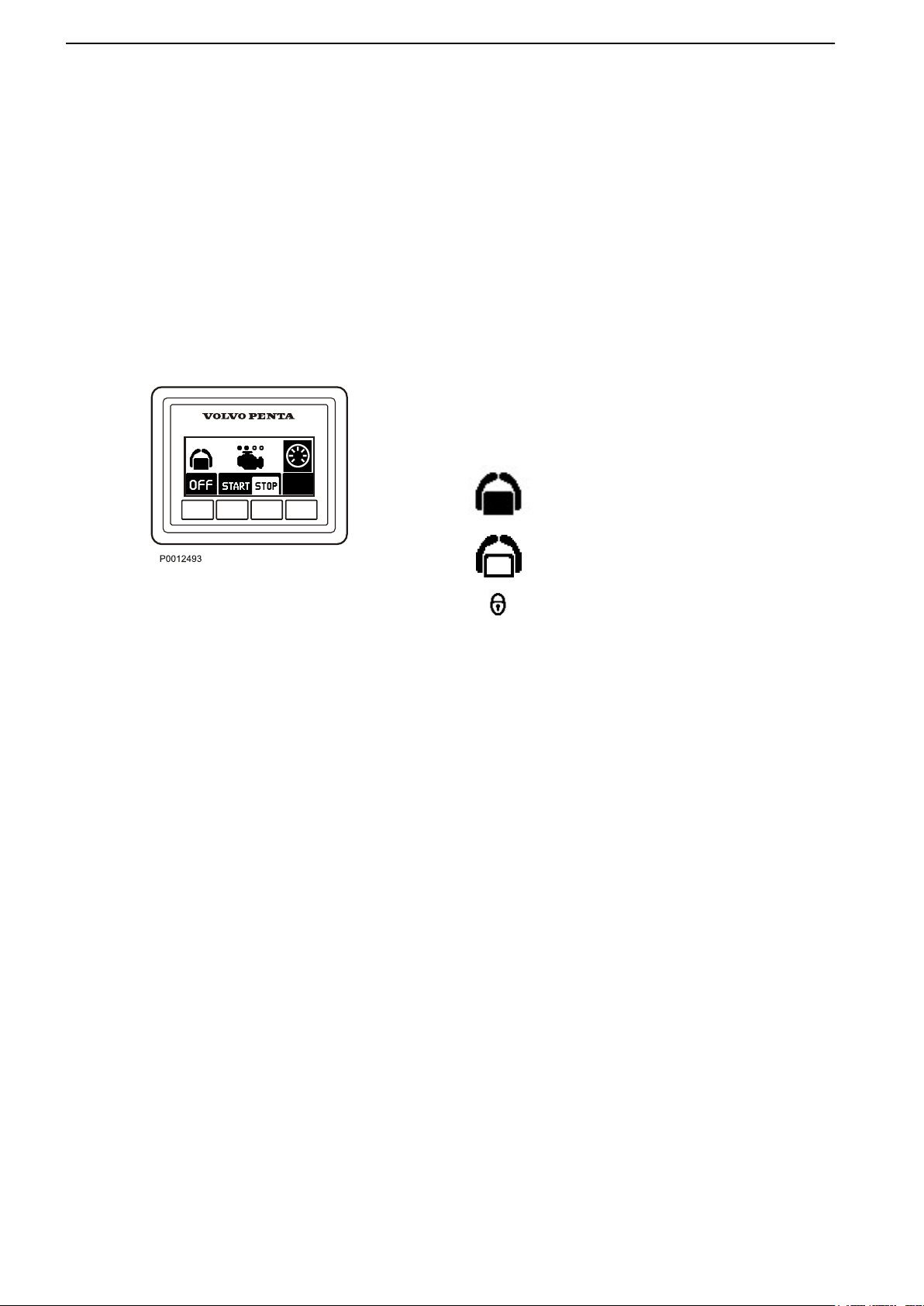

Start/Stop Panel

The start/stop panel is used for starting and stopping

the engine from stations without a start key.

To start the engine it is necessary for the start key to

be in the ”I” operating position.

Read the starting instructions in chapter

Starting page 56 and Engine Shutdown page

ensure you use the correct start procedure.

64

to

Cruise Control

Switch on cruise control by pressing the

Make fine adjustments to the locked engine speed by

pressing the + or – buttons to increase or reduce it.

button.

Sport fish panel

Sport fishing

Single lever

Silent idle

For more information regarding these functions, refer

to the Optional page 37

section.

12 47705796 05-2014 © AB VOLVO PENTA

Page 15

P0001088

Instruments and Controls

Station Panel

Activation

Activate the

ton. Further pressure locks the helm station.

To render the helm station inactive, hold the button

down for 3 seconds.

helm station with a single press of the but-

Inactive helm station

For further information about the function, refer to

chapter Optional page 36.

The gearshift

control lever only operates the throttle. The neutral

button disengages the drive/reverse gear so that

engine speed may be increased without driving the

boat; (warm-up mode).

When the single-lever function is activated, the lever

that is moved from its position first becomes the control

lever for both engines. The other control lever has no

function as long as the single-lever function is activated.

Active helm station

Locked helm station

Low speed

Neutral button

function can be disconnected so that the

The drive is disengaged.

Drive engaged for movement ahead/astern.

Single lever

47705796 05-2014 © AB VOLVO PENTA 13

Page 16

Instruments and Controls

Docking Panel

When the boat is operated from a docking station

engines, can be stopped and started and messages

can be managed using the docking panel.

The joystick can be used for maneuvering when the

docking station is activated; refer to the Joystick section for further information.

Activation

Activate the

ton. A further pressure on the button locks the helm

station.

To switch off the function, hold the button down for 3

seconds.

Twin instalation

Both engines in a twin instalation must be running

before the docking station can be activated.

helm station by depressing the on/off but-

The helm station is inactive.

The helm station is active and the docking

function is switched on.

The helm station is locked.

Start/Stop

Press the STOP and START buttons to stop and start

all engines.

The circles above the engine symbols show which

engines are running. An empty circle means an engine

is running.

14 47705796 05-2014 © AB VOLVO PENTA

Page 17

P0001308

P 1992300

Instruments and Controls

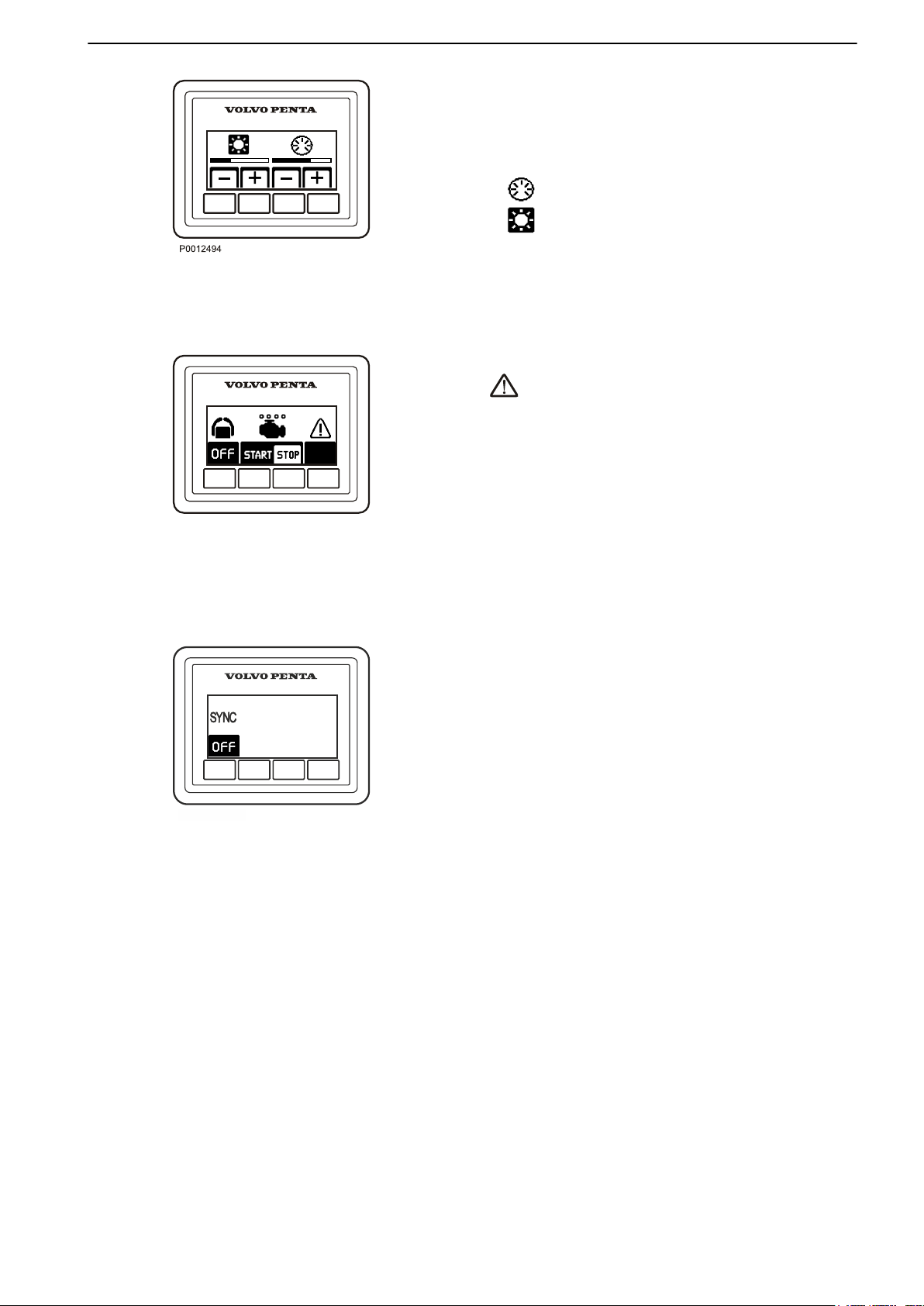

Contrast and backlighting

The button on the far right is used to adjust contrast

and panel

firm fault messages.

Press the button to adjust the contrast and the backlighting.

Use

lighting.

Adjustments affect all screens in the system.

Fault message

covers a fault.

All fault messages must be acknowledged. Acknowledge by

by an audible signal, the signal will silenced. Go to the

information panel to get information regarding the

alarm.

backlighting. The button is also used to con-

Backlighting

Contrast

+

and – to increase or reduce the contrast or back-

is displayed on the screen when the system dis-

pressing the button; if the fault is accompanied

For further information on how to handle fault messages and recommended actions, refer to the Fault

Handling page 67 and Fault Code Register chapters.

Syncronisation panel

The engine synchronization function can be switched

off at the synchronization panel to allow engine speeds

to be controlled independently. In triple installations,

the midships engine receives an average of the two

outboard engines' speeds.

Switch on synchronization by pressing the button.

47705796 05-2014 © AB VOLVO PENTA 15

Page 18

0

3

2

1

4

RPMX1000

P0012490

351

h

1

P0005255

Instruments and Controls

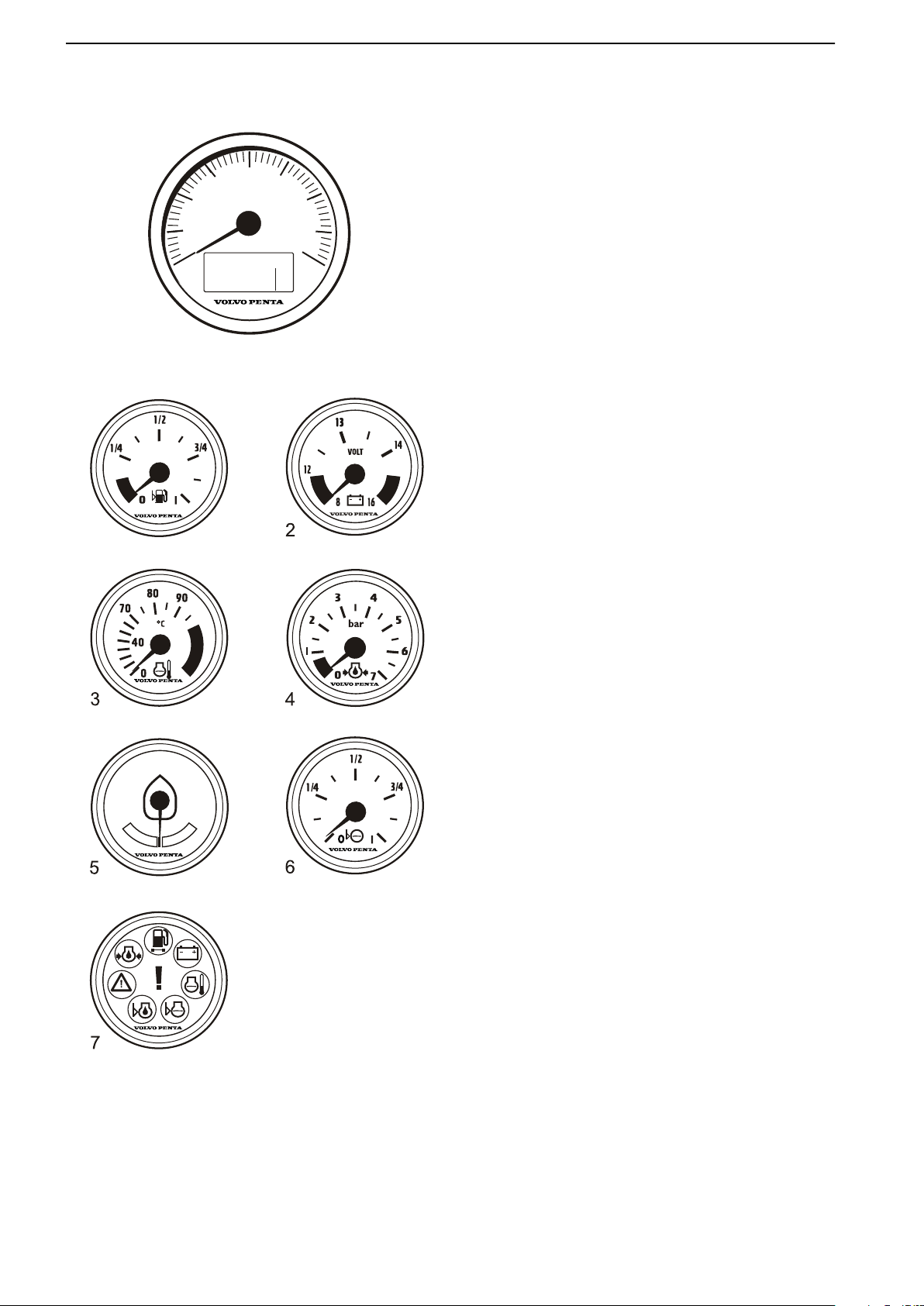

Gauges

These instruments

Penta.

The tachometer displays engine speed; multiply the

value shown on the dial by 1,000 to get the number of

engine revolutions per minute.

Engine hours is displayed in the tachometer window.

When a function is activated a symbol shows shortly in

the dispaly.

are sold as engine options by Volvo

1 Fuel level gauge

The fuel level gauge shows the quantity of remaining fuel.

2 Voltmeter, battery charging

The meter shows the alternator charge current.

During operations the charge voltage should be

around 28 V. When the engine is stopped and electrical power switched on the battery voltage should

be around 24 V.

3 Coolant temperature gauge

The instrument shows engine coolant temperature.

During operations coolant temperature should normally be between 75-90°C (167-194°F).

4 Oil pressure gauge

The oil pressure gauge displays engine oil pressure. During operations the oil pressure gauge

should normally show 3-5.5 bar (43.5-79.8 PSI). At

idle, lower values are normal.

5 Rudder position indicator

The instrument shows rudder position.

6 Fresh water level sensor

Freshwater tank level gauge.

7 Alarm monitor

The alarm monitor gives a visual warning to call

attention to any alarms that occur.

16 47705796 05-2014 © AB VOLVO PENTA

Page 19

P0001101

Instruments and Controls

4" Display

IMPORTANT!

Make a habit of protecting the screen with the protective cover

sure to strong sunlight can damage the screen and

cause function faults.

The Volvo Penta 4" screen is controlled by means of

buttons on the panel:

button.

The image reverts automatically a short while after

the button is released.

play. Scroll

pressing the appropriate button.

when the boat is not in use. Prolonged expo-

Return to the previous menu by pressing the

Press the button to adjust the display contrast.

Menu button functions are shown on the dis-

back and forth or confirm a selection by

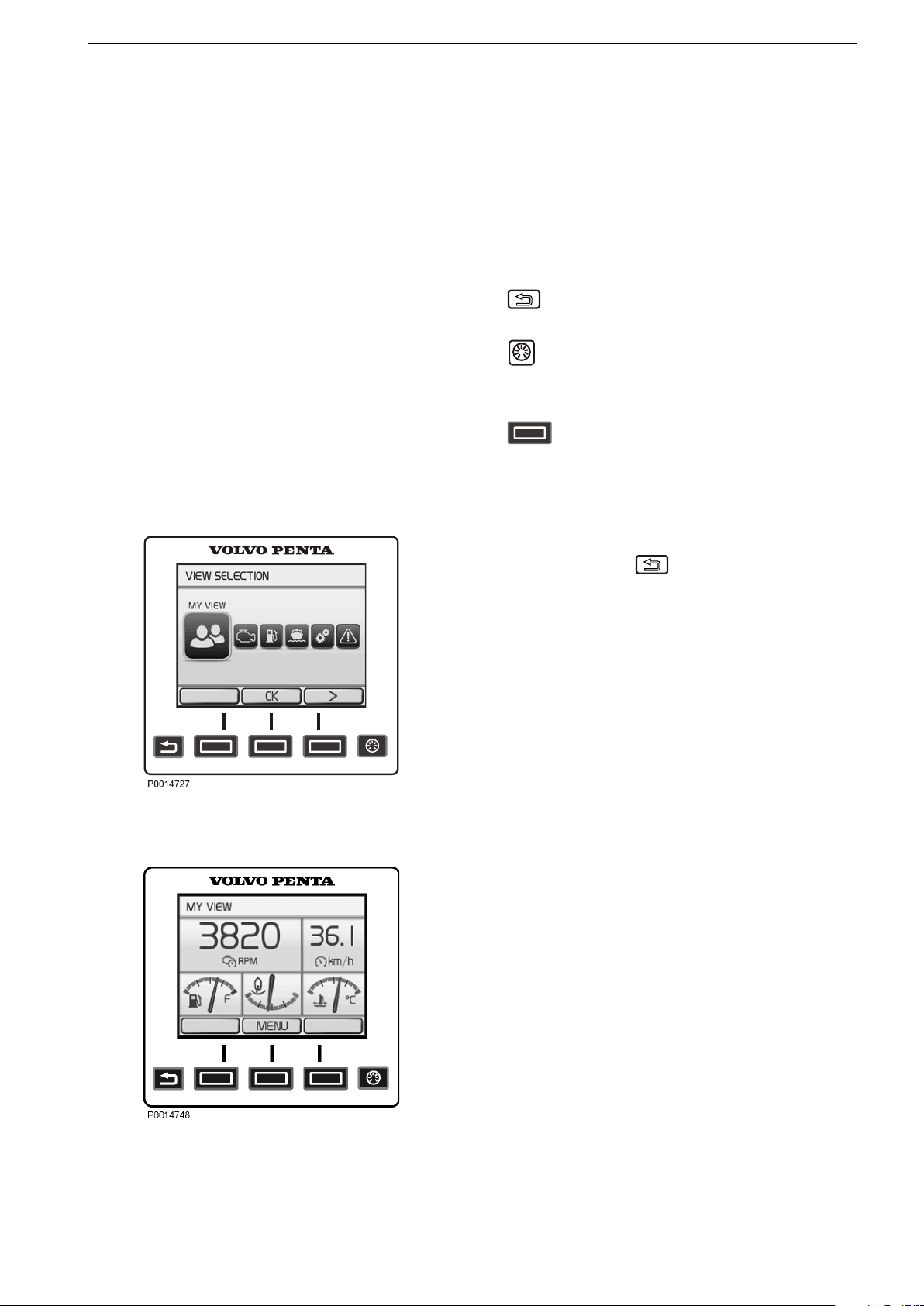

View Selection

View Selection

The last selected view is shown on start. To return to

the main menu, click

screen using the arrow buttons.

My Viewoperating information

•

Engine Viewengine information

•

Fuel economytrip computer

•

Vesselinformation regarding the boat's engine

•

installation

Settingssettings, display and installed functions

•

Warning Managershows system faults detected

•

and describes remedial actions

. Navigate to the desired

My View

Gauge and operations information is shown in the My

View window.

Some functions

can be switched on/off by pressing OK.

To change the gauge and information shown, refer to

Change gauge. Functions are also switched on and off

here.

are pre-set as quick selections. These

My View

47705796 05-2014 © AB VOLVO PENTA 17

Page 20

Instruments and Controls

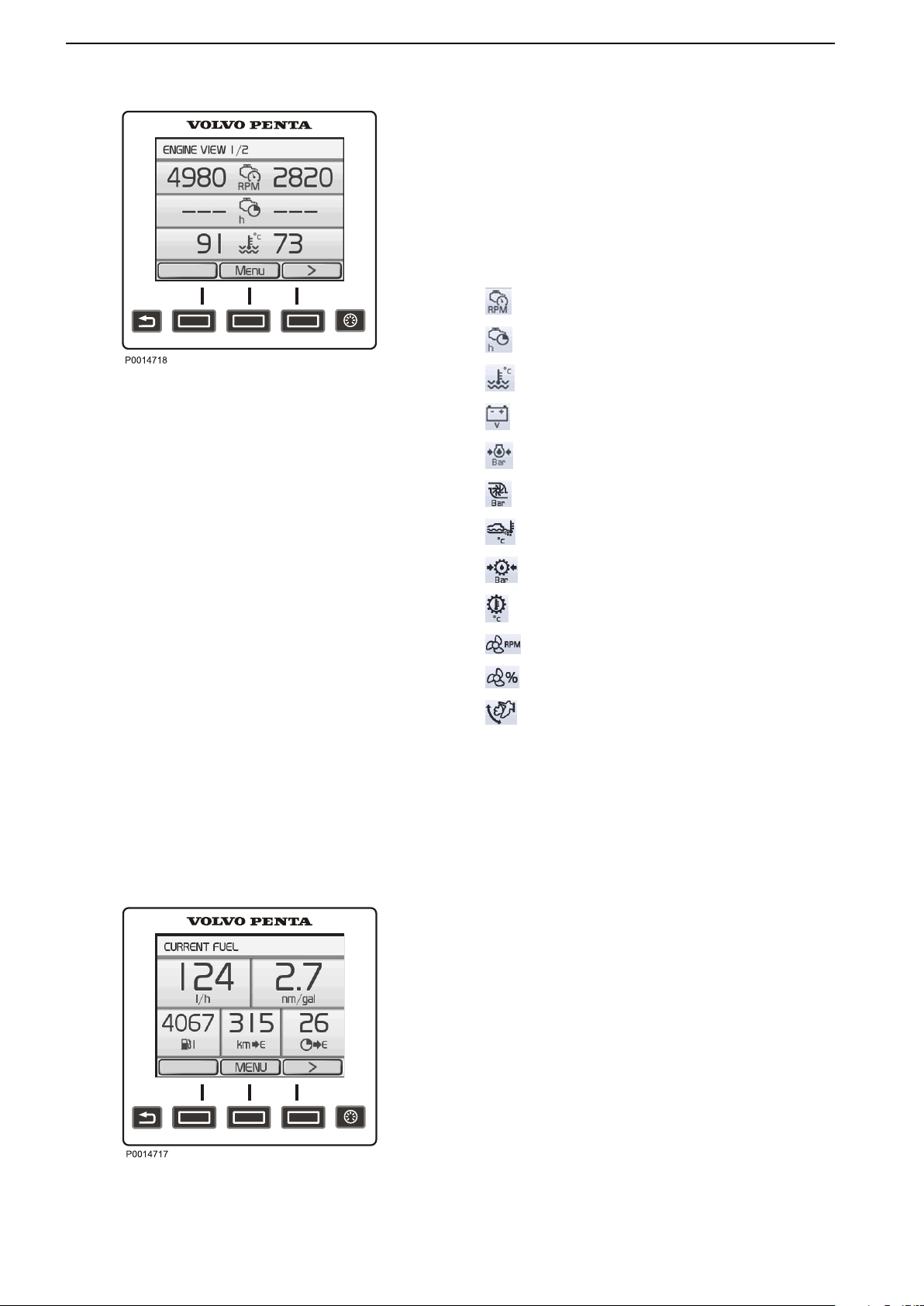

Engine View

Engine View

Information

shown in Engine View. The information is shown in two

windows; switch between the windows by pressing the

arrow buttons.

Up to six different pieces of operations data can be

shown on the display. The information shown can be

set under Change gauge.

Depending on the functions installed in the boat, the

following can be displayed:

concerning

Engine speed

Engine hours

Engine Coolant Temperature

the engine and transmission is

Battery Voltage

Engine oil pressure

Turbo pressure

Exhaust Temperature

Transmission Oil Pressure

Transmission oil temperature

Propeller Rotation

Propulsion

Power Trim angle

Fuel

This is the boat's trip computer and information is

shown in

Switch between screens by pressing the arrow buttons.

Current Fuel

•

•

•

two windows, Current Fuel and Average fuel.

Instant fuel ratecurrent fuel consumption per hour.

Instant fuel economybased on current fuel con-

sumption.

Remaining in tankamount of fuel remaining in the

tank.

Distance remainingtrip distance with fuel remain-

•

ing in the tank based on current fuel consumption.

Time to emptyoperating time with fuel remaining in

•

the tank based on current fuel consumption.

Current Fuel

18 47705796 05-2014 © AB VOLVO PENTA

Page 21

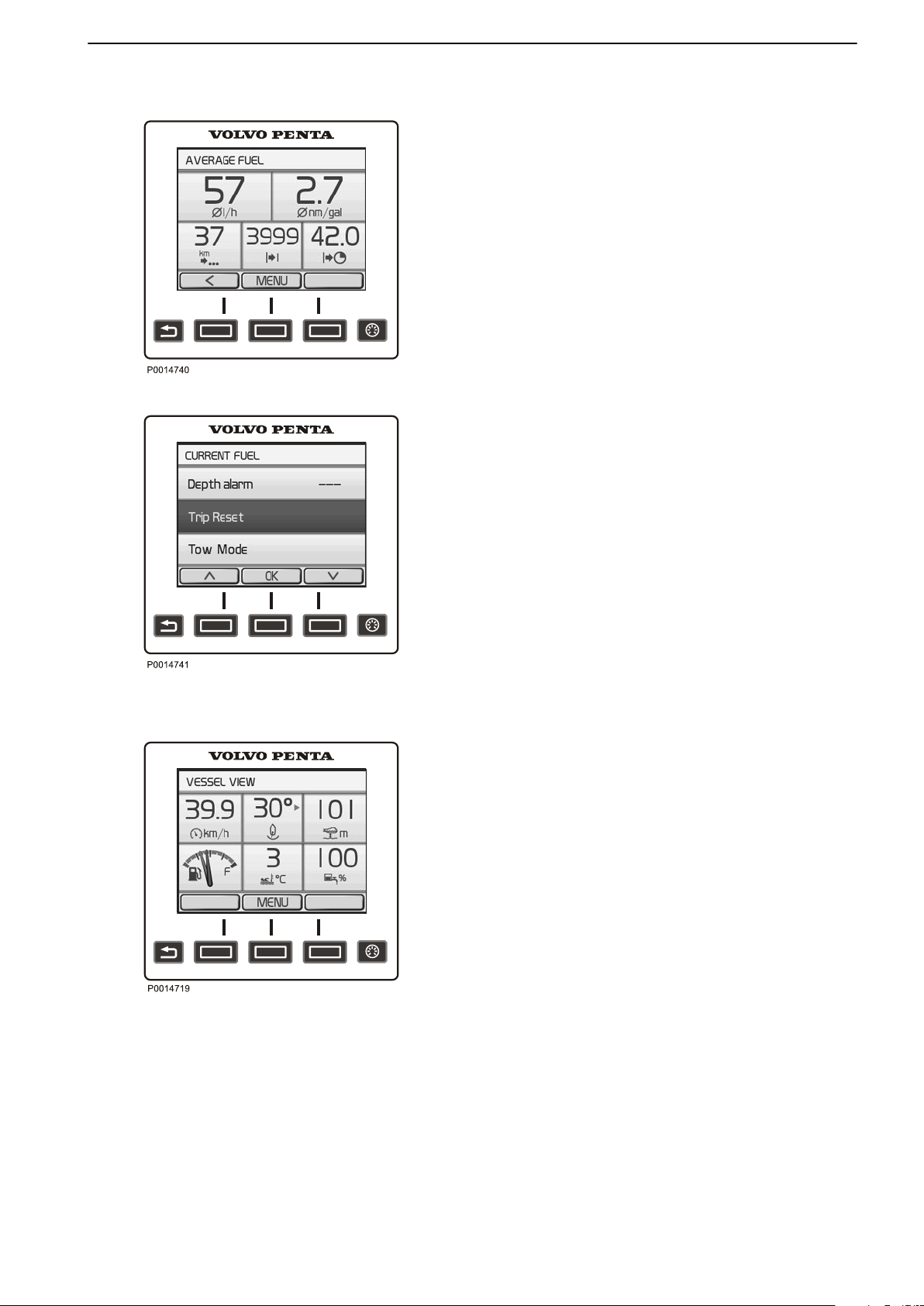

Average fuel

Instruments and Controls

Average fuel

Average fuel rateaverage fuel consumption since

•

the last trip computer zero reset.

Average fuel economyaverage since the last trip

•

computer zero reset.

Trip distancedistance traveled since the last trip

•

computer zero reset.

Trip fuelused quantity since the last trip computer

•

zero reset.

Trip hourstime since the last trip computer zero

•

reset.

Trip Computer Reset

zero

To

button and select Trip Reset.

all values in the trip computer, press the MENU

Trip Computer Reset

Vessel

Vessel

Shows information regarding the boat's installation.

The information shown can be set under Change

gauge. Functions are also switched on and off here.

Depending on the functions installed in the boat, the

following can be displayed:

Boat Speed

•

Rudder angle

•

Depthfor setting echo sounder, refer to Depth

•

Alarm page 122.

Fuel level

•

Sea water temperature

•

Freshwater level

•

ACP Infofor further information refer to

•

Optional page 53.

Interceptor positionfor further information refer to

•

Volvo Penta Interceptor System.

47705796 05-2014 © AB VOLVO PENTA 19

Page 22

Instruments and Controls

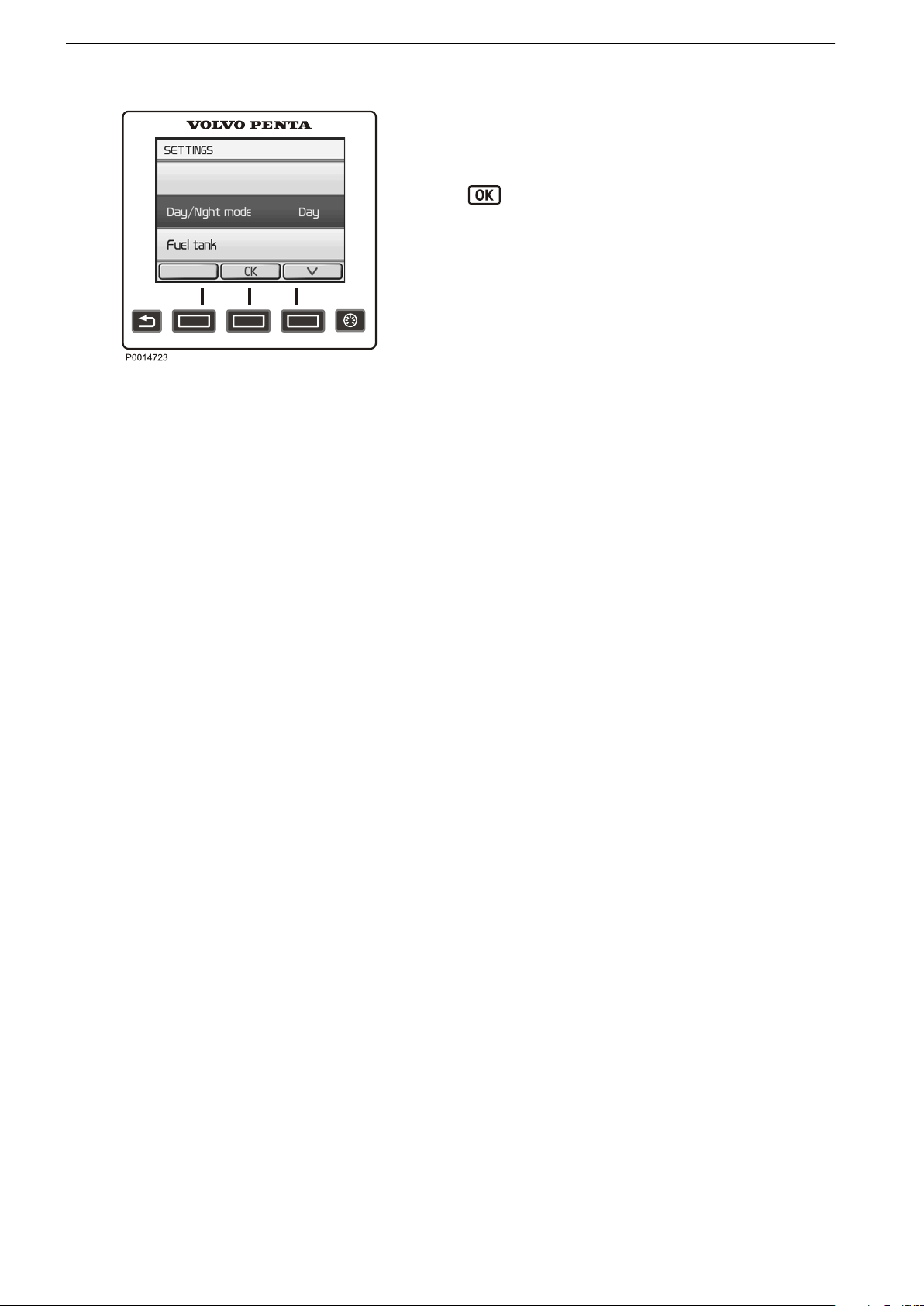

Settings

Settings

Display

various system function settings are made

and

in the settings menu. The information shown varies

depending on the installation.

Navigate to the desired setting or function and press

to reach the sub menu.

Key Managementadd and remove keys. Refer to Key

Management.

Day/Night-Mode

Day shows dark text against a light background and

Night text against a dark background.

Fuel Tank

Fuel tank calibration and settings. For information

regarding calibration, refer to Fuel Tank page 124.

Drive Type

The setting may only be made by authorized Volvo

Penta personnel.

Toe-In/Toe-Outadjustment

The setting may only be made by authorized Volvo

Penta personnel.

Neutral Beep

Switches the beeper that sounds when the control is in

the neutral position on and off.

Info Beep

Switches the signal that confirms when a function has

been activated or deactivated on and off.

Info Beeplevel

Sets the volume (%) of the Info Beepthat confirms

when a function has been activated, or deactivated.

PTA Calibration

Calibration and resetting, PTA. For information regarding calibration, refer to PTA Calibration.

Trip Reset

Zeroes all values in the trip computer.

ACP Mode

Setting the ACP protection position. For information on

the ACP function, refer to Optional page 53.

Depth Alarm

When setting the depth alarm function; refer to Depth

Alarm page 122.

Display Contrast

Contrast adjustments affect all displays in the system.

Display Type

Select the engines for which the information will be

shown in the display, and the type of installation the

display forms part of.

20 47705796 05-2014 © AB VOLVO PENTA

Page 23

Instruments and Controls

Units

Setting the

units (metric, US or Imperial) and distance

units (km, NM or miles) that distances will be shown in.

Language

Setting the language that information will be shown in.

Speed Factor

When setting the speed factor, refer to Speed

Factor page 125.

EVC Information

Information about components, software and functions

installed. Installed functions are checkmarked.

Service

The drive is fitted with a sensor that monitors oil level

and quality. If the oil level in the drive is low or if there

is water in the oil, the helmsman is alerted by an audible alarm and a message is shown on the display

simultaneously. Every time oil is changed, the waterin-oil sensor must be calibrated; refer to

Service page 121

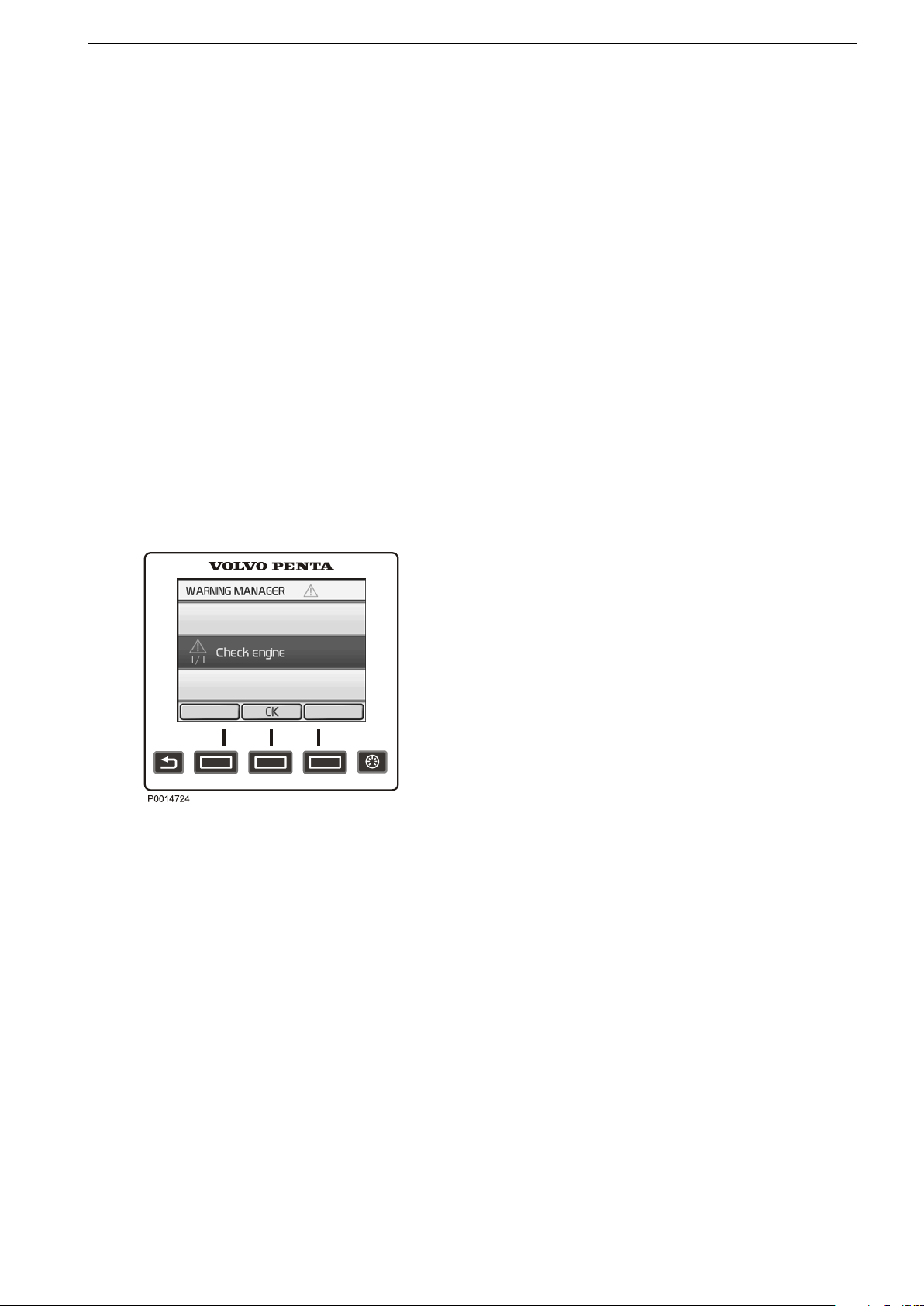

Warning Manager

Warning Manager

If the system discovers a fault, the helmsman is alerted

by a message on the display. The fault message must

be acknowledged by pressing OK.

All fault messages are stored in Warning Manager, the

drivetrain affected is also shown, the fault described

and suitable actions suggested. For further information

on the fault messages concerned, refer to Fault Code

Register page 71.

47705796 05-2014 © AB VOLVO PENTA 21

Page 24

Instruments and Controls

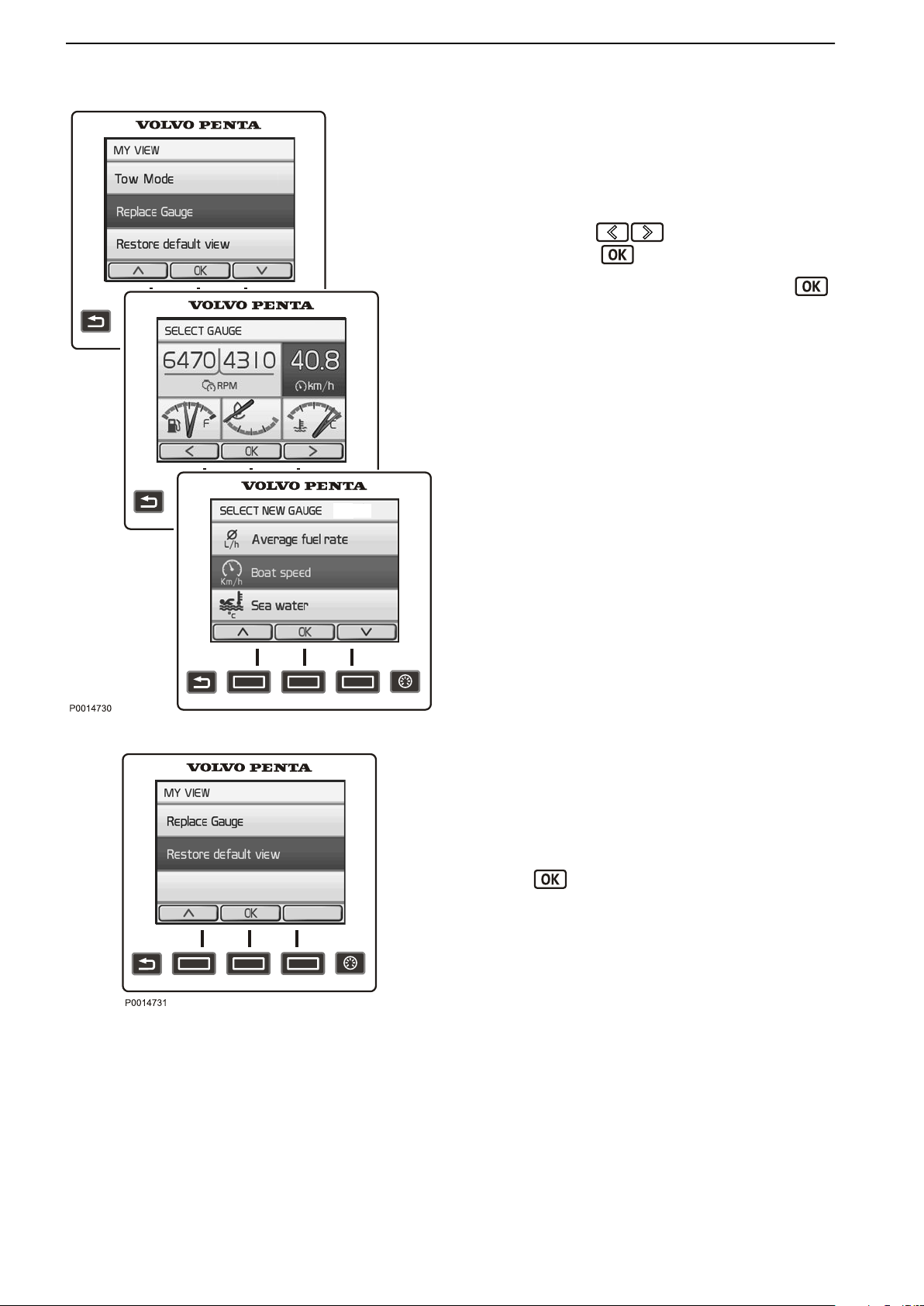

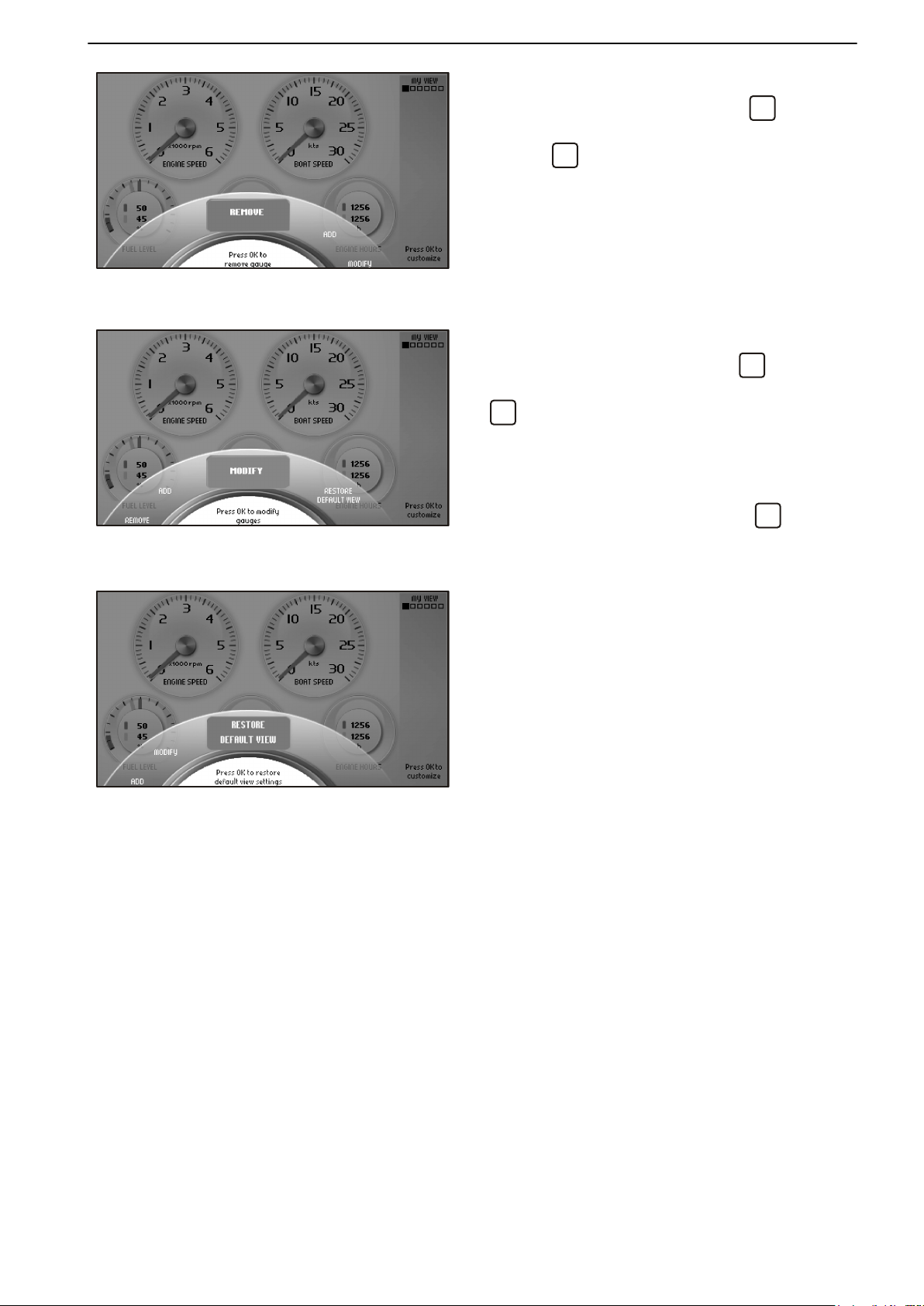

Replace gauge

In the views My View, Engine View and Vessel, the

owner can decide what information will be shown

where on the display. The procedure is the same for

all views.

1 Press

2

Navigate using

MENU button and select Replace gauge.

the

to the gauge for replace-

ment and press .

3

Select the gauge for replacement and press .

Replace gauge

Restore Default View

Restore Default View

The display has a basic setting that it is always possible to return to.

the

1 Press

MENU button and select Restore Default

View.

2

Press

.

22 47705796 05-2014 © AB VOLVO PENTA

Page 25

OK

P0001101

OK

P0001165

2

1

P0001050

Instruments and Controls

7" Display

The Volvo Penta 7" screen is controlled by means of

buttons:

Turn to browse through submenus and to return

to the main menu.

Return to the previous menu.

Confirms selection; also used to access sub-

menus and the Settings page 29

Controls boat instrument backlighting. The

page automatically returns a few seconds after the

button is released.

IMPORTANT!

Make a habit of protecting the screen with the protective cover

when the boat is not in use. Prolonged exposure to strong sunlight can damage the screen and

cause function faults.

.

1 Pop-up menu

2 Status field

The status field (2) on the right of the screen displays

the current view, active functions and repaired faults.

Pop-up

A number of pre-set functions can be switched on and

off in a pop-up. Press

and the functions will show

in the lower part of the screen (1).

Turn to the desired function and press OK to confirm

that the function is to be switched on or off.

Active functions

are displayed by a symbol in he status

field (2) on the right.

Trip Reset is also found here; refer to Fuel

economy page 27.

47705796 05-2014 © AB VOLVO PENTA 23

Page 26

OK

OK

OK

P0012481

P0001187

P0001188

Instruments and Controls

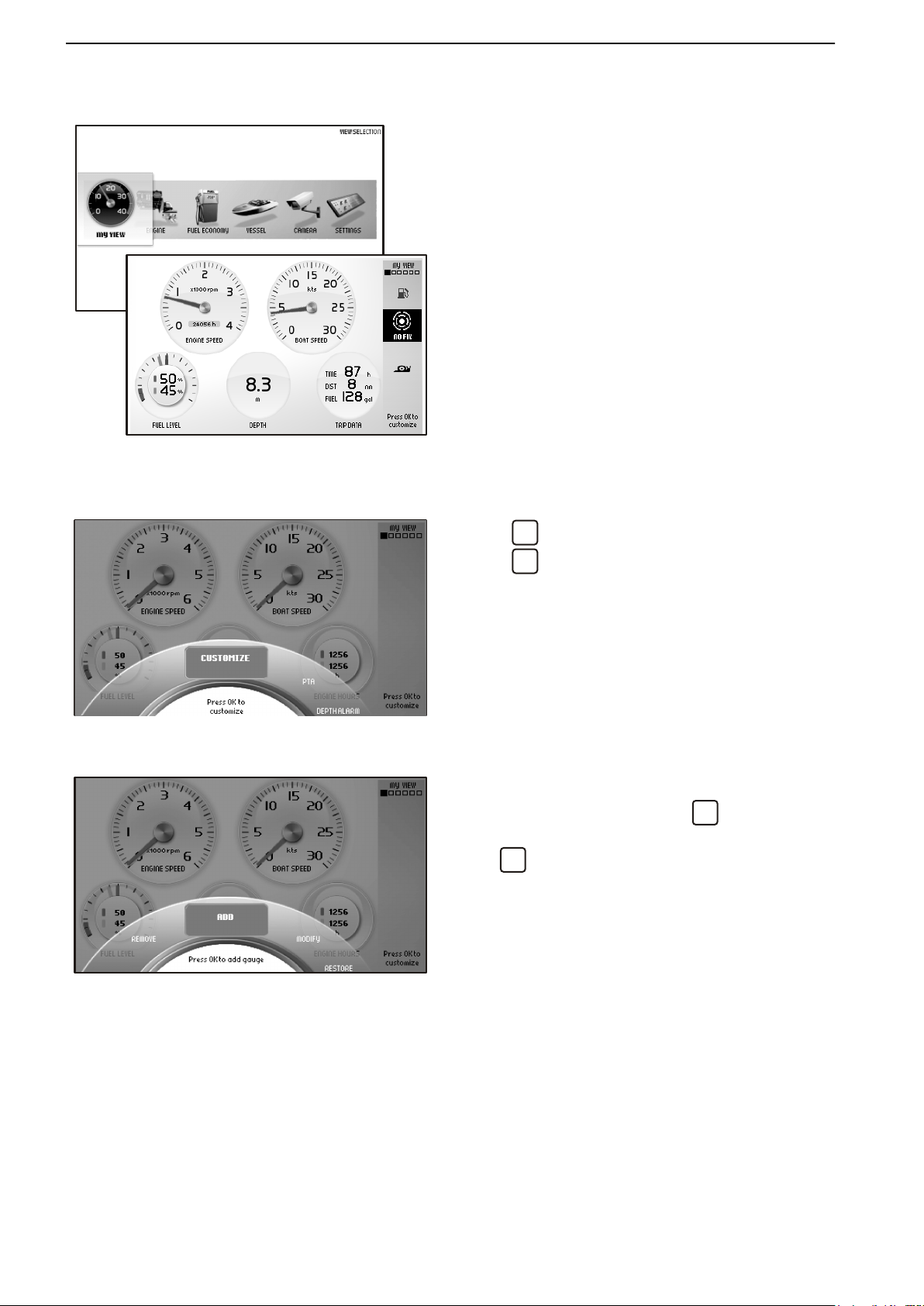

My View

Boat, engine and transmission data are displayed in

My View as analog or digital instruments.

Selection of instruments to be displayed and their

appearance is made under the Customize menu.

Information for up to three engines can be displayed

same screen in boats with multiple engine instal-

on the

lations; they are distinguished by different color dials

in the instruments.

Customize

Press

so that the Customize menu is displayed.

Press OK to access the submenus Add, Remove,

Modify and Return to basic setting..

Use the knob to browse between menus.

Adding instruments

Turn the knob to

Select

with

the

. The new instrument will position itself at the

Add and press

desired information is displayed and confirm

bottom right corner.

.

24 47705796 05-2014 © AB VOLVO PENTA

Page 27

OK

OK

OK

P0001184

P0001185

P0001097

Instruments and Controls

Removing instruments

Turn to the Remove menu and press OK.

Turn to the instrument that is to be removed and con-

firm with OK.

Changing instruments

Turn to the Modify menu and press

.

Select the instrument that is to be changed and press

.

Choose between:

Remove, removes the instrument.

Replace, changes

to the desired instrument and press

one instrument for another. Turn

.

Analogue/Numeric, specify whether the instrument will be displayed as analog or digital.

Restore Default View

The screen has a basic setting that can always be

returned to by pressing Restore Default View in the

Customize menu.

47705796 05-2014 © AB VOLVO PENTA 25

Page 28

P0012483

Instruments and Controls

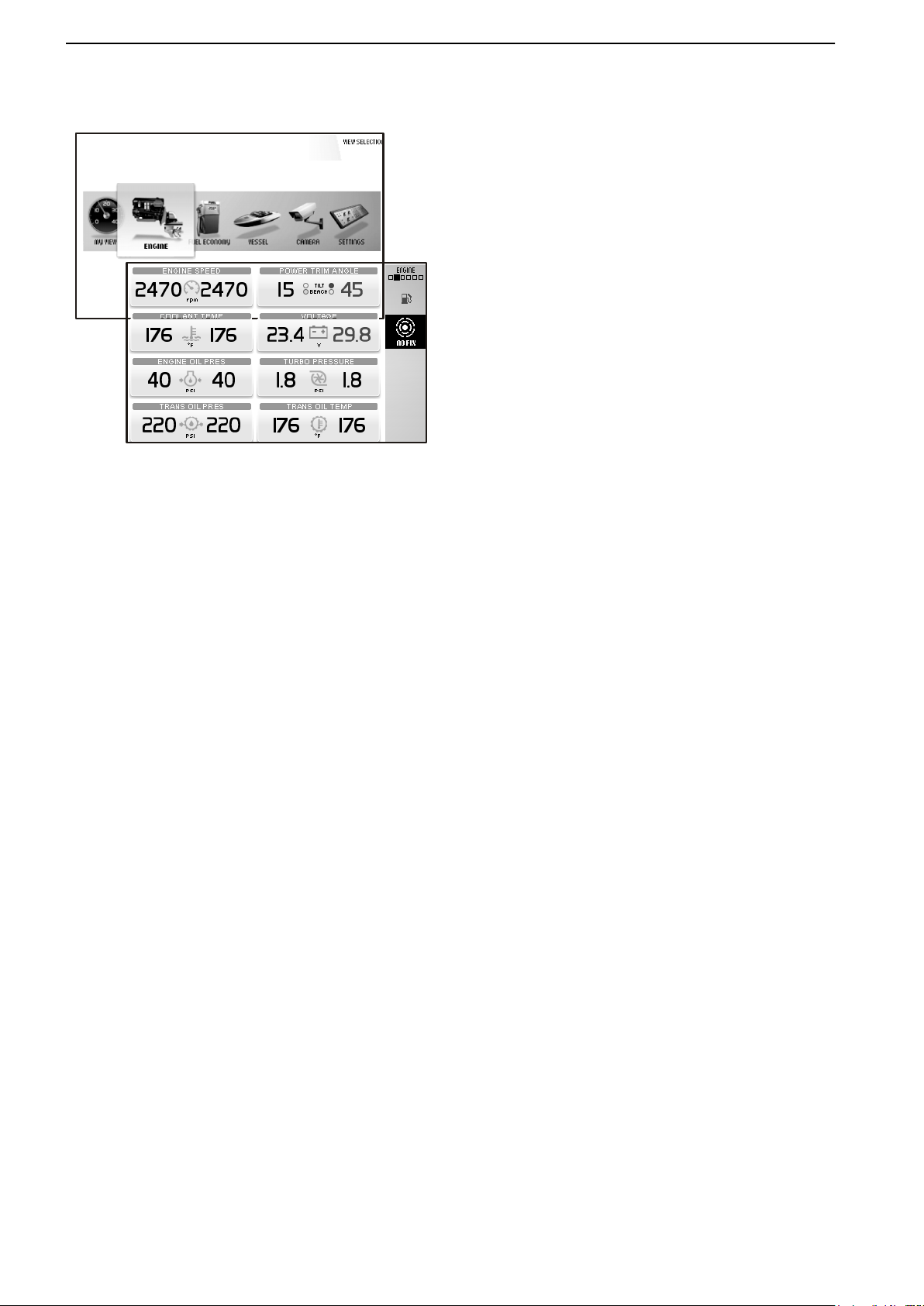

Engine

Information concerning

is displayed in this view.

Depending on the functions installed in the boat, the

following can be displayed:

- Engine Speed

- Rudder angle

- Coolant Temperature

- Voltage battery voltage

- Engine oil pressure

- Turbo pressure

- Engine hours, total operating hours.

- Transmission Oil Pressure

- Transmission oil temperature

The information in this view cannot be changed.

the engine and its transmission

26 47705796 05-2014 © AB VOLVO PENTA

Page 29

OK

P0012482

Instruments and Controls

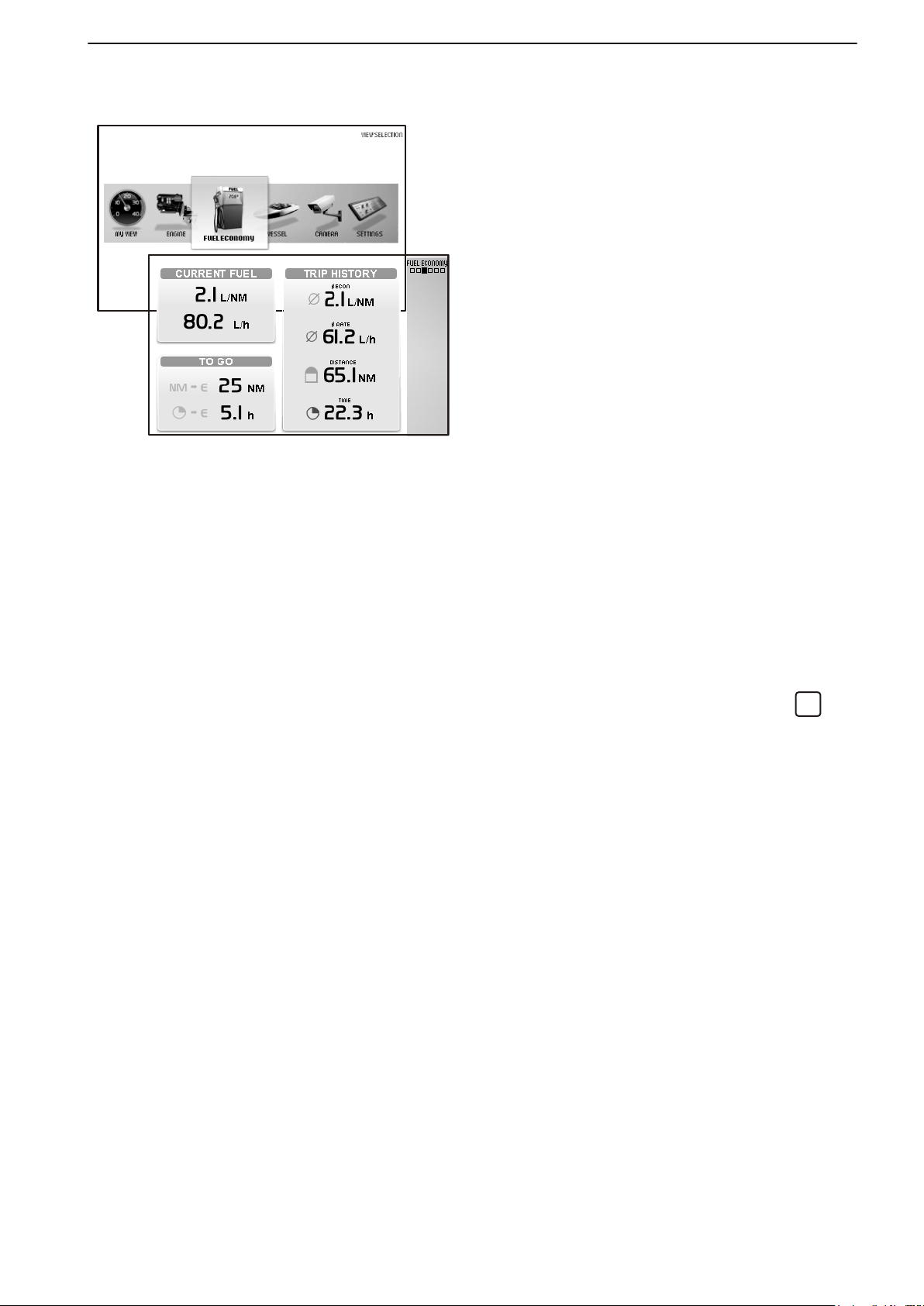

Fuel economy

This view functions as the boat's trip computer.

Depending on the functions installed in the boat, the

following can be displayed:

Current Fuel

Instant fuel rate, based on current fuel consump-

tion

Instant fuel economy, current fuel consumption

per hour.

To Go

Distance

remaining

, trip distance with fuel remaining in the tank based on current fuel consumption.

Time to empty, operating time with fuel remaining

in the tank based on current fuel consumption.

Trip History

Average fuel rate, average fuel consumption since

the last trip computer zero reset.

Average fuel economy, average since the last trip

computer zero reset.

Trip distance, distance travelled since the last trip

computer zero rest.

Trip Time, time travelled since the last trip computer

zero rest.

To zero all values in the trip computer press

.

The information in this view cannot be changed.

47705796 05-2014 © AB VOLVO PENTA 27

Page 30

P0001175

Instruments and Controls

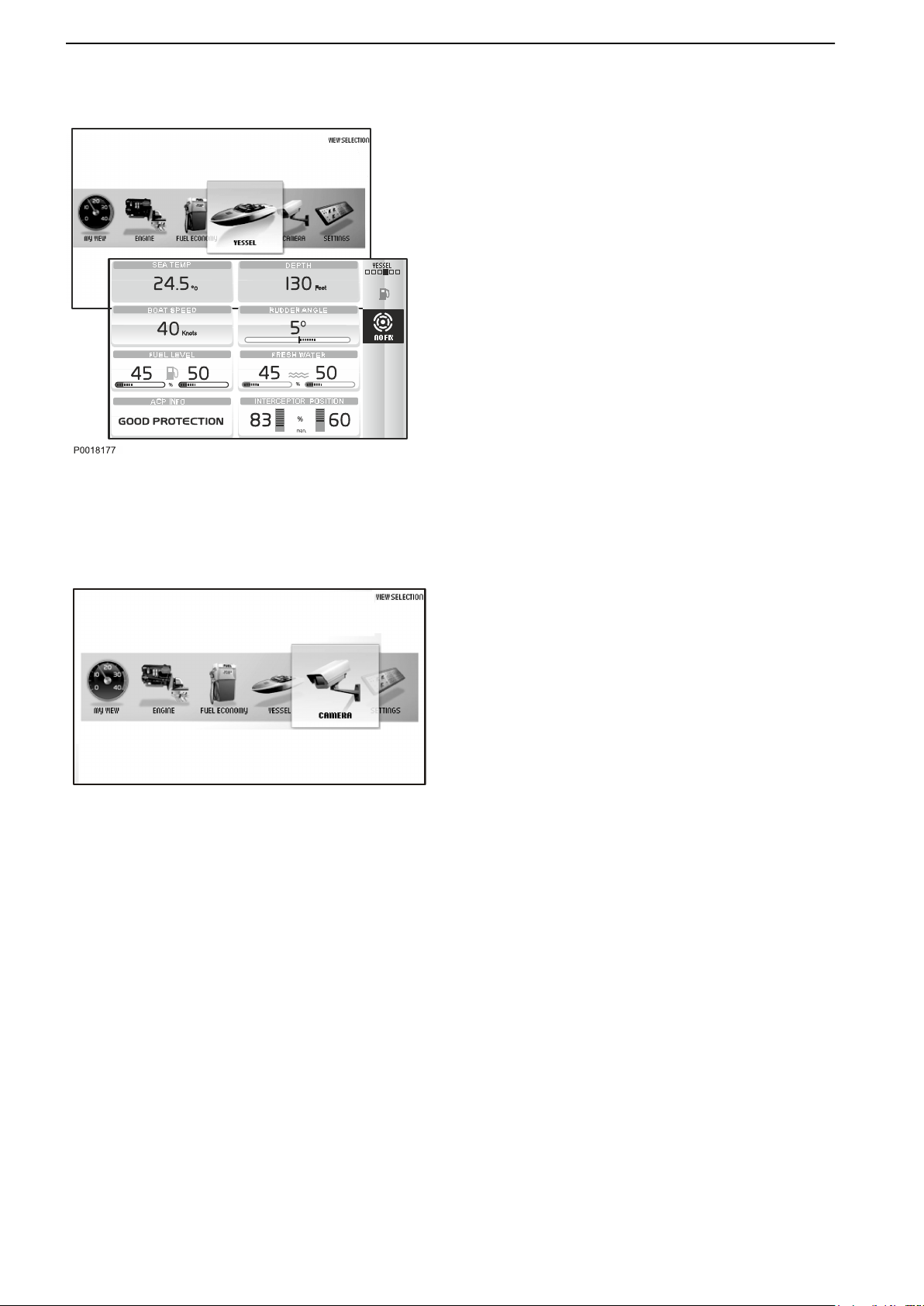

Vessel

Information concerning boat installations is displayed

in this view.

Depending on the functions installed in the boat, the

following can be displayed:

- Sea water temperature

- Depth,to set the echo sounder refer toDepth

Alarm in chapter Settings Menu page 120 .

- Boat Speed

- Rudder angle

- Fuel level

- Freshwater level

- ACP Info

Optional page 53 chapter.

- Interceptor position, for further information refer to

the Volvo Penta Interceptor System chapter.

The information in this view cannot be changed.

,for further ACP information, refer to the

Camera

It is possible to connect a camera to the screen (e.g.

for monitoring the engine compartment or swimming

platform).

If a camera is installed, images will be displayed in this

view.

28 47705796 05-2014 © AB VOLVO PENTA

Page 31

OK

OK

P0001098

P0001043

Instruments and Controls

Settings

Screen settings and different function settings are

made in

Mode

Choose between

background) or Night (light text on a dark background).

Press

Background

Choose between the background colors Gray, Aqua,

White, Carbon and Red.

this view. Turn to the desired menu and press

to access the sub menus.

the modes Day (dark text on a white

to switch between modes.

EVC Settings

Press OK to access the settings menu.

Settings for

audible alarm settings, alarm limits, language and

units. Information regarding boat installations is also

found here.

Neutral Beepswitching on and off the beeper that

sounds when the control is in the neutral position.

Info Beep Levelsetting the volume of the signal that

confirms when a function has been activated, or deactivated.

Trip Computer Resetzeroes all values in the trip computer.

Service

The drive is fitted with a sensor that monitors oil level

and quality. If the oil level in the drive is low or if there

is water in the oil, the helmsman is alerted by an audible alarm and a message is shown on the display

simultaneously. Every time oil is changed, the waterin-oil sensor must be calibrated; refer to

Service page 121

the display, switching functions on and off,

Camerafor laterally inverting the image shown or

showing the camera at a docking station.

Display Typefor selecting the engines the information

in the display concerns, and the type of installation the

display forms part of.

Infodisplay Contrast for adjusting the contrast on all

displays at the helm station.

Unitssetting units (metric/US/imperial) and unit of distance (km, NM or miles).

Languageselecting the display language.

47705796 05-2014 © AB VOLVO PENTA 29

Page 32

OK

3

4

1

2

5

P0001049

Instruments and Controls

Gauge Rangesetting the instrument's maximum

range.

Boat Speed10 – 100 knots in 10 knot stages.

Engine Speed2500, 3000, 4000, 5000, 6000 rpm.

Propeller speed1000, 2000, 3000 rpm.

EVC Informationthis information cannot be changed.

Featuresinstalled functions are marked blue.

Componentspress OK to see installed compo-

nents..

Softwareinformation regarding the software ID

number.

Calibration

The following is only displayed if the function is installed. For further information refer to the appropriate

section in the Settings Menu page 120

chapter.

Speed Correctionsetting the speed factor.

Depthsetting the echo sounder depth alarm. Follow

the instructions on the screen.

Fuel Tankfuel tank calibration. Follow the instructions

on the screen.

ACP Infosetting the ACP protection position.

PTAPTA calibration. Follow the instructions on the

screen.

Warning Manager

If the system discovers a fault, the helmsman is alerted

by a message on the display. The fault message must

be acknowledged by pressing

.

All faults are stored in Warning Manager.

The fault message indicates the driveline affected,

describes the fault and suggests suitable actions.

For further information on fault messages, refer to

Fault Handling page 67.

1 Symbol

2 Shows which driveline the fault was detected in.

3

List of registered faults; turn the knob to browse.

4 Fault message with description and suggestion for action.

5 Service information.

30 47705796 05-2014 © AB VOLVO PENTA

Page 33

OK

!

!

!

!

PT

SB

1

2

3

4

P 1993700

PT

N N

SB

STEERING GEAR

RUDDER ANGLE

OVERLOAD

ACTUATOR

BRAKE

POWER

COMMUNICATION

STEERING GEAR STATUS

DIRECTION OF THRUST

AUTOPILOT ACTIVE

0 0

1

2

3

P 1994600

Instruments and Controls

Alarm display

The alarm display shows a summary of current and

historical engine and transmission alerts.

1 Summary of registered engine and transmission

alerts.

Use the knob to browse between alerts.

Fault message with description and suggestion for

2

action.

3 Service information.

4 Engine status; the color of the lamp next to the

engine symbol shows engine status.

Gray lamp; engine stopped

Green lamp; engine running

Orange lamp; minor malfunction

Red lamp; major malfunction

If the system discovers a fault, the helmsman is alerted

by a message on the display. The fault message must

be acknowledged by pressing

For further information on fault messages, refer to

Fault Handling page 67.

Steering gear display

The rudder angle view is a monitor that shows drive

angle (1

- Direction of thrust

- Overload

- Actuator

- Brake

- Power

- Communication

- Steering gear status

The color of the lamp (2) shows the status of each

drive.

Gray lamp; drive stopped

Green lamp; status OK.

Orange lamp; drive malfunction, steering unaffected

Red lamp; steering affected

Autopilot (3) is shown when the autopilot is running.

) plus status and alerts for:

47705796 05-2014 © AB VOLVO PENTA 31

Page 34

Instruments and Controls

Controls

This section describes the controls Volvo Penta sells

for your engine. Contact your dealer if your boat is

equipped with controls other than those described

here, and you feel uncertain about their function.

Triple installation

Both the

function are controlled using the control levers. The

two control levers controls all engines and propulsion

units.

A If the control levers are in different positions the

B If one of the control levers is in neutral propulsion

C Are the control levers in different positions, one

adjustment of engine speed and the gear shift

centre engine (2) will operate in this range of revolutions.

the centre propulsion unit (2) is also in neutral.

engaged for forward motion and the other for reward

motion, the centre propulsion unit will be in neutral.

Quadruple Installation

Both the adjustment of engine speed and the gear

shift function are controlled using the control levers.

The port side control lever (A) controls the port side

engines and propulsion units 1 and 2. The starboard

control lever (B) controls the starboard engines and

propulsion units 3 and 4.

32 47705796 05-2014 © AB VOLVO PENTA

Page 35

R

F

N

T

T

P0012501

Instruments and Controls

N = Neutral position. Reverse gear/drive disengage-

dand engine at idle.

F = Reverse gear/drive engaged for forward motion.

R = Reverse gear/drive engaged for rearward

motion.

T = Engine rpm control (throttle).

Engine and drive features are controlled with push buttons on the control. What buttons and functions available is depending on the installation.

1 STATION

The

button lamp is lit if the helm station is active and

lit. Refer to Operation page 61 for further information.

2 CRUISE CONTROL

Switch on cruise control by pressing the button.

Fine tune the locked engine speed by increasing (+)

or reducing (-) engine rpm with the button on the

back of the control.

3 LOW SPEED

Refer to Optional page 36 for information.

4 THROTTLE ONLY

Disconnects the shift function so that the control

lever only affects engine speed; refer to "Disengaging shift function" in this chapter for further information.

5 SINGLE LEVER

Switch on the single-lever function by pressing the

button. The lever that is moved from its position first

becomes the control lever for both engines. The

other control lever has no function as long as the

single-lever function is activated. The button lamp

lights up to show that the function is active. Exit the

single-lever function by pressing the button again.

Read more about the single-lever function in

Optional page 37.

6

Neutral position. The symbol shows that the drive/

reverse gear is disengaged.

7

47705796 05-2014 © AB VOLVO PENTA 33

The warning triangle lights up if the system discovers a fault; refer to Fault Handling page 67 for

information.

The

warning triangle lights up on the same side as

the driveline with the indicated fault. In triple installations, both triangles light up if the center driveline

registers a fault.

8 This function is not available.

Page 36

Instruments and Controls

Disengaging the Shift Function

The gearshift function can be disconnected so that the

control lever only operates the throttle.

1 Put the control levers in neutral.

2 Press the control “Throttle Only” button or the

neutral button (N) on the helm station panel.

3 Release the button. The N symbol on the control

will light up as confirmation that the gearshift

function is disengaged and that the lever will

only affect engine revolutions.

To exit neutral mode, press the button again.

Adjusting the friction brake

The control lever has a friction brake that can be

adjusted for lighter or stiffer lever movement. Resistance in click mode can also be adjusted.

1

Switch off the engine.

Remove the cover (3).

2

3 Adjust the friction brake (1) and/or click mode (2)

by turning the screw clockwise for stiffer lever

movement, and counterclockwise for lighter

lever movement.

4 Replace the cover.

34 47705796 05-2014 © AB VOLVO PENTA

Page 37

1

2

3

4

P0016686

Instruments and Controls

Joystick

The joystick is optional. The features are controlled

with push buttons on the control. What buttons and

functions available is depending on the installation.

1 Docking

operation and further function information, refer

For

to Joystick for docking page 39.

2 Dynamic Positioning System

For operation and further function information, refer

to Optional page 49.

3 Joystick Driving

For operation and further function information, refer

to Joystick Driving page 42.

4 High Mode

For operation and further function information, refer

to Joystick for docking page 39.

47705796 05-2014 © AB VOLVO PENTA 35

Page 38

Optional

P0012978

B

B

R

F

N

A

A

P0012499

Low speed

The Volvo Penta low speed function is available for

engines with hydraulic transmissions.

Boats with powerful engines can have high speeds

even at low revolutions; the low speed function

reduces speed.

N = Neutral position.

Transmission is disengaged and engine revolutions are at idle.

F = Forward at idle.

The transmission is engaged for operations

ahead and the engine is at idle; this involves

maximum trolling in the transmission.

R = Reverse at idle.

The transmission is engaged for operations

astern and the engine is at idle; this involves

maximum trolling in the transmission.

A = Low speed engaged.

The transmission affects propeller revolutions.

The engine is not affected.

B = Low speed disengaged.

The control affects engine speed and propeller

revolutions.

Engaging the low speed function

1 Move the lever to the neutral position.

2

Press the Low Speed button on the control or

on the helm station panel to activate the

low speed function.

An audible signal and the message “Lowspeed

activated” (A) will be displayed on screen to

confirm that the function is on.

is shown on the screen if the low speed function

is active (B).

When the

occur when shifting.

Disengage the low speed function

1

2

low speed function is engaged a delay may

Move the lever to the neutral position.

Press the Low Speed button on the control or

on the helm station panel to disengage the

low speed function.

Two audible signals confirm that the function is

switched off and the “Lowspeed deactivated”

(C)message is displayed on the screen.

36 47705796 05-2014 © AB VOLVO PENTA

Page 39

Sport Fishing Mode

P0001219

P0002114

Optional

The Volvo

deep-sea fishing. When the function is activated, the

IPS units are angled outwards and the helmsman can

quickly rotate and maneuver forward/backwards to follow the movement of the fish. When activated, the

wheel is disconnected and the boat is maneuvered

solely via the control levers.

When the function is activated, the wheel is disconnected and the boat is steered with the control levers.

Penta sport fish function was developed for

WARNING!

There is a risk that the boat may take in water if the

movements are too violent.

The single-lever function used together with the sport

fish function makes it possible to control both engines

using just one of the control levers.

Sport fishing

Switching on the sport fishing function

1 Move both control levers to neutral.

2

Press the sport fishing button on the panel.

An audible signal and the message “Sport fishing

activated” will

to confirm that the function is activated.

If it is not possible to switch on the function, check that

the controls are in neutral.

Switching off the sport fishing function

When the function is switched off, both IPS units are

set to dead ahead.

IMPORTANT!

If the controls are at full throttle when the function is

switched off the boat will accelerate forward.

1 Exit the function by pressing the sport fish button

on the panel. An audible signal and the message

“Sport fish deactivated” will be displayed on screen

to confirm that the function is on.

2 It is also possible to exit the function by turning the

wheel more than 30 degrees.

be displayed on screen for 5 seconds

47705796 05-2014 © AB VOLVO PENTA 37

Page 40

P0002114

Optional

Single lever

Switching on the single-lever function

1 In

control levers in neutral.

2

Press the

function.

An audible signal and the message “Single lever

activated” will be displayed on screen to confirm

that the function is on.

3

When the single-lever function is activated, the

lever that is moved from its position first becomes

the control lever for both engines.

The other control lever has no function as long as

the single-lever function is activated.

Switching off the single-lever function

1 Move the levers to neutral.

2 Press the single lever button. A double audible sig-

nal and the message “Single lever deactivated” will

be displayed on screen to confirm that the function

is off.

to activate the single-lever function, put the

order

button to switch on the single-lever

Clear Wake Exhaust System

When running at idle it is possible to select exhaust

discharge above the waterline, which provides

improved comfort, lower noise and reduced vibrations

in the boat.

1

Press the

off.

button to switch the function on and

38 47705796 05-2014 © AB VOLVO PENTA

Page 41

Optional

Joystick

Joystick for docking

Volvo Penta Joystick is a control used for docking and

maneuvering. Practise using the joystick and its functions in a safe and proper manner. Practise how to

operate the boat with both joystick docking and steering functions.

CAUTION!

The joystick maneuvering works differently

depending on if the docking function or steering

function is active.

Practise using

all conditions.

The docking function is designed to be used when

docking or maneuvering in close quarters. Use the

steering wheel and throttle control levers in all other

situations.

The boat is maneuvered by moving the joystick forward, aft, abeam, twisting the top of the joystick and

combinations of the movements.

all means of steering and throttle under

47705796 05-2014 © AB VOLVO PENTA 39

Page 42

Optional

CAUTION!

The boat

even when the joystick has been released.

To slow the boat or reverse its direction, move the joystick in the opposite direction. In order to achieve a

diagonal movement, move the joystick diagonally and

use the joystick knob to adjust the boat’s direction

accordingly.

will continue to move in the selected direction

When the docking function is activated, engine revolutions are limited and the boat can only be steered by

the joystick.

In order to activate the docking function, the following

must be fulfilled:

engines running

•

control levers in neutral

•

helm station active

•

joystick in center position

•

Activating the docking function

Activate docking mode by depressing the docking button (A) on the joystick.

An audible signal will confirm that docking mode is

activated and the docking button lamp will light up.

Exiting the docking function

To exit the function, press the joystick docking button

(A). An audible signal will sound twice to confirm that

docking mode is deactivated, and the docking light will

go out.

The docking function is also deactivated if the controls

are moved from the neutral position.

40 47705796 05-2014 © AB VOLVO PENTA

Page 43

Optional

High Mode

If extra power, e.g. when there is a strong wind or

strong current, the High Mode function may be

engaged.

Activate High Mode

1 Activate the joy stick by depressing the docking

button (

stick is activated and the docking button lights up.

2 Activate the High Mode function by depressing but-

ton (B) on the joy stick.

3 An audible signal confirms that the function is acti-

vated and the high Mode button lights up.

Disengage High Model

Disengage the function by pressing the button again.

An audible signal will sound twice to confirm that docking mode is deactivated, and the light will go out.

The system is now in normal docking mode.

A). An audible signal confirms that the joy

47705796 05-2014 © AB VOLVO PENTA 41

Page 44

P0016372

P0004011

Optional

Joystick Driving

NOTICE! Joystick steering only works together with

Volvo Penta autopilot.

The joystick steering function allows the joystick to be

used during

maneuver the boat in the same way as with the autoplilot and helm steering unit.

Throttle and gear shift controls work in the normal

manner.

Learn to maneuver the boat with the joystick in calm,

open waters.

Joystick steering is activated and de-activated by

pressing the

passage to adjust the boat's heading and

button on the joystick.

When joystick

steering is activated the autopilot is also

started. While the boat is under joystick control the

autopilot is in standby mode; when the joystick is

released to its central position the autopilot is activated

and locks in on the new heading after a few seconds.

Like the autopilot, the helm steering unit is locked when

joystick steering is active but it may always be used for

e.g. changing course or giving way for an obstacle.

Twist the top of the joystick or move it sideways to

reengage joystick steering.

If the autopilot is put in standby mode manually by

means of the STBY button, joystick steering is

switched off and must be reengaged using the button

on the joystick.

Heading adjustments

Twist the top of the joystick to change heading incrementally. A short twist changes the heading by a fixed

increment while a twist held firm will change the heading through several increments.

The autopilot shows the heading with a digital value

and a indicator in shape of a blue triangle, a yellow

arrow shows the new heading that the boat will be set

to.

Maneuvering

The joystick can also be used to maneuver the boat in

the same manner as with a helm steering unit. Move

the joystick sideways to steer the boat in the same

direction. When the joystick is released the autopilot

will set a new heading that corresponds to boat heading.

NOTICE! Full joystick movement to one side corresponds to full helm.

Maneuvering abeam provides a faster response than

adjusting the heading by twisting the top of the joystick.

42 47705796 05-2014 © AB VOLVO PENTA

Page 45

P 1994500

P0004011

P0016372

Optional

Joystick steering, type approved installation

The joystick steering function allows the joystick to be

used during passage to adjust the boat's course and

maneuver

boat in the same way as with the steer-

the

ing wheel. Throttle and gear shift controls work in the

normal manner.

Learn to maneuver the boat with the joystick in calm,

open waters.

Joystick steering is activated and de-activated by

pressing the

button on the joystick.

The steering wheel can also be used when joystick

steering is active e.g. to change course or avoid an

obstacle. Twist the top of the joystick or move it sideways to re-activate joystick steering.

Maneuvering

Twist the top of the joystick to change rudder angle

gradually. A short twist changes the rudder one

degree while a twist held firm will change course

through several degrees.