Page 1

OPERATOR’S MANUAL

D1, D2

Page 2

CALIFORNIA PROPOSITION 65 WARNING

Engine exhaust, some of its constituents, and a broad range of engine parts are known to the State of California to cause cancer, birth

defects, and other reproductive harm. Additionally, lubricants, fuels, and other uids used in engines–including any waste created through

the wearing of engine parts–contain or produce chemicals known to the State of California to cause cancer and birth defects or other

reproductive harm.

Battery posts, terminals, and related accessories contain lead and lead compounds. Wash your hands after handling. Used engine oil

contains chemicals that have caused cancer in laboratory animals. Always protect your skin by washing thoroughly with soap and water.

47702088 - Downloaded from www.volvopenta.com 02/06/2011 18:54:55

Page 3

Content

Foreword ...................................................................................................... 2

Safety Information ...................................................................................... 3

Introduction ................................................................................................. 8

Instruments and Controls ........................................................................ 10

Starting ...................................................................................................... 18

Operation ................................................................................................... 20

Engine Shutdown ...................................................................................... 23

Fault Handling ........................................................................................... 25

In Case of Emergency .............................................................................. 29

Maintenance Schedule ............................................................................. 31

Maintenance .............................................................................................. 33

Storage ....................................................................................................... 64

Technical Data ........................................................................................... 68

Operator's Manual Order .......................................................................... 74

Alphabetical index .................................................................................... 75

47702088 - Downloaded from www.volvopenta.com 02/06/2011 18:54:55

1

Page 4

Foreword

Volvo Penta marine engines are used all over the world. They are used in all possible operating conditions for

professional as well as leisure purposes. This is not a coincidence. After 100 years as an engine manufacturer

the Volvo Penta name has become a symbol of reliability, technical innovation, top of the range performance and

long service life. We also believe that this is what you demand and expect of your Volvo Penta engine.

We would like you to read this operator’s manual thoroughly and consider the advice we give on running and

maintenance before your maiden voyage so that you will be ensured of fulfilling your expectations. Please pay

attention to the safety instructions contained in the manual.

As owner of a Volvo Penta marine engine, we would also like to welcome you to a worldwide network of dealers

and service workshops to assist you with technical advice, service requirements and replacement parts. Please

contact your nearest authorized Volvo Penta dealer for assistance.

You will find your closest dealer at our home page on the Internet www.volvopenta.com - amongst other

useful information about your Volvo Penta engine - we invite you to visit!

47702088 - Downloaded from www.volvopenta.com 02/06/2011 18:54:55

2 47702088 05-2011

Page 5

Safety Information

!

Read this chapter very carefully. It has to do with your safety. This describes how safety information is presented

in the operator’s manual and on the product. It also gives you an introduction to the basic safety rules for using

and looking after the engine.

Check that you heave received the correct operator’s manual before you read on. If not, please contact

your Volvo Penta dealer.

This symbol is used in the operator’s manual and on the product, to call your attention

to the fact that this is safety information. Always read such information very carefully.

Safety texts in the operator’s manual have the following order of priority:

DANGER!

Indicates a hazardous situation which, if not avoided, will result in death or serious

injury.

WARNING!

Indicates a hazardous situation which, if not avoided, could result in death or serious

personal injury.

CAUTION!

Indicates a hazardous situation which, if not avoided, could result in minor or moderate

personal injury.

IMPORTANT!

Indicates a situation which, if not avoided, could result in property damage.

47702088 - Downloaded from www.volvopenta.com 02/06/2011 18:54:55

NOTICE! Used to draw attention to important information that will facilitate work or

operations.

This symbol is used on our products in some cases and refers to important information

in the operator’s manual. Make sure that warning and information symbols on the

engine are clearly visible and legible. Replace symbols which have been damaged or

painted over.

47702088 05-2011 3

Page 6

Safety Information

Your new boat

Read the instruction books and other information

carefully, which came with your new boat. Learn to

handle the engine, controls and other equipment in a

safe and correct manner.

If this is your first boat, or a type of boat you are not

experienced in using, we recommend that you practice operating the boat in peace and quiet. Get to know

the way the boat reacts to sea and to the controls

under different speed, sea and loading conditions

before you cast off for your first “real” maiden voyage.

Remember that the captain of every boat is required

by law to know and to observe applicable rules for

traffic and safety at sea. Get to know the rules which

apply to you and your waters, by contacting the relevant authority or sea safety organization.

It is a good idea to go on some kind of boat operation

course. We recommend that you contact a regional

boat or sea safety organization to find a suitable

course.

Daily checks

Make it a habit to give the engine and engine bay a

visual check before driving (before starting the

engine) and after operation (when you have stopped

the engine). This helps you to quickly discover

whether any leakage of fuel, coolant, oil or any other

abnormal event has happened, or is about to happen.

Fuel filling

There is always a risk of fire and explosion during fuel

filling. Smoking is not permissible, and the engine

should be stopped.

Never over-fill the tank. Shut the tank cap securely.

Only use the fuel recommended in the instruction

book. The wrong grade of fuel can cause serious malfunctions, power loss or stop the engine.

Do not start the engine

Do not start the engine if you suspect a fuel or LPG

leak in the boat, close to explosive media, or if there

is a spillage of explosive media. An explosive environment entails a risk of fire and/or explosion.

Manoeuvring

Avoid sudden or surprising rudder movements and

gear shifting. There is a risk that passengers could fall

over, or overboard.

A rotating propeller can cause severe injury. Check

that there is nobody in the water before you engage

forward / astern (reverse) drive. Never drive close to

47702088 - Downloaded from www.volvopenta.com 02/06/2011 18:54:55

bathers or in areas where you could reasonably

expect that people could be in the water.

Accidents and near misses

Life saving statistics show that inadequate care of

boats and engines, and deficiencies in safety equipment are frequent causes of accidents and near

misses at sea.

Make sure that your boat and engine are maintained

in accordance with the advice in each instruction

book, and that the necessary safety equipment is on

board, and is in working condition.

4 47702088 05-2011

Page 7

Carbon monoxide poisoning

P0003073

When a boat moves forwards, an area of low pressure

air forms behind the boat. In adverse conditions, this

low pressure can be so strong that the boat’s own

exhaust fumes are sucked into the cockpit or cabin,

which entails a risk of carbon monoxide poisoning for

all aboard.

The problem of low-pressure suction is worst in high,

wide boats with a square transom. But even in other

types of boats, low-pressure suction can be a problem

in some conditions, such as if you drive with the hood

up. Other factors which increase the low-pressure

effect are wind conditions, load distribution, pitching,

trimming, open windows and ventilators etc.

Safety Information

Most modern boats are designed so that the problem

of low-pressure suction is very rare, however. If lowpressure suction does occur anyway, do not open

hatches or ventilators in the forward part of the boat.

Strangely enough, this makes the problem worse. Try

changing speed, trimming or load distribution instead.

Also try taking down/opening the hood or modifying it

in some other manner. Ask your boat dealer for advice

about the best solution for your particular boat.

Remember

• Safety equipment: Life jackets for everybody aboard, communication equipment, emergency

rockets, approved fire extinguisher, first aid kit, life buoy, anchor, paddle, torches etc.

• Spare parts and tools: Impeller, fuel filters, fuses, tape, hose clamps, engine oil, propeller and

tools for the jobs you could be expected to have to do.

47702088 - Downloaded from www.volvopenta.com 02/06/2011 18:54:55

• Take your chart out and study your planned route. Calculate distance and fuel consumption.

Listen to weather reports.

• Tell your friends/relatives about route plans if you undertake a long journey. Remember to

notify changed plans or delays.

• Inform everybody aboard about where the safety equipment is located, and how it works. Make

sure that there is more than one person aboard who can start and operate the boat safely.

This list can be extended, since the need for safety equipment varies with the type of boat, and

where or how it is used etc. We recommend that you ask a regional boat or sea safety organization

for more detailed maritime safety information.

47702088 05-2011 5

Page 8

Safety Information

Preparations

Knowledge

The operator’s manual contains instructions on how

to carry out general maintenance and service operations safely and correctly. Read the instructions carefully before starting work.

Service literature covering more complicated operations is available from your Volvo Penta dealer.

Never carry out any work on the engine if you are

unsure of how it should be done, contact your Volvo

Penta dealer who will be glad to offer assistance.

Stop the engine

Stop the engine before opening or removing engine

hatches. Unless otherwise specified all maintenance

and service must be carried out with the engine stopped.

To prevent accidental start of the boat engine, remove

the ignition key, turn off the power supply to the engine

at the main switches and lock them in the OFF position before starting work. Put up a warning sign in the

control position that work on the engine is being carried out.

Approaching or working on an engine which is running

is a safety risk. Loose clothing, hair, fingers or a dropped tool can be caught in the rotating parts of the

engine and cause serious personal injury. Volvo

Penta recommend that all servicing with the engine

running should be undertaken by an authorized Volvo

Penta workshop.

Lifting the engine

When lifting the engine, use the lifting eyes installed

on the engine (reverse gear where installed). Always

47702088 - Downloaded from www.volvopenta.com 02/06/2011 18:54:55

check that lifting equipment is in good condition and

has sufficient load capacity to lift the engine (engine

weight including reverse gear and any extra equipment installed). For safety’s sake lift the engine using

an adjustable lifting beam. All chains and cables

should run parallel to each other and as perpendicular

as possible in relation to the top of the engine. Bear

in mind that extra equipment installed on the engine

may alter its center of gravity. Special lifting equipment may then be required in order to maintain the

correct balance and make the engine safe to handle.

Never carry out work on an engine suspended on a

hoist.

Before starting the engine

Reinstall all protective parts removed during service

operations before starting the engine. Check that no

tools or other items have been left on the engine.

Never start a turbocharged engine without installing

the air cleaner (ACL). The rotating compressor in the

Turbocharger unit can cause serious personal injury.

Foreign objects can also be sucked in and cause

mechanical damage to the unit.

Fire and explosion

Fuel and lubrication oil

All fuel, most lubricants and many chemicals are

inflammable. Read and follow the instructions on the

packaging.

When carrying out work on the fuel system, make sure

the engine is cold. A fuel spill onto a hot surface or

electrical components can cause a fire.

Store fuel soaked rags and other flammable material

so that there is no danger of them catching fire. Fuelsoaked rags can self-ignite under certain conditions.

Do not smoke when filling fuel, oil or in proximity of a

filling station or in the engine room.

Non-original components

Components used in the fuel and electrical systems

on Volvo Penta products are designed and constructed to minimize the risk of fire and explosion.

Using spare parts other than by Volvo Penta

approved spare parts can result in fire or explosion on

board.

Batteries

The batteries contain and emit oxyhydrogen gas,

especially during charging. This gas is easily ignited

and highly volatile.

Do not under any circumstances smoke or use naked

flame or allow sparks in the vicinity of the batteries or

battery compartment.

An incorrect connection of a battery terminal cable or

jump-start cable can cause a spark which in its turn

can be sufficient to cause an explosion.

Start spray

Never use start spray or similar agents to start an

engine equipped with air pre-heating (glow plugs/

starter element). This may cause an explosion in the

inlet manifold. Danger of personal injury.

6 47702088 05-2011

Page 9

Safety Information

Hot surfaces and fluids

There is always a risk of burns when working with a

hot engine. Beware of hot surfaces. For example: the

exhaust pipe, turbo unit, oil pan, charge air pipe,

starter element, hot coolant and hot oil in oil lines and

hoses.

Carbon monoxide poisoning

Only start the engine in a well-ventilated area. If operating the engine in an enclosed space, ensure that

there is proper ventilation in order to remove exhaust

gases and crankcase ventilation emissions from the

working area.

Chemicals

Most chemicals such as anti-freeze, rustproofing

agent, inhibiting oil, degreasing agent etc. are hazardous to health. Read and follow the instructions on

the packaging.

Some chemicals such as inhibiting oil are inflammable

and dangerous if breathed in as well. Ensure good

ventilation and use a protective mask when spraying.

Read and follow the instructions on the packaging.

Store chemicals and other hazardous materials out of

the reach of children. To protect the environment,

please dispose of used or leftover chemicals at a

properly designated disposal site for destruction.

Cooling system

There is a risk of flooding when working on the seawater system. Turn off the engine and close the sea

cock (where installed) before starting work on the system.

47702088 - Downloaded from www.volvopenta.com 02/06/2011 18:54:55

Avoid opening the coolant filler cap when the engine

is hot. Steam or hot coolant can spray out and cause

burns.

Fuel system

Always use protective gloves when tracing leaks. Liquids ejected under pressure can penetrate body tissue and cause serious injury. There is a danger of

blood poisoning.

Always cover the generator if it is located under the

fuel filter. The generator can be damaged by spilled

fuel.

Electronic Vessel Control (EVC)

The boat has a advanced control system. Never cut

or modify connectors, wiring or splice of the components.

Installing non Volvo Penta components may cause

the system to malfunction.

Service must be done by approved workshops.

Electrical system

Cutting off power

Always stop the engine and break the current using

the main switches before working on the electrical

system. Isolate shore current to the engine block

heater, battery charger, or accessories mounted on

the engine.

Batteries

The batteries contain an extremely corrosive electrolyte. Protect your skin and clothes when charging or

handling batteries. Always use protective goggles and

gloves.

If battery electrolyte comes into contact with unprotected skin, wash off immediately using plenty of

water and soap. If battery acid comes into contact with

the eyes, flush immediately with plenty of water and

obtain medical assistance without delay.

If work must be carried out with the engine at operating temperature and the coolant filler cap or a cock

open or a coolant hose disconnected, open the coolant filler cap carefully and slowly to release pressure

before removing the cap completely. Note that the

coolant may still be hot and can cause burns.

Lubrication system

Hot oil can cause burns. Avoid skin contact with hot

oil. Ensure that the lubrication system is not under

pressure before commencing work on it. Never start

or operate the engine with the oil filler cap removed,

oil can spray out.

47702088 05-2011 7

Page 10

Introduction

This Operator's Manual has been prepared to give you the greatest possible benefit from your Volvo Penta marine

engine. It contains the information you need to be able to operate and maintain the engine safely and correctly.

Please read the Operator's Manual carefully and learn to handle the engine, controls and other equipment in a

safe manner before you cast off on your maiden voyage.

Always have the Operator's Manual available. Store it safely and do not forget to hand it over to the next owner

if you sell your boat.

The Operator’s Manual describes the engine and equipment sold by Volvo Penta. The illustrations in this book

covers several varieties and might differ, the essential information is always correct though. Installations with e.g.

different controls and instrumentation might occur, in these cases we refer to this products manual.

Warranty

Your new Volvo Penta marine engine is covered by a

limited warranty, under the conditions compiled in the

Warranty book.

Please note that AB Volvo Penta’s liability is limited to

the specification in the Warranty book. Read it carefully, as soon as possible after delivery. It includes

important information about warranty cards, service,

maintenance, which it is the responsibility of the

owner to know, check and carry out. If this is not done,

AB Volvo Penta may fully or partly refuse to honour its

warranty undertakings.

Please contact your Volvo Penta dealer if you

have not received a Warrant book, a Service book

or a customer copy of the warranty card.

Environmental care

All of us want to live in a clean, healthy environment.

Where we can breathe clean air, see healthy trees,

have clean water in lakes and seas, and be able to

enjoy the sunlight without fearing for our health.

Unfortunately, this is not self-evident these days, it is

47702088 - Downloaded from www.volvopenta.com 02/06/2011 18:54:55

something all of us must work hard for.

As a manufacturer of marine engines, Volvo Penta

has particular responsibility and for this reason, environmental care is a core value in our product development. Volvo Penta has a wide engine programme

these days, where considerable progress has been

made in reducing exhaust fumes, fuel consumption,

engine noise etc.

We hope that you will be want to preserve these values. Always observe the advice in the Operator's

Manual about fuel grades, operation and maintenance, to avoid unnecessary environmental impact.

Please contact your Volvo Penta dealer if you notice

any changes such as increased fuel consumption or

increased exhaust smoke.

Moderate your speed and distance so that wake and

noise do not disturb or damage animal life, moored

boats, jetties etc. Leave the archipelago and harbours

in the same state you would like to find them. Remember to always hand in drained oil, coolant, paint and

wash residue, used batteries etc. for destruction at a

recycling station.

If we all pull together, we can make a valuable contribution to the environment together.

Running in

The engine must be “run in” during its first 10 hours,

as follows:

Use the engine in normal operation. Full load should

only be applied for short periods. Never run the engine

for a long period of time at constant speed during this

period.

Higher oil consumption is normal during the running

in period. For this reason, check the oil level more

frequently than normally recommended.

After the first period of operation, the specified warranty inspection “First service inspection” can be

done. For more information: Please refer to the Maintenance Schedule.

Fuel, oils and coolant

Only use the fuels and oils recommended in the Operator's Manual. Other grades can cause malfunctions,

increased fuel consumption and eventually even

shorten the life of the engine.

Always change the oil, oil filters and fuel filter at the

specified intervals.

Future warranty claims related to engine and accessories may be refused if an unsuitable coolant has

been used, or if the instructions for coolant mixture

have not been followed.

8 47702088 05-2011

Page 11

Introduction

Service and spare parts

Volvo Penta marine engines are designed for high

reliability and long life. They are built to withstand a

marine environment, but also to have the smallest

possible environmental impact. Through regular service and use of by Volvo Penta approved spare parts,

these qualities are retained.

Volvo Penta’s world-wide network of authorised dealers is at your service. They are Volvo Penta product

specialists, and have the accessories, original spares,

test equipment and special tools needed for high quality service and repair work.

Always observe the maintenance intervals in the

Operator's manual, and remember to note the engine/

transmission identification number when you order

service and spare parts.

Certified engines

If you own or operate an emission certified engine it

is important to be aware of the following:

Certification means that an engine type has been

checked and approved by the relevant authority. The

engine manufacturer guarantees that all engines

made of the same type are equivalent to the certified

engine.

This makes special demands on the care and

maintenance you give your engine, as follows:

• Maintenance and service intervals recommended by Volvo Penta must be complied with.

• Only Volvo Penta original spares may be used.

• Service on injection pumps, pump settings and

injectors must always be done by an authorised

Volvo Penta workshop.

• The engine must not be converted or modified,

except for the accessories and service kits

which Volvo Penta has approved for the engine.

• Installation changes to the exhaust pipe and

engine air inlet ducts must not be done.

47702088 - Downloaded from www.volvopenta.com 02/06/2011 18:54:55

• No seals may be broken by unauthorised personnel.

The general advice in the Operator's manual about

operation, care and maintenance apply.

Late or inadequate maintenance/service or the use of

spare parts not approved by Volvo Penta will invalidate AB Volvo Penta’s responsibility for the engine

specification being in accordance with the certificated

variant.

Volvo Penta accepts no responsibility or liability for

any damage or costs arising due to the above.

47702088 05-2011 9

Page 12

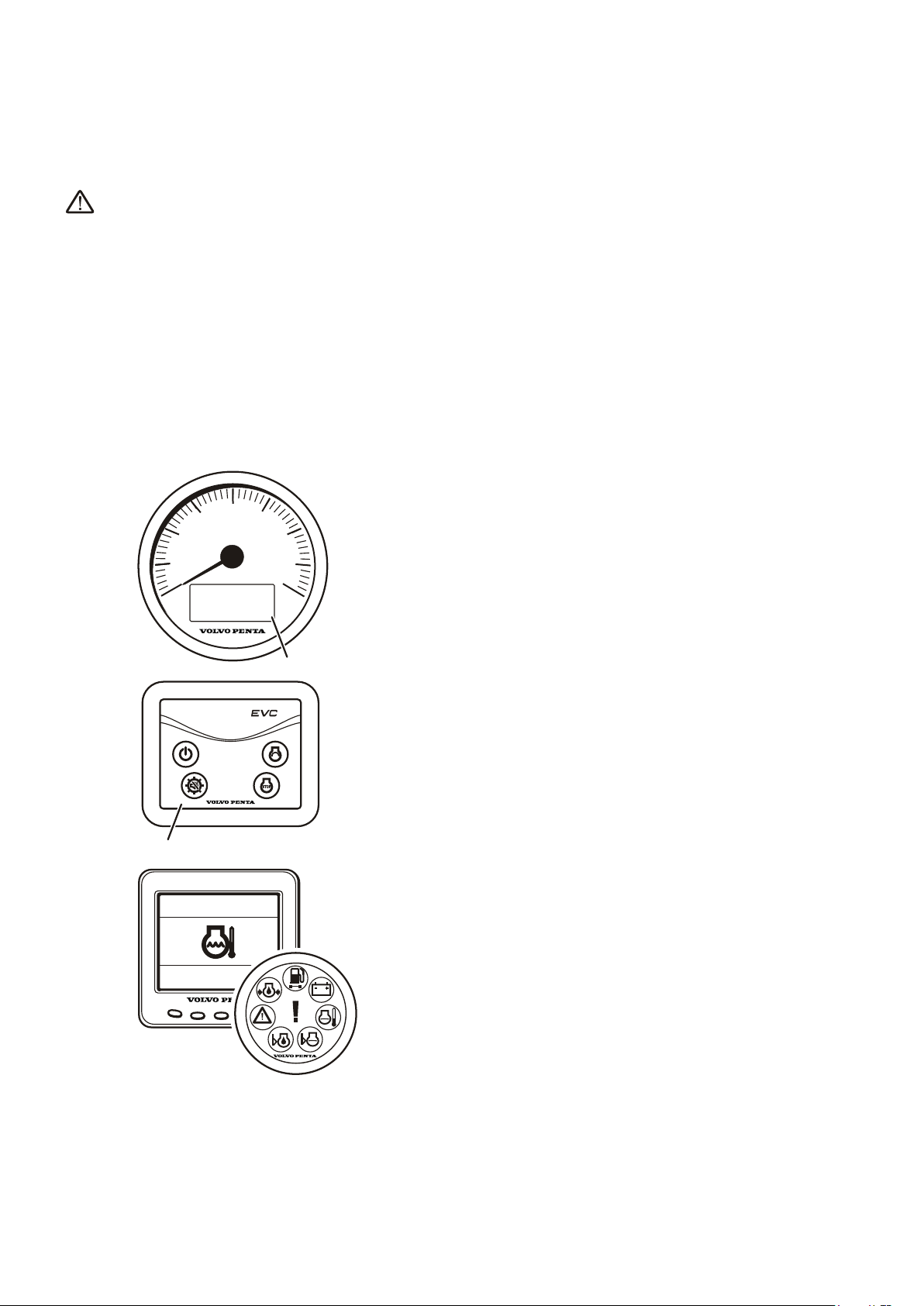

Instruments and Controls

1

2

3

4

This chapter describes the instruments, panels and controls Volvo Penta sells for your engine.

If you would like to complement your instrumentation, or if your boat is equipped with instruments not described

here, we ask that you contact your Volvo Penta dealer.

Ignition Lock

The system lacks a start lock. Therefore, the helm station should be lockable, or alternatively a lockable main

switch should be fitted, to prevent unauthorized engine

start.

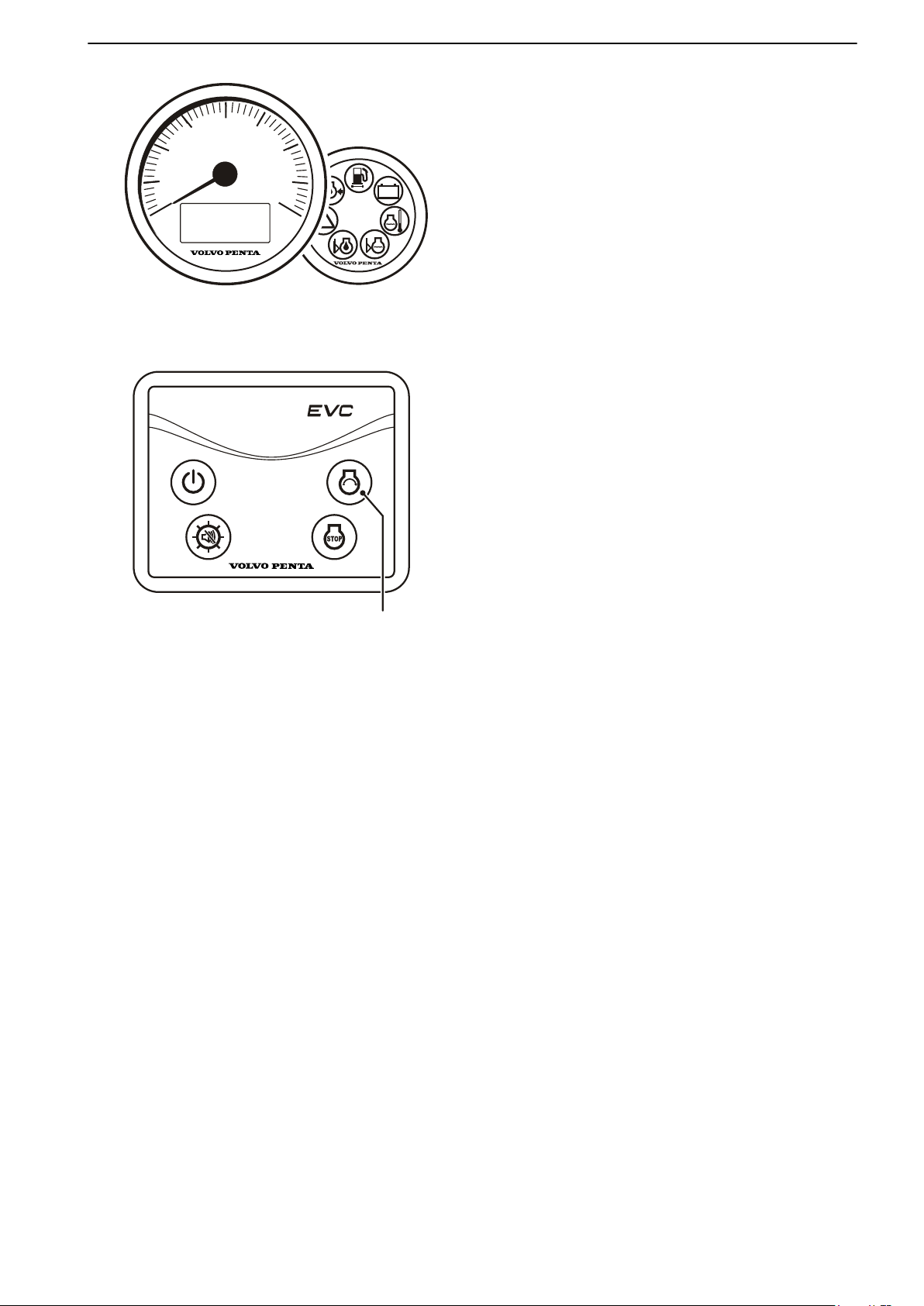

Start/Stop Panel

Control Panel

On/Off button (1)

Depress the button to start or stop the system.

The panel cannot be switched off when the engine is

running.

47702088 - Downloaded from www.volvopenta.com 02/06/2011 18:54:55

Start button (4)

When the button is depressed the pre-heat function is

activated and the start motor engaged.

Multi-function button (2)

Confirm the alarm. If an alarm occurs, a flashing

•

warning symbol will be displayed in the tachometer

window and an audible alarm will sound.

The alarm is confirmed by depressing the multifunction button. The audible alarm is silenced and

the warning symbol is lit continuously until the fault

is remedied.

Backlighting. To switch tachometer window back-

•

lighting on or off, depress the button for 1 - 5 seconds.

The backlighting can be adjusted in five steps by

depressing the button for less than 1 second.

Adjust the tachometer window contrast by holding

•

down the button for more than 5 seconds.

Stop button (3)

The engine stops running when the button is

depressed.

10 47702088 05-2011

Page 13

AUX

1

2

3

4

5

6

7

8

9

0

3

2

1

4

RPMX1000

P0007517

Instruments and Controls

Gauges

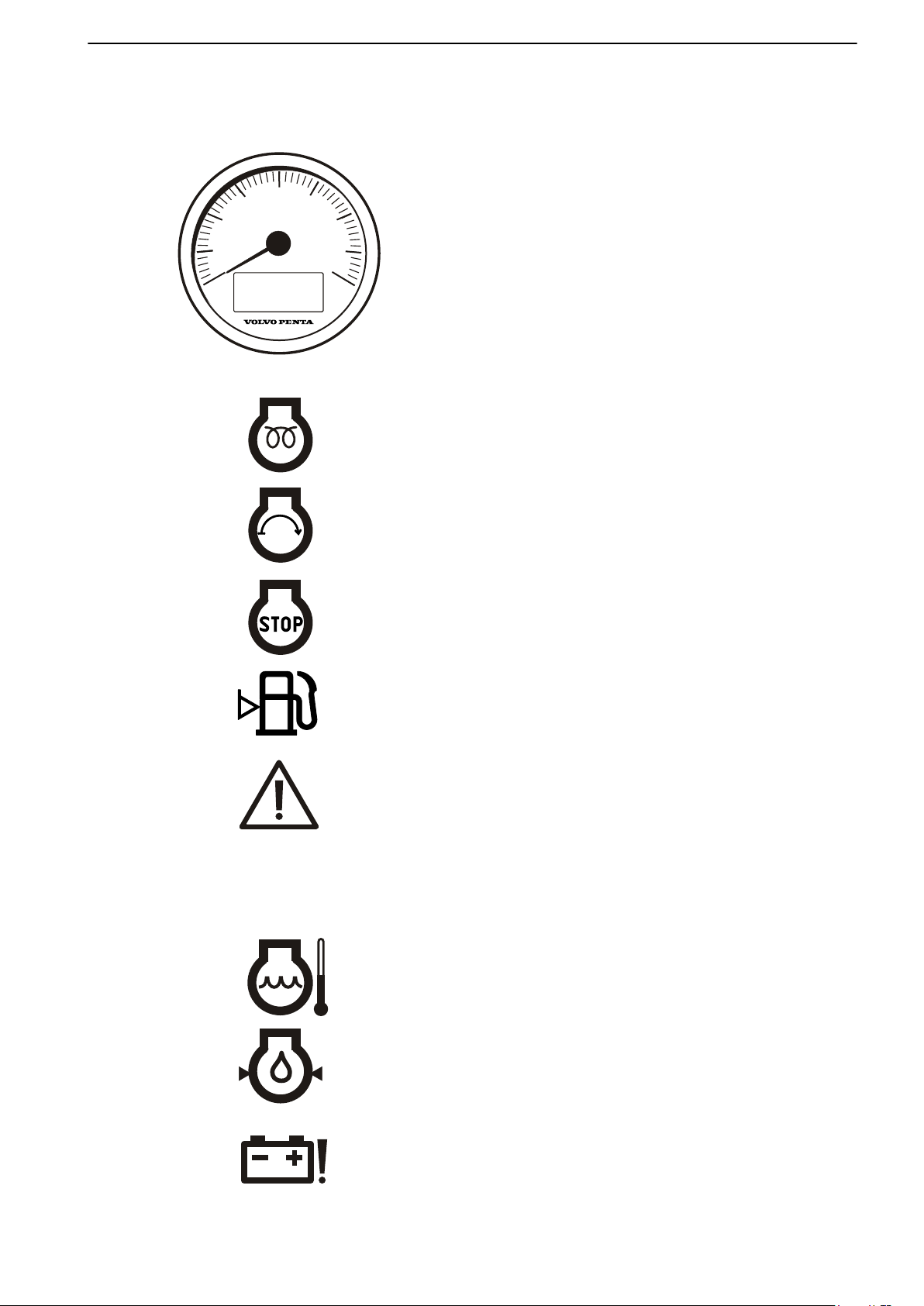

Tachometer

The tachometer shows engine speed; multiply the

value shown on the dial by 1,000 to get the number of

engine revolutions per minute.

Operating information is displayed in the tachometer

window.

47702088 - Downloaded from www.volvopenta.com 02/06/2011 18:54:55

Operating information symbols

1 Pre-heating

The pre-heat symbol is displayed when the glow

function is active.

2 Starting

The start symbol is displayed when the start motor

is engaged.

3 Stopping

The stop symbol is shown when the stop button is

depressed.

4 Fuel level

If a fuel level sensor is installed (accessory) the fuel

level symbol is displayed when there is around 20%

of fuel remaining in the tank.

The engine must run for at least one minute before

the function is activated.

5 System fault

The system fault symbol lights up in the case of

short circuits or cable breaks.

6 Auxiliary alarm

Auxiliary alarm for accessory sensors.

7 Coolant temperature

The coolant temperature symbol lights up if the

engine coolant temperature is too high.

8 Oil pressure

If the oil pressure lamp lights up during operations,

the engine oil pressure is too low.

9 Charging

The charging lamp lights up if the alternator stops

charging.

47702088 05-2011 11

Page 14

1

P0007518

Instruments and Controls

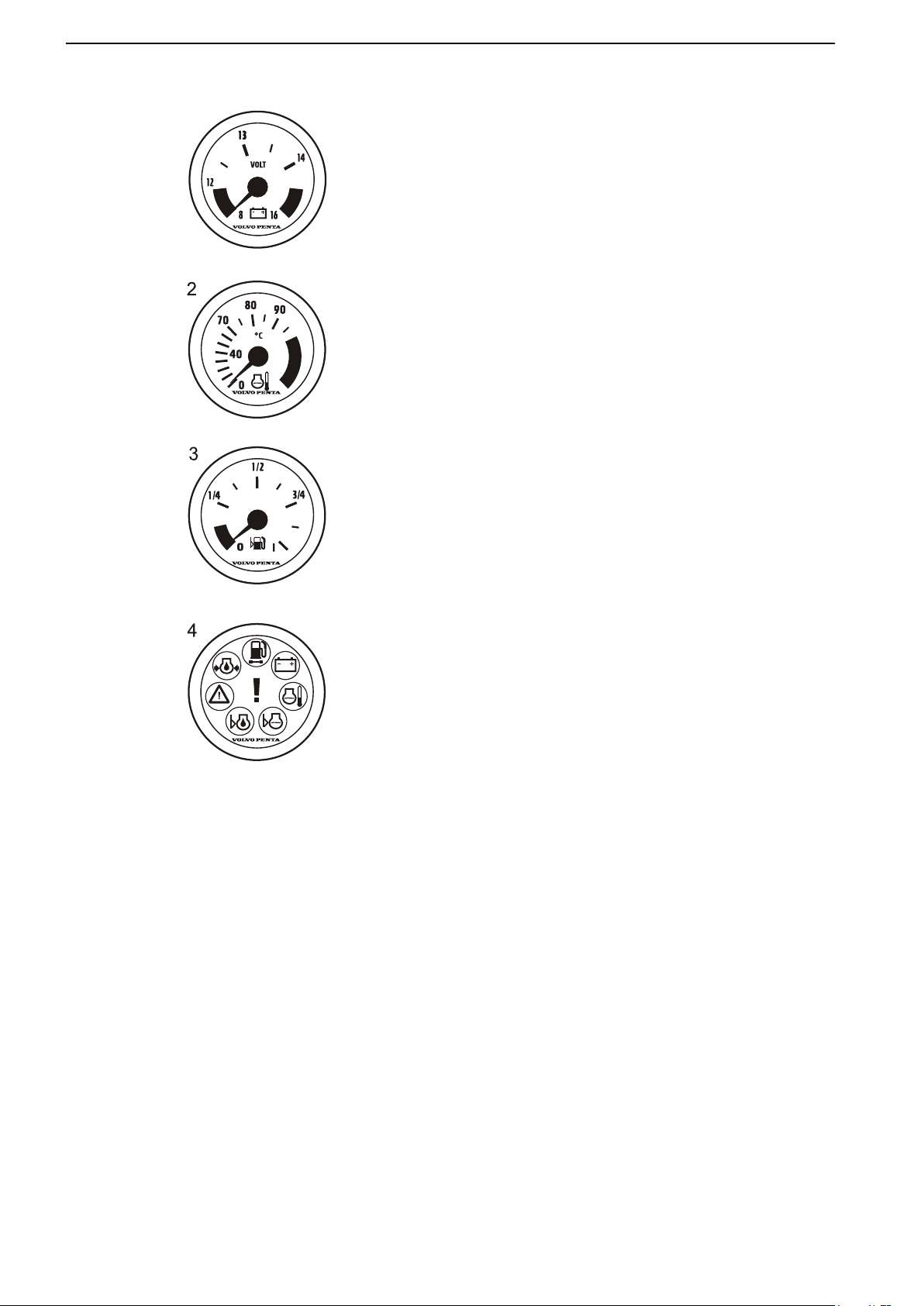

Optional instruments

These instruments are sold as engine accessories by

Volvo Penta.

1 Voltmeter, battery charging

The meter shows the alternator charge current.

During operations the charge voltage must be

around 14 V. When the engine is stopped and electrical power switched on, battery voltage is around

12 V.

2 Coolant temperature gauge

The instrument shows engine coolant temperature.

During operations coolant temperature must normally be between 75-95°C (167-203°F).

3 Fuel level gauge

The fuel level gauge shows the quantity of remaining fuel.

4 Alarm monitor

The alarm monitor gives a visual warning to call

attention to any alarms that occur.

47702088 - Downloaded from www.volvopenta.com 02/06/2011 18:54:55

12 47702088 05-2011

Page 15

1 2

3

4 5

G H

P0001168

0

ENGINE HOURS

HOURS

P0003010

Instruments and Controls

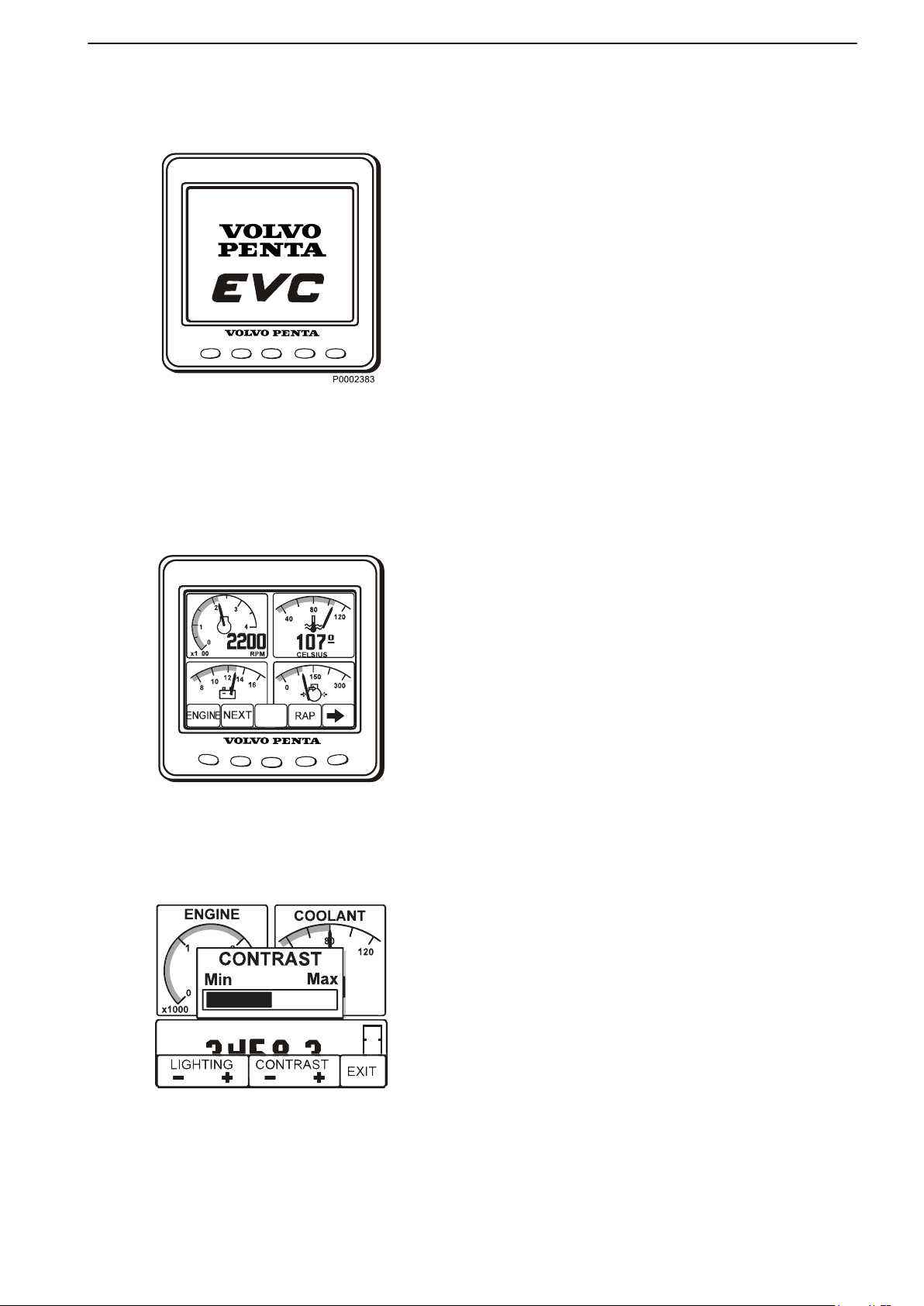

EVC System Display

It is possible to present several windows with different

operational information in the EVC system display. The

various screens are selected using the instrument buttons.

Before the display is put to use certain settings must

be entered in the configuration menu; refer to Config-

uration menu.

It is also possible to bring up a menu identical to that

shown in the tachometer display by navigating to System information in the Configuration menu, or by

depressing button 2; refer to Multi, button 2.

47702088 - Downloaded from www.volvopenta.com 02/06/2011 18:54:55

A self-test is performed at start; the display will emit a

constant audible signal if a fault is detected. The display will continue to function, but may behave in unexpected ways.

Only installed functions are shown in the display.

Screens

Depress any of the buttons 1 to 4 to bring up the function menu for the buttons on the lower part of the display.

Buttons 1, 2 and 4 provide different screens.

Button 1 – Engine

Button 2 – Multi

Button 4 – Graph

Use button 5 to adjust contrast and to access the configuration menu for display settings; refer to Configu-

ration menu.

Exit the menu by waiting a few seconds or by depressing button 5 (EXIT).

Contrast

The display has five contrast settings. Depress button

5 (far right) and change the contrast by depressing +

(button 4) or – (button 3).

Store the setting by depressing EXIT (button 5).

47702088 05-2011 13

Page 16

P0007392

P0003011

Instruments and Controls

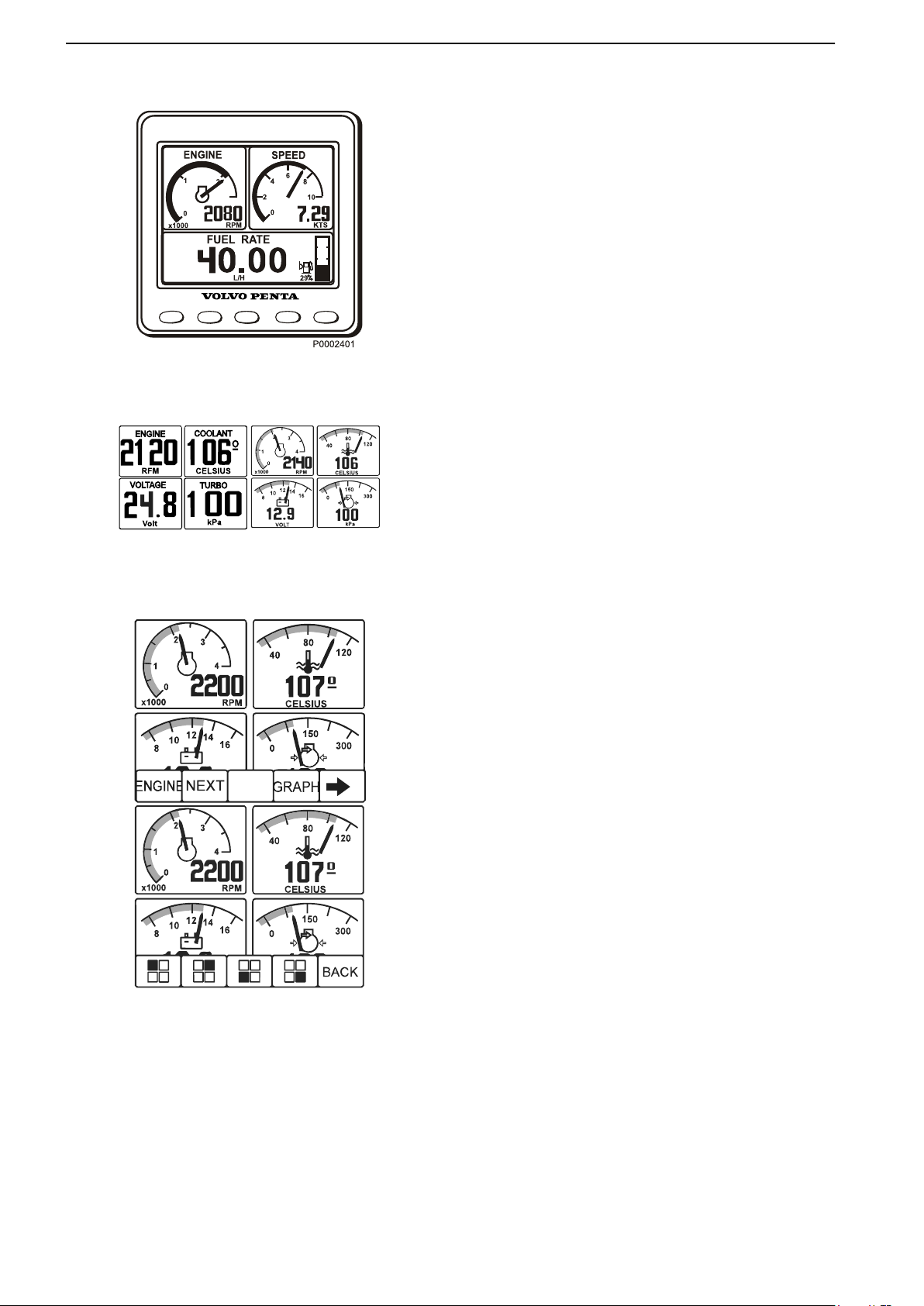

Engine, button 1

Engine revolutions and speed are shown in the upper

part of the window. Operating hours are displayed in

the lower part, along with a fuel level indicator if this

function is installed.

If speed information is lacking, coolant temperature will

be shown instead.

Multi, button 2

Operational information is displayed in four analog or

digital windows in the multi screen. The display can

either show several windows, or be divided so that the

lower part shows System information. To switch

between the different screens depress button 2 repeatedly.

47702088 - Downloaded from www.volvopenta.com 02/06/2011 18:54:55

If the selected information is lacking, the symbol “—”

will be displayed: for analog instruments the dial will be

absent.

Selecting screens

Depress the right arrow (button 5) to select the information to be displayed in each respective window.

Then repeatedly depress the button that corresponds

to the window to be set until the desired information is

shown.

The type of information accessible depends on the

type of electrical system and sensors the boat is equipped with.

14 47702088 05-2011

Page 17

4000

2000

P0002420

Instruments and Controls

Graph, button 4

This screen displays operational information in the

form of graphs. Depress button 4 repeatedly to select

the information to be displayed. To set the time interval,

refer to Configuration menu.

If contact with the system is lost, a straight line will proceed across the screen.

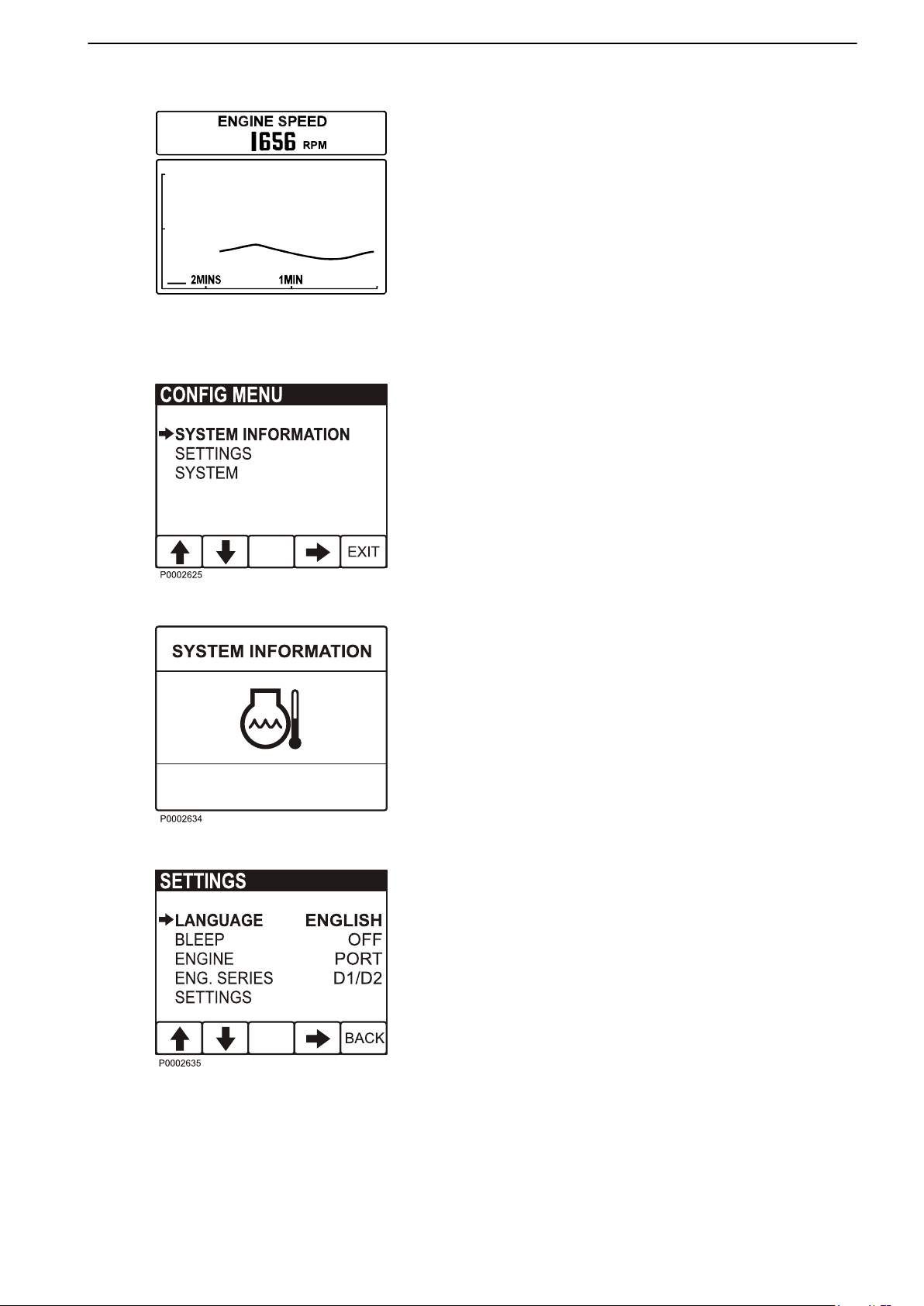

Configuration menu

Open the Configuration menu by holding down button

5 for at least 3 seconds. In this screen it is possible to

retrieve System information, enter various display settings, calibrate depth compensation and speed and

retrieve other system information.

47702088 - Downloaded from www.volvopenta.com 02/06/2011 18:54:55

Engine ignition must be switched on when changing

display settings or calibrating functions.

Navigate through the menu using the up and down

arrows, and select using the right arrow.

System Information

This screen shows the same information as that shown

in the tachometer display; refer to Instruments and

Controls page 11 for further information.

Alarm

When the system detects a fault, the display automatically switches to the System Information screen. For

further information, refer to Fault Handling page 25.

Settings

Language: setting the display language.

Bleep: setting button bleep On or Off.

Engine: setting the installation the display forms part

of, and the engine to be shown in the display (single,

port, starboard or twin).

Eng. series: setting the engine series for the display

(D1/D2, <D2). The display is factory set for engines

larger than D1/D2, therefore the display must be re-set

before it can be used on D1/D2 engines.

Display: setting speed indicator and tachometer intervals.

47702088 05-2011 15

Page 18

P0003002

P0003005

Instruments and Controls

- Rpm intervals, 2500–9000 rpm in 500 rpm stages.

Set 4000 rpm.

- Speed, on/off.

- Speed intervals, 10–100 knots in 10 knot stages.

- Graph intervals: 2 min, 10 min, 30 min, 60 min, 2 h,

4 h or 8 h.

- Speed (Speed): KNOTS, MPH, KM/H

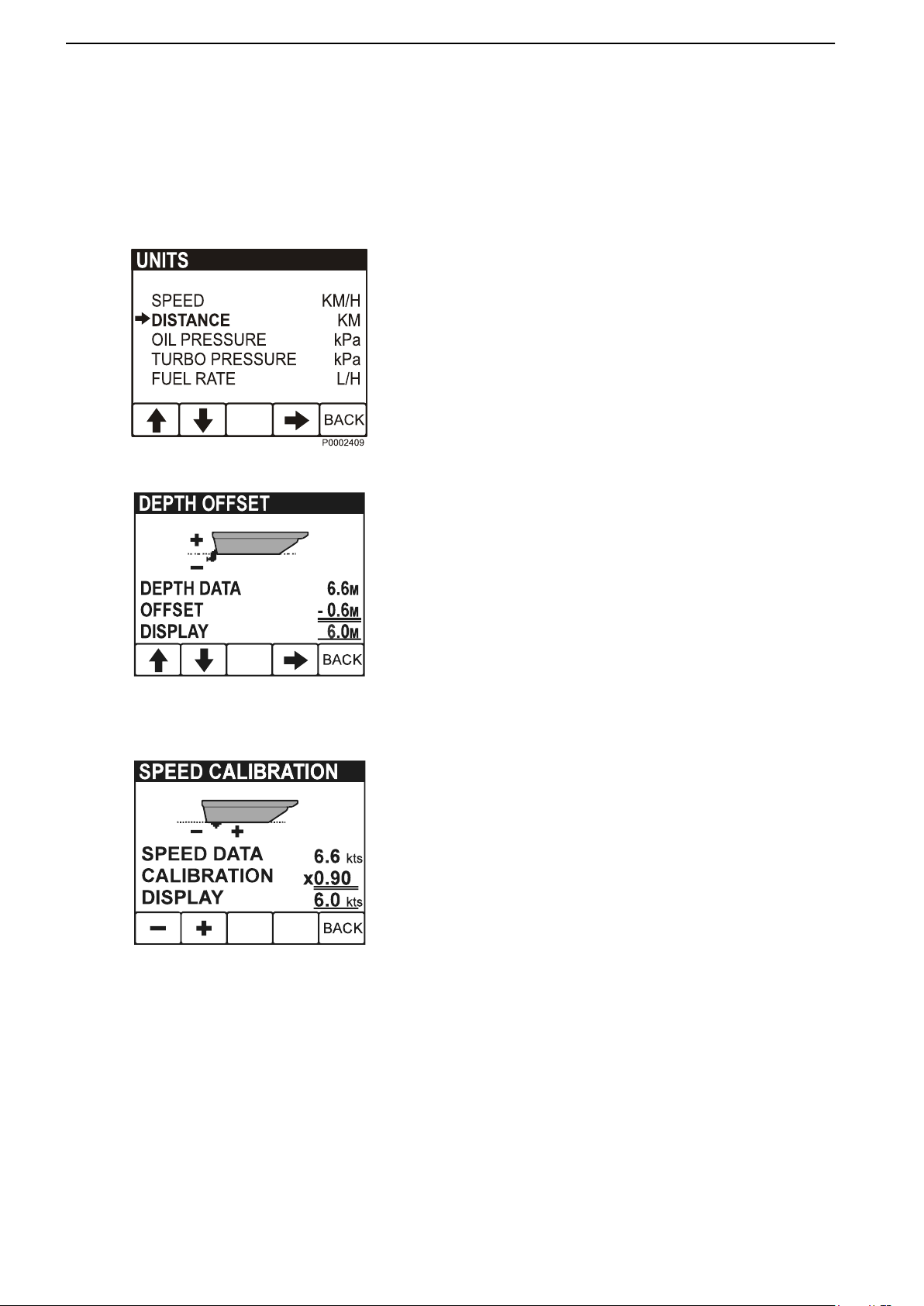

Units: Selection of operational information units to be

shown (this menu is only displayed if “Local” is selected

in the settings menu: “Local” must always be selected

for D1/D2 engines).

- Distance: NM, MILE, KM

- Oil pressure/Turbo pressure: kPa, psi

- Fuel rate: L/H, GAL/H, IGAL/H

- Temperature: °C, °F

Calibration: the engine must be switched on during

calibration.

47702088 - Downloaded from www.volvopenta.com 02/06/2011 18:54:55

Depth compensation

Setting the Volvo Penta echo sounder. The echo-sounder can be installed anywhere between the waterline

and the boat's deepest point. Set the deviation – off set

– so that the display value shows one of these points.

To adjust the value up (+), set the distance between

the echo-sounder and the waterline; to adjust the value

down (–), set the distance between the echo-sounder

and the boat's deepest point. The value can be set in

0.1 unit stages.

Store the set value by depressing BACK (button 5).

Speed factor

The speed factor must be set while the boat is under

way. Compare the displayed boat speed value with

GPS data (or another boat) and adjust the speed factor

until the values agree.

The speed sensor calibration value can be adjusted

upwards (+) or downwards (-) in stages of 0.01 units

(+ or - 1%). Store the adjusted value by depressing

BACK (button 5).

16 47702088 05-2011

Page 19

N

F

R

T

T

1

P0002427

Instruments and Controls

Controls

This section describes the controls Volvo Penta sells

for your engine. Contact your dealer if your boat is

equipped with controls other than those described

here, and you feel uncertain about their function.

Maneuvering

A single-lever control operates both gearshift and

throttle functions from the same lever.

The engine can only be started with the control lever

in the neutral position.

N = Neutral position. Reverse gear/drive disengaged

and engine at idle.

F = Reverse gear/drive engaged for movement

ahead.

R = Reverse gear/drive engaged for movement

astern.

T = Engine rpm control (throttle).

47702088 - Downloaded from www.volvopenta.com 02/06/2011 18:54:55

Disconnecting the gearshift function

The gearshift function can be disconnected so that the

control lever only operates the throttle.

1 Put the control lever in neutral (N).

2 Depress the neutral button (1), and keep it

depressed at the same time as the lever is moved

forward.

3 Release the neutral button, the shift function is dis-

engaged and the lever only influences engine revolutions.

The gear shift function is reconnected automatically

when the lever is returned to the neutral position.

CAUTION!

Take care not to engage the gear by mistake.

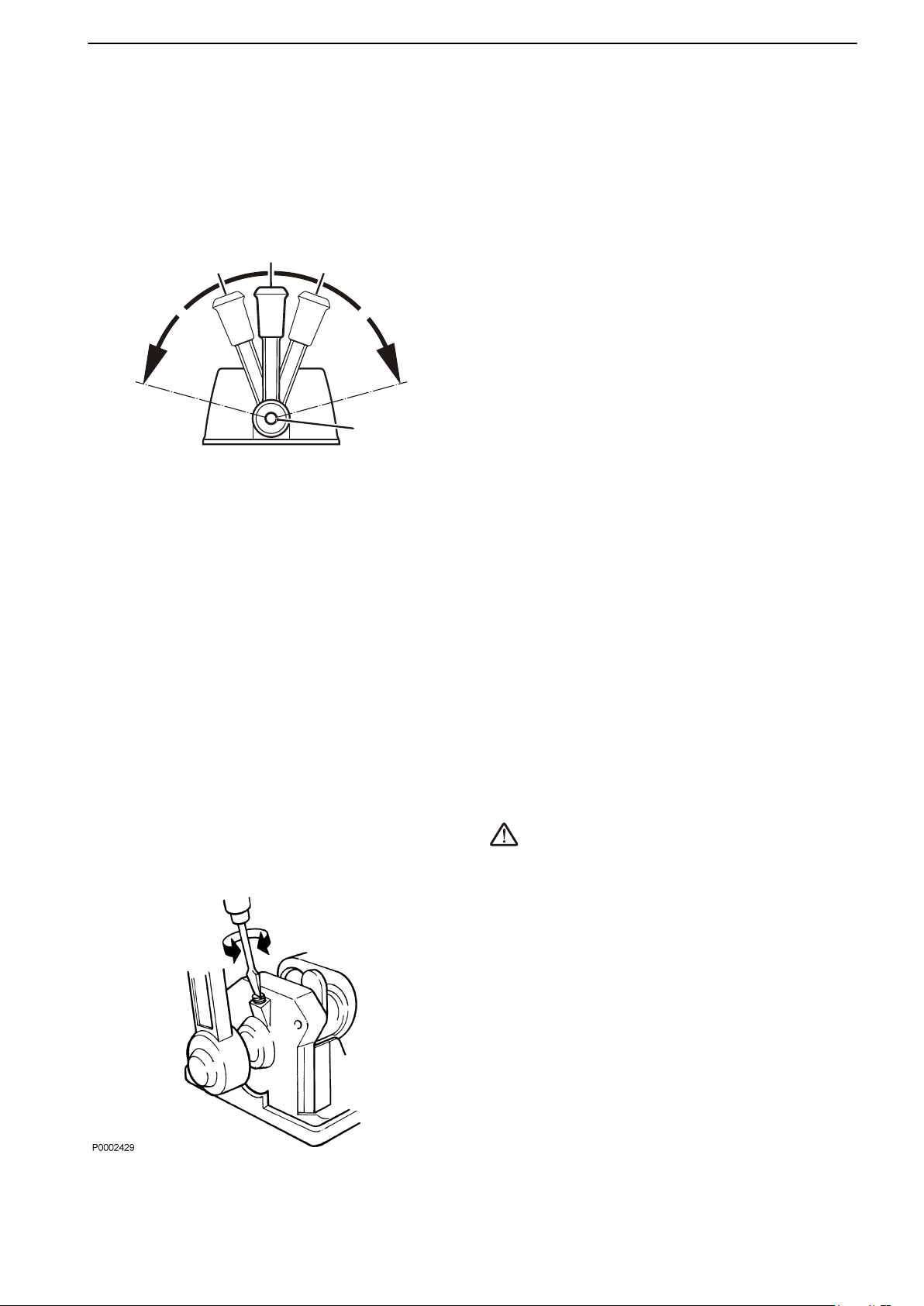

Adjusting the friction brake

The lever is fitted with a friction brake to allow adjustment for easier or stiffer movement as required. The

friction brake only affects movement of the throttle control lever.

1 Lift away the cover from the control. On side-

mounted controls the lever must be removed first.

2 Move the lever to the half throttle/astern position.

3 Adjust the friction brake by turning the screw clock-

wise (+) for stiffer lever movement, and counterclockwise (-) for easier movement.

4 Replace the cover and the lever.

47702088 05-2011 17

Page 20

Starting

1

0

P0005851

1

P0007529

Make a habit of visually checking the engine, engine bay and transmission before start. This will help you to

discover quickly if anything abnormal has happened, or is about to happen. Also check that instruments and

warning displays show normal values when you have started the engine.

To minimize cold start smoke we recommend the installation of an engine heater or engine bay heater if temperatures below +5°C (41°F) are encountered.

WARNING!

Never use start spray or similar products as starting aid. Explosion risk!

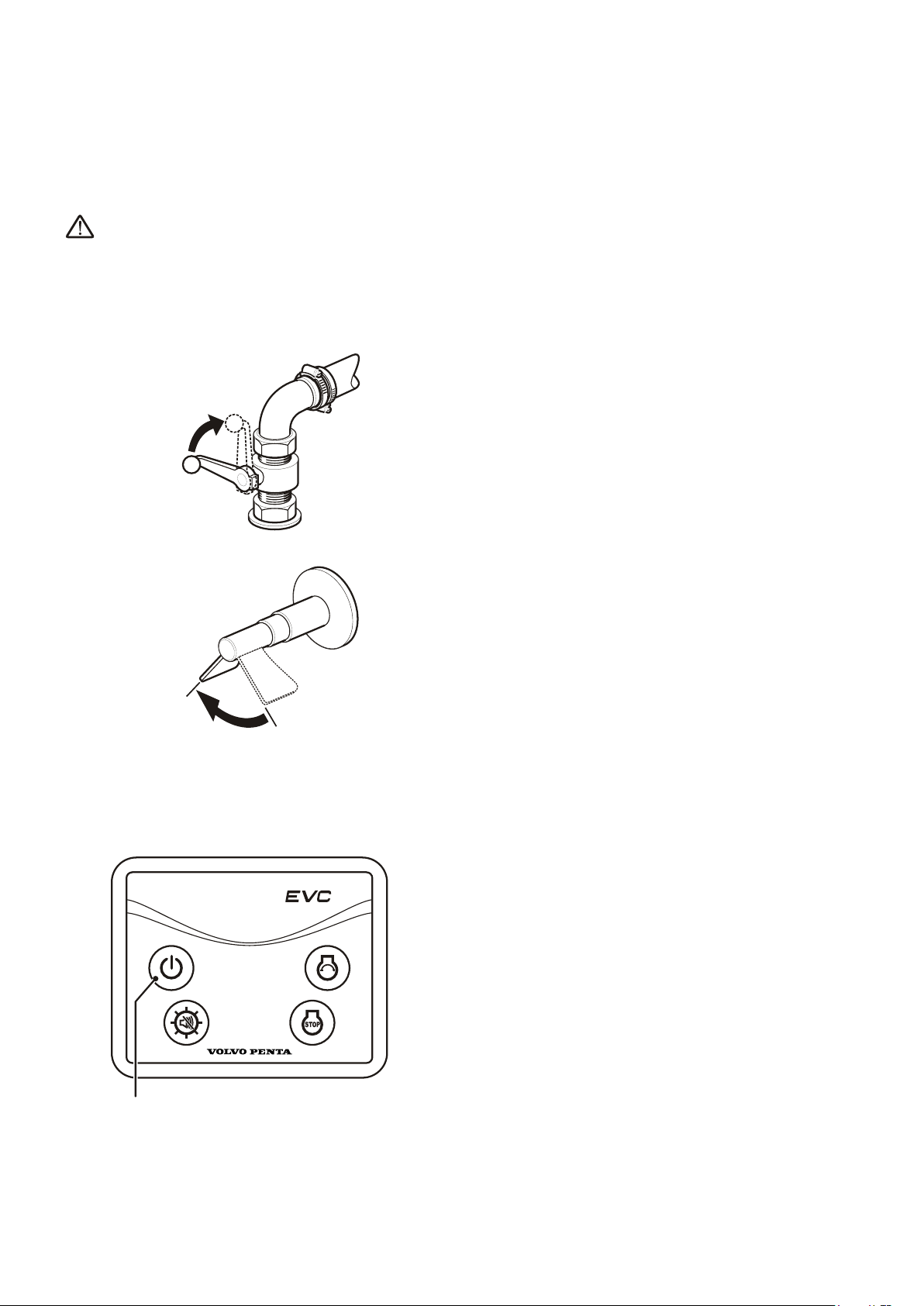

Before Starting

Check the engine and transmission oil levels.

•

Check coolant level.

•

Open the sea cock.

•

Open the fuel cock.

•

Turn the main switch(es) on.

•

IMPORTANT!

Never disconnect the current with the main switches

when the engine is running. The alternator and electronics could be damaged.

47702088 - Downloaded from www.volvopenta.com 02/06/2011 18:54:55

Start the engine bay fan, where fitted, and allow it to

•

run for at least four minutes.

Check that there is sufficient fuel for the planned trip.

•

Starting the Engine

Activate the control panel by depressing the on/off button (1). The Volvo Penta logo is displayed in the window. Two audible signals are sounded to indicate the

system is ready and that the engine may be started.

18 47702088 05-2011

Page 21

!

!

+

-

0

3

2

1

4

RPMX1000

P0008437

4

P0007951

Starting

Check the tachometer

If an operational fault occurs an audible alarm will

sound and a symbol will flash in the tachometer window. Refer to the Fault Handling page 25 chapter for

more detailed information and recommended actions.

Check the alarm instrument (accessory).

The lamps in the alarm instrument light up each time the

ignition is turned on. Check that all lamps light up and

then extinguish. If any lamp flashes, a fault has been

registered; refer to the Fault Handling page 25 chapter for more detailed information and recommended

actions.

Start the engine

Press the start button (4). Release the start button as

soon as the engine starts.

The pre-heating symbol is displayed in the tachometer

window. Pre-heating is automatic and lasts for 20 seconds.

Pre-heating only takes place if engine temperature is

below 50° (122° F).

Pre-heating may be activated before the engine is

started by depressing the start button (4) for a short

moment. Pre-heating will continue for 20 seconds. The

pre-heating symbol is displayed in the tachometer window.

47702088 - Downloaded from www.volvopenta.com 02/06/2011 18:54:55

Read off the instruments and warm up the

engine

Allow the engine to idle for the first 10 seconds. Read

off the instruments and check that they show normal

values. Check that no warning lamps are flashing. If any

lamp flashes, a fault has been registered; refer to the

Fault Handling page 25 chapter for more detailed

information and recommended actions.

Warm up the engine at low speed and low load, so that

normal working temperature is reached before full

power is applied.

47702088 05-2011 19

Page 22

Operation

0

3

2

1

4

RPMX1000

SYSTEM INFORMATION

1

2

P0007519

Learn to handle the engine, controls and other equipment in a safe and proper manner before casting off on your

maiden voyage. Remember to avoid sudden and extreme rudder maneuvers and gear shifts. There is a risk for

passengers and crew falling over or falling overboard.

WARNING!

A rotating propeller can cause serious injury. Check that nobody is in the water before engaging ahead or astern.

Never drive near bathers or in areas where people could be in the water.

Reading the Instruments

Read off the instruments and alarm display immediately after start, and then regularly during operation.

Alarms

If an alarm is tripped, an audible alarm will sound and

a symbol will flash in the tachometer window (1).

If optional equipment such as alarm instruments or an

EVC display are installed, the relevant warning lamp

will flash there also.

47702088 - Downloaded from www.volvopenta.com 02/06/2011 18:54:55

1 Reduce engine speed to idle.

2 Cancel the alarm by depressing the multi-function

button (2).

The audible alarm will be silenced. The symbol will

be lit continuously until the fault is remedied

3 Take the necessary action: refer to the Fault Han-

dling page 25 section.

20 47702088 05-2011

Page 23

1

2

3

P0005856

Operation

Maneuvering

Shifting between ahead and astern must be done at

idle revolutions. Shifting at higher revolutions can be

uncomfortable for those on board and cause unnecessary stress to the transmission or make the engine

stall.

Always shift between ahead and astern in

the following manner:

1 Reduce engine revolutions to idle and allow the

boat to lose most of its speed.

2 Move the control lever to the neutral position with

a quick, firm movement. Pause a moment.

3 Move the control lever back with a quick, firm

movement and increase revolutions.

47702088 - Downloaded from www.volvopenta.com 02/06/2011 18:54:55

47702088 05-2011 21

Page 24

Operation

Sailing

When sailing, set the control lever to astern if a folding

propeller is fitted.

Is a fixed propeller is fitted the control lever should be

set in neutral or reverse. When using a fixed propeller

and sailing with the control lever set to reverse the

speed is slowed down though less noise is being

made.

Cruising Speed

47702088 - Downloaded from www.volvopenta.com 02/06/2011 18:54:55

Avoid operations at full throttle for best fuel economy.

We recommend a cruising speed that is around

500-1000 rpm below the maximum rpm at top speed

(full throttle).

Depending on the type of hull, choice of propeller, load

and sea state etc., maximum revolutions at top speed

may vary, but should be within the full throttle range;

refer to the Engines section.

22 47702088 05-2011

Page 25

Engine Shutdown

1

3

2

P0014272

1

0

P0005914

Allow the engine to run at low idle, in neutral, for a few minutes after operations are completed. In this way afterboiling is avoided at the same time as temperature equalization takes place. This is especially important when

the engine has been run under heavy load at high rpm .

Stop the Engine

Press the Stop button (3) until the engine stops running.

Press the On/Off button (1) to cut the power to the system.

If the engine is stopped and the ignition still turned on,

an alarm sounds after 10 seconds to prevent the ignition is left on unintentionally and the battery will

become discharged.

Silence the alarm by turning the ignition off, or reset

the alarm with the multifunction button (2) if the ignition

is to be turned on.

47702088 - Downloaded from www.volvopenta.com 02/06/2011 18:54:55

Auxiliary stop

If the engine cannot be stopped in a normal procedure,

it is possible to stop the engine via the auxiliary stop

mounted on the side of the engine.

After Engine Shutdown

Check the engine and engine bay for leakages.

•

Close the fuel tap.

•

Close the sea cock where fitted.

•

Take an hour meter reading and carry out preven-

•

tive maintenance according to the maintenance

schedule.

Turn off the main switch before any long stoppage.

•

47702088 05-2011 23

Page 26

C

0

10

10

F

32

50

10

20

70

20

20

60

P0005905

Engine Shutdown

Operation break with the boat in water

If the boat is not used, but left in the water, the engine

must be warmed up at least once every fortnight. This

prevents corrosion damage in the engine.

If you expect the boat to be unused for two months or

more, it must be laid up, please refer to Stor-

age page 64

Operation break with the boat out of water

Where boats are kept laid up on land when not in use,

there is a lower level of galvanic corrosion protection

due to oxidation on the sacrificial anodes. Before

launching the boat the sacrificial anodes on the drive

and shield must be cleaned with emery paper to

remove any oxidation.

If you expect the boat to be unused for two months or

more, it must be laid up, please refer to Stor-

age page 64.

IMPORTANT!

Use emery paper. Do not use a wire brush or other

steel tools when cleaning, as these may damage the

galvanic protection.

47702088 - Downloaded from www.volvopenta.com 02/06/2011 18:54:55

Cold Weather Precautions

If the engine bay cannot be kept frost free, the raw

water system must be drained and the freshwater system coolant must have sufficient frost protection to

prevent frost bursting; refer to Seawater System,

Draining page 48 and Maintenance page 43

respectively for more detailed information.

Check the charge status of the battery. A poorlycharged battery can freeze and burst.

24 47702088 05-2011

Page 27

Fault Handling

0

3

2

1

4

RPMX1000

SYSTEM INFORMATION

1

2

P0007519

Despite regular maintenance according to the maintenance schedule and perfect operation conditions faults may

occur which must be attended to before the boat can travel further. This chapter describes alarms and fault

handling.

If an operational fault arises an audible alarm will

sound and a symbol will flash in the tachometer window(1) If optional equipment such as an alarm monitor or an EVC display are installed, the relevant warning lamp will flash there also.

Cancel the alarm by depressing the multi-function

button (2). The audible alarm will be silenced. The

symbol will be lit continuously until the fault is remedied.

This chapter describes faults and actions to be taken.

CAUTION!

Read the safety precautions for maintenance and

service in the Safety Information chapter before starting work.

47702088 - Downloaded from www.volvopenta.com 02/06/2011 18:54:55

47702088 05-2011 25

Page 28

Fault Handling

Coolant Temperature

The coolant temperature lamp is lit if the coolant temperature is too high.

IMPORTANT!

Continued operations with too-high engine temperature may cause serious engine damage.

• Check coolant level. Refer toCoolant Level,

Checking and Topping Up page 45.

• Check that the raw water filter, where such is

fitted, is not clogged. Refer to Seawater Filter,

Check and Cleaning page 51.

• Check the impeller in the seawater pump. Refer

toImpeller, Check and Change page 49.

If the alarm continues despite the above actions being

carried out, run the engine at low revolutions and drive

the boat to the nearest service workshop for repair.

47702088 - Downloaded from www.volvopenta.com 02/06/2011 18:54:55

Oil pressure

If the oil pressure lamp lights up during operations, the

engine oil pressure is too low.

IMPORTANT!

Continued operations with too-low oil pressure will

cause serious engine damage.

• Checking Engine Oil Level, refer to Oil level,

checking and topping up page 39.

• Check that the oil filter is not blocked. Change

the oil filter as necessary; refer to Engine oil and

engine oil filter, changing page 40.

• Please contact a Volvo Penta workshop if the

fault remains.

Battery

The charging lamp lights up when the alternator stops

charging the batteries, which may result from a fault

in the electrical system or the need to tension the

alternator drive belt.

• Check belt tension. Refer to Drive Belt, Check

and Change page 37.

• Check to see if there are no short circuit, chafed

wires or wires with loose connections.

• Check the fluid level in the battery; refer to Bat-

tery, Maintenance page 53.

• Please contact a Volvo Penta workshop if the

fault remains.

26 47702088 05-2011

Page 29

1

2

3

4

5

6

7

P0004761

Fault Handling

System failure

The "system fault" symbol is displayed when there is

a short circuit or cable break.

The symbol shows if the ignition is left on, refer to

Engine Shutdown page 23.

• Check to see if there are any chafed wires or

wires with loose connections.

• Please contact a Volvo Penta workshop if the

fault remains.

Fuel level

The fuel level symbol is displayed when less than 20%

fuel remains in the tank if a fuel level sensor is installed (optional equipment).

47702088 - Downloaded from www.volvopenta.com 02/06/2011 18:54:55

Auxiliary alarm

Alarm for auxiliary sensors (optional equipment).

Alarm Display (optional instrument)

1 The fuel level symbol lights up during operation

when less than 20% fuel remains in the tank if a

fuel level sensor is installed (optional equipment).

2 The battery lamp lights up if the alternator is not

charging.

3 The coolant temperature lamp lights up when

the coolant temperature is too high.

4 This indicator is not activated for the engine.

5 This indicator is not activated for the engine.

6 The "System Failure lamp" will light up at short

circuit, broken wire and AUX failure.

7 If the oil pressure lamp lights up during opera-

tion, the oil pressure in the engine is too low.

47702088 05-2011 27

Page 30

Fault Handling

Fault Tracing

A number of symptoms and possible causes of engine malfunctions are described in the table below. Always

contact your Volvo Penta dealer if any problems occur which you cannot solve by yourself.

NOTICE! Read the safety regulations for care and maintenance in the Safety Information page 6 chapter before

work you start work.

Symptoms and possible causes

Start motor will not turn, or turns slowly 1, 2

Engine does not start 3, 4, 5, 6, 7, 8

Engine starts but stops again 5, 6, 7, 8

Engine is difficult to start 5, 6, 7, 8

Engine does not reach correct operating speed at full throttle 6, 7, 8, 9, 10, 11, 12, 17

Engine knocks 13

Engine runs roughly 5, 6, 7, 8, 12, 13

Engine vibrates 17, 18

High fuel consumption 9, 10, 12, 14, 17

Black exhaust smoke 4, 12, 14, 17

Blue or white exhaust smoke 14, 24

Lubrication oil pressure too low 15, 16

Coolant temperature too high 19, 20, 21, 22, 23

No charge, or poor charge 1, 25

1. Flat battery

2. Poor contact/open circuit in cables

3. The stop lever is pulled out

4. Insufficient preheat

5. Lack of fuel

6. Blocked air filter

47702088 - Downloaded from www.volvopenta.com 02/06/2011 18:54:55

7. Air in the fuel system

8. Water/contamination in fuel

9. Boat abnormally loaded

10. Fouling on hull, drive or propeller

11. Limited movement in engine control lever

12. Insufficient air supply to engine

13. Coolant temperature too high

14. Coolant temperature too low

15. Oil level too low

16. Blocked oil filter

17. Faulty / wrong propeller

18. Faulty engine mounting

19. Coolant level too low

20. Blocked raw water inlet, lines or filters

21. Circulation pump drive belt slipping

22. Faulty impeller

23. Faulty / wrong thermostat

24. Oil level too high

25. Alternator drive belt slipping

28 47702088 05-2011

Page 31

In Case of Emergency

P0002107

Despite regular service in accordance with the planned

maintenance schedule and perfect operating conditions, faults may occur that must be remedied before

the boat can continue its trip. This chapter provides

advice on how to remedy a number of conceivable

faults.

If a fault occurs, confirm any fault alarm and take the

necessary actions. See this chapter and refer to the

Fault Handling page 25 chapter.

Starting Using Auxiliary

Batteries

WARNING!

Explosion hazard. Batteries contain and give off an

explosive gas which is highly flammable and explosive.

A short circuit, open flame or spark could cause a violent explosion. Ventilate well.

47702088 - Downloaded from www.volvopenta.com 02/06/2011 18:54:55

WARNING!

Never confuse the positive and negative poles on the

batteries. Risk of arcing and explosion.

1 Check that the auxiliary battery has the same volt-

age as the engine system voltage.

2 Connect the red positive cable to the plus (+) ter-

minal on the discharged battery and then to the plus

terminal on the auxiliary battery.

3 Connect the black start cable to the minus (–) ter-

minal on the auxiliary battery and to a place a little

distance away from the discharged battery, e.g. the

start motor's negative terminal.

WARNING!

Under no circumstances may the black jumper cabel

(–) come in contact with the positive connection on the

starter motor.

4 Start the engine and let it run at fast idle for approx-

imately 10 minutes to charge the batteries. Make

sure there is no extra equipment connected to the

electrical system.

47702088 05-2011 29

Page 32

In Case of Emergency

WARNING!

Working with or going close to a running engine is a

safety risk. Watch out for rotating components and hot

surfaces.

WARNING!

Do not touch the connections during the start attempt:

Risk of arcing.

Do not bend over any of the batteries either.

5 Turn off the engine. Remove the start cables in the

exact opposite order to their connection.

47702088 - Downloaded from www.volvopenta.com 02/06/2011 18:54:55

30 47702088 05-2011

Page 33

Maintenance Schedule

Your Volvo Penta engine and its equipment are designed for high reliability and long life. The engines are built to

withstand the marine environment, but also to have the smallest possible environmental impact. If the engine and

transmission are serviced regularly according to the schedule, these qualities will be retained and unnecessary

malfunctions will be avoided.

Warranty inspection

During the initial period of use a special warranty inspection - a First service inspection - must be carried out by

an authorized Volvo Penta workshop. Instructions regarding when this must be done can be found in the Warranty

and service book.

Extended protection for leisure use

Volvo Penta offers extended protection for marine diesel engines, including power trains, applicable only to leisure

boats. For the warranty to be valid, all prescribed services must have been carried out at the owner's expense by

an authorized Volvo Penta dealer or service workshop before the 12 month warranty period has expired. Further

instructions are contained in the Warranty and service book.

C

=

Clean

R

=

Replace

A

=

Adjust

L

=

Lubricate

I

=

Inspect (Clean, Adjust, Lubricate or Replace if necessary)

First service inspection, after 20–50 running hours

Transmission, oil level I

Coolant level and antifreeze mixture I

Drive belt (tension) I

Seawater filter I C

Instrument panel function I

Start and warm up engine

Engine and transmission, oil / fuel / water leakage I

Engine and transmission, abnormal noises I

47702088 - Downloaded from www.volvopenta.com 02/06/2011 18:54:55

Stop Engine

Engine oil and oil filters L

Restart engine

Oil pressure / oil leakage I

1)

Or within 180 days of the date of delivery, or the end of the first season, whichever comes first.

Daily, Before First Start

Engine and engine room. General inspection I

Checking Engine Oil Level I

Check coolant level. I

1)

47702088 05-2011 31

Page 34

Maintenance Schedule

Every 14 days

Drive belts, wear I

Seawater Filter, Check and Cleaning I C

Fuel pre-filter, draining water / contamination I

Batteries, electrolyte level I

Reverse gear, oil level I

S-drive, oil level I

Every 200 hours / at least once a year, included in extended protection

D1 Engine oil and oil filters

1)

Reverse gear, oil R

Reverse gear, propeller shaft seal I

S-drive, oil R

S-drive/reverse gear, corrosion protection I

1)

Oil change intervals vary, depending on engine type, oil grade and sulfur content of the fuel. Se avsnitt Oil

Grade and Oil Change Interval.

R

Every 500 operating hours / at least once per year; included in extended warranty

D2 Engine oil and oil filters

1)

Fuel pre-filter and fuel fine filter R

Idle I

Seawater pump impeller I

Vaccum Valve, Cleaning C

1)

Oil change intervals vary, depending on engine type, oil grade and sulfur content of the fuel. Se avsnitt Oil Grade

and Oil Change Interval.

Once per year; included in extended warranty

Folding Propeller C

47702088 - Downloaded from www.volvopenta.com 02/06/2011 18:54:55

S-drive, Rubber Sealing between Drive and Hull I

Every 500 operating hours / at least once every 2 years

Heat exchanger C

Injectors I

Valve clearance A

R

Every 4 years

Coolant R

Every 500 operating hours / at least once every 5 years

Reverse gear, propeller shaft seal R

Every 7 years

S-drive, Rubber Sealing between Drive and Hull R

32 47702088 05-2011

Page 35

Maintenance

1

2

3

4

5

6

P0008052

7

8

9

10

11

12

13

14

P0008053

This chapter contains general technical information and instructions on how the prescribed maintenance items

must be carried out. Read through the instructions carefully before starting work. The times when maintenance

items must be carried are indicated in the Maintenance Schedule page 31.

Read through the safety precautions for maintenance and service in the Safety Information page 4 chapter before

work on the engine is begun.

WARNING!

Care and maintenance work should be done with the engine stopped unless otherwise specified. Stop the engine

before opening or removing the engine hatch/hood. Make it impossible to start the engine by removing the start

key and cutting the system voltage with the main switches.

D1-20 with MS10A reverse gear

D1-20 with MS10A reverse gear

47702088 - Downloaded from www.volvopenta.com 02/06/2011 18:54:55

1 Coolant filling

2 Heat exchanger

3 Relay box

4 Alternator

5 Starter motor

6 Oil dipstick, reverse gear

7 Air filter/air intake

8 Fuel hand pump

9 Oil filler, engine

10 Oil dipstick, engine

11 Fuel filter

12 Oil filter

13 Injection pump

14 Raw water pump

47702088 05-2011 33

Page 36

1 2

3

4

5 6

7

P0008054

8

9

11

10

12

13

14

15

P0008055

Maintenance

D1-30 with MS15A reverse gear

D1-30 with MS15A reverse gear

1 Coolant filling

2 Heat exchanger

3 Relay box

4 Alternator

5 Starter motor

6 Oil cooler, reverse gear

7 Oil dipstick, reverse gear

8 Air filter/air intake

9 Fuel hand pump

10 Oil dipstick, engine

11 Oil filler, engine

12 Fuel filter

13 Oil filter

14 Injection pump

15 Raw water pump

47702088 - Downloaded from www.volvopenta.com 02/06/2011 18:54:55

34 47702088 05-2011

Page 37

1

2

3

4 5

6

7

8

P0008056

9

10

11

12

13

14

15

16 17

18

19

P0008057

Maintenance

D2-40 with 130S sailboat drive

1 Coolant filling

2 Heat exchanger

3 Relay box

4 Alternator

5 Starter motor

6 Sea cock, S-drive

7 Cooling water inlet, S-drive

8 Folding propeller

D2-40 with 130S sailboat drive

47702088 - Downloaded from www.volvopenta.com 02/06/2011 18:54:55

9 Oil dipstick, S-drive

10 Air filter/air intake

11 Fuel hand pump

12 Oil dipstick, engine

13 Oil filler, engine

14 Sacrificial anodes

15 Oil drain, S-drive

16 Fuel filter

17 Oil filter

18 Injection pump

19 Raw water pump

47702088 05-2011 35

Page 38

2

1

P0007521

Maintenance

Engine, General

General inspection

Make a habit of visually checking the engine and

engine bay before starting, and after operations when

you have stopped the engine. This will help you to discover abnormalities quickly, or if something is about to

happen.

Look especially carefully for oil, fuel and coolant leakages, loose bolts, worn or poorly-tensioned drive

belts, loose cable connections, damaged electrical

cables and hoses. This inspection only takes a few

minutes and can prevent serious malfunctions and

expensive repairs.

WARNING!

Accumulations of fuel, oil and grease on the engine or

in the engine room is a fire hazard and must be

removed immediately they are detected.

47702088 - Downloaded from www.volvopenta.com 02/06/2011 18:54:55

WARNING!

If an oil, fuel or coolant leak is detected, the cause must

be investigated and the fault rectified before the engine

is started.

Never direct the jet from a high-pressure washer at

seals, rubber hoses or electrical components. Never

use the high pressure setting for engine cleaning.

Air Filter, Change

1 Loosen the hose clamp (1) and undo the bolt (2)

and remove the filter.

Make sure that contaminants do not enter the

engine.

2 Install the new filter; fasten with the hose clamp and

the bolt.

36 47702088 05-2011

Page 39

3

1

2

10mm

PREHEAT

START

BATT

P0007520

Maintenance

Drive Belt, Check and Change

WARNING!

Stop the engine before doing any maintenance work.

Check belt tensions and condition regularly. A belt that

is tensioned too tightly may damage bearings, while a

belt too-loosely tensioned may slip.

Check and adjust the belt after operation, while the belt

is still warm.

A correctly-tensioned belt should be possible to

depress approx. 10 mm (0.4”) between the pulleys.

IMPORTANT!

Always replace a belt that appears worn or has cracks

(belts that work in pairs must always be changed

together).

Adjusting the drive belt

47702088 - Downloaded from www.volvopenta.com 02/06/2011 18:54:55

D1-30 and D2-40

1 Undo the alternator retaining bolts (1-2).

2 Using the adjuster screw (3), adjust the belt to the

correct tension.

3 Tighten the bolts (1-2) and check the tension.

Replacing the drive belt

1 Undo the alternator retaining bolts (1 and 2).

2 Press the alternator toward the engine block so

that the belt can be removed. Wipe clean the belt

grooves

3 Install the new belt. Adjust.

4 Check the belt tension again after a few hours'

operations.

IMPORTANT!

D1-30, D2-40: Ensure that the alternator belt is placed

in the groove closest to the alternator.

47702088 05-2011 37

Page 40

B

A

P0007955

Maintenance

Idling, adjustment

For engine idle revolutions, refer to the Engines section. Low idle revolutions may cause the engine to stall,

while higher idle revolutions cause extra stress on the

drive/reverse gear during shifting maneuvers.

Adjustment must be made while the engine is warm.

1 Put the control lever in neutral.

Check that the gap (A) is around 3 mm.

Undo locknut (B) and adjust screw (C) to give the

correct gap. Tighten the locknut.

2 Start the engine and let it idle with the control lever

in the neutral position.

WARNING!

Working with or going close to a running engine is a

safety risk. Watch out for rotating components and hot

surfaces.

(1)

47702088 - Downloaded from www.volvopenta.com 02/06/2011 18:54:55

3 Undo the locknut (D). Adjust to the correct revolu-

tions using the adjuster screw (E). Tighten the lock

nut.

4 Repeat item 1.

1. This item does not apply to boats with twin helm stations.

38 47702088 05-2011

Page 41

P0002089

MIN

MAX

1

2

P0007522

Maintenance

Lubrication System

Oil change intervals can vary depending on oil grade

and sulphur content of the fuel, please refer toTechni-

cal Data, Lubrication System.

Oil change intervals must never exceed a period of 12

months.

If you want longer oil change intervals than given in the

table Oil Grade and Oil Change Interval, the condition

of the oil must be checked by the oil manufacturers

through regular oil testing.

Oil level, checking and topping up

47702088 - Downloaded from www.volvopenta.com 02/06/2011 18:54:55

The oil level must be within the marked area on the oil

dipstick and must be checked daily before the first

start.

IMPORTANT!

Do not fill above the limit for max. oil level. Use only oil

of the recommended grade; refer to Technical Data,

Lubrication System.

1 Fill oil slowly through the oil filler on top of the

engine (1) or at the side (2).

2 Wait 5 minutes so that the oil has time to run down

into the engine.

3 Check the oil level again when the engine has

cooled.

47702088 05-2011 39

Page 42

P0007523

Maintenance

Engine oil and engine oil filter,

changing

Always follow the recommended oil change interval.

Use only oils of the recommended grades; refer to Oil

Grade and Oil Change Interval.

WARNING!

Hot oil and hot surfaces can cause burns.

1 Run the engine until warm so that the oil is easier

to pump. Stop the engine.

2 Connect an oil drain pump to the oil drain pipe.

Pump out the oil.

3 Unscrew the lubricating oil filter. Place a plastic bag

over the filter before it is unscrewed to avoid oil

spillage.

4 Check that the filter contact area on the engine is

clean.

47702088 - Downloaded from www.volvopenta.com 02/06/2011 18:54:55

5 Apply a film of oil on the new filter gasket. Screw

the filter on by hand until it touches the contact surface. Then tighten an extra half turn, no more!

6 Fill with oil to the correct level through the oil filler

on top or to the side of the engine. For oil quantity,

refer to the Technical Data, Lubrication System

section.

Start the engine. Run the engine until it reaches

normal operating temperature. Check that the low

oil pressure lamp goes out and that there are no

leaks around the oil filter.

7 Turn off the engine. Wait ten minutes before check-

ing the oil level. Top up as needed.

Hand in the old oil and oil filter to a re-cycling station.

40 47702088 05-2011

Page 43

P0003731

Maintenance

Fuel System

Only use the grades of fuel recommended in the fuel

specification, see Technical Data, Fuel System.

Always observe the greatest cleanliness during refuelling and work on the fuel system.

All work on the unit injectors of the engine must be

carried out by an authorized workshop.

WARNING!

Fire hazard. When carrying out work on the fuel system

make sure the engine is cold. A fuel spill onto a hot

surface or an electrical component can cause a fire.

Store fuel soaked rags so that they can not cause fire.

Engine Fuel Filter Replacement

47702088 - Downloaded from www.volvopenta.com 02/06/2011 18:54:55

1 Clean the filter bracket.

Avoid fuel spills by placing a plastic bag around the

filter

2 Unscrew the filter

3 Apply a film of oil on the new filter gasket.

4 Screw the filter on by hand until it touches the con-

tact surface. Then tighten an extra half turn, no

more!

5 Purge the fuel system, refer to the Fuel system,

bleeding page 42 section.

6 Start the engine and check for leaks.

7 Hand in the old filter to a re-cycling station.

47702088 05-2011 41

Page 44

1

2

3

4

P0007532

1

P0007533

Maintenance

Fuel system, bleeding

The fuel system must be purged after a filter change,

if the fuel tank has been run dry and after a long-term

stoppage.

1 Open the purge screw (1) on the fuel filter approx.

three turns. Avoid fuel spills; use rags to soak up

fuel at the purging point.

2 Pump fuel up with the hand pump (2) until fuel with-

out air bubbles can be seen. Continue pumping and

tighten the purging screw at the same time.

The pump inlet pipe contains a strainer (3) which

normally does not need to be cleaned since the

engine has a fuel pre-filter. If a fuel pre-filter is not

fitted, poor feed flow can be due to a blocked

strainer.

If either of the two O-rings (4) are damaged, they

must be replaced.

3 Start the engine and check for leaks.

47702088 - Downloaded from www.volvopenta.com 02/06/2011 18:54:55

Fuel pre-filter

The fuel pre-filter is an optional extra.

Draining

Wait a few hours after the enginehas been turned off

before draining the filter..

Position a container under the fuel filter. Drain offwater

and contaminants using the cock/plug at the bottom of

the filter bowl.

Replacing filter insert

1 Close fuel cock at the fuel tank. Position a contain-

erunder the fuel filter.

2 Remove the filter bowl by undoing screw (1).

3 Emptyand clean the filter bowl. Replace insert and

reinstallthe bowl.

4 Open fuel cock.

5 Vent the fuel system, please refer to sectionFuel

system, bleeding page 42.

6 Start the engine and check for leaks.

7 Depositthe old filter insert at a properly designated

disposal site.

42 47702088 05-2011

Page 45

Maintenance

Freshwater System

The freshwater system is the engine's internal cooling

system that ensures that the engine operates at the

correct temperature. It is a closed system that must

always be filled with a coolant mixture in order to protect the engine against internal corrosion, cavitation

and frost bursting.

IMPORTANT!

Coolant of a suitable chemical composition must be

used all year round. This applies even when there is

no risk for frost damage, so that the engine always has

complete corrosion protection.

The use of anti-corrosion agents alone is not permitted

in Volvo Penta engines. Never use water alone as the

coolant.

The corrosion protection additives become less effective over time, which means that the coolant must be

changed at regular intervals; refer to Maintenance

Schedule page 31. The cooling system must be

flushed whenever the coolant is changed, refer to

Freshwater system, Flushing.

47702088 - Downloaded from www.volvopenta.com 02/06/2011 18:54:55

Volvo Penta recommend ”Volvo Penta Coolant VCS,

Ready Mixed” or the concentrate ”Volvo Penta Coolant

VCS” mixed with pure water according to specifications, see Water Quality.

Volvo Penta Coolant VCS and VCS Ready Mixed are

based on organic acid technology (OAT). Using other

types of coolant, such as conventional or hybrid types,

can drastically reduce the heat transfer and result in

overheating of the engine.

47702088 05-2011 43

Page 46

Maintenance

Coolant, Mixing

WARNING!

All coolant is hazardous and harmful to the environment. Do not consume. Coolant is flammable.

IMPORTANT!

Different types of coolant must not be mixed with each

other!

Mix: 40% “Volvo Penta Coolant” (conc.

coolant)and 60% water

This mixture protects against internal corrosion, cavitation and frost bursting down to –28°C (–18°F). At60%

glycol concentration, the freezing point is lowered to –

54°C (–65°F).

Never mix more than 60% concentrate (Volvo Penta

Coolant) in the coolant. A greater concentration provides reduced cooling effect with the risk for overheating and reduced frost protection.

47702088 - Downloaded from www.volvopenta.com 02/06/2011 18:54:55

The coolant must be mixed with distilled, deionized

water. The water must fulfil the requirements specified

by Volvo Penta; refer toWater Quality.

It is extremely important that the system is filled with

the correct coolant concentration. Mix in a separate

clean vessel before filling the cooling system. Make

sure that the liquids mix.

44 47702088 05-2011

Page 47

MAX

MIN

MAX

MIN

P0007524

2

1

P0007525

Maintenance

Coolant Level, Checking and

Topping Up

WARNING!

Do not open the coolant filler cap when the engine is