Page 1

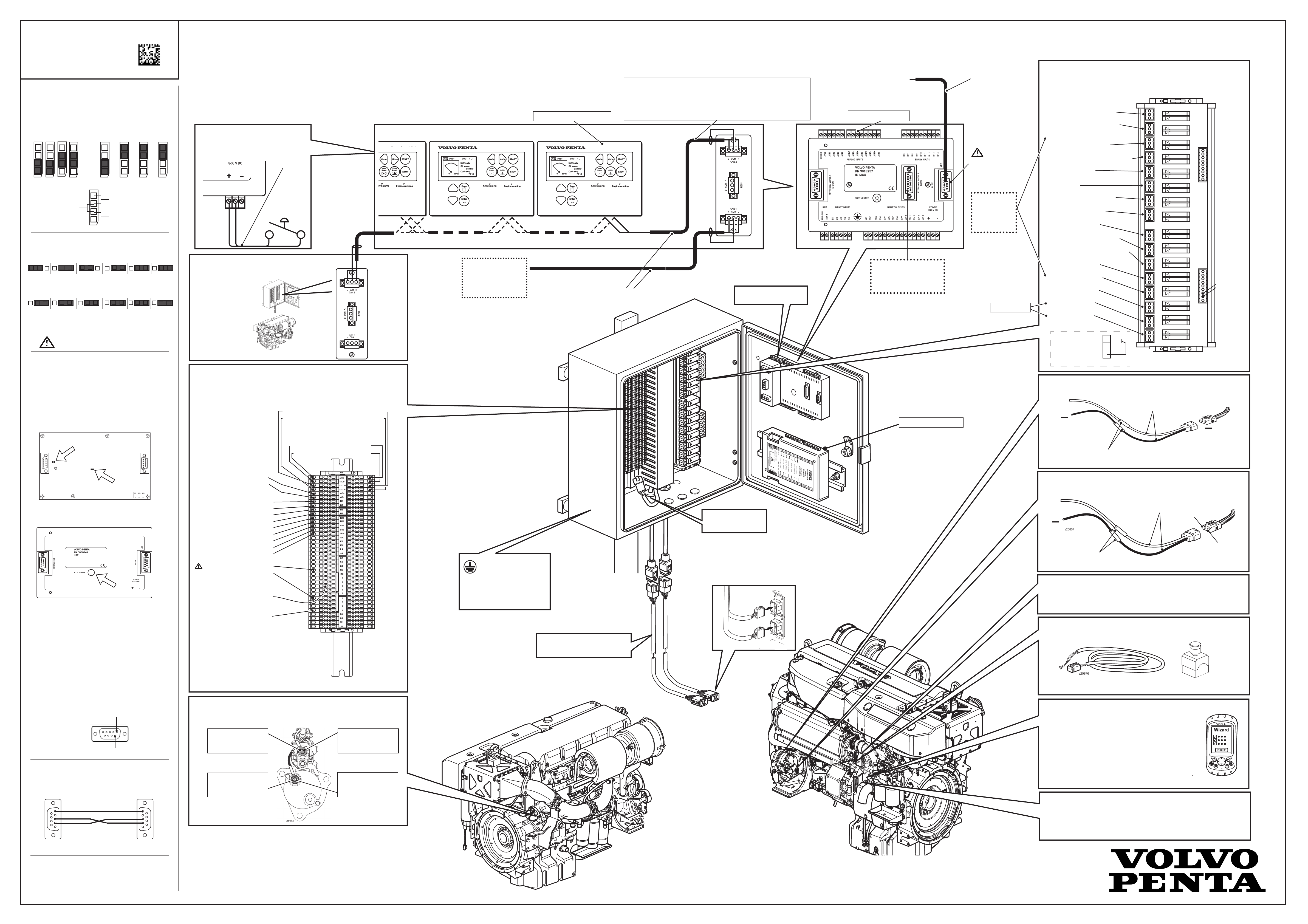

Installation Procedure: D9/D16 MH MCC

Document number: 47706462

Release date: XX-2015

Jumper settings

The jumpers factory setting show below.

If application requires additional sensors then change jumper settings.

See the Installation Manual , doc number: 47702399 (US). Contact your Volvo

Penta dealer for information in other langugages.

MCU jumper settings*

4

3

2

1

AI1 AI2 AI3 AI4 AI5 AI6 AI7 AI8

1

Installation Overview D9/D16 MH MCC

Propulsion

CAN2 speed 32C / 250kBd (< 200 meter between units) (default)

CAN2 speed 8C / 50kBd (< 900 meter between units) (slower response times)

MCC Electrical connection box

CAN2: Connect to optional Comap Internet Bridge

for remote monitoring via Internet/GSM

Switch for backlight

To use a switch to alternate between

adjusted brightness and 100% brightness

connect it as following:

Cables

Category A

BL

Remote Panel

Remote Panel jumper settings*

3

Remote PanelRemote Panel

Connect to PC Tool DriveCong*

Connect to external MODBUS system

Switch between PC tool and MODBUS via MCU menu.

Communication is connected here.

Standard RS232 max length 10 m.

Use a RS232 to RS485/422 converter to extend

length to 200 or 900 (set in MCU menu)

MCU jumper settings*

1

4

Cables

Category E

MODBUS connection!

Do not use 9 to 9 pin

cable. Only connect

pin 2,3, and 5.

Relay connetion (24 V Only)

Use cables Category A to all relay contact connections

Customize outputs to installation demands via tools and descriptions found on VPPN in MCC portal.

X1 Override indication

X2 Local mode indication

X3 Spare

Set in DriveCong

X4 EMS communication failure

X5 Start failure

X6 Horn

Resistance

Voltage

measurement

SDU jumper factory settings*

measurement

Current

measurement

2

AUX and combined AUX/EME is set:

ON OFF ON OFF ON OFF ON OFF ON OFF

S1 S2 S3 S4 S5* S6

ON OFF

EME is set:

ON OFF ON OFF ON OFF ON OFF ON OFF

S1 S2 S3 S4 S5* S6

Remote Panel Jumper settings*

ON OFF

Overspeed shutdown can not be switched o.

* Should be ON if used as emergency stop.

S5 External stop cannot be used if SD Override

is used as a function in the MCC system.

3

BL

1

BL

1

Loadsharing Operation (- Engine #2, #3...)

When using loadsharing connect the

COM module to the

remote panel in the

end of the chain.

The CAN2 bus is

terminated with the

COM module.

To enable load

sharing refer to:

Installation Manual

.

CAN H CAN L

5 9

Aux. I/O

equipment

CAN H CAN L

5 9

Cables

Category B

Congurable analog inputs:

1-4 and 6-8.

BL

Aux. I/O equipment

Comap RPU connection

(Redundant Protection Unit)

See the

InteliDrive User Guide

Output X3 - X13

can be congured. The stated

function is the

default setting.

Spare relay *

X7 Common shutdown

X8 Common alarm

X9 Derate alarm

X10 Ready to start engine

X11 Engine running indication

X12 Load sharing

X13 Clutch contact

X14 [internal use]

5

X15 Spare relay

X16 Spare relay

Relays X1 - X16

3. Normally Closed (NC)

2. Normally Open (NO)

X18

Pin 15,16

Connect to

0V if X15

and X16

shall be

activated.

Remove the cover to access termination jumper settings.

Remote panel CAN2 bus is terminated with120 Ohm resistor

inside the unit.

If one Remote Panel is used, leave the jumper closed (default).

If more than one Remote Panel is installed to each driveline,

the termination jumper need to have a removed (open) jumper

on all units except for the last one in the chain.

This last unit should have a closed jumper setting.

Termination jumper

CENTRAL UNIT

Boot jumper

The gure above shows the board with the cover removed.

RS 232

Power

Remote Panel Software update

BL

Remote Panel application software is uploaded automatically

from MCU during power up. Base software (rmware) do not

normally need to be downloaded. If future rmware updates

are required, the unit can be reprogrammed.

1. Power o the unit.

2. Remove the rubber plug and temporarily remove

the boot jumper.

3. Connect programming cable to RS232 and download rmware

(refer to VPPN MCC site for details)

4. Power o the unit.

5. Put back the boot jumper and the rubber plug.

Input Connections (24 V only)

Secondary battery backup

via Input connections

(to sec. battery) SEC. B+ (From engine)

(to sec. battery) SEC. B- (From engine)

Connecting the external stop

via input connection

(to external stop) STOP+ (From engine)

(to external stop) STOP- (From engine)

Use category A cable on all inputs

Lever Control 4-20 mA

A5+

A5-

Inputs external binary**

Shutdown Override B6

Aux Stop B7

Start blocking B8

Ackowledge B9

Backup Speed B10

Remote Start B11

Remote Stop B12

Spare B13

Spare B14

External Stop switch S5*

2

Connect to + at the 1

back of the remote panel.

Connect to - at the back of

the remote panel.

* Use 10 kOhms for broken wire

detection. The jumper for S5

needs to be set to enabled.

** Congurable input ports.

Ground should be applied by the shortest

cable possible with a

diameter of equal to or

greater than 2.5 mm

2

(13 AWG).

MCC to engine extension cable, 8 pin.

Total max. cable length 40 m (131 ft).

Connector A

Connector B

Diagnosis

(VODIA connection)

MCC connections

Connector B

Connector A

SDU jumper settings*

D9/D16: Secondary Battery (Backup)

+

24 V

2

16 A

Slow Fuse

Cables Category C

Secondary Battery

+

24 V

D16: Primary Battery (Air starter only)

+

24 V

16 A

Slow Fuse

Cables Category C

Pin 1

Use Crimp Tool

9512653 to crimp

From Engine

Pin 2

EasyLink connector

The connector is supporting engine mounted gauges

(not supplied with engine).

External stop switch (optional)

Only use normally open contact. Closed contact stops engine.

Remote Panel CAN2 Connection

The D-Sub (CENTRAL UNIT interface) uses the following pins:

CAN H - 5

CAN L - 9

Cable for DriveCong/DriveMonitor*

The Connector used for PC Tool (DriveCong/DriveMonitor )has

the following wiring:

5

3

2

4

5

3

2

PC MCU

Electrical and combined Electrical /Air starter

D16:

Connect + battery cable here.

D16:

Connect - battery cable here.

Bolt size M12. Tightening

torque 25 ± 5 Nm

D9:

Connect + battery cable here.

Bolt size M10. Tightening

torque 18 ± 2 Nm

D9:

Connect - battery cable here.

Bolt size M10. Tightening

torque 24 ± 2 Nm

Diagnose VODIA connection

Used for installation set-up and service. Commonly changed

parameters:

ISD Change EMS low voltage when running (18-25,5V)

25,5V default.

BPN Amount of droop (0,1% to 4,98%) 4% default.

Note! VODIA has software download support for EMS only.

Connector A and B (MCC connections)

Connector A: Engine interface to control and monitoring system.

CAN/J1939 communication bus.

Connector B: Shutdown system interface.

Spare Relay*

Relays marked with “Spare Relay” are allowed to use as desired.

Activate by 0V. Note that it may require special settings to make

them operational.

5

Page 2

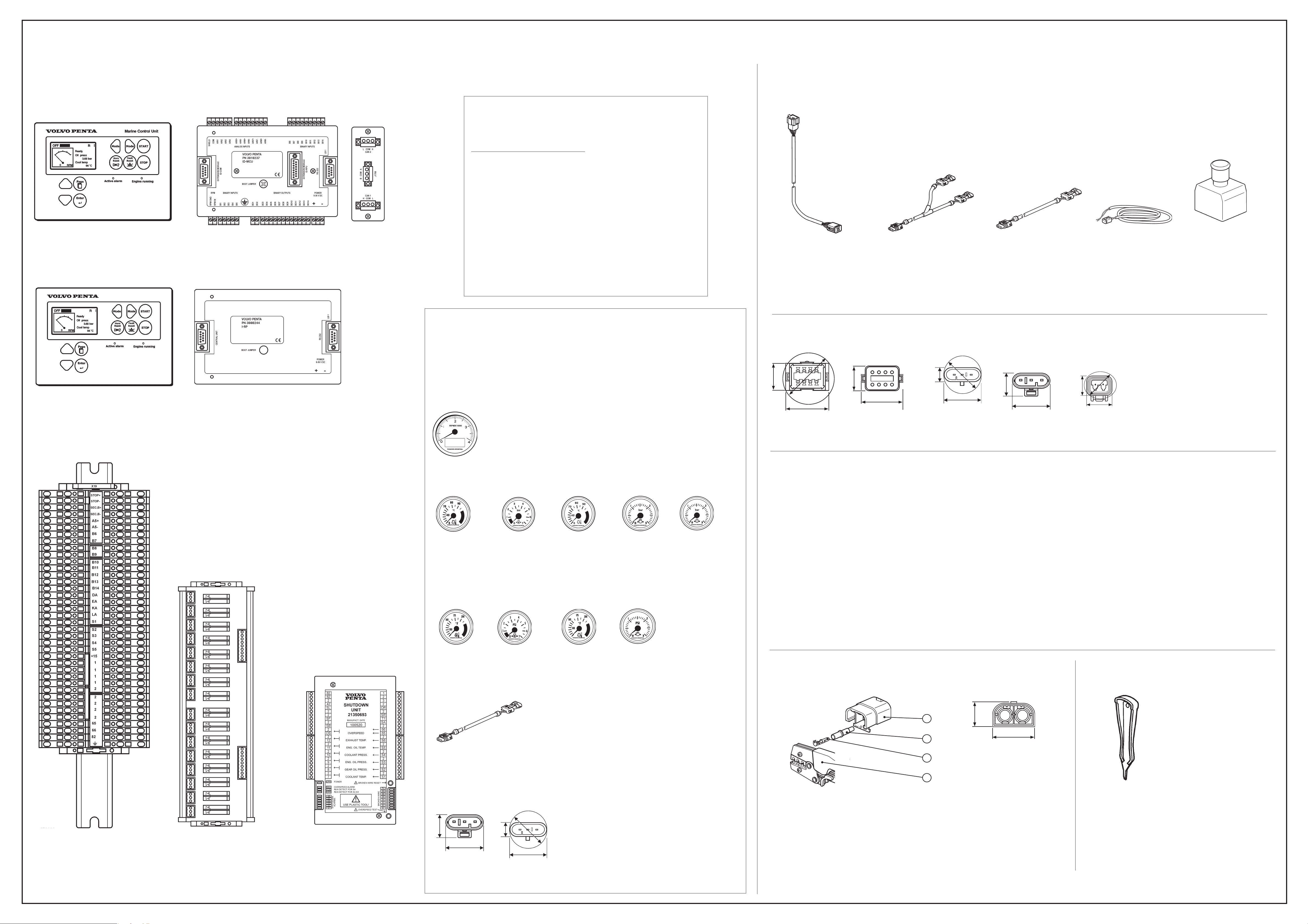

Components and Cables

Components

Cables

MCU / Remote Panel Engine Data

PRP

MCU Marine Control Unit

Part no.

3818237

Front View

Remote Panel

BL

Rear View

ID-COM

Part no.

3818364

Indicator Propulsion

Engine Speed X

Load X

Fuel Rate X

Actual Torque X

Demand Torque X

Throttle pos X

Oil Press X

Oil Temp X

Coolant Press X

Coolant Temp X

SeaWaterPres* X

Exhaust Temp X

ChrgAirPress X

ChrgAirTemp X

Fuel Press X

CrankcasPres X

*Depends on cooling system.

MCC to engine extension cable, 8-pin

Feet Meter Part no.

9.8 3 874414

16.4 5 874119

22.9 7 874386

29.5 9 874387

36.1 11 874388

Water in fuel Y-Split cable harness, 3-pin

Part no. 21495971

Water in fuel cable harness,

3-pin

Feet Meter Part no.

9.8 3 21415866

16.4 5 21415883

External stop switch cable,

2-pin

Feet Meter Part no.

32.8 10 3840677

External Stop Switch

Part no.

3589458

NO/NC contacts

Cable not included. Use External

Stop Switch Cable Part no. 3840677

Remote Panel

Part no.

3888244

PRP

Front View

BL

Rear View

Optional Engine Instruments (Easy Link)

Box

Part no. 3837995

Tachometer (rpm, h)

Engine speed and hours

Instruments

Use with Attachment ring: Part no. 874450. Hole diam. 52 mm (2.04”)

For installation of tachometer and max. three other instruments, see below.

H = 222 mm (8.74”)

W= 146 mm (5.78”)

D = 100 mm (3.93”)

Part Part no.

Tachometer 874903

Attachment ring 874449 Hole 85 mm (3.35”)

Front ring 874447

Connector dimensions

D

H

W

8-pin male

H = 20 mm (0.78”)

W = 37 mm (1.45”)

D = 43 mm (1.69”)

Category A

Crosscut area minimum 1,5 mm2 (16 AWG) type approved low voltage (30 V or more) ship cable, Max 50 meters (164 ft)

H

W

8-pin female

H = 20 mm (0.78”)

W = 37 mm (1.45”)

Terminal block / relay connections

H

3-pin male

H = 18 mm (0.71”)

W = 26 mm (1.02”)

D = 26 mm (1.02”)

D

H

W

W

3-pin female

H = 20 mm (0.79”)

W = 25 mm (0.98”)

D

H

W

2-pin plug

H = 11 mm (0.43”)

W = 16 mm (0.63”)

D = 18 mm (0.71”)

Oil temp (C°)

Color Part no.

Black 874905

White 874922

Oil pressure (Bar)

Color Part no.

Black 874908

White 874923

Coolant temp (C°)

Color Part no.

Black 874904

White 874921

Instruments US setup

Use with Attachment ring: Part no. 874450. Hole diam. 52 mm (2.04”)

Oil temp (F°)

Color Part no.

Black 881857

White 881858

Oil pressure (psi)

Color Part no.

Black 874919

White 874932

Coolant temp (F°)

Color Part no.

Black 874918

White 874931

Turbo pressure (Bar)

Color Part no.

Black 874910

White 874924

Turbo pressure (psi)

Color Part no.

Black 874920

White 874933

Coolant pressure (Bar)

Color Part no.

Black 874911

Category B

Crosscut area min. 0,25 mm2 (23 AWG) 120 Ohm nominal impedance, Maximal attenuation (at 1 MHz) 2 dB / 100 m (328 ft), Max 900 meters (2953 ft) Nominal Velocity of Propagation min. 75% (max. 4,4 ns/m)

Category C

Crosscut area 2,5 mm2 (13 AWG) type approved low voltage (30 V or more) ship cable, Max 30 meters (98 ft)

Category D

Refer to Installation manual D5-D16 Publ. no: 47704151 for dimensions.

Category E

RS232: Use signal cable with 2-3, 3-2, 5-5 cable (max. 10 meter / 32.8 ft). Note! MODBUS failures will occur if 9 to 9 pin cable is used.

RS485/422: Less than 40 meters (131 ft): Crosscut min. 0,75 mm2, (18 AWG) 120 Ohm impedance, Max. attenuation (at 1 MHz) 1,7 dB / 100 m (328 ft)

RS485/422: Longer than 40 meters (131 ft): Drain wired, crosscut min. 0,75 mm2 (18 AWG) 120 Ohm impedance, Max. attenuation (at 1 MHz) 1,7 dB / 100 m (328 ft)

Secondary Battery (backup) Connection (D9/D16) and

CAN communication. Shielded, pairtwisted

Secondary Battery

Battery cables

RS232 / MODBUS. Shielded, pairtwisted

Input Connection Tool

Primary battery Connection (D16 only)

Input Connection

Part no.

21350704

Relay Connection

Part no.

3818362

SDU - Shutdown Unit

Part no.

21350693

Spare part no.

(includes reference to calibration document)

3819845

Cables

EasyLink ,

3-pin

Feet Meter Part no.

3.3 1 874759

9.8 3 3807043

Connector dimensions

D

H

W

3-pin female

H = 20 mm (0.79”)

W = 25 mm (0.98”)

H

W

3-pin male

H = 18 mm (0.71”)

W = 26 mm (1.02”)

D = 26 mm (1.02”)

1

2

3

4

Crimping parts

Part Part no.

1. Housing* 1307049

2. Isolator* 1608765

3. Pin* 969832 (2,5 mm2 /13 AWG) Max. insulation diam. 3,1 mm (included in engine harness)

Pin 948291 (2,5 mm2 /13 AWG) Max. insulation diam. 4,5 mm (not included)

4. Crimping tool 951 2653

* Included in engine delivery.

Note!

Remove the blind plugs before crimping.

H

W

2-pin

H = 15 mm (0.59”)

W = 24 mm (0.94”)

Tool

Part

Tool Included in Steel box MCC

47705609 03-2014

Loading...

Loading...