Volvo Penta 4.3GS/SX, 4.3GL/DP-S, 4.3GL/SX, 4.3GS/DP-S, 4.3Gi/SX Owner's Manual

...

OWNERS MANUAL

3.0GS/SX, 4.3GL/SX/DP-S, 4.3GS/SX/DP-S, 4.3Gi/SX/DP-S

5.0GL/SX/DP-S, 5.0Gi/SX/DP-S , 5.7GS/SX/DP-S, 5.7GSi/DP-S

7738812 - Downloaded from www.volvopenta.com 8/2/2009 1:19:46 AM

Owner’s Manual

Marine engines

3.0GS/SX

4.3GL/SX, DP-S • 4.3GS/SX, DP-S • 4.3Gi/SX, DP-S

5.0GL/SX, DP-S • 5.0Gi/SX, DP-S

5.7GS/SX, DP-S • 5.7GSi/SX, DP-S

7738812 - Downloaded from www.volvopenta.com 8/2/2009 1:19:46 AM

This Owner´s Manual is intended for

markets outside North America only.

1

Welcome aboard

Congratulations on your new boat and your choice of a Volvo Penta marine engine.

A choice that will give you many years of boating pleasure.

Your new marine engine is the result of 90 years experience in marine engine

design, coupled with revolutionary new ideas and concern for the environment,

7738812 - Downloaded from www.volvopenta.com 8/2/2009 1:19:46 AM

where traditional Volvo Penta qualities such as first class performance, reliability

and durability have been upheld. We believe that this also reflects what you require

and expect from your new marine engine.

To help you fulfill your expectations, we want you to read through this instruction

manual carefully, and take our advice about operating and maintaining the engine,

before you cast off on your maiden voyage.

Best regards

AB VOLVO PENTA

All rights to changes or modifications reserved

2

© 1997 AB VOLVO PENTA

Printed on environmentally-friendly paper

Contents

Safety Precautions ................................................ 4

Safety precautions to be taken when operating

the boat ................................................................... 5

Safety precautions for maintenance and service .... 7

Introduction ........................................................... 9

Responsibility for the environment .......................... 9

Running-in............................................................... 9

Fuel and oils............................................................ 9

Service and replacement parts ............................... 9

Certificated engines ................................................ 9

Warranty................................................................ 10

Identification numbers ........................................... 11

Presentation ........................................................ 13

Instrumentation ................................................... 16

Emergency stop switch ......................................... 18

Controls ............................................................... 19

Power Trim........................................................... 21

Trim controls ......................................................... 21

Trim instruments ................................................... 23

Impact protection................................................... 25

Starting the Engine ............................................. 26

Preparations.......................................................... 26

Starting.................................................................. 27

7738812 - Downloaded from www.volvopenta.com 8/2/2009 1:19:46 AM

If engine floods...................................................... 28

Operation ............................................................. 29

Checking instruments............................................ 29

Engine protection mode ........................................ 30

How to shift and control speed .............................. 31

Twin unit maneuvering .......................................... 31

Cruising speed ...................................................... 32

Power Trim............................................................ 32

After Use .............................................................. 35

Stopping the engine .............................................. 35

Salt water operation .............................................. 36

Cold weather precautions ..................................... 36

Laying up............................................................... 36

Transporting on a trailer ........................................ 37

Laying up on land.................................................. 37

Other Product Information ................................. 38

Fuel requirements ................................................. 38

Electronic engine control....................................... 39

Maintenance and Care ........................................ 40

Engine ................................................................... 40

Lubrication system ................................................ 43

Cooling system...................................................... 45

Fuel system........................................................... 50

Ignition system ...................................................... 54

Electrical systems ................................................. 56

Drive. SX and DP-S............................................... 62

Steering................................................................. 69

Propellers .............................................................. 70

Propeller replacement, SX drive............................ 72

Propeller replacement, DP-S drive........................ 73

Maintenance Schedule........................................ 74

Laying up/Launching .......................................... 75

Inhibiting................................................................ 75

Bringing out of storage .......................................... 76

Painting the drive and keel .................................... 77

Troubleshooting .................................................. 78

Technical Data ..................................................... 79

3

Safety Precautions

Read this chapter carefully. It concerns your safety. This section describes how safety information is presented

in the Instruction Manual and on the engine. It also gives a general account of basic safety precautions to be

taken when operating the boat and maintaining the engine.

Check that you have the correct Instruction Manual before you read on. If this is not the case please

contact your Volvo Penta dealer.

If operations are performed incorrectly it could result in personal injury, or damage to property

or the engine. Read the Instruction Manual carefully before operating or servicing the engine. If

anything is unclear please contact your Volvo Penta dealer for assistance.

This symbol is used in the book and on the engine to make you aware of safety information.

Always read these safety precautions very carefully.

In the Instruction Manual warning texts have the following priority:

WARNING! If these instructions are not followed there is a danger of personal injury, exten-

sive damage to the product or serious mechanical malfunction.

7738812 - Downloaded from www.volvopenta.com 8/2/2009 1:19:46 AM

IMPORTANT! Used to draw your attention to something that can cause damage, product

malfunction or damage to property.

NOTE! Used to draw your attention to important information that will facilitate work or operations.

This symbol is used in certain cases on our products and refers to important information in

the Instruction Manual. Ensure that warning and information symbols on the engine and transmission are always visible and legible. Replace symbols that have been damaged or painted

over.

4

Safety precautions to be taken when operating the boat

Your new boat

Read Instruction Manuals and other information

supplied with your new boat. Learn to operate the

engine, controls and other equipment safely and correctly.

If this is your first boat, or is a boat type with which

you are not familiar, we recommend that you practice

controlling the boat in peace and quiet. Learn how

the boat behaves at different speeds, weather conditions and loads before casting off for your “real” maiden voyage.

Remember that the person driving a boat is legally

required to know and follow the current rules regarding traffic and safety at sea. Make sure you know

the rules that apply to you and the waters you are

sailing in by contacting the relevant authorities or organization.

A good piece of advice is to take a course in seamanship. We recommend that you contact your local

boating organization to find a suitable course.

Accidents

Statistics show that poor maintenance of boats and

engines and a lack of safety equipment are often the

cause of accidents at sea.

Ensure that your boat is maintained in accordance

with the relevant Instruction Manual and that the necessary safety equipment is on-board and is serviceable.

Daily checklist

7738812 - Downloaded from www.volvopenta.com 8/2/2009 1:19:46 AM

Make a habit of checking the engine and engine

compartment visually before operating the boat (be-

fore the engine is started) and after operating the

boat (after the engine has been stopped). This will

help you to quickly detect fuel, coolant and oil leaks

and spot anything else unusual that has or is about

to happen.

Maneuvering

Avoid violent and unexpected changes in course and

gear engagement. There is a risk that someone

aboard will fall down or overboard.

A rotating propeller can cause serious injury. Check

that nobody is in the water before engaging ahead or

astern. Never drive near bathers or in areas where

people could be in the water.

Avoid trimming an outboard drive too much, as steering will be severely reduced.

Refueling

When refueling there is always a danger of fire and

explosion. Smoking is forbidden and the engine must

be switched off.

Never overfill the tank. Close the fuel tank filler cap

properly.

Only use the fuel recommended in the Instruction

Manual. The wrong grade of fuel can cause operating problems or cause the engine to stop. On a diesel engine poor quality fuel can cause the control rod

to seize and the engine to overrev with a resultant

risk of damage to the engine and personal injury.

Safety breaker

We recommend that you install and use a safety

breaker (accessory), especially if you boat can travel

at high speeds. The safety breaker stops the engine

if the driver falls down and loses control over the

boat.

5

Carbon monoxide poisoning

When a boat moves forward through the water a vacuum is created behind it to a greater or lesser extent. In some circumstances this vacuum effect can

be so great that the boat’s own exhaust gases are

sucked into its cockpit or cabin. This poses a risk of

carbon monoxide poisoning to those on-board.

This problem is greatest for high, wide beamed boats

with a vertical stern. However, it can be a problem for

other types of boat in certain conditions (running with

the cover up for example). Other factors that exacer-

bate the problem are wind conditions, load distribution, sea conditions, trim, open hatches and ventilators etc.

Most modern boats are designed so that vacuum effect problems are very rare. If a vacuum forms behind the boat do not open ventilators or hatches at

the front of the boat. Strangely enough this leads to

an increase in the vacuum effect. Instead, try changing speed, trim or load distribution. Try also to take

down, open or in some other way change the configuration of the cover. Contact your boat dealer to

find a solution for your particular boat.

7738812 - Downloaded from www.volvopenta.com 8/2/2009 1:19:46 AM

Remember

● Safety equipment: Life jackets for everybody on board, communication equipment, distress

flares, approved fire extinguishers, life-buoys, anchors, paddles, torches etc.

● Replacement parts and tools: impeller, fuel filter, fuses, tape, hose clamps, engine oil, propeller

and the tools for jobs that may be necessary.

● Get out up-to-date charts for the planned route. Calculate distance and fuel consumption. Listen

to weather reports.

● Tell friends or relatives about your planned route when undertaking longer journeys. Remember

to tell people about changes to your plans.

● Teach those on-board the location of safety equipment and how to use it. Ensure that there is

more than one person on-board who can start and drive the boat safely.

This list should be added to if the type of boat requires extra safety equipment. We recommend that

you contact your local boating organization to find a suitable course.

6

Safety precautions for maintenance and service

Preparations

Knowledge base

The Instruction Manual contains instructions on how

to carry out the commonest maintenance and service

operations safely and correctly. Read them carefully

before starting work.

Service literature for more extensive work can be obtained from your Volvo Penta dealer.

Never undertake an operation if you are not completely sure how to do it. Contact your Volvo Penta

dealer for assistance instead.

Stopping the engine

Stop the engine before the engine compartment cover is opened or removed. Unless otherwise specified all maintenance and service must be carried out

with the engine stopped.

Immobilize the engine by removing the ignition key,

turning off the power supply with the main switch and

locking it in the OFF position. Fix a warning that

work is being undertaken to the control position.

Approaching a running engine is dangerous. Loose

clothing, long hair, fingers or tools can get caught in

rotating parts and cause serious personal injury.

Volvo Penta recommend that all servicing with the

engine running be undertaken by an authorized

Volvo Penta workshop.

Fire and explosion

Fuel and lubricating oil

All fuels, most lubricating oils and many chemicals

pose a fire hazard. Read and follow the instructions

on packaging.

Work on the fuel injection system must be carried out

on a cold engine. A fuel leak or spill onto a hot surface or an electrical component can cause a fire.

Store oil and fuel soaked rags and other flammable

material in fireproof conditions. In certain circumstances oil soaked rags can spontaneously combust.

Never smoke when refueling, changing the oil or close to filling stations or in the engine compartment.

Non-original components

The components in the fuel injection system, ignition

system and electrical system in Volvo Penta products are designed and manufactured to minimize

the risk of fire and explosion.

Using non-original Volvo Penta parts which do not

meet the above standards, can result in fire or explosion on board.

Batteries

Batteries contain and produce oxyhydrogen, especially when they are being charged. This gas is easily

ignited and highly volatile.

Lifting out the engine

Use the lifting eyes mounted on the engine/reverse

gear when lifting the drive unit. Always check that

7738812 - Downloaded from www.volvopenta.com 8/2/2009 1:19:46 AM

lifting equipment is in good condition and has sufficient load capacity to lift the engine (engine weight

including reverse gear and any extra equipment installed). For safety reasons the engine should be lifted with an adjustable lifting beam. All chains and

cables should run parallel to each other and as perpendicular as possible to the top of the engine. Note

that extra equipment mounted on the engine can

change its center of gravity. Special hoists may be

necessary to balance the engine and make handling

it safe. Never carry out work on an engine suspended on a hoist.

Before starting the engine

Reinstall all protective components that have been

removed before starting the engine. Check that no

tools or other objects have been left on the engine.

Never allow a naked flame or sparks near the batteries or battery compartment.

Incorrect connection of a battery lead or jump lead

can cause a spark which is sufficient to cause the

battery to explode.

7

Hot surfaces and liquids

When the engine is at operating temperature there is

always a danger of burns. Avoid hot surfaces. For

example: exhaust manifold, oil sump, hot coolant and

hot lubricating oil in pipes and hoses.

Carbon monoxide poisoning

Only start the engine in a well-ventilated area. If operating the engine in an enclosed space, ensure that

exhaust gases and crankcase emissions are ventilated out of the working area.

Chemicals

Most chemicals such as glycol, rustproofing agents,

inhibiting oils and degreasing agents are hazardous

to health. Read and follow the instructions on packaging.

Certain chemicals such as inhibiting oils are inflammable and also hazardous to health if inhaled. Ensure that ventilation in the workplace is good and use a

protective mask when spraying. Read and follow the

instructions on packaging.

Store chemicals and other hazardous material away

from children. Deposit excess or used chemicals at a

properly designated disposal site.

Cooling system

There is a risk of water penetration when working on

the seawater system. Turn off the engine and close

the sea cock before starting work on the system.

Avoid opening the coolant filler cap when the engine

is hot. Steam or hot coolant can spray out and cause

burns.

7738812 - Downloaded from www.volvopenta.com 8/2/2009 1:19:46 AM

If work must be carried out with the engine at operating temperature and the coolant filler cap or a cock

open or a coolant hose disconnected, open the coolant filler cap carefully and slowly to release pressure

before removing the cap completely. Note that the

coolant may still be hot and can cause burns.

Lubrication system

Hot oil can cause burns. Avoid skin contact with hot

oil. Ensure that the lubrication system is not under

pressure before commencing work on it. Never start

or operate the engine with the oil filler cap removed,

otherwise oil could be ejected.

Fuel system

Always use protective gloves when tracing leaks.

Liquids ejected under pressure can penetrate body

tissue and cause serious injury. There is a danger of

blood poisoning.

Always cover the generator if it is located under the

fuel filter. The generator can be damaged by spilled

fuel.

Electrical system

Cutting off power

Always stop the engine and break the current using

the main switches before working on the electrical

system. Isolate shore current to the engine block

heater, battery charger, or accessories mounted on

the engine.

Batteries

The batteries contain an extremely corrosive electrolyte. Protect your skin and clothes when charging or

handling batteries. Always use protective goggles

and gloves.

If battery electrolyte comes into contact with unprotected skin wash off immediately using plenty of water and soap. If battery acid comes into contact with

the eyes, flush immediately with plenty of water and

obtain medical assistance without delay.

8

Introduction

This Instruction Manual has been compiled to help you get the most from your Volvo Penta engine. It contains

all the information you need in order to operate and maintain your engine safely and correctly. Please read the

Instruction Manual carefully and learn how to operate the engine, controls and other equipment safely.

Always have the Instruction Manual available. Keep it in a safe place and do not forget to give it to the new

owner if you sell your boat.

Responsibility for the environment

We all want to live in a clean environment. Where we

can breathe clean air, see healthy trees, have clean

water in our lakes and oceans and enjoy the sunshine without worrying about our health. Unfortunately

this is no longer something we can take for granted,

we must work hard together for the environment.

As a manufacturer of marine engines Volvo Penta

has a particular responsibility. This is why concern

for the environment is one of the cornerstones of our

product development. Today great advances have

been made in reducing exhaust emissions, fuel consumption and engine noise in Volvo Penta’s wide

range of engines.

We hope that you will take care to maintain these

properties. Always follow the advice in the Instruction

Manual about fuel grades, operation and maintenance and you will avoid unnecessary negative impact

on the environment. If you notice changes such as

increased fuel consumption or exhaust smoke, please contact your Volvo Penta dealer.

Adapt speed and distance so that swell and noise

generated by the boat do not disturb or harm wildlife,

moored boats, landing stages etc. Leave islands and

harbors in the same condition you would like to find

them. Always dispose of environmentally harmful

waste such as engine and transmission oil, coolant,

7738812 - Downloaded from www.volvopenta.com 8/2/2009 1:19:46 AM

old paint, degreasing agents, cleaning residue and

old batteries at proper disposal areas.

Together we can work to make a valuable improvement to the environment.

Check the oil level regularly and more frequently

during the running-in period. The First Service inspection should be carried out after 20 hours of operation.

Fuel and oils

Only use the fuel and oils recommended in the chapter Technical Data. Other grades of fuel and oil can

cause operating problems, increased fuel consumption and, in the long-term, a shorter engine service

life.

Always change oil, oil filters and fuel filters at the recommended intervals.

Service and replacement parts

Volvo Penta engines and are designed for maximum

service life and reliability. They are built to survive in

a tough marine environment, but also to cause as little environmental impact as possible. Regular service

and the use of Volvo Penta Genuine parts will maintain these properties.

Volvo Penta have built up a world wide network of

authorized dealers. They specialize in Volvo Penta

products and can help you to maintain your engine in

top condition. They have the accessories, genuine

replacement parts, test equipment and special tools

necessary to provide high-quality service and repair

work.

Running-in

A new marine engine needs to be run in for its first

20 operating hours. Run the engine at varying engine speeds but at a maximum of 3/4 throttle for the

first two hours. In the next 8 hours of operation use

the same operating method as earlier but with a

maximum of 2 minutes at wide open throttle (WOT)

included. During the last 10 hours the periods of running at WOT can be increased to 5-10 minutes at a

time. Reduce throttle to idle engine speed between

WOT running so that engine temperature drops. Never run an engine at a constant engine speed for

long periods during the running-in period. The engine

can be expected to use more engine oil during the

running-in period than would otherwise be normal.

Always follow the maintenance intervals contained in

the Instruction Manual. Remember to state the engine/transmission identification number when ordering

service and replacement parts.

Certified engines

If you own an engine certificated for Lake Constance

and Switzerland or for any other area where exhaust

emissions are regulated by law,

the following is important:

In some countries and regions environmental legislation requires that the engines in use there be certified.

9

Certification means that an engine type is tested and

approved by the authorities, and that the engine manufacturer guarantees that all engines of that type

manufactured thereafter, correspond to the certified

engine. The manufacturer is also responsible for ensuring that all engines of that type in operation fulfill

the statutory environmental regulations. This places

special requirements on maintenance, service and

replacement parts as follows:

● The maintenance and service intervals recom-

mended by Volvo Penta must be observed.

● Only Volvo Penta genuine replacement parts, in-

tended for the certificated engine, may be used.

● The servicing of ignition, timing and fuel injection

systems (gasoline) or injector pumps, pump settings and injectors (diesel) must always be carried

out be an authorized Volvo Penta workshop.

● The engine must not be modified in any way apart

from with accessories and service kits developed

for it by Volvo Penta.

● No modifications to the exhaust pipes and air

supply ducts for the engine room (ventilation

ducts) may be undertaken as this may effect exhaust emissions.

● Seals may only be broken by authorized person-

nel.

Otherwise the general instructions contained in the

Instruction Manual concerning operation, service and

maintenance must be followed. Always contact your

Volvo Penta dealer if you are not sure about the operation or maintenance of your engine.

IMPORTANT! Use only Volvo Penta Genuine

Parts. Use of non-original AB Volvo Penta spare

parts will result in AB Volvo Penta being unable

to assume liability for the engine meeting engine certification requirements. Any type of damage and/or costs resulting from the use of nonoriginal Volvo Penta replacement parts for the

product will not be covered under any warranty

provided by AB Volvo Penta.

7738812 - Downloaded from www.volvopenta.com 8/2/2009 1:19:46 AM

Warranty

Your new Volvo Penta marine engine is covered by a limited warranty according to the

conditions and instructions contained in the Warranty and Service book.

Note that AB Volvo Penta’s liability is limited to that contained in the Warranty and Service

Book. Read this book as soon as you take delivery of the engine. It contains important

information about warranty cards, service and maintenance which you, the owner, must be

aware of, check and carry out. Liability covered in the warranty may otherwise be refused by

AB Volvo Penta.

* Contact your Volvo Penta dealer if you have not received a Warranty and Service Book.

10

B

Type Approval Number

A type approval number is assigned to an engine

model when it is certified for exhaust emissions.

There are two certification decals placed on the

A

Y

L

N

O

2 1 84 1

L

E

U

14 0

F

D

M

E

O

D

S

A

D

E

L

N

U

engine to verify engine certification; one on the EFI

computer cover, and the other at the front of the port

cylinder head (A). These decals must be maintained

so engine certification can be verified in the future.

When an emissions check is required, the plug (B)

located on the port high-rise elbow can be removed

for installation of a test probe.

7738812 - Downloaded from www.volvopenta.com 8/2/2009 1:19:46 AM

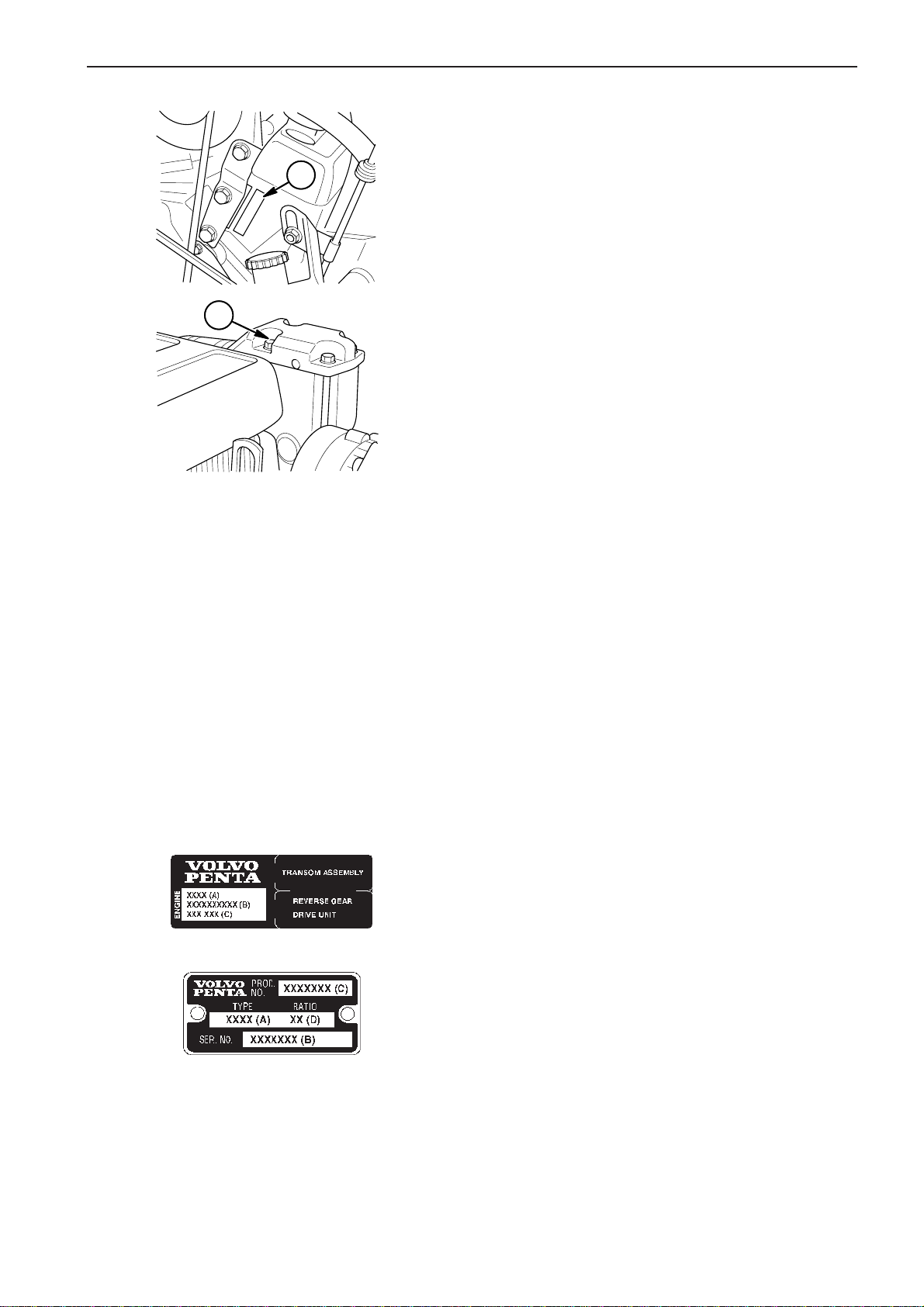

Identification Numbers

Immediately after you have taken delivery of your

boat, make a note of the serial/product number and

model designation of the engine, drive and shield.

Include the serial number and model designation of

the boat and any extra equipment.

This information is necessary when you contact your

Volvo Penta or boat dealer for service and spare

parts. Take a copy of the information and keep it in a

safe place so it is available should the boat be

stolen.

Engine

Product Designation (A) ........................................

Serial Number (B) .................................................

Product Number (C) ..............................................

Drive/Shield

Product Designation (A) ........................................

Serial Number (B) .................................................

Product Number (C) ..............................................

Gear Ratios (D) .....................................................

Propeller designation ............................................

SX/DP-S

Boat

Model/Serial Number ............................................

Extra equipment ....................................................

..............................................................................

..............................................................................

..............................................................................

..............................................................................

11

3.0 4.3, 5.0, 5.7

Location of type approval plate, engine type

The engine type approval plate is located on the lefthand valve cover of the engine (3.0 models) and on

the inside of the port valve cover (4.3, 5.0 and 5.7

models).

Location of drive/shield type plate SX/DP-S

The drive type plate is located on the drive unit behind

the port trim/tilt cylinder.

The shield type plate is located on the top of the inner

transom shield.

7738812 - Downloaded from www.volvopenta.com 8/2/2009 1:19:46 AM

12

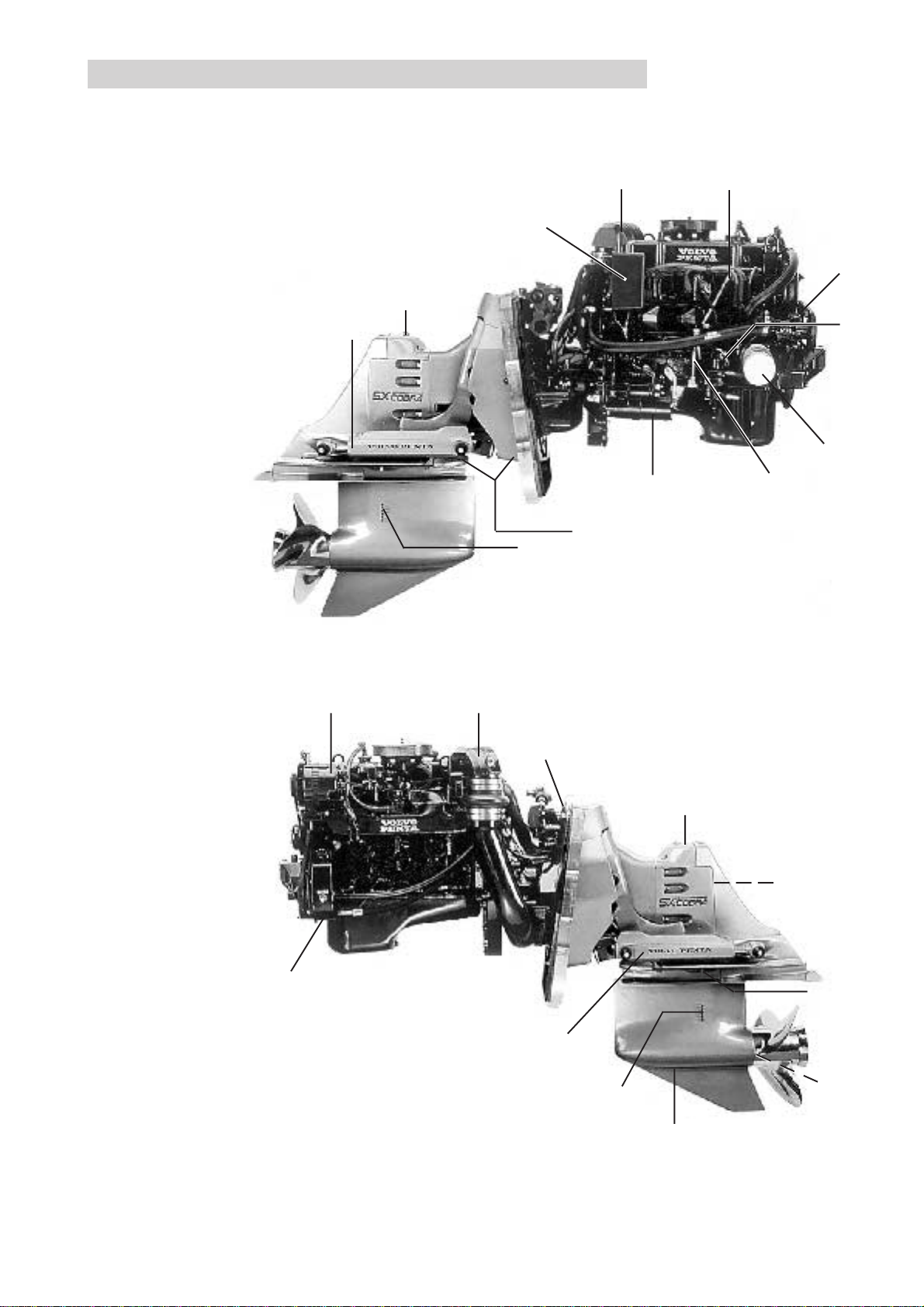

Presentation

Please note! The photos below do not show all engine/transmission combinations. If your engine does not have

the drive shown, refer to another engine with the relevant drive for an introduction to the transmission.

Engine 3.0GS

1. Starter Motor

2. Oil Withdrawal Tube

3. Oil Filter

4. Fuel Pump

5. Oil Level Dipstick

6. Circuit Breakers

7. Type Plate (engine).

See page 12

8. Water-Cooled

Exhaust Pipe

9. Type Plate (shield).

See page 12

10. Seawater Pump

21

19

85

6

10

4

11

3

1

18

17

813

9

SX-C, SX-M Drive

16. Draining Oil

17. Seawater Intake

18. Sacrificial Anodes

19. Oil Level Dipstick

20. Topping Up Oil

21. Trim Cylinder

22. Type Plate

23. Sacrificial Anode,

2

SX-C

7738812 - Downloaded from www.volvopenta.com 8/2/2009 1:19:46 AM

15

11. Fuel Filter

12. Cover for flame arrestor

and carburetor

13. Generator (GEN)

14. Cover for flame arrestor

and throttle housing and

electronic controls

15. Power Steering Pump

21

17

19

20

22

23

16

13

Engine 4.3GL, 4.3GS, 4.3Gi

1. Starter Motor

2. Oil Withdrawal Tube

3. Oil Filter

4. Fuel Pump

5. Oil Level Dipstick

6. Circuit Breakers

7. Type Plate (engine).

See page 12

8. Water-Cooled

Exhaust Pipe

9. Type Plate (shield).

See page 12

10. Seawater Pump

5

20

19

12,1413

17

6

8

4

9

11

10

1

21

SX-C, SX-M Drive

16. Draining Oil

17. Seawater Intake

18. Sacrificial Anodes

19. Oil Level Dipstick

20. Topping Up Oil

21. Trim Cylinder

22. Type Plate

23. Sacrificial Anode,

SX-C

8

7738812 - Downloaded from www.volvopenta.com 8/2/2009 1:19:46 AM

2

15

11. Fuel Filter

12. Cover for flame arrestor

and carburetor

13. Generator (GEN)

14. Cover for flame arrestor

and throttle housing and

electronic controls

15. Power Steering Pump

21

3

18

17

22

23

16

14

Engine 5.0GL, 5.0Gi, 5.7GS, 5.7GSi

1. Starter Motor

2. Oil Withdrawal Tube

3. Oil Filter

4. Fuel Pump

5. Oil Level Dipstick

6. Circuit Breakers

7. Type Plate (engine).

See page 12

8. Water-Cooled

Exhaust Pipe

9. Type Plate (shield).

See page 12

10. Seawater Pump

19

12,14 6

9

4

11

13

5

7738812 - Downloaded from www.volvopenta.com 8/2/2009 1:19:46 AM

2

17

12,14

18

21

1

10

DP-S, DP-SM Drive

16. Draining Oil

17. Seawater Intake

18. Sacrificial Anodes

19. Oil Level Dipstick

20. Topping Up Oil

21. Trim Cylinder

22. Type Plate

8

15

11. Fuel Filter

12. Cover for flame arrestor

and carburetor

13. Generator (GEN)

14. Cover for flame arrestor

and throttle housing and

electronic controls

15. Power Steering Pump

20

21

3

18

22

17

16

15

Instrumentation

The instrument panel for Volvo Penta petrol engines is equipped with a tachometer, temperature gauge, oil

pressure gauge, voltmeter, 2 fuses, instrument lighting switch and an ignition switch. Instruments, fuses and

ignition switch can also be installed separately without an instrument panel. The boat builder’s instrumentation

can also be supplemented with extra Volvo Penta instruments, such as: synchronization tachometers, fuel

gauge, fresh water gauge, clock, speed log or rudder indicator.

21531. Tachometer

Shows the rpm of the engine. Multiply this value by

100 for revolutions per minute. Integral "Hours run"

meter (only on separately installed instrument).

Displays the engine’s operating time in hours and

tenths of an hour.

476

7738812 - Downloaded from www.volvopenta.com 8/2/2009 1:19:46 AM

Engine speed range: See chapter

Operation

.

2. Temperature gauge

Indicates the engine coolant temperature. Normal

operating temperature is approx. 70-90°C (158 194°F).

3. Oil pressure gauge

Indicates the oil pressure in the engine. Normal

operating oil pressure is approx. 150-500 kPa (21-71

psi). At engine idle this is normally lower.

4. Voltmeter

Indicates the charge current from the generator

which should normally be approx. 14 V. With the

engine stopped the current indicated is that in the

starter battery circuit, normally 12 V.

5. Instrument lighting

Switch for instrument lighting.

16

6. Fuses, 8 A

Fuses for the starter function and system voltage. To

change fuses: Press the button and turn anticlockwise.

IMPORTANT Always carry extra fuses on

board.

7. Ignition switch

The ignition switch has three positions (these

0

I

II

positions are not marked):

0 = The key can be inserted and taken out.

I = Operating and running position. System voltage

connected

II = Starter position (spring-loaded). The starter

motor is engaged.

IMPORTANT Read the starting instructions in

the chapter

Starting the engine

.

The ignition keys are marked with a key code used

when ordering extra keys. Make a note of this key

code so that keys can be ordered if the old keys get

lost. Keep the code in a safe place where

unauthorized persons do not have access to it.

7738812 - Downloaded from www.volvopenta.com 8/2/2009 1:19:46 AM

17

Emergency stop switch

An emergency stop switch may be a feature of your

boat. Use of this switch is highly recommended. To

properly use this feature, attach the lanyard securely

to your clothing. Do not attach the lanyard to clothing

that will tear away before the lanyard is pulled from

the switch to stop the engine. If the lanyard is too

long, shorten the lanyard by knotting or looping it.

DO NOT cut and retie the lanyard.

Using this switch is simple and should not interfere

with normal operation of the boat. Care must be

taken to avoid accidentally pulling the lanyard during

normal operation. Unexpected loss of forward motion

will occur. This could allow occupants to be thrown

forward. In an emergency situation, any occupant of

the boat can restart the engine. Just press in and

hold the emergency stop switch button, then follow

normal starting procedure. When the button is

released, the engine will stop.

IMPORTANT! The emergency stop switch can

only be effective when in good working condition. Observe the following:

● Lanyard must always be free of

entanglements that could hinder its operation.

● Once a month, check the switch for proper

operation. With engine running, pull lanyard.

If engine does not stop, see your dealer.

7738812 - Downloaded from www.volvopenta.com 8/2/2009 1:19:46 AM

IMPORTANT! If your boat is not equipped with

an emergency stop switch and it falls into one of

the following categories, installation of an emergency stop switch is recommended.

● High performance sport boats

● Small runabouts

● Boats with sensitive steering

● Boats where the distance from the top of the

gunwale down to the driver’s seat is less than

30 cm.

See your Volvo Penta dealer for installation of an

emergency stop switch.

18

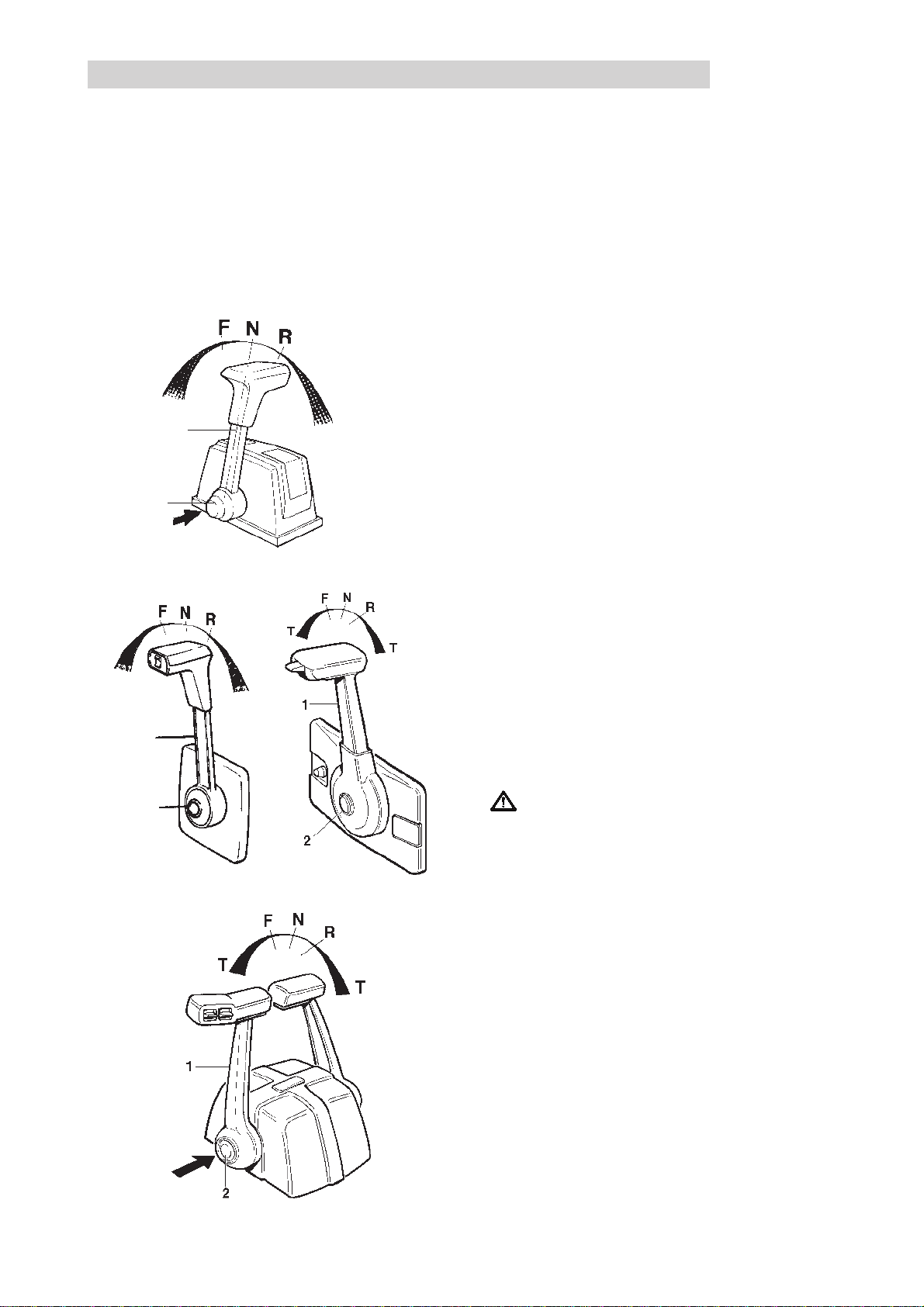

Controls

The shift function and engine speed control are combined in one lever. The shift function can be simply

disengaged so that only engine speed is affected. The Volvo Penta controls are available for top or side

mounting. The control levers have an adjustable friction brake. A neutral position switch is available as an

accessory, this will only permit the engine to be started with the drive disengaged.

Your boat may be equipped with remote controls other than those described above. If Volvo Penta controls are

not used, ask your selling dealer for operating instructions for the remote control used in your boat since operation and function may differ from Volvo Penta remote controls.

Maneuvering

Shifting and engine speed are controlled with the

same lever (1).

T

1

2

T

T

1

7738812 - Downloaded from www.volvopenta.com 8/2/2009 1:19:46 AM

2

N = Neutral position. Drive/reverse gear disengaged

T

F = Drive/reverse gear engaged for forward movement

(ahead).

R = Drive/reverse gear engaged for backward move-

ment (astern).

T = Engine speed control.

Disengaging the shift function

Move lever (1) to the neutral position (N). Press in

button (2), move the lever slightly forward and release

button. The shift function is now disengaged and the

lever affects only engine speed.

When the lever is moved back to the neutral position

it will automatically re-engage.

IMPORTANT! Take care not to engage the

drive by mistake.

19

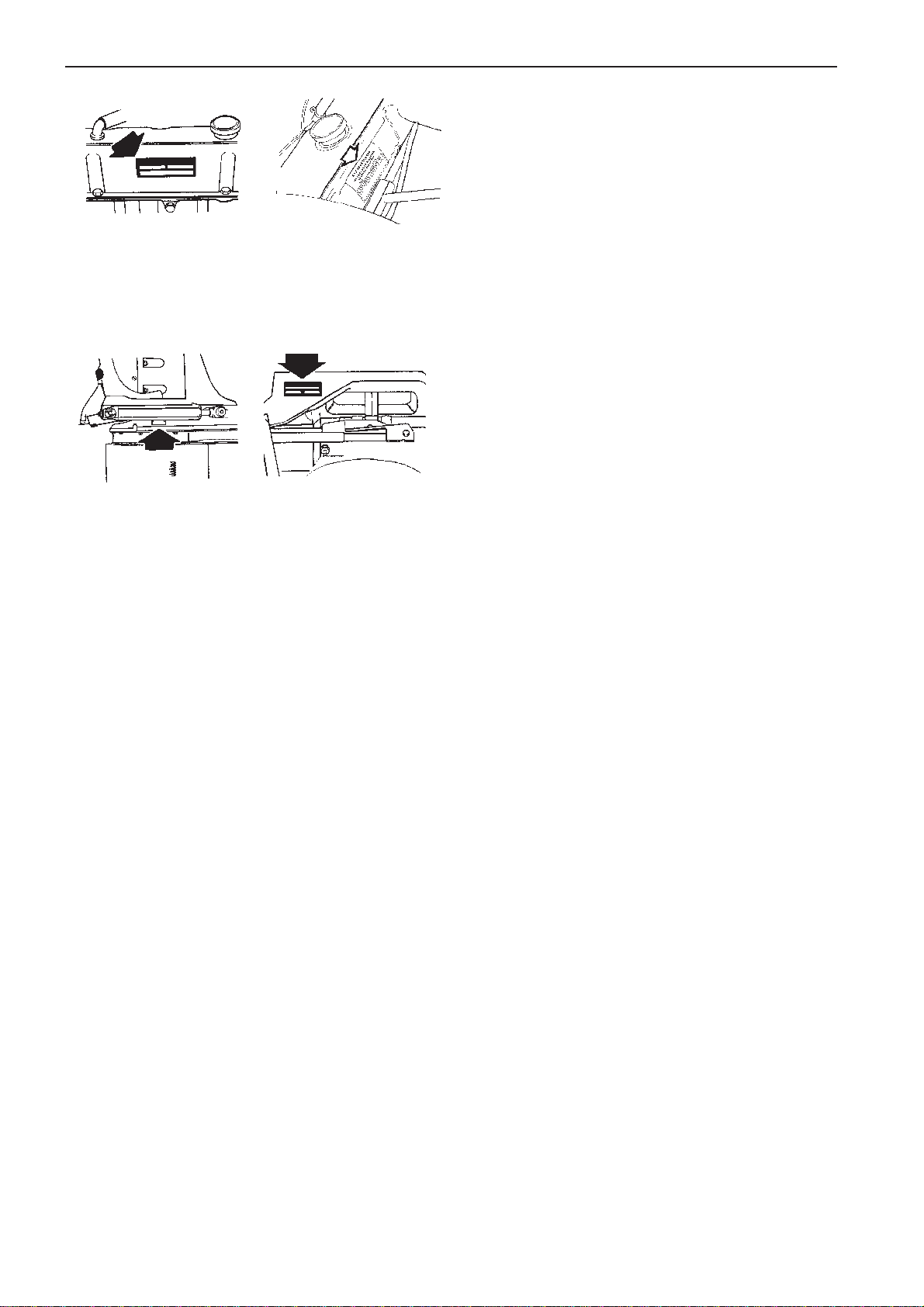

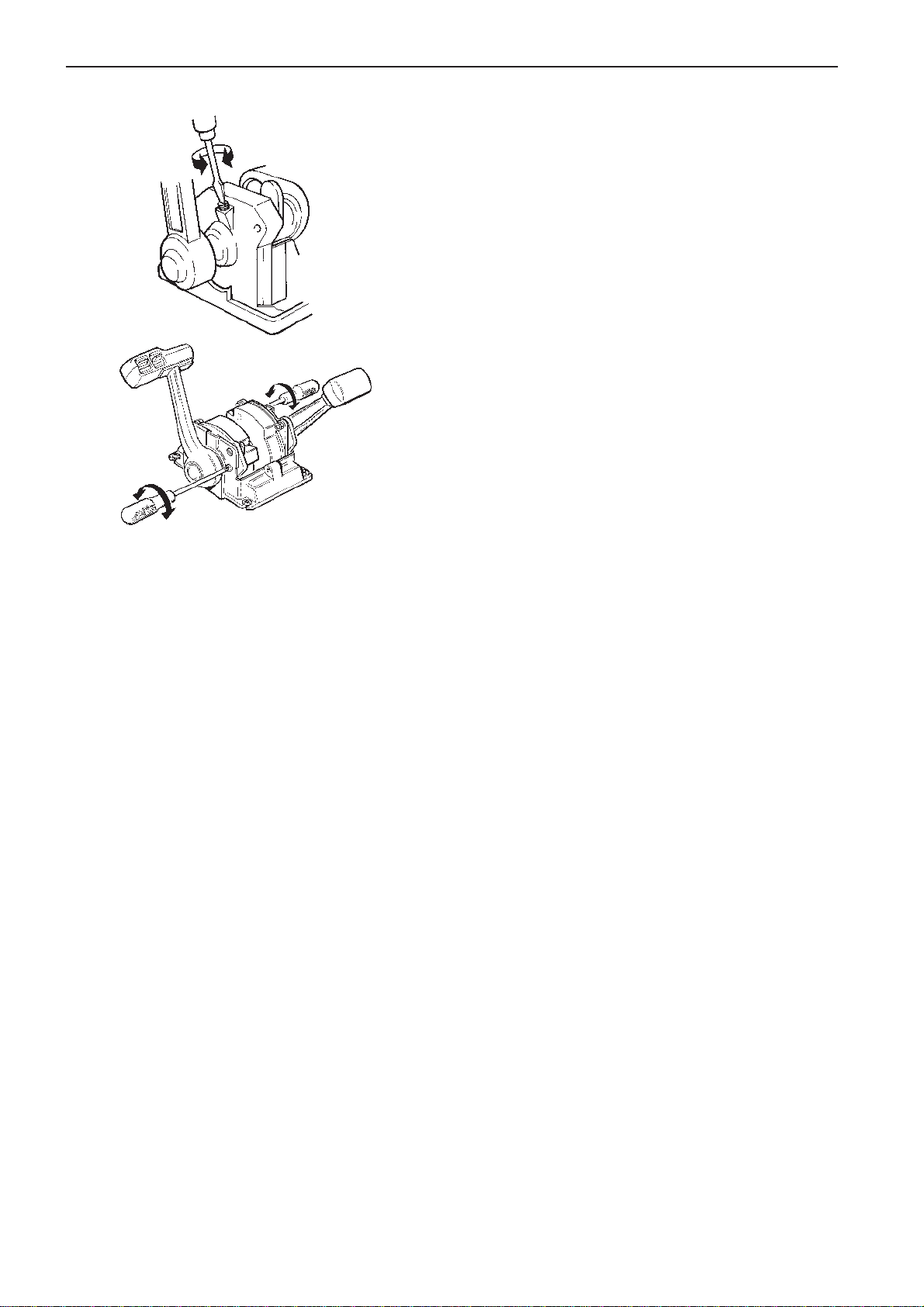

Adjustment of friction brake

The friction brake only affects engine speed adjustment. Adjust with the lever in the throttle half open

position (forward/reverse).

l Remove the cover over the control. For side-

mounted controls the lever must first be

removed.

l Adjust the friction brake by turning the screw at the

arrow (see figure).

l Turn clockwise (+) for more friction and

counterclockwise (-) for less friction.

l Reinstall the cover and lever.

7738812 - Downloaded from www.volvopenta.com 8/2/2009 1:19:46 AM

20

Power T rim

Your Volvo Penta drive has a Power Trim system as standard equipment. The purpose of Power Trim is to allow the helmsman to change the angle at which the drive is set, without leaving the cockpit. Changing this angle

relative to the bottom of the boat is referred to as trimming. Trimming gives the following advantages: Improved

acceleration to planing, keeps the boat planing when the throttles are cut, improves fuel economy, more even

and/or drier running in a choppy sea, increased maximum speed. Some installations also have a trim limiter to

prevent the drive from involuntarily being put into the “Beach” position. The trim limiter is available as an optional accessory for boats with analogue trim gauges. On boats with digital trim gauges, the trim limiter is built into

the gauge. Read more about trimming below and in the

Operation

chapter.

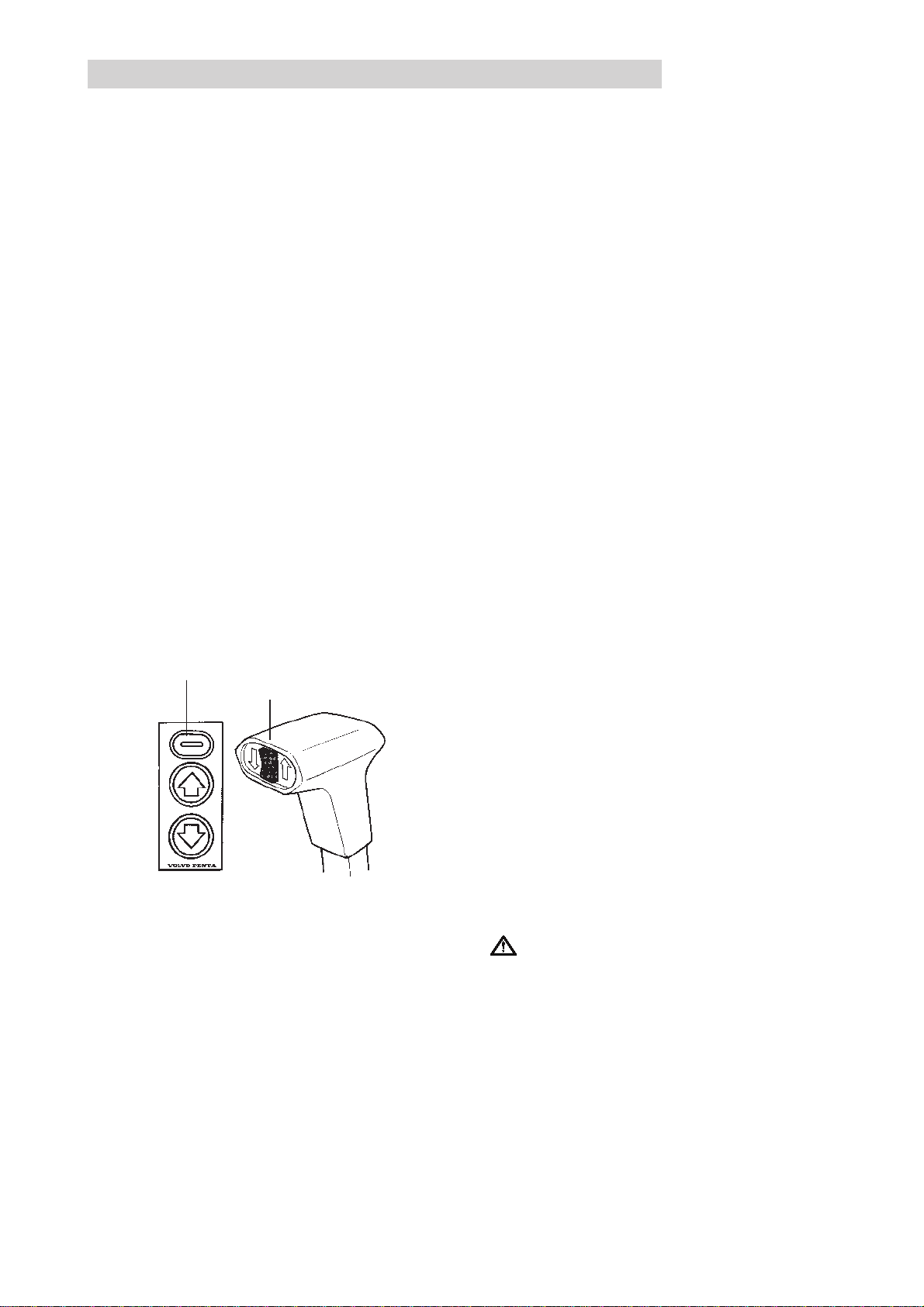

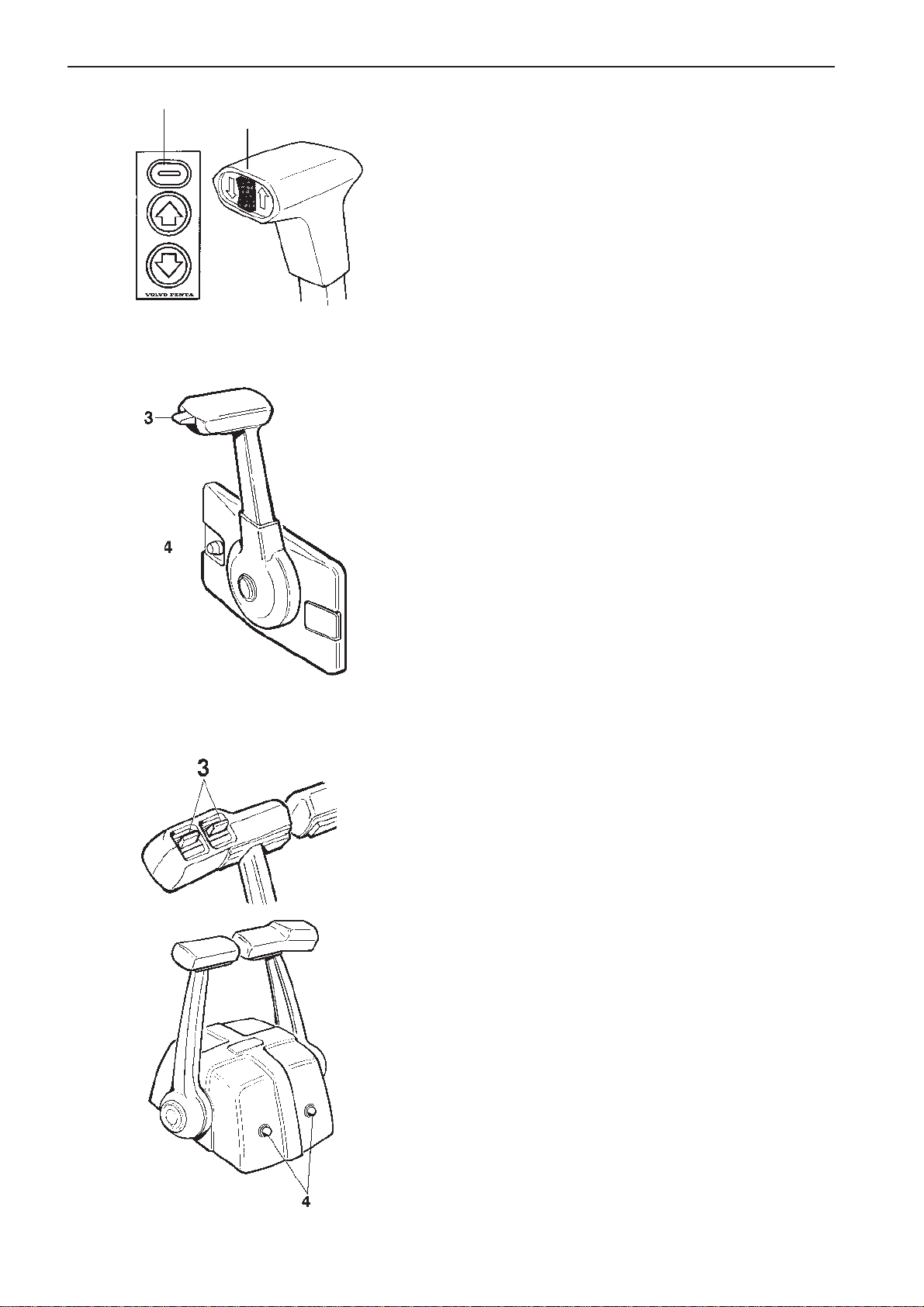

Trim controls

Trimming, i.e. raising and lowering the drive, can

either be done by means of a separate control panel

on the instrument panel, the control button on the

control lever or the control buttons on the port control

lever in a twin installation.

1

2

7738812 - Downloaded from www.volvopenta.com 8/2/2009 1:19:46 AM

The current trim position of the drive is indicated on

a special trim gauge.

Operation

Control panel

The control panel (1) has three buttons. The centre

button moves the drive trim out, and the bow of the

boat is raised. Using the lower button, the drive is

trimmed in, and the bow is lowered.

The top button is used to disconnect a “catch” for the

“Beach” position, so that the drive can be trimmed

into this position. The button should be pressed at

the same time as the centre button.

Note! The catch button does not have any function if

the drive does not have a trim limiter.Please refer to

Trim instrument,

IMPORTANT! The drives must be operated wit-

hin the trim range limits, –2° — +5°. When operating outside of trim range the engine speed

must be reduced to 1000 rpm.

and the

Operation

chapter.

21

1

2

Control lever

Control button (2) in the control lever is used to raise

the bow, by pressing the top half, and to lower the

bow by pressing the lower half of the button.

To put the drive in the “Beach” position, you have to

press a separate switch to bypass the catch which

prevents entry to the “Beach” area. This switch is on

the instrument panel.

Note! The switch does not have any function if the

drive does not have a trim limiter.

Control with catch button

There is a tumbler switch (3) on the control lever to

trim the drive. By pressing the tumbler switch upwards, the drive is trimmed out and the bow is raised. When the switch is pressed down, the drive is

trimmed in and the bow is lowered. Button (4) is used

to bypass the catch which prevents entry to the “Beach” area.

7738812 - Downloaded from www.volvopenta.com 8/2/2009 1:19:46 AM

Note! The catch button does not have any function if

the drive does not have a trim limiter.

Controls with catch button, twin installation

There are two tumbler switches (3) on the port control lever for individual adjustment of drive trim. By

pressing the tumbler switches upwards, the drives

are trimmed out and the bow is raised. When the

switches are pressed down, the drives are trimmed

in and the bow is lowered. Buttons (4) are used to

bypass the catch which prevents entry to the “Beach” area for each drive and make it possible to adjust the trim in this area.

Note! The catch button does not have any function if

the drive does not have a trim limiter.

22

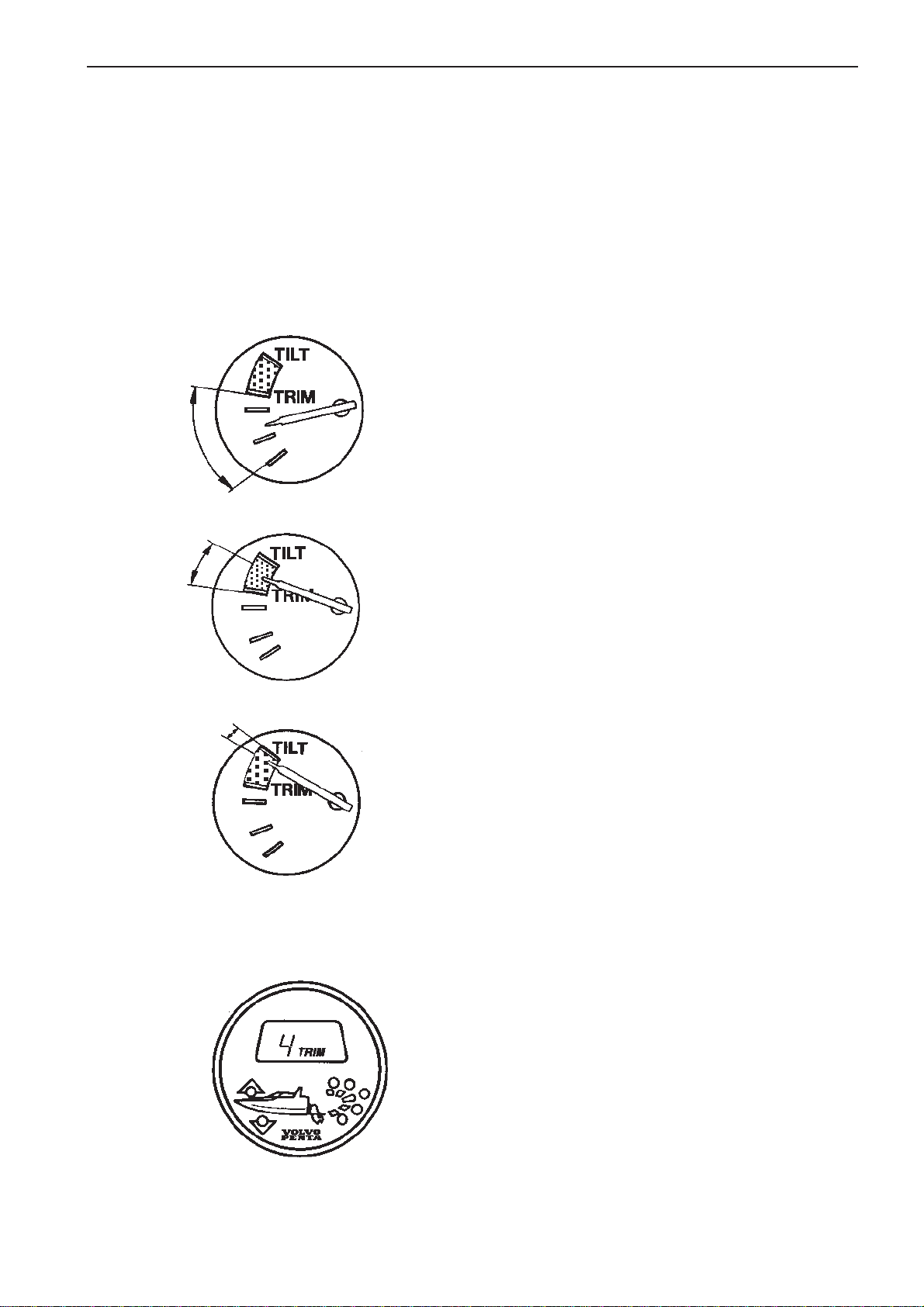

Trim instruments

The SX drive only has an analogue trim instrument.

The DP-S drive can either have an analogue or digi-

tal trim instrument.

Analogue trim instrument (SX, DP-S)

The trim instrument indicates the current trim position.

It has a scale with five segments and three main

ranges:

1. Trim range

The trim range is used to achieve maximum comfort

under normal operation from start to maximum

speed.

7738812 - Downloaded from www.volvopenta.com 8/2/2009 1:19:46 AM

2. Beach range

The beach range is used for operation at reduced

speed (max. 1000 rpm) in shallow water where water

depth is uncertain. This range is also used when

launching and taking the boat out of the water onto a

trailer ramp.

3. Lift range

The lift range is used for lifting the drive to its maximum angle, however this cannot be used during

operation. This range is used for transporting the

boat and to minimize fouling of the drive. The Power

Trim has an automatic stop which cuts off the current

when the stop position is reached. The stop is automatically reset when trimming down.

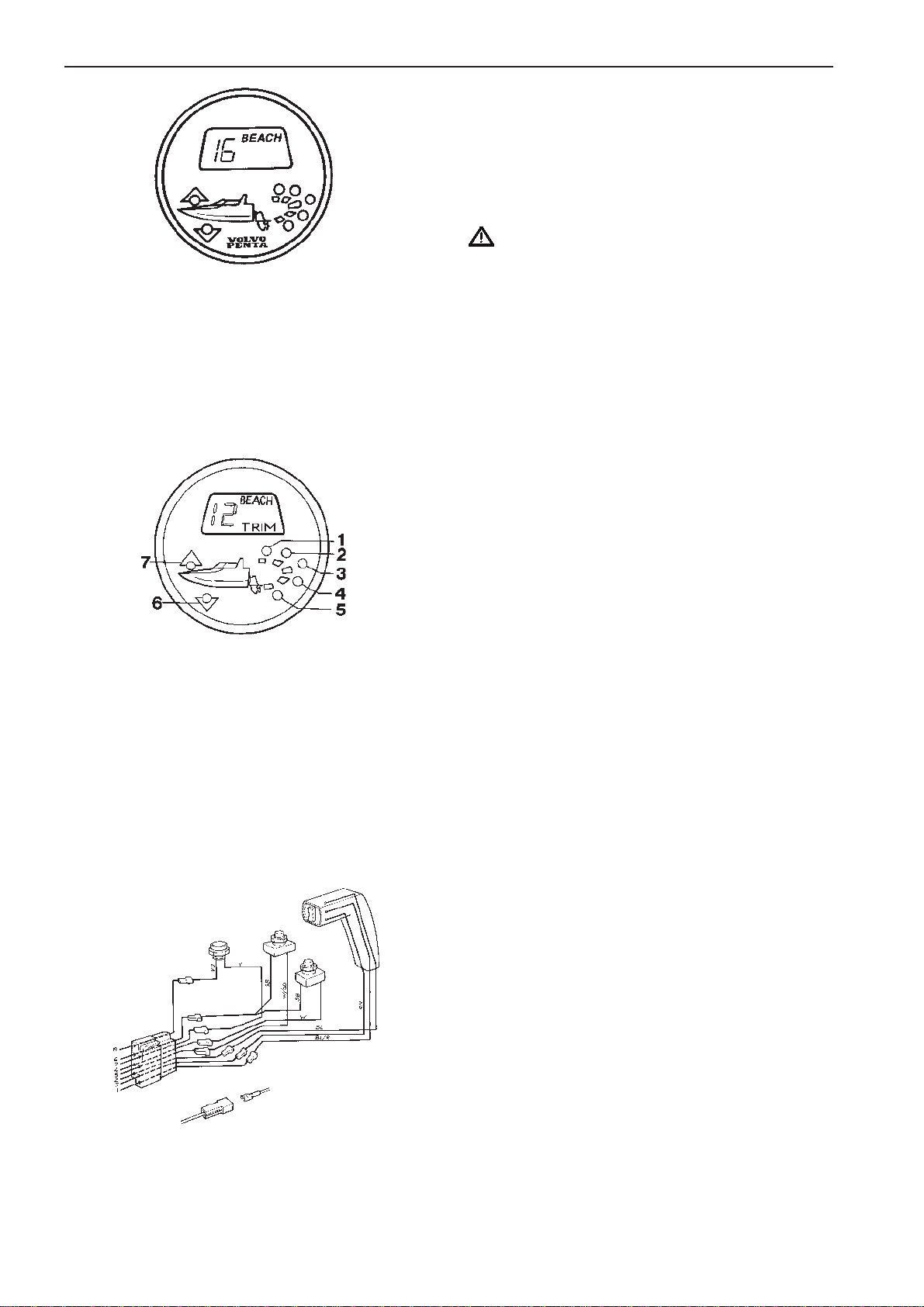

Digital trim instrument (DP-S)

Displays a figure within the range. This figure is the

angle of the drive to perpendicular (stationary boat).

The instrument has a built in control program which

starts each time the instrumentation is switched on

with the ignition key. When this control program is

run, all LCD segments light and A- BEACH is

displayed. The instrument then returns to displaying

the current drive angle.

23

TRIM = Drive position at all speeds. Max trim up to 5.

BEACH = Used for operation at in shallow water

where water depth is uncertain. Speed should always

be low, max. 1000 rpm. 5 - 40.

LIFT = Flashing red warning lamp. Drive up completely

41 - 51. See LEDs position 1.

IMPORTANT! The engine must not be run with

the drive in this position.

LEDs

1 Flashes red within the lift range above 41. Other-

wise out.

2 Constant red light: 6 - 40. Otherwise out.

3 Constant green light: 2 - 5. Otherwise out.

4 Constant green light in the range 0 - 2. Otherwise

out.

7738812 - Downloaded from www.volvopenta.com 8/2/2009 1:19:46 AM

5 Constant green light in trimmed range up to 0.

Otherwise out.

6 Constant yellow light in maximum trimmed posi-

tion up to 0. Flashes when above 0. The drive

moves and the bow is lowered. Otherwise out.

7 Constant yellow light. 2 - 5. Flashes when the

drive moves within trimrange and the bow is raised.

BEACH hold function

Boats with digital trim instruments and separate switches for bypassing the catch which prevents entry to

the “Beach” area can be equipped with a further

switch with warning lamp, a so-called hold function

(optional). Trimming to and inside the “Beach” area is

done as follows:

Press the button to activate the hold function. At the

same time, trim the drive into the “Beach” area. The

indication lamp is now lit, to indicate that the bypass

hold function is now in action. The drives can now be

trimmed in the “Beach” area by a one-hand operation, by just pressing the trim adjustment buttons.

The hold function is retained for as long as the drives

remain in the “Beach” area. When the drive is lowered and the drive re-enters the “Trim” area, the catch

which prevents entry to the “Beach” area is re-activated and the indication lamp goes out.

24

Trim/tilt motor protection

IMPORTANT! Always allow the trim/tilt switch to

return to its center position when the drive unit

reaches the maximum raised or lowered position.

This will prevent your trim/tilt motor from overheating.

The trim/tilt motor is protected from overheating by an

internal thermal overload switch. Should the electric

motor stop while tilting, release the switch and allow

the overload switch to cool and automatically reset itself. When the overload switch has reset, tilting may

be resumed. Make sure the drive unit is not being restrained, causing the motor to overheat. If the trim motor still does not function, check the circuit breaker on

the pump/pump bracket (10 A), the inline fuse (5A) in

the Power Trim switch cabling (if mounted). Also

check the circuit breaker on the fuse box (50 A). Please refer to

Electric system

for more information.

7738812 - Downloaded from www.volvopenta.com 8/2/2009 1:19:46 AM

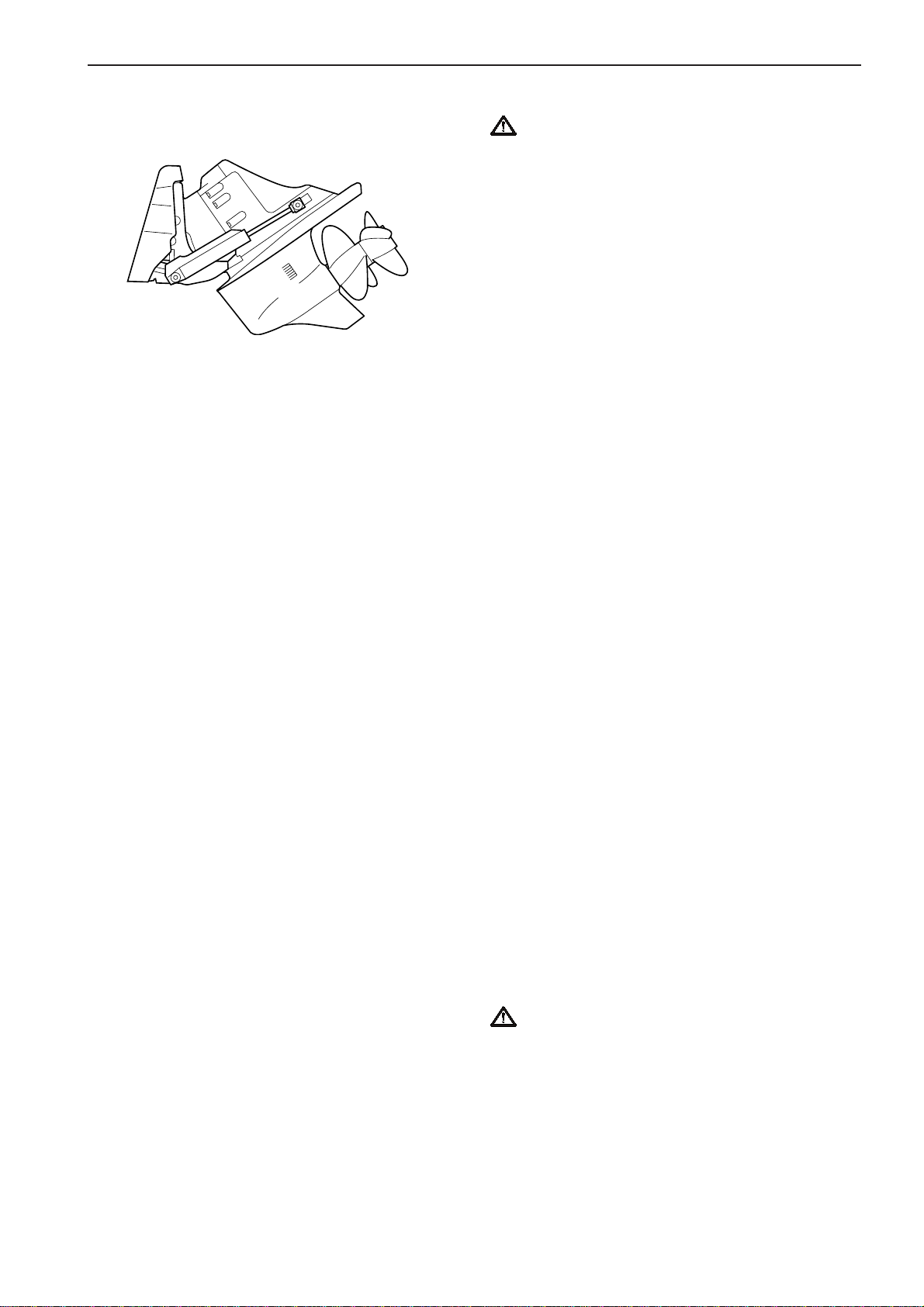

Impact protection

The trim/tilt system provides impact protection for the

drive unit. Still, impact damage can occur in either

forward or reverse directions. Care must be taken:

l When operating in forward or reverse

l When backing at low speed

l When trailering boat

l When launching boat

Impact damage is more likely to occur when in a turn

where side loads are placed on the drive unit.

If the drive unit strikes a solid object, throttle back

and shut off engine immediately. Closely inspect the

boat and drive unit for damage, particularly the

transom shield assembly that contains steering

system components. Check engine compartment for

water leakage.

If there is obvious or suspected damage, operate boat

at low RPM and take your boat to a Volvo Penta

dealer for inspection. Have necessary repairs made

immediately. Operating a damaged drive unit could

cause additional damage and could become very

costly to repair.

IMPORTANT! Failure to inspect for damage

may:

l Result in sudden loss of steering control.

l Adversely affect your boat and drive unit’s

ability to resist subsequent high speed

impacts.

NOTE! When moving in reverse there is no impact

protection. Use caution when moving in reverse.

Do not exceed 2500 RPM.

25

Loading...

Loading...