Volvo Penta D4, D6 Operator's Manual

OPERATOR’S MANUAL

D4, D6

CALIFORNIA

Proposition 65 Warning

Diesel engine exhaust and some of its constituents are known

to the State of California to cause cancer, birth defects, and

other reproductive harm.

This operator‘s manual is available in

English.

Compelte the form t the end of the operator‘s

manual to order a copy.

Diese Betriebsanleitung ist auch auf

Deutsch erhältlich.

Ein Bestellcoupon ist am Ende der Betriebsanleitung zu finden.

Ce manuel d’instructions peut être

commandé en français.

Vous trouverez un bon de commande à la fin

du manuel d’instructions.

Este libro de instrucciones puede solicitarse en español.

El cupón de pedido se encuentra al final del

libro.

Den här instruktionsboken kan beställas på svenska.

Beställningskupong finns i slutet av instruktionsboken.

Questo manuale d’istruzioni può essere ordinato in lingua italiana.

Il tagliando per l’ordinazione è riportato alla

fine del manuale.

Dit instructieboek kan worden besteld

in het Nederlands.

De bestelcoupon vindt u achter in het instructieboek.

Denne instruktionsbog kan bestilles

på dansk.

Bestillingskupon findes i slutningen af instruktionsbogen.

Tämän ohjekirjan voi tilata myös suomenkielisenä.

Tilauskuponki on ohjekirjan lopussa.

Este manual de instruções pode ser

encomendado em português.

O talão de requerimento encontra-se no fim

do manual.

Бхфь фп егчейсЯдйп чсЮузт

дйбфЯиефбй уфзн бгглйкЮ глюууб.

Гйб нб рбсбггеЯлефе Энб бнфЯфхрп,

ухмрлзсюуфе фз цьсмб рпх всЯукефбй уфп

фЭлпт бхфпэ фпх егчейсйдЯпх чсЮузт.

This operator’s manual is available in

Turkish/Russian.

Complete the form at the end of the operator’s

manual to order a copy.

Bu kullanýcý el kitabý Türkçe dillerinde mevcuttur.

Birnüshasýný sipariþ etmek için kullanýcý el

kitabýnýn sonundaki formu doldurun.

Welcome aboard

Volvo Penta marine engines are used all over the world. They are used in all possible operating

conditions for professional as well as leisure purposes. That’s not surprising.

After 100 years as an engine manufacturer the Volvo Penta name has become a symbol of reliability, technical innovation, top of the range performance and long service life. We also believe

that this is what you demand and expect of your Volvo Penta engine.

We would like you to read this operator’s manual thoroughly and consider the advice we give on

operation and maintenance before your maiden voyage so that you will be ensured of fulfilling

your expectations. Please pay attention to the safety instructions contained in the manual.

As owner of a Volvo Penta marine engine, we would also like to welcome you to a worldwide

network of dealers and service workshops to assist you with technical advice, service requirements and replacement parts. Please contact your nearest authorized Volvo Penta dealer for

assistance.

We also invite you to visit our home page on the Internet at www.volvopenta.com

With warm regards

AB VOLVO PENTA

Safety Information ............................................ 3–7

General ................................................................... 3

Boat travel...............................................................4

Maintenance and service ....................................... 6

Introduction ................................................... 8–12

Running-in ............................................................. 8

Fuel and oil types .................................................. 8

Certificated engines ............................................... 9

Warranty information ............................................. 9

Identification numbers ..........................................

12

Presentation ................................................... 13–20

Technical Description

............................................ 13

Engine monitoring and EVC ................................

14

Orientation ...........................................................

17

Instrumentation ..............................................21-44

Ignition lock ........................................................... 21

Start/stop panel ....................................................21

Instruments ........................................................... 22

Alarm display ........................................................ 23

EVC control panel................................................. 26

EVC system tachometer .......................................

27

EVC system display .............................................. 37

Controls .......................................................... 45-47

Starting the engine ........................................48-50

Before starting ......................................................

48

General about starting .......................................... 48

Starting method .................................................... 50

Operation .........................................................51-57

Reading instruments ...........................................

51

Acknowleging alarms and messages ................. 51

Cruising speed .....................................................

52

Synchronising engine speed .............................. 52

Changing helm station ........................................ 53

Operation ............................................................ 54

Power trim

........................................................... 54

Power trim Assistant ............................................ 58

Volvo Penta Lowspeed ....................................... 59

Running aground ..................................................

60

Stopping the engine ...................................... 61-62

Stopping ..............................................................

61

Laying up ............................................................. 61

Cold weather precautions .................................... 62

Maintenance schedule ................................... 63-65

Maintenance ................................................... 66–96

Engine, general ....................................................66

Lubrication system ............................................... 70

Freshwater system ............................................... 73

Seawater system .................................................. 76

Fuel system ......................................................... 80

Electrical system ..................................................

83

Reverse gear ........................................................

88

Drive ..................................................................... 90

Steering ................................................................ 93

Propellers .............................................................96

Laying up/Launching .....................................97-99

Inhibiting ............................................................... 97

Bringing out of winter storage ...............................

98

Painting the drive and underwater hull ................. 99

In case of emergency ..................................100-106

Starting using auxiliary batteries ........................ 100

Emergency shifting ............................................. 101

Emergency trimming .......................................... 102

Engine stop after crash-stop ............................... 102

Fault-tracing ........................................................ 103

Diagnostic function ............................................. 104

Malfunction message engine and EVC-system .. 105

Faults list ............................................................106

Erasing faults ..................................................... 106

Fault register ............................................... 107-113

Technical Data ............................................ 114-116

Engine ................................................................114

Fuel specification ............................................... 115

Drive .................................................................. 116

Reverse gear ...................................................... 116

Power Trim .......................................................... 116

Steering .............................................................. 116

© 2007 AB VOLVO PENTA

All rights to changes or modifications reserved.

Printed on environmentally friendly paper.

(Cover: Department of transport (shipping), license 9809095)

Contents

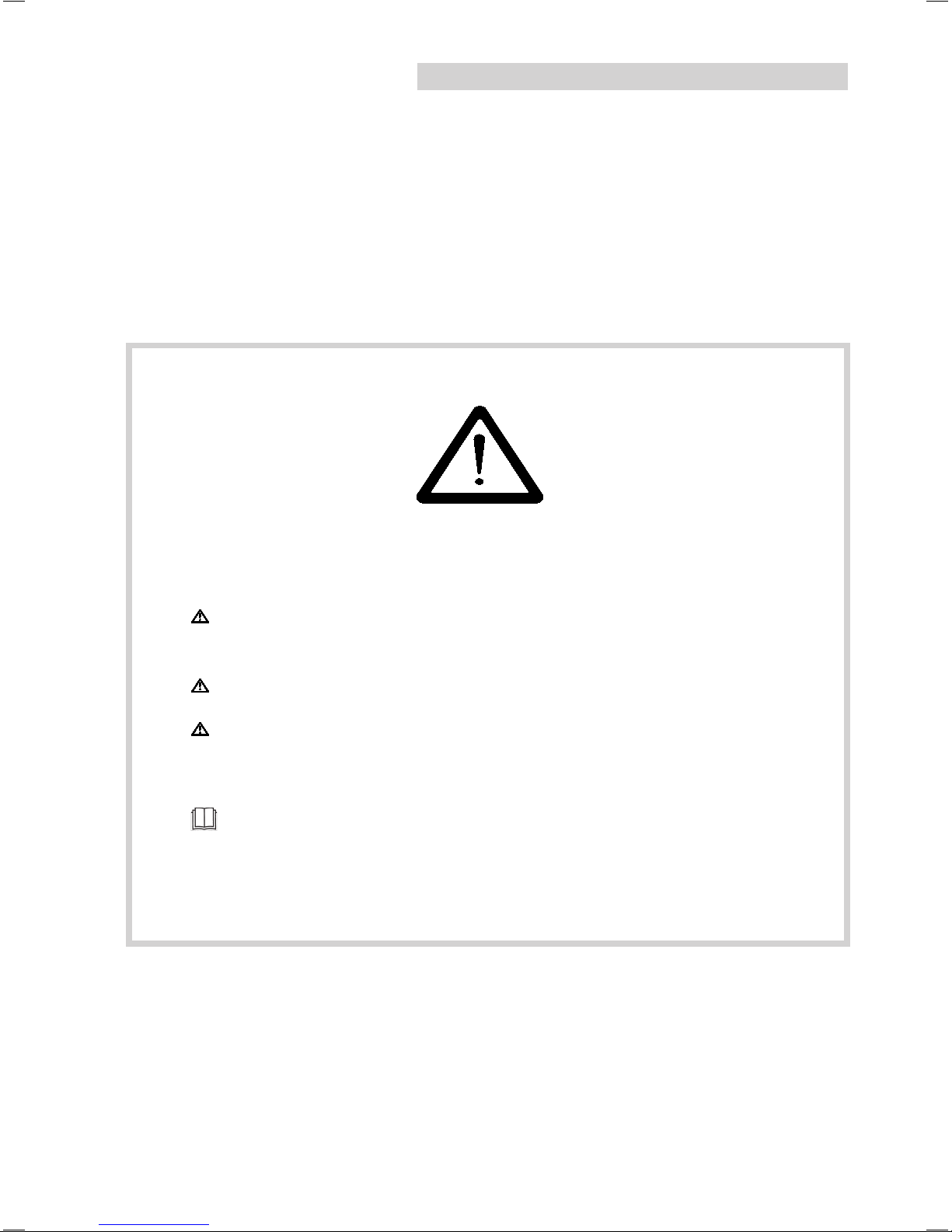

Safety Information

Read this chapter carefully. It concerns your safety. This section describes how safety information is presented in

the operator’s manual and on the engine. It also gives a general account of basic safety precautions to be taken

when operating the boat and maintaining the engine.

Check that you have the correct operator’s manual before you read on. If this is not the case please contact your Volvo Penta dealer.

If operations are performed incorrectly it could result in personal injury, or damage to property

or the engine. Read the operator’s manual carefully before operating or servicing the engine. If

anything is unclear please contact your Volvo Penta dealer for assistance.

This symbol is used in the book and on the engine to make you aware of safety information.

Always read these safety precautions very carefully.

In the operator’s manual warning texts have the following priority:

WARNING! If these instructions are not followed there is a danger of personal injury, exten-

sive damage to the product or serious mechanical malfunction.

IMPORTANT! Used to draw your attention to something that can cause damage, product

malfunction or damage to property.

NOTE! Used to draw your attention to important information that will facilitate work or opera-

tions.

This symbol is used in certain cases on our products and refers to important information in

the operator’s manual. Ensure that warning and information symbols on the engine and transmission are always visible and legible. Replace symbols that have been damaged or painted

over.

3

Safety precautions to be taken when operating the boat

Your new boat

Read operator’s manuals and other information

supplied with your new boat. Learn to operate the

engine, controls and other equipment safely and correctly.

If this is your first boat, or is a boat type with which

you are not familiar, we recommend that you practice controlling the boat in peace and quiet. Learn

how the boat behaves at different speeds, weather

conditions and loads before casting off for your “real”

maiden voyage.

Remember that the person driving a boat is legally

required to know and follow the current rules regarding traffic and safety at sea. Make sure you know the

rules that apply to you and the waters you are sailing

in by contacting the relevant authorities or organization.

A good piece of advice is to take a course in seamanship. We recommend that you contact your local

boating organization to find a suitable course.

Accidents

Statistics show that poor maintenance of boats and

engines and a lack of safety equipment are often the

cause of accidents at sea.

Ensure that your boat is maintained in accordance

with the relevant Instruction Manual and that the necessary safety equipment is on-board and is serviceable.

Daily checklist

Make a habit of checking the engine and engine

compartment visually before operating the boat (be-

fore the engine is started) and after operating the

boat (after the engine has been stopped). This will

help you to quickly detect fuel, coolant or oil leaks

and spot anything else unusual that has or is about to

happen.

Maneuvering

Avoid violent and unexpected changes in course and

gear engagement. This could cause someone on the

boat to lose their balance and fall over or overboard.

A rotating propeller can cause serious injury. Check

that nobody is in the water before engaging ahead or

astern. Never drive near bathers or in areas where

people could be in the water.

Avoid trimming an outboard drive too much, as steering will be severely reduced.

Refueling

When refueling there is always a danger of fire and

explosion. Smoking is forbidden and the engine must

be switched off.

Never overfill the tank. Close the fuel tank filler cap

properly.

Only use the fuel recommended in the operator’s

manual. The wrong grade of fuel can cause operating problems or cause the engine to stop. On a diesel

engine poor quality fuel can cause the control rod to

seize and the engine to overrev with a resultant risk

of damage to the engine and personal injury.

Do not start the engine

Do not start or run the engine with a suspected fuel

or LPG leak in the boat, nor when you are close to or

in a discharge of explosive media, etc. There is risk

for fire and/or explosion in explosive surroundings.

Safety breaker

We recommend that you install and use a safety

breaker (accessory), especially if you boat can travel

at high speeds. The safety breaker stops the engine if

the driver falls down and loses control over the boat.

Safety Information

4

Carbon monoxide poisoning

When a boat is moving forward, it will cause a certain vacuum to form behind the boat. In unfortunate

circumstances, the suction from this vacuum can be

so great that the exhaust gases from the boat are

drawn into the cockpit or cabin and cause carbon monoxide poisoning.

This problem is most prevalent on high, wide boats

with abrupt stern. In certain conditions, however, this

suction can be a problem on other boats, e.g. when

running with the cover up. Other factors that can increase the effect of the suction are wind conditions,

load distribution, swells, trim, open hatches and portholes, etc.

Most modern boats, however, are designed in such

a way that this problem is very rare. If suction should

arise anyway, do not open hatches or portholes at

the fore of the boat. Surprisingly, this will otherwise

increase the suction. Try changing speed, trim or load

distribution instead. Try taking down/opening or in any

other way changing the setup of the cover as well.

Get in touch with your boat dealer for help in obtain

-

ing the best solution for your boat.

Checklist

● Safety equipment Life jackets for all passengers, communication equipment, emergency rockets,

approved fire extinguisher, first-aid equipment, life belt, anchor, paddle, torch etc.

● Replacement parts and tools: impeller, fuel filters, fuses, tape, hose clamps, engine oil, propeller

and tools for any repairs that might have to be carried out.

● Get out your charts and go over the planned route. Calculate distance and fuel consumption. Lis-

ten to the weather reports

● Make sure that relations or contact persons are informed when planning a longer voyage. Re-

member to inform them if your plans have changed or been delayed.

● Tell your passengers and crew where the safety equipment is stored and how to operate it. Make

sure you are not the only person on board who knows how to start the boat and operate it safely.

This list can be added to because safety equipment and other requirements vary depending on the

type of boat and how it is used. We recommend that you contact your local boating organization for

more detailed information on safety afloat.

Safety Information

5

Safety precautions for maintenance and service operations

Preparations

Knowledge

The operator’s manual contains instructions on how

to carry out general maintenance and service opera

tions safely and correctly. Read the instructions carefully before starting work.

Service literature covering more complicated operations is available from your Volvo Penta dealer.

Never carry out any work on the engine if you are

unsure of how it should be done, contact your Volvo

Penta dealer who will be glad to offer assistance.

Stop the engine

Stop the engine before opening or removing engine

hatches. Unless otherwise specified all maintenance

and service must be carried out with the engine

stopped.

To prevent accidental start of the boat engine remove

the ignition key, turn off the power supply to the engine at the main switches and lock them in the OFF

position before starting work. Put up a warning sign

in the control position that work on the engine is being carried out.

Approaching or working on an engine that is running is a safety risk. Loose clothing, hair, fingers or

a dropped tool can be caught in the rotating parts of

the engine and cause serious personal injury. Volvo

Penta recommend that all servicing with the engine

running be undertaken by an authorized Volvo Penta

workshop.

Lifting the engine

When lifting the engine use the lifting eyes installed

on the engine (reverse gear where installed). Always

check that lifting equipment is in good condition and

has sufficient load capacity to lift the engine (engine

weight including reverse gear and any extra equipment installed). For safety’s sake lift the engine using an adjustable lifting beam. All chains and cables

should run parallel to each other and as perpendicular as possible in relation to the top of the engine.

Bear in mind that extra equipment installed on the

engine may alter its center of gravity. Special lifting

equipment may then be required in order to maintain

the correct balance and make the engine safe to handle. Never carry out work on an engine suspended on

a hoist.

Before starting the engine

Reinstall all protective parts removed during service

operations before starting the engine. Check that no

tools or other items have been left on the engine.

Never start a turbocharged engine without installing

the air cleaner (ACL). The rotating compressor in the

Turbocharger unit can cause serious personal injury.

Foreign objects can also be sucked in and cause me

-

chanical damage to the unit.

Fire and explosion

Fuel and lubrication oil

All fuel, most lubricants and many chemicals are

inflammable. Read and follow the instructions on the

packaging.

When carrying out work on the fuel system make

sure the engine is cold. A fuel spill onto a hot surface

or electrical components can cause a fire.

Store fuel soaked rags and other flammable material

so that there is no danger of them catching fire. Fuelsoaked rags can self-ignite under certain conditions.

Do not smoke when filling fuel, oil or in proximity of a

filling station or in the engine room.

Non-original components

Components used in the fuel and ignition system

(gasoline engines) and electrical systems on Volvo

Penta products are designed and constructed to

minimize the risk of fire and explosion.

Using non-original Volvo Penta parts can result in fire

or explosion on board.

Batteries

The batteries contain and give off oxyhydrogen gas,

especially during charging. This gas is easily ignited

and highly volatile.

Do not under any circumstances smoke or use naked

flame or allow sparks in the vicinity of the batteries or

battery compartment.

Incorrectly connection a battery terminal cable or

jump-start cable can cause a spark which in its turn

can be sufficient to cause an explosion.

Start spray

Never use start spray or similar agents to start an engine equipped with air pre-heating (glow plugs/starter

element). This may cause an explosion in the inlet

manifold. Danger of personal injury.

Safety Information

6

Hot surfaces and fluids

There is always a risk of burns when working with

a hot engine. Beware of hot surfaces. For example:

the exhaust pipe, Turbo unit, oil pan, charge air pipe,

starter element, hot coolant and hot oil in oil lines and

hoses.

Carbon monoxide poisoning

Only start the engine in a well-ventilated area. If operating the engine in an enclosed space, ensure that

there is proper ventilation in order to remove exhaust

gases and crankcase ventilation emissions from the

working area.

Chemicals

Most chemicals such as anti-freeze, rustproofing

agent, inhibiting oil, degreasing agent etc. are hazardous to health. Read and follow the instructions on

the packaging.

Some chemicals such as inhibiting oil are inflammable and dangerous if breathed in as well. Ensure

good ventilation and use a protective mask when

spraying. Read and follow the instructions on the

packaging.

Store chemicals and other hazardous materials out

of the reach of children. To protect the environment

please dispose of used or leftover chemicals at a

properly designated disposal site for destruction.

Cooling system

There is a risk of flooding when working on the seawater system. Turn off the engine and close the sea

cock (where installed) before starting work on the

system.

Avoid opening the coolant filler cap when the engine

is hot. Steam or hot coolant can spray out and cause

burns.

If work must be carried out with the engine at operating temperature and the coolant filler cap or a cock

open or a coolant hose disconnected, open the coolant filler cap carefully and slowly to release pressure

before removing the cap completely. Note that the

coolant may still be hot and can cause burns.

Lubrication system

Hot oil can cause burns. Avoid skin contact with hot

oil. Ensure that the lubrication system is not under

pressure before commencing work on it. Never start

or operate the engine with the oil filler cap removed,

oil can spray out.

Fuel system

Always use protective gloves when tracing leaks.

Liquids ejected under pressure can penetrate body

tissue and cause serious injury. There is a danger of

blood poisoning.

Always cover the generator if it is located under the

fuel filter. The generator can be damaged by spilled

fuel.

Electrical system

Cutting off power

Always stop the engine and break the current using

the main switches before working on the electrical

system. Isolate shore current to the engine block

heater, battery charger, or accessories mounted on

the engine.

Batteries

The batteries contain an extremely corrosive electrolyte. Protect your skin and clothes when charging

or handling batteries. Always use protective goggles

and gloves.

If battery electrolyte comes into contact with unprotected skin wash off immediately using plenty of water and soap. If battery acid comes into contact with

the eyes, flush immediately with plenty of water and

obtain medical assistance without delay.

Safety Information

7

Introduction

This operator’s manual has been compiled to help you get the most from your Volvo Penta engine. It contains

all the information you need in order to operate and maintain your engine safely and correctly. Please read the

operator’s manual carefully and learn how to operate the engine, controls and other equipment safely.

Always have the operator’s manual available. Keep it in a safe place and do not forget to give it to the new owner

if you sell your boat.

Care of the environment

We would all like to live in a clean and healthy environment. Somewhere where we can breathe clean

air, see healthy trees, have clean water in our lakes

and oceans, and are able to enjoy the sunshine without being worried about our health. Unfortunately,

this cannot be taken for granted nowadays but is something we must work together to achieve.

As a manufacturer of marine engines, Volvo Penta has

a special responsibility, why care of the environment is

a core value in our product development. Today, Volvo

Penta has a broad range of engines where progress

has been made in reducing exhaust emissions, fuel

consumption, engine noise, etc.

We hope you will take care in preserving these qualities. Always follow any advice given in the instruction manual concerning fuel grades, operation and

maintenance and you will avoid causing unecessary

interference to the environment. Get in touch with your

Volvo Penta dealer if you notice any changes such as

increased fuel consumption exhaust smoke.

Adapt speed and distance to avoid wash and noise

disturbing or injuring animal life, moored boats, jetties,

etc. Leave islands and harbours in the same condition

as you want to find them. Remember to always leave

hazardous waste such as waste oil, coolant, paint and

wash residue, flat batteries, etc., for disposal at a destruction plant.

Our joint efforts will make a valuable contribution

to our environment.

Running-in

The engine must be run in for its first 10 operating

hours as follows: Operate the engine normally. Do not

operate it at full load except for short periods. Never

run the engine at a constant engine speed for long periods during the running-in period.

The engine can be expected to use more engine oil

during the running-in period than would otherwise be

normal. Check the oil level more often than is normally

recommended.

A First Service Inspection must be carried out after

20–50 running hours. For further information: See the

Warranty and Service Book.

Fuel and oils

Only use the fuel and oils recommended in the chapter Technical Data. Other grades of fuel and oil can

cause operating problems, increased fuel consumption and, in the long-term, a shorter engine service

life.

Always change oil, oil filters and fuel filters at the recommended intervals.

Service and replacement parts

Volvo Penta marine engines are designed for high

operational reliability and long service life. They are

constructed to withstand the marine environment

while also affecting it as little as possible. Through

regular service and the use of Volvo Penta original

spare parts, these qualities will be retained.

The Volvo Penta worldwide network of authorized

dealers are at your service. They are specialists in

Volvo Penta products and have accessories and

the original replacement parts, test equipment and

special tools necessary for high quality service and

repair work.

Always follow the maintenance intervals contained

in the operator’s manual. Remember to state the engine/transmission identification number when ordering service and replacement parts.

8

Warranty

Your new Volvo Penta marine engine is covered by a limited warranty according to the conditions and

instructions contained in the Warranty and Service book.

Note that AB Volvo Penta’s liability is limited to that contained in the Warranty and Service Book. Read

this book as soon as you take delivery of the engine. It contains important information about warranty

cards, service and maintenance which you, the owner, must be aware of, check and carry out. Liability

covered in the warranty may otherwise be refused by AB Volvo Penta.

Contact your Volvo Penta dealer if you have not received a Warranty and Service Book and a

customer copy of the warranty card.

Certified engines

It is important to be aware of the following information

if you own or run an engine that is exhaust emission

certified:

Certification means that an engine type is inspected

and approved by the authorities. The engine manufacturer guarantees that all engines manufactured of

that type correspond to the certified engine.

This places special requirements for maintenance

and service as follows:

● The maintenance and service intervals recom-

mended by Volvo Penta must be observed.

● Only genuine Volvo Penta replacement parts may

be used.

● The service of injection pumps and injectors or

pump settings must always be carried out by an

authorized Volvo Penta workshop.

● The engine must not be modified in any way

except with accessories and service kits approved

by Volvo Penta.

● No modifications to the exhaust pipes and air sup-

ply ducts for the engine may be undertaken.

● Seals may only be broken by authorized person-

nel.

Otherwise the general instructions contained in the

Operator's Manual concerning operation, service and

maintenance must be followed.

IMPORTANT! Late or inadequate maintenance/

service or the use of spare parts other than

Volvo Penta original spare parts will invalidate

AB Volvo Penta’s responsibility for the engine

specification being in accordance with the certificated variant.

Volvo Penta accepts no responsibility or liabil

ity for any damage or costs arising due to the

above.

Introduction

9

Declaration of Conformity for Recreational Craft Propulsion Engines with the

exhaust emission requirements of Directive 94/25/EC as amended by 2003/44/EC

Engine manufacturer:

AB Volvo Penta

Gropegårdsgatan

405 08 Göteborg

Sweden

This declaration of conformity is issued under the sole responsibility of the manufacturer. I declare on behalf of the engine manufacturer that the engine(s) mentioned above complie(s) with all applicable essential requirements in the way specified and is in conformity with the type for which above mentioned EC type examination certificate(s) has been issued.

Body for exhaust emission assessment

International Marine Certification Institute

Rue Abbé Cuypres 3

B-1040 Bruxells

Belgium

ID Number:0609

Module used for exhaust emission assessment .........B+C

Other Community Directives applied ...........................EMC 89/336/EEC

Description of engine(s) and essential requirements

Engine type .........................................................4 stroke diesel engine with stern drive with integral exhaust

Engine model(s) covered by this declaration EC Type certificate number

D4-180 ................................................................................EXVOLV001

D4-210 ................................................................................EXVOLV001

D4-225 ................................................................................EXVOLV001

D4-260 ................................................................................EXVOLV001

D4-300 ................................................................................EXVOLV001

D6-280 ................................................................................EXVOLV001

D6-310 ...............................................................................EXVOLV001

D6-330 ...............................................................................EXVOLV001

D6-350 ...............................................................................EXVOLV001

D6-370 ...............................................................................EXVOLV001

D6-435 ................................................................................EXVOLV001

D4, D6

Essential requirements

Annex I.B – Exhaust Emissions

Engine identification

Exhaust emission requirements

Durability

Operator’s manual

EMC Directive

Standards Used

Volvo Penta std

EN ISO 8178-1:1996

Volvo Penta std

ISO 10240:2004

EN 61000-3-2,

EN 61000-3-3,

CISPR 25

Other normative

document used

Annex 1.B.1

Annex 1.B.2

Annex 1.B.3

Annex 1.B.4

PL-99/07

Name and function: Sam Behrmann, Laws and Regulations

(identification of the person empowered to sign on behalf of the

engine manufacturer or his authorised representative)

Signature and title:

(or an equivalent marking)

Date and place of issue: (yr/month/day) 2007/04/26 Göteborg

10

Declaration of Conformity for Recreational Craft Propulsion Engines with the

sound emission requirements of Directive 94/25/EC as amended by 2003/44/EC

Engine manufacturer:

AB Volvo Penta

Gropegårdsgatan

405 08 Göteborg

Sweden

This declaration of conformity is issued under the sole responsibility of the manufacturer. I declare on behalf of the engine manufacturer that the engine(s) mentioned above complie(s) with all applicable essential requirements in the way specified and is in conformity with the type for which above mentioned EC type examination certificate(s) has been issued.

Module used for sound emission assessment ...... Aa

Internal production control

Test according to Annex VI

Other Community Directives applied ......................EMC 89/336/EEC

Description of engine(s) and essential requirements

Engine type .......................................................4 stroke diesel engine with stern drive with integral exhaust

Engine model(s) covered by this declaration EC Type certificate number

D4-210 drive DPH ........................................................ SDVOLV002

D4-225 drive DPH ........................................................

SDVOLV002

D4-260 drive DPH ........................................................ SDVOLV002

D4-300 drive DPH ........................................................ SDVOLV002

D6-280 drive DPH ........................................................ SDVOLV003

D6-310 drive DPR/DPH ................................................ SDVOLV003

D6-330 drive DPR/DPH ................................................ SDVOLV003

D6-350 drive DPR/DPH ................................................ SDVOLV003

D6-370 drive DPR/DPH ................................................ SDVOLV003

Body for sound emission assessment

International Marine Certification Institute

Rue Abbé Cuypres 3

B-1040 Bruxells

Belgium

ID Number:0609

D4, D6

Essential requirements

Annex I.C – Noise Emissions

Sound emission levels

Operator’s manual

EMC Directive

Standards Used

Other normative

document used

Annex 1.C.1

Annex 1.C.2

EN ISO 14509:2000/

prA1:2004

ISO 10240:2004

EN 61000-3-2,

EN 61000-3-3,

CISPR 25

PL-100/07

Name and function: Sam Behrmann, Laws and Regulations

(identification of the person empowered to sign on behalf of the

engine manufacturer or his authorised representative)

Signature and title:

(or an equivalent marking)

Date and place of issue: (yr/month/day) 2007/04/26 Göteborg

11

Identification numbers

Always provide the engine and transmission identification numbers when ordering service or replacement components.

The identification numbers are on an information decal located on the front edge of the engine. Note the information below. Make a copy of the page. Store the information so that it is available in event of the boat being

stolen.

Engine

Product designation (1*)

Serial number (2*)

Product number (3*)

Drive/Reverse gear

Product designation (4*)

Gear ratio (5*)

Serial number (6*)

Product number (7*)

Shield (Drive)

Product designation (8*)

Serial number (9*)

Product number (10*)

* The numbers refer to the position of the

identification numbers on the information decal

Introduction

Engine plate

Warranty decal, IMO decal and EPA decal

Drive plate

Reverse gear plate

Transom shield plate

Warranty decal

(Engine/Transom shield/Drive/Reverse gear )

Engine plate

Transom shield plate

Drive plate

Reverse gear plate

Location of information decal and identification plates:

12

Presentation

Volvo Penta’s D4 and D6 is developed from the latest design in modern diesel technology. The engine has common rail fuel injection system, double overhead camshafts, 4 valves per cylinder, turbocharger, compressor, and

aftercooler. The interaction of these, the large swept volume, and the EVC system results in exceptional diesel

performance combined with low emissions.

Technical description:

Engine block and head

— Cylinder block and cylinder head made of cast-

iron

— Combined ladder frame and balance shafts (D4)

— Ladder frame fitted to engine block (D6)

— Double overhead camshafts

— Oil-cooled pistons with two compression rings and

one oil scraper ring

— Integrated cylinder liners

— Replaceable valve seats

— Seven-bearing crankshaft

— Rear-end transmission

Engine mounting

— Flexible engine mounting

Lubrication system

— Easily replaceable separate full-flow and by-pass

oil filter

— Seawater-cooled tubular oil cooler

Fuel system

— Common rail fuel injection system

— Control unit for processing the injection

— Fine filter with water separator

— Emergency stop device

Air inlet and exhaust system

— Belt-driven compressor with silencer of absorption

type on both inlet and output port

— Air filter with replaceable insert

— Crankcase gases vented into the air inlet

— Exhaust elbow or exhaust riser

— Freshwater-cooled turbocharger

Cooling system

— Thermostatically regulated freshwater cooling

— Tubular heat exchanger with separate large vo-

lume expansion tank

— Coolant system prepared for hot water outlet

— Seawater strainer and easily accessible impeller

pump

Electrical system

— 12V/24V two-pole electrical system

— 115A/80A marine alternator with Zener-diodes to

protect the system from peak voltage, and integra-

ted charging regulator with battery sensor cable

for maximum use of alternator

— Fuses with automatic reset

Instruments/control

— Complete instrumentation including key switch

and interlocked alarm

— Digital Power trim instrument with analog or digital

reading

— EVC monitoring panels for single or twin installa-

tions

— Electronic remote control for throttle and shift

— Plug-in connections

Drive

— Complete with transom shield, and installation

components

— Max tilt angle 50° (adjustable)

— Protective zinc anodes to prevent corrosion

— Built-in kick-up function to reduce possible da-

mage, in the event the drive strikes an underwater

object

— Electrical shifting performed by electronic actuator

— Power trim with one-button operation in twin in-

stallation

— Fully integrated water inlet and exhaust system

— Fully hydraulic power-assisted steering system

— Isolated propellers to prevent corrosion

Reverse gear

— Reverse gear with matched drop center and 8°

down angel for compact installation and minimum

propeller shaft angel. V-drive available

— Bevel gears which resualts in smooth running at

all speeds

— Hydraulically operated clutch for smooth shifting

— Electrical shifting performed by elctromagnetic

valves.

— When under sail propeller shaft can rotate 24

hours without engine start.

— Seawater-cooled oilcooler

Accessories

— An extensive range of accessories are available.

For detailed information, please see Accessory

catalogs.

13

Engine Management System

The engines are equipped with common rail system

and electronically controlled injectors with an electronic control module.

The injectors contain an electro-magnetic valve which

sets the amount of fuel injected and the correct timing. The monitoring system measures the charge air

pressure and temperature, and calculates the available air mass. This determines the maximum amount

of fuel that can be injected (smoke limiter function).

The system also limits the maximum torque available

at the engine speed registered to protect the engine

from overload.

Engine Management and EVC system

To protect the engine at too high coolant or charge air

temperatures and boost pressure as well as oil pressure the monitoring system reduces the amount of

fuel (reduced engine output) until the current values

normalises.

The engine monitoring system also has a diagnostic

system, which helps users and service technicians to

determine the cause of malfunctions.

Users get information about faults by pop-ups that

are shown on the EVC system tachometer display.

Helm station Con-

trol Unit

(HCU)

Power train

Control Unit

(PCU)

Engine Management

System

(EMS)

Helm station Con

-

trol Unit

(HCU))

CAN bus

14

Presentation

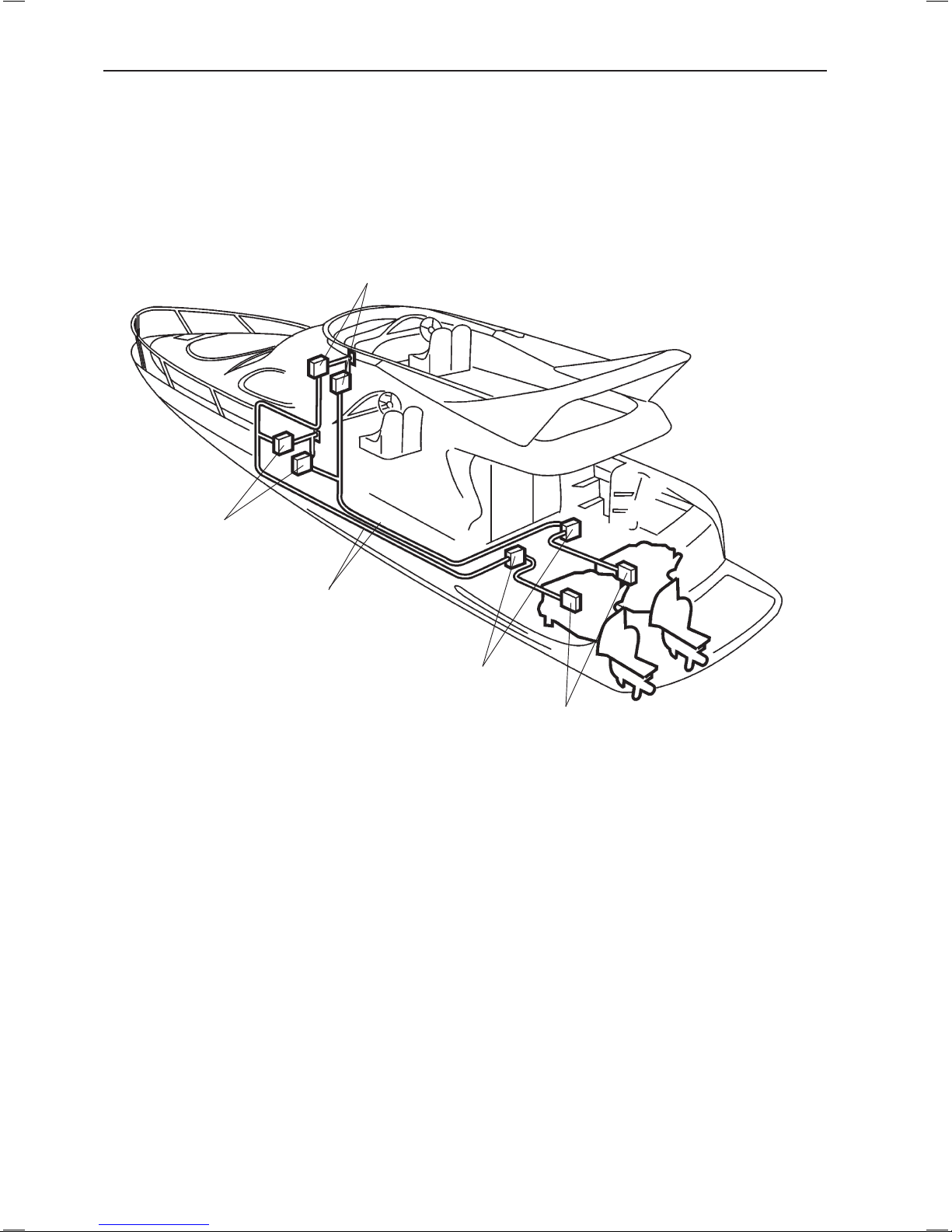

The EVC system

The Electronic Vessel Control (EVC) system is a so

called distributed system. The principle of a distributed system is to have many small electonic units,

called nodes, located on suitable places in the boat.

The EVC nodes are the Powertrain Control Unit

(PCU) and the Helm station Control Unit (HCU).

Nodes are located close to the components they

control. A helm node is located close to the helm. A

powertrain node is mounted in the engine room.

Each node controls a number of adjacent components, for example sensors, controls, instruments and

actuators.

Each PCU and HCU is programmed for a specific

engine individual. On the PCU and HCU there is a

sticker with chassis no. The chassis no. shall correspond to the sticker on the engine.

A data bus, a CAN bus, connects the nodes to each

other. Together they form a network and exchange

information and take advantage of each others’ services. The principle of forming a network of nodes to

which all components are connected reduces wiring

radically.

CAN stands for Controller Area Network, an industry

standard for communication between nodes in distributed systems.

A distributed system supports a growing multiplicity

of system configurations and optional features. New

nodes can be connnected to the network with minimal wiring redesign. New effective functionality can

be created by letting the nodes interact and combine

their capabilities, creating a more useful and safe

product.

Functionalities

Engine speed and gear shift

Speed and gear shift contol is handled electronically.

The reverse gear or stern drive has high speed shifting protection. Dual function electronic controls works

in the EVC system as well as mechanical controls

with control adapters.

Engine synchronization

Engine synchronization results in better comfort,

good fuel ecomomy and minimized wear due to less

vibration and reduced noise level. To enable synchronization the master (port) and slave (starboard)

systems must be able to communicate. Therefore a

synchronization cable has to be installed at the each

helm.

Instrumentation

The instruments use a serial communication bus. The

serial communication bus in combination with EVC

radically reduces wiring and simplifies installation.

Gauges are available with white or black dial face

and chromed or black bezel.

EVC system tachometer

The EVC system tachometer is mandatory for boats

with EVC, unless the optional EVC system display

is installed. The tachometer display shows operation

information, information massages and alarms. The

user selects what operation information to display

with the control panel.

NOTE! Only one operation in-

formation can be displayed at one and the same time.

The EVC system tachometer and control panel is

also used when calibrating EVC functions.

Power Trim

The function is considerably improved compared

to non EVC governed Power trim systems. EVC introduces a new trim panel with the same design as

other EVC control panels. If you have a twin engine

installation the stern drives can be both individually

and simultaneously controlled.

Trimming in and out can be calibrated to suit the specific installation. To protect the drive it cannot be tilted

when engine is running above a certain rpm.

The Power trim control panel shall be connected to

the multilink bus and the gauge to the instrument

cable harness from the HCU. The cable harness for

stern drives has connectors for the power trim angle

sensor and the power trim pump.

Extra optional equipment

EVC system display

The EVC system display is a complement or replacement for EVC system tachometer and optional instruments. The display shows operation information,

information massages and alarms. The user selects

what operation information to display with the buttons

on the display. The EVC system display can display

more than one operation information at one and the

same time. The display also has access to the same

display mode and calibration functions as for the EVC

system tachometer display.

Trim indicator

A trim indicator sender is included in all aquamatic

drives. The trim angle can be displayed on the EVC

system tachometer. It is also advised to install a trim

instrument. The instrument shows trim angle and trim

range. If a trim instrument is used it must be connected to the instrument serial communication bus.

Fuel level

Fuel level can be displayed on the EVC system tachometer if a (3-180 ohm or 240-30 ohm) fuel level

sender is installed in the fuel tank. The sender is

connected to the PCU–engine cable harness. If a

fuel level gauge is used it must be connected to the

instrument serial communication bus.

15

Presentation

Fresh water level

Fresh water level can be displayed on the EVC system tachometer if a (3-180 ohm) fuel level sender is

installed in the water tank. The sender is connected to

the PCU–engine cable harness. If a fresh water level

gauge is used it must be connected to the instrument

serial communication bus.

Rudder indicator

Rudder angle can be displayed on the EVC system

tachometer if a (3-180 ohm) rudder indicator is installed to the drive/rudder. The sender is connected to

the PCU–engine cable harness. If a rudder instrument

is used it must be connected to the instrument serial

communication bus.

Multisensor (Boat speed, depth and water temp)

Boart speed, depth and water temperature canbe displayed on the EVC system tachometer if a multi sensor is installed on the boat. The sensor is connected

to the multilink cable. If instruments (speed, depth,

water temp.) are used they must be connected to the

instrument serial communication bus.

Power Trim Assistant

The function power trim assistant adjust trim angle

automatically according to engine speed (rpm). EVC

supports power trim assistant if software for powertrim assistance is installed (order and download from

VODIA website).

Boat speed

Boat speed can be shown on the EVC system tachometer, if a multisensor or NMEA 0183/NMEA 2000

compatible component (plotter, GPS, paddle wheel

etc) is installed. If a speedometer is used it must be

connected to the instrument serial communication

bus. .

Trip computer

EVC supports trip computer functions if following are

installed.

- Multisensor or NMEA 0183/NMEA 2000 compatible component (plotter, GPS, paddle wheel etc)

- Fuel level sender

- Software for trip computer (order and download

from VODIA website).

Trip computer information can be displayed on the

EVC system tachometer or/and on the optional EVC

system display.

16

Presentation

Orientation

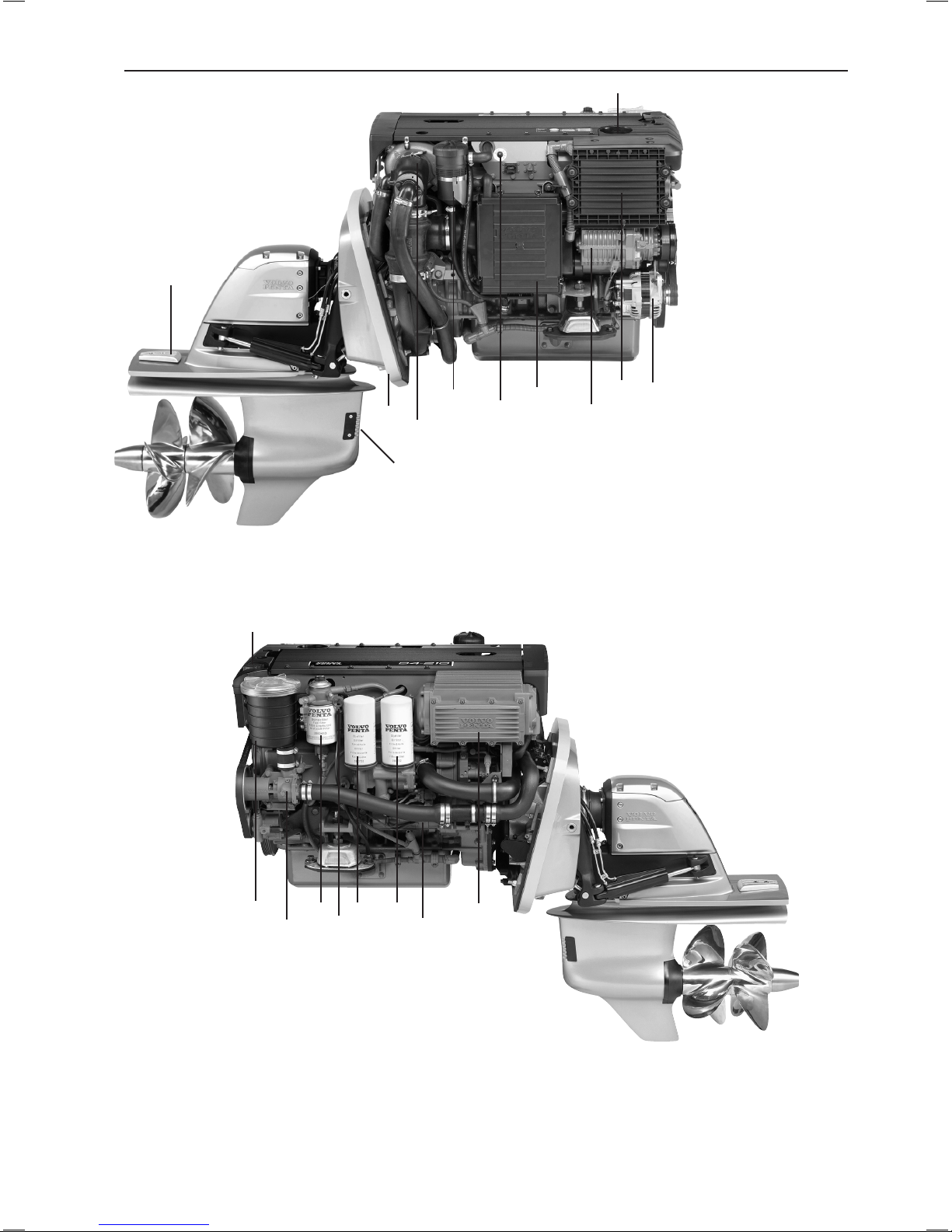

D4 with drive, port

11. Sea water filter

12. Sea water pump

13. Fuel filter

14. Oil dipstick

15. Oil bypass filter

16. Oil filter

17. Starter

18. Charge air cooler

19. Expansion tank

D4 with drive, starboard

1. Zinc anode

2. Cooling water intake

3. Zinc anode

4. Turbocharger

5. Crankcase ventilation filter

6. Aux Stop

7. Air filter

8. Compressor

9. EDC control module

10. Generator

11. Oil filler cap

1

2

3

4

5

6

7

8

9

11

10

11

12

13

14

15

16

17

18

19

17

Presentation

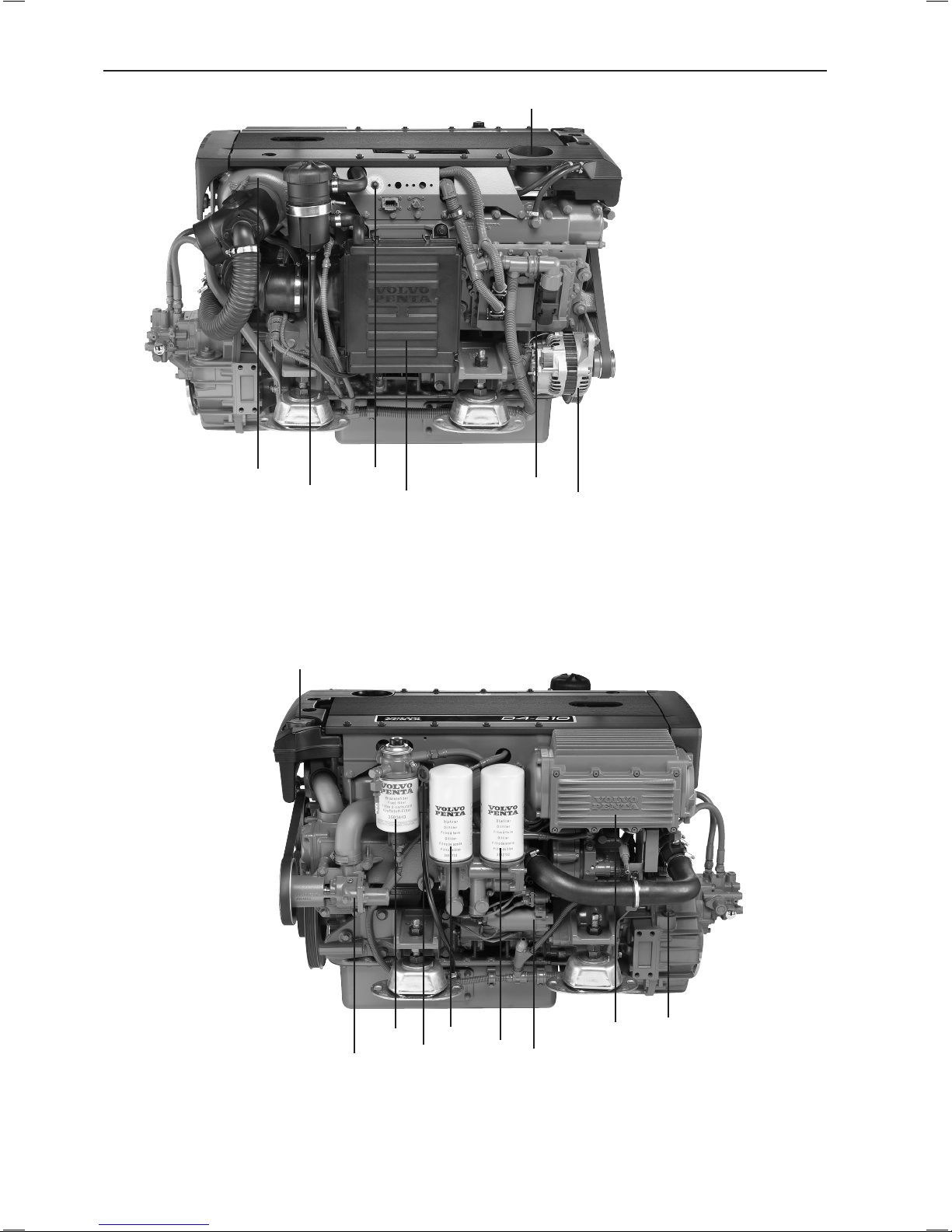

D4 with reverse gear, port

8. Sea water pump

9. Fuel filter

10. Oil dipstick (engine)

11. Oil bypass filter

12. Oil filter

13. Starter

14. Charge air cooler

15. Oil dipstick (reverse gear)

16. Expansion tank

D4 with reverse gear, starboard

1. Turbocharger

2. Crankcase ventilation filter

3. Aux Stop

4. Air filter

5. EDC control module

6. Generator

7. Oil filler cap

8

9

10

11

12

13

14

15

16

1

2

3

4

5

6

7

18

Presentation

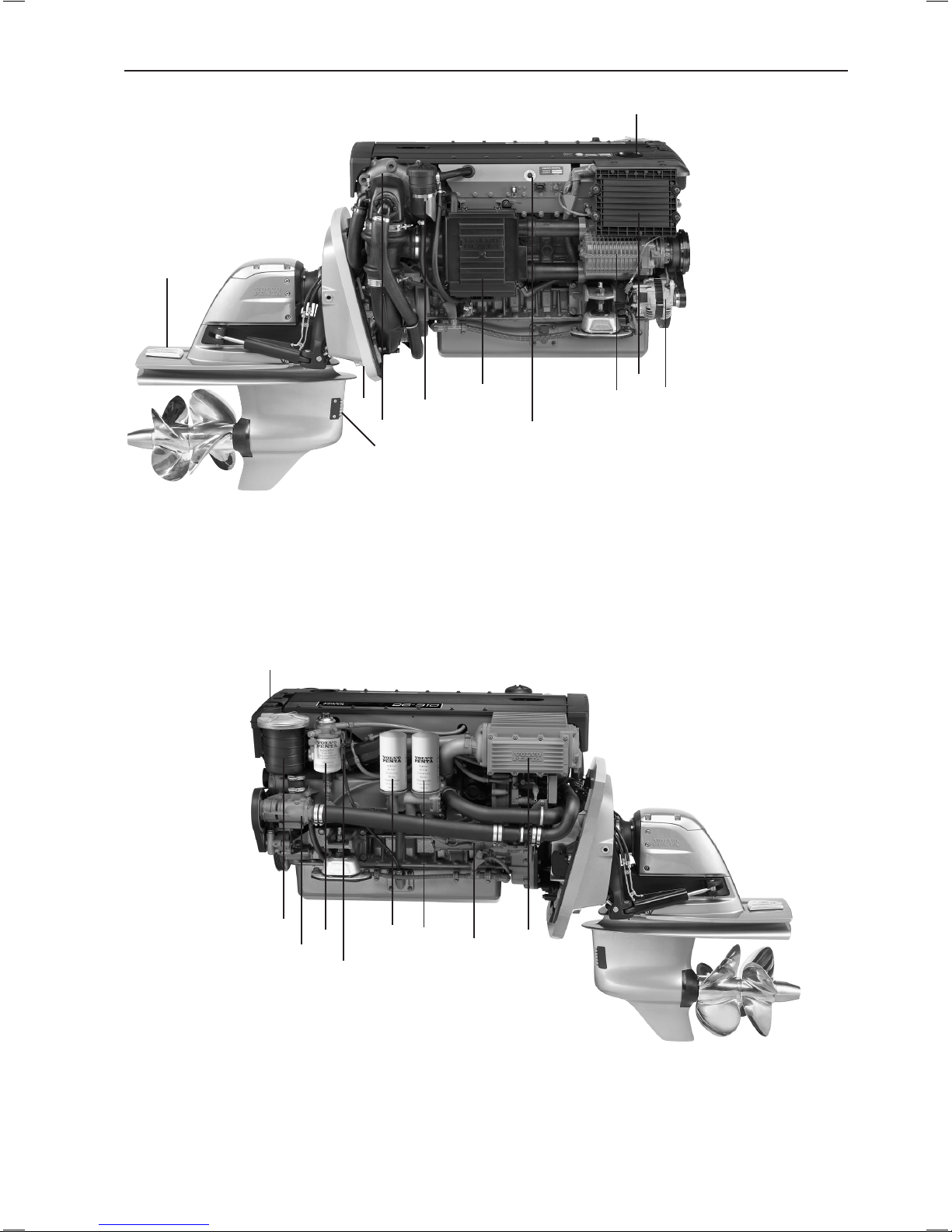

D6 with drive, starboard

1. Zinc anode

2. Cooling water intake

3. Zinc anode

4. Turbocharger

5. Crankcase ventilation filter

6. Aux Stop

7. Air filter

8. Compressor

9. EDC control module

10. Generator

11. Oil filler cap

D6 with drive, port

11. Sea water filter

12. Sea water pump

13. Fuel filter

14. Oil dipstick

15. Oil bypass filter

16. Oil filter

17. Starter

18. Charge air cooler

1

2

3

4

5

7

6

8

9

11

11

12

13

14

15

16

17

18

19

10

19

Presentation

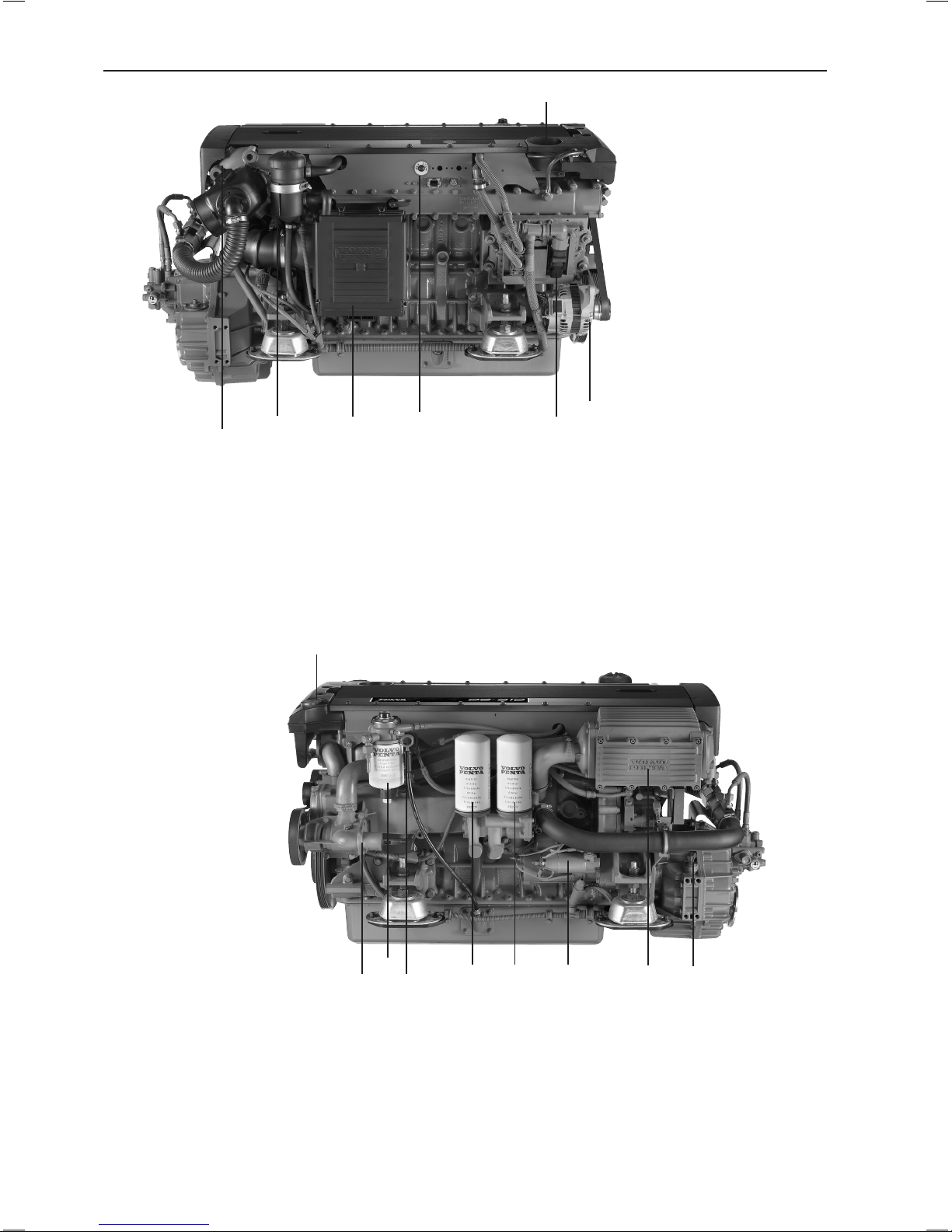

D6 with reverse gear, starboard

1. Turbocharger

2. Crankcase ventilation filter

3. Air filter

4. Aux Stop

5. EDC control module

6. Generator

7. Oil filler cap

D6 with reverse gear, port

8. Sea water pump

9. Fuel filter

10. Oil dipstick (engine)

11. Oil bypass filter

12. Oil filter

13. Starter

14. Charge air cooler

15. Oil dipstick (reverse gear)

16. Expansion tank

8

9

10

11

12

13 14 15

16

1

2

3

4

5

6

7

20

Presentation

Instruments

This chapter describes the instrument and control panels sold by Volvo Penta for your engine.

If you want to supplement the instrumentation, or if your boat is equipped with instruments not described here,

or you are not sure about their function, please contact your Volvo Penta dealer.

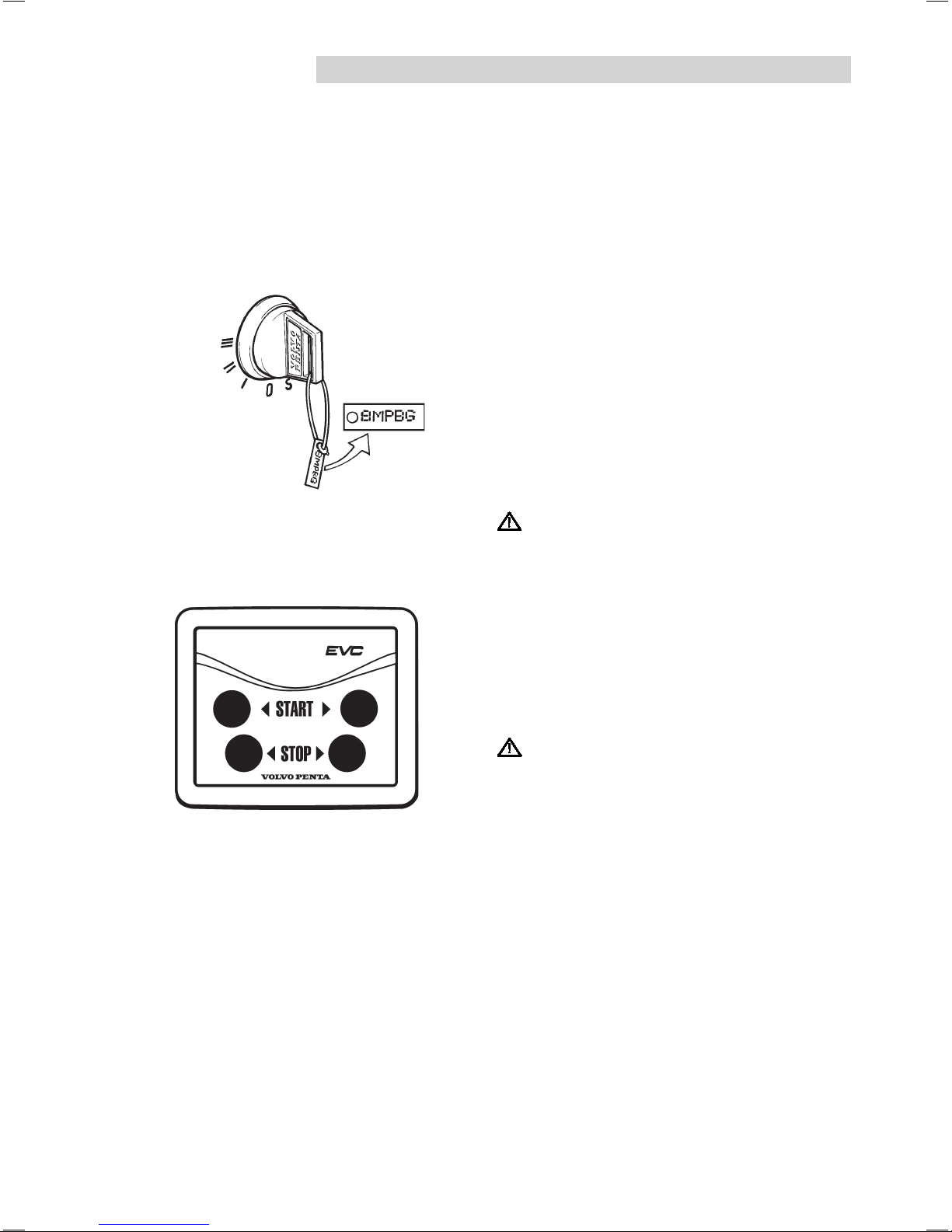

Ignition lock

A tab with the key code accompanies the ignition

keys, and is used to order extra ignition keys. Do not

store the code where it is accessible to unauthorized

persons.

S = Stop position.

0 = Key can be inserted and removed.

I = System voltage on (drive position).

II = Not used.

III = Start position.

IMPORTANT! Read the starting instructions in

the “Engine starting” chapter.

Start/stop panel

The start/stop panel is used to start or stop the engine. The starter key on the main helm station must be

in position “I” (driving position) for the engine to start.

The engine can only be stopped if the control panel is

activated.

IMPORTANT! Read the starting instructions in

the “Engine starting” chapter.

21

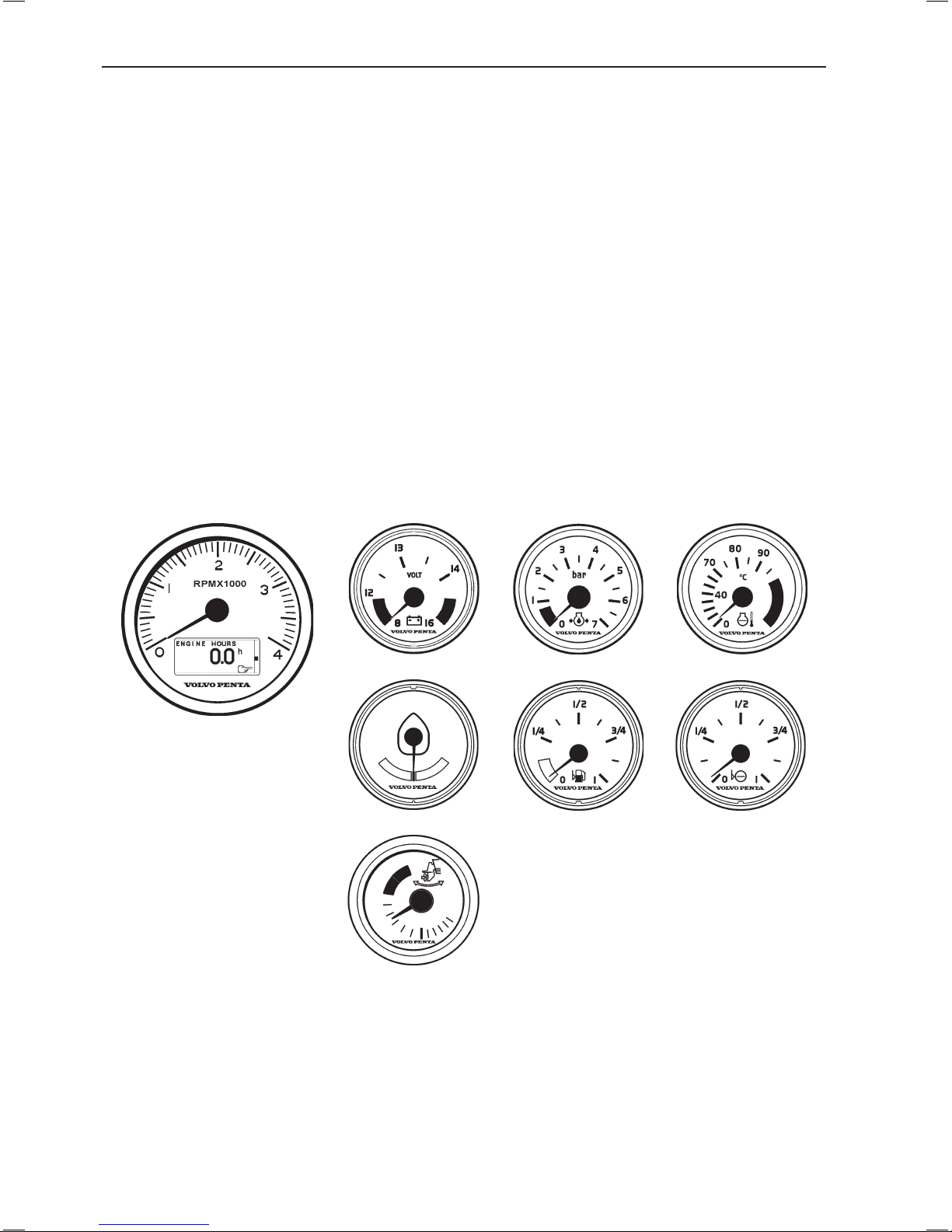

Instruments

1. EVC system tachometer (with display)

Extra optional instruments

2. Voltmeter

3. Oil pressure gauge

4. Temperature gauge

5. Rudder indicator

6. Fuel level gauge

7. Water level gauge

8. Trim instrument

2.

3.

4.

1.

6.

7.

5.

8.

22

Instruments

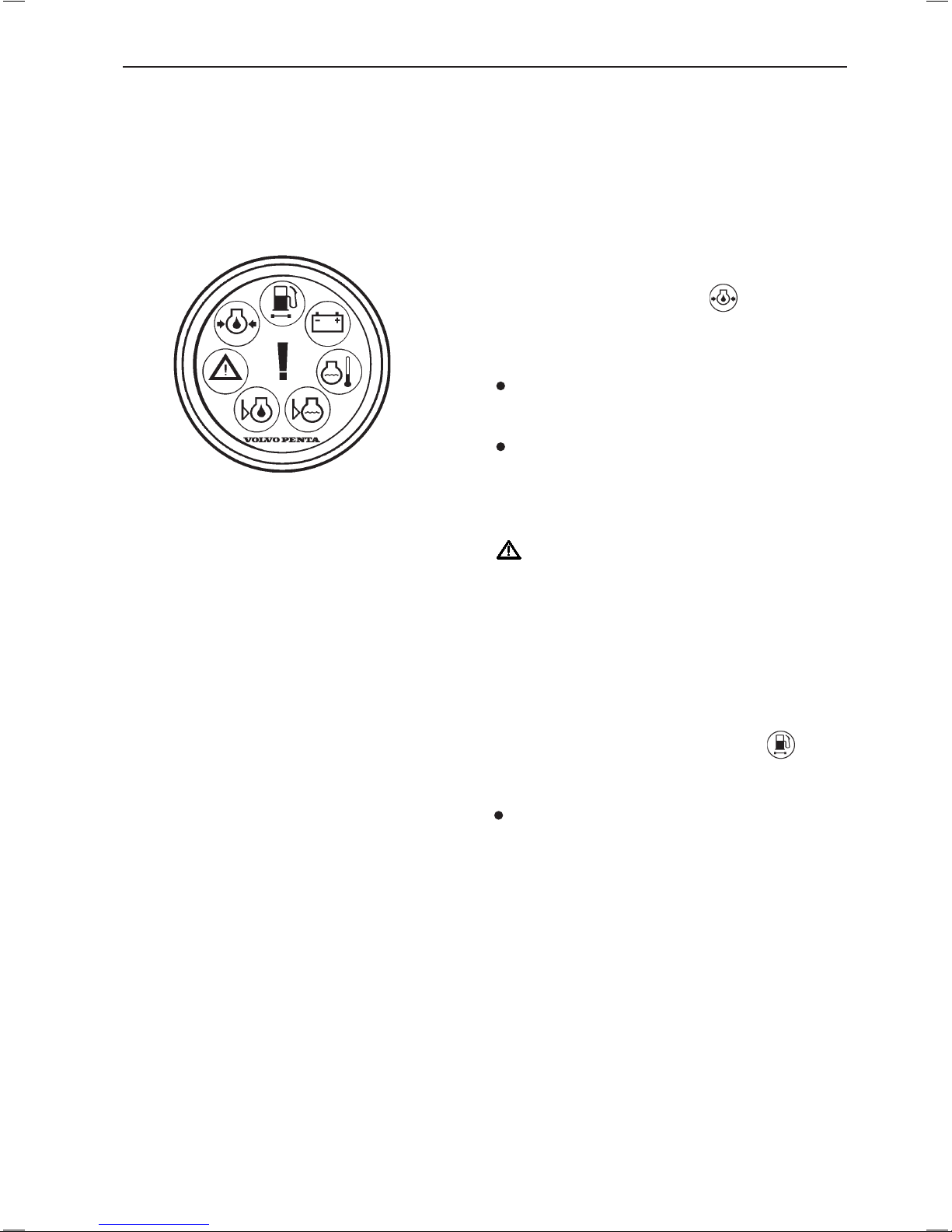

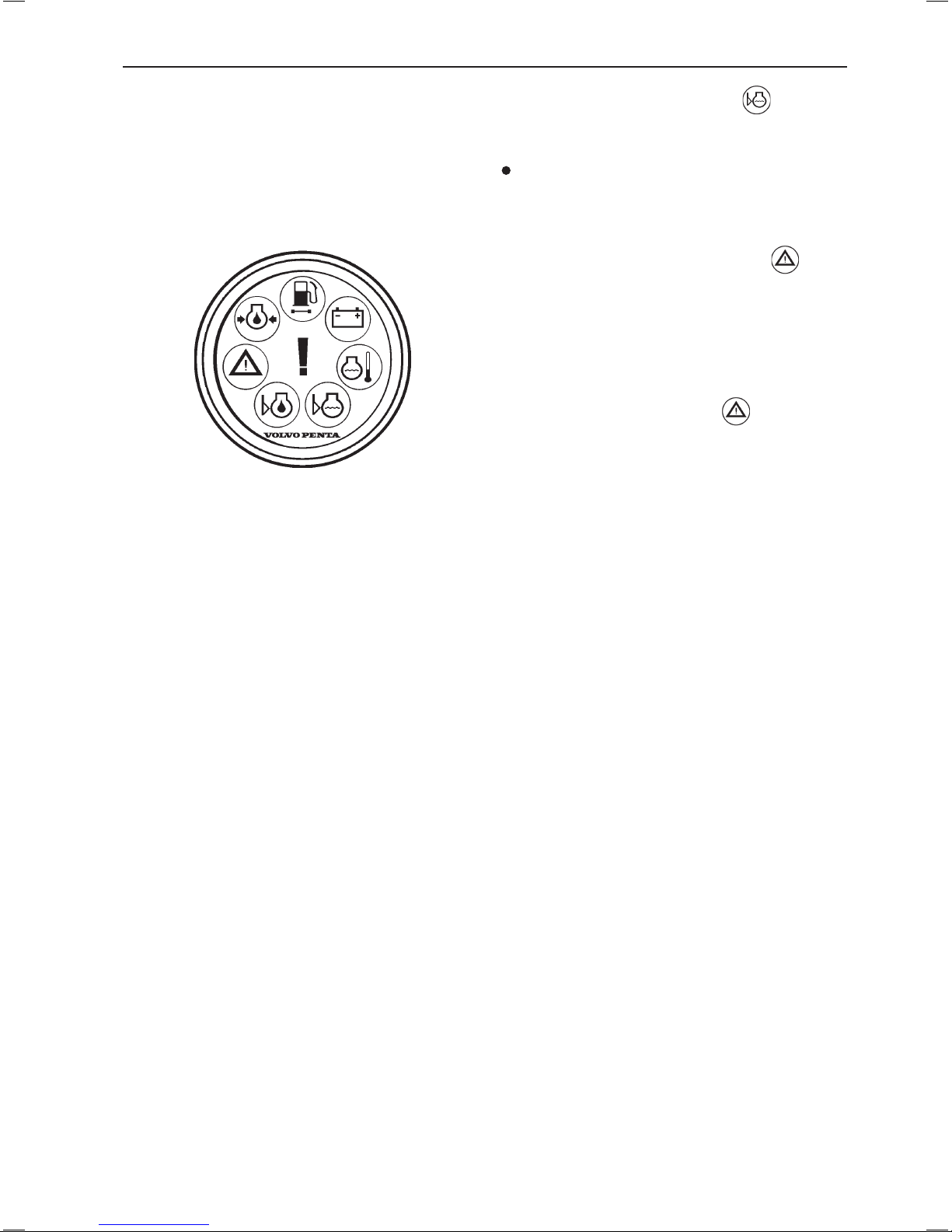

Alarm display (extra optional)

The following warning lamps should never light up during operation. On the other hand, the warning lamps light

up when the starter key is first turned to the drive position. Check that all lamps function. When the engine has

started, all lamps should have gone out. The lamps flash if the diagnostic function has registered malfunction.

When the fault has been acknowledged, the lamp gives continuous light.

Warning lamps (should never light up

during operation).

Oil pressure (red indication)

If the oil pressure lamp lights up during operation, the

oil pressure in the engine is too low. Stop the engine at

once.

Check the oil level in the engine. Please refer to

“Maintenance: Lubrication” to check and top the oil

up.

Also check that the oil filters are not blocked.

Please refer to “Maintenance: Lubrication system”

Please refer to the “In case of emergency” chapter,

and you will find detailed information about recommended action in the “Diagnostic function” section.

WARNING! Continued operation when the oil

pressure is too low can cause serious engine damage.

Water in fuel filter (orange indication)

If the lamp lights up, there is too much water in the water trap in the fuel filters.

Empty the water trap underneath the fuel filter on

the engine and pre filters. Please refer to “Maintenance: Fuel system”.

23

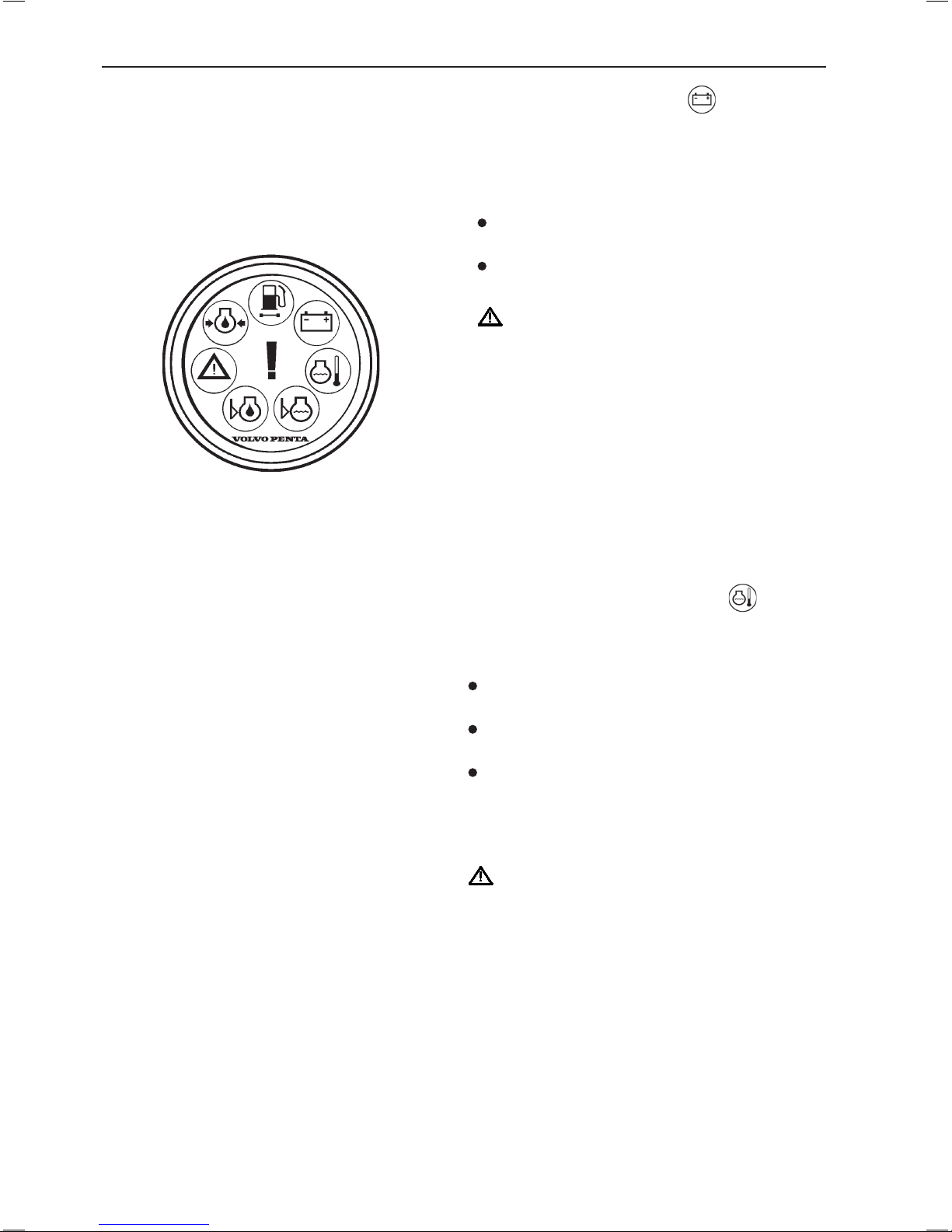

Instruments

Battery (orange indication)

The battery lamp lights up if the alternator is not

charging. Stop the engine if this lamp lights up during

operation. If the lamp lights up, this can be due to a

fault in the electrical system or because the alternator

drive belt is slack.

Check the alternator drive belts. Please refer to

“Maintenance: Engine, general”.

Also check that there is no poor contact/broken wires.

WARNING! Do not continue operation if there is

any problem with the alternator drive belts. This

could cause serious engine damage.

Coolant temperature (red indication)

The coolant temperature lamp lights up when the

coolant temperature is too high. Stop the engine if this

lamp lights up during operation.

Check the coolant level. Please refer to “Maintenan-

ce: Fresh water system”.

Check that the sea water filter is not blocked. Please

refer to “Maintenance: Sea water system”

Also check the impeller in the sea water pump.

Please refer to “Maintenance: Sea water system”.

Please refer to the “In case of emergency” chapter, and

you will find detailed information about recommended

action in the “Diagnostic function” section.

WARNING! Do not open the coolant filler cap

when the engine is warm, except in emergencies.

Steam or hot fluid could spray out.

24

Instruments

Coolant level (orange indication)

The coolant lamp lights up when the coolant level is

too low.

Check coolant level. Please refer to “Maintenan-

ce: Fresh water system”.

Red warning indication, serious fault

If the red warning indication is shown during operation, a serious fault has occured.

Please refer to the “In case of emergency” chapter,

and you will find detailed information about recommended action in the “Diagnostic function” section.

Orange alarm indication, fault

If the orange alarm indication is shown during opera

-

tion, a fault has occured.

Please refer to the “In case of emergency” chapter,

and you will find detailed information about recommended action in the “Diagnostic function” section.

25

Instruments

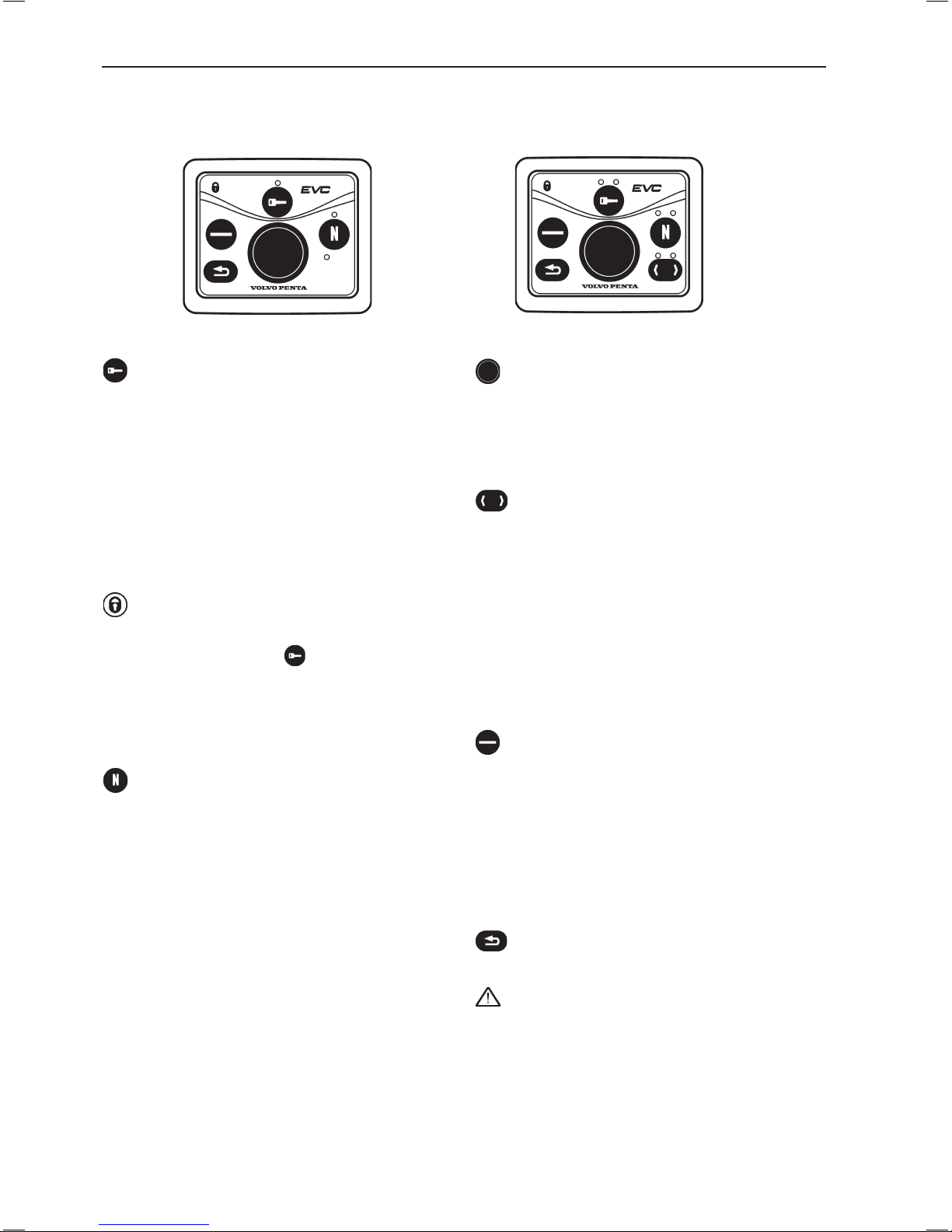

Navigation wheel

Used to navigate through the menus shown on the

tachometer EVC system display. Navigate through

the menus by turning the wheel. Depress the wheel to

confirm a selection.

Tachometer display selection (twin installa-

tion, port or starboard tachometer)

Is used to select which of the engines menu systems

should be navigable from the control panel. The menu

is shown on the display of the corresponding engines

tachometer. Select port or starboard.

Indication (red/green):

Off: Not possible to navigate in menu.

Lit: Possible to navigate in menu for selected engine,

port (red), starboard (green).

Multifunction button

Used to increase or decrease the instrument’s and

panel’s backlighting.

Depress the button for at least 1 second to turn the

backlighting on or off. The backlighting can be adjust

-

ed in five stages by pressing the multifunction button.

If the button is pressed on a inactive control panel, op

erating information is shown on the display(s) and it is

possible to navigate in the menus.

Back button

Used to back a step in the menu.

IMPORTANT! Always press the buttons firmly,

and for at least one second each time.

Activation button

Used to activate and lock the control panel and the

helm station.

Indication (red):

Off: Control panel not activated.

Lit: Control panel activated.

Flashes: Control panel not activated due to the con-

trol lever not being in neutral or the system has been

locked from another control panel.

Padlock

The padlock symbol lights if the control panel is locked

manually by depressing the -button, or if exchange

has been activated by routine ”Change of control

panel during journey”.

Lit: The system is locked and the engine can only be

controlled from the activated control panel.

Neutral button

Used to disengage the drive/reverse gear so that the

engine speed can be increased without driving (warm

-

ing up mode).

Indication (green):

Off: Drive/reverse gear engaged.

Lit: Control lever in neutral.

Flashes: Drive/reverse gear disengaged or system in

calibration mode.

This button is also used for:

- Activation of the Volvo Penta Lowspeed/Trolling func

tion (optional). For more information please refer to

chapter “Operation” section “Volvo Penta Lowspeed/

Trolling”.

- Enabeling of emergency trimming. For more informa-

tion please refer to chapter “In case of emergency:

Emergency trimming”.

EVC control panel

The control panel is used in combination with the EVC system tachometer. The tachometer display shows operating information and menus that can be navigated from the control panel.

26

Instruments

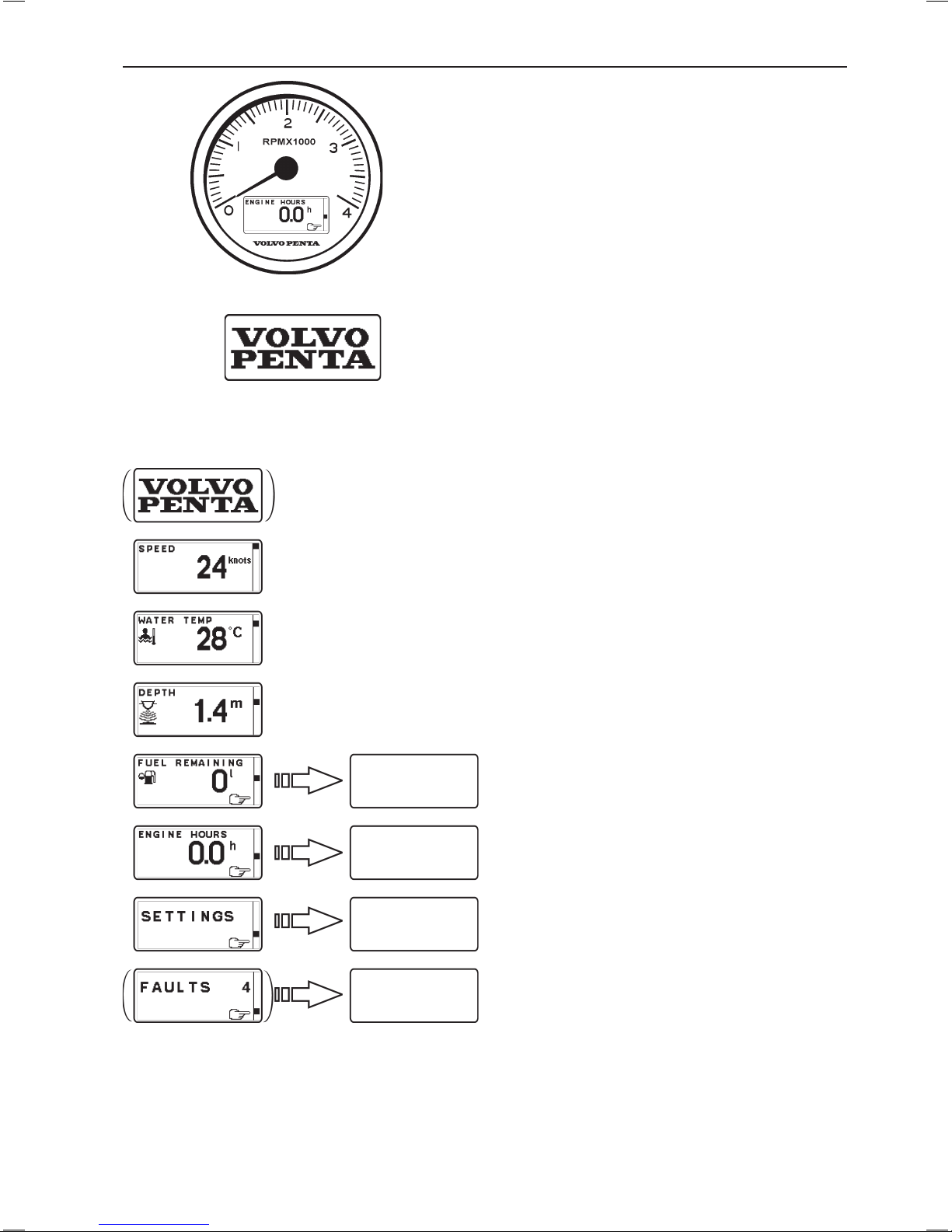

Main menu structure

EVC System Tachometer

Introduction

Volvo Penta EVC System Tachometer presents relevant boat and engine information to the helmsman. Information is presented on a display in the tachometer.

Information is depending on engine model, number of

sensors and type of accessories.

Using the instrument

Start-up screen

This is the start-up screen for the EVC System Tachometer. After a few seconds the first item in MAIN

MENU will appear.

Main menu

Navigating the menus

Navigate the menus by turning NAVIGATION WHEEL

clockwise or counter-clockwise. Views with a POINTING HAND-symbol indicates a SUB-MENU. To enter

a SUB-MENU, push NAVIGATION WHEEL.

Speed (Optional)

Boat speed. Requires multisensor or GPS.

Water temp (Optional)

Water temperature. Requires multisensor.

Depth (Optional)

Water depth. Requires multisensor.

Trip menu (Optional)

Shows trip information. Requires the following:

- Multisensor or NMEA 0183/NMEA 2000 compatible

component (plotter, GPS, paddle wheel etc)

- Fuel level sender

- Trip computer software

Gauges menu

Shows data parameters.

Settings menu

The SETTINGS MENU allows the user to set various

options for the EVC System and to calibrate various

parameters.

Faults list

Number after word FAULTS indicates number of faults

stored in FAULTS LIST. List is reset when system is

rebooted.

NOTE! Faults list is not shown if no faults are registered.

Trip menu

Gauges menu

Settings menu

Faults list

27

Instruments

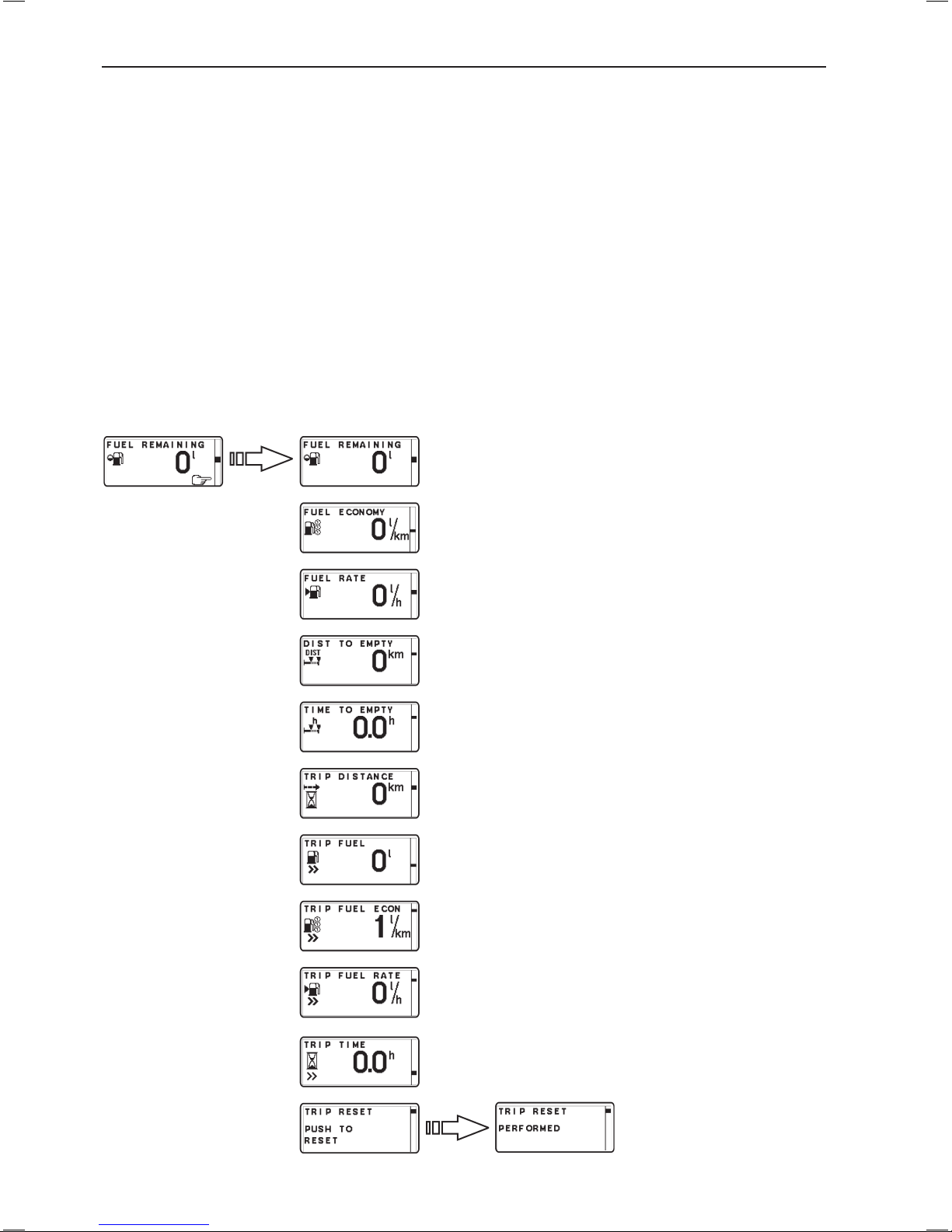

Trip menu (extra optional)

In the TRIP MENU the user gets trip information from the EVC System and the user is allowed to select which

view that should be presented in the EVC System Tachometers MAIN MENU as trip information. To get trip information following are required:

- Multisensor or NMEA 0183/NMEA 2000 compatible component (plotter, GPS, paddle wheel etc)

- Fuel level sender

- Trip computer software

NOTE! The accuracy of trip information concerning, and based on, remaining fuel volume depends on which

method the user has choosen for calibrating the fuel tank.

When in TRIP MENU, select view by turning NAVIGATION WHEEL. To select view as favorite, push NAVIGATION WHEEL. System returns to MAIN MENU.

Push BACK BUTTON to return to MAIN MENU without setting a new favorite.

Units are user selectable. See section "Units"

TRIP RESET: Reset all trip data.

FUEL REMAINING: Fuel remaining (l, Gal).

FUEL ECONOMY: Instantaneous fuel rate per dis-

tance (l/nm, l/km, l/mile, Gal/nm, Gal/km, Gal/mile).

FUEL RATE: Instantaneous fuel rate per hour (l/h,

Gal/h).

DISTANCE TO EMPTY: Distance to empty based on

instantaneous fuel rate, remaining fuel and speed

(nm, km, miles).

TIME TO EMPTY: Time to empty based on instantaneous fuel rate and remaining fuel (h).

TRIP DISTANCE: Trip distance since last reset (nm,

km, miles).

TRIP FUEL: Trip fuel used since last reset (l, Gal).

TRIP FUEL ECONOMY: Average fuel rate per dis-

tance since last reset (l/nm, l/km, l/mile, Gal/nm, Gal/

km, Gal/mile).

TRIP FUEL RATE: Average fuel rate per hour since

last reset (l/h, Gal/h).

TRIP TIME: Trip engine hours since last reset (h).

Trip menu structure

28

Instruments

Loading...

Loading...