Page 1

Operator’s manual

D1/D2

Page 2

WARNING!

Operating, servicing and maintaining a marine vessel can expose you to chemicals including

engine exhaust, carbon monoxide, phthalates, and lead which are known to the State of

California to cause cancer and birth defects or other reproductive harm.

Breathing diesel engine exhaust exposes you to chemicals known to the State of California

to cause cancer and birth defects or other reproductive harm. To minimize exposure, avoid

breathing exhaust when operating, servicing and maintaining the engine.

• Always start and operate the engine in a well-ventilated area.

• If in an enclosed area, vent the exhaust to the outside.

• Wear gloves or wash your hands frequently when servicing the vessel.

• Do not modify or tamper with the exhaust system.

• Do not idle the engine except as necessary.

For more information

www.P65warnings.ca.gov/marine

www.p65warnings.ca.gov/products/diesel

© 2019 AB VOLVO PENTA

Volvo reserves the right to make changes

Printed on environmentally friendly paper

Page 3

Table of Content

Foreword ...................................................................................................... 3

Safety Information ...................................................................................... 4

Maneuvering .......................................................................................... 13

Introduction ............................................................................................... 15

About this Manual ................................................................................... 15

Warranty .................................................................................................. 16

Your New Boat ........................................................................................ 16

Running in the engine ............................................................................. 16

Fuel, oils and coolant .............................................................................. 17

Maintenance and replacement parts ....................................................... 17

Excessive strain on a product and components ...................................... 18

Volvo Penta EVC system, integrity and modification .............................. 18

Environmental care ................................................................................. 19

Recording engine data ............................................................................ 19

Certified Engines ..................................................................................... 20

Volvo Penta Dealer Network ................................................................... 21

Volvo Penta Action Service ..................................................................... 21

Instruments and Controls ........................................................................ 22

Ignition Lock .......................................................................................... 22

Start/Stop Panel .................................................................................... 22

Control Panel ....................................................................................... 22

Gauges ................................................................................................... 23

EVC system display .............................................................................. 25

Controls ................................................................................................. 30

Starting ...................................................................................................... 32

Before Starting ...................................................................................... 32

Starting the Engine ............................................................................... 33

Operation ................................................................................................... 35

Reading the Instruments ...................................................................... 35

Alarms .................................................................................................... 35

Maneuvering .......................................................................................... 36

Cruising Speed .................................................................................... 37

Engine Shutdown ...................................................................................... 38

Stop the Engine ..................................................................................... 38

After Engine Shutdown ........................................................................ 39

Cold Weather Precautions ................................................................... 40

Fault handling ........................................................................................... 41

Fault Tracing .......................................................................................... 44

In Case of Emergency .............................................................................. 45

Starting Using Auxiliary Batteries ....................................................... 45

Maintenance Schedule ............................................................................. 46

Maintenance .............................................................................................. 47

Engine, General ..................................................................................... 52

Drive belt, check and change ............................................................... 53

Idling .................................................................................................... 54

Lubrication System ............................................................................... 55

Oil level, checking and topping up ....................................................... 55

Fuel System ........................................................................................... 56

Engine Fuel Filter Replacement ........................................................... 56

Fuel system, bleeding .......................................................................... 57

47711262 01-2019 © AB VOLVO PENTA 1

Page 4

Fuel pre-filter ........................................................................................ 57

Freshwater System ............................................................................... 58

Coolant Level, Checking and Topping Up ........................................... 59

Seawater System ................................................................................... 60

Seawater System, Draining ................................................................. 61

Impeller, Check and Change ............................................................... 62

Seawater System, Cleaning and Inhibiting .......................................... 63

Seawater Filter, Check and Cleaning .................................................. 64

Vacuum Valve ...................................................................................... 64

Electrical System .................................................................................. 65

Main switch .......................................................................................... 65

Fuses ................................................................................................... 65

Electrical Connections ......................................................................... 65

Battery .................................................................................................. 66

Electrical Installations .......................................................................... 68

Reverse Gear ......................................................................................... 70

Oil level, checking and topping up ....................................................... 70

Reverse Gear, Oil Change ................................................................... 70

Propeller Shaft Sealing, Check ............................................................ 70

Drive ....................................................................................................... 71

Transmission lubricant, checking and topping up ................................ 71

Corrosion protection, checking and changing ...................................... 72

Rubber Bellow ...................................................................................... 72

Propeller ................................................................................................. 73

Storage ....................................................................................................... 75

Bringing Out of Storage ....................................................................... 77

Painting the Drive and Underwater Hull .............................................. 78

Technical Data ........................................................................................... 79

Coolant, Mixing ....................................................................................... 82

Identification Numbers ......................................................................... 84

Declaration of Conformity .................................................................... 85

Declaration of Conformity .................................................................... 85

Declaration of Conformity .................................................................... 86

Index ........................................................................................................... 87

2 47711262 01-2019 © AB VOLVO PENTA

Page 5

Foreword

Welcome!

Congratulations on your new boat equipped with a Volvo Penta marine engine.

Volvo Penta engines are designed to fulfill Volvo’s core values; quality, safety and

environmental care. After more than 100 years as an engine manufacturer, the

Volvo Penta brand has also become a symbol of reliability, technical innovation, top-ofthe-range performance and long service life. Volvo Penta marine engines are used all

over the world, in all possible operating conditions for professional as well as leisure

purposes.

Make sure to thoroughly read through this Operator’s Manual and take necessary actions

regarding running and maintenance before your maiden voyage. It contains the

information you need to be able to operate and maintain the engine safely and correctly.

Pay careful attention to the safety instructions included in the manual.

As the owner of a Volvo Penta marine engine, you become part of a worldwide network

of dealers and service workshops that assist you with technical advice, service

requirements and replacement parts. Contact your nearest authorized Volvo Penta dealer

for assistance.

It is possible to buy additional literature about your Volvo Penta engine, e.g. the Service

& Maintenance manual. More information on how to do this can be found at

www.volvopenta.com.

Information about your closest Volvo Penta dealer and other useful news and

information can be found at www.volvopenta.com and by following Volvo Penta on

Facebook.

www.volvopenta.com

www.facebook.com/volvopenta

47711262 01-2019 © AB VOLVO PENTA 3

Page 6

Safety Information

!

This chapter describes how safety precautions are

presented in the manual and on the product. Read the

chapter through very carefully before you start the

engine or do any maintenance or service. It has to do

with your safety; an incorrect operation can lead to

personal injury and damage to products or property.

It also gives you an introduction to the basic safety

rules for using and looking after the engine.

Safety texts have the following order of priority:

DANGER!

Indicates a hazardous situation, which, if not avoided, result in death or serious injury.

WARNING!

Indicates a hazardous situation, which, if not avoided, could result in death or serious

personal injury.

CAUTION!

Indicates a hazardous situation, which, if not avoided, could result in minor or moderate

personal injury.

If anything remains unclear or if you are unsure of

something, contact your Volvo Penta dealer for

assistance.

IMPORTANT:

Always follow local safety instructions and

regulations.

IMPORTANT:

Indicates a situation, which, if not avoided, could result in property damage.

NOTICE! Used to draw attention to important information that facilitates work or

operations.

This symbol is may be used on the product to call your attention to the fact that this is

safety information. Always read such information very carefully.

Make sure that warning and information symbols on the engine are clearly visible and

legible. Replace symbols that have been damaged or have been painted over.

In some cases, this symbol is used on our products and refers to important information

in the Operator’s Manual.

4 47711262 01-2019 © AB VOLVO PENTA

Page 7

Safety Information

Most chemicals such as engine and transmission oils,

glycol, petrol and diesel oil and chemicals used in

workshops such as degreasing agents, paint and

solvents are harmful to health.

Carefully read the instructions on the product

packaging! Always follow the safety regulations, such

as the use of protective masks, goggles, gloves, etc.

Make sure that other personnel are not exposed to

substances that are hazardous to health. Ensure good

ventilation.

Manage used and leftover chemicals in the prescribed

manner.

Daily Checks

WARNING!

Do not start the engine if there is reason to suspect fuel

leaks or if there is explosive material nearby.

Make it a habit to give the engine and engine

compartment a visual check before the engine is

started and after operations, once the engine has

stopped. This helps you to quickly discover fuel,

coolant or oil leakages or any other abnormality that

has occurred, or is about to occur.

P0024482

Personal safety equipment

CAUTION!

Always use appropriate safety equipment. Personal

protective equipment does not eliminate the risk of

injury but it will reduce the degree of injury if an

accident does happen.

Some examples are ear protection, eye and face

protection, protective footwear, personal protective

equipment, head protection, protective clothing,

gloves and respirators.

WARNING!

Ensure that all machine guards and safety devices are

in place and are functional.

CAUTION!

Never use tools or products that show signs of

damage.

47711262 01-2019 © AB VOLVO PENTA 5

Page 8

Safety Information

Protect your eyes

CAUTION!

Wear safety glasses.

Always wear safety glasses if there is a risk of

splintering, sparks and spray from the electrolyte (socalled battery acid), or other chemicals. Your eyes are

very delicate and damage can result in loss of sight!

Protect your skin

CAUTION!

Risk of skin damage.

Avoid getting oil on your skin! Prolonged or repeated

exposure to oil can dry out the skin. Thereafter,

irritation, dryness and eczema and other skin problems

may occur.

Use protective gloves and avoid oil-soaked clothes

and rags. Wash regularly, especially before eating.

Wear suitable protective creams to prevent skin from

drying out and to facilitate cleaning.

P0024470

Fire safety

WARNING!

Fire and Explosion Risk!

Accidental spark could ignite fuel vapors.

All fuels – as well as many lubricants and chemicals –

are flammable. Do not allow open flames or sparks

near them. Smoking forbidden! Hydrogen from the

batteries is also very flammable and explosive in

certain mixture with air.

Ensure that the workplace is well ventilated and take

the necessary precautions before welding or grinding

begins. Always ensure that there is a fire extinguisher

close at hand in the work area.

6 47711262 01-2019 © AB VOLVO PENTA

Page 9

Safety Information

Spare parts — safety

WARNING!

Always use spare parts with the same quality as

genuine Volvo Penta parts to minimize the risk of an

explosion or fire.

Components in fuel systems and electrical systems on

Volvo Penta engines are designed and manufactured

to minimize the risk of explosions and fire, in

accordance with applicable legal requirements.

Used oils, filters and chemicals etc.

WARNING!

Risk of fire.

Store fuel soaked rags and other flammable material

so that there is no danger of them catching fire.

Oil-soaked rags can spontaneously ignite under

certain circumstances.

P0024481

IMPORTANT:

Used fuel and oil filters are environmentally hazardous

waste and must be taken to an approved waste

management facility for correct handling, as must any

used lubricating oil, contaminated fuel, paint residue,

solvents, degreasers and wash residue.

Prevent start of the engine

WARNING!

Immobilize the engine by turning off the power supply

with the main switch(es) and lock it (them) in the off

position before starting work. Place a warning notice

at the main switch.

If the engine is equipped with BMS (Battery

Management System), always disconnect both battery

cables from the battery terminals.

Ventilation when running the engine

WARNING!

Only start the engine in a well-ventilated area. If

operating the engine in a closed area ensure that there

is exhaust ventilation leading out of the work area to

remove exhaust gases and crankcase ventilation

emissions.

The engine must not be operated in areas where there

are explosive materials or stored gas.

47711262 01-2019 © AB VOLVO PENTA 7

Page 10

Safety Information

P0024808

Rotating parts and hot surfaces

DANGER!

Working with or approaching a running engine is a

safety risk. Watch out for rotating components and hot

surfaces.

If the engine is in operation and operates another

device, you must not, under any circumstances,

staying close to the engine.

Work on running engines is strictly prohibited. There

are however adjustments that require the engine to be

run. Approaching a running engine is a safety risk.

Loose clothing and long hair can get caught in the

rotating parts; careless movements or a dropped tool

can lead to serious personal injury.

Be careful to avoid hot surfaces (exhaust pipes,

turbochargers, charge air manifolds, start elements

etc.) and hot fluids in pipes and hoses on engines that

are running or have just stopped. Re-install all

protective covers that were removed during

maintenance work before starting the engine.

P0024483

Information on the engine

IMPORTANT:

Make sure that all warning and information decals on

the product are always visible. Replace decals which

have been damaged or painted over.

Prohibition on use of start spray

WARNING!

Never use start spray or similar agents to start an

engine. This may cause an explosion in the inlet

manifold. Risk of personal injury.

8 47711262 01-2019 © AB VOLVO PENTA

Page 11

P0024688

Safety Information

Before start of engine

WARNING!

Never start the engine if there is reason to suspect fuel

and/or gas leaks, or if there is explosive material

nearby.

IMPORTANT:

Only start the engine with the air filter and protective

caps fitted. Foreign objects in the inlet line could cause

machine damage. Also make sure that no tools or other

parts have been left next to the engine.

WARNING!

Never start the engine with the valve cover removed.

There is a risk of personal injury.

For engines with turbochargers, the rotating

compressor turbine can in addition cause serious

personal injuries.

Before any work on the electrical system

WARNING!

Always stop the engine first. Then disconnect the

current at the main switches and any external power

supply before working on the electrical system – to

minimize the risk of electrical hazards.

IMPORTANT:

Never disconnect the current using the main switches

when the engine is running or by disconnecting the

battery cables.

The alternator and electronics could be damaged.

Avoid damage to the engine control

module and other electronics

IMPORTANT:

Switch off the main switch before connecting or

disconnecting a connector.

Before welding work

IMPORTANT:

Before any work with electric weld can begin, the

connection to all control units must be disconnected.

After finished welding, re-connect the connection to all

control units before connecting any battery cable.

Before any work on the cooling system

WARNING!

Stop the engine and let it cool before starting work on

the cooling system. Hot fluids and hot surfaces can

cause burns.

47711262 01-2019 © AB VOLVO PENTA 9

Page 12

Safety Information

P0024484

Risk of water penetration/sinking

WARNING!

If a launched boat is equipped with sea water tap and

safety valve, ensure that these are closed before any

work is allowed to begin on the cooling system.

Remember to open the tap and valve before starting

the engine!

Hot coolant under pressure

CAUTION!

Hot coolant can cause burns. Avoid opening the filler

cap for the coolant when the engine is still hot. Steam

or hot coolant can spray out and system pressure is

lost.

Open the filler cap slowly and release the pressure in

the cooling system if the filler cap or valve must be

opened – or if a plug or a coolant hose must be

removed from a hot engine.

Hot oil under pressure

CAUTION!

Hot oil can cause burns. Avoid getting hot oil on the

skin. Ensure that the lubrication system is not

pressurized before starting any work. Never start or

operate the engine without the oil filler cap is on. There

is a risk that hot oil can spray out.

Refueling

WARNING!

There is always a risk of fire and explosion during

refueling. Smoking is forbidden and the engine must

be stopped.

Proper fuel quality

IMPORTANT:

Always use the fuel recommended by Volvo Penta.

See Technical Data in Operator’s Manual. Other fuel

can damage the engine.

Wrong fuel quality can also lead to higher service

costs.

P0024477

10 47711262 01-2019 © AB VOLVO PENTA

WARNING!

Risk of personal injury.

Wrong fuel quality in a diesel engine can cause the fuel

control mechanism to bind which can cause the engine

to overspeed!

Page 13

P0024488

Safety Information

Legal requirements to use proper fuel

IMPORTANT:

To meet regulatory requirements for certified emission

levels must always recommended fuel according to

Technical Data in the Operator’s Manual be used.

At any leak detection on the fuel system

WARNING!

Wear safety goggles!

Be extremely careful when searching for leaks in the

fuel system high-pressure circuits. There is very high

pressure in the jet from pipes and injectors. The fuel

may penetrate the tissue and cause serious risk of

blood infection (septicemia).

Handling of fuel pipes

IMPORTANT:

High pressure pipes for fuel must not be bent or

straightened under any circumstances. Cracks may

occur. Damaged pipes must be replaced.

P0024468

Safe handling of batteries

WARNING!

Risk of fire and explosion. Never allow an open flame

or electric sparks near the batteries.

A spark caused by an incorrectly connected battery

can be enough for the battery to explode with serious

injuries.

Do not touch the connections during start attempts.

Sparking hazard! Do not lean over batteries.

Correct polarity of the batteries

IMPORTANT:

Make sure that the positive (+) and negative (–) battery

cables are correctly connected to the corresponding

battery terminals. Wrong connection may cause

severe damage to electrical equipment.

47711262 01-2019 © AB VOLVO PENTA 11

Page 14

Safety Information

Risks of electrolyte in batteries

WARNING!

Always wear protective goggles when charging or

handling batteries.

Battery electrolyte is highly corrosive.

Rinse immediately with copious amounts of water if the

electrolyte gets in your eyes. Search directly after the

rinsing help by medical staff.

If it comes electrolyte to unprotected skin, wash

immediately with soap and water.

Layout of the battery compartment

IMPORTANT:

Make sure the battery compartment is designed

according to current safety standards.

Cleaning the engine and components

P0024486

IMPORTANT:

Never use a high pressure washer for cleaning of

engine or engine components.

Cleanliness for sensitive components

IMPORTANT:

Observe meticulous cleanliness when handling

system components.

Even minimal amounts of dirt could cause a

breakdown.

Adjustment of the clutch

CAUTION!

Clutch adjustments must be carried out with the engine

stopped.

12 47711262 01-2019 © AB VOLVO PENTA

Page 15

Safety Information

Maneuvering

WARNING!

A rotating propeller can cause serious injury. Check

that nobody is in the water before engaging ahead or

astern. Never drive near bathers or in areas where

people could be in the water.

To avoid passengers falling overboard, refrain from

extreme and sudden rudder movements and ahead/

astern movements.

Lanyard switch

We recommend installing and using a lanyard switch

(optional), especially if the boat is capable of high

speeds. The lanyard switch stops the engine if the

driver looses control of the boat.

Accidents at sea

Maritime rescue statistics show that a large number of

boat accidents are caused by inadequate engine and

boat maintenance and the lack of safety equipment.

Make sure that the boat engine is properly maintained

by making sure that the recommended service is

performed, and that necessary safety equipment is

available and functional.

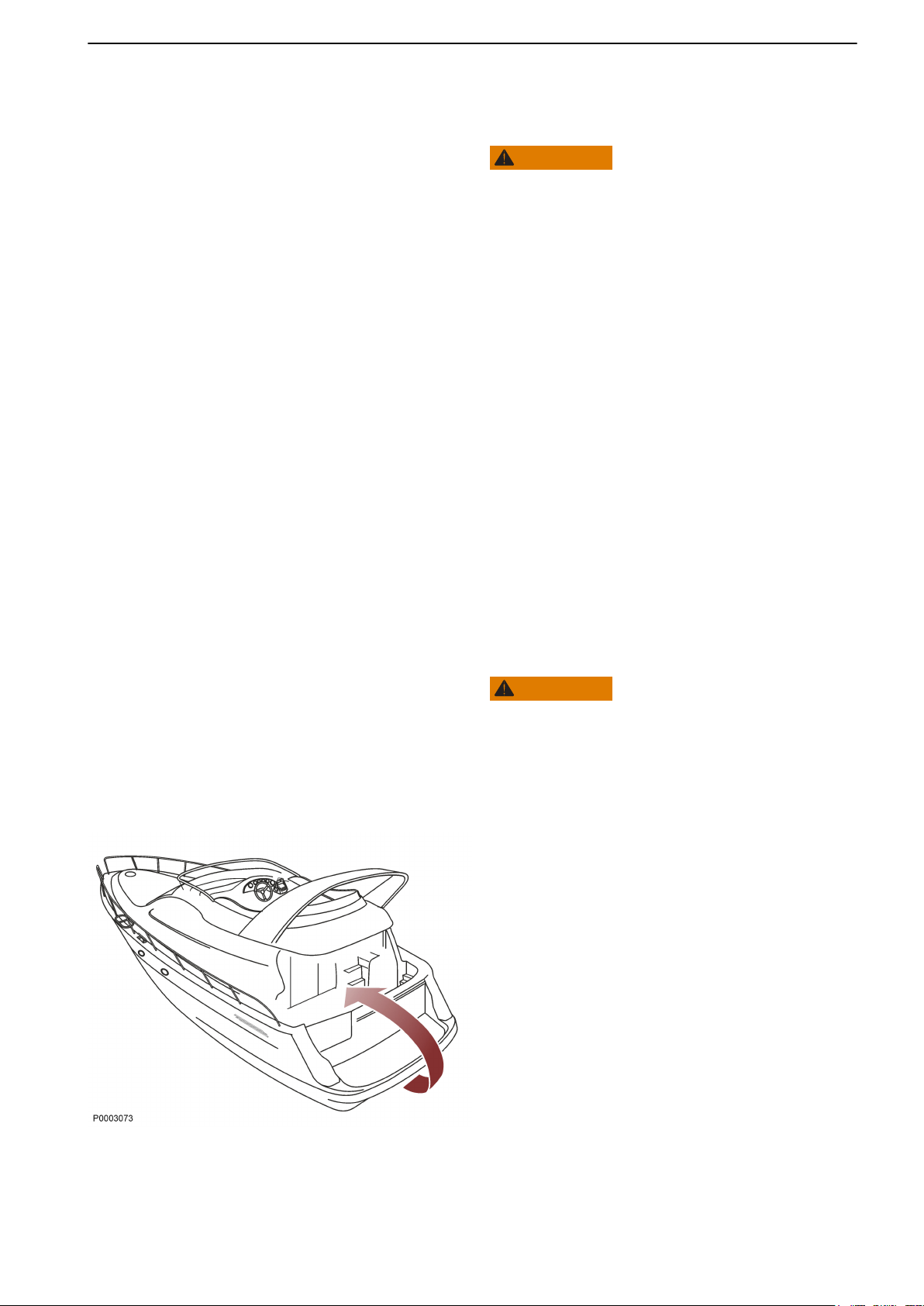

Stern turbulence

WARNING!

Carbon Monoxide Poisoning. When the boat moves

forward, an area of lower pressure air is formed behind

the boat — so-called turbulence. In certain conditions,

this turbulence can be powerful enough to draw the

exhaust fumes into the cockpit or cabin, creating a risk

of carbon monoxide poisoning to people on board.

The turbulence problem is most pronounced on tall,

broad-beamed boats with a transom stern. But even

for other boat types, low-pressure suction can be a

problem in certain conditions, such as driving with

cockpit awnings rigged. Other factors that can increase

the effect of turbulence are wind conditions, load

distribution, swell, trim, open hatches and ventilators

etc.

Most modern boats are, however, designed so that the

problem of low-pressure suction is very rare. Should

turbulence nevertheless occur, hatches or ventilators

must not be opened since this might exacerbate the

problem. Instead, try to change the speed, trim or load

distribution. If possible, take down or open the cockpit

awning. Contact your boat dealer for the best solution

for your boat.

47711262 01-2019 © AB VOLVO PENTA 13

Page 16

Safety Information

To remember before the boat trip

The lists below includes some tips on what to

remember to bring on any boat trip. The list can be

extended since the need for safety equipment varies

with the boat type and where or how it is used etc. We

recommend you ask a regional boat or sea safety

organization for more detailed maritime safety

information.

Take your chart out and study your planned route.

•

Calculate distance and fuel consumption. Listen to

weather reports.

Tell your friends/relatives about route plans if you

•

undertake a long journey. Remember to notify

changed plans or delays.

Inform everybody aboard about where the safety

•

equipment is located, and how it works. Make sure

that there is more than one person aboard who can

start and operate the boat safely.

Safety Equipment:

life jackets

•

communication equipment

•

emergency rockets

•

approved fire extinguisher

•

first aid kit

•

life buoy

•

anchor

•

paddle

•

flashlights

•

Spare Parts and Tools:

impeller

•

fuel filters

•

fuses

•

tape

•

hose clamps

•

engine oil

•

other tools that may be required

•

14 47711262 01-2019 © AB VOLVO PENTA

Page 17

Introduction

Check that you heave received the correct

operator’s manual before continuing reading. If

not, please contact your Volvo Penta dealer. Read

the Operator’s Manual carefully and learn to handle the

engine, controls and other equipment in a safe manner

before you start the engine.

For engine designations, refer to Technical

Data, page 79. The designation is stated on the

engine plate, refer to Technical Data, page 84.

The illustrations in this book may cover several product

types, which means that there may be slight

differences between the illustrations and the

purchased product. This does, however, not affect the

validity of the information and/or instructions in the

manual. Volvo Penta reserves the right to make

alterations to specifications, design features, and

illustrations without prior notice.

At service, software can be updated that affects the

functionality described in this manual.

About this Manual

This Operator's Manual has been prepared to give you

the greatest possible benefit from your Volvo Penta

marine engine. It contains necessary information

regarding safe and correct engine operation and

maintenance.

Always have the Operator's Manual available. Store it

safely and do not forget to hand it over to the next

owner if you sell your boat.

47711262 01-2019 © AB VOLVO PENTA 15

Page 18

Introduction

Warranty

Your new Volvo Penta marine engine is covered by a

limited warranty, subject to the conditions compiled in

the Warranty Information. Note that AB Volvo Penta’s

liability is limited to the specification in the Warranty

Information (included CD) and Emission Control

System Warranty Statement.

Read the information carefully, as soon as possible

after delivery. It includes important information about

service and maintenance; the owner is responsible for

being familiar with, checking and implementing these.

Otherwise AB Volvo Penta may deny its warranty

obligations in part or in full.

NOTICE! Make sure that a Commissioning has been

carried out on your Volvo Penta engine. This should be

done together with your Volvo Penta dealer when

finalizing the purchase. Without a proper

Commissioning registration the warranty will not be

valid.

Contact your Volvo Penta dealer if you have not

received the Warranty Information or Service

Book.

Your New Boat

Carefully read through the instructions and other

information that is delivered with the new boat. Learn

to handle the engine, controls and other equipment in

a safe and proper manner. If this is your first boat or if

the boat type is unfamiliar to you, we recommend that

you practice maneuvering the boat before casting off

on the maiden voyage. Make yourself familiar with the

boat’s seakeeping and maneuvering qualities at

different speeds, sea states and load conditions.

Bear in mind that a person in charge of a boat under

way bears the legal responsibility of knowing and

following the regulations for passage and safety afloat.

Learn which regulations apply to you and your waters

by contacting the relevant authorities or maritime

safety organization. We recommend that you complete

a boat driver’s course.

Running in the engine

The engine must be run in during the first 10 hours of

operation. Do this by using the engine in normal

operation, where full load is only applied for short

periods of time. Never run the engine at constant

speed for any longer periods of time.

Since oil consumption is higher during the running in

period, be sure to control the oil level more frequently

than normally recommended. See Maintenance for

more information.

16 47711262 01-2019 © AB VOLVO PENTA

Page 19

Introduction

Fuel, oils and coolant

Only use the fuels and oils recommended in the

Operator’s Manual, since other grades may cause

malfunctions, increased fuel consumption and

possibly shorten the life of the engine.

Always change the oil, oil filters and fuel filters at the

specified maintenance intervals.

Make sure to always use suitable and correctly mixed

coolant.

Future warranty claims related to engine and

accessories may be denied if an unsuitable coolant

has been used, or if the instructions for coolant mixture

have not been followed.

Maintenance and replacement parts

Volvo Penta engines are designed for maximum

reliability and long life and built to withstand a

demanding environment. The engines are also

designed to have a minimal environmental impact.

These qualities will be maintained through regular

servicing and the use of spare parts with the same

quality as genuine Volvo Penta parts. If reliable and

purpose-built parts are not used, your safety, health,

and the machine’s function may be compromised.

Volvo Penta has a world-wide network of authorized

dealers.

The authorized dealers are Volvo Penta product

specialists, and have the accessories, genuine parts,

test equipment and special tools needed for high

quality service and repair work. Always observe the

maintenance intervals in the manual, the complete

Service Protocol can be found at volvopenta.com.

Remember to note the engine / transmission

identification number when you order service and

spare parts.

47711262 01-2019 © AB VOLVO PENTA 17

Page 20

Introduction

Excessive strain on a product and

components

Volvo Penta products and components are not

dimensioned for external loads. Never stand or step

onto an engine, transmission or its components. Loads

can bring about damage and the malfunction of a

product or property.

Volvo Penta EVC system, integrity

and modification

The Electronic Vessel Control (EVC) system is a

complete vessel control system for engine, gear, and

vessel steering control. Modifying the EVC system or

connecting spare parts or systems that do not comply

with the quality of genuine Volvo Penta parts may

adversely affect the system performance, safety, and

warranty coverage.

Volvo Penta recommends only the use of electronic

systems and spare parts with the same quality as

genuine Volvo Penta parts. Contact your local Volvo

Penta dealer for detailed information and advice.

18 47711262 01-2019 © AB VOLVO PENTA

Page 21

Introduction

Environmental care

Environmental care is a core value at Volvo Penta.

Energy efficiency and low emissions are among the

most important product related aspects and priority

focus areas for Volvo Penta business. Several of the

global challenges the world faces are directly or

indirectly related to power industries and transports.

We recognize that Volvo Penta is part of the

environmental problems, but we are also convinced

that we are a part of the solution.

Volvo Penta currently has a broad engine program in

which great advances have been made in reducing

exhaust emissions in the same time as the fuel

consumption has been improved. Through regular

maintenance, the Volvo Penta engines retain its low

fuel consumption and low emissions. We hope that you

will be keen to preserve these qualities.

Always follow the directions in the Operator’s Manual

regarding fuel grades, operation and maintenance to

avoid unnecessary environmental impact. Contact

your Volvo Penta dealer if you notice any changes

such as increased fuel consumption or exhaust smoke.

Remember always to hand in environmental

hazardous waste such as drained oil, coolant, old

batteries, etc. for treatment at a recycling facility. Our

united efforts can make a valuable contribution to the

environment.

Recording engine data

One or more computers in your Volvo Penta engine

can record detailed information. Data — such as usage

and information of other systems and modules on the

engine — can be included. This data can include information such as boat position and usage. Only a limited amount of data can be stored.

AB Volvo Penta and authorized workshops will not

distribute this stored information without permission.

AB Volvo Penta may, however, be forced to provide

this information if required by national legislation. In

general, AB Volvo Penta and authorised workshops

may read and use the information.

47711262 01-2019 © AB VOLVO PENTA 19

Page 22

Introduction

Certified Engines

If you own an emission-certified engine used in an

area where exhaust emissions are regulated by

law, this places special demands on the care and

maintenance you provide your engine.

NOTICE! Neglects or failure to follow the points listed

here may invalidate the engine emission certificate.

This means AB Volvo Penta can no longer guarantee

engine conformity with the certified model. Volvo Penta

is not responsible for damages or costs arising as a

result of this.

Certification means that an engine type has been

•

checked and approved by the relevant authority.

The engine manufacturer guarantees that all

engines of the same type are equivalent to the

certified engine.

It is the responsibility of the operator/user to ensure

•

that no intentional misuse of the engine takes place.

Volvo Penta maintenance and service intervals

•

must be complied with.

Any case of malfunction must be rectified without

•

delay.

Only use genuine Volvo Penta parts or spare parts

•

with the same quality as genuine Volvo Penta parts.

Volvo Penta recommends that service to injection

•

pumps, pump settings and injectors always are

carried out by a qualified workshop.

The engine must not be converted or modified in any

•

way, except with accessories and service kits that

Volvo Penta has approved for the engine.

No installation changes to the exhaust pipe and

•

engine air inlet ducts may be made.

No warranty seals (where present on the product)

•

may be broken by unauthorized persons.

The general instructions in the Operator's Manual

•

concerning operation, service and maintenance

apply.

20 47711262 01-2019 © AB VOLVO PENTA

Page 23

Introduction

Volvo Penta Dealer Network

The Volvo Penta global network of authorized dealers

is at your service. We strongly recommend that you

take your product to an authorized Volvo Penta dealer

for service and repair. They are specialists in Volvo

Penta products and have the accessories, genuine

Volvo Penta parts, the special tools and the latest

service information for high quality service and repair

work.

Dealer Locator Services

Locate the nearest Volvo Penta dealer through our

dealer locator on www.volvopenta.com or download

the dealer locator app to your smartphone.

Volvo Penta Action Service

Our global dealer network, your first line of contact, is

backed up by Volvo Penta Action Service, a phone

based breakdown and support service providing

assistance 24 hours a day, every day of the year.

How it works

A dedicated operator will support you all the way

through your case and keep you updated on status and

progress.

Whenever on-site assistance or technical support is

needed, the operator will put you in contact with the

closest Volvo Penta dealer that can support your

product.

Phone numbers

Find your Volvo Penta Action Service phone number

and more information on www.volvopenta.com.

47711262 01-2019 © AB VOLVO PENTA 21

Page 24

Instruments and Controls

This chapter describes the instruments, panels and controls Volvo Penta sells for your engine.

If you would like to complement your instrumentation, or if your boat is equipped with instruments not described

here, we ask that you contact your Volvo Penta dealer.

Ignition Lock

The system lacks a start lock. Therefore, the helm

station should be lockable, or alternatively a lockable

main switch should be fitted, to prevent unauthorized

engine start.

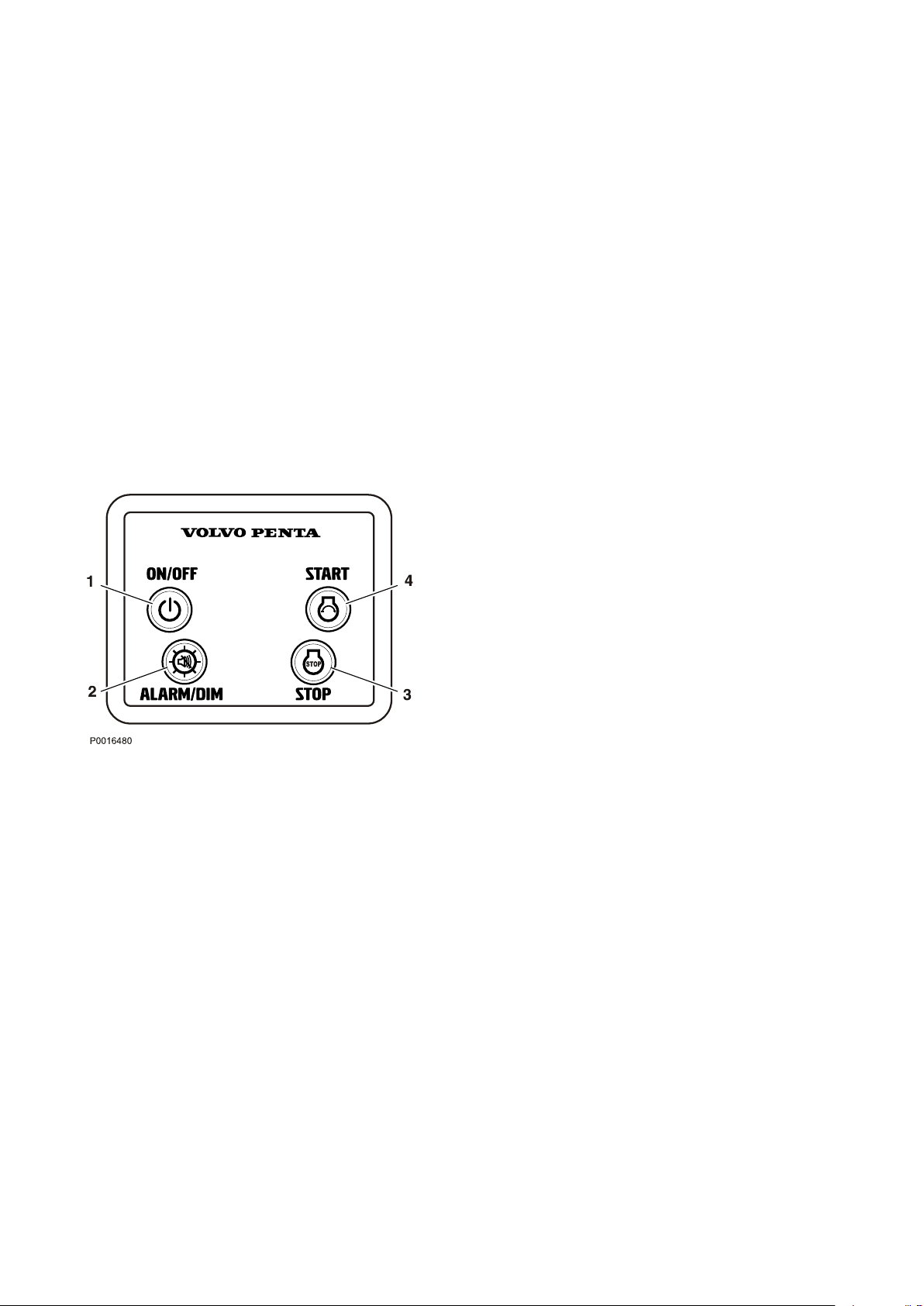

Start/Stop Panel

Control Panel

On/Off button (1)

Depress the button to start or stop the system.

The panel cannot be switched off when the engine is

running.

Start button (4)

When the button is depressed the pre-heat function is

activated and the start motor engaged.

Multi-function button (2)

Confirm the alarm. If an alarm occurs, a flashing

•

warning symbol will be displayed in the tachometer

window and an audible alarm will sound.

The alarm is confirmed by depressing the multifunction button. The audible alarm is silenced and

the warning symbol is lit continuously until the fault

is remedied.

Backlighting. To switch tachometer window

•

backlighting on or off, depress the button for 1 - 5

seconds.

The backlighting can be adjusted in five steps by

depressing the button for less than 1 second.

Adjust the tachometer window contrast by holding

•

down the button for more than 5 seconds.

Stop button (3)

The engine stops running when the button is

depressed.

22 47711262 01-2019 © AB VOLVO PENTA

Page 25

AUX

1

2

3

4

5

6

7

8

9

0

3

2

1

4

RPMX1000

P0007517

Instruments and Controls

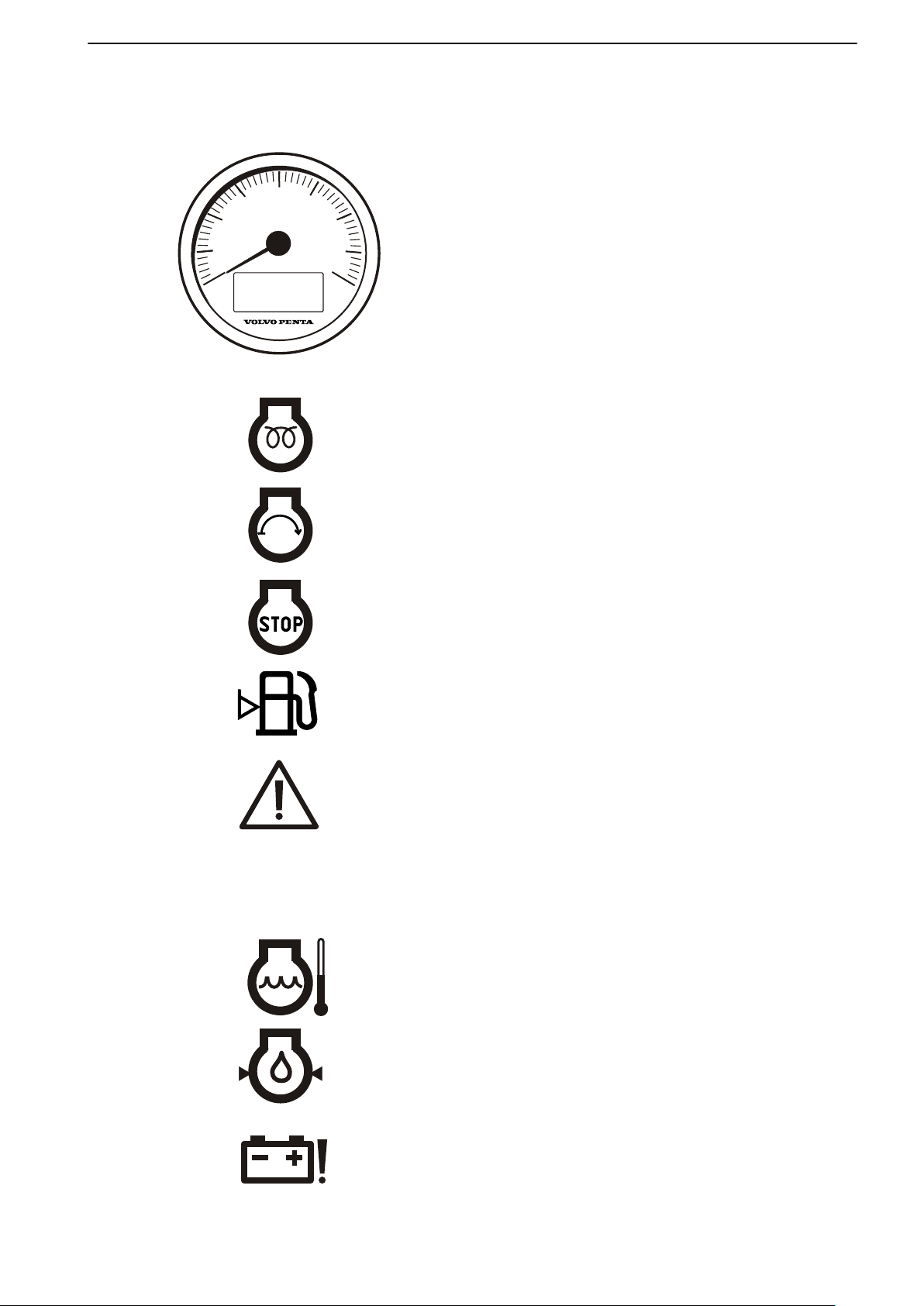

Gauges

Tachometer

The tachometer shows engine speed; multiply the

value shown on the dial by 1,000 to get the number of

engine revolutions per minute.

Operating information is displayed in the tachometer

window.

Operating information symbols

1 Pre-heating

The pre-heat symbol is displayed when the glow

function is active.

2 Starting

The start symbol is displayed when the start motor

is engaged.

3 Stopping

The stop symbol is shown when the stop button is

depressed.

4 Fuel level

If a fuel level sensor is installed (accessory) the fuel

level symbol is displayed when there is around 20%

of fuel remaining in the tank.

The engine must run for at least one minute before

the function is activated.

5 System fault

The system fault symbol lights up in the case of

short circuits or cable breaks.

6 Auxiliary alarm

Auxiliary alarm for accessory sensors.

7 Coolant temperature

47711262 01-2019 © AB VOLVO PENTA 23

The coolant temperature symbol lights up if the

engine coolant temperature is too high.

8 Oil pressure

If the oil pressure lamp lights up during operations,

the engine oil pressure is too low.

9 Charging

The charging lamp lights up if the alternator stops

charging.

Page 26

1

P0007518

Instruments and Controls

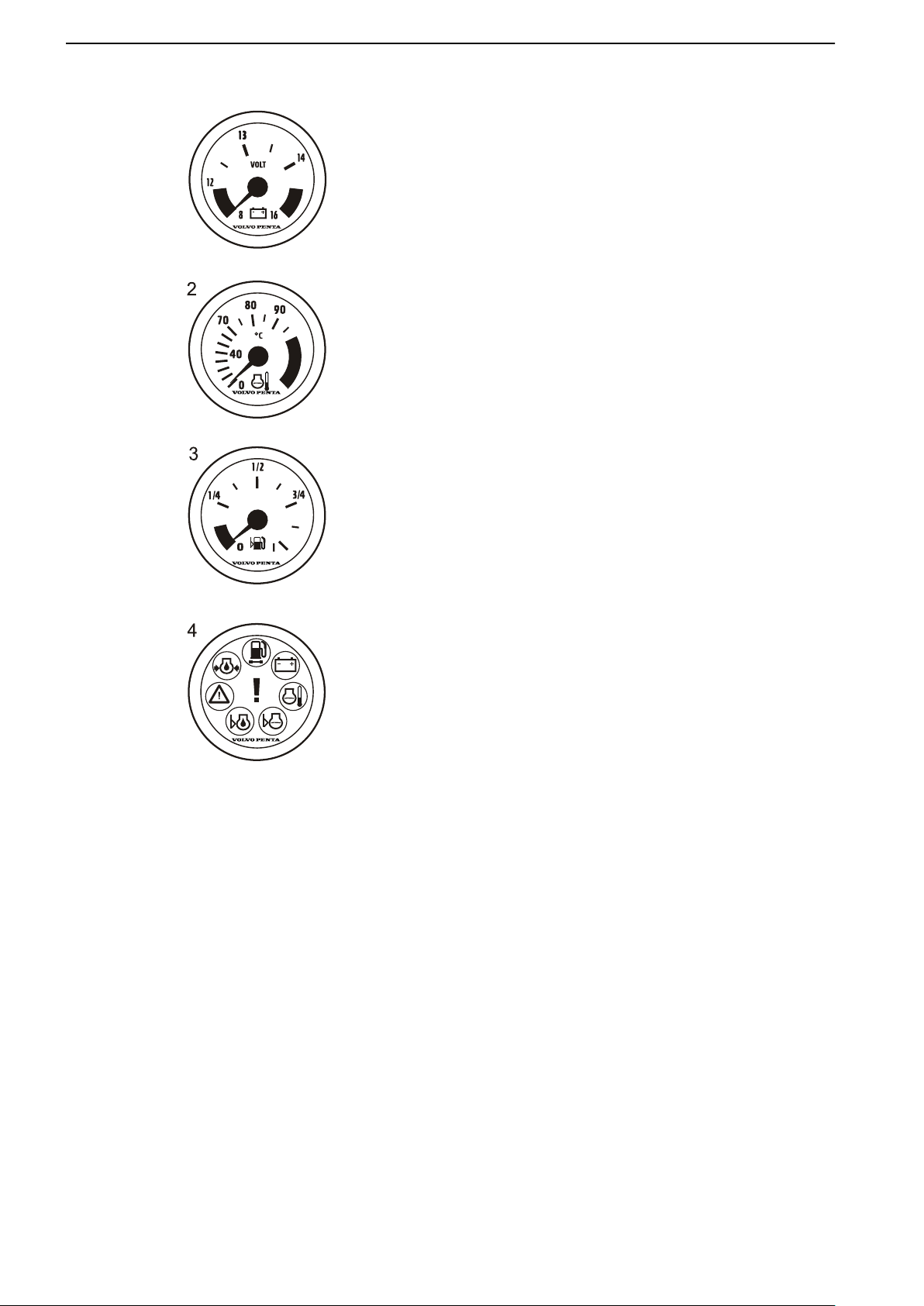

Optional instruments

These instruments are sold as engine accessories by

Volvo Penta.

1 Voltmeter, battery charging

The meter shows the alternator charge current.

During operations the charge voltage must be

around 14 V. When the engine is stopped and

electrical power switched on, battery voltage is

around 12 V.

2 Coolant temperature gauge

The instrument shows engine coolant temperature.

During operations coolant temperature must

normally be between 75-95°C (167-203°F).

3 Fuel level gauge

The fuel level gauge shows the quantity of

remaining fuel.

4 Alarm monitor

The alarm monitor gives a visual warning to call

attention to any alarms that occur.

24 47711262 01-2019 © AB VOLVO PENTA

Page 27

1 2

3

4 5

G H

P0001168

0

ENGINE HOURS

HOURS

P0003010

Instruments and Controls

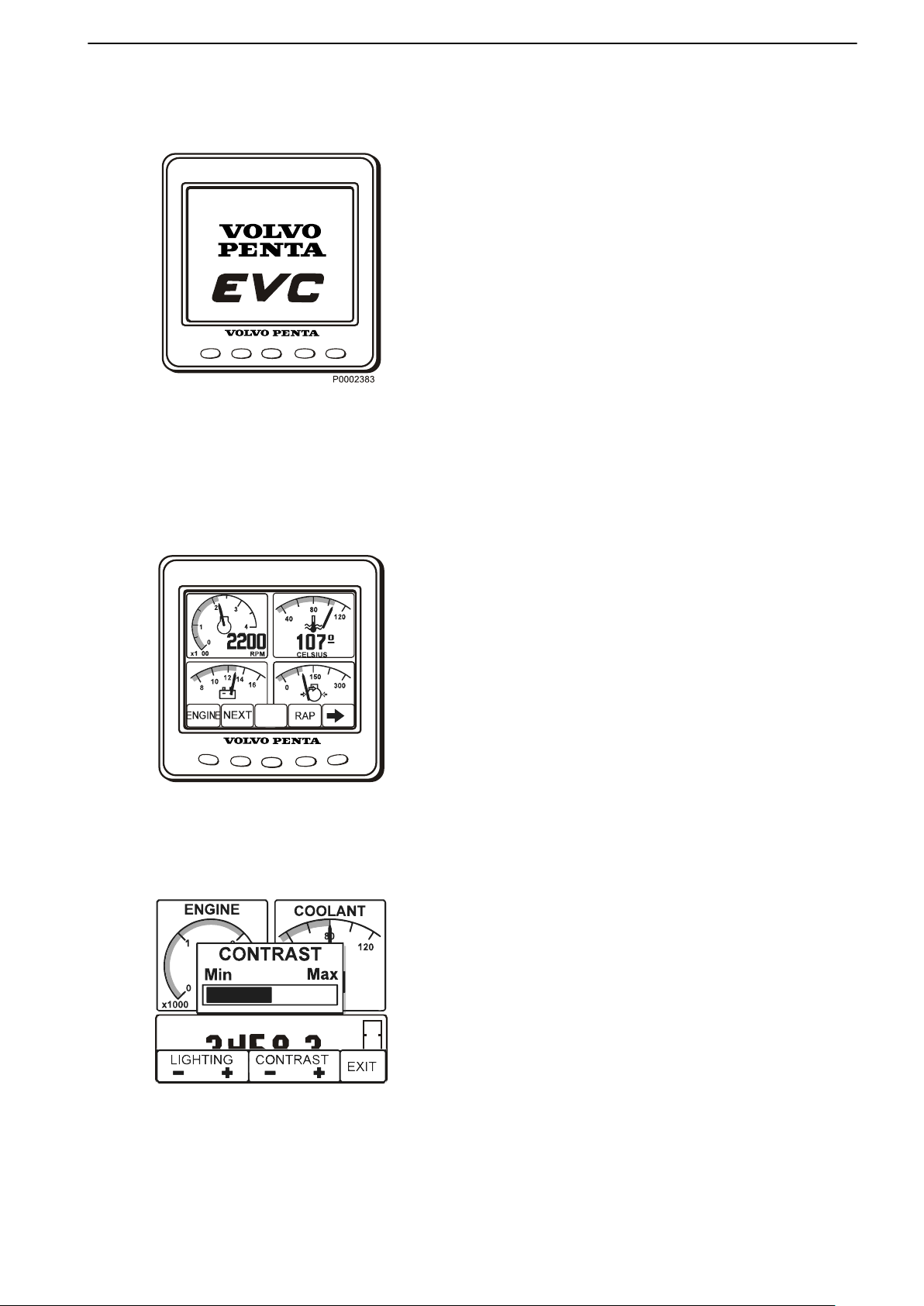

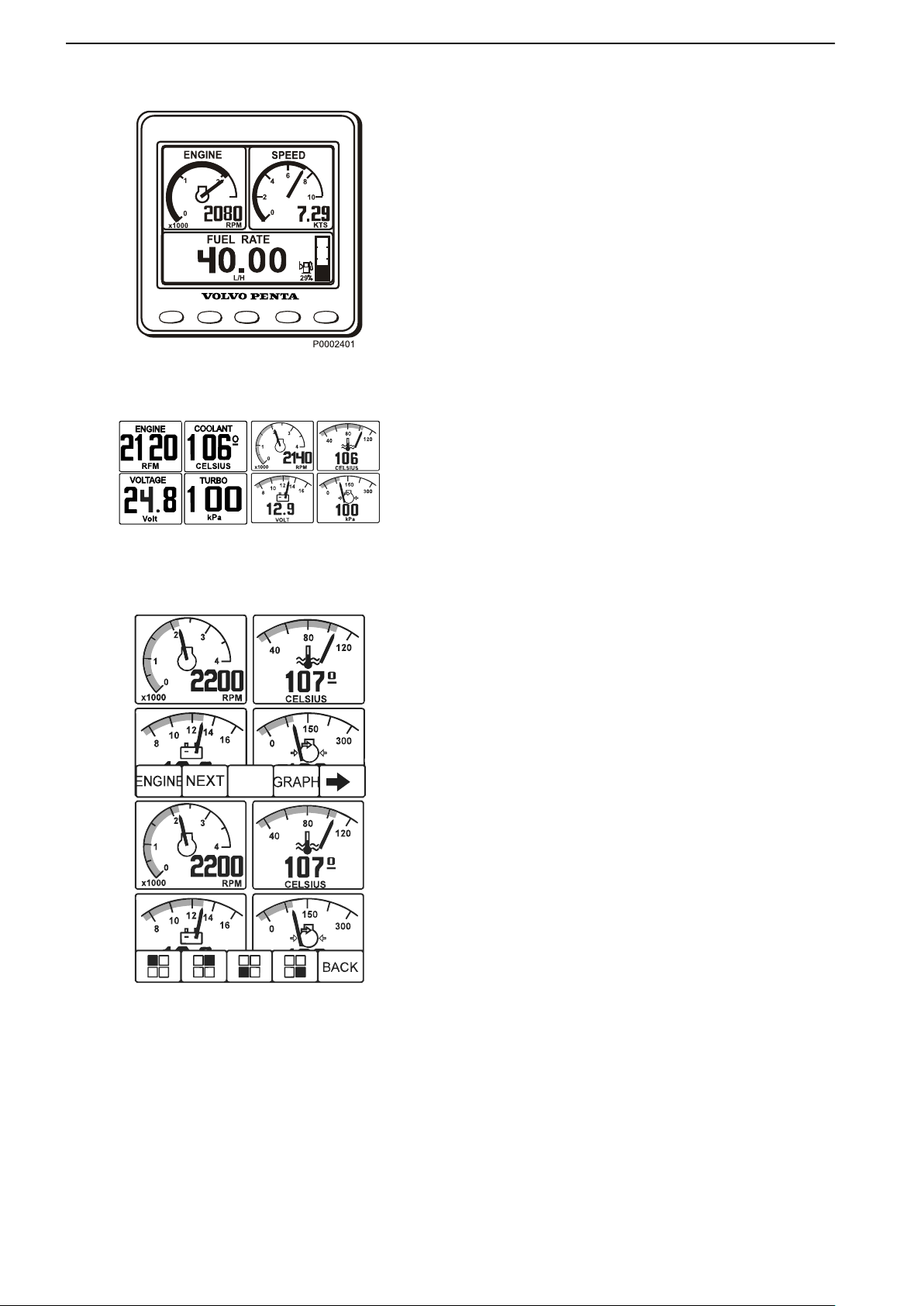

EVC system display

It is possible to present several windows with different

operational information in the EVC system display. The

various screens are selected using the instrument

buttons.

Before the display is put to use certain settings must

be entered in the configuration menu; refer to

Configuration menu.

It is also possible to bring up a menu identical to that

shown in the tachometer display by navigating to

System information in the Configuration menu, or by

depressing button 2; refer to Multi, button 2.

A self-test is performed at start; the display will emit a

constant audible signal if a fault is detected. The

display will continue to function, but may behave in

unexpected ways.

Only installed functions are shown in the display.

Screens

Depress any of the buttons 1 to 4 to bring up the

function menu for the buttons on the lower part of the

display.

Buttons 1, 2 and 4 provide different screens.

Button 1 – Engine

Button 2 – Multi

Button 4 – Graph

Use button 5 to adjust contrast and to access the

configuration menu for display settings; refer to

Configuration menu.

Exit the menu by waiting a few seconds or by

depressing button 5 (EXIT).

Contrast

The display has five contrast settings. Depress button

5 (far right) and change the contrast by depressing +

(button 4) or – (button 3).

Store the setting by depressing EXIT (button 5).

47711262 01-2019 © AB VOLVO PENTA 25

Page 28

P0007392

P0003011

Instruments and Controls

Engine, button 1

Engine revolutions and speed are shown in the upper

part of the window. Operating hours are displayed in

the lower part, along with a fuel level indicator if this

function is installed.

If speed information is lacking, coolant temperature will

be shown instead.

Multi, button 2

Operational information is displayed in four analog or

digital windows in the multi screen. The display can

either show several windows, or be divided so that the

lower part shows System information. To switch

between the different screens depress button 2

repeatedly.

If the selected information is lacking, the symbol “—”

will be displayed: for analog instruments the dial will be

absent.

Selecting screens

Depress the right arrow (button 5) to select the

information to be displayed in each respective window.

Then repeatedly depress the button that corresponds

to the window to be set until the desired information is

shown.

The type of information accessible depends on the

type of electrical system and sensors the boat is

equipped with.

26 47711262 01-2019 © AB VOLVO PENTA

Page 29

4000

2000

P0002420

Instruments and Controls

Graph, button 4

This screen displays operational information in the

form of graphs. Depress button 4 repeatedly to select

the information to be displayed. To set the time interval,

refer to Configuration menu.

If contact with the system is lost, a straight line will

proceed across the screen.

Configuration menu

Open the Configuration menu by holding down button

5 for at least 3 seconds. In this screen it is possible to

retrieve System information, enter various display

settings, calibrate depth compensation and speed and

retrieve other system information.

Engine ignition must be switched on when changing

display settings or calibrating functions.

Navigate through the menu using the up and down

arrows, and select using the right arrow.

System Information

This screen shows the same information as that shown

in the tachometer display; refer to Instruments and

Controls, page 23 for further information.

Alarm

When the system detects a fault, the display

automatically switches to the System Information

screen. For further information, refer to Fault

handling, page 41.

47711262 01-2019 © AB VOLVO PENTA 27

Page 30

P0003002

Instruments and Controls

Settings

Language: setting the display language.

Bleep: setting button bleep On or Off.

Engine: setting the installation the display forms part

of, and the engine to be shown in the display (single,

port, starboard or twin).

Eng. series: setting the engine series for the display

(D1/D2, <D2). The display is factory set for engines

larger than D1/D2, therefore the display must be re-set

before it can be used on D1/D2 engines.

Display: setting speed indicator and tachometer

intervals.

- Rpm intervals, 2500–9000 rpm in 500 rpm stages.

Set 4000 rpm.

- Speed, on/off.

- Speed intervals, 10–100 knots in 10 knot stages.

- Graph intervals: 2 min, 10 min, 30 min, 60 min, 2 h,

4 h or 8 h.

- Speed (Speed): KNOTS, MPH, KM/H

Units: Selection of operational information units to be

shown (this menu is only displayed if “Local” is selected

in the settings menu: “Local” must always be selected

for D1/D2 engines).

- Distance: NM, MILE, KM

- Oil pressure/Turbo pressure: kPa, psi

- Fuel rate: L/H, GAL/H, IGAL/H

- Temperature: °C, °F

Calibration: the engine must be switched on during

calibration.

Depth compensation

Setting the Volvo Penta echo sounder. The echosounder can be installed anywhere between the

waterline and the boat's deepest point. Set the

deviation – off set – so that the display value shows

one of these points.

To adjust the value up (+), set the distance between

the echo-sounder and the waterline; to adjust the value

down (–), set the distance between the echo-sounder

and the boat's deepest point. The value can be set in

0.1 unit stages.

Store the set value by depressing BACK (button 5).

28 47711262 01-2019 © AB VOLVO PENTA

Page 31

P0003005

Instruments and Controls

Speed factor

The speed factor must be set while the boat is under

way. Compare the displayed boat speed value with

GPS data (or another boat) and adjust the speed factor

until the values agree.

The speed sensor calibration value can be adjusted

upwards (+) or downwards (-) in stages of 0.01 units

(+ or - 1%). Store the adjusted value by depressing

BACK (button 5).

47711262 01-2019 © AB VOLVO PENTA 29

Page 32

N

F

R

T

T

1

P0002427

Instruments and Controls

Controls

This section describes the controls Volvo Penta sells

for your engine. Contact your dealer if your boat is

equipped with controls other than those described

here, and you feel uncertain about their function.

Maneuvering

A single-lever control operates both gearshift and

throttle functions from the same lever.

The engine can only be started with the control lever

in the neutral position.

N = Neutral position. Reverse gear/drive

disengaged and engine at idle.

F = Reverse gear/drive engaged for movement

ahead.

R = Reverse gear/drive engaged for movement

astern.

T = Engine rpm control (throttle).

Disconnecting the gearshift function

The gearshift function can be disconnected so that the

control lever only operates the throttle.

1 Put the control lever in neutral (N).

2 Depress the neutral button (1), and keep it

depressed at the same time as the lever is

moved forward.

3 Release the neutral button, the shift function is

disengaged and the lever only influences engine

revolutions.

The gear shift function is reconnected automatically

when the lever is returned to the neutral position.

CAUTION!

Take care not to engage the gear by mistake.

30 47711262 01-2019 © AB VOLVO PENTA

Page 33

Instruments and Controls

Adjusting the friction brake

The lever is fitted with a friction brake to allow

adjustment for easier or stiffer movement as required.

The friction brake only affects movement of the throttle

control lever.

1 Lift away the cover from the control. On side-

mounted controls the lever must be removed first.

2 Move the lever to the half throttle/astern position.

3 Adjust the friction brake by turning the screw

clockwise (+) for stiffer lever movement, and

counterclockwise (-) for easier movement.

4 Replace the cover and the lever.

47711262 01-2019 © AB VOLVO PENTA 31

Page 34

Starting

Make a habit of visually checking the engine, engine bay and transmission before start. This will help you to

discover quickly if anything abnormal has occurred, or is about to occur. Also check that instruments and warning

displays show normal values when you have started the engine.

To minimize cold start smoke we recommend you install an engine heater or engine bay heater if temperatures

below +5°C (41°F) are encountered.

WARNING!

Never use start spray or similar agents to start an engine. This may cause an explosion in the inlet manifold. Risk

of personal injury.

Before Starting

Check the engine and transmission oil levels.

•

Check coolant level.

•

Open the sea cock.

•

Open the fuel cock.

•

Turn the main switch(es) on.

•

IMPORTANT:

Never disconnect the current using the main

switches when the engine is running or by

disconnecting the battery cables.

The alternator and electronics could be damaged.

Start the engine bay fan, where fitted, and allow it to

•

run for at least four minutes.

Check that there is sufficient fuel for the planned trip.

•

32 47711262 01-2019 © AB VOLVO PENTA

Page 35

!

!

+

-

0

3

2

1

4

RPMX1000

P0008437

Starting

Starting the Engine

Activate the control panel by depressing the on/off

button (1). The Volvo Penta logo is displayed in the

window. Two audible signals are sounded to indicate

the system is ready and that the engine may be started.

Check the tachometer

If an operational fault occurs an audible alarm will

sound and a symbol will flash in the tachometer

window. Refer to theFault handling, page 41 chapter

for more detailed information and recommended

actions.

Check the alarm instrument (accessory).

The lamps in the alarm instrument light up each time the

ignition is turned on. Check that all lamps light up and

then extinguish. If any lamp flashes, a fault has been

registered; refer to the Fault handling, page 41 chapter

for more detailed information and recommended

actions.

Start the engine

Press the start button (4). Release the start button as

soon as the engine starts.

The pre-heating symbol is displayed in the tachometer

window. Pre-heating is automatic and lasts for 20

seconds.

Pre-heating only takes place if engine temperature is

below 50° (122° F).

Pre-heating may be activated before the engine is

started by depressing the start button (4) for a short

moment. Pre-heating will continue for 20 seconds. The

pre-heating symbol is displayed in the tachometer

window.

47711262 01-2019 © AB VOLVO PENTA 33

Page 36

Starting

Overheating Protection

If the starter motor is engaged for its maximum

activation time (30 seconds), the starter motor circuit

is cut automatically to protect the starter motor from

overheating. If possible, leave the starter motor to cool

for at least five minutes before making a new start

attempt.

Read off the instruments and warm up the

engine

Allow the engine to idle for the first 10 seconds. Read

off the instruments and check that they show normal

values. Check that no warning lamps are flashing. If

any lamp flashes, a fault has been registered; refer to

the Fault handling, page 41 chapter for more detailed

information and recommended actions.

Warm up the engine at low speed and low load, so that

normal working temperature is reached before full

power is applied.

34 47711262 01-2019 © AB VOLVO PENTA

Page 37

Operation

Learn to handle the engine, controls and other equipment in a safe and proper manner before casting off on your

maiden voyage. Remember to avoid sudden and extreme rudder maneuvers and gear shifts. There is a risk for

passengers and crew falling over or falling overboard.

WARNING!

A rotating propeller can cause serious injury. Check that nobody is in the water before engaging ahead or astern.

Never drive near bathers or in areas where people could be in the water.

Reading the Instruments

Read off the instruments and alarm display

immediately after start, and then regularly during

operation.

Alarms

If an alarm is tripped, an audible alarm will sound and

a symbol will flash in the tachometer window (1).

If optional equipment such as alarm instruments or an

EVC display are installed, the relevant warning lamp

will flash there also.

1 Reduce engine speed to idle.

2 Cancel the alarm by depressing the multi-function

button (2).

The audible alarm will be silenced. The symbol will

be lit continuously until the fault is remedied

3 Take the necessary action: refer to the Fault

handling, page 41 section.

47711262 01-2019 © AB VOLVO PENTA 35

Page 38

1

2

3

P0005856

Operation

Maneuvering

Shifting between ahead and astern must be done at

idle revolutions. Shifting at higher revolutions can be

uncomfortable for those on board and cause

unnecessary stress to the transmission or make the

engine stall.

Always shift between ahead and astern in

the following manner:

1 Reduce engine revolutions to idle and allow the

boat to lose most of its speed.

2 Move the control lever to the neutral position with

a quick, firm movement. Pause a moment.

3 Move the control lever back with a quick, firm

movement and increase revolutions.

36 47711262 01-2019 © AB VOLVO PENTA

Page 39

Operation

Sailing

When sailing, set the control lever to astern if a folding

propeller is fitted.

If a fixed propeller is fitted the control lever should be

set to neutral or reverse. When using a fixed propeller

and sailing with the control lever set to reverse the

speed is slowed down though less noise is being

made.

IMPORTANT:

If a fixed propeller is fitted the engine needs to be

started and kept running for five minutes every fourth

hour of sailing to avoid problems with the transmission

system. The control lever must be set to neutral during

the whole procedure.

Cruising Speed

Avoid operations at full throttle for best fuel economy.

We recommend a cruising speed that is around

500-1000 rpm below the maximum rpm at top speed

(full throttle).

Depending on the type of hull, choice of propeller, load

and sea state etc., maximum revolutions at top speed

may vary, but should be within the full throttle range;

refer to the Engines section.

47711262 01-2019 © AB VOLVO PENTA 37

Page 40

Engine Shutdown

Allow the engine to run at low idle, in neutral, for a few minutes after operations are completed. In this way afterboiling is avoided at the same time as temperature equalization takes place. This is especially important when

the engine has been run under heavy load at high rpm .

Stop the Engine

Press the Stop button (3) until the engine stops

running.

Press the On/Off button (1) to cut the power to the

system.

If the engine is stopped and the ignition still turned on,

an alarm sounds after 10 seconds to prevent the

ignition is left on unintentionally and the battery will

become discharged.

Silence the alarm by turning the ignition off, or reset

the alarm with the multifunction button (2) if the ignition

is to be turned on.

Auxiliary stop

If the engine cannot be stopped in a normal procedure,

it is possible to stop the engine via the auxiliary stop

(A) mounted on the side of the engine.

38 47711262 01-2019 © AB VOLVO PENTA

Page 41

Engine Shutdown

After Engine Shutdown

Check the engine and engine bay for leakages.

•

Close the fuel tap.

•

Close the sea cock where fitted.

•

Take an hour meter reading and carry out

•

preventive maintenance according to the

maintenance schedule.

Boats with stern drives: Trim the stern drive down to

•

maximum to protect the trim ram piston's untreated

surfaces from fouling.

If there is a risk of the boat striking bottom with the

stern drive, the drive must instead be trimmed up to

the maximum lift position.

Turn off the main switch before any long stoppage.

•

NOTICE! Depending on the model and setup, there

could be more than one switch.

NOTICE! Do not turn off the main switch within 30

seconds after turning off the ignition. This in order to

save engine data to the engine control unit.

47711262 01-2019 © AB VOLVO PENTA 39

Page 42

Engine Shutdown

Operation break with the boat in water

If the boat is not used, but left in the water, the engine

must be warmed up at least once every fortnight. This

prevents corrosion damage in the engine.

If you expect the boat to be unused for two months or

more, it must be inhibited, please refer to

Storage, page 75

Operation break with the boat out of water

Where boats are kept laid up on land when not in use,

there is a lower level of galvanic corrosion protection

due to oxidation on the sacrificial anodes. Before

launching the boat the sacrificial anodes on the drive

and shield must be cleaned with emery paper to

remove any oxidation.

If you expect the boat to be unused for two months or

more, it must be inhibited, please refer to

Storage, page 75.

IMPORTANT:

Use emery paper. Do not use a wire brush or other

steel tools when cleaning, as these may damage the

galvanic protection.

Cold Weather Precautions

If the engine bay cannot be kept frost free, the sea

water system must be drained and the freshwater

system coolant must have sufficient freeze protection

to prevent freeze bursting; refer to

Maintenance, page 58 and Seawater System,

Draining, page 61 respectively for more detailed

information.

Check the charge status of the battery. A poorlycharged battery can freeze and burst.

40 47711262 01-2019 © AB VOLVO PENTA

Page 43

Fault handling

0

3

2

1

4

RPMX1000

SYSTEM INFORMATION

1

ON/Off START

ALARM/DIM STOP

2

P0016957

Despite regular maintenance according to the maintenance schedule and perfect operation conditions, faults that

need to be attended to during travel, may occur. This chapter describes some possible alarms and fault handling.

Note that the content of this chapter does not provide full coverage of the possible fault messages and alarms.

Contact a Volvo Penta workshop for assistance with diagnostic readouts and unresolved faults.

If an operational fault arises an audible alarm will

sound and a symbol will flash in the tachometer

window(1) If optional equipment such as an alarm

monitor or an EVC display are installed, the relevant

warning lamp will flash there also.

Cancel the alarm by depressing the multi-function

button (2). The audible alarm will be silenced. The

symbol will be lit continuously until the fault is

remedied.

This chapter describes faults and actions to be taken.

CAUTION!

Read the safety precautions for maintenance and

service in the Maintenance Safety Information

chapter before starting work.

47711262 01-2019 © AB VOLVO PENTA 41

Page 44

Fault handling

Coolant Temperature

The coolant temperature lamp is lit if the coolant

temperature is too high.

IMPORTANT:

Continued operations with too-high engine

temperature can cause serious engine damage.

• Check coolant level. Refer toCoolant Level,

Checking and Topping Up, page 59.

• Check that the raw water filter, where such is

fitted, is not clogged. Refer to Seawater Filter,

Check and Cleaning, page 64.

• Check the impeller in the sea water pump. Refer

toImpeller, Check and Change, page 62.

If the alarm continues despite the above actions being

carried out, run the engine at low revolutions and drive

the boat to the nearest service workshop for repair.

Oil pressure

If the oil pressure lamp lights up during operations, the

engine oil pressure is too low.

IMPORTANT:

Continued operations with too-low oil pressure

causes serious engine damage.

• Checking Engine Oil Level, refer to Oil level,

checking and topping up, page 55.

• Check that the oil filter is not blocked. Change

the oil filter as necessary; refer to Engine oil and

engine oil filter, changing.

• Contact a Volvo Penta workshop if the fault

remains.

Battery

The charging lamp lights up when the alternator stops

charging the batteries, which may result from a fault

in the electrical system or the need to tension the

alternator drive belt.

• Check belt tension. Refer to Drive belt, check

and change, page 53.

• Check to see if there are no short circuit, chafed

wires or wires with loose connections.

• Check the fluid level in the battery; refer to

Battery, page 66.

• Contact a Volvo Penta workshop if the fault

remains.

42 47711262 01-2019 © AB VOLVO PENTA

Page 45

Fault handling

System failure

The "system fault" symbol is displayed when there is

a short circuit or cable break.

The symbol shows if the ignition is left on, refer to

Engine Shutdown, page 38.

• Check to see if there are any chafed wires or

wires with loose connections.

• Contact a Volvo Penta workshop if the fault

remains.

Fuel Level

The fuel level symbol is displayed when less than 20%

fuel remains in the tank if a fuel level sensor is

installed (optional equipment).

Auxiliary alarm

Alarm for auxiliary sensors (optional equipment).

Alarm handling display (optional

instrument)

1 The fuel level symbol lights up during operation

when less than 20% fuel remains in the tank if a

fuel level sensor is installed (optional

equipment).

2 The battery lamp lights up if the alternator is not

charging.

3 The coolant temperature lamp lights up when

the coolant temperature is too high.

4 This indicator is not activated for the engine.

5 This indicator is not activated for the engine.

6 The "System Failure lamp" will light up at short

circuit, broken wire and AUX failure.

7 If the oil pressure lamp lights up during

operation, the oil pressure in the engine is too

low.

47711262 01-2019 © AB VOLVO PENTA 43

Page 46

Fault handling

Fault Tracing

A number of symptoms and possible causes of engine malfunctions are described in the table below. Always

contact your Volvo Penta dealer if any problems occur which you cannot solve by yourself.

NOTICE! Read the safety regulations for care and maintenance in the Safety precautions for maintenance and

service operations chapter before work you start work.

Symptoms and possible causes

Start motor will not turn, or turns slowly 1, 2, 26

Engine does not start 3, 4, 5, 6, 7, 8, 27

Engine starts but stops again 5, 6, 7, 8

Engine is difficult to start 5, 6, 7, 8

Engine does not reach correct operating speed at full throttle 6, 7, 8, 9, 10, 11, 12, 17

Engine knocks 13

Engine runs roughly 5, 6, 7, 8, 12, 13

Engine vibrates 17, 18

High fuel consumption 9, 10, 12, 14, 17

Black exhaust smoke 4, 12, 14, 17

Blue or white exhaust smoke 14, 24

Lubrication oil pressure too low 15, 16

Coolant temperature too high 19, 20, 21, 22, 23

No charge, or poor charge 1, 25

1. Flat battery

2. Poor contact/open circuit in cables

3. The stop lever is pulled out

4. Insufficient preheat

5. Lack of fuel

6. Blocked air filter

7. Air in the fuel system

8. Water/contamination in fuel

9. Boat abnormally loaded

10. Fouling on hull, drive or propeller

11. Limited movement in engine control lever

12. Insufficient air supply to engine

13. Coolant temperature too high

14. Coolant temperature too low

15. Oil level too low

16. Blocked oil filter

17. Faulty / wrong propeller

18. Faulty engine mounting

19. Coolant level too low

20. Blocked raw water inlet, lines or filters

21. Circulation pump drive belt slipping

22. Faulty impeller

23. Faulty / wrong thermostat

24. Oil level too high

25. Alternator drive belt slipping

26. Time limit for cranking the starter motor

27. Stop solenoid has stuck

44 47711262 01-2019 © AB VOLVO PENTA

Page 47

In Case of Emergency

Despite regular service in accordance with the planned

maintenance schedule and perfect operating

conditions, faults may occur that must be remedied

before the boat can continue its trip. This chapter

provides advice on how to remedy a number of

conceivable faults.

If a fault occurs, confirm any fault alarm and take the

necessary actions. See this chapter and refer to the

Fault handling, page 41 chapter.

Starting Using Auxiliary

Batteries

WARNING!

Explosion hazard. Batteries contain and give off an

explosive gas which is highly flammable and

explosive. A short circuit, open flame or spark could

cause a violent explosion. Ventilate well.

WARNING!

Never confuse the positive and negative poles on the

batteries. Risk of arcing and explosion.

1 Check that the auxiliary battery has the same

voltage as the engine system voltage.

2 Connect the red positive cable to the plus (+)

terminal on the discharged battery and then to

the plus terminal on the auxiliary battery.

3 Connect the black start cable to the minus (–)

terminal on the auxiliary battery and to a place

a little distance away from the discharged

battery, e.g. the start motor's negative terminal.

WARNING!

The black jumper cable (–) must never come in

contact with the positive connection on the starter

motor.

4 Start the engine and let it run at fast idle for

approximately 10 minutes to charge the

batteries. Make sure there is no extra equipment

connected to the electrical system.

WARNING!

Working with or approaching a running engine is a

safety risk. Watch out for rotating components and

hot surfaces.

WARNING!

Do not touch the connections during the start

attempt: Risk of arcing.

Do not bend over any of the batteries either.

5 Turn off the engine. Remove the start cables in

the exact opposite order to their connection.

47711262 01-2019 © AB VOLVO PENTA 45

Page 48

Maintenance Schedule

Your Volvo Penta engine and its equipment are designed for high reliability and long life. The engines are built to

have the smallest possible environmental impact. If preventive maintenance is carried out, according to the

maintenance schedule, these qualities will be retained and unnecessary malfunctions will be avoided. It is the

owner's responsibility to make sure that the services in the service intervals are performed in order for the warranty

to be valid.

NOTICE! For emission related warranty rights see Emission Control System Warranty Statement.

Service Intervals

Service intervals are shown below. The service content can be found in the Service Protocol available for

download at www.volvopenta.com.

The Operator’s Manual shows a selection of service points and how these should be carried out; also included

are points that must be checked/implemented between regular scheduled services or points that the user/owner

should be able to perform for reasons of safety in the event that anything unforeseeable should occur when under

way. All service and maintenance points can be found in the product’s Service and Maintenance Manual. Any

owner wishing to carry out some maintenance and service himself can purchase this manual. For products

covered by the warranty, please refer to the terms and conditions of the warranty with regard to documentation

of completed services.

Where both operational and calendar times are specified, perform the maintenance item at whichever time is the

sooner.

S1 = Special Interval Service

A - F = Type of service (regular service)

S1 Service After first 50 hours of operation.

Replace transmission oil and oil filter.

Type A Service Every 200 hours of operation. (Recommended once a year.)

Type B Service Every 400 hours of operation. (Recommended once a year.)

Type C Service Every 400 hours of operation. (Recommended every second year.)

Type D Service Every 600 hours of operation. (Recommended every fourth year.)

Type E Service Every 2000 hours of operation. (Recommended every fourth year.)

Type F Service Every seventh year.

IMPORTANT!

Make sure that the service book is stamped after each performed service.

1) Reverse gear HS25, oil filter replace.

(1)

46 47711262 01-2019 © AB VOLVO PENTA

Page 49

Maintenance

This chapter contains general technical information and instructions on how the prescribed maintenance items

must be carried out. Read through the instructions carefully before starting work. The times when maintenance