Page 1

OPERATOR’S MANUAL

D11

Page 2

An English version of this Operator’s Manual may

be ordered free of charge up to 12 months after delivery, via

internet, mail or fax. Refer to the order form in the back of

the book.

All information is stored internally at AB Volvo Penta and will

not be passed on to third parties.

Diese deutsche Version dieses Handbuches kann

innerhalb von 12 Montane ab Lieferung kostenlos online,

per Brief oder per Fax bestellt werden. Bitte Bestellformular

hinten im Buch verwenden.

Alle Angaben werden bei AB Volvo Penta gespeichert und

nicht Dritten übermittelt.

Une version française de ce manuel d’instructions

peut être commandée gratuitement, jusqu’à 12 mois après

la date de livraison, via Internet, la poste ou par fax. Voir à

la n de ce document.

Toutes les informations sont stockées en interne chez AB

Volvo Penta et ne sont divulguées à aucun tiers.

Hay disponible una versión en español gratuita de

este manual de instrucciones, la cual puede pedirse, a través de Internet, correo postal o fax, en el plazo de 12 meses

después de la entrega del producto. Véase el formulario de

pedido en las últimas páginas del manual.

Todos los datos recibidos son almacenados de forma in-

En svensk version av denna instruktionsbok kan

beställas kostnadsfritt, upp till 12 månader efter leverans,

via internet, post eller fax. Se beställningsformulär i slutet av

boken.

Alla uppgifter lagras internt hos AB Volvo Penta och lämnas

inte ut till tredje part.

Een Nederlandse versie van dit instructieboek kan

kosteloos worden besteld tot 12 maanden na aevering, internet, post of fax. Zie het bestelformulier achterin het boek.

Alle gegevens worden intern opgeslagen bij AB Volvo Penta

en niet verstrekt aan derden.

En dansk version af denne instruktionsbog kan

bestilles gratis, op til 12 måneder efter levering, via internet,

post eller telefax. Se bestillingsformular i slutningen af bogen.

Alle oplysninger gemmes internt hos AB Volvo Penta og

overgives ikke til tredje part.

Tämän ohjekirjan suomenkielisen version voi tilata

veloituksetta 12 kuukauden sisällä toimituksesta internetistä,

postin kautta tai faksilla. Katso tilauslomake kirjan lopusta.

AB Volvo Penta tallentaa kaikki tiedot sisäisesti eikä niitä

luovuteta kolmannelle osapuolelle.

Pode-se encomendar uma versão gratuita deste

manual de instruções em português, até 12 meses após a

entrega, através de Internet, correio ou fax. Consultar o for-

mulário de encomenda no m do manual.

Todas as informações são armazenadas internamente pela

Volvo Penta e não são partilhadas com terceiros.

Εντός 12 μηνών από την παράδοση μπορείτε να

παραγγείλετε μέσω Internet, ταχυδρομικής επιστολής ή φαξ

μια ελληνική έκδοση του Βιβλίου χρήσης χωρίς χρέωση.

Χρησιμοποιήστε το δελτίο παραγγελίας στο τέλος του

βιβλίου.

Όλες οι πληροφορίες αποθηκεύονται από την AB Volvo Pen-

Вариант настоящего руководства по

эксплуатации на русском языке можно заказать

бесплатно в течение 12 месяцев после доставки по

Интернету, электронной почте или по факсу. См. бланк

заказа на обложке руководства.

Вся информация используется компанией AB Volvo Penta конфиденциально и не передается третьим сторонам.

Bu Kullanım Kılavuzunun Türkçe versiyonu teslim-

den 12 ay sonrasına kadar internet, posta veya faks yoluya

sipariş edilebilir. Kitabın arka kısmında bulunan sipariş formuna bakınız.

Tüm bilgiler AB Volvo Penta’da saklıdır ve üçüncü kişilere

verilmez.

Una versione in lingua italiana di questo manuale di

istruzioni può essere ordinata gratuitamente, no a 12 mesi

dopo la consegna, via internet, per posta o via fax. Vedere il

modulo per l’ordinazione alla ne del manuale.

Tutti i dati forniti saranno memorizzati internamente presso

AB Volvo Penta e non saranno divulgati a terzi.

CALIFORNIA

Proposition 65 Warning

Diesel engine exhaust and some of its constituents are known

to the State of California to cause cancer, birth defects, and

other reproductive harm.

Page 3

Content

Foreword ...................................................................................................... 2

Safety Information ...................................................................................... 3

Introduction ................................................................................................. 8

Instruments and Controls ........................................................................ 11

Optional ..................................................................................................... 24

Starting ...................................................................................................... 28

Operation ................................................................................................... 32

Engine Shutdown ...................................................................................... 36

Fault Handling ........................................................................................... 39

Fault Code Register .................................................................................. 44

In Case of Emergency .............................................................................. 55

Maintenance Schedule ............................................................................. 57

Maintenance .............................................................................................. 60

Storage ....................................................................................................... 86

Calibration and Settings ........................................................................... 88

Technical Data ........................................................................................... 96

Alphabetical index .................................................................................. 103

1

Page 4

Foreword

Volvo Penta marine engines are used all over the world. They are used in all possible operating conditions for

professional as well as leisure purposes. This is not a coincidence. After 100 years as an engine manufacturer

the Volvo Penta name has become a symbol of reliability, technical innovation, top of the range performance and

long service life. We also believe that this is what you demand and expect of your Volvo Penta engine.

We would like you to read this operator’s manual thoroughly and consider the advice we give on running and

maintenance before your maiden voyage so that you will be ensured of fulfilling your expectations. Please pay

attention to the safety instructions contained in the manual.

As owner of a Volvo Penta marine engine, we would also like to welcome you to a worldwide network of dealers

and service workshops to assist you with technical advice, service requirements and replacement parts. Please

contact your nearest authorized Volvo Penta dealer for assistance.

You will find your closest dealer at our home page on the Internet www.volovpenta.com - amongst other

useful information about your Volvo Penta engine - we invite you to visit!

2 7748887 04-2008

Page 5

Safety Information

Read this chapter very carefully. It has to do with your safety. This describes how safety information is presented

in the instruction book and on the product. It also gives you an introduction to the basic safety rules for using and

looking after the engine.

Check that you heave received the correct instruction book before you read on. If not, please contact your

Volvo Penta dealer.

!

This symbol is used in the instruction book and on the product, to call your attention to

the fact that this is safety information. Always read such information very carefully.

Safety texts in the instruction book have the following order of priority:

DANGER!

Indicates a hazardous situation which, if not avoided, will result in death or serious

injury.

WARNING!

Indicates a hazardous situation which, if not avoided, could result in death or serious

personal injury.

CAUTION!

Indicates a hazardous situation which, if not avoided, could result in minor or moderate

personal injury.

IMPORTANT!

Indicates a situation which, if not avoided, could result in property damage.

NOTICE! Used to draw attention to important information that will facilitate work or

operations.

This symbol is used on our products in some cases and refers to important information

in the instruction book. Make sure that warning and information symbols on the engine

are clearly visible and legible. Replace symbols which have been damaged or painted

over.

7748887 04-2008 3

Page 6

Your new boat

Read the instruction books and other information

carefully, which came with your new boat. Learn to

handle the engine, controls and other equipment in a

safe and correct manner.

If this is your first boat, or a type of boat you are not

experienced in using, we recommend that you practice operating the boat in peace and quiet. Get to know

the way the boat reacts to sea and to the controls

under different speed, sea and loading conditions

before you cast off for your first “real” maiden voyage.

Remember that the captain of every boat is required

by law to know and to observe applicable rules for

traffic and safety at sea. Get to know the rules which

apply to you and your waters, by contacting the relevant authority or sea safety organization.

It is a good idea to go on some kind of boat operation

course. We recommend that you contact a regional

boat or sea safety organization to find a suitable

course.

Fuel filling

There is always a risk of fire and explosion during fuel

filling. Smoking is not permissible, and the engine

should be stopped.

Never over-fill the tank. Shut the tank cap securely.

Only use the fuel recommended in the instruction

book. The wrong grade of fuel can cause malfunctions

or stop the engine. In a diesel engine, it can also

cause the regulation rod to bind and the engine will

over-rev, entailing a strong risk of personal injury and

machinery damage.

Daily checks

Make it a habit to give the engine and engine bay a

visual check before driving (before starting the

engine) and after operation (when you have stopped

the engine). This helps you to quickly discover

whether any leakage of fuel, coolant, oil or any other

abnormal event has happened, or is about to happen.

Do not start the engine

Do not start the engine if you suspect a fuel or LPG

leak in the boat, close to explosive media, or if there

is a spillage of explosive media. An explosive environment entails a risk of fire and/or explosion.

Manoeuvring

Avoid sudden or surprising rudder movements and

gear shifting. There is a risk that passengers could fall

over, or overboard.

A rotating propeller can cause severe injury. Check

that there is nobody in the water before you engage

forward / astern (reverse) drive. Never drive close to

bathers or in areas where you could reasonably

expect that people could be in the water.

Accidents and near misses

Life saving statistics show that inadequate care of

boats and engines, and deficiencies in safety equipment are frequent causes of accidents and near

misses at sea.

Make sure that your boat and engine are maintained

in accordance with the advice in each instruction

book, and that the necessary safety equipment is on

board, and is in working condition.

Safety Information

4 7748887 04-2008

Page 7

Carbon monoxide poisoning

When a boat moves forwards, an area of low pressure

air forms behind the boat. In adverse conditions, this

low pressure can be so strong that the boat’s own

exhaust fumes are sucked into the cockpit or cabin,

which entails a risk of carbon monoxide poisoning for

all aboard.

The problem of low-pressure suction is worst in high,

wide boats with a square transom. But even in other

types of boats, low-pressure suction can be a problem

in some conditions, such as if you drive with the hood

up. Other factors which increase the low-pressure

effect are wind conditions, load distribution, pitching,

trimming, open windows and ventilators etc.

Most modern boats are designed so that the problem

of low-pressure suction is very rare, however. If lowpressure suction does occur anyway, do not open

hatches or ventilators in the forward part of the boat.

Strangely enough, this makes the problem worse. Try

changing speed, trimming or load distribution instead.

Also try taking down/opening the hood or modifying it

in some other manner. Ask your boat dealer for advice

about the best solution for your particular boat.

Remember

• Safety equipment: Life jackets for everybody aboard, communication equipment, emergency

rockets, approved fire extinguisher, first aid kit, life buoy, anchor, paddle, torches etc.

• Spare parts and tools: Impeller, fuel filters, fuses, tape, hose clamps, engine oil, propeller and

tools for the jobs you could be expected to have to do.

• Take your chart out and study your planned route. Calculate distance and fuel consumption.

Listen to weather reports.

• Tell your friends/relatives about route plans if you undertake a long journey. Remember to

notify changed plans or delays.

• Inform everybody aboard about where the safety equipment is located, and how it works. Make

sure that there is more than one person aboard who can start and operate the boat safely.

This list can be extended, since the need for safety equipment varies with the type of boat, and

where or how it is used etc. We recommend that you ask a regional boat or sea safety organization

for more detailed maritime safety information.

Safety Information

7748887 04-2008 5

Page 8

Preparations

Knowledge

The operator’s manual contains instructions on how

to carry out general maintenance and service operations safely and correctly. Read the instructions carefully before starting work.

Service literature covering more complicated operations is available from your Volvo Penta dealer.

Never carry out any work on the engine if you are

unsure of how it should be done, contact your Volvo

Penta dealer who will be glad to offer assistance.

Stop the engine

Stop the engine before opening or removing engine

hatches. Unless otherwise specified all maintenance

and service must be carried out with the engine stopped.

To prevent accidental start of the boat engine, remove

the ignition key, turn off the power supply to the engine

at the main switches and lock them in the OFF position before starting work. Put up a warning sign in the

control position that work on the engine is being carried out.

Approaching or working on an engine which is running

is a safety risk. Loose clothing, hair, fingers or a dropped tool can be caught in the rotating parts of the

engine and cause serious personal injury. Volvo

Penta recommend that all servicing with the engine

running should be undertaken by an authorized Volvo

Penta workshop.

Lifting the engine

When lifting the engine, use the lifting eyes installed

on the engine (reverse gear where installed). Always

check that lifting equipment is in good condition and

has sufficient load capacity to lift the engine (engine

weight including reverse gear and any extra equipment installed). For safety’s sake lift the engine using

an adjustable lifting beam. All chains and cables

should run parallel to each other and as perpendicular

as possible in relation to the top of the engine. Bear

in mind that extra equipment installed on the engine

may alter its center of gravity. Special lifting equipment may then be required in order to maintain the

correct balance and make the engine safe to handle.

Never carry out work on an engine suspended on a

hoist.

Before starting the engine

Reinstall all protective parts removed during service

operations before starting the engine. Check that no

tools or other items have been left on the engine.

Never start a turbocharged engine without installing

the air cleaner (ACL). The rotating compressor in the

Turbocharger unit can cause serious personal injury.

Foreign objects can also be sucked in and cause

mechanical damage to the unit.

Fire and explosion

Fuel and lubrication oil

All fuel, most lubricants and many chemicals are

inflammable. Read and follow the instructions on the

packaging.

When carrying out work on the fuel system, make sure

the engine is cold. A fuel spill onto a hot surface or

electrical components can cause a fire.

Store fuel soaked rags and other flammable material

so that there is no danger of them catching fire. Fuelsoaked rags can self-ignite under certain conditions.

Do not smoke when filling fuel, oil or in proximity of a

filling station or in the engine room.

Non-original components

Components used in the fuel and ignition system

(gasoline engines) and electrical systems on Volvo

Penta products are designed and constructed to minimize the risk of fire and explosion.

Using non-original Volvo Penta parts can result in fire

or explosion on board.

Batteries

The batteries contain and emit oxyhydrogen gas,

especially during charging. This gas is easily ignited

and highly volatile.

Do not under any circumstances smoke or use naked

flame or allow sparks in the vicinity of the batteries or

battery compartment.

An incorrect connection of a battery terminal cable or

jump-start cable can cause a spark which in its turn

can be sufficient to cause an explosion.

Start spray

Never use start spray or similar agents to start an

engine equipped with air pre-heating (glow plugs/

starter element). This may cause an explosion in the

inlet manifold. Danger of personal injury.

Safety Information

6 7748887 04-2008

Page 9

Hot surfaces and fluids

There is always a risk of burns when working with a

hot engine. Beware of hot surfaces. For example: the

exhaust pipe, turbo unit, oil pan, charge air pipe,

starter element, hot coolant and hot oil in oil lines and

hoses.

Carbon monoxide poisoning

Only start the engine in a well-ventilated area. If operating the engine in an enclosed space, ensure that

there is proper ventilation in order to remove exhaust

gases and crankcase ventilation emissions from the

working area.

Chemicals

Most chemicals such as anti-freeze, rustproofing

agent, inhibiting oil, degreasing agent etc. are hazardous to health. Read and follow the instructions on

the packaging.

Some chemicals such as inhibiting oil are inflammable

and dangerous if breathed in as well. Ensure good

ventilation and use a protective mask when spraying.

Read and follow the instructions on the packaging.

Store chemicals and other hazardous materials out of

the reach of children. To protect the environment,

please dispose of used or leftover chemicals at a

properly designated disposal site for destruction.

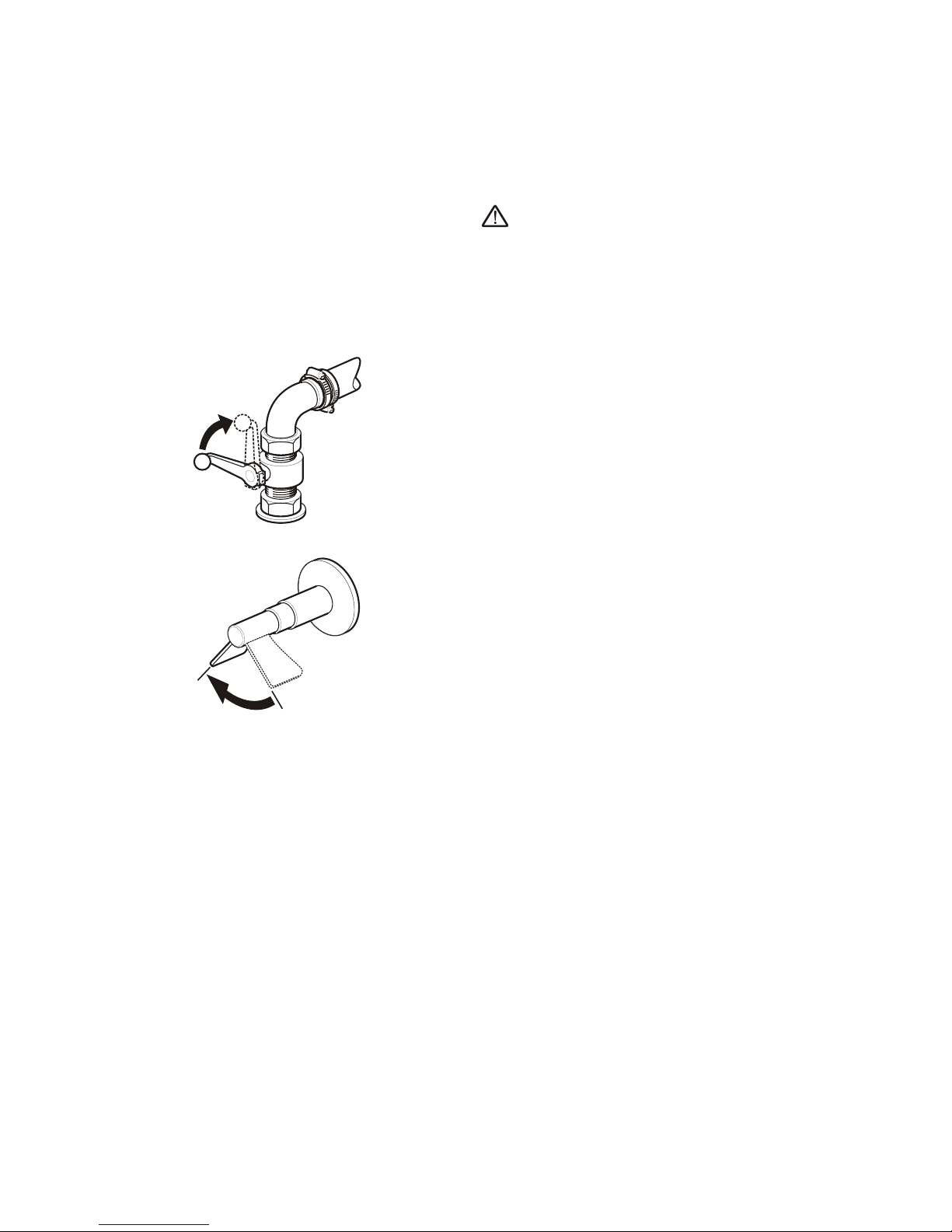

Cooling system

There is a risk of flooding when working on the seawater system. Turn off the engine and close the sea

cock (where installed) before starting work on the system.

Avoid opening the coolant filler cap when the engine

is hot. Steam or hot coolant can spray out and cause

burns.

If work must be carried out with the engine at operating temperature and the coolant filler cap or a cock

open or a coolant hose disconnected, open the coolant filler cap carefully and slowly to release pressure

before removing the cap completely. Note that the

coolant may still be hot and can cause burns.

Lubrication system

Hot oil can cause burns. Avoid skin contact with hot

oil. Ensure that the lubrication system is not under

pressure before commencing work on it. Never start

or operate the engine with the oil filler cap removed,

oil can spray out.

Fuel system

Always use protective gloves when tracing leaks. Liquids ejected under pressure can penetrate body tissue and cause serious injury. There is a danger of

blood poisoning.

Always cover the generator if it is located under the

fuel filter. The generator can be damaged by spilled

fuel.

Steering system

The boat has a advanced steering system. DO NOT

change connectors, wiring or splice of the components.

Service must be done by approved workshops which

have certifed personnel with qualified professional

training.

Electrical system

Cutting off power

Always stop the engine and break the current using

the main switches before working on the electrical

system. Isolate shore current to the engine block

heater, battery charger, or accessories mounted on

the engine.

Batteries

The batteries contain an extremely corrosive electrolyte. Protect your skin and clothes when charging or

handling batteries. Always use protective goggles and

gloves.

If battery electrolyte comes into contact with unprotected skin, wash off immediately using plenty of

water and soap. If battery acid comes into contact with

the eyes, flush immediately with plenty of water and

obtain medical assistance without delay.

Safety Information

7748887 04-2008 7

Page 10

Introduction

This Operator's Manual has been prepared to give you the greatest possible benefit from your Volvo Penta marine

engine. It contains the information you need to be able to operate and maintain the engine safely and correctly.

Please read the Operator's Manual carefully and learn to handle the engine, controls and other equipment in a

safe manner before you cast off on your maiden voyage.

Always have the Operator's Manual available. Store it safely and do not forget to hand it over to the next owner

if you sell your boat.

The Operator’s Manual describes the engine and equipment sold by Volvo Penta. The illustrations in this book

covers several varieties and might differ, the essential information is always correct though. Installations with e.g.

different controls and instrumentation might occur, in these cases we refer to this products manual.

8 7748887 04-2008

Page 11

Warranty

Your new Volvo Penta marine engine is covered by a

limited warranty, under the conditions and instructions

compiled in the Warranty and Service book.

Please note that AB Volvo Penta’s liability is limited to

the specification in the Warranty and Service book.

Read it carefully, as soon as possible after delivery. It

includes important information about warranty cards,

service, maintenance, which it is the responsibility of

the owner to know, check and carry out. If this is not

done, AB Volvo Penta may fully or partly refuse to

honour its warranty undertakings.

Please contact your Volvo Penta dealer if you

have not received a Warranty and Service book,

or a customer copy of the warranty card.

Running in

The engine must be “run in” during its first 10 hours,

as follows:

Use the engine in normal operation. Full load should

only be applied for short periods. Never run the engine

for a long period of time at constant speed during this

period.

Higher oil consumption is normal during the running

in period. For this reason, check the oil level more

frequently than normally recommended.

After the first period of operation, the specified warranty inspection “First service inspection” can be

done. For more information: Please refer to the Warranty and Service book.

Environmental care

All of us want to live in a clean, healthy environment.

Where we can breathe clean air, see healthy trees,

have clean water in lakes and seas, and be able to

enjoy the sunlight without fearing for our health.

Unfortunately, this is not self-evident these days, it is

something all of us must work hard for.

As a manufacturer of marine engines, Volvo Penta

has particular responsibility and for this reason, environmental care is a core value in our product development. Volvo Penta has a wide engine programme

these days, where considerable progress has been

made in reducing exhaust fumes, fuel consumption,

engine noise etc.

We hope that you will be want to preserve these values. Always observe the advice in the instruction book

about fuel grades, operation and maintenance, to

avoid unnecessary environmental impact. Please

contact your Volvo Penta dealer if you notice any

changes such as increased fuel consumption or

increased exhaust smoke..

Moderate your speed and distance so that wake and

noise do not disturb or damage animal life, moored

boats, jetties etc. Leave the archipelago and harbours

in the same state you would like to find them. Remember to always hand in drained oil, coolant, paint and

wash residue, used batteries etc. for destruction at a

recycling station.

If we all pull together, we can make a valuable contribution to the environment together.

Fuel and oils

Only use the fuels and oils recommended in the

instruction book. Other grades can cause malfunctions, increased fuel consumption and eventually

even shorten the life of the engine.

Always change the oil, oil filter and fuel filter at the

specified intervals.

Service and spare parts

Volvo Penta marine engines are designed for high

reliability and long life. They are built to withstand a

marine environment, but also to have the smallest

possible environmental impact. Through regular service and use of by Volvo Penta approved spare parts,

these qualities are retained.

Volvo Penta’s world-wide network of authorised dealers is at your service. They are Volvo Penta product

specialists, and have the accessories, original

spares, test equipment and special tools needed for

high quality service and repair work.

Always observe the maintenance intervals in the

Operator's manual, and remember to note the engine/

transmission identification number when you order

service and spare parts.

Introduction

7748887 04-2008 9

Page 12

Certified engines

If you own or operate an emission certified engine it is

important to be aware of the following:

Certification means that an engine type has been

checked and approved by the relevant authority. The

engine manufacturer guarantees that all engines made

of the same type are equivalent to the certified engine.

This makes special demands on the care and maintenance you give your engine, as follows:

•

Maintenance and service intervals recommended

by Volvo Penta must be complied with.

•

Only Volvo Penta original spares may be used.

•

Service on injection pumps, pump settings and

injectors must always be done by an authorised

Volvo Penta workshop.

•

The engine must not be converted or modified,

except for the accessories and service kits which

Volvo Penta has approved for the engine.

•

Installation changes to the exhaust pipe and engine

air inlet ducts must not be done.

•

No seals may be broken by unauthorised personnel.

The general advice in the Operator's manual about

operation, care and maintenance apply.

Late or inadequate maintenance/service or the use of

spare parts not approved by Volvo Penta will invalidate

AB Volvo Penta’s responsibility for the engine specification being in accordance with the certificated variant.

Volvo Penta accepts no responsibility or liability for any

damage or costs arising due to the above.

Introduction

10 7748887 04-2008

Page 13

Instruments and Controls

This chapter describes the instruments, panels and controls Volvo Penta sells for your engine.

If you would like to complement your instrumentation, or if your boat is equipped with instruments not described

here, we ask that you contact your Volvo Penta dealer.

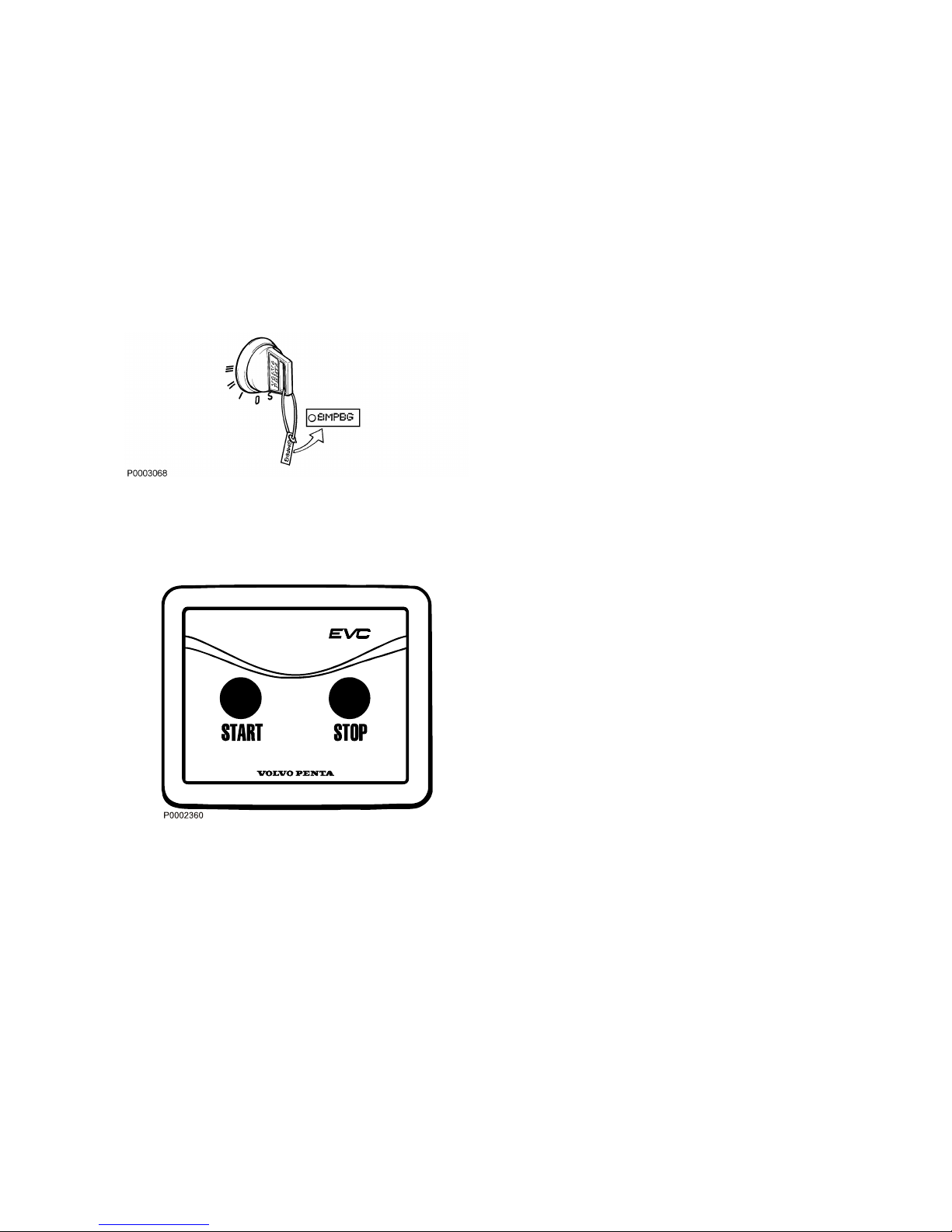

Ignition Lock

The start keys are supplied with a plate bearing the

start code to be used when ordering spare keys. Keep

the code beyond the reach of unauthorized people.

S = Stop position.

0 = The key can be inserted or removed.

I = Operating position. System voltage is connected.

II = Not used.

III = Start position. Start motor is engaged.

Read the starting instructions in chapter Starting page 28 to ensure you use the correct start

procedure.

Start/Stop Panel

The start/stop panel is used for starting and stopping

the engine.

To start the engine it is necessary for the start key at

the main station to be in the ”I” operating position. The

engine can only be stopped from an activated control

panel.

Read the starting instructions in chapter Start-

ing page 28 to ensure you use the correct start

procedure.

7748887 04-2008 11

Page 14

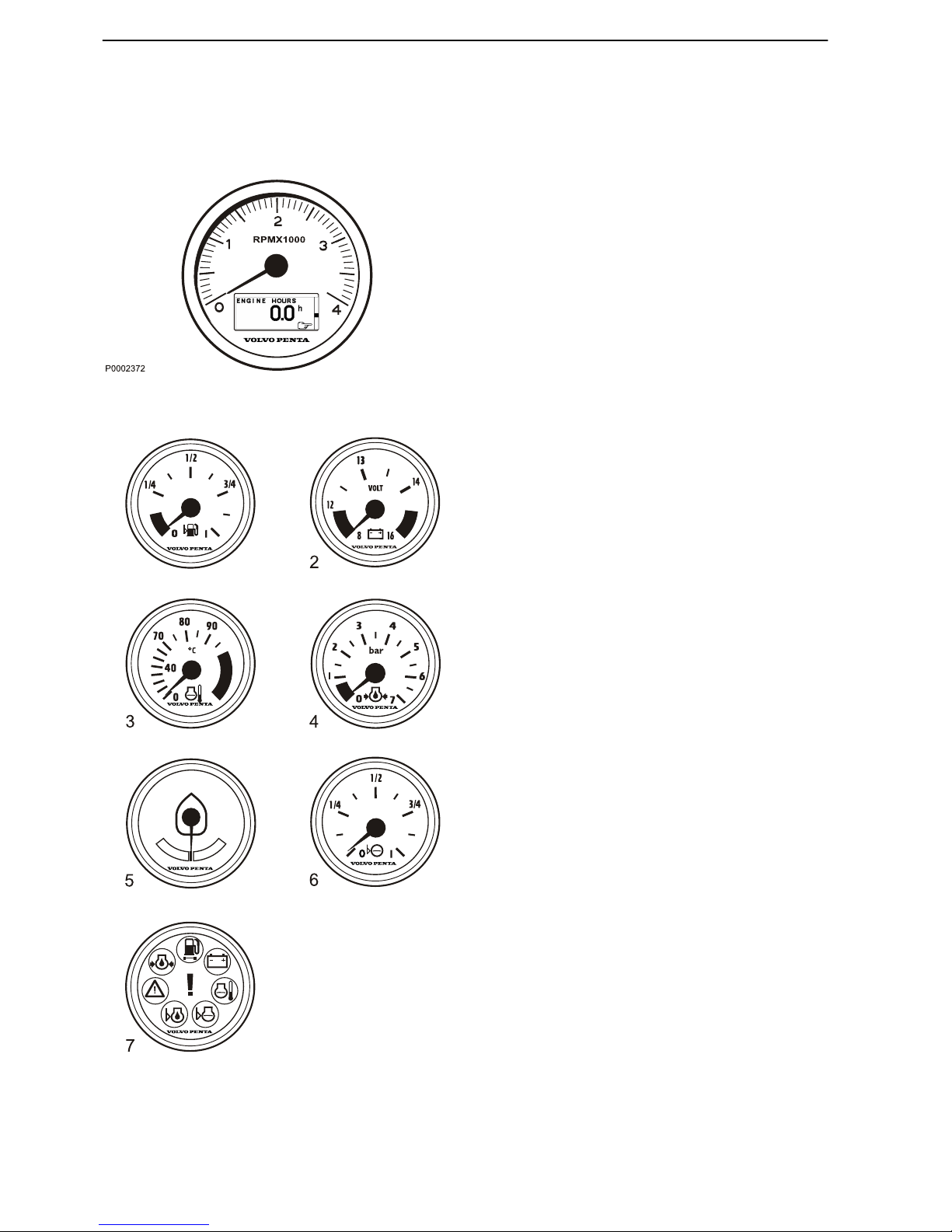

Gauges

Tachometer

The tachometer displays engine speed; multiply the

value shown on the dial by 1,000 to get the number of

engine revolutions per minute.

Boat and engine information is displayed in the tachometer window. Information displayed depends on

engine type, the number of sensors and which accessories are installed.

Optional instruments

These instruments are sold as engine options by Volvo

Penta.

1 Fuel level gauge

The fuel level gauge shows the quantity of remaining fuel.

2 Voltmeter, battery charging

The meter shows the alternator charge current.

During operations the charge voltage should be

around 14 V. When the engine is stopped and electrical power switched on the battery voltage should

be around 12 V.

If a 24 V system is installed, the charge voltage

should be around 28 V during operations.

3 Coolant temperature gauge

The instrument shows engine coolant temperature.

During operations coolant temperature should normally be between 75-90°C (167-194°F).

4 Oil pressure gauge

The oil pressure gauge displays engine oil pressure. During operations the oil pressure gauge

should normally show 4-5.5 bar. At idle, lower values are normal.

5 Rudder position indicator

The instrument shows rudder position.

6 Fresh water level sensor

Freshwater tank level gauge.

7 Alarm monitor

The alarm monitor gives a visual warning to call

attention to any alarms that occur.

1

P0005255

Instruments and Controls

12 7748887 04-2008

Page 15

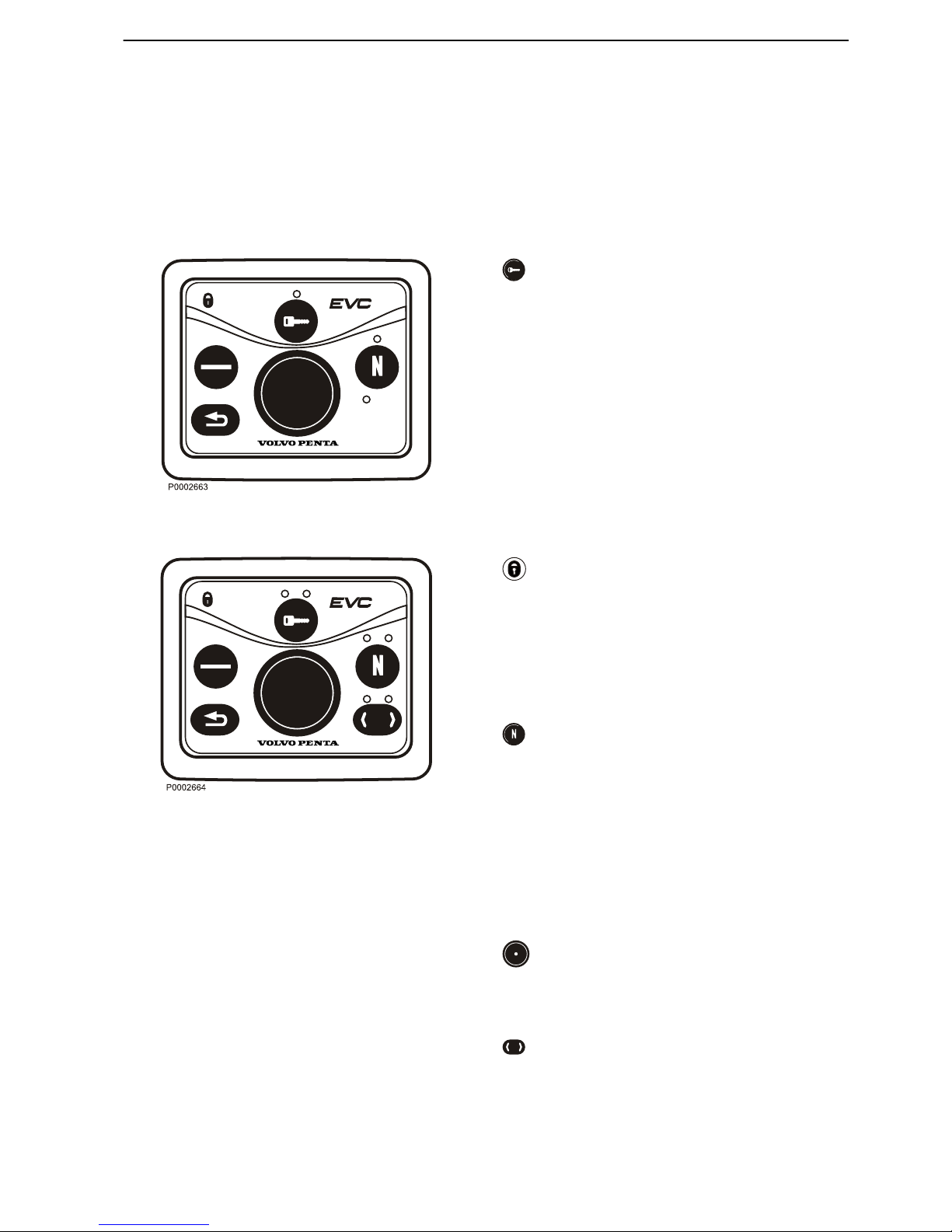

Control Panel

The control panel is used for station handling, disengaging the gear/drive and to navigate the EVC system

menu. There is one control panel for single installations

and one for twin installations.

Always push the buttons firmly and for at least one

second.

Activation button

The control panel and station are activated by pushing

the activation button once. Push twice to lock the station. On boats with only one station, this is always

active.

The lamp above the activation button shows the status

of the station.

Red lamp: Active station

Lamp off: Station not activated.

Lamp flashing: A fault that limits the function of the

station has been detected.

Padlock

The padlock symbol lights when the station is locked

with the activation button or if change of stations is

under way, please refer to section Helm Sta-

tions page 34.

Lit: The station is locked and the boat can only be controlled from this station.

Flashing: Another station is locked.

Neutral button

The neutral button is used to disengage the drive/gear

enabling the engine rpm to increase without affecting

the drive/gear, to warm up the engine. The lamp above

the neutral button shows the status of the station.

Green lamp: Gear in neutral. The drive/gear is in neutral position and the engine runs at idle speed.

Lamp off: The drive/gear is engaged for movement

forward/astern.

Flashing lamp: The drive/gear is disengaged and the

engine speed can be adjusted.

Knob

Navigate the display menu by turning the knob.

Push the knob to confirm a selection or acknowledge

an alarm.

Tachometer Display Selection

Boats with twin installations with one tachometer for

port engine and one for starboard can choose which

engine menu to handle from the station. The lamp

Control panel single installation

Control panel twin installation

Instruments and Controls

7748887 04-2008 13

Page 16

above the button shows which engine is chosen, green

lamp for starboard engine and red lamp for port engine.

Lamp off: Menu inactivated.

Lamp lit: Menu activated.

Multifunction Button

With the multifunction button the instruments and panels backlighting is adjusted.

Push the button for over a second to turn the backlighting on or off. The backlighting can be adjusted in

five stages by repeatedly pushing the multifunction

button quickly (less than 1 second).

If the button is pressed on an inactive station, operating

information is shown on the display(s) and the menu

structure is activated.

Back Button

Used to return a step up in the menu structure.

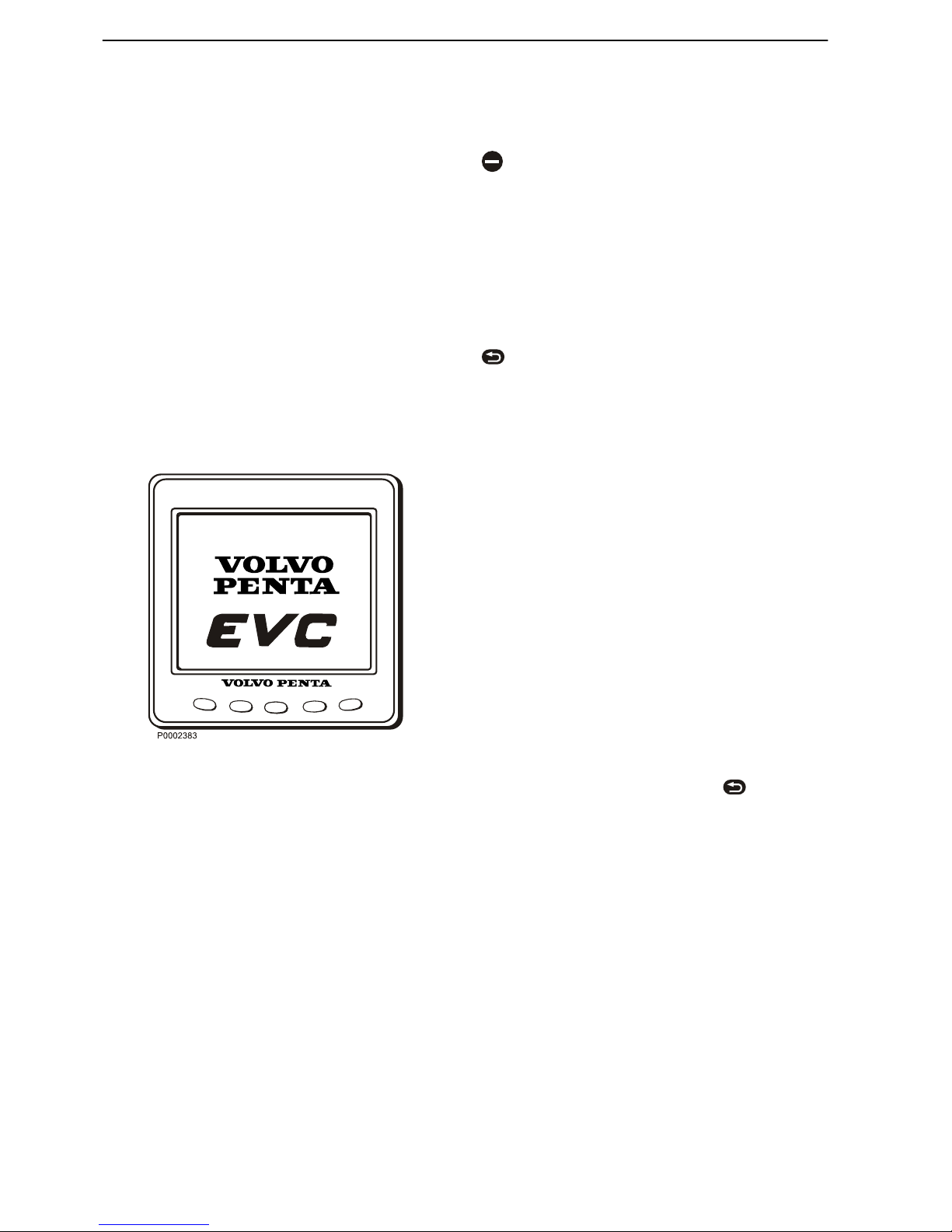

EVC System Display

In the EVC system display it is possible to show multiple windows with different information. There are four

display modes which can be chosen using the buttons

on the instrument.

Button 1–4 shows the different display modes. Button

5 i used to adjust the contrast and to access the configuration menu, please refer to section Configuration

menu.

The EVC menu can be shown in the display by entering

System information, refer to section Multi, button 2, or

the Configuration menu. In this mode the display works

the same way as the display in the tachometer and is

handled via the separate control panel, please refer to

section Instruments and Controls page 19.

If no tachometer is installed the EVC meny can be

reached by pressing the knob on the control panel. To

get back to the display modes, press

.

At start up, the display performs a self-test. If an constant signal is heard, the system has discovered a

malfunction. The display will work but may act in an

unexpected way.

NOTICE! Only installed functions will be shown in the

display.

Instruments and Controls

14 7748887 04-2008

Page 17

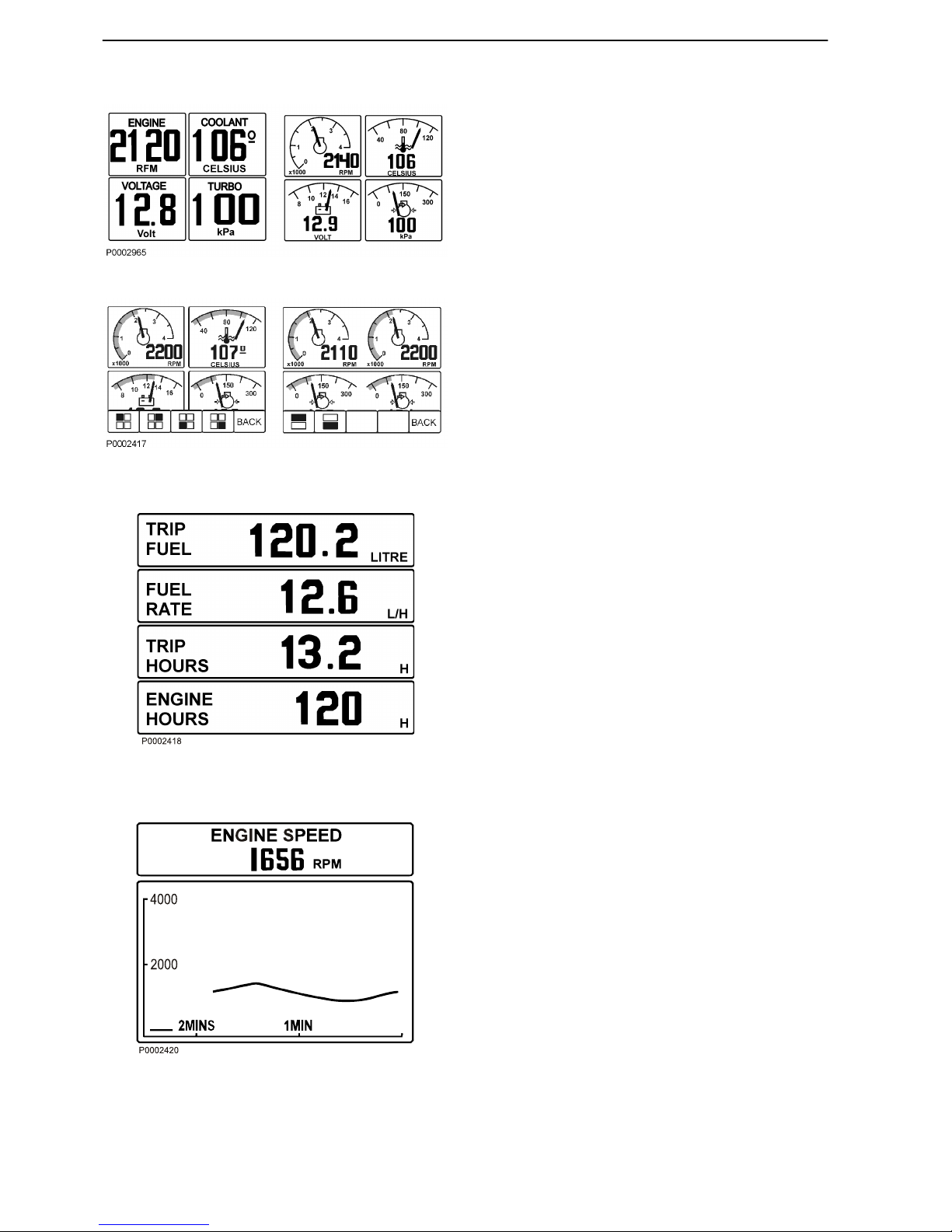

Display modes

Press button 1–4 to view the function menu for the

buttons, apperaring in the lower part of the display.

Press button 1–4 to choose the desired display mode.

1 Engine

2 Multi

3 Trip

4 Graph

To leave the menu, wait a few seconds or press button

5 (EXIT).

Contrast

In the display modes Engine, Trip and Graph, it is possible to adjust the contrast.

Press button 5 when outside the menu and then +

(button 4) and – (button 3).

Engine, button 1

Rpm and speed is shown in the upper part of the display. In the lower part it will show trip computer and a

fuel level indicator, if these functions are installed.

If speed information is missing, coolant temperature

will be shown instead.

Navigate in the trip computer by repeatedly press button 1.

•

Fuel Rate, fuel consumption per hours

Fuel Economy, fuel consumption per distance

•

Trip Fuel, fuel used since last reset

•

Fuel Remaining, remaining fuel in tank

•

Dist. to Empty, remaining distance until tank is

empty, based on fuel consumption per distance

•

Trip Distance, trip distance since last reset

Instruments and Controls

7748887 04-2008 15

Page 18

Multi, button 2

In the multi mode the information can be shown in several windows, analogue or digital. The display can

show windows with different information or be divided

to show windows and system information. To handle

the system information, see section Instruments and

Controls page 19. To go between the different display modes, press button 2 repeatedly.

By pressing button 5 (the right arrow) you can choose

which information to be shown in the different windows.

Press repeatedly on the button which correspond to

the window, until desired information is shown.

Trip, button 3

The display works as trip computer and shows:

Trip Fuel, since last reset

Fuel Rate, fuel consumption

Trip hours, since last reset

Engine hours, total amount of operating hours

Reset by pressing button 3 for three seconds until a

beep is heard.

For twin installations the values are summarized,

except for engine hours that are shown for each

engine.

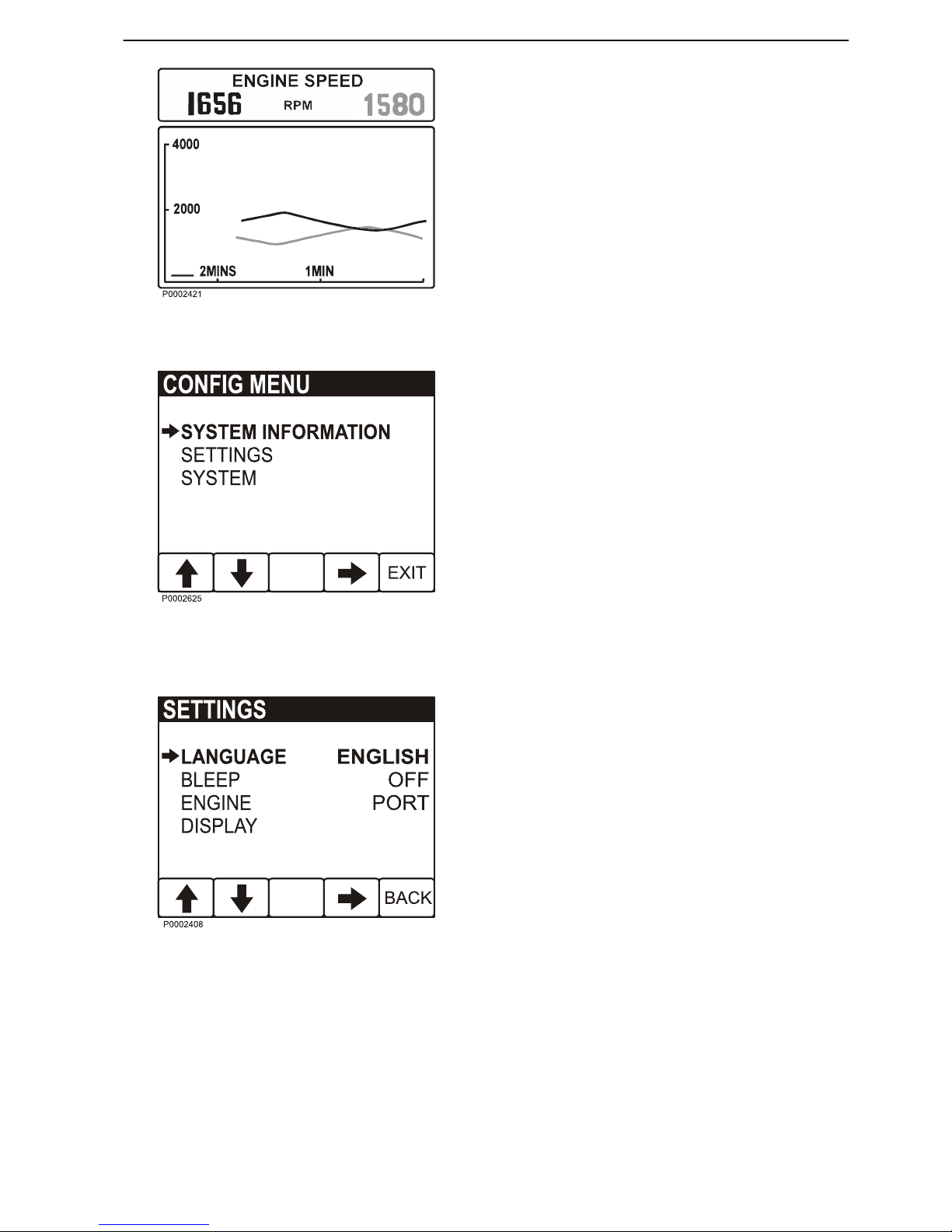

Graph, button 4

The information is shown as graphs. Press button 4

repeatedly to choose which information will be shown.

The time interval is set in the Configuration menu.

If the connection is broken there will be a straight line

in the display.

Single installation

Instruments and Controls

16 7748887 04-2008

Page 19

In a twin installation the port engine is shown as a black

line and the starboard engine as a grey line.

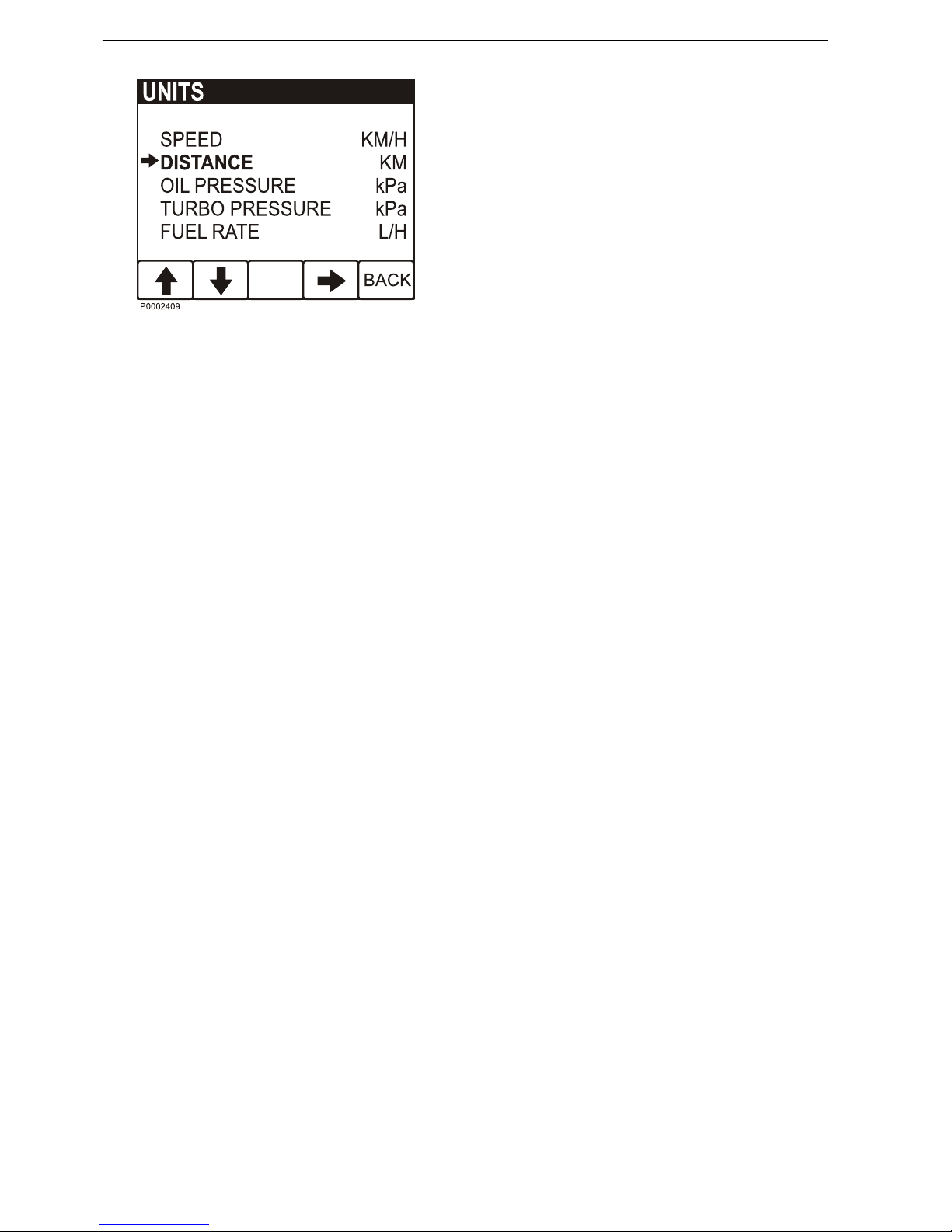

Configuration menu

Press button 5 for five seconds to enter the Configuration menu. Navigate with the up and down arrows,

select with the right arrow.

NOTICE! The port engine, or both engines, must have

the ignition on when display settings are made.

System information

System information shows the EVC-menyn and is han-

dled by the knob on the control panel. For more information, see Instruments and Controls page 19.

Settings

- Language: Setting of what language the information is to be presented in are made in the EVC menu,

see Instruments and Controls page 19.

- Bleep: On/Off, setting if pressing the instrument

buttons will be followed by a beep or not.

- Engine: Setting of what kind of installation the display is a part of and which engine is to be shown in

the display.

Twin installation

Instruments and Controls

7748887 04-2008 17

Page 20

- Display: Setting of intervals (unit settings are made

in the EVC menu, see Instruments and Con-

trols page 19):

Rpm interval, 2500–9000 rpm, in steps of 500 rpm

Speed, on/off

Speed interval, 10–100 knots, in steps of 10 knots

Graph interval, 2 min, 10 min, 30 min, 60 min, 2 h,

4 h or 8 h

Instruments and Controls

18 7748887 04-2008

Page 21

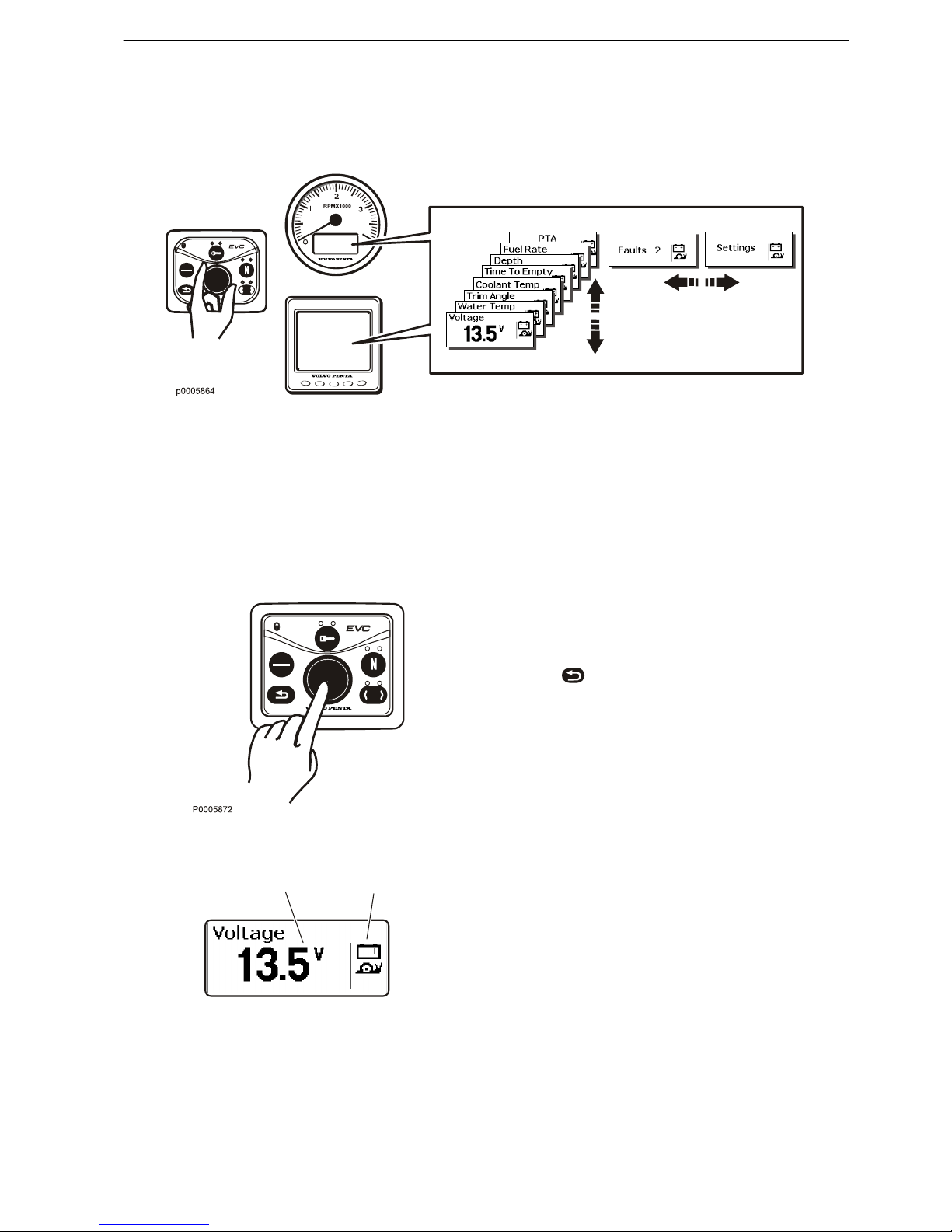

EVC menu

The EVC menu can be shown in both the EVC system

display and the tachometer display. The main menu

shows operating information, the settings menu and

the fault menu (only shown when a fault in the system

is detected).

Only installed functions are shown in the menu.

Turn the knob to navigate through the menus.

Press the knob to access sub menus and to confirm

selections in the settings menu.

It is always possible to return to the previous menu by

pressing

. Press repeatedly to return to the main

menu; alternatively, hold down the button for a couple

of seconds.

A This field displays engine operating data.

B This field displays warning symbols and active func-

tion symbols.

A

B

P0001006

Instruments and Controls

7748887 04-2008 19

Page 22

Settings

Turn the control panel wheel until the start screen for

the settings menu is displayed. Press the wheel to

reach the sub menus.

Turn to move between the available setting functions.

For further information, refer to section Settnings

menu page 88.

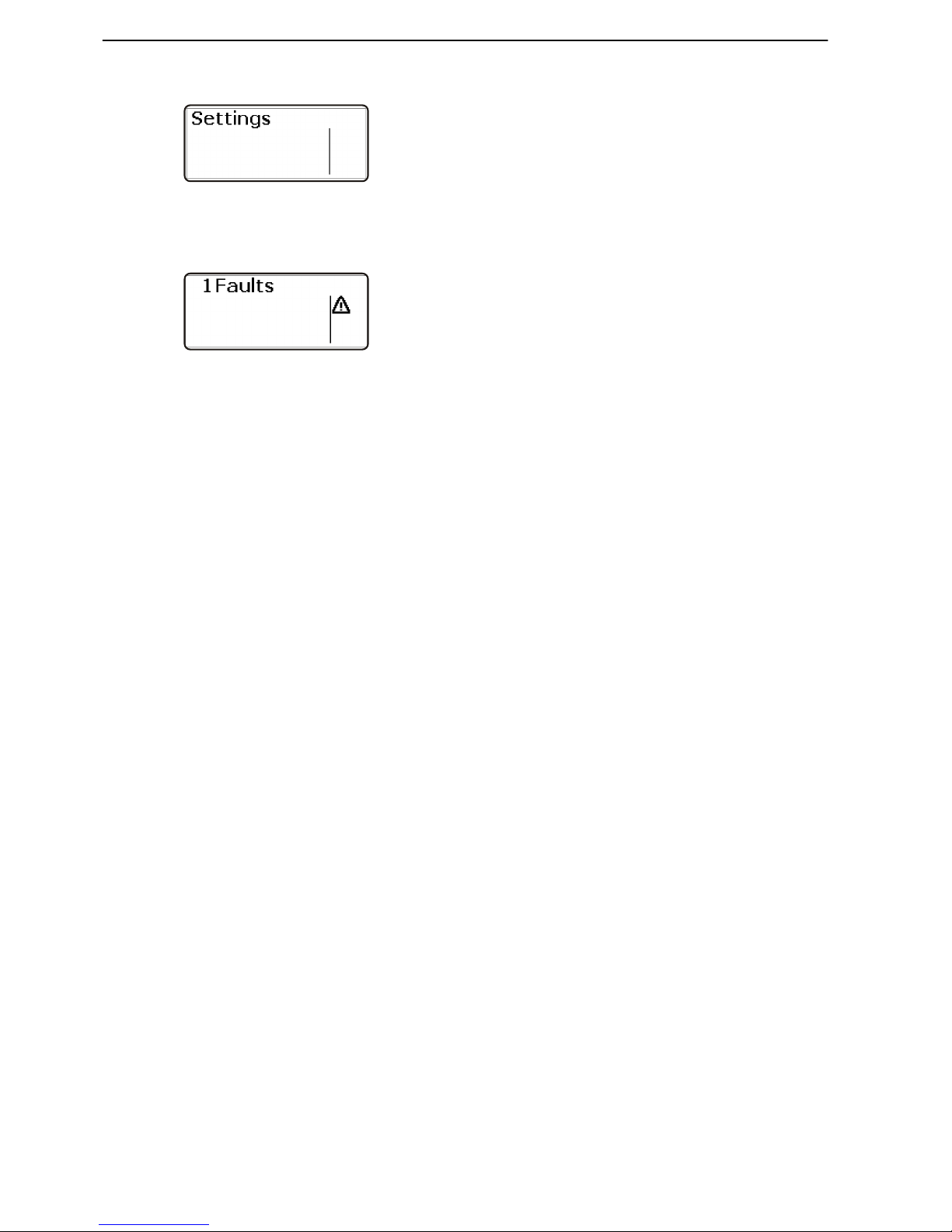

Fault

The fault window is only shown in the main menu if a

fault has been detected.

For further information, refer to section Fault Han-

dling page 39.

P0001015

P0001315

Instruments and Controls

20 7748887 04-2008

Page 23

Controls

This section describes the controls Volvo Penta sells

for your engine. Contact your dealer if your boat is

equipped with controls other than those described

here, and you feel uncertain about their function.

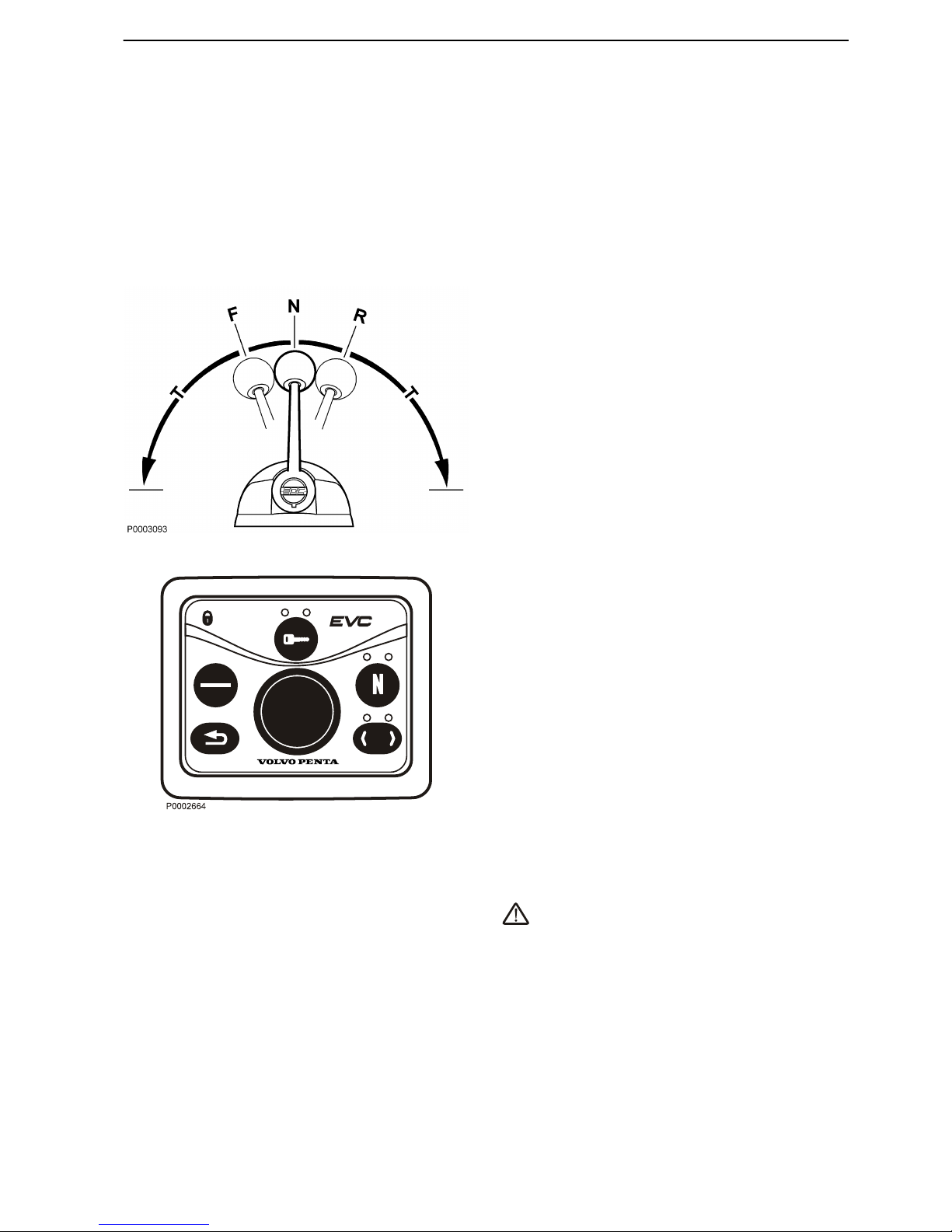

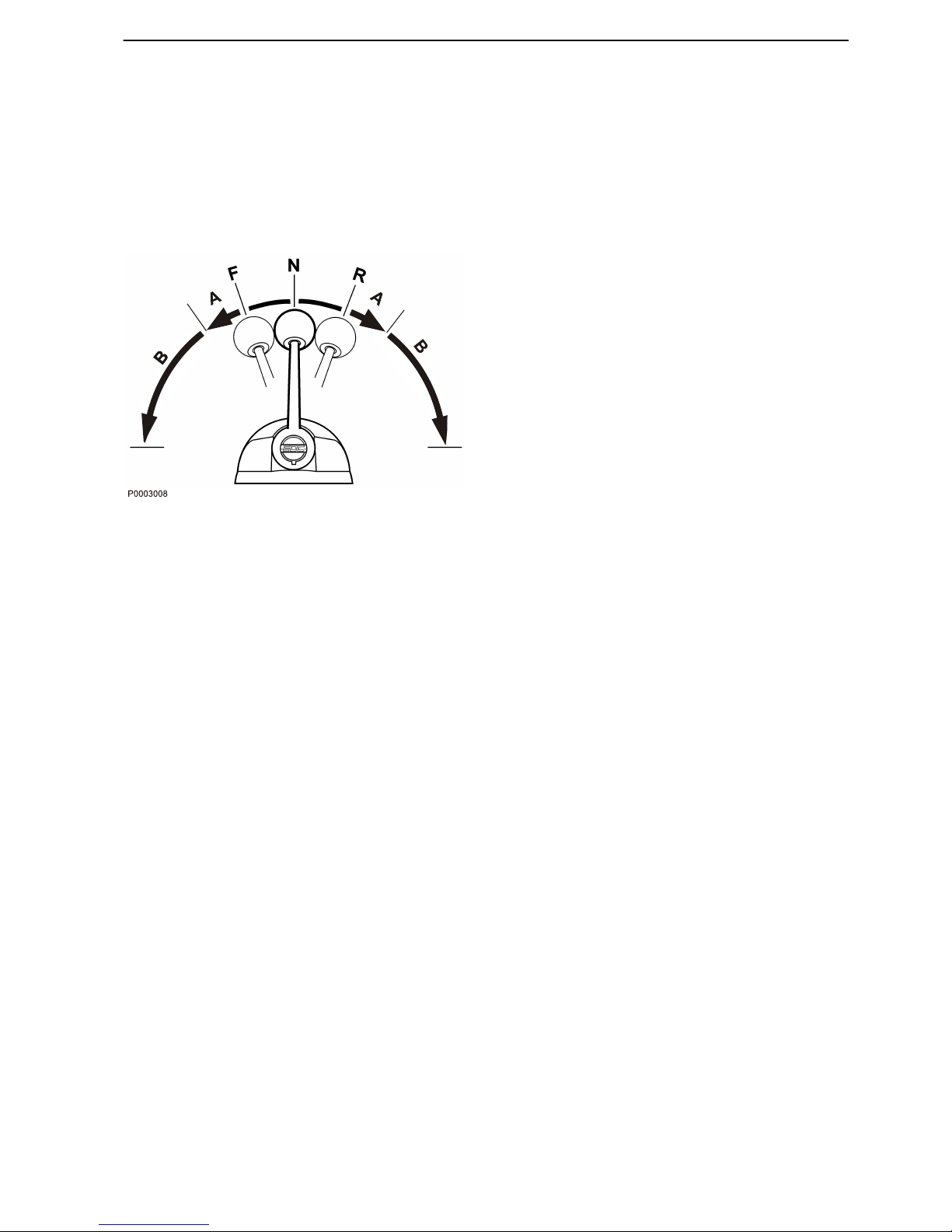

Single Lever Control

Maneuvering

A single-lever control operates both gearshift and

throttle functions with the same lever.

The engine can only be started with the control lever

in the neutral position.

N = Neutral position. Reverse gear/drive disengaged

and engine at idle.

F = Reverse gear/drive engaged for forward motion.

R = Reverse gear/drive engaged for rearward

motion.

T = Engine rpm control (throttle).

Disconnecting the gearshift function

The gearshift function can be disconnected so that the

control lever only operates the throttle.

1 Put the control lever in neutral (N).

2 Depress the neutral button (N) and keep it

depressed at the same time as the lever is moved

forwards to the gearshift position (F).

3 Release the neutral button. The green indicator will

flash as confirmation that the gearshift function is

disconnected and the that lever will only affect

engine revolutions.

The gear shift function is reconnected automatically

when the lever is returned to the neutral position. This

is confirmed by the green indicator shining continuously.

CAUTION!

Take care not to engage the drive by mistake.

Instruments and Controls

7748887 04-2008 21

Page 24

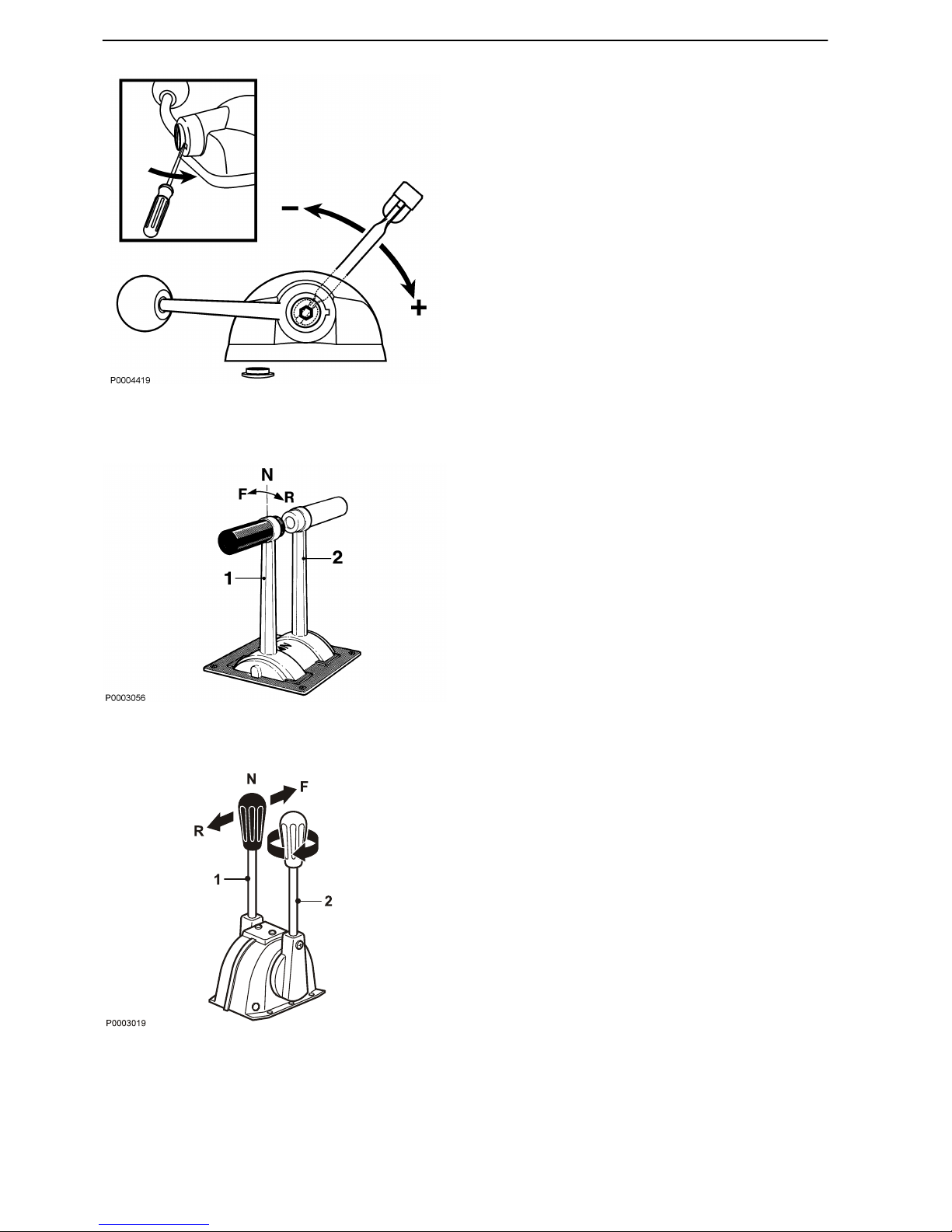

Adjusting the friction brake

The control lever is fitted with a friction brake that can

be adjusted to apply more or less resistance to lever

movement. The friction brake only affects movement

of the throttle control lever.

1 Stop the engine.

2 Move the control lever forward so that the groove

in the lever hub is accessible.

3 Remove the plug with the aid of a screwdriver.

4 Adjust the friction brake (wrench, 8 mm) by turning

the bolt clockwise (+) for stiffer lever movement,

and counterclockwise (-) for easier movement.

5 Reinstall the plug.

Dual lever control

Maneuvering

A twin-lever control has separate levers for the gearshift function (1) and rpm control (throttle) (2).

The engine can only be started with the control lever

in the neutral position.

Black lever (1)

N = Neutral position. Reverse gear/drive disengaged

and engine at idle.

F = Reverse gear/drive engaged for forward motion.

R = Reverse gear/drive engaged for rearward

motion.

Red lever (2)

Engine rpm control (throttle).

Control A

Control B

Instruments and Controls

22 7748887 04-2008

Page 25

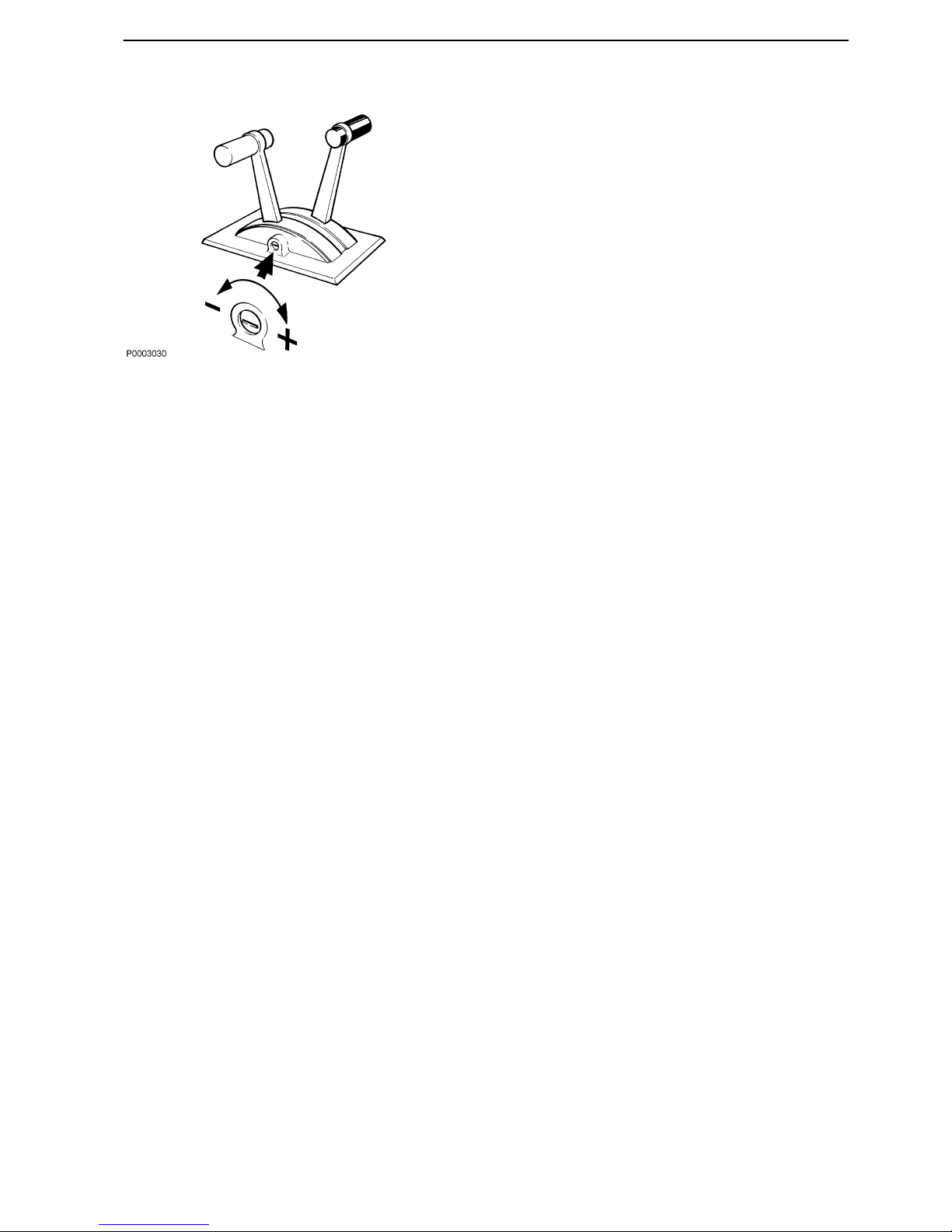

Adjusting the friction brake

The control lever is fitted with a friction brake that can

be adjusted to apply more or less resistance to lever

movement. Adjust the friction brake by turning the

screw (control A), or by twisting the lever (control B).

Turn clockwise (+) for stiffer lever movement, and

counterclockwise (-) for easier movement.

Instruments and Controls

7748887 04-2008 23

Page 26

Optional

Trolling

The Volvo Penta trolling function is available for

engines with some versions of hydralic reverse gear.

Trolling requires two control levers, one for throttle/

gear, and the other to control the slip function. Trolling

makes it possible to use higher engine power without

increasing boat speed.

WARNING!

If engine speed exceeds the maximum permissible

engine speed for trolling (approx. 1000 rpm, depending

on reverse gear), the EVC system automatically disengages trolling and full propeller effect returns.

Depending on the position that the control lever is in

when automatic disengagement occurs, the boat

speed can increase rapidly.

Engage the trolling function

1 Move the throttle/gear lever to a position where the

engine speed is within the permissible engine

speed range and move the slip control lever to a slip

position.

Active trolling is indicated by the symbol

in

the display.

If trolling initializing symbol

shows in the

display trolling is not ready to use. Gear shifting as

normal until trolling is activated.

Delay in gear shifting may occur when Trolling is

active.

At maximum slip there is no propeller effect.

Disengaging the trolling function

1 To disengage the trolling function, move the slip

control lever to minimum slip position.

The indication in the tachometer display disapeares.

24 7748887 04-2008

Page 27

Low speed

The Lowspeed function is available for engines with

some hydralic reverse gear.

Boats with powerful engines can have high speed even

at idle. The Lowspeed function reduces the boat

speed.

N = Neutral. Reverse gear is disengaged and engine

runs at idle speed.

F = Forward idling.

Reverse gear engaged for movement ahead and

engine runs at idle speed. Maximum slip in

reverse gear.

R = Reverse idling

Reverse gear engaged for movement astern and

engine runs at idle speed. Maximum slip in

reverse gear.

A = Lowspeed active.

Propeller rpm is increased with increase of throttle, engine rpm is not affected.

B = Lowspeed deactivated.

Propeller rpm is increased with engine rpm,

engine rpm will increase with throttle.

Optional

7748887 04-2008 25

Page 28

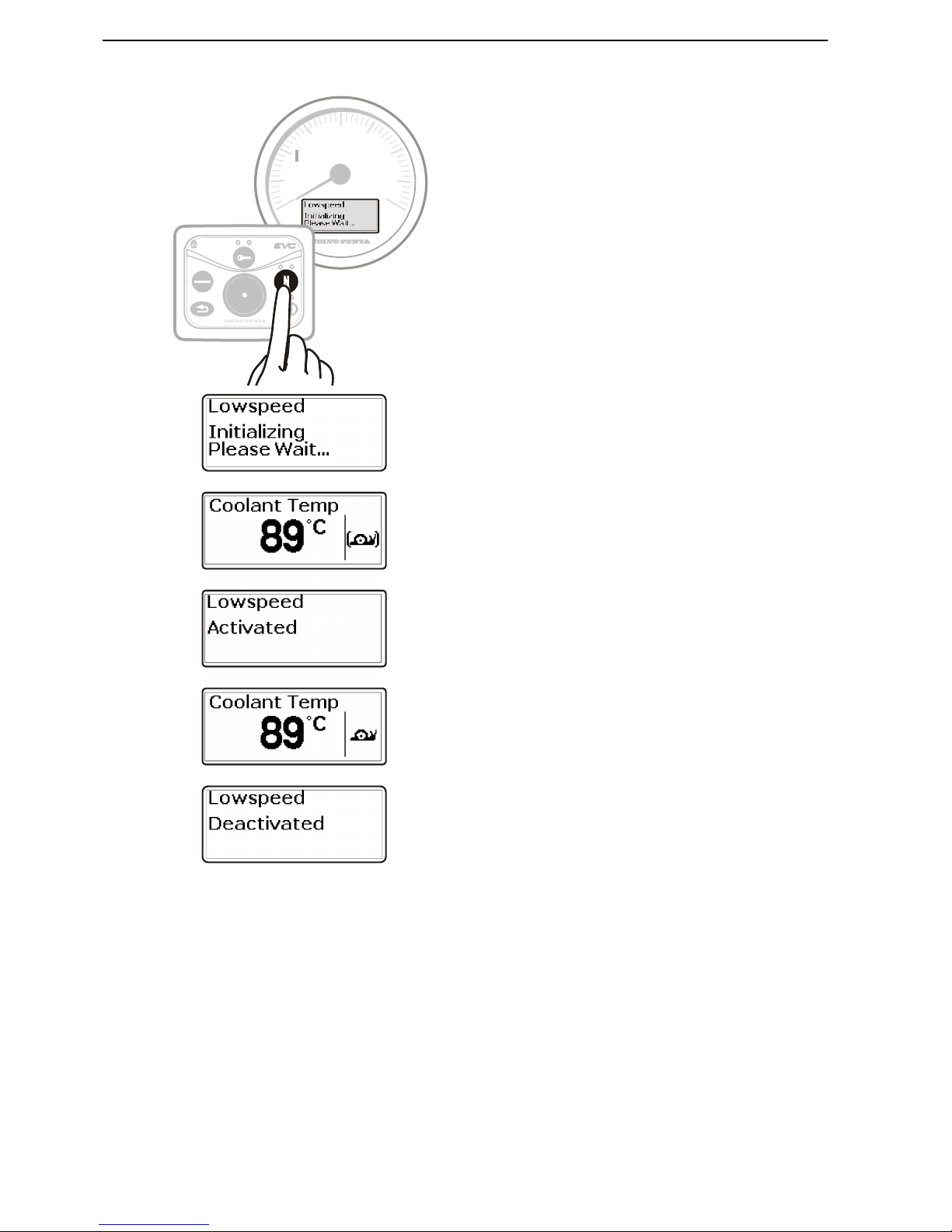

Engaging Lowspeed

1 Move the lever to neutral position.

2 Press the neutral button (N) to activate Lowspeed.

If the message “Lowspeed initierate” (A) followd by

the snail symbol (B) in the display the lowspeed

function is not ready. Normal gear shifting until Lowspeed is activated.

When Lowspeed is engaged “Lowspeed activated” (C) shows on the display.

3 Active Lowspeed is indicated by the snail symbol

on the display.

Delay in gear shifting may occur when Lowspeed is

active.

Disengaging Lowspeed

1 Move the lever to neutral position.

2 Press the neutral button (N) to disengage the low-

speed function.

The message “Lowspeed deactivated” (E) shows in

the dispaly.

Propeller Shaft Brake

In certain operational circumstances the propeller may

cause the propeller shaft to rotate when the engine is

stopped. This passive rotation is uncomfortable and

can be harmful to the reverse gear as its oil pump,

which is driven by the input shaft, will not operate when

the engine is stopped.

The propeller shaft may be allowed to rotate with a

stopped engine up to 6–8 hours. After this, the engine

must be started and run for at least five minutes for

lubrication and cooling of the reverse gear.

0

3

2

4

RPMX100

A

B

C

D

E

P0005941

Optional

26 7748887 04-2008

Page 29

In cases where the propeller shaft may rotate faster

than in normal operations, e.g. boat under sail, a temperature gauge should be installed for monitoring the

oil temperature.

Max. permissible temperature for ZF reverse gears is

95°C (203°F).

When the above-mentioned regulations cannot be

met, or when the shaft needs to be stopped or reasons

of comfort, a shaft brake must be fitted. On isolated

occasions the propeller shaft flange may be locked in

a suitable manner instead.

Optional

7748887 04-2008 27

Page 30

Starting

Make a habit of visually checking the engine, engine bay and transmission before start. This will help you to

discover quickly if anything abnormal has happened, or is about to happen. Also check that instruments and

warning displays show normal values when you have started the engine.

To minimize cold start smoke we recommend the installation of an engine heater or engine bay heater if temperatures below +5° C are encountered.

WARNING!

Never use start spray or similar products as starting

aid. Explosion risk!

Before Starting

•

Open the fuel cock.

•

Open the sea cock where fitted.

•

Check the engine and transmission oil level.

•

Check the coolant level.

•

Turn the main switches on.

IMPORTANT!

Never disconnect the current with the main

switches when the engine is running. The alternator and electronics could be damaged.

•

Start the engine bay fan, where fitted, and allow it to

run for at least four minutes.

•

Check that there is sufficient fuel for the planned trip.

1

0

P0005850

28 7748887 04-2008

Page 31

Starting the Engine

Shifting, adjusting speed and performing EVC settings

and calibrations is only possible at an active station.

On a boat with one station the station is always active.

On a boat with two or more stations the main station

automatically becomes active when the EVC system

is started up with the ignition key(s). If the engine(s) is/

are started from another station this station automatically becomes active instead.

Put the reverse gear in neutral

Put the reverse gear in neutral by moving the control

lever(s) to neutral at all stations.

Two lever control: Also check that the engine speed

lever is in the idling position.

Turn the ignition on

Turn the starter key to position I to switch the ignition

on.

Check the tachometer display

If a fault is registered it will be shown in the tachometer

display, please refer to Fault Handling page 39 for

further information and recomended actions.

Starting

7748887 04-2008 29

Page 32

Check lamps

Each time the ignition is turned on, all lamps in the

alarm instrument are illuminated. Check that all lamps

light up and go out. If a lamp flashes a fault has been

registred, please refer to section Fault Han-

dling page 39 for further information and recomended actions.

If the boat has more than one station, it has to be activated before the lamps can vbe checked.

Start the engine

If a station is locked the engines can only be started

and stopped from this station

Start using the ignition switch

Turn the key to position III. Release the key and let it

spring back to position I as soon as the engine has

started.

If repeated start attempts are needed, the key must be

turned back to position 0 first.

Starting with the starter button

Press the starter button. Release the button as soon

as the engine has started.

If you start from a secondary station, the starter key at

the main control station must be in position I.

Overheating protection

If the starter motor is engaged for its maximum activation time (30 seconds), the starter motor circuit is cut

automatically to protect the starter motor from overheating. If possible, leave the starter motor to cool for

at least five minutes before making a new start attempt.

Read the instruments and warm the

engine up

Allow the engine to idle for the first ten seconds. Check

that instruments and warning displays show normal

values. Check that no alarms are displayed and no

warning lamps are flashing. If an alarm is registred,

please refer to section “Fault Handling” for further information and recomended actions.

Warm the engine up at low speed and low load, so

normal operating temperature is reached before full

power is used.

IMPORTANT!

Never race the engine when it is cold.

!

!

+

-

P0002435

START

STOP

P0005860

Starting

30 7748887 04-2008

Page 33

Check the oil level in the reverse gear

Check the oil level when the reverse gear has reached

operating temperature, please refer to the section

“Maintenance, Reverse Gear”.

Starting

7748887 04-2008 31

Page 34

Operation

Learn to handle the engine, controls and other equipment in a safe and proper manner before casting off on your

maiden voyage. Remember to avoid sudden and extreme rudder maneuvers and gear shifts. There is a risk for

passengers and crew falling over or falling overboard.

WARNING!

A rotating propeller can cause serious injury. Check that nobody is in the water before engaging ahead or astern.

Never drive near bathers or in areas where people could be in the water.

Reading the Instruments

Read all instruments and alarm displays directly after

starting, and then regularly during the voyage. Values

from the analog instruments are also shown in the

tachometer display.

Alarms

Alarms and messages are shown in the display, some

alarms do also have a sound alarm. Is there an alarm

instrument installed the lamp in question will flash.

If a malfunction is discovered the sound alarm starts

and the lamp in question in the alarm instrument

flashes. The display will show a fault message.

1 Read the alarm/fault message.

2 Acknowledge the alarm by pressing the knob on the

control panel.

3 Take the indicated actions, see chapter Fault Code

Register page 44.

The fault will be stored as long as the fault remains. It

is possible to read out the fault code at an upcoming

service.

32 7748887 04-2008

Page 35

Maneuvering

Shifting between forward and reverse should be done

at idling. Shifting at higher engine speeds can be

uncomfortable for passengers and cause unnecessary

stress on the stern drive/reverse gear, or cause the

engine to stop.

If you attempt to shift gear at an excessive engine

speed, a safety function cuts in automatically, and

delays shifting until engine speed has fallen to 1000

rpm.

Always do a forwards/reverse operation

as follows:

1 Reduce engine speed to idle and let the boat more

or less lose way.

WARNING!

Never shift to reverse when the boat is planing.

2 Move the control lever to neutral with a rapid, dis-

tinct movement. Make a brief pause.

3 Then move the control lever to reverse with a rapid,

distinct movement and increase engine speed.

IMPORTANT!

It is important all engines are running during reversing

maneuvers to avoid the risk of water entry via the

exhaust pipe into the stationary engine.

1

2

3

P0005856

Operation

7748887 04-2008 33

Page 36

Helm Stations

Changing and activating stations

Changing stations

1 Put the gear in neutral.

The lamp above the neutral button (1) is lit when the

gear is in neutral.

2 Unlock, if locked, the station you leave by pushing

the activation button (2).

3 Activate the station you change to by pressing the

activation button (2).

The lamp above the activation button lights when

the station is active.

An active station is indicated by the lit lamp above the

activation button.

Is the light above the activation button off, the station

is inactive.

If the padlock sign (3) flashes the station can not be

activated. Another station is either active and locked,

or active with the gear engaged (not in neutral)

A flashing light above the activation button (2) indicates

a fault that limits the functionality of the station. The

fault is also indicated by a pop-up appearing in the display, please refer to section “Fault handling”.

Locking/Unlocking station

Is a station locked it is only possible to start or stop the

engine and change stations from this station.

Lock an active station by pressing the activation button

(2). Unlock an active, locked station by pressing the

activation button (2). The padlock sign (3) on the control panel indicates whether the station is locked (lit) or

not (off).

Cruising Speed

For best fuel economy operations at full must be

avoided. We recommend a cruising speed that is at

least 10% below the maximum engine revolutions at

top speed (full throttle).

Depending on hull type, the choice of propeller, the

load and sea state etc., the maximum revolutions at

top speed may vary, but they should be within the full

throttle range; refer to the “Technical data” chapter.

If the engine does not reach its maximum throttle range

it can depend on a number of factors mentioned in the

“Fault tracing” chapter.

Select a propeller with greater pitch if actual engine

revolutions exceed the full throttle range. Contact your

Volvo Penta dealer for advice.

3

2

1

P0006366

Operation

34 7748887 04-2008

Page 37

Synchronizing Engine Speed

When driving with twin engines, both the operating

economy and comfort will be increased when the

engines are operating at the same engine speed (rpm).

When the synchronization function is activated, the

engine speed (rpm) of the starboard engine is automatically adjusted to that of the port engine. The synchronization function is activated automatically if the

following conditions are met.

1 The engine speed levers for both engines are in

(approximately) the same position.

2 The engine speed on both engines exceeds 800

rpm.

NOTICE! The synchronizer is disengaged as soon as

the conditions are no longer met.

Operation

7748887 04-2008 35

Page 38

Engine Shutdown

Allow the engine to run at low idle, in neutral, for a few minutes after operations are completed. In this way afterboiling is avoided at the same time as temperature equalization takes place. This is especially important when

the engine has been run at high rpm or under heavy load.

Stop the Engine

If a station is active and locked the engine(s) can only

be started and stopped from that station.

IMPORTANT!

Never disconnect the current with the main switches

when the engine is running. The alternator and electronics could be damaged.

IMPORTANT!

Make sure the starter key is in 0-position or removed

before main switches are switched off. Otherwise the

alternator and electronics could be damaged.

Stop with key

1 Disengage the reverse gear by putting the control

lever in neutral.

2 Turn the key to stop position “S”. Keep the key

turned until the engine stops. The key will automatically return to the “0” position when it is released

and can then be removed.

The starter key must be in the “0” position or

removed before main switches are switched off.

Stopping with the stop button

1 Disengage the reverse gear by putting the control

lever in neutral.

2 Push the stop button(s). Release the button(s)

when the engine(s) has/have stopped.

36 7748887 04-2008

Page 39

Auxiliary stop

If the engine cannot be stopped in a normal procedure,

it is possible to stop the engine via auxiliary stop

mounted on the side of the engine.

After Engine Shutdown

•

Check the engine and engine bay for leakages.

•

Close the fuel tap.

•

Close the sea cock where fitted.

•

Take an hour meter reading and carry out preventive maintenance according to the maintenance

schedule.

•

Turn off the main switch before any long stoppage.

Operation break with the boat in water

If the boat is not used, but left in the water, the engine

must be warmed up at least once every fortnight. This

prevents corrosion damage in the engine.

If you expect the boat to be unused for two months or

more, it must be laid up, please refer to Short Term

Storage

Operation break with the boat out of water

Where boats are kept laid up on land when not in use,

there is a lower level of galvanic corrosion protection

due to oxidation on the sacrificial anodes. Before

launching the boat the sacrificial anodes on the drive

and shield must be cleaned with emery paper to

remove any oxidation.

10

10

STOP

1

P0004514

1

0

P0005914

Engine Shutdown

7748887 04-2008 37

Page 40

If you expect the boat to be unused for two months or

more, it must be laid up, please refer to Short Term

Storage.

IMPORTANT!

Use emery paper. Do not use a wire brush or other

steel tools when cleaning, as these may damage the

galvanic protection.

Cold Weather Precautions

If the engine bay cannot be kept frost free, the raw

water system must be drained and the freshwater system coolant must have sufficient frost protection to

prevent frost bursting; refer to the sections Seawater

System, Draining page 75 and Maintenance page 70 respectively for more detailed infor-

mation.

Check the charge status of the battery. A poorlycharged battery can freeze and burst.

C

0

10

10

F

32

50

10

20

70

20

20

60

P0005905

Engine Shutdown

38 7748887 04-2008

Page 41

Fault Handling

Despite regular maintenance according to the maintenance schedule and perfect operation conditions faults may

occur which must be attended to before the boat can travel further. This chapter describes alarms and fault

handling.

Alarm handling

Fault information from engine and EVC

system

If a malfunction is discovered the driver is warned by a

buzzer sounding and a pop-up showing in the display.

The pop-ups will toggles between cause of fault and

tasks to perform.

Information regarding ”cause of fault” and ”measures

to take” is found in chapter Fault Code Regis-

ter page 44.

The engine, transmission and EVC system is monitored by the diagnostic function. Should the diagnostic

function discover a malfunction it protects the engine

and ensures continued operation by affecting the

engine. Depending on how serious the malfunction is

the effect on the engine varies.

•

Minor malfunction which does not damage the

engine or transmission.

Affect on engine: None.

•

Serious malfunction which will not immediately damage the engine or transmission e.g. high coolant

temperature.

Affect on engine: Engine power is reduced until

faulty value becomes normal.

•

Serious malfunction which will cause serious damage to engine or transmission.

Affect on engine: Engine power is reduced.

•

Serious malfunction which makes it impossible to

control the engine or transmission.

Affect on engine: Transmission is disengaged and

engine speed is reduced.

It is possible to perform emergency shifting, please

refer to In Case of Emergency page 56.

•

Serious malfunction on transmission or in the engine

fuel injection system.

Affect on engine: Engine is stopped.

It is possible to perform emergency shifting, please

refer to In Case of Emergency page 56. In emergency situations it is also possible to start the engine

with gear engaged after acknowledging the alarm.

!

!

+

-

P0006368

7748887 04-2008 39

Page 42

Acknowledging alarm

1 Push the knob on the control panel to ackowledge

the alarm. The buzzer becomes silent.

2 Read the alarm or message in the pop-up.

3 Push the knob on the control panel again and the

pop-up disappears.

NOTICE! The alarm has to be acknowledged before

the engine can be started.

Popup windows

There are three levels of fault messages showing in

the pop-up: danger, warnign and caution.

Danger

If the Danger pop-up is shown during operation, a serious fault has occured.

Acknowledge the alarm and stop the engine immediately.

Warning

If the Waring pop-up is shown during operation, a fault

has occured.

Acknowledge the alarm and stop the engine at once.

Caution

If the Caution pop-up is shown during operation, a fault

has occured.

Acknowledge the alarm.

P0004987

DANGER! Stop the engine immediately.

P0004986

WARNING! Stop the engine.

P0004985

CAUTION! See operator's manual.

Fault Handling

40 7748887 04-2008

Page 43

Faults list

Is a fault registered the display shows Faults in the

EVC menu along with the number of faults.

Push the knob on the control panel to open the menue.

Turn the knob to see all faults registred.

The popup toggles between cause of fault and tasks

to perform.

Erasing faults in faults list

Acknowledged faults that has been stored automatically erased every time the starter key is turned to the

stop position (S).

Stop the engine and check that the ignition key(s) is

(are) in position 0 in all control positions.

When system voltage is switched on again, the diagnostic function checks whether there are faults in the

EVC system. If this is the case, new fault pop-ups are

shown.

Faults which have been attended to or have disappeared are automatically erased.

Faults which have not been attended to must be

acknowledged every time the system voltage is

switched on.

P0004375

Fault Handling

7748887 04-2008 41

Page 44

Fault Tracing

A number of symptoms and possible causes of engine malfunctions are described in the table below. Always

contact your Volvo Penta dealer if problems occur which you can not solve by yourself.

NOTICE! Read through the safety advice for care and maintenance work in the Safety Information page 6 chapter

before starting work.

Symptoms and possible causes

Pop-ups are shown in the tachometer display See chapter Fault Code Register page 44

Engine can not be stopped 2, 4, 5, 7, 8

Starter motor does not rotate 1, 2, 3, 4, 5, 6, 8, 9, 10, 36, 39

Starter motor rotates slowly 1, 2

Starter motor rotates normally but engine does not start 1, 11, 12, 13, 14, 38, 39

Engine starts but stops again 1, 11, 12, 13, 14, 19, 37, 39

Engine does not reach full operating speed at full throttle 12, 13, 14, 15, 16, 17, 18, 19, 20, 23, 34, 37, 39, 40

Engine runs unevenly 14, 15, 40

Engine vibrates 24

High fuel consumption 15, 16, 18, 21, 37

Black exhaust smoke 19

Blue or white exhaust smoke 21, 35

Lubrication oil pressure too low 22

Coolant temperature too high 25, 26, 27, 28, 29, 30, 31, 32, 33

Coolant temperature too low 32

No charge or poor charge 2, 27

1. Flat batteries

2. Poor contact/open circuit in cables

3. Main switch turned off

4. One of the circuit breakers in the distribution box has tripped

5. Faulty key switch

6. Control lever not in neutral/control position not activated

7. Faulty stop relay

8. Faulty main relay

9. Faulty starter relay

10. Faulty starter motor/solenoid

11. Lack of fuel:

- fuel taps closed

- fuel tank empty

- wrong tank connected

12. Blocked fine fuel filter/pre-filter

(caused by contamination or fuel stratification at low temperature)

13. Air in the fuel system

14. Water/contamination in fuel

15. Boat abnormally loaded

16. Fouling on hull/propeller

17. Cablage to unit injector damaged

18. Faulty unit injectors

Fault Handling

42 7748887 04-2008

Page 45

19. Insufficient air supply to engine:

- blocked air filter

- air leakage between turbocharger and engine inlet manifold

- fouled compressor section in turbocharger

- faulty turbocharger

- poor engine bay ventilation

20. Excessive coolant temperature

21. Too low coolant temperature

22. Too low oil level

23. Faulty / wrong propeller

24. Faulty engine mounting

25. Coolant level too low

26. Air in the freshwater system

27. Drive belt broken/slips

28. Faulty circulation pump

29. Closed seawater inlet

30. Blocked seawater inlet/pipe/filter

31. Defective impeller in seawater pump

32. Defective thermostat

33. Blocked heat exchanger insert

34. Blocked charge air cooler

35. Too high oil level

36. Water entry into engine

37. High back pressure in exhaust system

38. Faulty engine speed sensor

39. Stored fault codes

40. Non-return valve in feed pump leaks

Fault Handling

7748887 04-2008 43

Page 46

Fault Code Register

CAUTION!

Read the safety precautions for maintenance and service in the Safety Information chapter before starting work.

When a malfunction i discovered the driver is warned by a sound alarm and at the same time a pop-up window

is shown in the display. The fault message gives information about what has caused the fault and what actions

to take.

This chapter gives a more detailed description of cause and actions.

Explanation of fault message

A Description of current fault, affect on the system and

measures to take.

B Current warning lamp which flashes during an

alarm. O/R means that an orange or red lamp

flashes.

C Audible warning.

D Fault pop-up which is shown on the EVC tachometer

display.

A.

Explanation:

Battery voltage too low.

B. D.

P0005024

Symptom:

None.

C.

Action:

• Check the batteries fluid level.

• Check belt tension.

• Please contact a Volvo Penta workshop if the fault remains.

1 Is the orange “water in fuel” lamp lit there is to much

water in the water separator on the fuel pre-filter.

2 Is the charging lamp lit the alternator has stopped

charging.

3 Is the coolant temperature lamp lit the coolant tem-

perature is to high.

4 Is the orange coolant level lamp lit during operation

the coolant level is to low.

5 Is the orange oil level lamp lit during operation the

engine oil level is to low.

6 Is the red (R) warning lamp lit during operation a

serious malfunction has been discovered.

Is the orange (O) warning lamp lit during operation

a malfunction has been discovered.

7 Is the red oil pressure lamp lit during operation the

engine oil pressure is to low.

1

2

3

4

5

6

7

P0004761

44 7748887 04-2008

Page 47

Engine Speed

Explanation:

Fault in engine speed sensor.

P0005008

DANGER! Engine Speed See Operator's Manual

Stop engine

Symptom:

Engine power is reduced.

Action:

Please contact a Volvo Penta workshop.

Water in Fuel

Explanation:

Water in water trap in fuel filters.

P0001200

CAUTION! Water in Fuel

See Operator's Manual

Symptom:

None.

Action:

• Empty the water trap underneath the fuel filters. Se Maintenance page 66.

• Please contact a Volvo Penta workshop if the fault remains.

Air Temperature

Explanation:

Charge air temperature too high.

P0005011

WARNING!

Air Temperature See Operator's Manual

Reduce rpm

Symptom:

Engine power is reduced.

Action:

Please contact a Volvo Penta workshop.

Fault Code Register

7748887 04-2008 45

Page 48

Coolant Level

Explanation:

Coolant level too low.

R

P0005012

WARNING! Coolant Level See Operator's Manual

Symptom:

None.

Action:

• Check coolant level. Se Coolant Level, Checking and Topping

Up page 71.

• Check that no coolant leakage occurs in auxiliary equipment

connected to the engine cooling system.

• Please contact a Volvo Penta workshop if the fault remains.

Coolant Temperature

Explanation:

Coolant temperature too high.

P0005014

WARNING! Coolant Temperature See

Operator's Manual

Reduce rpm

Symptom:

Engine power is reduced.

Action:

• Check coolant level. Se Coolant Level, Checking and Topping

Up page 71.

• Check that the seawater filter is not blocked. Se Seawater Filter, Check and Cleaning page 78.

• Check the impeller in the seawater pump. Se Impeller, Check

and Change page 77.

• Check that no leakage occurs.

• If the cooling water flow ceases, the exhaust hose should be

inspected internally and replaced if the hose shows signs of

damage.

• Please contact a Volvo Penta workshop if the fault remains.

Fuel Pressure

Explanation:

Fuel pressure too low.

P0005015

WARNING! Fuel Pressure See Operator's Manual

Reduce rpm

Symptom:

None.

Action:

• Check fuel level.

• Open the fuel taps and check that no leakage occurs.

• Check that the fuel filters are not blocked. Replace filters if

necessary. Se Maintenance page 66.

• Please contact a Volvo Penta workshop if the fault remains.

Fault Code Register

46 7748887 04-2008

Page 49

Fuel Temperature

Explanation:

Fuel temperature too high.

P0005016

WARNING! Fuel Temperature See

Operator's Manual

Reduce rpm

Symptom:

None.

Action:

• Check fuel level.

• Check that no leakage occurs.

• Please contact a Volvo Penta workshop if the fault remains.

Fault Code Register

7748887 04-2008 47

Page 50

Engine Oil Level

Explanation:

Oil level too low.

P0005017

WARNING! Engine Oil Level See Operator's Manual

NOTICE! In rough following seas or head seas, the system can

incorrectly sense that the engine oil level is too low. If this happens,

acknowledge the fault, and check the points below for safety reasons.

Symptom:

None.

Action:

• Check the oil level in the engine. Se Oil level, checking and

topping up page 63.

• Check that no leakage occurs.

• Please contact a Volvo Penta workshop if the fault remains.

Engine Oil Pressure

Explanation:

Oil pressure too low.

P0005018

WARNING! Engine Oil Pressure See

Operator's Manual

Stop Engine

Symptom:

Engine power is reduced.

Action:

• Check the oil level in the engine. Se Oil level, checking and

topping up page 63.

• Check that the oil filters are not blocked. Replace filters if necessary.

• Check that no leakage occurs.

• Please contact a Volvo Penta workshop if the fault remains.

Engine Oil Temperature

Explanation:

Engine oil temperature too high.

P0005019

WARNING! Engine Oil Temperature

See Operator's Manual

Reduce rpm

Symptom:

Engine power is reduced.

Action:

• Check the oil level. Se Oil level, checking and topping

up page 63.

• Check that no leakage occurs.

• Please contact a Volvo Penta workshop if the fault remains.

Fault Code Register

48 7748887 04-2008

Page 51

Transmission Oil Pressure

Explanation:

Reverse gear oil pressure too low.

P0005023

WARNING! Transmission Oil Pressure

See Operator's Manual

Symptom:

None.

Action:

• Check the oil level. Se Oil level, checking and topping

up page 84.