Volvo Penta IPS, IPS 350, IPS 400, IPS 450, IPS 500 Operator's Manual

...

OPERATOR’S MANUAL

Volvo Penta IPS

An English version of this Operator’s Manual may

be ordered free of charge up to 12 months after delivery, via

internet, mail or fax. Refer to the order form in the back of

the book.

All information is stored internally at AB Volvo Penta and will

not be passed on to third parties.

Diese deutsche Version dieses Handbuches kann

innerhalb von 12 Montane ab Lieferung kostenlos online,

per Brief oder per Fax bestellt werden. Bitte Bestellformular

hinten im Buch verwenden.

Alle Angaben werden bei AB Volvo Penta gespeichert und

nicht Dritten übermittelt.

Une version française de ce manuel d’instructions

peut être commandée gratuitement, jusqu’à 12 mois après

la date de livraison, via Internet, la poste ou par fax. Voir à

la n de ce document.

Toutes les informations sont stockées en interne chez AB

Volvo Penta et ne sont divulguées à aucun tiers.

Hay disponible una versión en español gratuita de

este manual de instrucciones, la cual puede pedirse, a través de Internet, correo postal o fax, en el plazo de 12 meses

después de la entrega del producto. Véase el formulario de

pedido en las últimas páginas del manual.

Todos los datos recibidos son almacenados de forma in-

En svensk version av denna instruktionsbok kan

beställas kostnadsfritt, upp till 12 månader efter leverans,

via internet, post eller fax. Se beställningsformulär i slutet av

boken.

Alla uppgifter lagras internt hos AB Volvo Penta och lämnas

inte ut till tredje part.

Een Nederlandse versie van dit instructieboek kan

kosteloos worden besteld tot 12 maanden na aevering, internet, post of fax. Zie het bestelformulier achterin het boek.

Alle gegevens worden intern opgeslagen bij AB Volvo Penta

en niet verstrekt aan derden.

En dansk version af denne instruktionsbog kan

bestilles gratis, op til 12 måneder efter levering, via internet,

post eller telefax. Se bestillingsformular i slutningen af bogen.

Alle oplysninger gemmes internt hos AB Volvo Penta og

overgives ikke til tredje part.

Tämän ohjekirjan suomenkielisen version voi tilata

veloituksetta 12 kuukauden sisällä toimituksesta internetistä,

postin kautta tai faksilla. Katso tilauslomake kirjan lopusta.

AB Volvo Penta tallentaa kaikki tiedot sisäisesti eikä niitä

luovuteta kolmannelle osapuolelle.

Pode-se encomendar uma versão gratuita deste

manual de instruções em português, até 12 meses após a

entrega, através de Internet, correio ou fax. Consultar o for-

mulário de encomenda no m do manual.

Todas as informações são armazenadas internamente pela

Volvo Penta e não são partilhadas com terceiros.

Εντός 12 μηνών από την παράδοση μπορείτε να

παραγγείλετε μέσω Internet, ταχυδρομικής επιστολής ή φαξ

μια ελληνική έκδοση του Βιβλίου χρήσης χωρίς χρέωση.

Χρησιμοποιήστε το δελτίο παραγγελίας στο τέλος του

βιβλίου.

Όλες οι πληροφορίες αποθηκεύονται από την AB Volvo Pen-

Вариант настоящего руководства по

эксплуатации на русском языке можно заказать

бесплатно в течение 12 месяцев после доставки по

Интернету, электронной почте или по факсу. См. бланк

заказа на обложке руководства.

Вся информация используется компанией AB Volvo Penta конфиденциально и не передается третьим сторонам.

Bu Kullanım Kılavuzunun Türkçe versiyonu teslim-

den 12 ay sonrasına kadar internet, posta veya faks yoluya

sipariş edilebilir. Kitabın arka kısmında bulunan sipariş formuna bakınız.

Tüm bilgiler AB Volvo Penta’da saklıdır ve üçüncü kişilere

verilmez.

Una versione in lingua italiana di questo manuale di

istruzioni può essere ordinata gratuitamente, no a 12 mesi

dopo la consegna, via internet, per posta o via fax. Vedere il

modulo per l’ordinazione alla ne del manuale.

Tutti i dati forniti saranno memorizzati internamente presso

AB Volvo Penta e non saranno divulgati a terzi.

CALIFORNIA

Proposition 65 Warning

Diesel engine exhaust and some of its constituents are known

to the State of California to cause cancer, birth defects, and

other reproductive harm.

Content

Foreword ...................................................................................................... 2

Safety Information ...................................................................................... 3

Introduction ................................................................................................. 8

Presentation .............................................................................................. 10

Instruments and Controls ........................................................................ 12

Optional ..................................................................................................... 26

Starting ...................................................................................................... 31

Operation ................................................................................................... 34

Engine Shutdown ...................................................................................... 38

Fault Handling ........................................................................................... 41

Fault Code Register .................................................................................. 45

In Case of Emergency .............................................................................. 57

Maintenance Schedule ............................................................................. 65

Maintenance .............................................................................................. 67

Storage ....................................................................................................... 98

Calibration and Settings ......................................................................... 102

Technical Data ......................................................................................... 114

Alphabetical index .................................................................................. 120

1

Foreword

Volvo Penta marine engines are used all over the world. They are used in all possible operating conditions for

professional as well as leisure purposes. This is not a coincidence. After 100 years as an engine manufacturer

the Volvo Penta name has become a symbol of reliability, technical innovation, top of the range performance and

long service life. We also believe that this is what you demand and expect of your Volvo Penta engine.

We would like you to read this operator’s manual thoroughly and consider the advice we give on running and

maintenance before your maiden voyage so that you will be ensured of fulfilling your expectations. Please pay

attention to the safety instructions contained in the manual.

As owner of a Volvo Penta marine engine, we would also like to welcome you to a worldwide network of dealers

and service workshops to assist you with technical advice, service requirements and replacement parts. Please

contact your nearest authorized Volvo Penta dealer for assistance.

You will find your closest dealer at our home page on the Internet www.volvopenta.com - amongst other

useful information about your Volvo Penta engine - we invite you to visit!

2 7748921 04-2008

Safety Information

Read this chapter very carefully. It has to do with your safety. This describes how safety information is presented

in the instruction book and on the product. It also gives you an introduction to the basic safety rules for using and

looking after the engine.

Check that you heave received the correct instruction book before you read on. If not, please contact your

Volvo Penta dealer.

!

This symbol is used in the instruction book and on the product, to call your attention to

the fact that this is safety information. Always read such information very carefully.

Safety texts in the instruction book have the following order of priority:

DANGER!

Indicates a hazardous situation which, if not avoided, will result in death or serious

injury.

WARNING!

Indicates a hazardous situation which, if not avoided, could result in death or serious

personal injury.

CAUTION!

Indicates a hazardous situation which, if not avoided, could result in minor or moderate

personal injury.

IMPORTANT!

Indicates a situation which, if not avoided, could result in property damage.

NOTICE! Used to draw attention to important information that will facilitate work or

operations.

This symbol is used on our products in some cases and refers to important information

in the instruction book. Make sure that warning and information symbols on the engine

are clearly visible and legible. Replace symbols which have been damaged or painted

over.

7748921 04-2008 3

Your new boat

Read the instruction books and other information

carefully, which came with your new boat. Learn to

handle the engine, controls and other equipment in a

safe and correct manner.

If this is your first boat, or a type of boat you are not

experienced in using, we recommend that you practice operating the boat in peace and quiet. Get to know

the way the boat reacts to sea and to the controls

under different speed, sea and loading conditions

before you cast off for your first “real” maiden voyage.

Remember that the captain of every boat is required

by law to know and to observe applicable rules for

traffic and safety at sea. Get to know the rules which

apply to you and your waters, by contacting the relevant authority or sea safety organization.

It is a good idea to go on some kind of boat operation

course. We recommend that you contact a regional

boat or sea safety organization to find a suitable

course.

Fuel filling

There is always a risk of fire and explosion during fuel

filling. Smoking is not permissible, and the engine

should be stopped.

Never over-fill the tank. Shut the tank cap securely.

Only use the fuel recommended in the instruction

book. The wrong grade of fuel can cause serious malfunctions, power loss or stop the engine.

Daily checks

Make it a habit to give the engine and engine bay a

visual check before driving (before starting the

engine) and after operation (when you have stopped

the engine). This helps you to quickly discover

whether any leakage of fuel, coolant, oil or any other

abnormal event has happened, or is about to happen.

Do not start the engine

Do not start the engine if you suspect a fuel or LPG

leak in the boat, close to explosive media, or if there

is a spillage of explosive media. An explosive environment entails a risk of fire and/or explosion.

Manoeuvring

Avoid sudden or surprising rudder movements and

gear shifting. There is a risk that passengers could fall

over, or overboard.

A rotating propeller can cause severe injury. Check

that there is nobody in the water before you engage

forward / astern (reverse) drive. Never drive close to

bathers or in areas where you could reasonably

expect that people could be in the water.

Accidents and near misses

Life saving statistics show that inadequate care of

boats and engines, and deficiencies in safety equipment are frequent causes of accidents and near

misses at sea.

Make sure that your boat and engine are maintained

in accordance with the advice in each instruction

book, and that the necessary safety equipment is on

board, and is in working condition.

Safety Information

4 7748921 04-2008

Carbon monoxide poisoning

When a boat moves forwards, an area of low pressure

air forms behind the boat. In adverse conditions, this

low pressure can be so strong that the boat’s own

exhaust fumes are sucked into the cockpit or cabin,

which entails a risk of carbon monoxide poisoning for

all aboard.

The problem of low-pressure suction is worst in high,

wide boats with a square transom. But even in other

types of boats, low-pressure suction can be a problem

in some conditions, such as if you drive with the hood

up. Other factors which increase the low-pressure

effect are wind conditions, load distribution, pitching,

trimming, open windows and ventilators etc.

Most modern boats are designed so that the problem

of low-pressure suction is very rare, however. If lowpressure suction does occur anyway, do not open

hatches or ventilators in the forward part of the boat.

Strangely enough, this makes the problem worse. Try

changing speed, trimming or load distribution instead.

Also try taking down/opening the hood or modifying it

in some other manner. Ask your boat dealer for advice

about the best solution for your particular boat.

P0003073

Remember

• Safety equipment: Life jackets for everybody aboard, communication equipment, emergency

rockets, approved fire extinguisher, first aid kit, life buoy, anchor, paddle, torches etc.

• Spare parts and tools: Impeller, fuel filters, fuses, tape, hose clamps, engine oil, propeller and

tools for the jobs you could be expected to have to do.

• Take your chart out and study your planned route. Calculate distance and fuel consumption.

Listen to weather reports.

• Tell your friends/relatives about route plans if you undertake a long journey. Remember to

notify changed plans or delays.

• Inform everybody aboard about where the safety equipment is located, and how it works. Make

sure that there is more than one person aboard who can start and operate the boat safely.

This list can be extended, since the need for safety equipment varies with the type of boat, and

where or how it is used etc. We recommend that you ask a regional boat or sea safety organization

for more detailed maritime safety information.

Safety Information

7748921 04-2008 5

Preparations

Knowledge

The operator’s manual contains instructions on how

to carry out general maintenance and service operations safely and correctly. Read the instructions carefully before starting work.

Service literature covering more complicated operations is available from your Volvo Penta dealer.

Never carry out any work on the engine if you are

unsure of how it should be done, contact your Volvo

Penta dealer who will be glad to offer assistance.

Stop the engine

Stop the engine before opening or removing engine

hatches. Unless otherwise specified all maintenance

and service must be carried out with the engine stopped.

To prevent accidental start of the boat engine, remove

the ignition key, turn off the power supply to the engine

at the main switches and lock them in the OFF position before starting work. Put up a warning sign in the

control position that work on the engine is being carried out.

Approaching or working on an engine which is running

is a safety risk. Loose clothing, hair, fingers or a dropped tool can be caught in the rotating parts of the

engine and cause serious personal injury. Volvo

Penta recommend that all servicing with the engine

running should be undertaken by an authorized Volvo

Penta workshop.

Lifting the engine

When lifting the engine, use the lifting eyes installed

on the engine. Always check that lifting equipment is

in good condition and has sufficient load capacity to

lift the engine (engine weight including any extra

equipment installed). For safety’s sake lift the engine

using an adjustable lifting beam. All chains and cables

should run parallel to each other and as perpendicular

as possible in relation to the top of the engine. Bear

in mind that extra equipment installed on the engine

may alter its center of gravity. Special lifting equipment may then be required in order to maintain the

correct balance and make the engine safe to handle.

Never carry out work on an engine suspended on a

hoist.

Before starting the engine

Reinstall all protective parts removed during service

operations before starting the engine. Check that no

tools or other items have been left on the engine.

Never start a turbocharged engine without installing

the air cleaner (ACL). The rotating compressor in the

Turbocharger unit can cause serious personal injury.

Foreign objects can also be sucked in and cause

mechanical damage to the unit.

Fire and explosion

Fuel and lubrication oil

All fuel, most lubricants and many chemicals are

inflammable. Read and follow the instructions on the

packaging.

When carrying out work on the fuel system, make sure

the engine is cold. A fuel spill onto a hot surface or

electrical components can cause a fire.

Store fuel soaked rags and other flammable material

so that there is no danger of them catching fire. Fuelsoaked rags can self-ignite under certain conditions.

Do not smoke when filling fuel, oil or in proximity of a

filling station or in the engine room.

Non-original components

Components used in the fuel and electrical systems

on Volvo Penta products are designed and constructed to minimize the risk of fire and explosion.

Using non-original Volvo Penta parts can result in fire

or explosion on board.

Batteries

The batteries contain and emit oxyhydrogen gas,

especially during charging. This gas is easily ignited

and highly volatile.

Do not under any circumstances smoke or use naked

flame or allow sparks in the vicinity of the batteries or

battery compartment.

An incorrect connection of a battery terminal cable or

jump-start cable can cause a spark which in its turn

can be sufficient to cause an explosion.

Start spray

Never use start spray or similar agents to start an

engine equipped with air pre-heating (glow plugs/

starter element). This may cause an explosion in the

inlet manifold. Danger of personal injury.

Safety Information

6 7748921 04-2008

Hot surfaces and fluids

There is always a risk of burns when working with a

hot engine. Beware of hot surfaces. For example: the

exhaust pipe, turbo unit, oil pan, charge air pipe,

starter element, hot coolant and hot oil in oil lines and

hoses.

Carbon monoxide poisoning

Only start the engine in a well-ventilated area. If operating the engine in an enclosed space, ensure that

there is proper ventilation in order to remove exhaust

gases and crankcase ventilation emissions from the

working area.

Chemicals

Most chemicals such as anti-freeze, rustproofing

agent, inhibiting oil, degreasing agent etc. are hazardous to health. Read and follow the instructions on

the packaging.

Some chemicals such as inhibiting oil are inflammable

and dangerous if breathed in as well. Ensure good

ventilation and use a protective mask when spraying.

Read and follow the instructions on the packaging.

Store chemicals and other hazardous materials out of

the reach of children. To protect the environment,

please dispose of used or leftover chemicals at a

properly designated disposal site for destruction.

Cooling system

There is a risk of flooding when working on the seawater system. Turn off the engine and close the sea

cock before starting work on the system.

Avoid opening the coolant filler cap when the engine

is hot. Steam or hot coolant can spray out and cause

burns.

If work must be carried out with the engine at operating temperature and the coolant filler cap or a cock

open or a coolant hose disconnected, open the coolant filler cap carefully and slowly to release pressure

before removing the cap completely. Note that the

coolant may still be hot and can cause burns.

Lubrication system

Hot oil can cause burns. Avoid skin contact with hot

oil. Ensure that the lubrication system is not under

pressure before commencing work on it. Never start

or operate the engine with the oil filler cap removed,

oil can spray out.

Fuel system

Always use protective gloves when tracing leaks. Liquids ejected under pressure can penetrate body tissue and cause serious injury. There is a danger of

blood poisoning.

Always cover the generator if it is located under the

fuel filter. The generator can be damaged by spilled

fuel.

Steering system

The boat has a advanced steering system. DO NOT

change connectors, wiring or splice of the components.

Service must be done by approved workshops which

have certifed personnel with qualified professional

training.

Electrical system

Cutting off power

Always stop the engine and break the current using

the main switches before working on the electrical

system. Isolate shore current to the engine block

heater, battery charger, or accessories mounted on

the engine.

Batteries

The batteries contain an extremely corrosive electrolyte. Protect your skin and clothes when charging or

handling batteries. Always use protective goggles and

gloves.

If battery electrolyte comes into contact with unprotected skin, wash off immediately using plenty of

water and soap. If battery acid comes into contact with

the eyes, flush immediately with plenty of water and

obtain medical assistance without delay.

Safety Information

7748921 04-2008 7

Introduction

This Operator's Manual has been prepared to give you the greatest possible benefit from your Volvo Penta marine

engine. It contains the information you need to be able to operate and maintain the engine safely and correctly.

Please read the Operator's Manual carefully and learn to handle the engine, controls and other equipment in a

safe manner before you cast off on your maiden voyage.

Always have the Operator's Manual available. Store it safely and do not forget to hand it over to the next owner

if you sell your boat.

The Operator’s Manual describes the engine and equipment sold by Volvo Penta. The illustrations in this book

covers several varieties and might differ, the essential information is always correct though. Installations with e.g.

different controls and instrumentation might occur, in these cases we refer to this products manual.

Warranty

Your new Volvo Penta marine engine is covered by a

limited warranty, under the conditions and instructions

compiled in the Warranty and Service book.

Please note that AB Volvo Penta’s liability is limited to

the specification in the Warranty and Service book.

Read it carefully, as soon as possible after delivery. It

includes important information about warranty cards,

service, maintenance, which it is the responsibility of

the owner to know, check and carry out. If this is not

done, AB Volvo Penta may fully or partly refuse to

honour its warranty undertakings.

Please contact your Volvo Penta dealer if you

have not received a Warranty and Service book,

or a customer copy of the warranty card.

Environmental care

All of us want to live in a clean, healthy environment.

Where we can breathe clean air, see healthy trees,

have clean water in lakes and seas, and be able to

enjoy the sunlight without fearing for our health.

Unfortunately, this is not self-evident these days, it is

something all of us must work hard for.

As a manufacturer of marine engines, Volvo Penta

has particular responsibility and for this reason, environmental care is a core value in our product development. Volvo Penta has a wide engine programme

these days, where considerable progress has been

made in reducing exhaust fumes, fuel consumption,

engine noise etc.

We hope that you will be want to preserve these values. Always observe the advice in the Operator's

Manual about fuel grades, operation and maintenance, to avoid unnecessary environmental impact.

Please contact your Volvo Penta dealer if you notice

any changes such as increased fuel consumption or

increased exhaust smoke.

Moderate your speed and distance so that wake and

noise do not disturb or damage animal life, moored

boats, jetties etc. Leave the archipelago and harbours

in the same state you would like to find them. Remember to always hand in drained oil, coolant, paint and

wash residue, used batteries etc. for destruction at a

recycling station.

If we all pull together, we can make a valuable contribution to the environment together.

Running in

The engine must be “run in” during its first 10 hours,

as follows:

Use the engine in normal operation. Full load should

only be applied for short periods. Never run the engine

for a long period of time at constant speed during this

period.

Higher oil consumption is normal during the running

in period. For this reason, check the oil level more

frequently than normally recommended.

After the first period of operation, the specified warranty inspection “First service inspection” can be

done. For more information: Please refer to the Maintenance Schedule.

Fuel and oils

Only use the fuels and oils recommended in the Operator's Manual. Other grades can cause malfunctions,

increased fuel consumption and eventually even

shorten the life of the engine.

Always change the oil, oil filters and fuel filter at the

specified intervals.

8 7748921 04-2008

Service and spare parts

Volvo Penta marine engines are designed for high

reliability and long life. They are built to withstand a

marine environment, but also to have the smallest

possible environmental impact. Through regular service and use of by Volvo Penta approved spare parts,

these qualities are retained.

Volvo Penta’s world-wide network of authorised dealers is at your service. They are Volvo Penta product

specialists, and have the accessories, original spares,

test equipment and special tools needed for high quality service and repair work.

Always observe the maintenance intervals in the

Operator's manual, and remember to note the engine/

transmission identification number when you order

service and spare parts.

Certified engines

If you own or operate an emission certified engine it

is important to be aware of the following:

Certification means that an engine type has been

checked and approved by the relevant authority. The

engine manufacturer guarantees that all engines

made of the same type are equivalent to the certified

engine.

This makes special demands on the care and

maintenance you give your engine, as follows:

• Maintenance and service intervals recommended by Volvo Penta must be complied with.

• Only Volvo Penta original spares may be used.

• Service on injection pumps, pump settings and

injectors must always be done by an authorised

Volvo Penta workshop.

• The engine must not be converted or modified,

except for the accessories and service kits

which Volvo Penta has approved for the engine.

• Installation changes to the exhaust pipe and

engine air inlet ducts must not be done.

• No seals may be broken by unauthorised personnel.

The general advice in the Operator's manual about

operation, care and maintenance apply.

Late or inadequate maintenance/service or the use of

spare parts not approved by Volvo Penta will invalidate AB Volvo Penta’s responsibility for the engine

specification being in accordance with the certificated

variant.

Volvo Penta accepts no responsibility or liability for

any damage or costs arising due to the above.

Introduction

7748921 04-2008 9

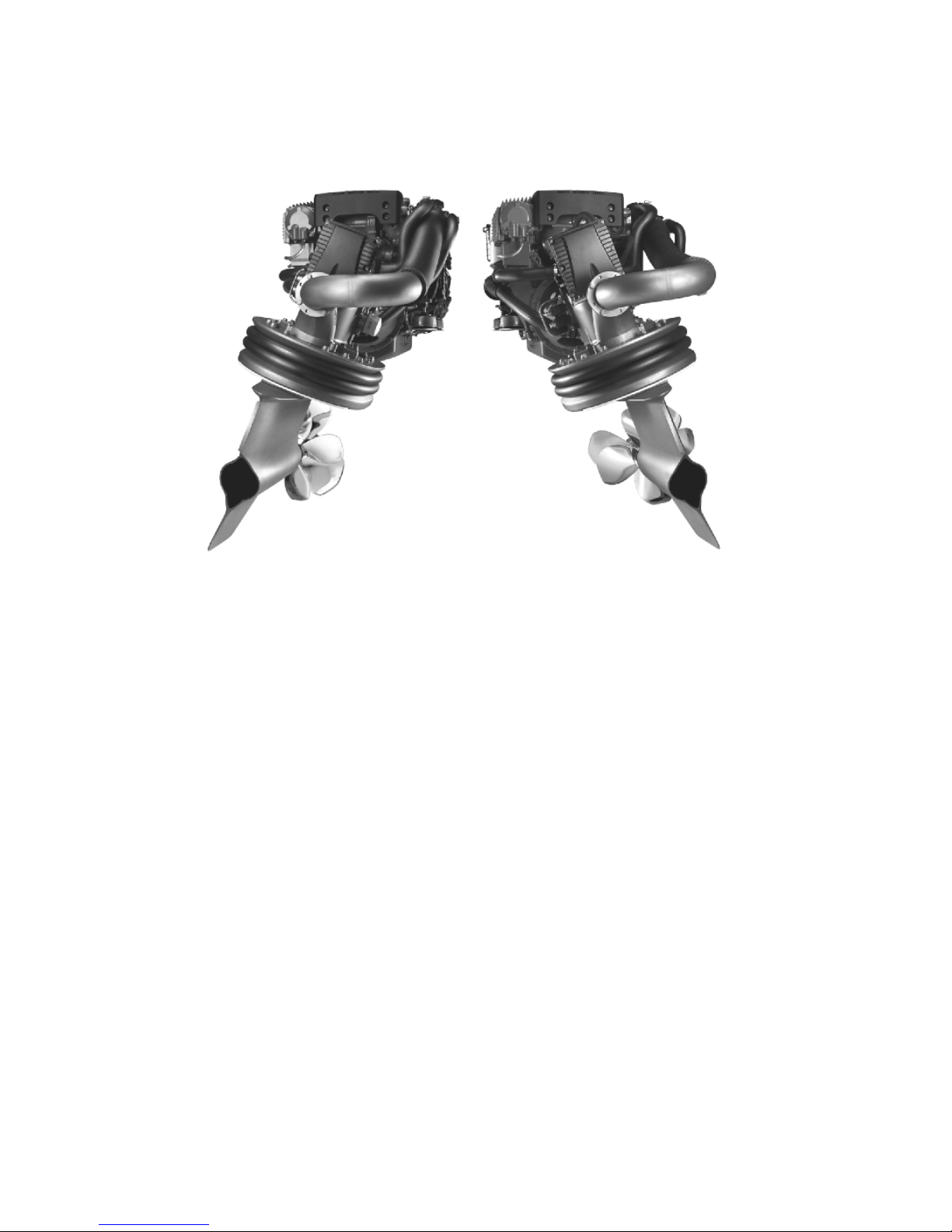

Presentation

Volvo Penta IPS - Inboard

Performance System

p0006599

Volvo Penta IPS overview

Volvo Penta IPS is setting a new standard:

- Much improved efficiency, higher top speed,

reduced fuel consumption/extended range and

great acceleration.

- Low-speed maneuvering is easier than ever

before, and high speed handling is a dream.

- Onboard comfort is greatly enhanced thanks to

much lower levels of sound and vibrations.

- Installation is greatly simplified.

- More space available for accommodation.

- Improved safety and quality.

- Ease of service and a complete system supported by one supplier.

- Improved overall environmental care.

Maneuvering and handling

The reasons for the amazing maneuverability are:

- The Volvo Penta IPS drive-units are steerable,

turning and pointing the entire thrust in the

desired direction. This results in much higher

efficiency and far greater response to driver

commands.

- Two counter-rotating propellers on each propulsion unit means that there are no lateral forces

to consider and that tracking is completely

straight.

- Electronic controls give a distinct and precise

feeling, and shifting is immediate. Thanks to the

progressive electronic steering, the wheel spins

easier at low speed, further reducing driver

effort.

All this is combined with the usual benefits of a traditional inboard such as a robust, high strength construction, excellent corrosion resistance and the

propellers under the hull.

10 7748921 04-2008

Comfort

Volvo Penta IPS new technology leads to major

improvements for all comfort enhancing factors.

- The propulsion forces and vibrations are absorbed by the combined rubber suspension and

sealing.

- A U-joint in the drive shaft makes it possible to

have the engine soft suspended, which efficiently reduces engine vibrations.

- The propellers are working in undisturbed water

with no cavitation, and have good clearance

from the hull.

- There is an increased number of propeller

blades to distribute the forces. This means that

the pulses created by the propellers have very

little effect on the hull.

- Exhaust fumes are truly minimized. First of all,

the new engine has very low exhaust emissions,

and secondly, the exhausts are emitted through

the propulsion unit into the prop wash and carried well behind the boat.

Environmental care

The Volvo Penta IPS has been developed as a complete system with excellent environmental performance as one of the main design targets. The very high

efficiency of the Volvo Penta IPS system gives greatly

reduced overall emissions.

Volvo Penta’s new D4/D6 in-line engines have been

developed from the latest design in modern diesel

technology. The engines have common rail fuel injection system, double overhead camshafts, 4 valves per

cylinder, turbocharger, compressor (Volvo Penta IPS

500), and aftercooler. The interaction of these, the

large swept volume, and the EVC system results in

exceptional diesel performance combined with low

emissions.

Installation

The Volvo Penta IPS system can be installed in various ways, either as a compact system or with an

extended jackshaft, giving opportunities for different

boat designs.

The system is always used in twin engine installation

configuration.

Safety and quality

Heavy duty material throughout means excellent corrosion resistance. Everything in contact with seawater

is either made from a specially formulated nickel-aluminum- bronze alloy or stainless steel. Propulsion

unit, bearings, couplings, etc. are all robustly dimensioned to cope with the unexpected and ensure a

really long and trouble-free service life.

EVC handles all communication and monitoring

including shift, throttle and steering. Several safety

functions in the system minimize the risk of damage

to engine or propulsion unit.

The Volvo Penta IPS system is designed with full

redundancy, i.e. even if you have a total breakdown

in one driveline, the remaining one will bring you home

safely.

Presentation

7748921 04-2008 11

Instruments and Controls

This chapter describes the instruments, panels and controls Volvo Penta sells for your engine.

If you would like to complement your instrumentation, or if your boat is equipped with instruments not described

here, we ask that you contact your Volvo Penta dealer.

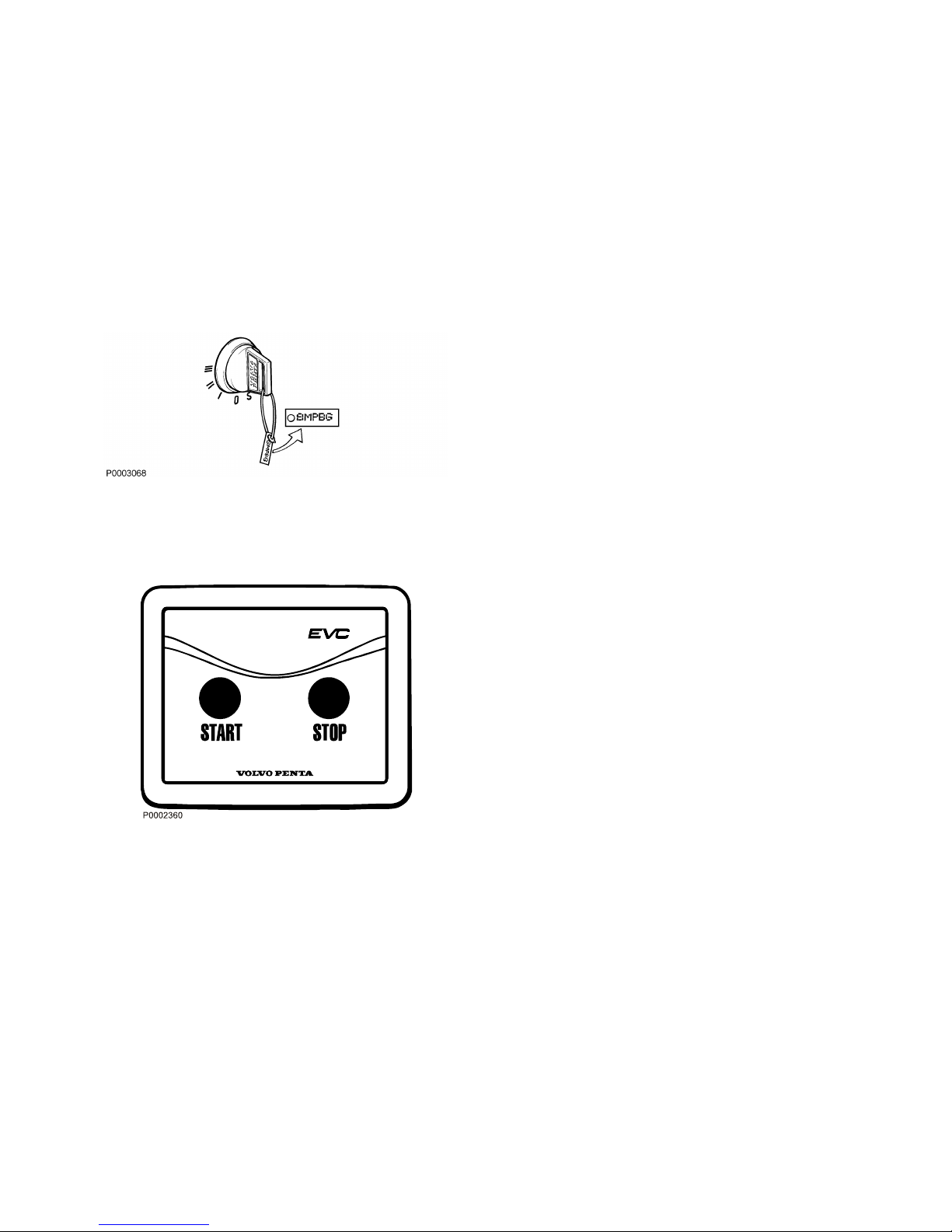

Ignition Lock

The start keys are supplied with a plate bearing the key

code to be used when ordering spare keys. Keep the

code beyond the reach of unauthorized people.

S = Stop position.

0 = The key can be inserted or removed.

I = Operating position. System voltage is connected.

II = Not used.

III = Start position. Start motor is engaged.

Read the starting instructions in chapter Starting page 31 to ensure you use the correct start

procedure.

Start/Stop Panel

The start/stop panel is used for starting and stopping

the engine.

To start the engine it is necessary for the start key at

the main station to be in the ”I” operating position. The

engine can only be stopped from an activated control

panel.

Read the starting instructions in chapter Start-

ing page 31 to ensure you use the correct start

procedure.

12 7748921 04-2008

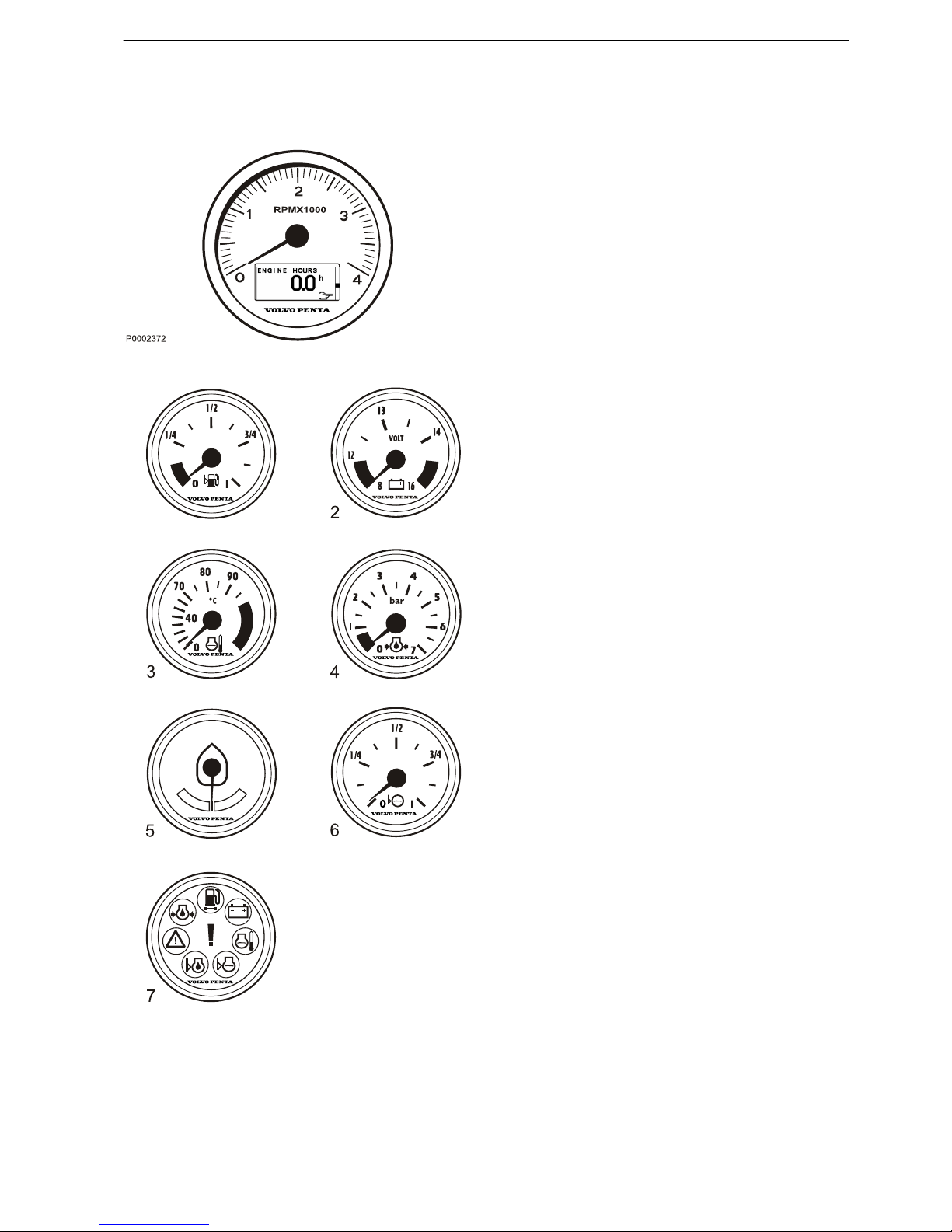

Gauges

Tachometer

The tachometer displays engine speed; multiply the

value shown on the dial by 1,000 to get the number of

engine revolutions per minute.

Boat and engine information is displayed in the tachometer window. Information displayed depends on

engine type, the number of sensors and which accessories are installed.

Optional instruments

These instruments are sold as engine options by Volvo

Penta.

1 Fuel level gauge

The fuel level gauge shows the quantity of remaining fuel.

2 Voltmeter, battery charging

The meter shows the alternator charge current.

During operations the charge voltage should be

around 14 V. When the engine is stopped and electrical power switched on the battery voltage should

be around 12 V.

If a 24 V system is installed, the charge voltage

should be around 28 V during operations.

3 Coolant temperature gauge

The instrument shows engine coolant temperature.

During operations coolant temperature should normally be between 75-90°C (167-194°F).

4 Oil pressure gauge

The oil pressure gauge displays engine oil pressure. During operations the oil pressure gauge

should normally show 4-5.5 bar. At idle, lower values are normal.

5 Rudder position indicator

The instrument shows rudder position.

6 Fresh water level sensor

Freshwater tank level gauge.

7 Alarm monitor

The alarm monitor gives a visual warning to call

attention to any alarms that occur.

1

P0005255

Instruments and Controls

7748921 04-2008 13

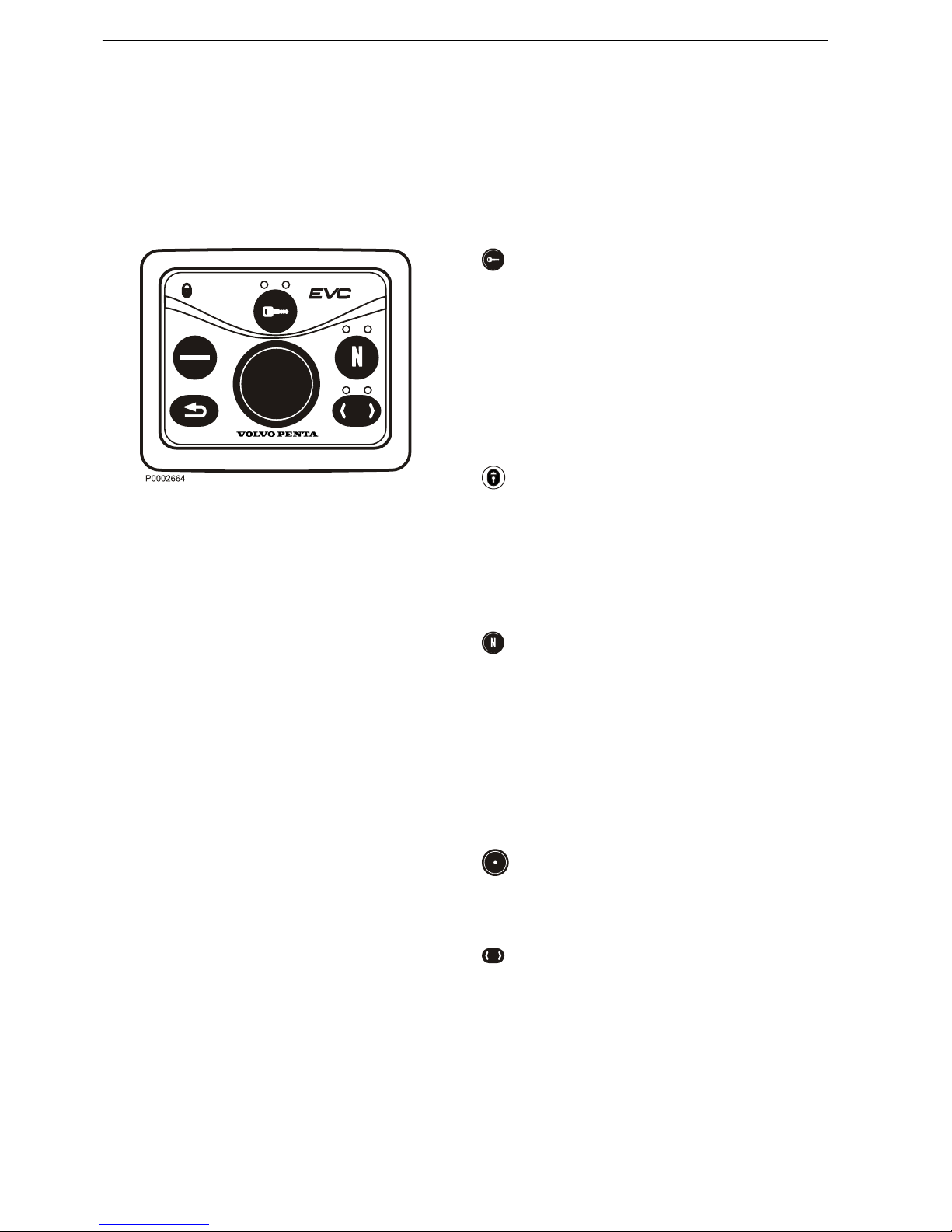

Control Panel

The control panel is used for station handling, disengaging the drive and to navigate the EVC system

menu.

Always push the buttons firmly and for at least one

second.

Activation button

The control panel and station are activated by pushing

the activation button once. Push twice to lock the station. On boats with only one station, this is always

active.

The lamp above the activation button shows the status

of the station.

Red lamp: Active station.

Lamp off: Station not activated.

Lamp flashing: A fault that limits the function of the

station has been detected.

Padlock

The padlock symbol lights when the station is locked

with the activation button or if change of stations is

under way, please refer to section Helm Sta-

tions page 36.

Lit: The station is locked and the boat can only be controlled from this station.

Flashing: Another station is locked.

Neutral button

The neutral button is used to disengage the drive enabling the engine rpm to increase without affecting the

drive, to warm up the engine. The lamp above the neutral button shows the status of the station.

Green lamp: Gear in neutral. The drive is in neutral

position and the engine runs at idle speed.

Lamp off: The drive is engaged for movement forward/

astern.

Flashing lamp: The drive is disengaged and the

engine speed can be adjusted.

Knob

Navigate the display menu by turning the knob.

Push the knob to confirm a selection or acknowledge

an alarm.

Tachometer Display Selection

Boats with one tachometer for port engine and one for

starboard can choose which engine menu to handle

from the station. The lamp above the button shows

which engine is chosen, green lamp for starboard

engine and red lamp for port engine.

Lamp off: Menu inactivated.

Lamp lit: Menu activated.

Instruments and Controls

14 7748921 04-2008

Multifunction Button

With the multifunction button the instruments and panels backlighting is adjusted.

Push the button for over a second to turn the backlighting on or off. The backlighting can be adjusted in

five stages by repeatedly pushing the multifunction

button quickly (less than 1 second).

If the button is pressed on an inactive station, operating

information is shown on the display(s) and the menu

structure is activated.

Back Button

Used to return a step up in the menu structure.

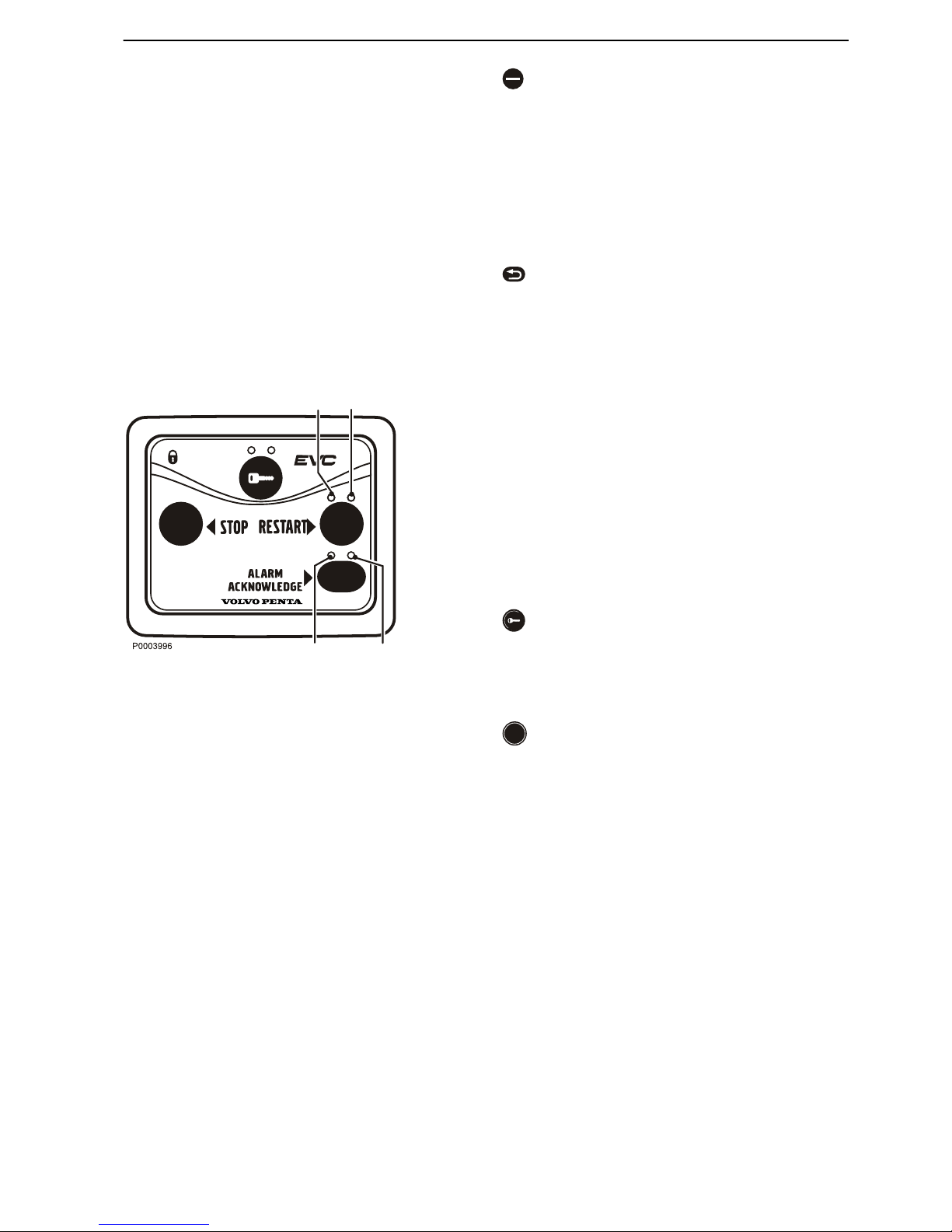

Docking Station Panel

The docking station panel allow stopping and restarting of the engines and handling of faults when operating the boat from a docking station.

The docking function (maneuvering with the joystick)

is enabled when the docking station is activated.

Please refer to the section Joystick page 23 for further information on docking.

Docking station can only be activated when the

engines are running.

Always push the buttons firmly and for at least one

second.

Activation button

Push this button on the docking station panel to activate and lock/unlock the docking station. Please refer

to section Instruments and Controls page 14 for further

information.

Stop and start buttons

Push these buttons to stop or restart the engines.

Both engines must be running when using the docking

function.

Lamp above the button: White

Lit: Port engine (1)/Starboard (2) engine are/is running.

Off: Port engine (1)/Starboard (2) engine are/is shut

off. Flashing and accompanied with a buzzer: The

engine(s) has stopped without a stop request. Silence

the buzzer with the Alarm acknowledge button and

restart the engine(s).

1

1

2

2

Instruments and Controls

7748921 04-2008 15

Alarm acknowledge button

Push this button to acknowledge an alarm of a fault. A

fault is always indicated with a flashing lamp above the

button and a more serious faults is also indicated with

a buzzer. When the fault is acknowledged the lamp will

light continuously and the buzzer will silence. The fault

pop-up must be read and acknowledged on a station

that is equipped with displays. Please refer to the

“Operation” chapter, section “Acknowleging alarms

and messages”.

Lamp above the button: Red

Flashing: Port (1)/Starboard (2) engine has a fault. Lit:

The fault is acknowledged.

Acknowledging faults on Docking Station

Since a docking station is not equipped with displays

and a control panel, an alarm of a fault is handled in a

different way.

On a docking station a fault is always indicated with a

flashing red lamp above the

Alarm acknowledge

button the docking station panel. The flashing lamp

indicates which engine (1/2/3) is faulty. A more serious

fault is also indicated with a buzzer.

1

Acknowledge the fault with the

Alarm acknowl-

edge button. The lamp above the button stops

flashing and lights continuosly. The buzzer is

silenced.

2 Activate a station that is equipped with displays in

order to read and acknowledge the fault pop-up.

3 Take the recommended actions. Please refer to

Fault Code Register page 45.

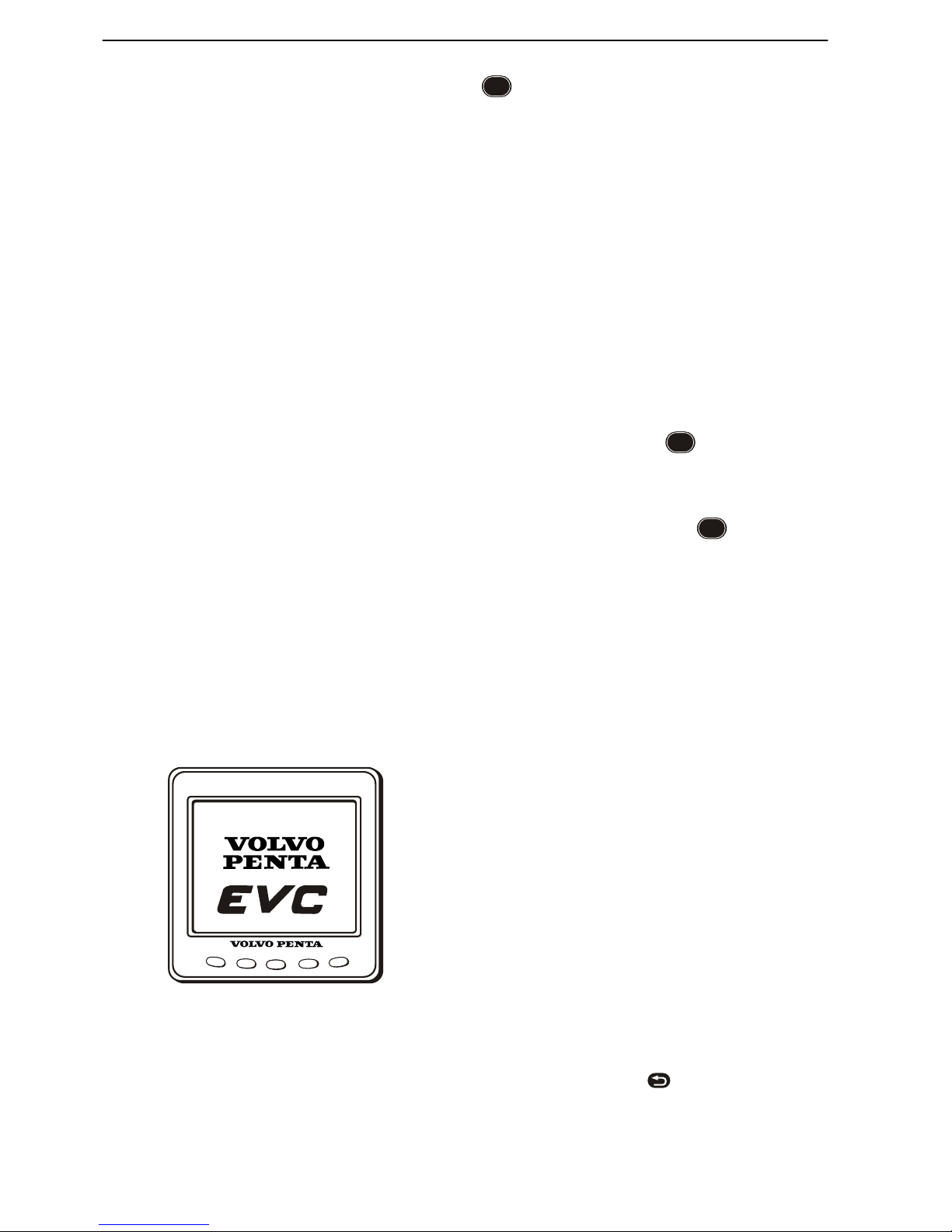

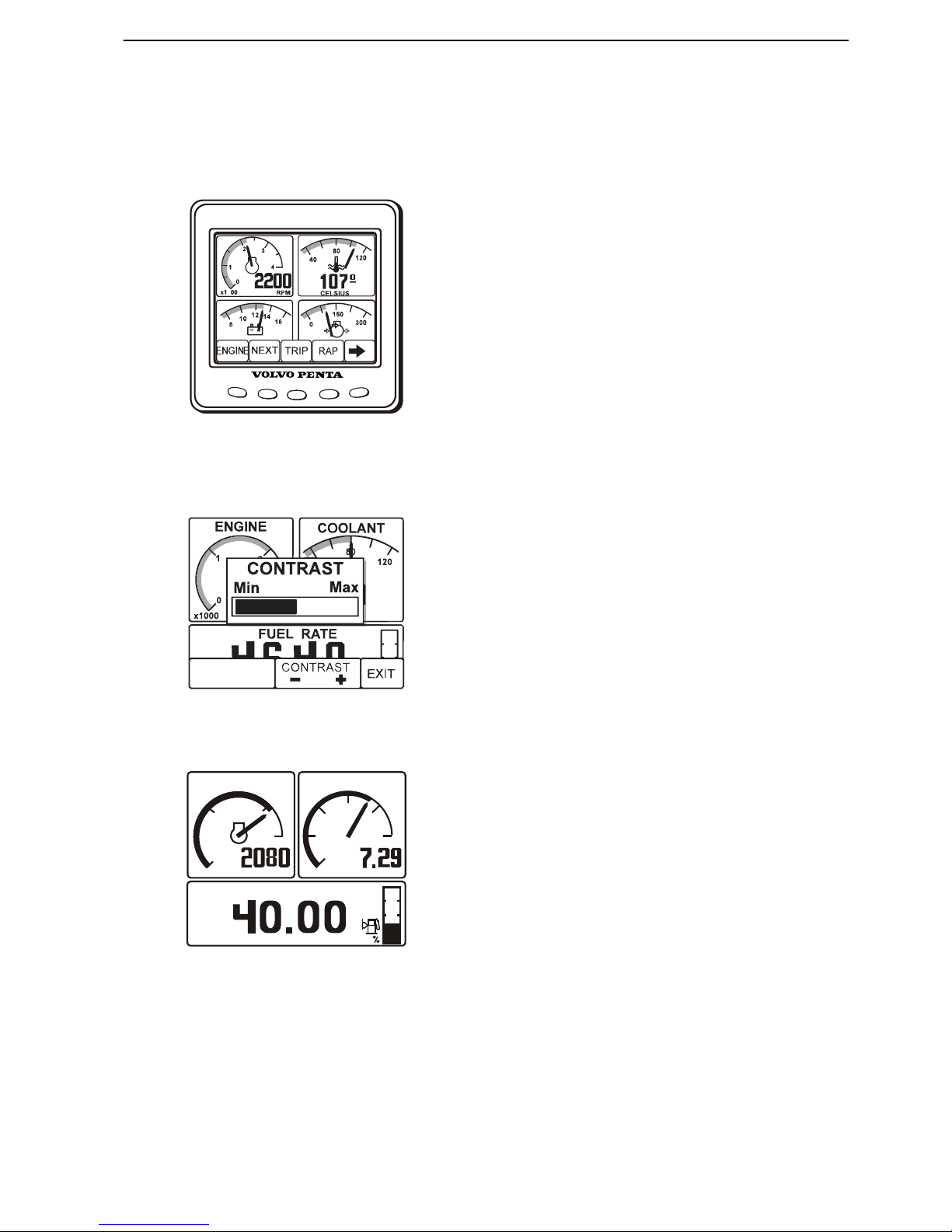

EVC System Display

In the EVC system display it is possible to show multiple windows with different information. There are four

display modes that can be chosen with the buttons on

the instrument.

Button 1–4 shows the different display modes. Button

5 i used to adjust the contrast and to access the configuration menu. Please refer to section Konfiguration-

smeny.

The EVC menu can be shown in the display by entering

Systeminformation (se section Multi, button 2) or the

Configuration menu. In this mode the display works the

same way as the display in the tachometer and is handled via the separate control panel, see chapter Instru-

ments and Controls page 20. If there is no tachometer installed the EVC meny can be reached by

pressing the knob on the control panel. To get back to

the display modes, press

.

At start up, the display performs a self-test. If an constant signal is heard, the system has discovered a

P0002383

Instruments and Controls

16 7748921 04-2008

malfunction. The display will work but may act in an

unexpected way.

NOTICE! Only installed functions will be shown in the

display.

Display modes

Press button 1–4 to view the function menu for the

buttons, apperaring in the lower part of the display.

Press button 1–4 to choose the desired display mode.

1 Engine

2 Multi

3 Trip

4 Graph

To leave the menu, wait a few seconds or press button

5 (EXIT).

Contrast

In the display modes Engine, Trip and Graph, it is possible to adjust the contrast.

Press button 5 outside the menu and then + (button 4)

and – (button 3).

Engine, button 1

Rpm and speed is shown in the upper part of the display. In the lower part it will show trip computer and a

fuel level indicator, if these function are installed.

If speed information is missing, coolant temperature

will be shown instead.

Navigate in the trip computer by repeatedly press button 1.

•

Fuel Rate, fuel consumption per hours

•

Fuel Economy, fuel consumption per distance

•

Trip Fue, fuel used since last reset

•

Fuel Remaining, remaining fuel in tank

•

Dist. to Empty, remaining distance until tank

isempty, based on fuel consumption per distance

•

Trip Distance, trip distance since last reset

1 2

3

4 5

G H

P0002382

P0002403

ENGINE

FUEL RATE

SPEED

0

0

2

4

6

8

10

1

2

RPM KTS

L/H

29

x1000

P0002401

Instruments and Controls

7748921 04-2008 17

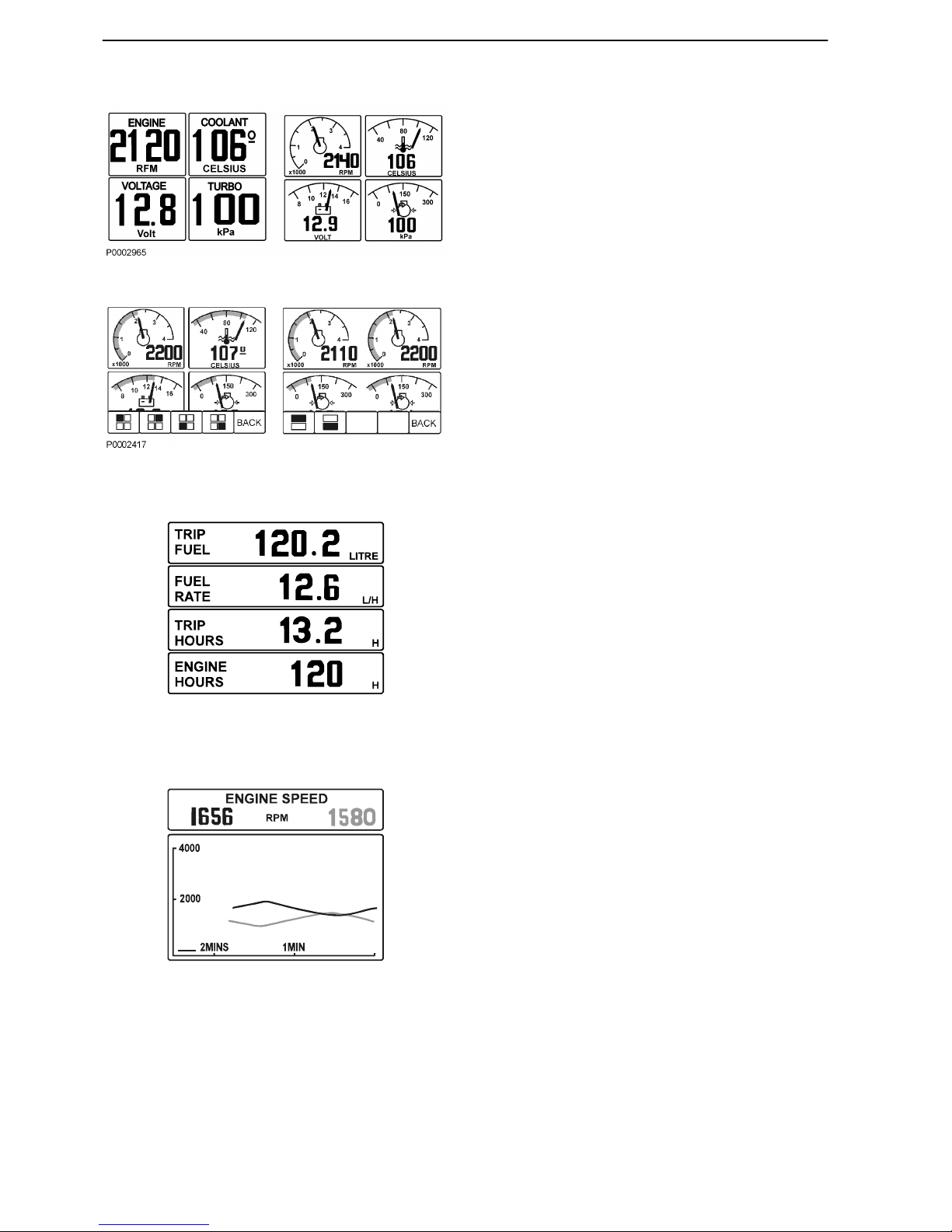

Multi, button 2

In the multi mode the information can be shown in several windows, analogue or digital. The display can

show windows with different information or be dividedto show windows and system information. To handle

the system information, see chapter Instruments and

Controls page 20. To go between the different display modes press button 2 repeatedly.

By pressing button 5, the right arrow, you choose what

information to be shown in the different windows. Press

repeatedly on the button that correspond to the window, until desired information is shown.

Trip, button 3

The display works as trip computer and shows:

Trip Fuel, since last reset

Fuel Rate, fuel consumption

Trip hours, since last reset

Engine hours, total amount of operating hours

Reset by pressing button 3 for three seconds until a

beep is heard.

The values from the engines are summarized, except

for engine hours that are shown for each engine.

Graph, button 4

The information is shown as graphs. Press button 4

repeatedly to choose what information will be shown.

The time interval is set in the Configuration menu.

If the connection is broken there will be a straight linein

the display.

The port engine is shown as a black line and the starboard engine as a grey line.

P0002418

P0002421

Instruments and Controls

18 7748921 04-2008

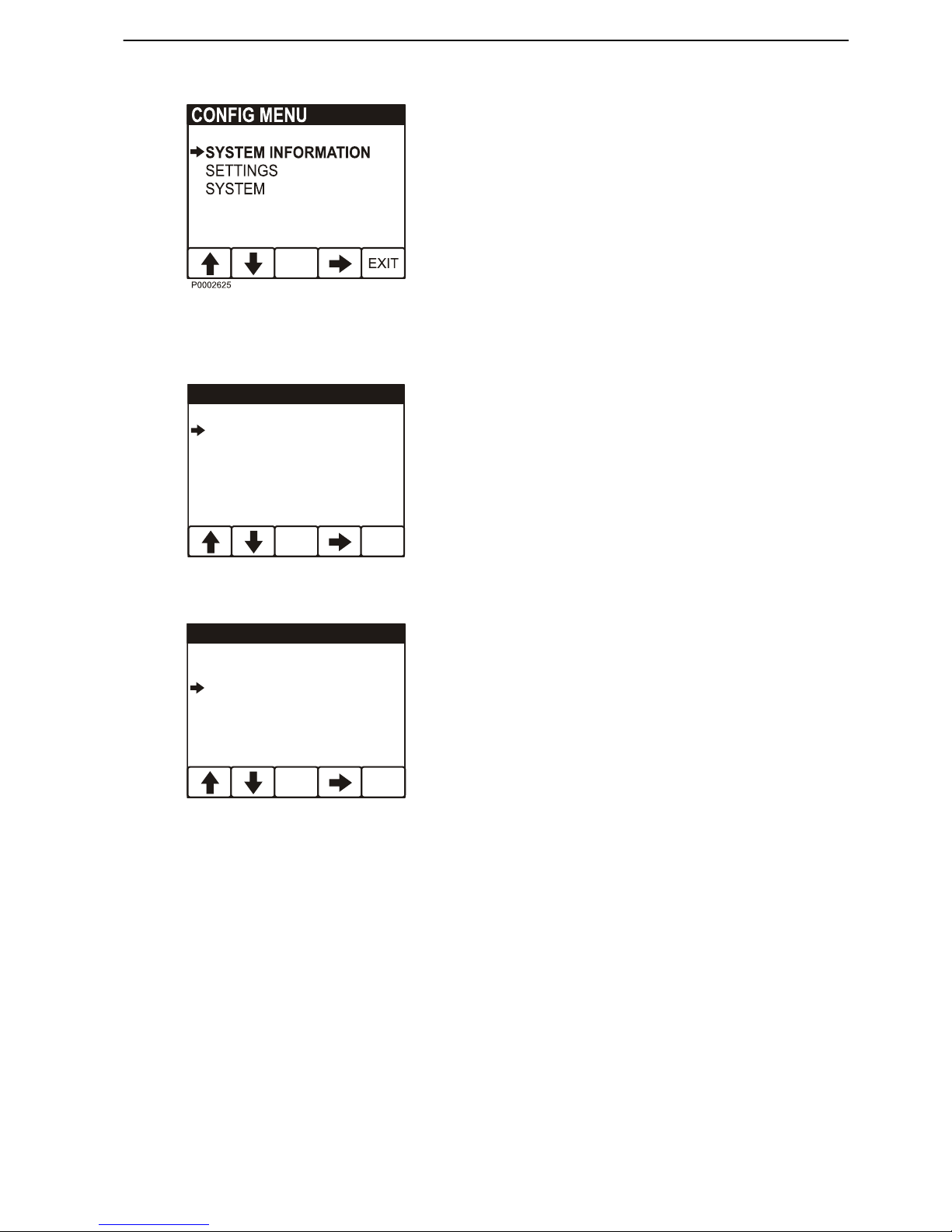

Configuration menu

Press button 5 for five seconds to enter the Configuration menu. Navigate with the up and down arrows,

select with the right arrow.

NOTICE! The port engine, or both engines must have

the ignition on when display settings are made.

System information

System information shows the EVC-menyn and is han-

dled by the knob on the control panel. For more information, see chapter Instruments and Con-

trols page 20.

Settings

- Language: Setting of what language the information is to be presented in are made in the EVCmenu, see Instruments and Controls page 20.

- Bleep: On/Off, setting if pressing the instrument

buttons will be followed by a beep or not.

- Engine: Setting of what kind of installation the display is a part of and which engine is to be shown

inthe display.

- Display: Setting of intervals (unit settings are made

in the EVC-menu, see Instruments and Con-

trols page 20):

Rpm interval, 2500–9000 rpm, in steps of 500 rpm

Speed, on/off

Speed interval, 10–100 knots, in steps of 10 knots

Graph interval, 2 min, 10 min, 30 min, 60 min, 2 h,4

h or 8 h

BACK

SETTINGS

LANGUAGE

BLEEP

ENGINE

DISPLAY

ENGLISH

OFF

PORT

P0002408

BACK

UNITS

SPEED

OIL PRESSURE

TURBO PRESSURE

FUEL RATE

DISTANCE

KM/H

KM

kPa

kPa

L/H

P0002409

Instruments and Controls

7748921 04-2008 19

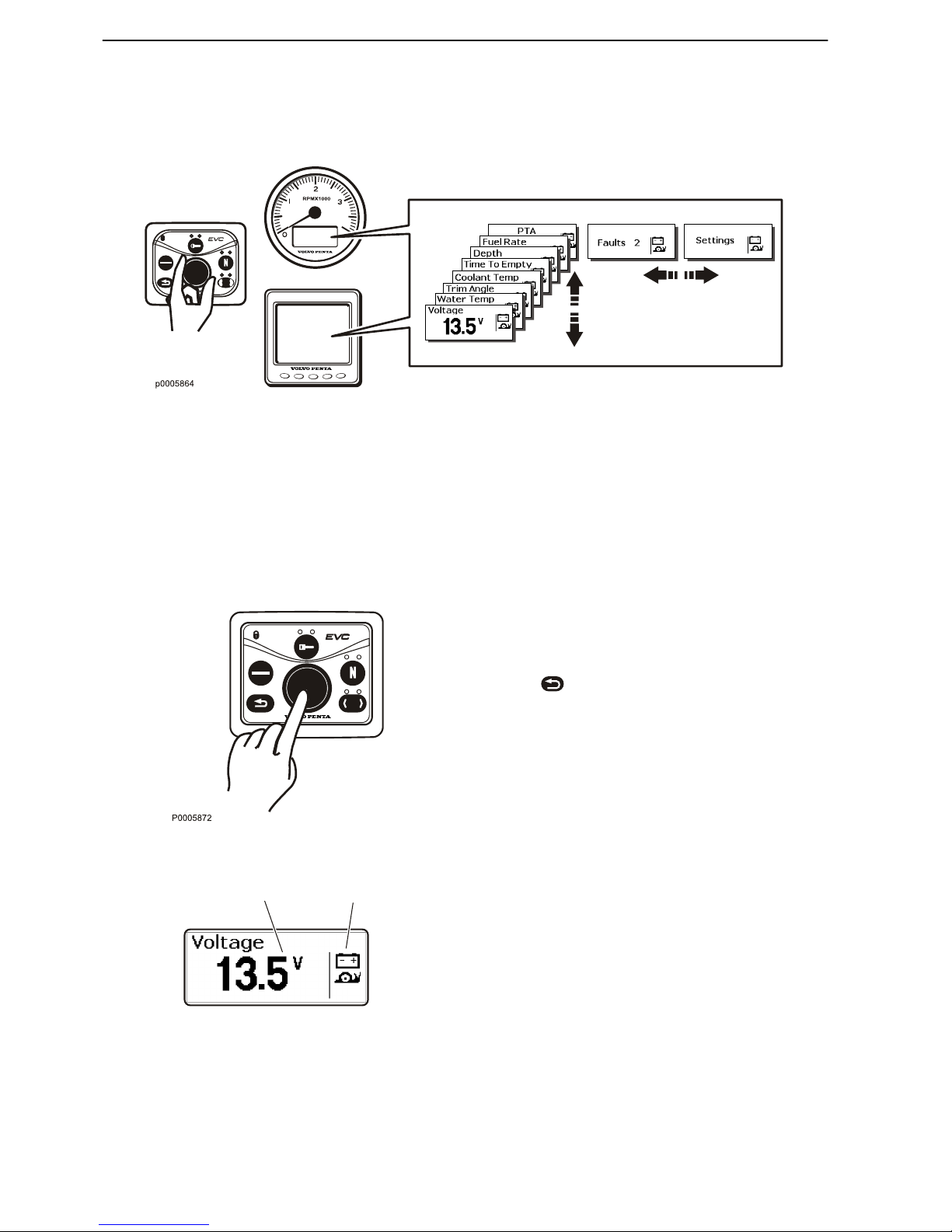

EVC Menu

The EVC menu can be shown in both the EVC system

display and the tachometer display. The main menu

shows operating information, the settings menu and

the fault menu (only shown when a fault in the system

is detected).

Only installed functions are shown in the menu.

Turn the knob to navigate through the menus.

Press the knob to access sub menus and to confirm

selections in the settings menu.

It is always possible to return to the previous menu by

pressing

. Press repeatedly to return to the main

menu; alternatively, hold down the button for a couple

of seconds.

A This field displays engine operating data.

B This field displays warning symbols and active func-

tion symbols.

A

B

P0001006

Instruments and Controls

20 7748921 04-2008

Settings

Turn the control panel wheel until the start screen for

the settings menu is displayed. Press the wheel to

reach the sub menus.

Turn to move between the available setting functions.

For further information, refer to section Settnings

menu page 102.

Fault

The fault window is only shown in the main menu if a

fault has been detected.

For further information, refer to section Fault Han-

dling page 41.

P0001015

P0001315

Instruments and Controls

7748921 04-2008 21

Controls

Single Lever Control

Maneuvering

A single-lever control operates both gearshift and

throttle functions with the same lever.

The engine can only be started with the control lever

in the neutral position.

N = Neutral position. Reverse gear/drive disengaged

and engine at idle.

F = Reverse gear/drive engaged for forward motion.

R = Reverse gear/drive engaged for rearward

motion.

T = Engine rpm control (throttle).

Disconnecting the gearshift function

The gearshift function can be disconnected so that the

control lever only operates the throttle.

1 Put the control lever in neutral (N).

2 Depress the neutral button (N) and keep it

depressed at the same time as the lever is moved

forwards to the gearshift position (F).

3 Release the neutral button. The green indicator will

flash as confirmation that the gearshift function is

disconnected and the that lever will only affect

engine revolutions.

The gear shift function is reconnected automatically

when the lever is returned to the neutral position. This

is confirmed by the green indicator shining continuously.

CAUTION!

Take care not to engage the gear by mistake.

P0006664

Instruments and Controls

22 7748921 04-2008

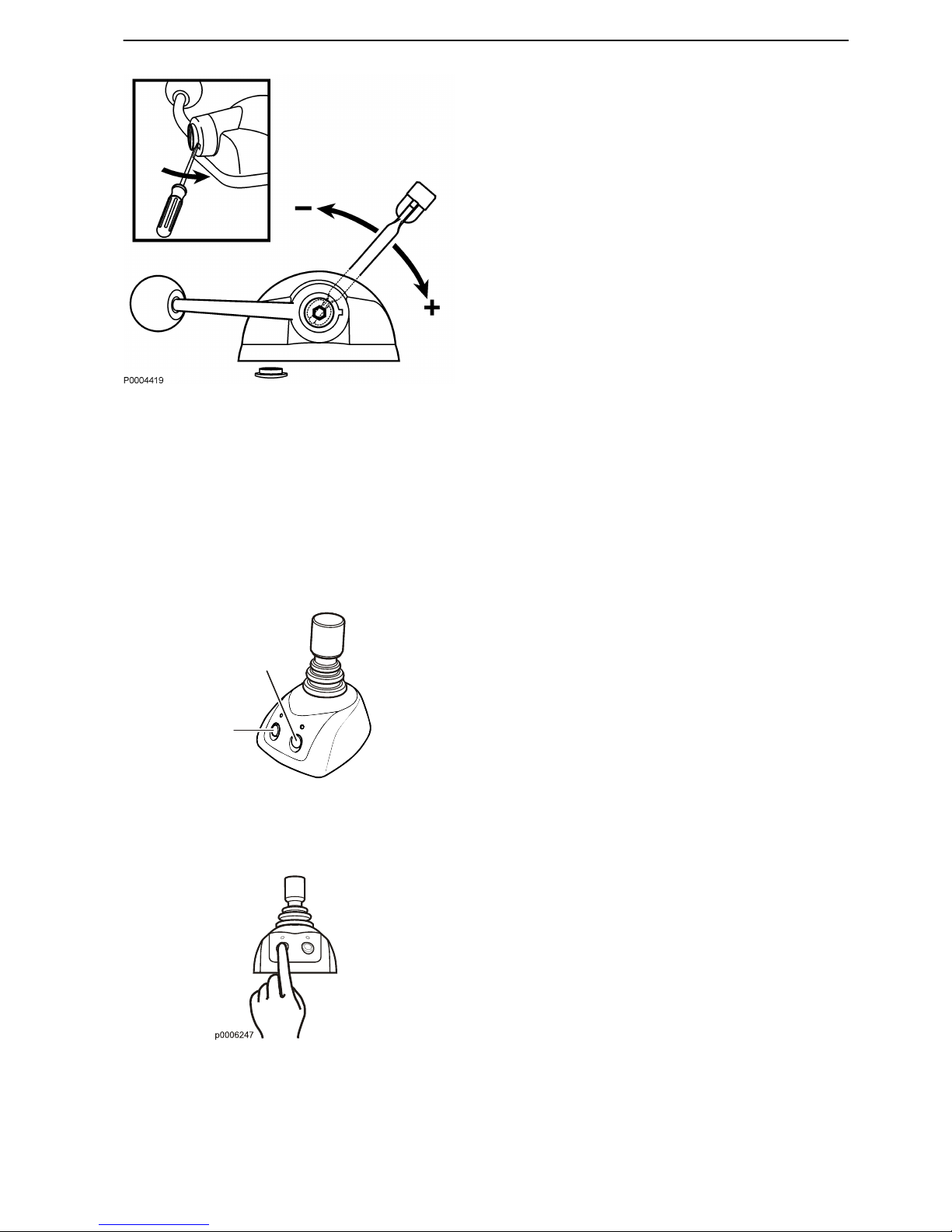

Adjusting the friction brake

The lever is fitted with a friction brake to allow adjustment for easier or stiffer movement as required. The

friction brake only affects movement of the throttle control lever.

1 Stop the engine.

2 Move the control lever forward so that the groove

in the lever hub is accessible.

3 Remove the plug with the aid of a screwdriver.

4 Adjust the friction brake (wrench, 8 mm) by turning

the bolt clockwise (+) for stiffer lever movement,

and counterclockwise (–) for easier movement.

5 Reinstall the plug.

Joystick

Volvo Penta IPS Joystick is a control used for docking

and maneuvering in low speed. The joystick makes it

possible to rotate the boat and maneuver the boat in

different directions – sideways, diagonally, forward

and backward.

Learn to handle the joystick in a safely and correct

manner before you start using the function in a marina.

When the docking function is active the engine speed

is reduced and the boat can only be maneuvered with

the joystick.

Activating the docking function

Before activating the docking function the following has

to be fulfilled:

•

the engines must to be running

•

the controls must to be in neutral

•

the helm station must be active

•

the joystick in its middle position

A

B

p0005186

A. Docking (ON/OFF)

B. Boost (ON/OFF)

Instruments and Controls

7748921 04-2008 23

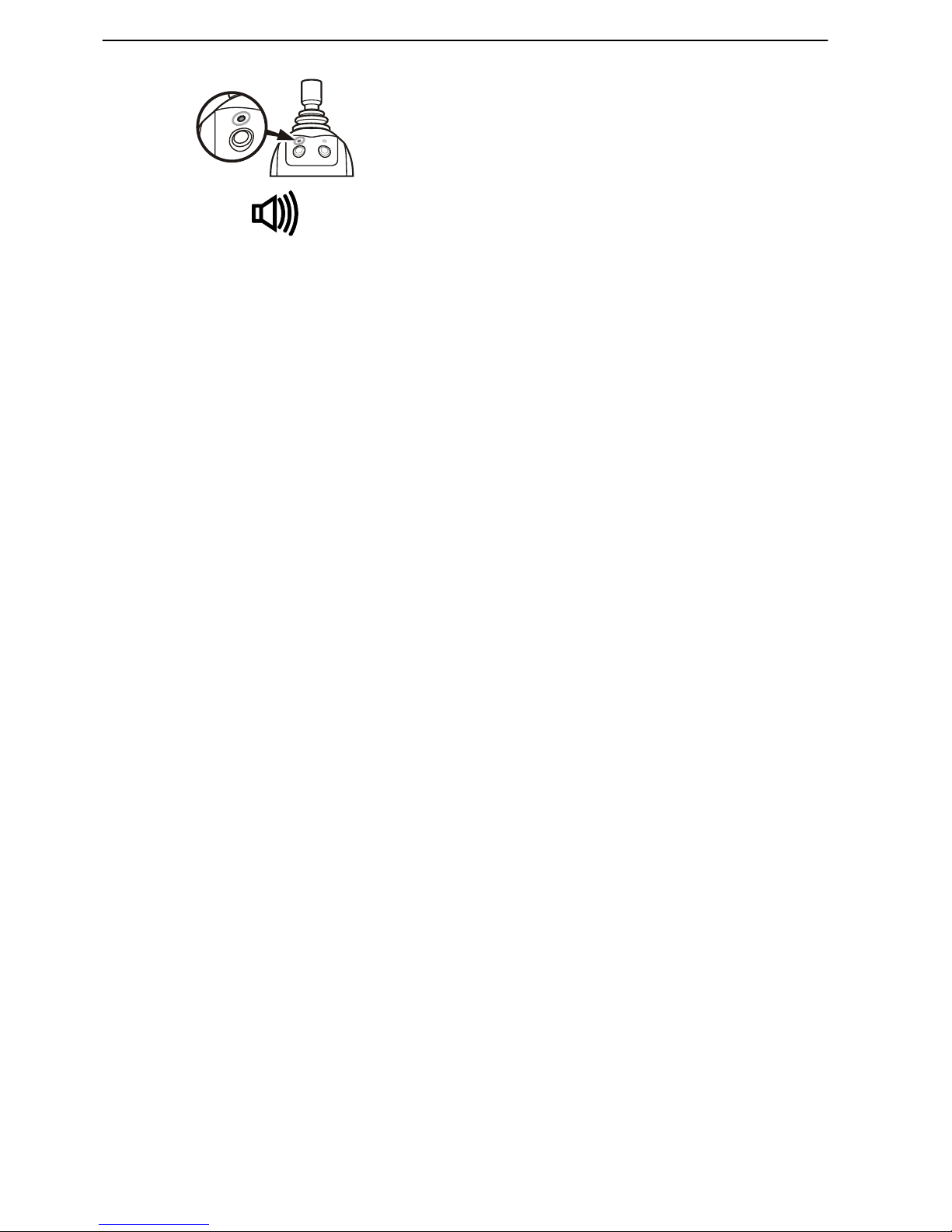

1 Activate the docking function by pressing the dock-

ing button (A) on the joystick.

2 A sound signal confirms that the docking function is

active and the lamp by the docking button is lit.

3 To inactivate the function press the docking button.

To confirm that the function is inactivated the signal

sounds twice and the lamp goes out.

4 The docking function is also deactivated if the con-

trols is moved out of neutral.

Activating the boost function

If the driver needs extra power, e.g. in windy weather

or if there is a strong currant, the boost function can be

activated.

1 Activate the boost function by pressing the boost

button (B) on the joystick.

2 A sound signal confirms that the function is active

and the lamp by the button is lit.

3 Inactivate the function press the boost button. To

confirm that the function is in active the signal

sounds twice and the lamp goes out.

4 The system is now back in docking mode.

P0006292

Instruments and Controls

24 7748921 04-2008

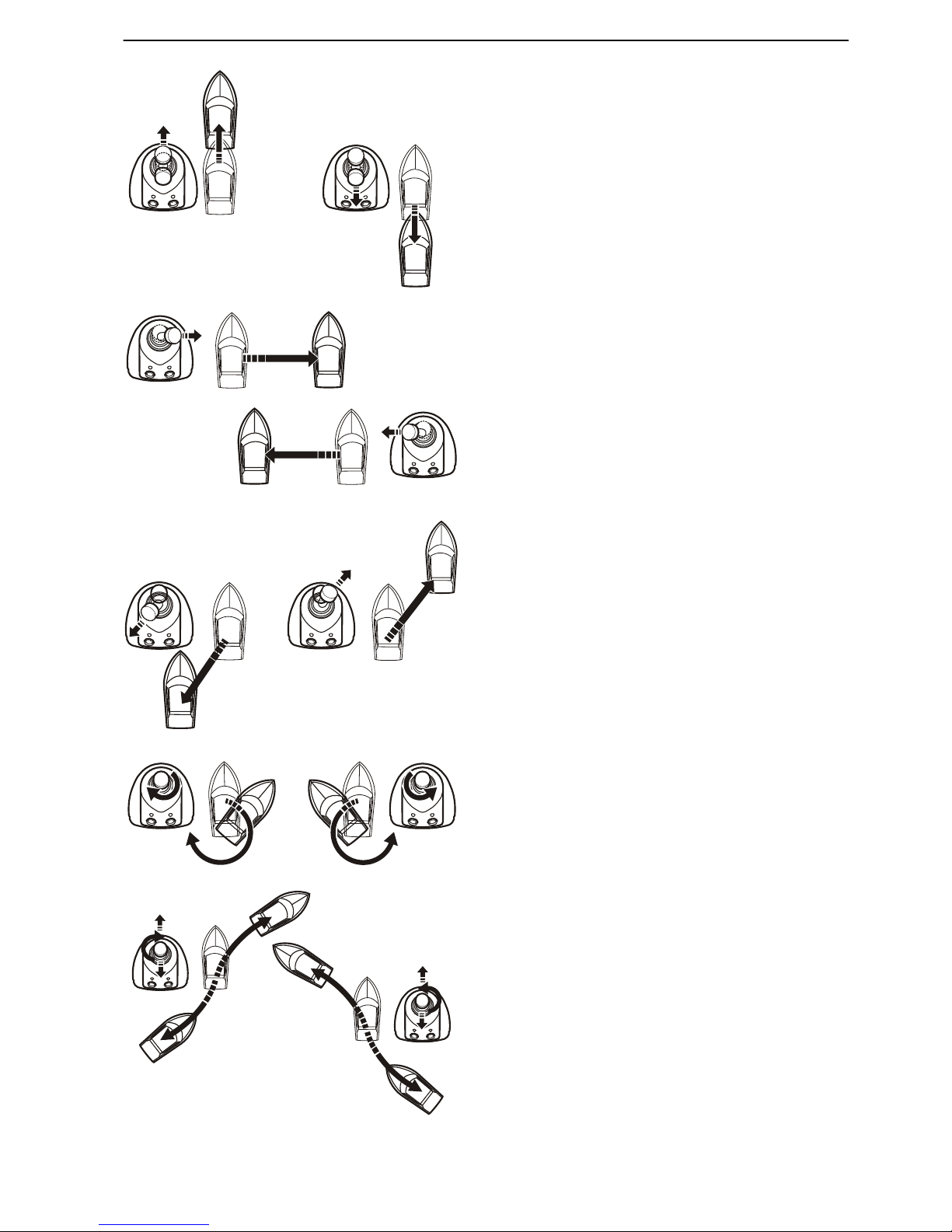

Maneuvering with joystick

To maneuver the boat move the joystick forwards, backwards, sideways or by turning the top of the joystick, see

figure.

IMPORTANT!

The boat keeps moving even after the joystick is

released, compensate this by moving the joystick in

opposite direction.

P0001191

Instruments and Controls

7748921 04-2008 25

Optional

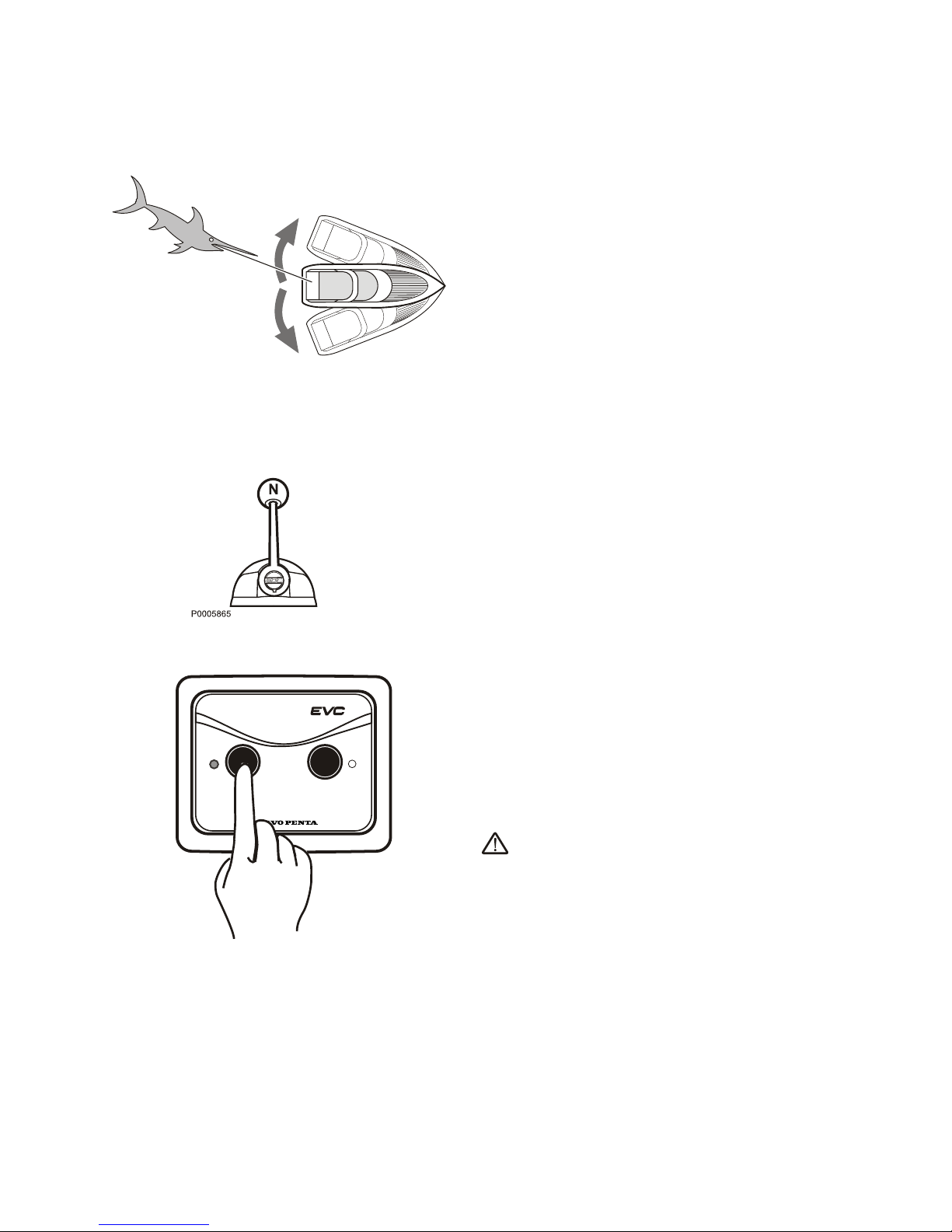

Sport Fishing Mode

Volvo Penta's sport fish function has been developed

by deep-sea fishermen. When the function is activated,

the IPS units are angled outwards and the helmsman

can quickly rotate and maneuver forward/backwards

to follow the movement of the fish. When activated, the

wheel is disconnected and the boat is maneuvered

solely via the control lever.

When the function is disengaged, both the IPS units

are set to straight forward.

The single-lever function used together with the sport

fish function makes it possible to control both engines

with just one of the control levers.

Activating the sport fish function

1 Move both control levers to neutral.

2 Press the sport fish button on the panel. The acti-

vation of the function is acknowledged by an acoustic signal and the lamp next to the button lighting.

An image stating that the sport fish function is active

is shown on the display for 5 seconds.

3 If the lamp flashes, all is not in order, e.g. the control

levers are not in neutral.

4 When the function is activated, the wheel is discon-

nected and the boat is steered with the control

lever.

5 Exit the function by pressing the sport fish button

on the panel. Inactivation of the function is acknowledged by an acoustic signal and the lamp next to

the button going out. An image stating that the function is inactive is shown on the display.

It is also possible to exit the function by turning the

wheel more than 30 degrees.

WARNING!

There is a risk that the boat may take in water if the

movements are too violent.

P0001219

SINGLE LEVER

SPORT FISH

P0001215

26 7748921 04-2008

Activating single-lever function

1 In order to activate the single-lever function, the

control levers must be roughly the same position,

max 10% difference.

2 Press the single lever button. The activation of the

function is acknowledged by an acoustic signal and

the lamp next to the button lighting. An image stating that the function is active is shown on the display

for 5 seconds.

3 When the function is activated, the control lever that

is moved first steers the boat and steers both

engines. The other control lever now has no function as long as the single lever function is activated.

4 To inactivate the function, the control levers must

again be in roughly the same position. Press the

single lever button; that the function is inactive is

confirmed by an acoustic signal and the lamp going

out. An image stating that the function is inactive is

shown on the display.

SINGLE LEVER

SPORT FISH

P0001214

Optional

7748921 04-2008 27

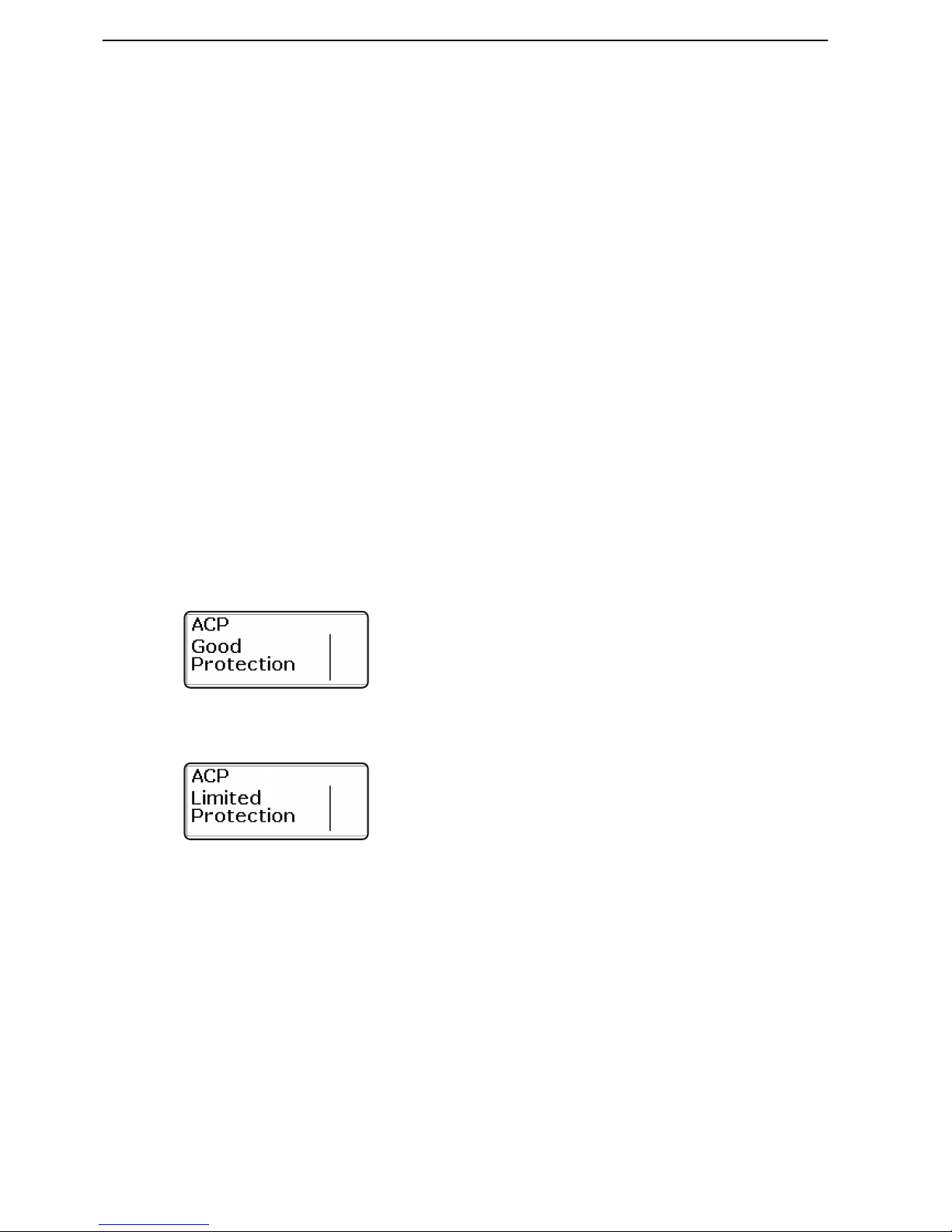

ACP

Volvo Penta ACP (Active Corrosion Protection) protects against galvanic corrosion by controlling an electric current that can be monitored by the engine

electrical system.

It is preferable to connect the boat to shore supply, if

such is available. If shore power is unavailable, ACP

utilizes the batteries, as it is connected to the boat's 12

V/24 V system. If the batteries begin to discharge, the

ACP switches from primary to secondary protection.

The IPS is then protected by the consumption of a

sacrificial zinc anode installed in the ACP unit on the

transom.

When the primary protection is in use, a small quantity

of chlorine gas is produced by the ACP; if desired it can

be switched off temporarily. The ACP then switches

over to secondary protection.

The ACP reverts automatically to normal mode after 4

hours; earlier reversion can be arranged in the settings

menu (see below) or when ignition is switched on.

Protection levels

The ACP has three protection levels; the active level

is displayed in the EVC menu.

•

Good Protection; the IPS unit is optimally protected

by the ACP function.

•

Limited Protection; secondary protection - the IPS

has complete corrosion protection via the sacrificial

anode.

Check that the batteries are being charged by shore

power; alternatively, start the engine so that the

alternator charges the batteries.

There is no risk of corrosion as the sacrificial anode

protects the IPS. However, seek service for system

checks at the first suitable opportunity if the system

remains in the limited protection mode for more than

approx. 2 hours.

If the system remains in this mode for a longer break

in operations, more than 8 weeks, service should be

sought for system checks.

P0001217

P0003747

Optional

28 7748921 04-2008

Loading...

Loading...