Page 1

OPERATOR’S MANUAL

Plus d'informations sur : www.dbmoteurs.fr

D25A MS/MT

D30A MS/MT

Page 2

CALIFORNIA

Plus d'informations sur : www.dbmoteurs.fr

Proposition 65 Warning

Diesel engine exhaust and some of its constituents are known

to the State of California to cause cancer, birth defects, and

other reproductive harm.

Page 3

Foreword

Plus d'informations sur : www.dbmoteurs.fr

Thank you for purchasing this Volvo Penta diesel engine.

This manual contains operation instructions and maintenance and inspection information. In order to ensure safety and bring out the maximum performance of the engine, do not operate the

engine until you have read and fully understood the contents of this manual. Do not hesitate to

consult your Volvo Penta dealer.

Failure to follow the instructions and cautions in this manual may result in serious accidents.

* Keep this manual at hand for easy reference.

* If this manual is damaged or misplaced, immediately order a new copy from your dealer.

Page 4

Contents

Plus d'informations sur : www.dbmoteurs.fr

Foreword .................................................................. 3

Safety Information ................................................... 6

Safety regulations during engine operation ............. 7

Safety directions for maintenance and service ....... 8

Warning labels D25A / D30A MS ......................... 10

Warning labels D25A / D30A MT .......................... 11

Introduction ............................................................ 12

Care of the environment ....................................... 12

Fuel and oil .......................................................... 12

Service and spare parts ....................................... 12

Certified engines .................................................. 13

Warranty .............................................................. 13

Presentation ........................................................... 14

D25A/D30A MS ................................................... 14

D25A/D30A MT .................................................... 15

New Engine Initial service ...................................... 16

General ................................................................ 16

External Inspection .............................................. 16

Valves and Plugs ................................................. 16

Electrical Wiring ................................................... 16

Fill Fuel system ................................................... 16

Fill Lubrication system ......................................... 16

Fill Cooling system .............................................. 16

Starting .................................................................. 17

Before starting ..................................................... 17

Warming-up .......................................................... 17

Standard control system ........................................ 18

Instrument panels ................................................ 18

Warning displays .................................................. 19

After an alarm ...................................................... 19

Alarm test ............................................................ 19

Starting switch ..................................................... 19

Starting procedure ................................................ 20

Operation ............................................................. 21

Alarms and fault indication ................................... 22

Stopping the engine ............................................. 22

Emergency stop ................................................... 22

Operation ............................................................... 23

General ................................................................ 23

Applying Load ...................................................... 24

Running in ............................................................ 24

Forced propeller rotation ....................................... 24

Manoeuvring ........................................................ 24

Manual speed control ........................................... 25

Start using auxiliary batteries ............................... 27

Stopping ................................................................ 28

Manual Stop Lever ............................................... 28

After stopping ........................................................ 29

General ................................................................ 29

Anti-freezing measures ........................................ 29

Breaks in operation [not using the engine]............ 29

Maintenance .......................................................... 30

Maintnenance schedule D25A/D30A MS .............. 31

Maintnenance schedule D25A/D30A MT .............. 34

Overhaul information ............................................ 37

Recommendation of Daily Operation Records ...... 39

Engine ................................................................... 40

Valve Clearance ................................................... 40

Firing order ........................................................... 41

Vibration Damper Inspection ................................ 42

Re-tighten Bolts and Nuts .................................... 42

How to use the Turning Gear ............................... 43

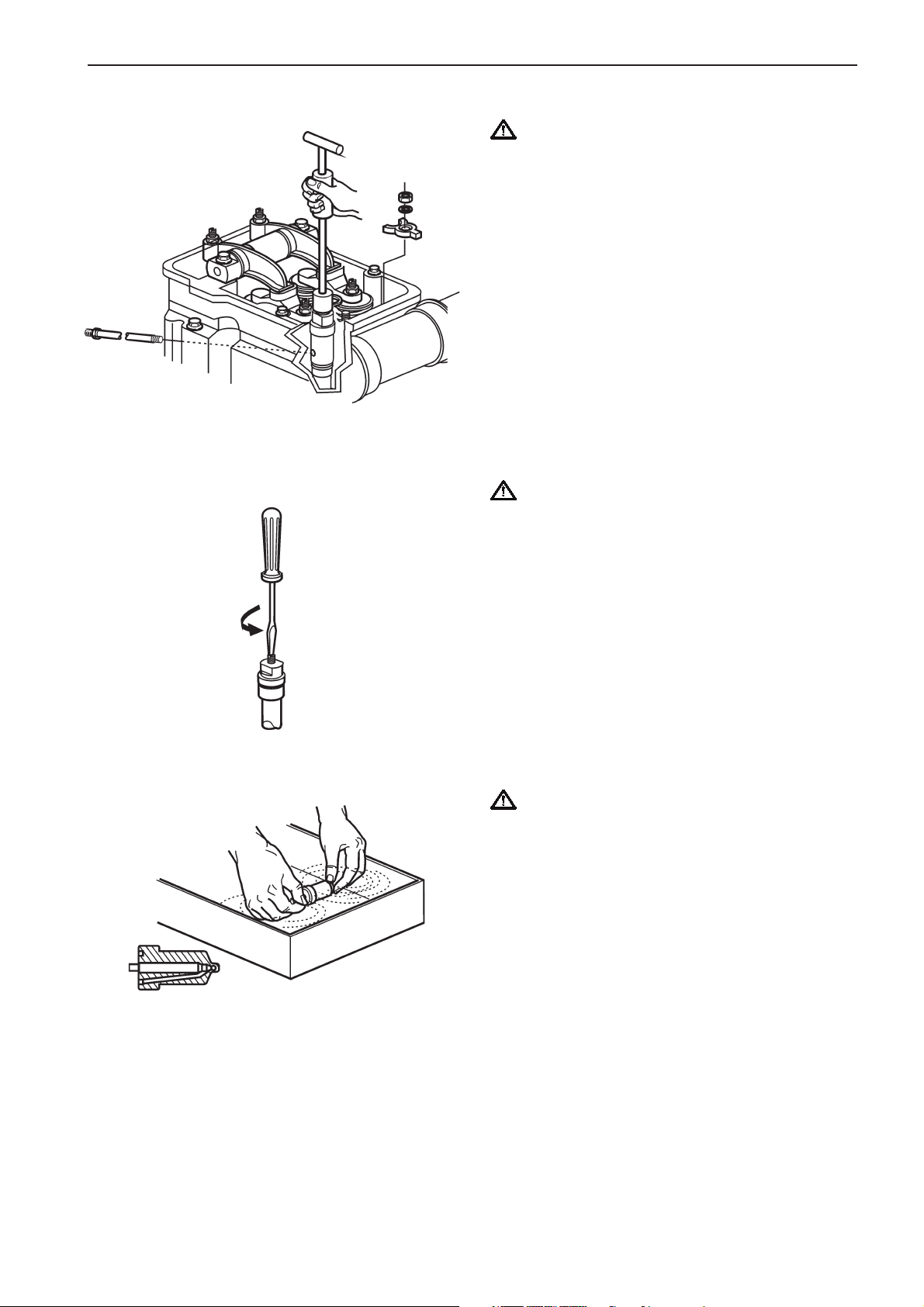

Fuel system ........................................................... 44

Fuel system bleeding ........................................... 44

Fuel filter change ................................................. 46

Fuel tank drain ..................................................... 47

Fuel injection nozzle tip change ........................... 47

Fuel injection pressure ......................................... 48

Injection timing inspection .................................... 50

Fuel control .......................................................... 51

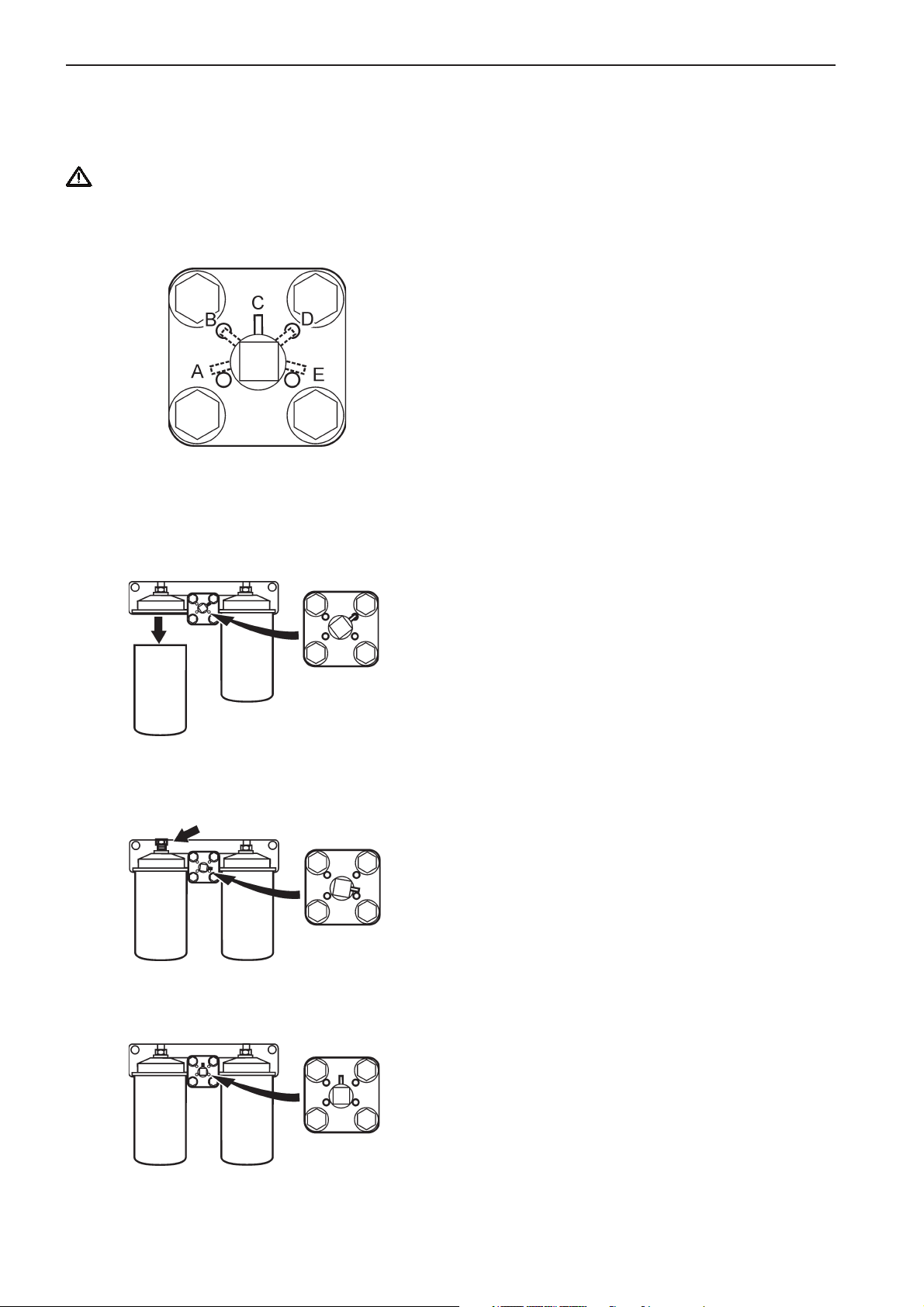

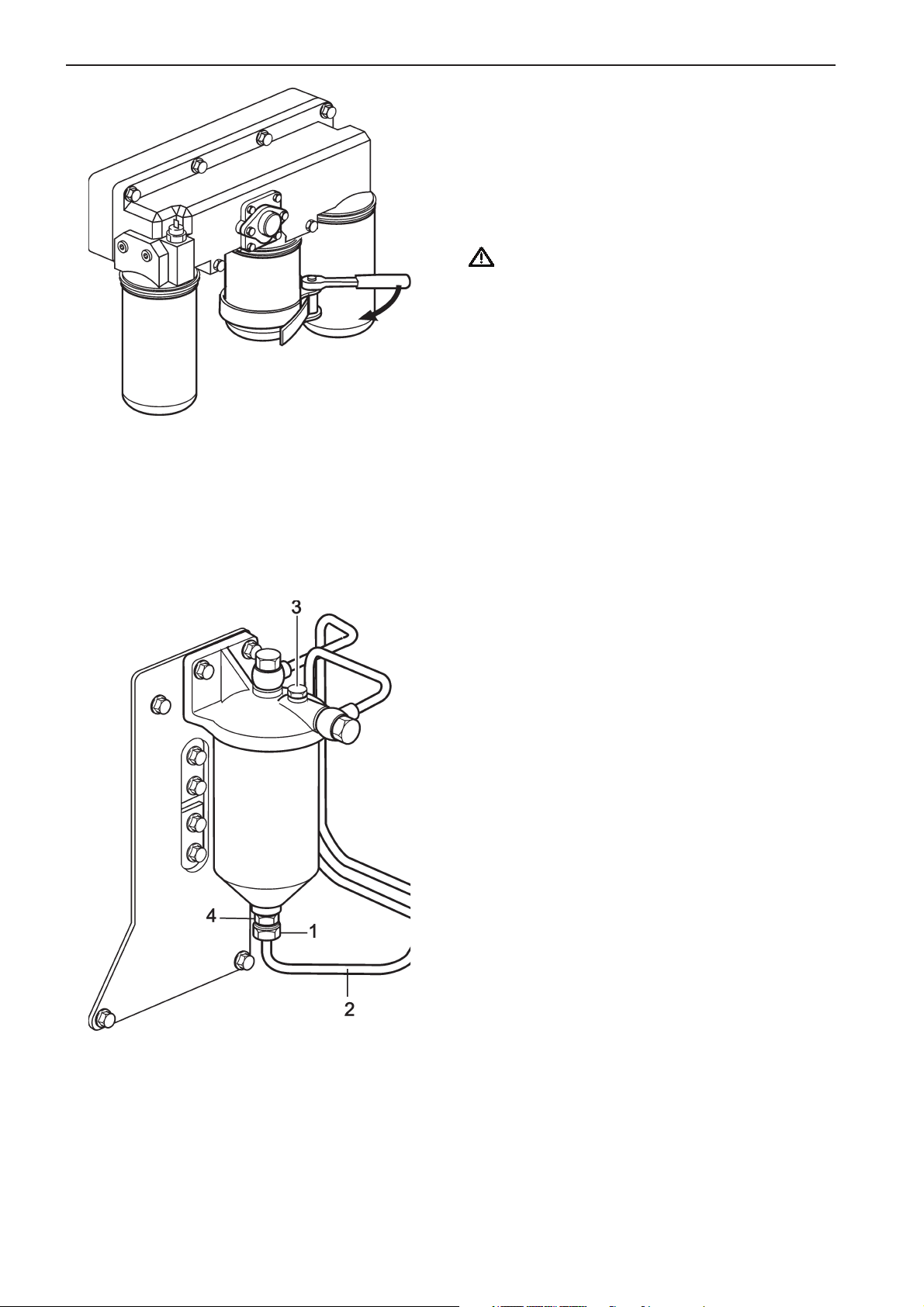

Twin fuel pre-filter/water separator ........................ 52

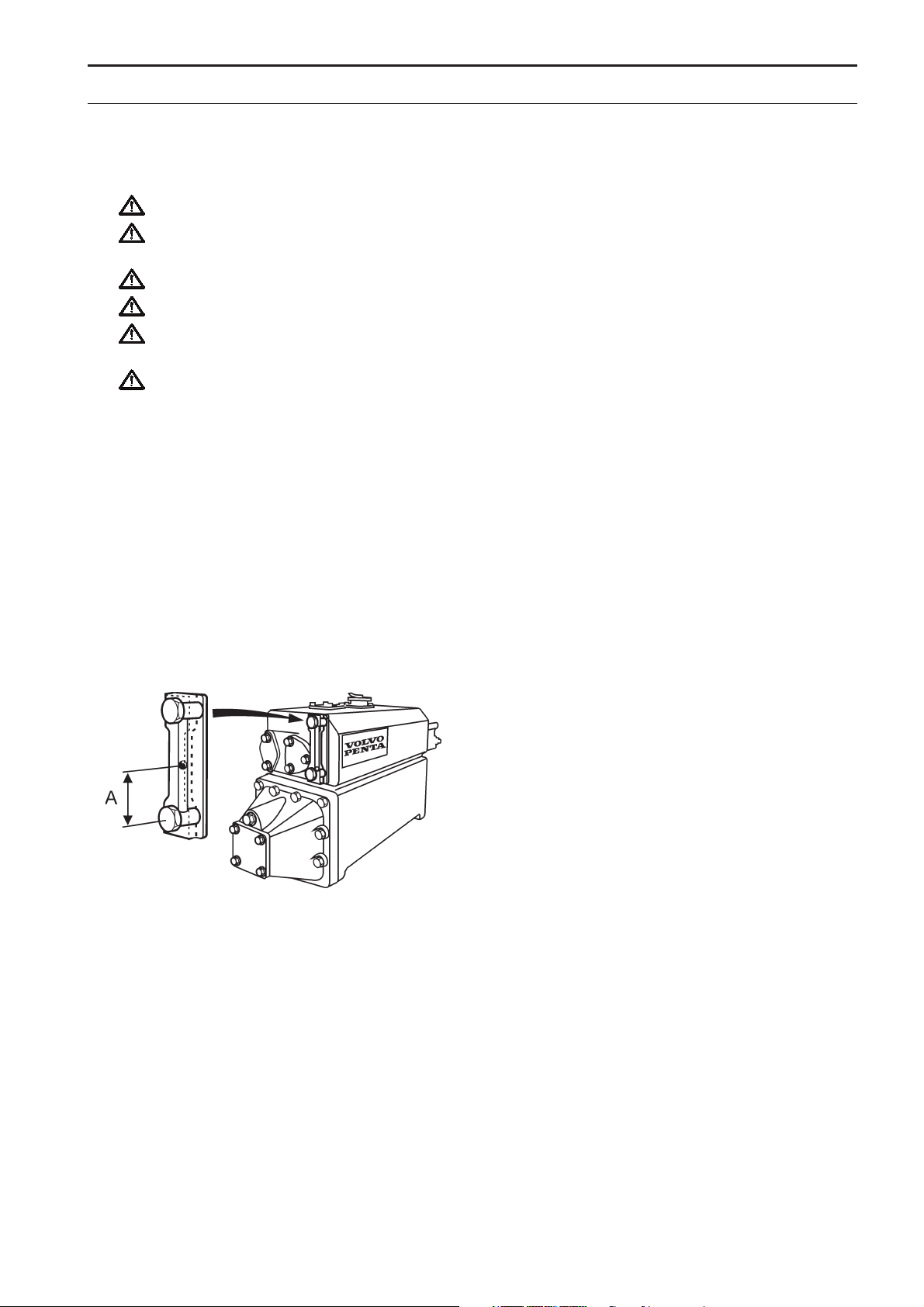

Lubrication system ................................................. 54

Lubrication oil level check .................................... 54

Lubrication oil filling .............................................. 54

Lubrication oil change .......................................... 56

Oil filter change .................................................... 57

Lubrication oil by-pass filter change ..................... 58

Hydraulic governor oil filter change ....................... 58

Freshwater system ................................................ 59

Coolant level check .............................................. 59

Coolant filling ....................................................... 60

Coolant drain ........................................................ 60

Freshwater system flushing ................................. 61

Seawater system ................................................... 62

Draining the seawater system .............................. 62

Check and Change the zinc anodes ..................... 62

Seawater filter check/change ............................... 62

Seawater pump impeller check/hange .................. 63

Heat exchanger cleaning ...................................... 63

4

Page 5

Air Inlet and Exhaust Systems .............................. 64

Plus d'informations sur : www.dbmoteurs.fr

Turbocharger Inspection ....................................... 64

Cleaning the Air Cooler ........................................ 64

Check air cooler drain pipe ................................... 64

Wash the air filter ................................................. 65

Electrical system ................................................... 66

Protective Devices Inspection.............................. 66

Check the electrical wiring ................................... 66

Starter motor inspection ....................................... 66

Alternator Inspection ............................................ 66

Drive belts. Check/Adjust/Change ........................ 66

Inhibiting ................................................................ 67

General ................................................................ 67

Preparation .......................................................... 67

Care during storage .............................................. 67

Return the engine to service ................................ 67

Storage of Engine in operating condition .............. 68

Troubleshooting ..................................................... 69

Technical Data ....................................................... 70

D25A MS ............................................................. 70

D25A MT ............................................................. 71

D30A MS ............................................................. 72

D30A MT ............................................................. 73

Fuel specification ................................................. 74

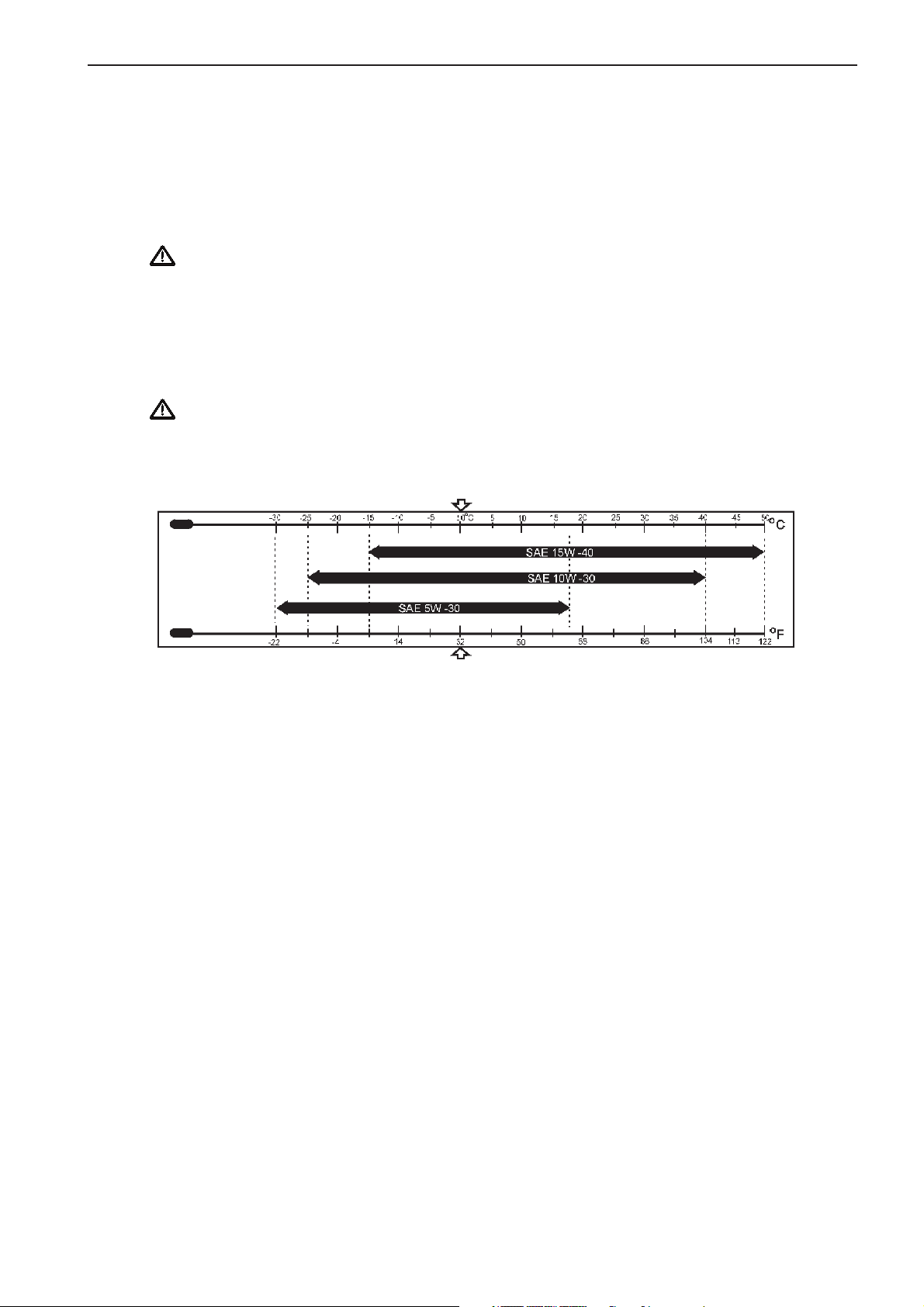

Lubrication oil specification .................................. 75

Coolant specification ............................................ 76

Tightening Torque Tables ..................................... 77

Identification numbers D25A / D30A .................... 83

Sea trial data ....................................................... 84

5

Page 6

Safety Information

Plus d'informations sur : www.dbmoteurs.fr

Read this chapter thoroughly. It concerns your safety. This section describes how safety information is presented

in this manual and on the product. It also includes a summary of basic safety regulations for operation and maintenance of the engine.

Make sure you are in possession of the right operator’s manual before reading on. If this is not the case,

please get in touch with your Volvo Penta dealer.

If operations are performed incorrectly it could result in personal injury or damage to property or the engine. Read the Operator’s Manual carefully before operating or servicing the engine. If anything is unclear

please contact your Volvo Penta dealer for assistance.

This symbol is used in the book and on the engine to make you aware of safety infor-

mation. Always read these safety precautions very carefully.

In the Operator’s Manual warning texts have the following priority:

WARNING! If these instructions are not followed there is a danger of personal injury,

extensive damage to the product or serious mechanical malfunction.

IMPORTANT! Used to draw your attention to something that can cause damage,

product malfunction or damage to property.

NOTE! Used to draw your attention to important information that will facilitate work or

operations.

This symbol is used in certain cases on our products and refers to important information in the Operator’s Manual. Ensure that warning and information symbols on the engine

and transmission are always visible and legible. Replace symbols that have been damaged

or painted over.

6

Page 7

Safety regulations during engine operation

Plus d'informations sur : www.dbmoteurs.fr

Safety information

The new engine

Read instruction manuals and other information accompanying the new vessel thoroughly. Accustom

yourself with handling the engine, controls and other

equipment in a safe and correct manner.

Remember that when operating a vessel, you have a

legal responsibility to be aware of and follow regulations concerning traffic and safety at sea. Inform yourself of the regulations applicable to your vessel and

the waters your in by getting in touch with the relevant

authorities or marine safety organization.

Accidents and other incidents

Sea rescue statistics show that deficient maintenance

of vessels and engines together with defective safety

equipment often causes accidents and other incidents

at sea.

Make sure your vessel and engine are maintained in

accordance with directions in the instruction manuals

and that the safety equipment on board is in good

working order.

Daily inspection

Make a habit of visually inspecting the engine and

engine room before starting and after stopping the

engine. This will help you to quickly detect any fuel,

coolant or oil leaks and any other abnormalities that

have occurred or are about to occur.

Maneuvering

Avoid violent and rapid rudder movement and gear

shifting. There is a risk of the passengers falling down

or falling overboard. A rotating propeller can cause serious injury. Make sure there is nobody in the water

before engaging forward/reverse. Never run close to

bathers or in places where you have reason to

believe there are people in the water.

Filling fuel

There is a risk of fire and explosion when filling fuel.

Smoking is prohibited and the engine must be turned

off. Never overfill the tank. Close the filler cap

securely. Use only fuel recommended in the operators

manual. The incorrect grade of fuel can disturb operation or cause breakdown. This can also lead to the

control rod jamming on diesel engines, which will cause the engine to overspeed and risk damaging machinery and causing personal injury.

Combustible enviroment

Due to the risk of fire and/or explosion, do not start or

continue to run the engine if there is a suspected leak

or discharge of combustible media, e.g. fuel oil or

LPG, in the engine surroundings.

Carbon monoxide poisoning

When a vessel is moving forward, it will cause a certain vacuum to form behind the vessel. In unfortunate

circumstances, the suction from this vacuum can be

so great that the exhaust gases from the vessel are

drawn into the bridge or cabin and cause carbon monoxide poisoning. This problem is most prevalent on

high, wide vessels with abrupt stern. Other factors

that can increase the effect of the suction are wind

conditions, load distribution, swells, trim, open hatches and portholes, etc. Most modern vessels, however, are designed in such a way that this problem is

very rare. If suction should arise anyway, do not open

hatches or portholes at the fore of the vessel. Surprisingly, this will otherwise increase the suction. Try

changing speed, trim, or load distribution instead. Get

in touch with your Volvo Penta dealer for help in obtaining the best solution for your vessel.

7

Page 8

Safety information

Plus d'informations sur : www.dbmoteurs.fr

Safety directions for maintenance and service

Preparations

Knowledge

The operator’s manual contains directions for performing normal maintenance and service in a safe and

correct manner. Read the directions carefully before

starting work. More detailed service literature is available from your Volvo Penta dealer. Never perform a

task unless you are absolutely sure how it is to be

carried out; call your Volvo Penta dealer for assistance instead.

Stop the engine

Stop the engine before opening or dismantling the

engine hatch/hood. Maintenance and service must be

carried out with the engine stationary unless stated

otherwise in the instructions. Prevent inadvertent start

of the engine by removing the starter key and turning

off the power with the main switch, locking it in the off

position. Place warning signs stating that service is in

progress in every position from which the engine can

be started. Working on or approaching a running engine is a safety hazard. Loose clothing, hair, fingers or

a dropped tool can be caught in rotating parts and

cause serious bodily injury. Volvo Penta recommend

leaving all work requiring the engine to be running to

an authorized Volvo Penta dealer.

Lifting the engine

Always use the lifting eyes mounted on the engine

when lifting the engine. Always make sure lifting

equipment is in good condition and constructed for the

lift (engine weight together with possible reverse gear

and extra equipment). Use an adjustable lifting boom

to ensure safe handling when lifting the engine. All

chains and wires must run parallel with each other and

as much at right angle as possible to the top of the

engine. Note that any extra equipment mounted on the

engine can change the center of gravity. Special lifting

devices may be required to obtain the right balance

and safe handling. Never perform service on an engine suspended only from a lifting device.

IMPORTANT! Engine must only be lifted

horizontally.

IMPORTANT! Engine lifting eyes are designed

only for lifting an engine. Do not use the engine

lifting eyes when lifting a complete genset or an

engine with a gearbox mounted.

Before starting

Refit all guards and covers that have been removed

before starting the engine. Make sure there are no

tools or other objects left on the engine. A turbocharged engine must never be started without the air filter

fitted. The rotating compressor wheel in the turbocharger can cause severe personal injury.

There is also a risk of foreign objects being drawn in

and causing mechanical damage.

Fire and explosion

Fuel and lubricants

All fuels, most lubricants, and many chemicals are

flammable substances. Always read and follow the

directions on the packaging. Work performed on the

fuel system must be done on a cold engine. Fuel

leaks and spills on hot surfaces or electrical

components can cause fires.

Keep oil- and fuel drenched rags and other hazardous

materials where they are safe in case of fire. Oil drenched rags can selfignite in certain conditions. Never

smoke when refueling, topping up with oil or when in

the vicinity of the fuel station or the engine room.

Non-original parts

Components in fuel, lubrication, ignition and electrical

systems on Volvo Penta engines are designed and

manufactured to minimize the risk of explosion and

fire in compliance with existing legislation.

The use of non-original parts can result in explosion

or fire.

Batteries

Batteries contain and generate oxyhydrogen gas,

especially when charging. Oxyhydrogen is easily

ignited and extremely explosive. Smoking, open flames and sparks must never occur in, or close to, the

batteries or battery compartment. A faulty battery connection or jumper cable can generate sparks that can

cause the battery to explode.

Start spray

Never use start spray or similar start help. Explosions

can occur in the intake manifold. Risk for personal

injury.

8

Page 9

Safety information

Plus d'informations sur : www.dbmoteurs.fr

Hot surfaces and fluids

At operating temperature, the engine and its components are hot. A hot engine always involves risk for

burn injuries. Take care with hot surfaces. E.g.: exhaust manifold, turbocharger, oil pan, charge air pipe,

starting heater, hot coolant and warm lubricant in pipes and hoses.

WARNING! Do not open the crankcase

covers while the engine is still hot.

Carbon monoxide poisoning

Start the engine in well-ventilated spaces only. When

running in confined spaces, the exhaust gases and

crankcase gases must be evacuated.

Chemicals

Most chemicals such as glycol, anti-corrosion agent,

preservatives, degreasing agent, etc., are hazardous

to health. Always read and follow the directions on

the packaging.

Certain chemicals such as preservatives are

flammable and harmful to inhale. Provide good

ventilation and use breathing protection when

spraying. Always read and follow the directions on the

packaging. Store chemicals and other hazardous

materials out of reach of children. Leave left over or

used chemicals to a destruction plant.

Always cover any electric component if it is located

under the fuel filter. Otherwise it might be damaged by

fuel spills.

Electrical system

Turn off the power before commencing work on the

electrical system, the engine must be stopped and the

powered turned off with the main switch/switches.

Shore power to the engine heater, battery charger or

other extra equipment fitted to the engine must be disconnected.

Batteries

Batteries contain a highly corrosive electrolyte. Protect your eyes, skin and clothing when charging and

handing batteries. Always use protective goggles and

gloves.

In case of splashes on the skin, wash with soap and

plenty of water. In case of splashes in the eyes, rinse

immediately with plenty of water and call a doctor.

Avoid burns and crushing or cutting!

At operating temperature, the engine coolant is hot

and under pressure. Steam can cause personal

injury. Check the coolant level only after the engine

has been stopped and the coolant filler cap has cooled enough to touch with your hand. Never adjust the

V-belts while the engine is running.

Cooling system

There is a risk of water entering when working on the

seawater system. Therefore, stop the engine and

close the seawater cock before starting work.

Avoid opening the coolant filler cap when the engine is

warm. Steam or hot coolant may spurt out and cause

burn injuries.

If the filler cap, coolant pipe, cock, etc., must

nevertheless be opened or dismantled while the

engine is warm, the filler cap must be opened

carefully to release the pressure before removing it

completely and starting work. Note that the coolant

can still be hot and cause burn injuries.

Lubricating system

Hot oil can cause burn injuries. Avoid skin contact

with warm oil. Make sure the lubricating system is

depressurized before starting work. Never start or run

the engine with the oil filler cap removed or there will

be a risk of the oil being thrown out.

Fuel system

Always protect your hands when carrying out leak detection.

Service batteries carefully!

If you spill electrolyte on yourself, flush skin immediately with lots of water. Apply baking soda to help neutralize the acid. If electrolyte gets in your eyes, rinse

immediately with large amounts of water then contact

a doctor at once.

Handle antifreeze carefully!

Antifreeze contains alkali. Avoid contact with skin

and eyes to prevent personal injury. Dispose of

drained antifreeze coolant according to local

regulations. For disposal, consult your dealer.

Dress properly for the job!

Wear protective devices - hard hat, face shield, safety

shoes, goggles, heavy gloves, ear protectors, etc. for your own safety.

Recommended fuel, lubrication oil and coolant!

Use of any other fuel oil, lurication oil or coolant than

the recommended can cause engine damage and reduce engine service life.

Perform all recommended inspections!

Perform pre-start inspection and periodic inspection

on items listed in this manual. Failure to follow this

recommendation can cause serious engine damage.

Escaping fluids under pressure can pierce bodily tissue and cause serious injury. Risk of blood poisoning.

9

Page 10

Safety information

Plus d'informations sur : www.dbmoteurs.fr

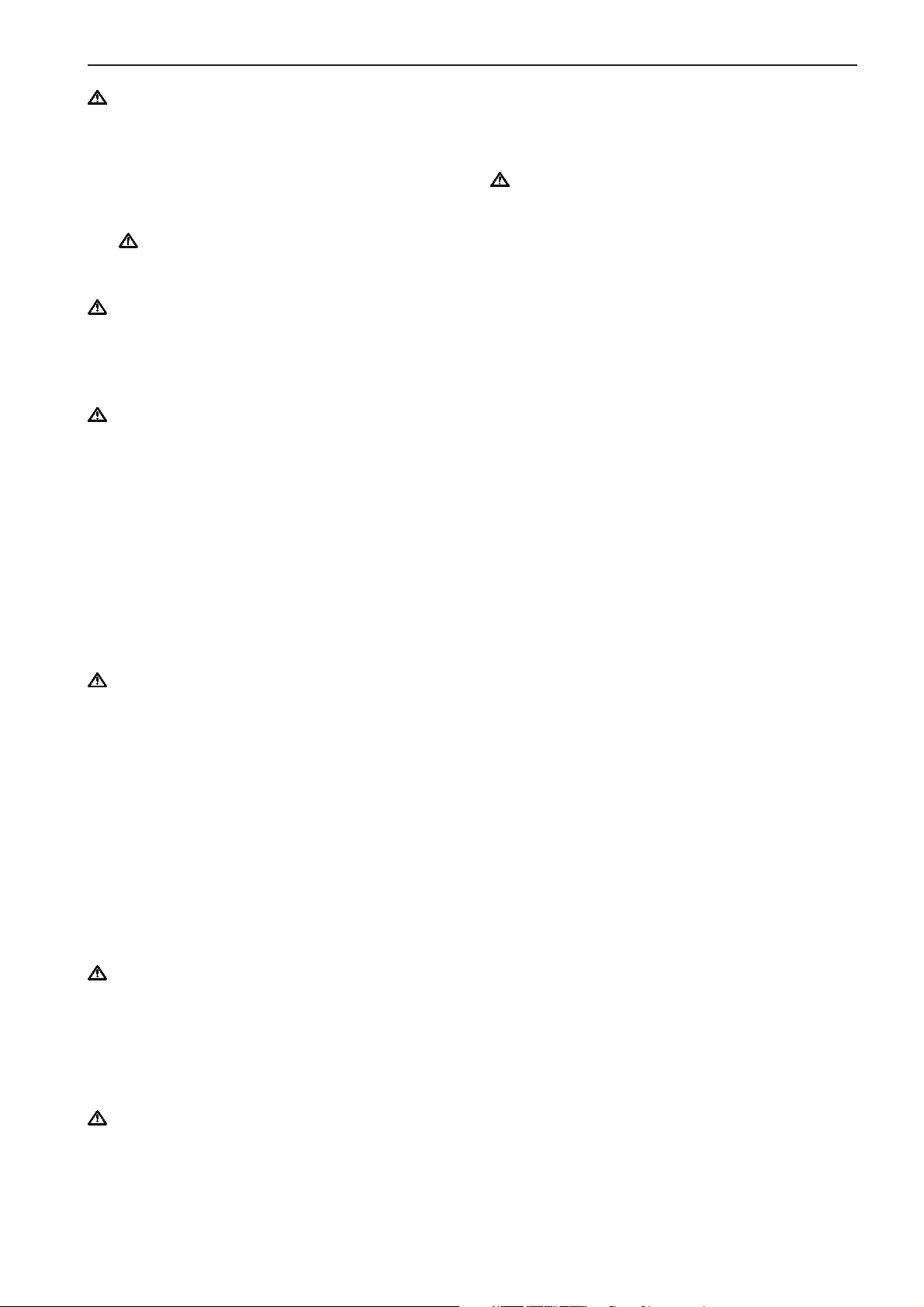

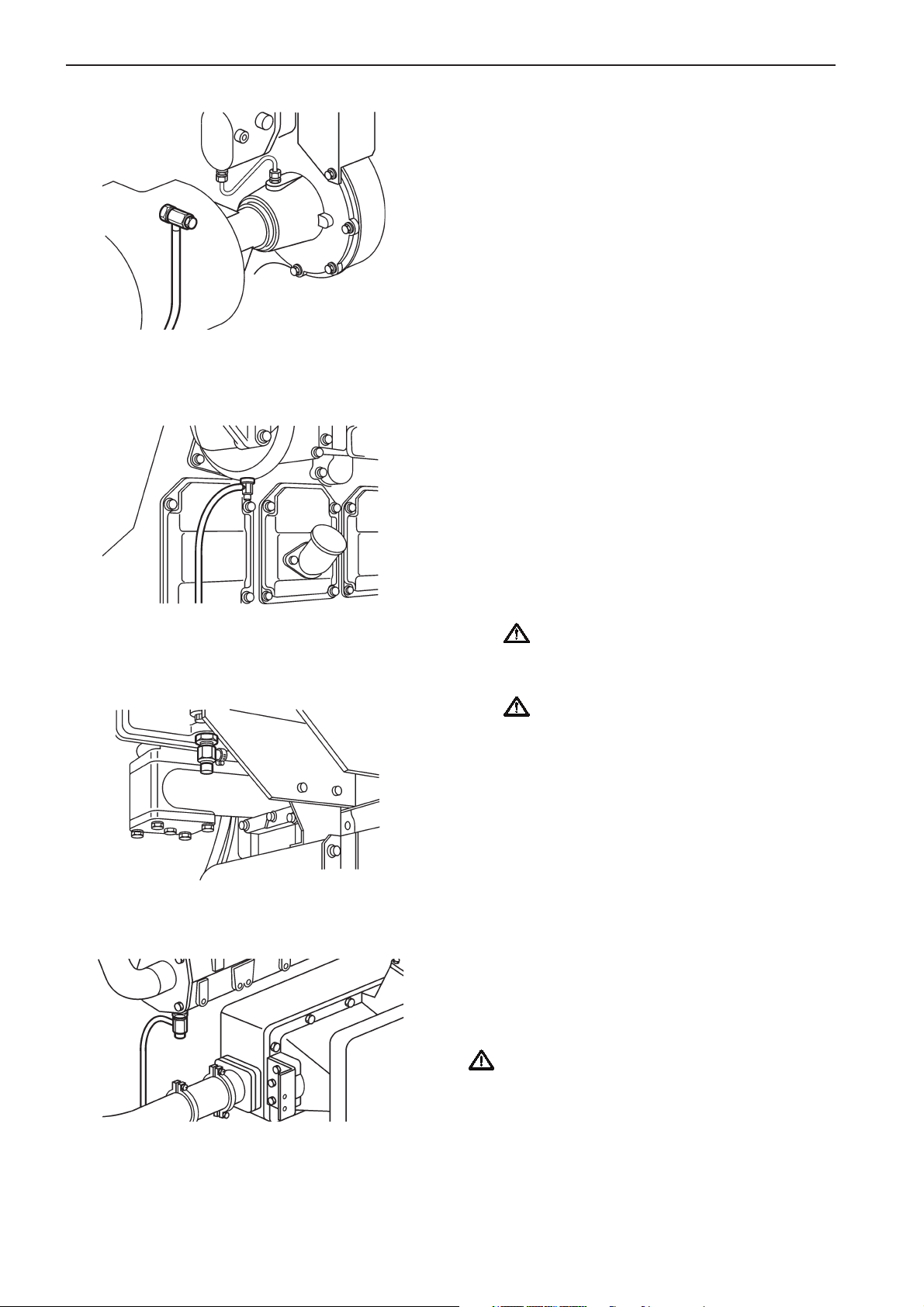

Warning labels D25A / D30A MS

The engine carries ‘Warning Labels’ at places where you are required to pay special attention. Please read them

carefully and make sure you understand the content of each label and the meaning of their position.

1. Make sure the labels are legible. If you find any letter or picture illegible in a label, remove soil from the label,

or replace it.

2. Clean the label with cloth and water or cleanser. Do not use organic solvent or gasoline, this would dissolve

the label’s adhesive and cause the label to fall off.

3. If any label is damaged, lost or illegible, replace it. When replacing a label, make sure the new label is

identical to the old one. For new labels, please contact your dealer.

10

Page 11

Safety information

Plus d'informations sur : www.dbmoteurs.fr

Warning labels D25A / D30A MT

The engine carries ‘Warning Labels’ at places where you are required to pay special attention. Please read them

carefully and make sure you understand the content of each label and the meaning of their position.

1. Make sure the labels are legible. If you find any letter or picture illegible in a label, remove soil from the label,

or replace it.

2. Clean the label with cloth and water or cleanser. Do not use organic solvent or gasoline, this would dissolve

the label’s adhesive and cause the label to fall off.

3. If any label is damaged, lost or illegible, replace it. When replacing a label, make sure the new label is

identical to the old one. For new labels, please contact your dealer.

11

Page 12

Introduction

Plus d'informations sur : www.dbmoteurs.fr

This operator’s manual has been produced to give you the greatest benefit of your Volvo Penta marine engine. It

contains the information necessary to handle and maintain your engine in a safe and correct manner. We would

like you to read this operator’s manual thoroughly and learn how to handle the engine, controls and other equipment in a safe manner before starting to operate the engine.

Keep the operator’s manual within reach at all times.

Care of the environment

We would all like to live in a clean and healthy environment. An environment where we can breathe clean air, see healthy trees, have clean water in our lakes and oceans, and are able to enjoy the sunshine

without being worried about our health. Unfortunately,

this cannot be taken for granted nowadays but is something we must work together to achieve.

As a manufacturer of marine engines, Volvo Penta

has a special responsibility, why care of the environment is a core value in our product development. Today, Volvo Penta has a broad range of engines where

progress has been made in reducing exhaust emissions, fuel consumption, engine noise, etc. We hope

you will take care in preserving these qualities.

Always follow any advice given in the operator’s manual concerning fuel grades, operation and maintenance and you will avoid causing unnecessary interference to the environment. Get in touch with your

Volvo Penta dealer if you notice any changes such as

increased fuel consumption exhaust smoke.

Adapt speed and distance to avoid wash and noise

disturbing or injuring animal life, moored boats, jetties,

etc. Leave islands and harbours in the same condition as you want to find them. Remember to always

leave hazardous waste such as waste oil, coolant,

paint and wash residue, flat batteries, etc., for disposal at a destruction plant. Our joint efforts will make a

valuable contribution to our environment.

Fuel and oil

Use only fuel and lubrication oil grades recommended

in the technical data section of this Operator’s Manual. Other grades can cause operational problems, increase fuel consumption and have long-range effects

on engine service life.

Service and spare parts

Volvo Penta marine engines are designed for high

operational reliability and long service life. They are

constructed to withstand the marine environment while affecting it as little as possible. Through regular

service and the use of Volvo Penta original spare

parts, these qualities will be retained.

The worldwide Volvo Penta network of authorized

dealers is at your service. They are specialists in

Volvo Penta products and stock accessories, original

spare parts, test equipment and the special tools required to perform high-quality service and repairs.

Always follow the maintenance intervals specified in

the operator’s manual and remember to specify the

engine number when ordering service and spare

parts.

12

Page 13

Introduction

Plus d'informations sur : www.dbmoteurs.fr

Certified engines

It is essential that owners and operators of emission certified engines, used in areas where exhaust emissions

are regulated by law, are aware of the following points:

A certification involves the engine type being checked and approved by applicable authorities. Engine manufacturers guarantee that all engines of the same type correspond with the certified engine.

This puts special demands on the maintenance and service of your engine:

* Maintenance and service intervals recommended by Volvo Penta must be followed.

* Only Volvo Penta original spare parts may be used.

* Service of injector pumps, pump settings and injectors must always be performed by an authorized Volvo

Penta service person.

* The engine must not be modified in any way with the exception of accessories and service kits approved by

Volvo Penta for use on the engine.

* Installation modifications must not be made to the engine exhaust pipe or inlet channels.

* Sealed sections must not be broken by anyone other than authorized personnel.

Otherwise, general directions concerning running, care and maintenance given in the operator’s manual apply.

IMPORTANT! Neglected or deficient maintenance/service and the use of non-original spare parts will

entail Volvo Penta renouncing any responsibility for the engine corresponding to the certified version.

Volvo Penta will not compensate for damage and/or costs arising from the above.

Warranty

Your new Volvo Penta marine engine is covered by a limited warranty complying with the conditions and instructions given in the Warranty and Service Book.

Note that AB Volvo Penta’s responsibility is limited to what is specified in the Warranty and Service Book. Read it

carefully as soon as possible after delivery. It contains important information concerning the warranty card, service, maintenance and what the owner is responsible to be aware of, check and perform. AB Volvo Penta will otherwise decline warranty liability completely or fully.

Get in touch with your Volvo Penta dealer if you have not received a Warranty and Service Book or a

copy of the warranty card.

13

Page 14

Presentation

Plus d'informations sur : www.dbmoteurs.fr

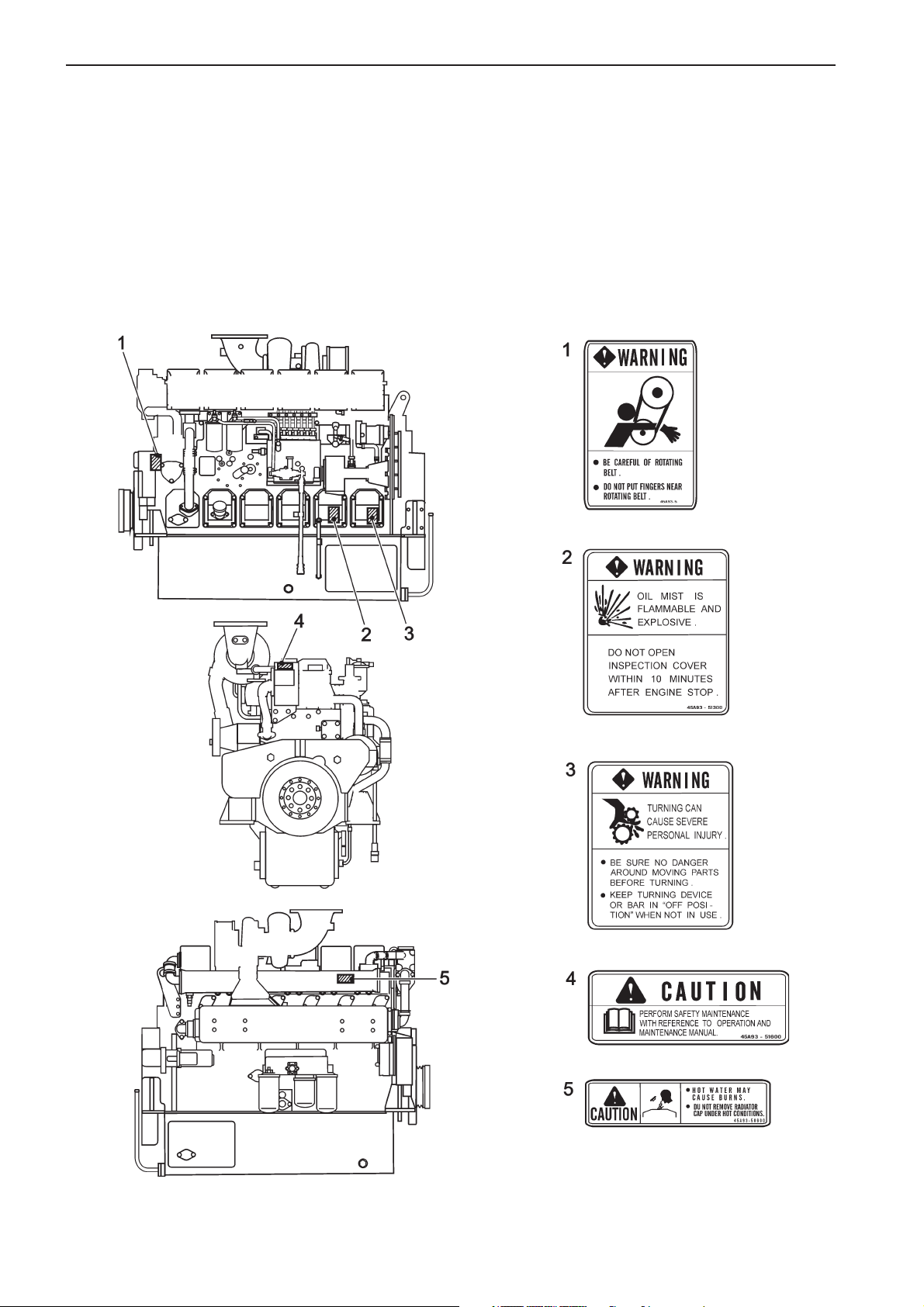

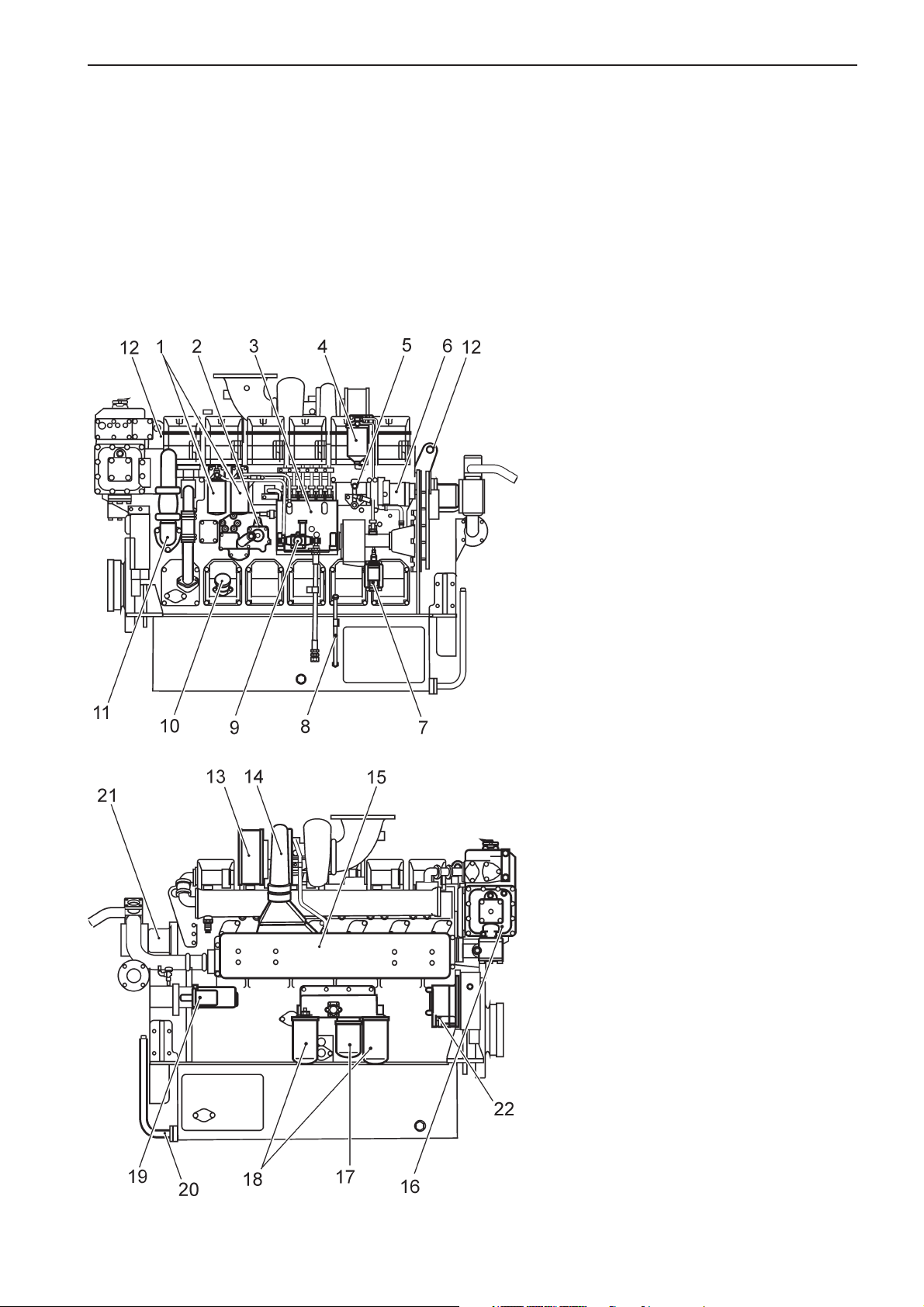

D25A/D30A MS

The D25A and D30A are in-line, direct injection, 6-cylinder, 4-stroke marine diesel engines. They are equipped

with turbocharger and fitted with either a heat exchanger for thermostat-regulated freshwater cooling or connections for keel cooling.

An optimal combination of combustion chambers, fuel injection system, effective turbocharger and charge air

cooling, provide excellent fuel consumption over the whole range of engine speeds where the engine is economical in operation.

D25A/D30A MS

1. Fuel filters

2. Oil cooler

3. Fuel injection pump

4. Governor oil filter

5. Manual stop lever

6. Governor

7. Stop solenoid

8. Oil dipstick

9. Fuel feed pump

10. Oil filler cap

11. Fresh water pump

12. Lifting eye

13. Intake air silencer

14. Turbocharger

15. Charge air cooler

16. Alternator

17. By-pass filter for engine oil

18. Oil filters

19. Engine oil drain pipe

20. Starter motor

14

Page 15

Presentation

Plus d'informations sur : www.dbmoteurs.fr

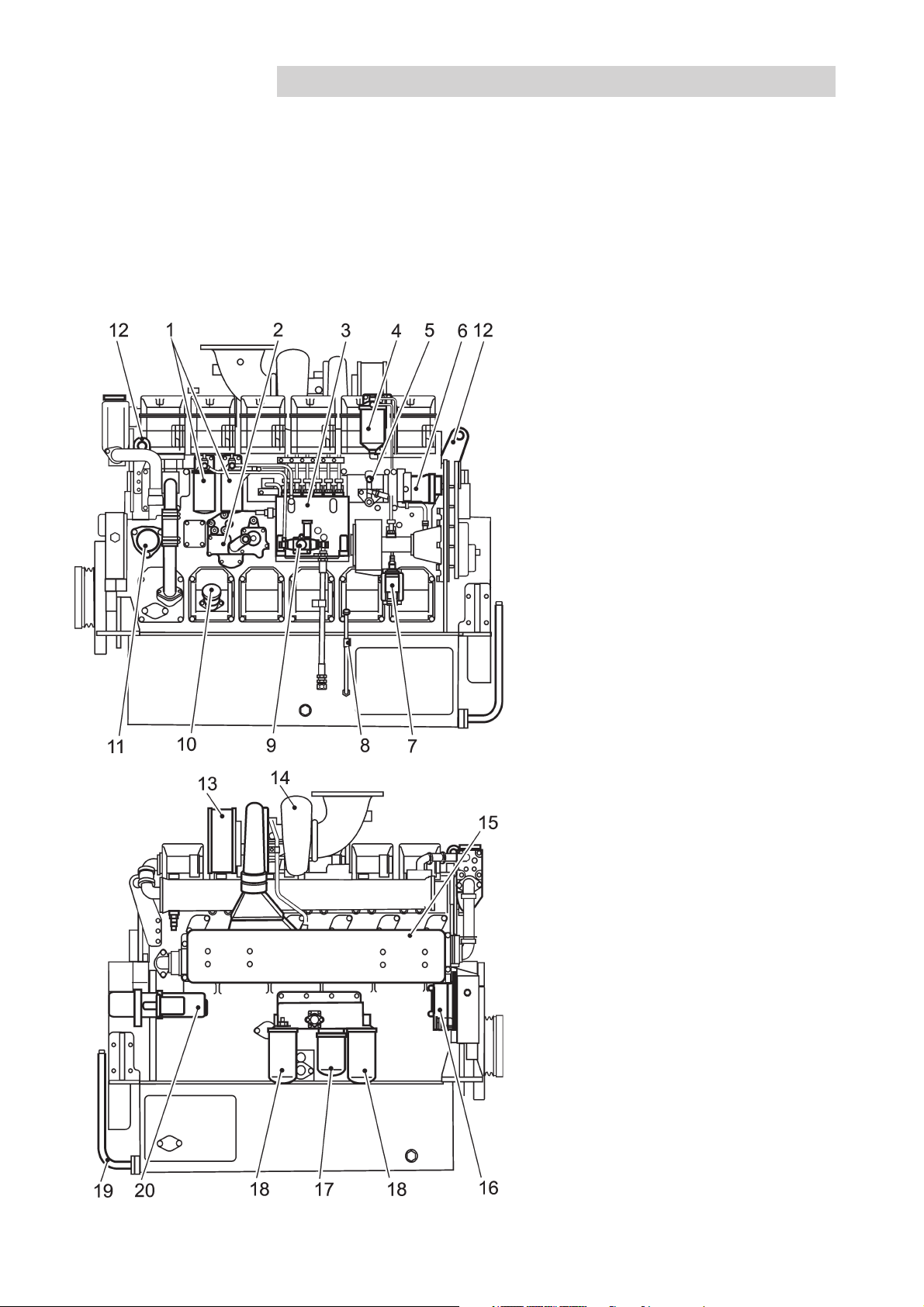

D25A/D30A MT

The D25A and D30A are in-line, direct injection, 6-cylinder, 4-stroke marine diesel engines. They are equipped

with turbocharger and fitted with either a heat exchanger for thermostat-regulated freshwater cooling or connections for keel cooling.

An optimal combination of combustion chambers, fuel injection system, effective turbocharger and charge air

cooling, provide excellent fuel consumption over the whole range of engine speeds where the engine is economical in operation.

D25A/D30A MT

1. Fuel filters

2. Oil cooler

3. Fuel injection pump

4. Governor oil filter

5. Manual stop lever

6. Governor

7. Stop solenoid

8. Oil dipstick

9. Fuel feed pump

10. Oil filler cap

11. Fresh water pump

12. Lifting eye

13. Intake air silencer

14. Turbocharger

15. Charge air cooler

16. Heat exchanger

17. By-pass filter for engine oil

18. Oil filters

19. Starter motor

20. Engine oil drain pipe

21. Sea water pump

22. Alternator

15

Page 16

New Engine Initial service

Plus d'informations sur : www.dbmoteurs.fr

General

Before starting a new or reconditioned engine for the first time, give it an initial inspection. This to guarantee your

own safety as well as the maximum service life of the engine.

External Inspection

1. Check the engine control system for loose terminals.

2. Check defects of engine parts.

3. Check the following components for loose bolts or

nuts:

* Plugs and covers of fuel, lubrication and cooling

system

* Coupling of fuel injection pump and shaft

* Crankshaft pulley and vibration damper

* Mounting brackets

* Fuel control linkage

* Turbocharger

* Timing gear case

* Exhaust manifolds

* Cylinder heads

* Air-duct connection-hose clamp

4. Check for Fuel, Oil, Coolant and Air leaks and repair if needed.

Electrical Wiring

Check for loose or damaged electrical wiring around

the engine and if necessary firmly reconnect to terminals or cable-joint portions. Damaged cables must

be replaced.

If your engine is reconditioned, make sure the wiring

is according to the drawings.

Fill Fuel system

Refer to chapter maintenance fuel system.

Fill Lubrication system

Refer to chapter maintenance lubrication system.

Fill Cooling system

Refer to chapter maintenance cooling system.

5. Make commissioning report for new or overhauled

engine.

IMPORTANT! All covers must be mounted before

attempting to start your engine.

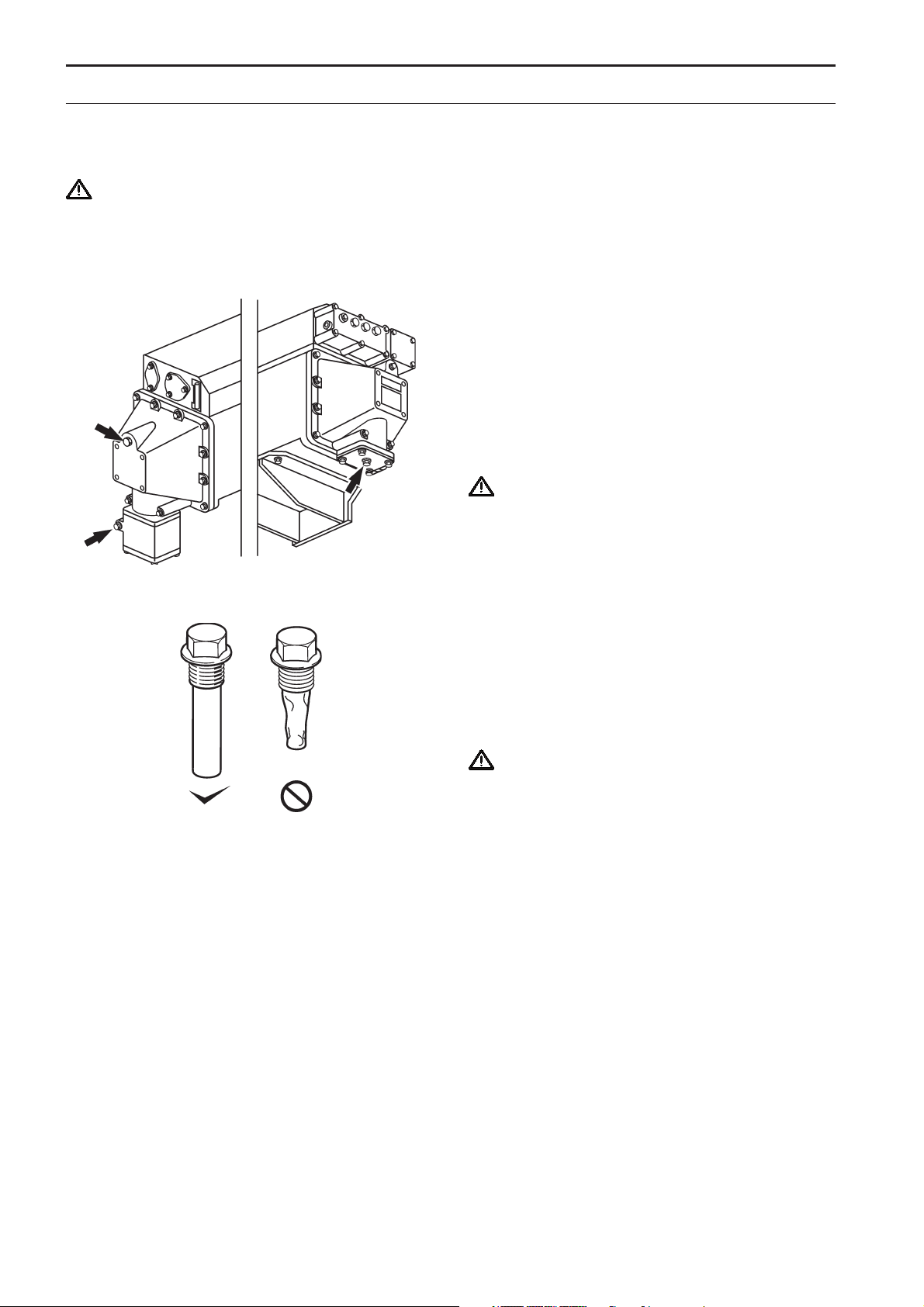

Valves and Plugs

Make sure the following valves and plugs are open or

closed properly:

Fuel supply valve Open

Coolant drain cock (engine) Closed

Coolant drain cock (water pump) Closed

Coolant drain cock (heat exchanger) Closed

IMPORTANT! If the coolant drain cocks are not

closed the coolant will drain from the engine and

this may cause severe damage to the engine.

16

Page 17

Starting

Plus d'informations sur : www.dbmoteurs.fr

Before starting

WARNING! Before starting the engine make sure that neither people, nor tools, are in contact with

moving parts of the engine. Notify the people in the vicinity of the engine when starting it.

WARNING! Make sure that you know how to stop the engine before you start it (in case of emergency).

If you are starting the engine for the first time, have someone stand-by at the emergency stop lever to

stop the engine in case abnormal noise occurs during start up. Block air intake in case of stop lever

malfunction, this has to be prepared in advance.

WARNING! Make sure that the manual speed control knob is locked in neutral position before starting

the engine (refer to page 26 of this manual).

IMPORTANT! If the starter motor has been engaged for the maximum time (30 seconds), it must be

allowed to cool down for at least one minute before a new attempt is made at starting.

Warming-up

WARNING! Do not conduct warm-up operation for an extended period of time. Prolonged warm-up

operation causes carbon buildup in the cylinders that leads to inperfect combustion.

* Operate at low idle speed for 5 to 10 minutes to warm up the engine.

* The oil pressure will be 0.20 to 0.29 MPa [28 to 43 psi] after the warm-up run. If the engine speed is increased

immediately after start-up, the oil pressure, due to cold lubrication oil and therefore higher viscosity, will exceed the normal level - 0.49 to 0.64 MPa [71 to 92 psi] (at rated speed) but it will normalize with increasing oil

temperature.

* If the Lubrication oil pressure does not increase when you have started the engine, immediately stop the engi-

ne and do not restart until the problem has been fixed.

* Make sure that the cooling water flow is sufficient.

* Make sure there is enough fuel aboard the vessel for the planned duration of operation.

17

Page 18

Standard control system

Plus d'informations sur : www.dbmoteurs.fr

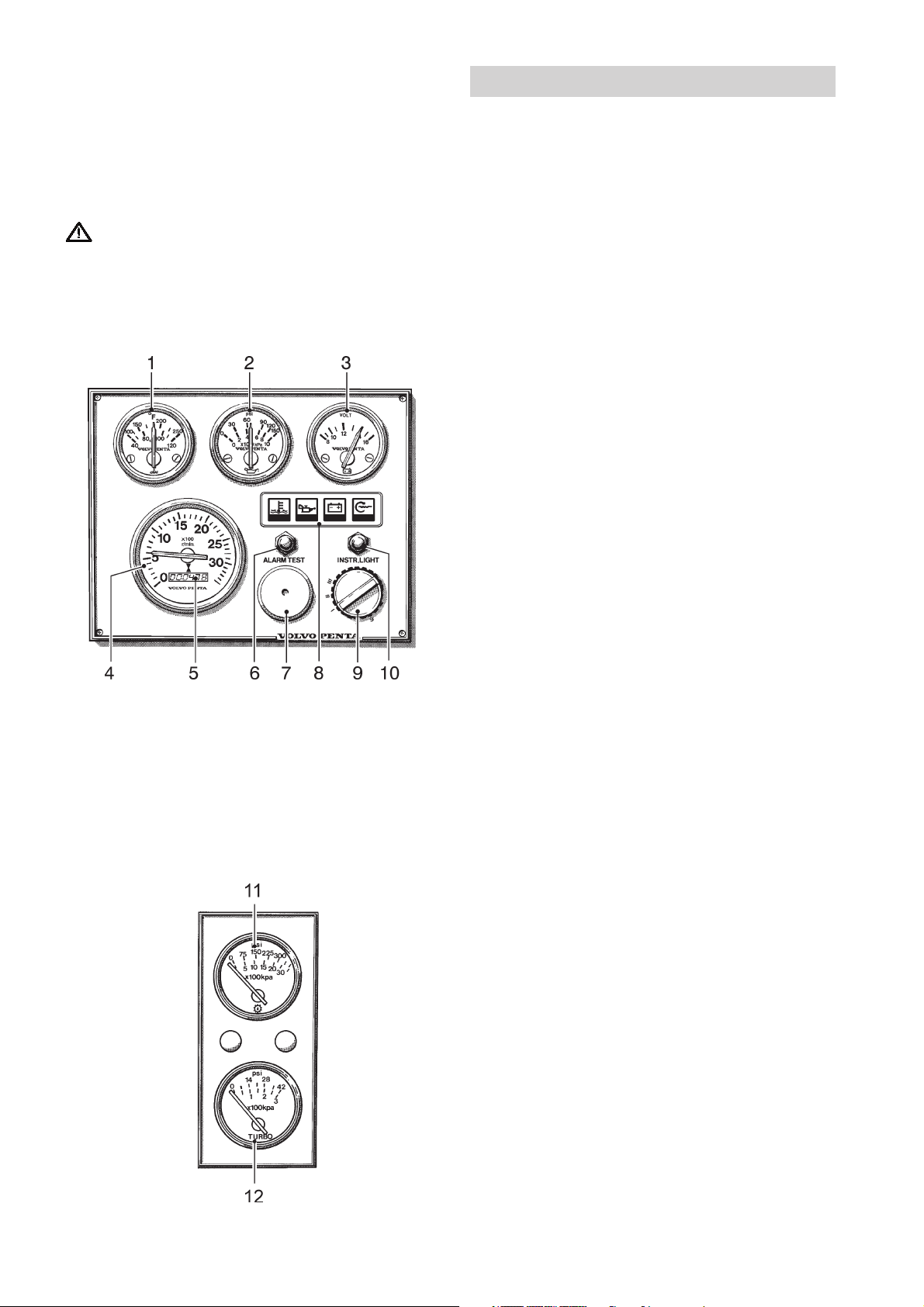

This chapter describes the standard Volvo Penta instruments that are available for your engine. Note that that

tachometer, oil gauge, temperature gauge, charge gauge, starting switch, etc., that are shown here as panel

mounted, in some cases may be mounted separately.

If the vessel is equipped with instruments not described here and you are not sure of their function, please get in

touch with the shipyard or the company that installed the installation aboard the vessel.

IMPORTANT! Read the chapter “Starting” before starting your engine.

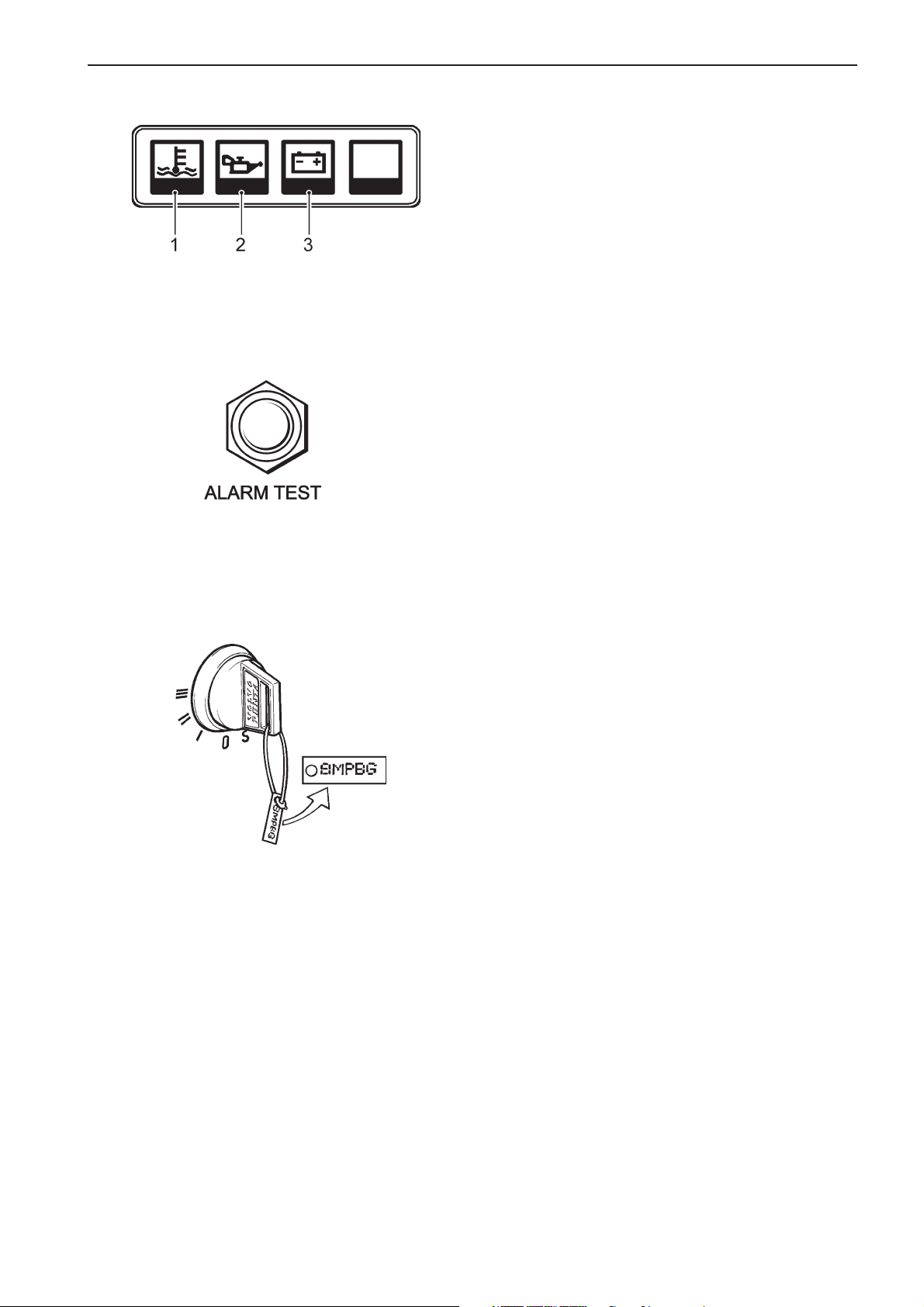

Instrument panels

Instrumentation for the main control position and auxiliary control position.

1. Temperature gauge. Indicates the engine coolant

temperature.

2. Oil pressure gauge. Indicates the pressure of the

engine lubricant.

3. Voltmeter. Indicates the charge voltage from the

generator when the engine is running and the battery voltage when the engine is stopped.

4. Tachometer. Indicates the speed of the engine in

rpm.

5. Hour counter. Shows the total number of engine

running hours as a decimal number.

6. Press button for testing and acknowledging

alarms (see next page “Warning displays”).

7. Siren for acoustic alarm that sounds if one of the

warning lamps comes on.

8. Warning display (see section “Warning displays”,

pos 1–3).

9. Starting switch (see next page).

10. Press button for instrument illumination.

11. Oil pressure gauge. Indicates the oil pressure in

the reverse gear.

12. Charge air pressure gauge. Indicates the turbocharger boost pressure.

18

Page 19

Standard Control System

Plus d'informations sur : www.dbmoteurs.fr

Warning displays

If the acoustic alarm sounds, one of the warning display lamps will immediately start to flash to indicate

the cause of the alarm.

1. Coolant temperature too high.

2. Lubricant pressure too low.

3. Generator not charging

After an alarm

Press the “Alarm test” button to acknowledge and

terminate the acoustic alarm. The relevant warning

lamp will continue to flash until the fault has been rectified.

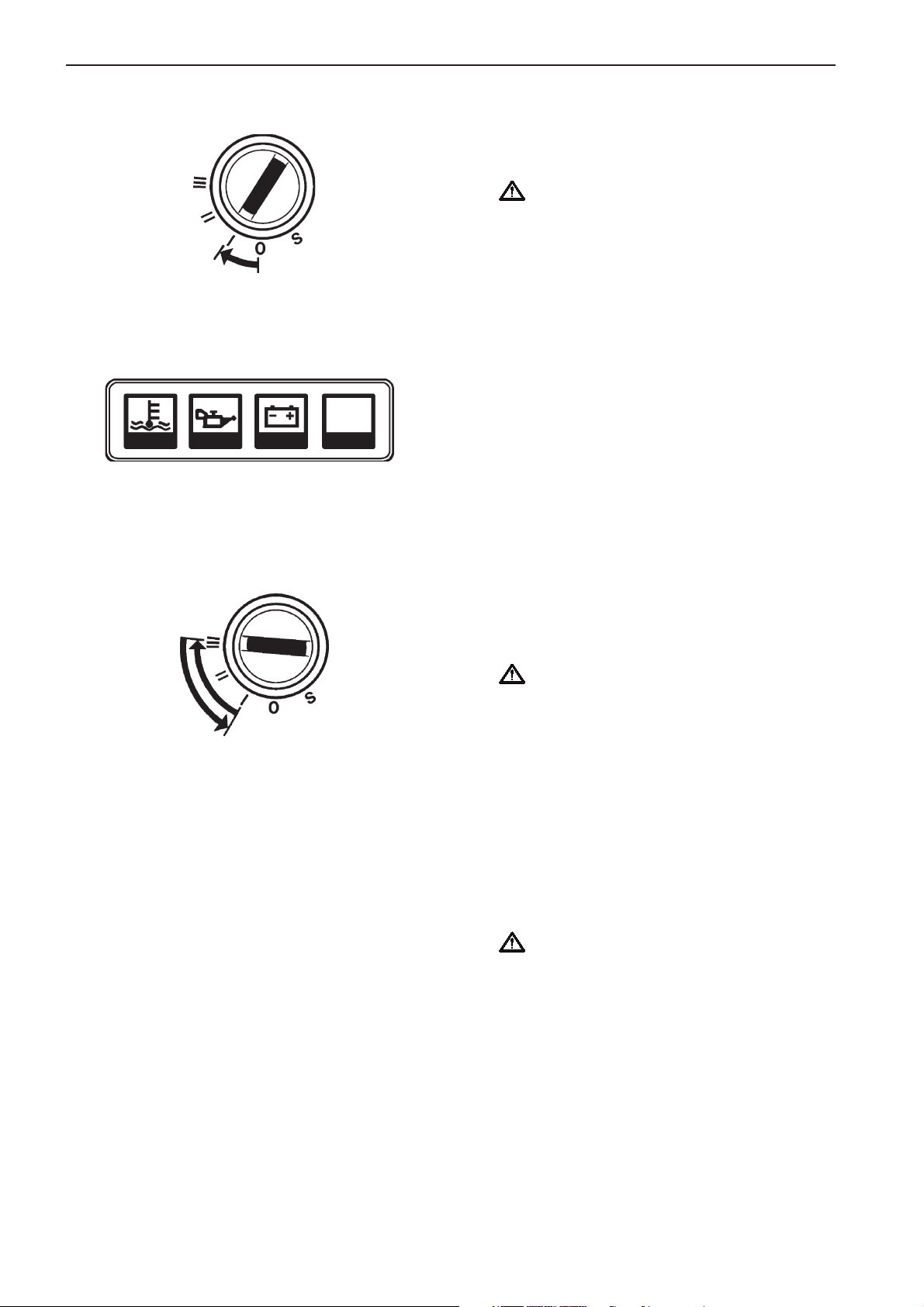

Alarm test

After pressing the “Alarm test” button, the warning

lamps will come on and the acoustic alarm will start to

sound. Make a habit of always performing an alarm

test before starting.

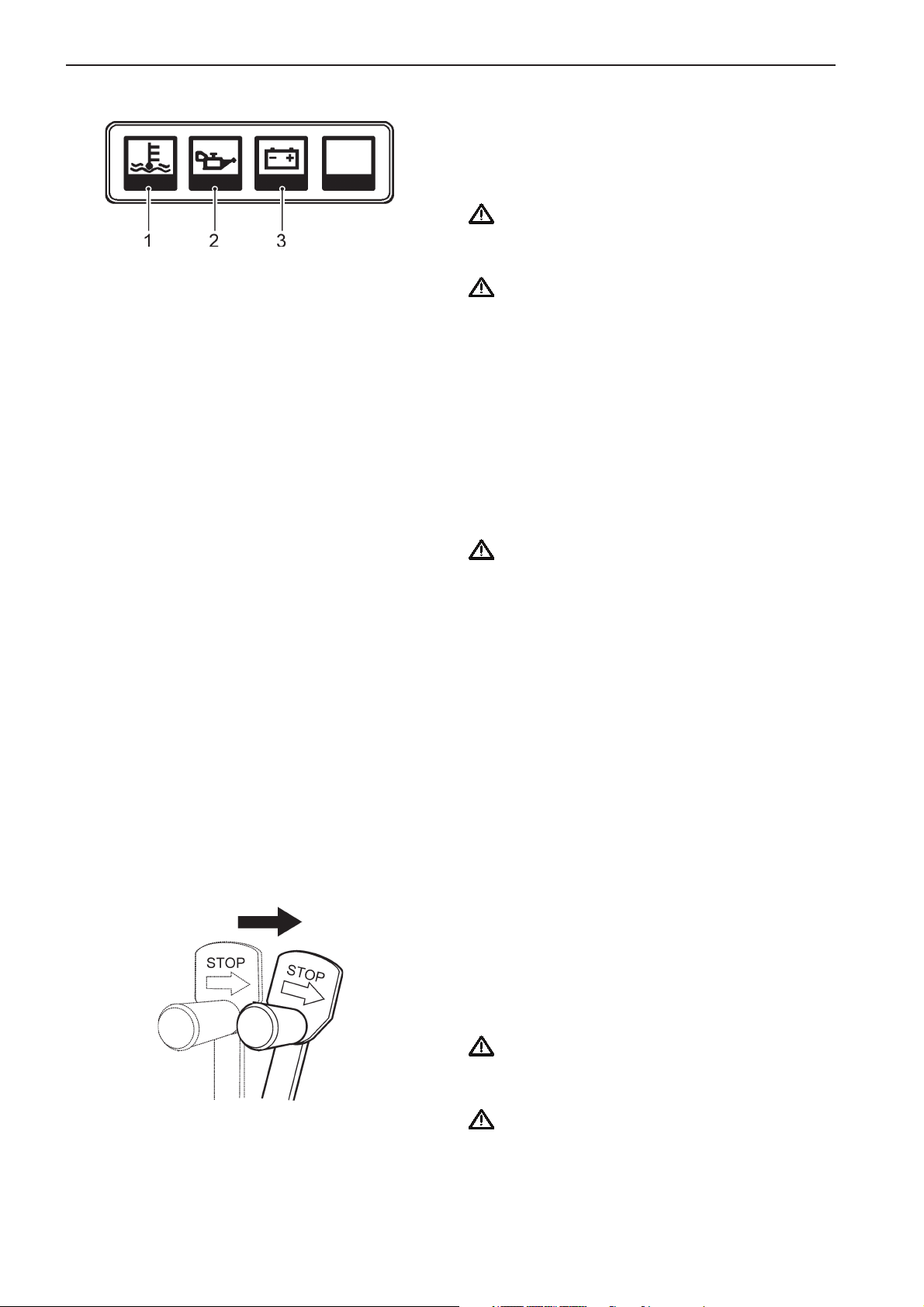

Starting switch

Together with the starter keys a plate containing the

key code is delivered. This code is required when

ordering additional starter keys. Keep the code in a

safe place.

S = Stop position.

0 = Key can be inserted and removed.

I = Voltage on (drive position).

II = Not used

III = Start position.

19

Page 20

Standard Control System

Plus d'informations sur : www.dbmoteurs.fr

Starting procedure

1. Disengage the reverse gear and make sure the

turning gear is not engaged. Put the control lever

into neutral and idle on all control positions

WARNING! If the vessel is equipped with

controls that allow starting the engine in

gear, it is essential to check all control

positions to make sure a gear is not

engaged.

2. Turn on the power by putting the starter key in position “I”.

3. Check warning lamps and alarms. Press the

“Alarm test” button on the instrument panel to

make sure the warning lamps come on and the

acoustic alarm sounds.

4. Start the engine. Start using the starting switch.

Turn the key to position “III”. Release the key so

that it returns to “I” immediately after the engine

has started.

IMPORTANT! If the starter motor has been

engaged for the maximum time (30

seconds), it must be allowed to cool down for

at least one minute before a new attempt is

made at starting.

NOTE! The key must first be turned to “S” before making a new attempt at starting.

5. Check the instruments and run the engine

warm. Let the engine idle for the first ten seconds

and make sure the instruments and warning display show normal values. Then run the engine at

low speed and low load so it attains normal operating temperature before using full power.

IMPORTANT! Do not race the engine when it

is cold.

20

Page 21

Standard Control System

Plus d'informations sur : www.dbmoteurs.fr

Operation

Learn how to handle the engine, controls and other equipment in a safe and correct manner before taking it into

operation.

Check the instruments

Check the instruments and warning display directly after

start and regularly during operation.

Oil pressure

During operation, the oil pressure gauge should show a reading of 0,50 - 0,64 MPa (71 - 93 psi). A lower value is normal at idling speed. The acoustic alarm will sound automatically in case of low oil pressure.

Coolant temperature

During operation, the temperature gauge should show a reading of 71–85°C (160–185°F). The acoustic alarm will

sound automatically in case the coolant temperature is too

high.

Charging

During operation, the charge voltage gauge should show a

reading of 28V. The acoustic alarm will sound automatically

in case the charge voltage is missing.

21

Page 22

Standard Control System

Plus d'informations sur : www.dbmoteurs.fr

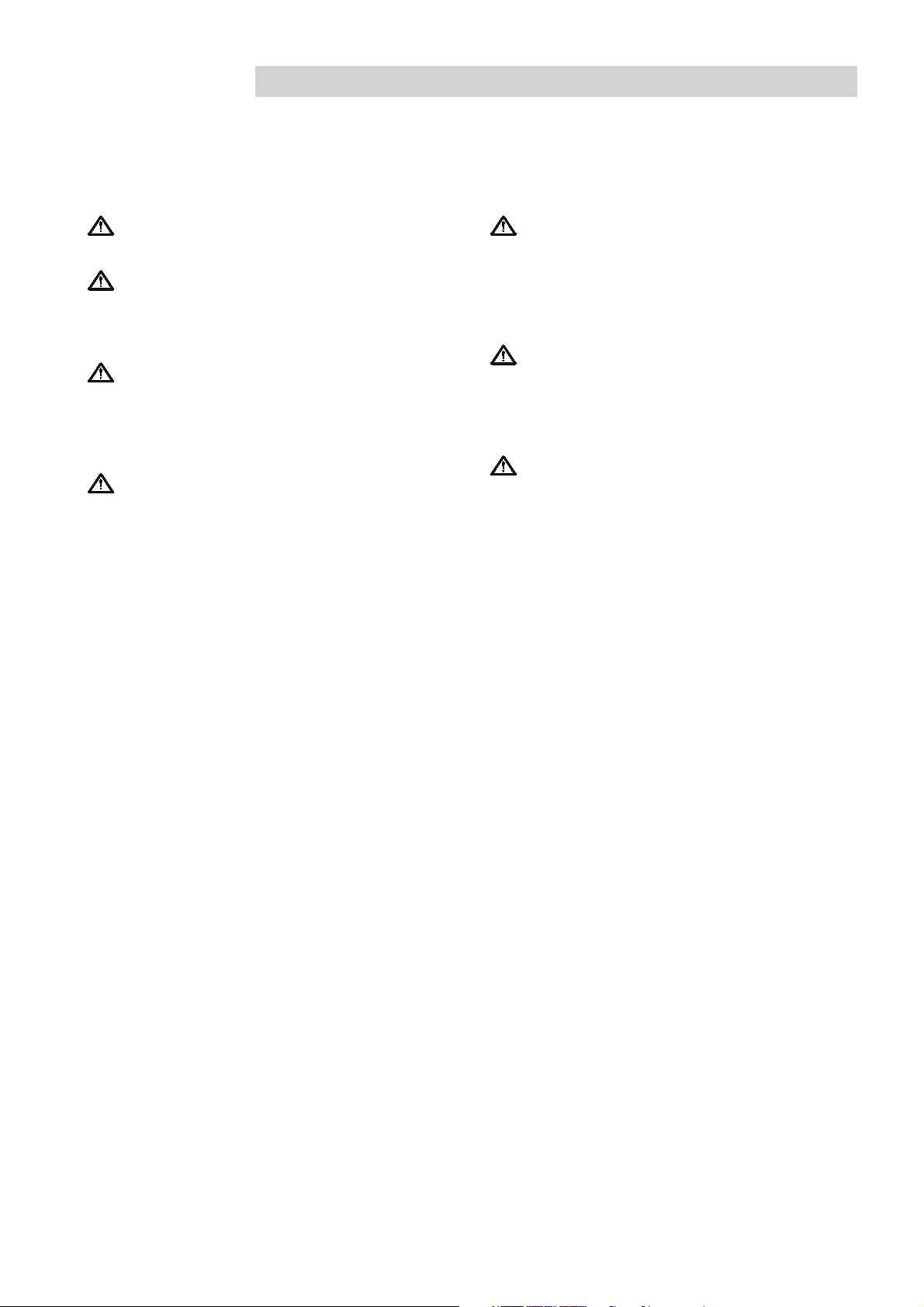

Alarms and fault indication

If the acoustic alarm sounds, one of the warning display lamps will immediately start to flash to indicate

the cause of the alarm: High coolant temperature (1),

low oil pressure (2) and no charge voltage (3).

IMPORTANT! Stop the engine immediately after

an alarm for low oil pressure. Investigate the

cause and rectify it.

IMPORTANT! Slow the engine speed to idle/

disengaged after an alarm for high coolant

temperature. If temperature does not drop, the

engine must be stopped. Investigate the cause

and rectify it.

Stopping the engine

Let the engine run at low idling speed (in neutral) for at

least three minutes before turning it off. This will keep

the engine temperature in balance and prevent it boiling.

IMPORTANT! The procedure described above is

especially important if the engine has been run

hard and/or exerted to heavy loads.

Stop

1. Disengage the marine gear by moving the lever to

neutral position.

2. Turn the key to stop position “S”.

3. Hold the key in position until the engine has stopped (the key will return to “0” automatically when

released and can then be removed).

NOTE! The stop solenoid will be activated for

approximately 40 seconds after stopping the

engine, but the engine can be restarted at any

time.

Emergency stop

If a fault occurs that prevents the engine being stopped by the normal method, it can be stopped manually

using the lever mounted on the engine. Move the lever

in the direction of the arrow and hold it there until the

engine has stopped.

WARNING! Working on or approaching a running

engine is a safety hazard. Beware of rotating

parts and hot surfaces.

WARNING! Never try to increase engine rpm with

the emergency stop lever since this will make

the engine overspeed and this will damage the

engine.

22

Page 23

Operation

Plus d'informations sur : www.dbmoteurs.fr

General

Learn how to handle the engine, controls and other equipment in a safe and correct manner before starting the

engine

WARNING! Stay clear of all rotating and moving

parts during operation.

IMPORTANT! Always keep the engine room well

ventilated. Insufficient airsupply to the engine

means imperfect combustion and a loss of

power.

IMPORTANT! During the first 50 hours of operation, operate the engine under a lighter load and

lower speeds than normal for break-in. Proper

break-in contributes to maximum service life of

the engine.

IMPORTANT! Do not turn OFF the battery

switch when the engine is running since this may

damage the alternator.

WARNING! At operating temperature, the engine

and its components are hot. A hot engine always

involves risk for burn injuries. Take care with hot

surfaces. E.g.: exhaust manifold, turbocharger,

oil pan, charge air pipe, starting heater, hot

coolant and warm lubricant in pipes and hoses.

IMPORTANT! Avoid overloading. This can cause

incomplete fuel combustion often indicated by

black exhaust, high fuel consumption and carbon

deposits in combustion chambers, affecting

engine life.

IMPORTANT! Do not turn the starter switch key

to the START position when the engine is

running this may damage the starter.

23

Page 24

Operation

Plus d'informations sur : www.dbmoteurs.fr

Applying Load

When the engine has reached operation temperature,

bring the engine to operating speed and apply the load

gradually.

During load operation make sure that:

1. No engine related alarms occur.

2. There are no visible leaks of fuel, lube oil, coolant

or exhaust gas

3. No abnormal noise or vibrations occur.

4. The color of the exhaust gas is normal.

5. The breather mist is of normal quantity and color.

6. Instrument readings are the normal.*

*Oil pressure: 0,50 to 0,64 Mpa (71 to 92 psi) (at

rated speed)

*Coolant temperature: 71 to 85°C (165 to 185 °F)

Running in

The engine must be “run in” during the first 10

hours of operation as follows:

Run the engine under normal operation. Do not run it

at full power except for short periods. Never run the

engine for long periods at constant rpm during this

time. A high consumption of lubricant is normal during

the running in period. Therefore, check the oil level

more often than recommended. The prescribed warranty inspection “First Service Inspection” must be

carried out during this first period of operation. For

more information: See Warranty and Service Book.

Forced propeller rotation

When the vessel is towed or anchoring in strong currents, the propeller can make the propeller shaft rotate

even though the engine is stationary. This may damage the marine gear.

Manoeuvring

The marine gear must be engaged at low idling speed.

There must be a brief pause after engaging gear before increasing the engine speed. Wait for approximately

two seconds to ensure that the gear clutch has engaged properly.

IMPORTANT! If the vessel is equipped with two

engines equipped with wed exhaust systems,

they must both be running while in reverse or

there will be a risk of water entering the engine

(through the exhaust passage).

Pulling away

1. Move the lever from neutral to the engagement

position for the desired direction of travel.

2. Apply load accordingly.

Forward–Reverse

1. Slow the engine speed to idling and allow the vessel to loose most of its speed.

2. Move the lever to neutral.

3. Move the lever to reverse. Wait for approximately

two seconds and then increase the engine speed

gradually.

IMPORTANT! A direct forward–reverse maneuver

can damage the marine gear and engine. It is

therefore always necessary to stop with the lever

in neutral for a few seconds and allow the vessel

to loose most of its speed before engaging. If the

speed of the vessel is too high, there is a risk of

the propeller windmilling which might cause the

engine to stop and start rotating in the wrong

direction. This may cause serious engine

damage.

24

Page 25

Operation

Plus d'informations sur : www.dbmoteurs.fr

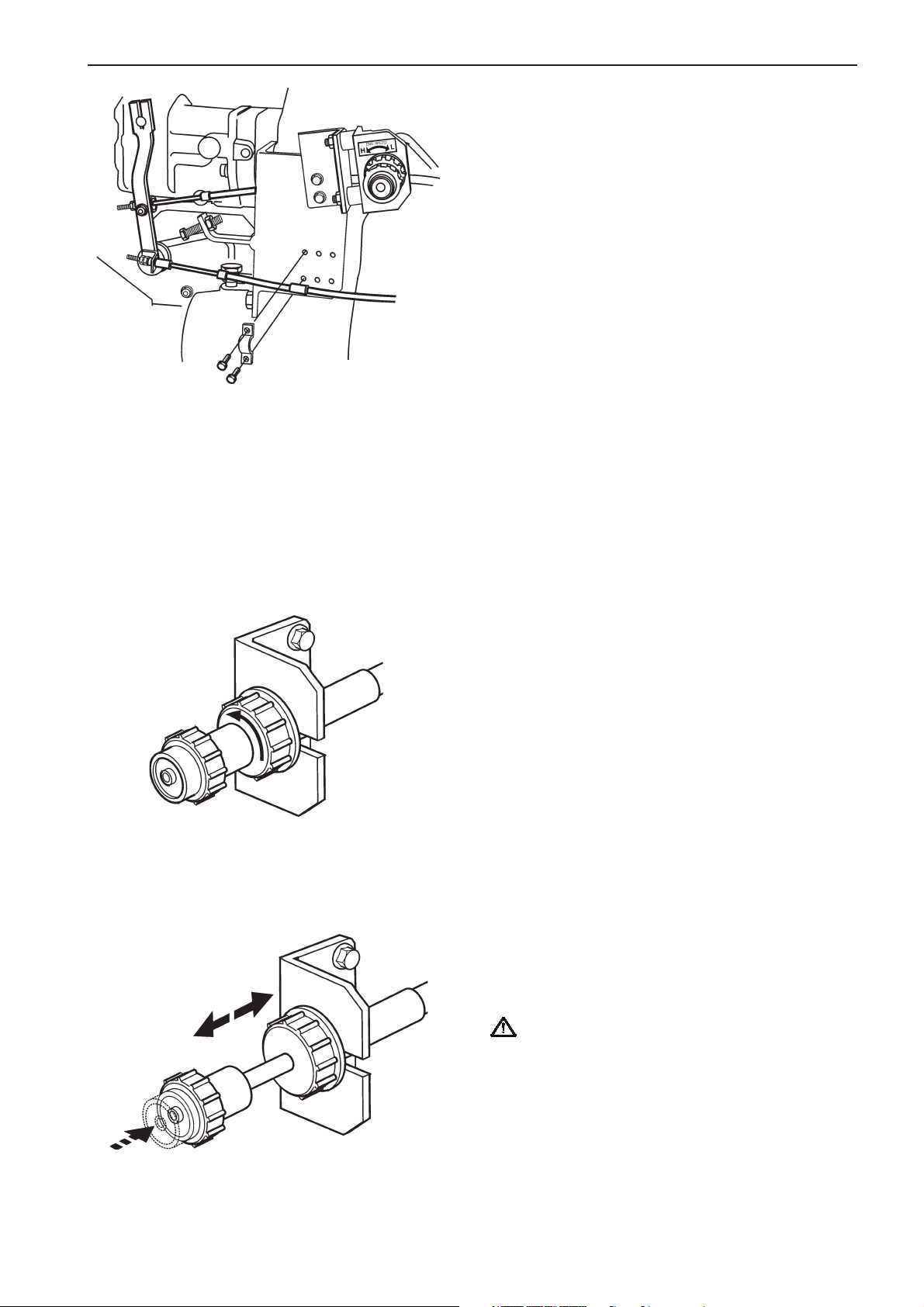

Manual speed control

Manual speed adjustment of the engine can be done

using the manual speed control knob.

1. Disconnect the control cable connected to the

remote speed adjustment.

2. Turn the Lock counterclockwise to unlock the manual speed adjustment knob.

3. By pushing the button and pulling the knob

towards you the engine speed will increase. By

bushing the knob towards the engine the engine

speed will decrease.

WARNING! When adjusting engine speed avoid

quick changes since this may harm the engine.

25

Page 26

Operation

Plus d'informations sur : www.dbmoteurs.fr

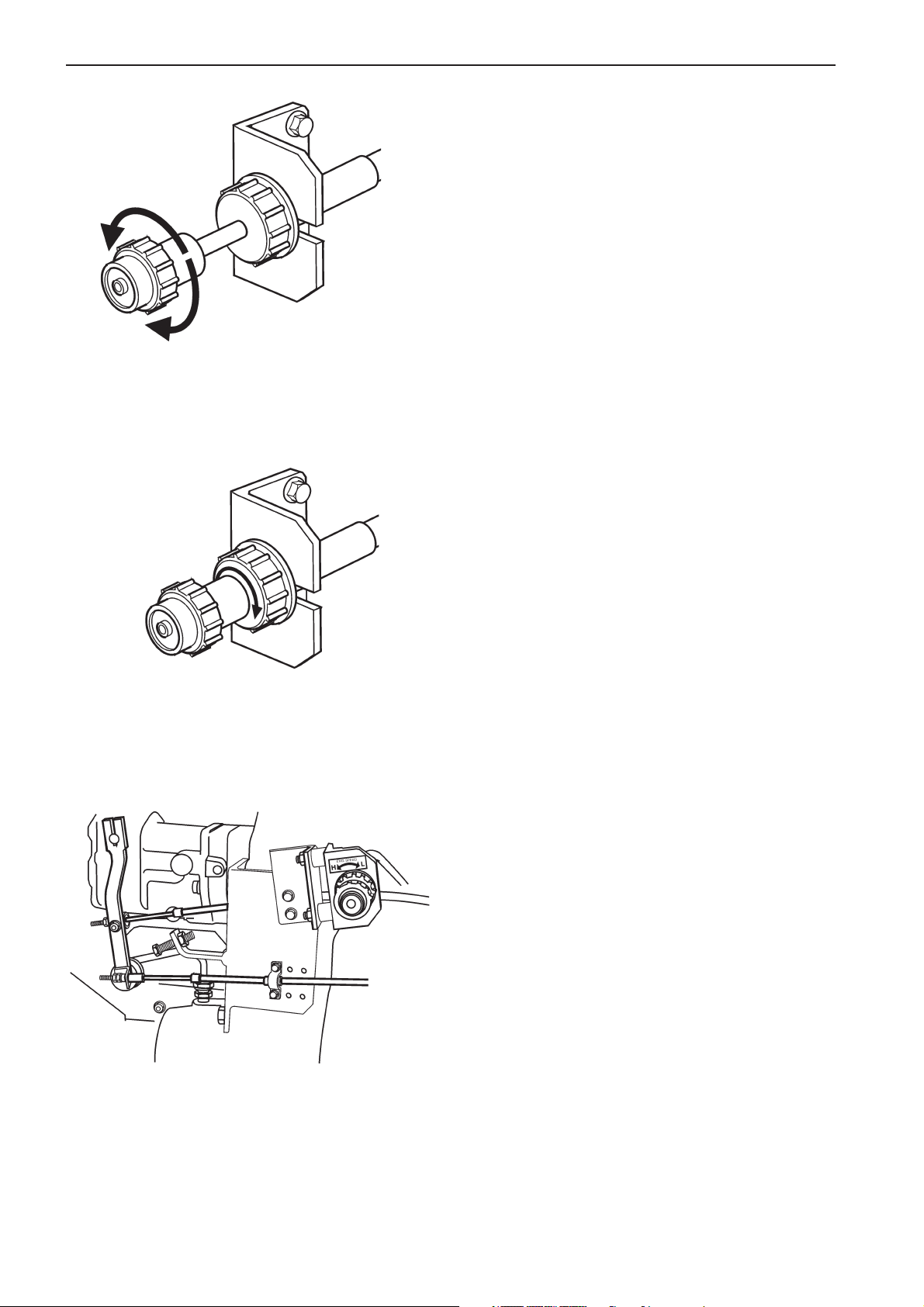

4. Fine-tuning of the engine speed can be done by

turning the control knob:

Turn the knob clockwise to decrease engine

speed. Turn it counterclockwise to increase

engine speed.

5. Bring the manual speed control knob in the neutral

position when ready with the manual speed

adjustment. Turn the lock clockwise to secure the

installation.

6. Connect the control cable for remote speed

adjustment so that the engine can be controlled

from the normal position.

26

Page 27

Operation

Plus d'informations sur : www.dbmoteurs.fr

Start using auxiliary batteries

WARNING! Ventilate well. Batteries generate

oxyhydrogen gas, which is extremely flammable

and explosive. A short circuit, naked flame or

spark can cause a powerful explosion.

Never reverse the polarity of the battery. Risk of

sparks and explosion.

1. Make sure the rated voltage of the auxiliary bat-

tery is the same as the system voltage of the

engine.

2. Connect the red auxiliary cable to the discharged

battery’s + terminal and then to the auxiliary

battery’s + terminal.

3. Connect the black jump lead to the auxiliary bat-

tery negative terminal and then to a position

slightly away from the discharged batteries, for

example at the negative cable’s connection to the

starter motor.

WARNING! The black auxiliary cable (–) must not

come in contact with the positive connection on

the starter motor.

4. Start the engine and run at fast idling speed for

about ten minutes to charge the batteries.

WARNING! Working on or approaching a running

engine is a safety hazard. Beware of rotating

parts and hot surfaces.

WARNING! Do not touch the connections while

attempting to start; Risk of sparks. Do not bend

over the batteries either.

5. Stop the engine. Remove the auxiliary cables in

reverse order to connecting.

27

Page 28

Stopping

Plus d'informations sur : www.dbmoteurs.fr

Let the engine run at low idling speed (in neutral) for at least 5 to 6 minutes before turning it off. This will keep the

engine temperature in balance and prevent it from boiling.

IMPORTANT! The procedure described above

is especially important if the engine has been

run hard and/or exerted to heavy loads.

IMPORTANT! Do not rev up the engine just

before stopping it.

IMPORTANT! If the engine stops abnormally,

try to locate the problem and make the

repairs needed before starting again. After

starting the engine, make sure the engine

runs properly.

Manual Stop Lever

By pulling the manual stop lever in the “STOP” direction the engine can be stopped manually. Use this lever only in an emergency when the engine can not be

stopped by the engine control system.

IMPORTANT! When stopping the engine by

pulling the stop lever, continue to pull the lever until the engine stops “rocking.”

Notice: If the engine cannot be stopped with the ma-

nual stop lever, shut off the fuel supply or block air intake to turbo.

28

Page 29

After stopping

Plus d'informations sur : www.dbmoteurs.fr

General

* Check the engine and engine room for leaks.

* Close the fuel cock and seawater cock.

IMPORTANT! Do not forget to open the cocks before starting the engine again.

* Read off the hour counter and carry out preventive maintenance according to the maintenance schedule.

* Turn off the main switch if the engine is not to be used for a long period.

IMPORTANT! Never turn the power off using the main switch while the engine is running. This can

damage the alternator.

Anti-freezing measures

If the engine room cannot be protected from frost, the sea-water system must be drained and the coolant in the

fresh-water system must contain sufficient anti-freeze to prevent it from freezing. Refer to chapter Maintenance

“Seawater system” and “Freshwater system” respectively.

WARNING! If the seawater system bursts due to freezing, it is possible for the vessel to sink.

IMPORTANT! If the coolant does not give sufficient anti-freeze protection, it may cause costly damage

to the engine. Check the charge of the battery. A poorly charged battery can freeze and break.

Breaks in operation [not using the engine]

During periods out of service, when the boat is in the water, the engine must be run warm once a fortnight. This

will prevent the engine from corroding.

IMPORTANT! The engine must be conserved if it is not to be used for longer than two months. Refer to

chapter Inhibiting.

29

Page 30

Maintenance

Plus d'informations sur : www.dbmoteurs.fr

Your Volvo Penta engine and associated equipment is designed to provide high operational reliability and long

service life. They are constructed to withstand the marine environment while also affecting it as little as possible.

Preventive maintenance in accordance with the maintenance schedule will ensure that it retains these qualities

and avoid unnecessary operational disturbances.

The maintenance chart shows the standard service intervals. When you think the engine should be serviced

more frequently due to particular operating conditions, adjust the intervals accordingly. Appropriate service intervals vary depending on the usage and operating conditions as well as the fuel, lubricant and coolant used. Due

to particular operating conditions the service intervals may be adjusted accordingly. Consult your Volvo Penta

dealer.

Daily operation records

It is recommended to keep daily operation records every day. Daily recording is a preventive maintenance program and when comparing values with engine history it will help you recognize conditions, signs or indications of

approaching trouble. Daily operation records also make trouble shooting easier and will lessen the down time (to

save time and money for servicing).

Maintenance records

Volvo Penta recommends that accurate maintenance records are kept. With accurate maintenance records your

Volvo Penta Dealer can help in fine tuning the recommended service intervals to meet the specific operating situation. This should result in a lower engine operation cost.

Fluids

It is also important to keep record of the fluids used in the engine. If brand or type of fuel, lubrication oil or coolant

is changed this should be recorded. For fluids used at sea trial refer to chapter Technical Data.

Warranty inspection

The prescribed warranty inspection “First Service Inspection” must be carried out at an authorized Volvo Penta

workshop during this first period of operation. Directions for when and where this is to be carried out can be

found in the Warranty and Service Book.

WARNING! Read the chapter “Maintenance” thoroughly before starting any maintenance work. It

contains directions for performing maintenance in a safe and correct manner.

WARNING! Working on or approaching a running engine is a safety hazard. Maintenance and service

must be carried out with the engine stationary unless stated otherwise in the instructions. Prevent

inadvertent start of the engine by removing the starter key and turning off the power with the main

switch, locking it in the off position.

WARNING! Place warning signs stating that service is in progress in every position from which the

engine can be started.

30

Page 31

MAINTENANCE SCHEDULE D25A/D30A MS

Plus d'informations sur : www.dbmoteurs.fr

Daily before first start

* General inspection engine and engine room

* Check and make sure all valves are in the right position

* Check lubrication oil level

* Check marine gear oil level

* Check lubrication oil filter differential pressure indicator

* Check air-filter differential pressure indicator

* Check coolant level

* Check fuel oil level

* Drain water from fuel tank

* Drain water from fuel pre-filter/water separator

* Drain water from air vessel and air filter

* Check engine control system (cables, etc.)

* Check fuel control linkage

* Check for leakages

* Check aftercooler drain pipe

* Daily operation records

* Inspection of valves and plugs

* Check if the instrumentation works properly

Weekly

* Check starting batteries; electrolyte level/load

* Check electrical system for loose terminals/contacts

* Check foundation bolts

* Check lubrication oil for abnormal smell or waterdilution

* Check safety valves of air system

* Check air system oiler

* Check settings of valves and move valve to keep them operationable

* Drain water from the fuel pre-filter/water separator

First 50-250 operating hours of new or recond. engines (First service)

* Change lubrication oil

* Change full flow and by-pass lubrication oil filters

* Change governor lubrication oil filter

* Check required lubrication oil change for marine gear

* Check/adjust V-belts

* Check/adjust valve clearance

* Check/adjust stop solenoid and/or fuel stop valve

* Check/retighten bolts and nuts

* Drain crankcase ventilation water trap

* Drain exhaust silencer(system) water trap

31

Page 32

Maintenance schedule

Plus d'informations sur : www.dbmoteurs.fr

Every 250 operating hours or every 12 months

* Change lubrication oil. Longer interval requires oil analysis

* Change full flow and by-pass lubrication oil filters

* Check/adjust V-belts

* Check sea water filter

* Check/wash air pre-cleaner (turbo)

Every 500 operating hours or every 12 months

* Change governor lubrication oil filter

Every 1000 operating hours or every 12 months

* Change fuel filter elements

* Change filter elements of the fuel pre-filter/water separator

* Check air filter (if installed)

* Check/retighten bolts and nuts

* Check/adjust fuel injection timing

* Check/adjust fuel injection pressure and spray pattern

* Change fuel injection nozzle o-rings

* Check and adjust valve clearance and valve mechanism

Every 2000 operating hours or every 12 months

* Check/adjust valve clearance. Check valvemechanism

* Check turbocharger

* Check starter motor

* Check alternator

* Check fuel injection pump flex drive plates

* Check fuel injection pump control rack operation

* Check fuel rack control ”ball joints”

* Check/clean charge air cooler(s)

* Check/clean cooling water heat exchanger

* Check coolant concentration

* Check torsional vibration dampers

* Check alarm and shut-down functions

* Check engine control panel functions

* Change V-belts

* Change fuel pre-filter/water separator element

* Check/change zinc anodes

* Change turbo charger air filter

32

Page 33

Every 4000 to 6000 operating hours or every 24 months

Plus d'informations sur : www.dbmoteurs.fr

* Full service inspection

(1)

Every 12 months

* Check rubber engine mounts

* Check rubber hoses and flex connections

* Check engine room ventilation fans

Every 10000 operating hours

* Check torsional vibration damper temp check

* Check rubber of flexible coupling for deformation and cracks

* Replace ball-joints in fuel pump control linkage

Every 15000 operating hours

* Full service inspection

(2)

Every 24 months

* Change coolant

Maintenance schedule

(1)Every 4000 to 6000 hours or every 24 months

Have an authorized dealer execute a full service inspection of your engine including:

Endoscopic investigation of cyl heads and liners

Replace all injector nozzles

Change water pump seals

Checking and cleaning of charge air cooler

Check turbo charger

Check battery-charging alternator

Check and test stop solenoid or fuel shut-off valve

(2)Every 15000 hours

Have an authorized dealer execute a full service inspection of your engine including:

As described at 4000 – 6000 hrs

Remove and inspect one piston, piston rings and liner

Inspect crankshaft and one bearing

Inspect camshaft and one bearing

33

Page 34

Maintenance schedule

Plus d'informations sur : www.dbmoteurs.fr

MAINTENANCE SCHEDULE D25A/D30A MT

Daily before first start

* General inspection engine and engine room.

* Check and make sure all valves are in the right position

* Check lubrication oil level

* Check marine gear oil level

* Check lubrication oil filter differential pressure indicator

* Check air-filter differential pressure indicator

* Check coolant level

* Check fuel oil level

* Drain water from fuel tank

* Drain water from fuel pre-filter/water separator48

* Drain water from air vessel and air filter

* Check engine control system (cables, etc.)

* Check fuel control linkage

* Check for leakages

* Check aftercooler drain pipe

* Daily operation records

* Inspection of valves and plugs

* Check if the instrumentation works properly

Weekly

* Check starting batteries; electrolyte level/load

* Check electrical system for loose terminals/contacts

* Check foundation bolts

* Check lubrication oil for abnormal smell or waterdilution

* Check safety valves of air system

* Check air system oiler

* Check settings of valves and move valve to keep them operationable

* Drain water from the fuel pre-filter/water separator

First 50-250 operating hours of new or recond. engines (First service)

* Change lubrication oil

* Change full flow and by-pass lubrication oil filters

* Change governor lubrication oil filter

* Check required lubrication oil change for marine gear

* Check/adjust V-belts

* Check/adjust valve clearance

* Check/adjust stop solenoid and/or fuel stop valve

* Check/retighten bolts and nuts

* Drain crankcase ventilation water trap

* Drain exhaust silencer(system) water trap

34

Page 35

Every 250 operating hours or every 12 months

Plus d'informations sur : www.dbmoteurs.fr

* Change lubrication oil. Longer interval requires oil analysis

* Change full flow and by-pass lubrication oil filters

* Check/adjust V-belts

* Check sea water filter

* Check/wash air pre-cleaner (turbo)

Every 500 operating hours or every 12 months

* Change governor lubrication oil filter

Every 1000 operating hours or every 12 months

* Change fuel filter elements

* Change filter elements of the fuel pre-filter/water separator

* Check air filter (if installed)

* Check/retighten bolts and nuts

* Check/adjust fuel injection timing

* Check/adjust fuel injection pressure and spray pattern

* Change fuel injection nozzle o-rings

* Check and adjust valve clearance and valve mechanism

Maintenance schedule

Every 2000 operating hours or every 12 months

* Check/adjust valve clearance. Check valvemechanism

* Check turbocharger

* Check starter motor

* Check alternator

* Check fuel injection pump flex drive plates

* Check fuel injection pump control rack operation

* Check fuel rack control ”ball joints”

* Check/clean charge air cooler(s)

* Check/clean cooling water heat exchanger

* Check coolant concentration

* Check torsional vibration dampers

* Check alarm and shut-down functions

* Check engine control panel functions

* Change V-belts

* Change fuel pre-filter/water separator element

* Check/change zinc anodes

* Change turbo charger air filter

35

Page 36

Maintenance schedule

Plus d'informations sur : www.dbmoteurs.fr

Every 4000 to 6000 operating hours or every 24 months

* Full service inspection

Every 12 months

* Check rubber engine mounts

* Check rubber hoses and flex connections

* Check engine room ventilation fans

Every 10000 operating hours

* Check torsional vibration damper temp check

* Check rubber of flexible coupling for deformation and cracks

* Replace ball-joints in fuel pump control linkage

Every 15000 operating hours

* Full service inspection

Every 24 months

* Change coolant

(1)

(2)

(1)Every 4000 to 6000 hours or every 24 months

Have an authorized dealer execute a full service inspection of your engine including:

Endoscopic investigation of cyl heads and liners

Replace all injector nozzles

Change water pump seals

Checking and cleaning of charge air cooler

Check turbo charger

Check battery-charging alternator

Check and test stop solenoid or fuel shut-off valve

(2)Every 15000 hours

Have an authorized dealer execute a full service inspection of your engine including:

As described at 4000 – 6000 hrs

Remove and inspect one piston, piston rings and liner

Inspect crankshaft and one bearing

Inspect camshaft and one bearing

36

Page 37

Maintenance schedule

Plus d'informations sur : www.dbmoteurs.fr

Overhaul information

Top overhaul

Dependent of your application, working conditions and service level a “top overhaul” might be required

in case of:

Gas leakage through valves

Too much valve clearance

Low compression pressure

Top overhaul includes:

Remove cylinder heads and check liners and combustion chambers of pistons

Disassemble cylinder heads

Check inlet and exhaust valves, check valve seats

(lap if necessary)

Check piston top

Check cylinder liner

Check instruments, alarms and shutdown functions

Check pipe clamp contact

Change fresh water pump seals

Change sea water pump seals

Overhaul turbo charger

Check vibration damper on burrs and leaks

Check exhaust pipe joints

Check governor control linkage

1st major overhaul

Dependent of your application, working conditions and service level a “major overhaul” might be required in case of:

Decreased power output

Increased fuel consumption

Increased lubrication oil consumption

Increased blow-by gases

Gas leakage through valves

Starting problems

Increased noise from engine parts

Abnormal color of exhaust gases from warm engine

Major overhaul includes:

Disassemble engine, clean, check and change major parts.

Major parts:

Inlet and exhaust valve seats

Inlet and exhaust valves

Valve rotators

Valve cotters

Rocker arm adjusting screws

Valve push rods

Bridge caps

Camshaft bushings

Camshaft expansion plugs

Lubrication oil pump

Main bearings

Cylinder liners

Main bearing cap bolts and washers

Piston rings

Connecting rod bearings

Vibration damper

Air duct rubber hoses

Cooling water rubber hoses

Consumable items (gaskets, oil seals, o-rings, etc.)

Change the torsional vibration damper

37

Page 38

Maintenance schedule

Plus d'informations sur : www.dbmoteurs.fr

nd

2

major overhaul

Disassemble engine, clean, check and change major parts.

Major parts:

Inlet and exhaust valve seats

Inlet and exhaust valves

Valve rotators

Valve cotters

Rocker arm adjusting screws

Valve push rods

Bridge caps

Camshaft bushings

Camshaft expansion plugs

Cylinder head bolts

Valve guides

Valve bridge guides

Valve bridges

Valve springs

Tappets

Camshaft thrust plates

Main bearings

Cylinder liners

Main bearing cap bolts and washers

Piston rings

Connecting rod bearings

Vibration damper

Air duct rubber hoses

Cooling water rubber hoses

Consumable items (gaskets, oil seals, o-rings, etc.)

Rocker bushings

Thrust plate crankshaft

Pistons and piston pins

Connecting rod bolts

Connecting rod bushings etc.

Check high-pressure fuel injection pump and fuel

supply pump

Change torsional vibration damper

38

Page 39

Maintenance: General

Plus d'informations sur : www.dbmoteurs.fr

Recommendation of Daily Operation Records

Daily recording is a preventive maintenance program and when comparing values with engine history it will help

you recognize conditions, signs or indications of approaching trouble. Daily operation records also make trouble

shooting easier and will lessen the down time (to save time and money for servicing).

Items to be recorded

The following items are recommended to be recorded

once a day:

1. Operating hours.

2. The amount of lubrication oil and coolant (fresh

water) required for refilling. Fuel consumption.

3. Lubrication oil and coolant (fresh water) change

intervals.

4. Lubrication oil pressure and temperature, engine

rpm, exhaust temperature, coolant temperature,

and charge air temperature and pressure.

5. Seawater pressure and seawater temperature

before and after heat exchanger. Ambient

temperature and engine room temperature at

turbo charger inlet.

6. Parts serviced and kinds of service (adjustment,

repairs, or replacement).

7. Change in operating conditions (for example,

“Exhaust smoke turned black,” etc.)

39

Page 40

Maintenance: Engine

Plus d'informations sur : www.dbmoteurs.fr

Engine

Valve Clearance

IMPORTANT! Check and adjust the valve clearance when the engine is cold and not running.

NOTE! Protective plugs should be fitted on the injectors.

Cleanliness should be observed when working on the fuel system

When adjusting the valves the engine should be cold. The engine must under no circumstances be running, since the valves can knock against the pistons and cause serious damage.

Make sure that the stop lever is pulled out and that the starter key is switched off.

The valves are adjusted according to the two stage method, but every pair of valves are also adjusted in two stages. The valve yoke is adjusted first, and then the clearance of the rocker arm.

Confirm top dead center on compression stroke

1. Turn the engine in the normal direction to align

the timing mark [1 .6] on the damper with the

pointer as shown.

2. Remove the rocker cover of the cylinder on which

the valve clearance is to be checked and adjusted, and make sure the inlet and exhaust valves

have some clearance. If the timing mark [1 .6] is

aligned with the pointer, either the No. 1 or No. 6

piston is at top dead center on the compression

stroke.

Adjust the height of valves

IMPORTANT! Make sure the clearance

between the valve yoke and valve rotator is 1.5

mm [0.059 in.] or more if not, interference will

occur between the yoke and rotator to cause the

valve cones to get out of place. If the clearance

is less than 1.5 mm [0.059 in.] after the height of

valves has been adjusted, consult your dealer.

NOTE! Before inspecting the valve clearance, adjust

the height of the two valves. Bring the yoke into contact with the valves, by means of the valve-yoke adjusting screw, so that there is no difference in height

between the two valves. If the valve seats are worn,

one valve will differ from another in height, increasing

the clearance between the valve stem and yoke,

leading to an increased valve clearance.

1. Unscrew the lock nut and adjusting screw on the

pair of valves on the cylinder so that there is clearance between the yoke and the valve stem.

2. Press the valve yoke down.Turn the adjusting

screw so that it makes contact with the valve

stem.

3. Turn an additional 10 degrees. Lock the adjusting

screw with the lock nut.

40

Page 41

Maintenance: Engine

Plus d'informations sur : www.dbmoteurs.fr

Valve clearance inspection

1. Check the valve clearance with feeler gauges in-

serted between the rocker arm and yoke cap.

Valve Clearance:

Inlet valve ..................................0.6 mm [ 0.024 in.]

Exhaust valve ............................ 0.8 mm [ 0.031 in.]

2. The clearance is correct if feeler gauge is slightly

gripped between the rocker arm and the yoke

cap. If the feeler does not fit into the clearance

exactly, perform adjustments as described below.

IMPORTANT! When performing the ”First Ser-

vice”, valves that are checked and deemed not

in need of adjustment must be checked again

within 250 hours.

Adjust valve clearance

1. Loosen the lock nut of the adjusting screw.

2. Turn in or back off the adjusting screw so that

feeler gauge is slightly gripped between the rocker arm and yoke cap.

3. After adjusting the clearance, tighten the lock nut

of the adjusting screw.

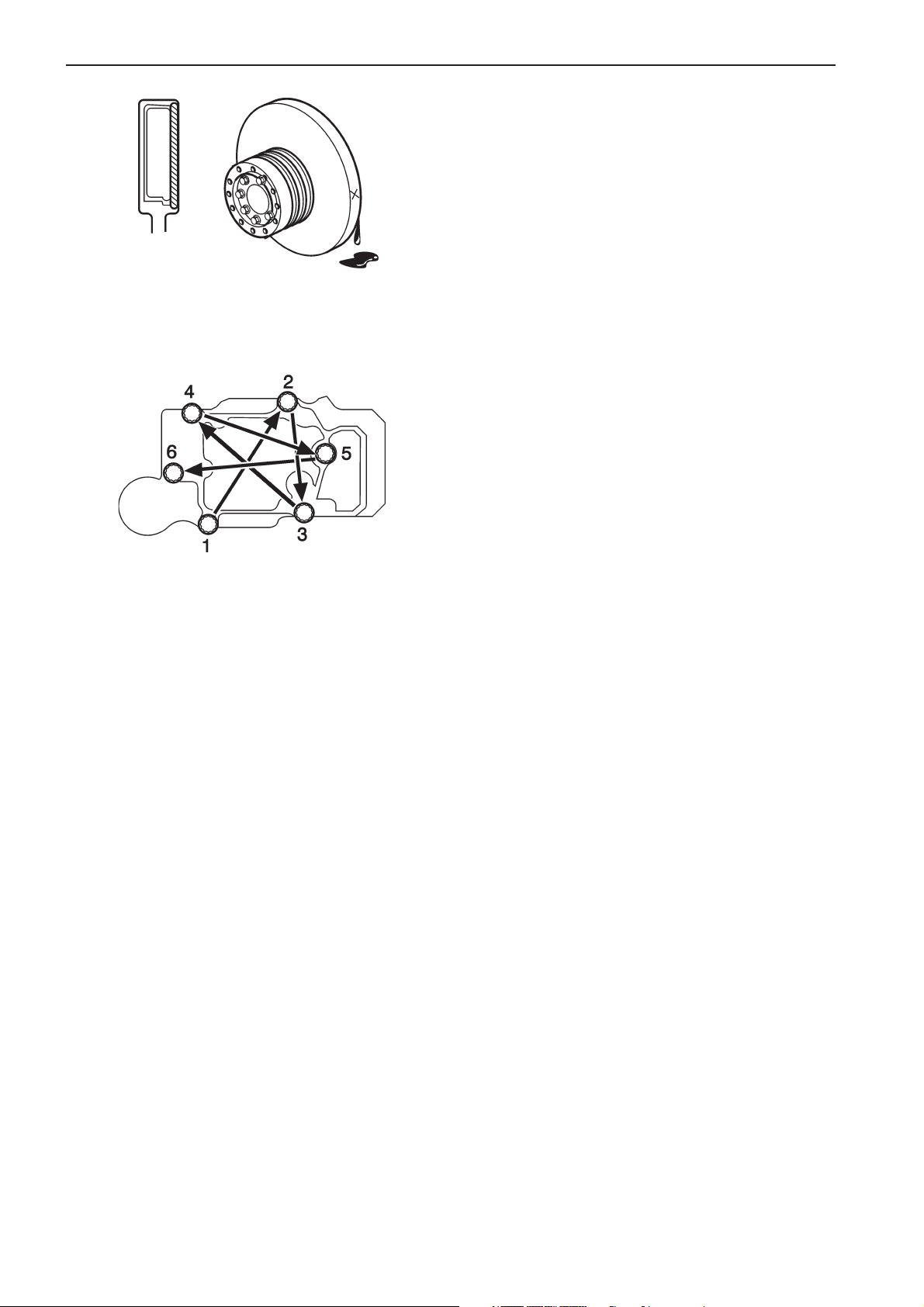

Firing order

Check and adjust the valve clearance in the firing order (injection sequence), turning the engine with each cylinder piston at top dead center on compression stroke.

Firing order 1 5 3 6 2 4

(Example): After checking and adjusting the cylinder No.1, turn the engine 120° and check and adjust the cylinder No.5.

Cylinder No. 1 5 3 6 2 4

Timing ( ° ) 0 120 240 360 480 600

41

Page 42

Maintenance: Engine

Plus d'informations sur : www.dbmoteurs.fr

Vibration Damper Inspection

NOTE! When installing a damper protective

cover to the engine, do not use a cover

enclosing the damper.

Visually check for fluid leaks, flaws, distortion, or discoloration or flaking of painted surfaces. Also check

for swelling (by measuring with a scale), and fluid leaks past staked portions.

Re-tighten Bolts and Nuts

Re-tighten the bolts and nuts on the following components:

* Timing gear case

* Crankshaft pulley

* Mounting brackets

* Exhaust manifold

* Turbocharger

* Cylinder heads

Check the cylinder head bolts and re-tighten them in

number sequence (1-2-3-4-5-6) if necessary. The

tightening torques of the bolts and nuts can be found

in technical data section of this manual.

42

Page 43

Maintenance: Engine

Plus d'informations sur : www.dbmoteurs.fr

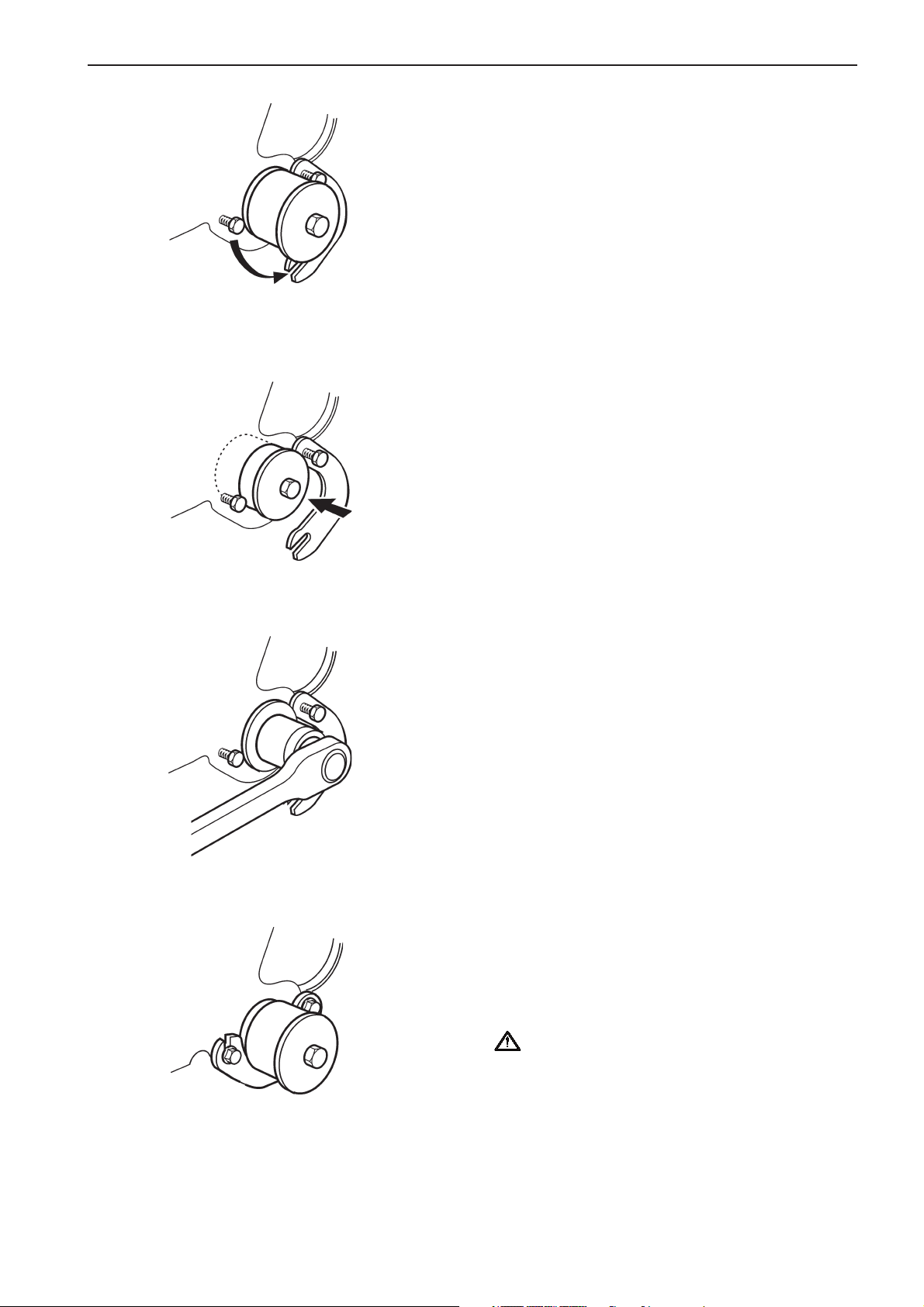

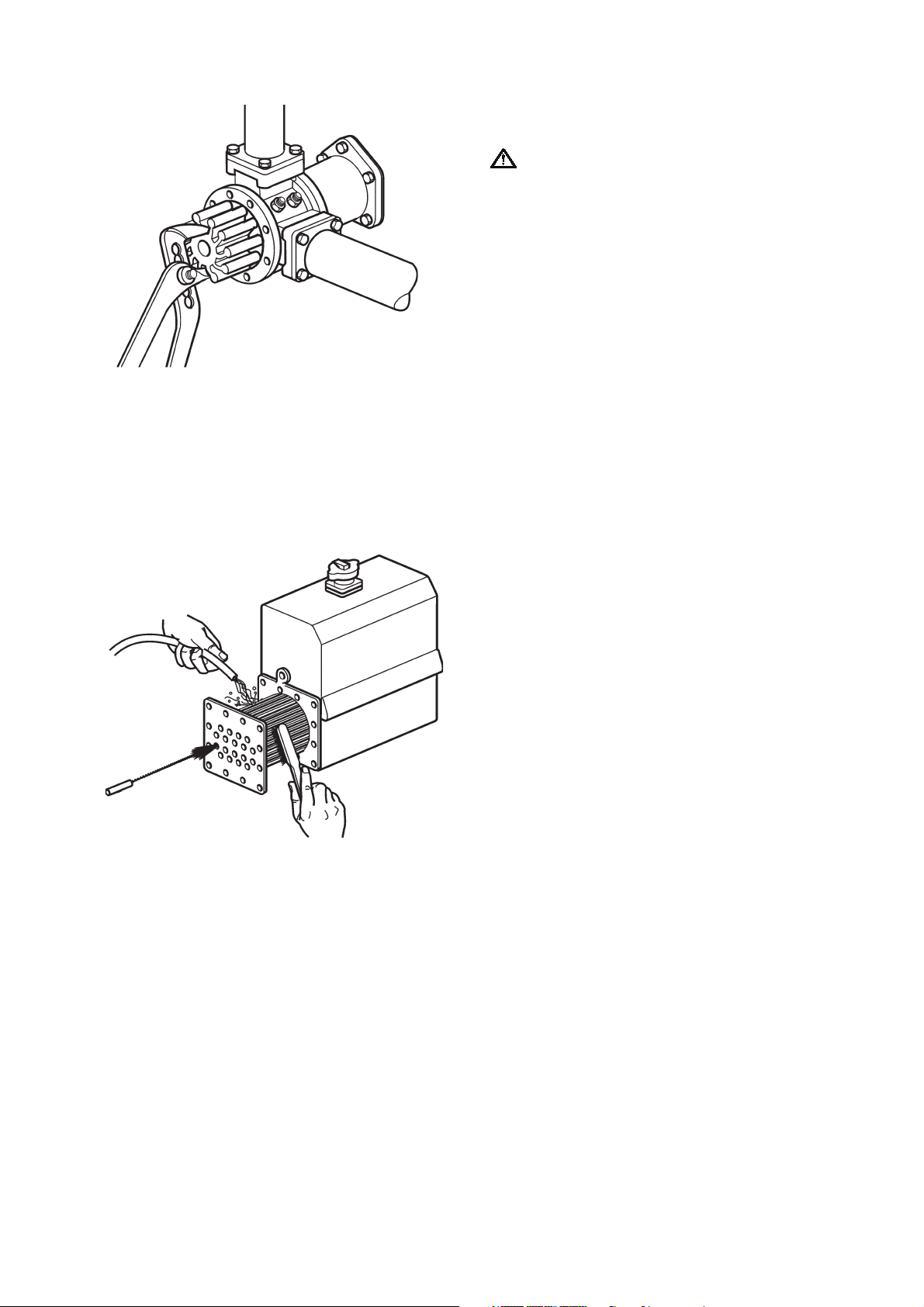

How to use the Turning Gear

1. Loosen the two bolts securing the shaft lock plate

and remove the plate from the shaft (groove).

2. Push in the shaft all the way to the TURN posi-

tion.

3. Put a socket to the hexagonal end of the shaft

and turn the shaft with a ratchet handle for turning.

4. After turning the engine, pull the shaft back to the

RUN position, secure the shaft with the locking

device and tighten the plate bolts. Make sure the

plate is secured properly.

WARNING! Before starting the engine, make

sure the turning gear is in the RUN position and