Volvo Penta 230, 250, AQ171, 251DOHC, AQ131 Workshop Manual

...

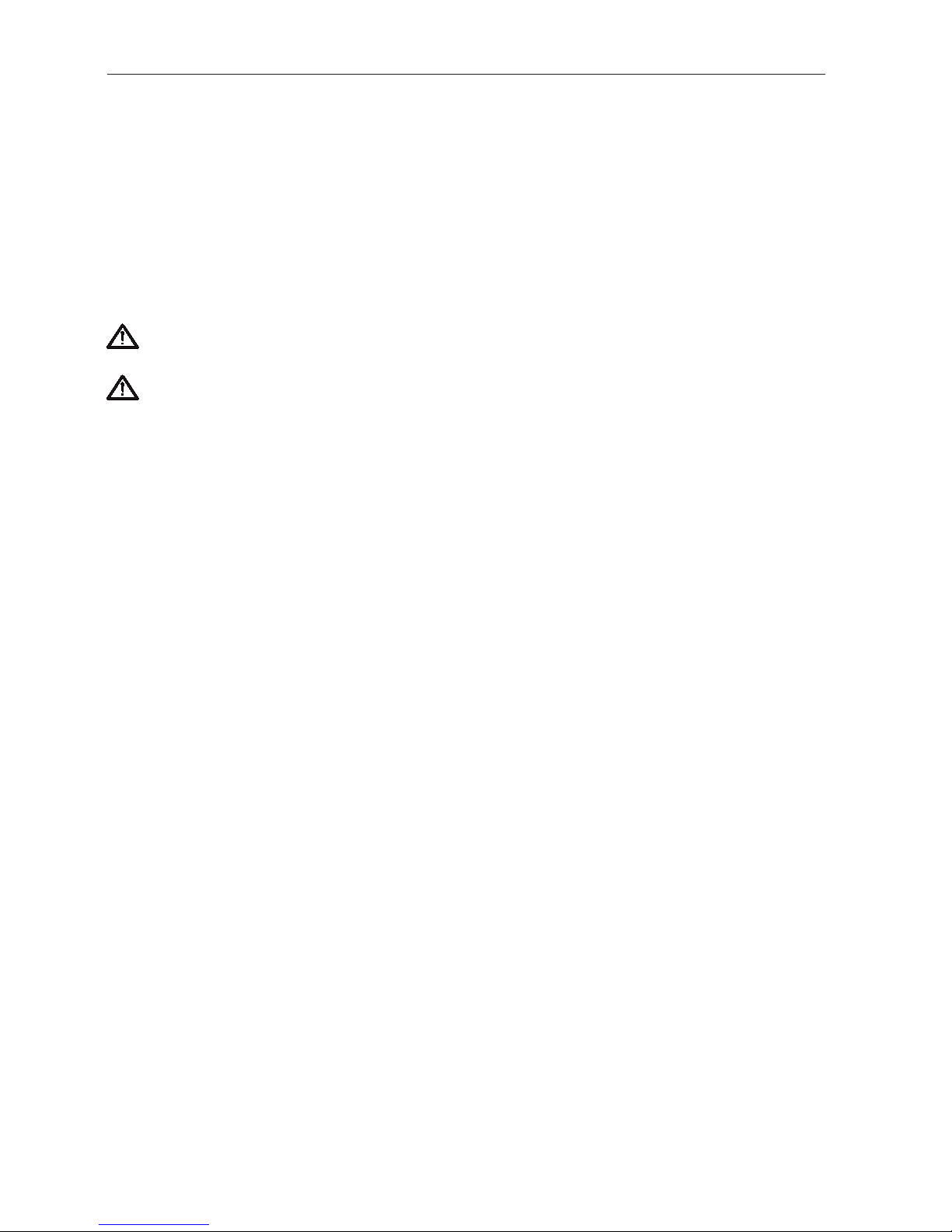

Engine

230, 250, 251DOHC

AQ131, AQ151, AQ171

Workshop Manual

2(0)

C

1

Safety Precautions .............................................................................. 2

General information............................................................................ 5

Repair instructions ............................................................................. 6

Presentation ........................................................................................ 8

Trouble-shooting Scheme ..................................................................11

1. Overhaul Data...............................................................................12

2. Special Tools ................................................................................20

3. Electrical System .........................................................................23

Wiring Diagram AQ131, AQ151, 230, 250 Alt. 1.........................24

Wiring Diagram 230, 250 Alt. 2..................................................26

Wiring Diagram AQ171, 251DOHC Alt.1. ..................................28

Wiring Diagram 251DOHC Alt. 2 ............................................... 30

4A. Fuel System ..................................................................................3 2

Trouble shooting and Remedies Fuel System ............................32

Overhauling and checking the carburetor...................................33

4B. Renix Ignition System..................................................................38

Trouble-shooting and repair ignition system 251DOHC, AQ171 38

4C. Cylinder Head ...............................................................................44

Removal of teh external components ......................................... 44

4D. Cooling System ............................................................................48

Overhauling the heat exchanger .................................................48

Overhauling the sea water pump ................................................49

Check the thermostat .................................................................. 49

4E. Overhauling the valve system .....................................................50

Overhauling the valve system 230, 250, AQ131, AQ151 ........... 50

Adjusting the valves 230, 250, AQ131, AQ151.......................... 59

Valve system 251DOHC, AQ171. Technical Description...........61

Overhauling the valve system 251DOHC, AQ171......................63

4F. Installing the toothed belt ...........................................................71

Installing the toothed belt 230, 250, AQ131, AQ151 ......................71

Installing the toothed belt 251DOHC, AQ171.................................73

4G. Installing the external components of the Cylinder Head ........74

5. Cylinder Block ..............................................................................78

5A. Removing the external components...........................................78

5B. Overhauling the Crank Assembly ...............................................80

The lubricating oil pump Overhauling..........................................87

5C. Installing the external components ............................................93

Overhauling the oil cooler 250, 251DOHC, AQ151, AQ171........95

Workshop Manual

Index

230, 250, 251DOHC,

AQ131, AQ151, AQ171

2

Safety Precautions

Check that the warning or information decals on

the product are always clearly visible. Replace

decals that have been damaged or painted over.

Engine with turbocharger: Never start the engine

without installing the air cleaner (ACL). The rotating compressor in the Turbo can cause serious personal injury. Foreign objects entering

the intake ducts can also cause mechanical

damage.

Never use start spray or similar to start the engine. The starter element may cause an explosion in the inlet manifold. Danger of personal injury.

Avoid opening the filler cap for engine coolant

system (freshwater cooled engines) when the

engine is still hot. Steam or hot coolant can

spray out. Open the coolant filler cap carefully

and slowly to release pressure before removing

the cap completely. Take great care if a cock,

plug or engine coolant line must be removed

from a hot engine. It is difficult to anticipate in

which direction steam or hot coolant can spray

out.

Hot oil can cause burns. Avoid skin contact with

hot oil. Ensure that the lubrication system is not

under pressure before commencing work on it.

Never start or operate the engine with the oil

filler cap removed, otherwise oil could be

ejected.

Stop the engine and close the sea cock before

carrying out operations on the engine cooling

system.

Only start the engine in a well-ventilated area. If

operating the engine in an enclosed space, ensure that exhaust gases and crankcase ventilation emissions are ventilated out of the working

area.

Introduction

This Workshop Manual contains technical data, descriptions and repair instructions for Volvo Penta products or product versions contained in the contents list.

Ensure that the correct workshop literature is being

used.

Read the safety information and the Workshop

Manual “General Information” and “Repair Instructions” carefully before starting work.

Important

In this book and on the engine you will find the following special warning symbols.

WARNING! If these instructions are not followed there is a danger of personal injury, extensive damage to the product or serious mechanical malfunction.

IMPORTANT! Used to draw your attention to

something that can cause damage, product

malfunction or damage to property.

NOTE! Used to draw your attention to important in-

formation that will facilitate work or operations.

Below is a summary of the risks and safety precautions you should always observe or carry out when

operating or servicing the engine.

Immobilize the engine by turning off the power

supply to the engine at the main switch (switches) and lock it (them) in the OFF position before

starting work. Set up a warning notice at the engine control point or helm.

Generally, all servicing should be carried out

with the engine switched off. Some work (carrying out certain adjustments for example) requires the engine to be running. Approaching a

running engine is dangerous. Loose clothing or

long hair can fasten in rotating parts and cause

serious personal injury. If working in proximity

to a running engine, careless movements or a

dropped tool can result in personal injury. Avoid

burns. Take precautions to avoid hot surfaces

(exhausts, turbochargers, charge air pipes and

starter elements etc.) and liquids in supply lines

and hoses when the engine is running or has

been turned off immediately prior to starting

work on it. Reinstall all protective parts removed

during service operations before starting the engine.

3

Always use protective goggles where there is

a danger of pieces of metal, sparks from grinding, acid or other chemicals being thrown into

your eyes. Your eyes are very sensitive, injury

can lead to loss of sight!

Avoid skin contact with oil. Long-term or repeated contact with oil can remove the natural

oils from your skin. The result can be irritation,

dry skin, eczema and other skin problems.

Used oil is more dangerous to health than new

oil. Use protective gloves and avoid using oilsoaked clothes and rags. Wash regularly, especially before meals. Use the correct barrier

cream to prevent dry skin and to make cleaning your skin easier.

Most chemicals used in products (engine and

transmission oils, glycol, petrol and diesel oil)

and workshop chemicals (solvents and paints)

are hazardous to health Read the instructions

on the product packaging carefully! Always follow safety instructions (using breathing apparatus, protective goggles and gloves for example). Ensure that other personnel are not

unwittingly exposed to hazardous substances

(by breathing them in for example). Ensure

that ventilation is good. Handle used and excess chemicals according to instructions.

Be extremely careful when tracing leaks in the

fuel system and testing fuel injection nozzles.

Use protective goggles! The jet ejected from a

fuel injection nozzle is under very high pressure, it can penetrate body tissue and cause

serious injury There is a danger of blood poisoning.

All fuels and many chemicals are inflammable.

Ensure that a naked flame or sparks cannot ignite fuel or chemicals. Combined with air in

certain ratios, petrol, some solvents and hydrogen from batteries are easily inflammable

and explosive. Smoking is prohibited! Ensure

that ventilation is good and that the necessary

safety precautions have been taken before

carrying out welding or grinding work. Always

have a fire extinguisher to hand in the workplace.

Store oil and fuel-soaked rags and fuel and oil

filters safely. In certain conditions oil-soaked

rags can spontaneously ignite. Used fuel and

oil filters are environmentally dangerous waste

and must be deposited at an approved site for

destruction together with used lubricating oil,

contaminated fuel, paint remnants, solvent, degreasing agents and waste from washing

parts.

Never allow a naked flame or electric sparks

near the batteries. Never smoke in proximity to

the batteries. The batteries give off hydrogen

gas during charging which when mixed with air

can form an explosive gas – oxyhydrogen.

This gas is easily ignited and highly volatile.

Incorrect connection of the battery can cause

a spark which is sufficient to cause an explosion with resulting damage. Do not disturb battery connections when starting the engine

(spark risk) and do not lean over batteries.

Never mix up the positive and negative battery

terminals when installing. Incorrect installation

can result in serious damage to electrical

equipment. Refer to wiring diagrams.

Always use protective goggles when charging

and handling batteries. The battery electrolyte

contains extremely corrosive sulfuric acid. If

this comes into contact with the skin, wash immediately with soap and plenty of water. If battery acid comes into contact with the eyes, immediately flush with copious amounts of water

and obtain medical assistance.

Turn off the engine and turn off power at main

switch(es) before carrying out work on the

electrical system.

Clutch adjustments must be carried out with

the engine turned off.

4

Use the lifting eyes mounted on the engine/reverse gear when lifting the drive unit.

Always check that lifting equipment is in good

condition and has sufficient load capacity to lift

the engine (engine weight including reverse

gear and any extra equipment installed).

To ensure safe handling and to avoid damaging

engine components on top of the engine, use a

lifting beam to raise the engine. All chains and

cables should run parallel to each other and as

perpendicular as possible in relation to the top

of the engine.

If extra equipment is installed on the engine altering its center of gravity, a special lifting device is required to achieve the correct balance

for safe handling.

Never carry out work on an engine suspended

on a hoist.

Never remove heavy components alone, even

where secure lifting equipment such as secured blocks are being used. Even where lifting equipment is being used it is best to carry

out the work with two people; one to operate

the lifting equipment and the other to ensure

that components are not trapped and damaged

when being lifted. When working on-board ensure that there is sufficient space to remove

components without danger of injury or damage.

Components in the electrical system, ignition

system (gasoline engines) and fuel system on

Volvo Penta products are designed and constructed to minimize the risk of fire and explosion. The engine must not be run in areas

where there are explosive materials.

Always use fuels recommended by Volvo Penta. Refer to the Instruction Book. The use of

lower quality fuels can damage the engine. On

a diesel engine poor quality fuel can cause the

control rod to seize and the engine to overrev

with the resulting risk of damage to the engine

and personal injury. Poor fuel quality can also

lead to higher maintenance costs.

5

General information

About the workshop manual

This workshop manual contains technical specification, descriptions and instructions for repairing the

standard versions of the following engines 230, 250,

251DOHC, AQ131, A Q151 and A Q171. The product

designation and number should be given in all correspondence about the product.

This Workshop Manual has been developed primarily

for Volvo Penta service workshops and qualified personnel. Persons using this book are assumed to

have a grounding in marine drive systems and be

able to carry out related mechanical and electrical

work.

Volvo Penta is continuously developing their products. We therefore reserve the right to make

changes. All the information contained in this book is

based on product data available at the time of going

to print. Any essential changes or modifications introduced into production or updated or revised service methods introduced after the date of publication

will be provided in the form of Service Bulletins.

Replacement parts

Replacement parts for electrical and fuel systems

are subject to statutory requirements (US Coast

Guard Safety Regulations for example). Volvo Penta

Genuine parts meet these requirements. Any type of

damage which results from the use of non-original

Volvo Penta replacement parts for the product will

not be covered under any warranty provided by Volvo Penta.

6

Repair instructions

The working methods described in the Service Manual apply to work carried out in a workshop. The

engine has been removed from the boat and is installed in an engine fixture. Unless otherwise stated

reconditioning work which can be carried out with

the engine in place follows the same working

method.

Warning symbols occurring in the Workshop Manual

(for their meaning see

Safety information

)

WARNING!

IMPORTANT!

NOTE!

are not in any way comprehensive since it is impossible to predict every circumstance under which service work or repairs may be carried out. For this reason we can only highlight the risks that can arise

when work is carried out incorrectly in a wellequipped workshop using working methods and

tools developed by us.

All procedures for which there are Volvo Penta special tools in this Workshop Manual are carried out

using these. Special tools are developed to rationalize working methods and make procedures as safe

as possible. It is therefore the responsibility of any

person using tools or working methods other than

the ones recommended by us to ensure that there is

no danger of injury, damage or malfunction resulting

from these.

In some cases there may be special safety precautions and instructions for the use of tools and chemicals contained in this Workshop Manual. These special instructions should always be followed if there

are no separate instructions in the Workshop Manual.

Certain elementary precautions and common sense

can prevent most risks arising. A clean workplace

and engine eliminates much of the danger of injury

and malfunction.

It is of the greatest importance that no dirt or foreign

particles get into the fuel system, lubrication system, intake system, turbocharger, bearings and

seals when they are being worked on. The result

can be malfunction or a shorter operational life.

Our joint responsibility

Each engine consists of many connected systems

and components. If a component deviates from its

technical specification the environmental impact of an

otherwise good engine may be increased significantly.

It is therefore vital that wear tolerances are maintained, that systems that can be adjusted are adjusted

properly and that Volvo Penta Genuine Parts as used.

The engine Maintenance Schedule must be followed.

Some systems, such as the components in the fuel

system, require special expertise and special testing

equipment for service and maintenance. Some components are sealed at the factory for environmental

reasons. No work should be carried out on sealed

components except by authorized personnel.

Bear in mind that most chemicals used on boats are

harmful to the environment if used incorrectly.

Volvo Penta recommends the use of biodegradable

degreasing agents for cleaning engine components,

unless otherwise stated in a workshop manual. Take

special care when working on-board, that oil and

waste is taken for destruction and is not accidentally

pumped into the environment with bilge water.

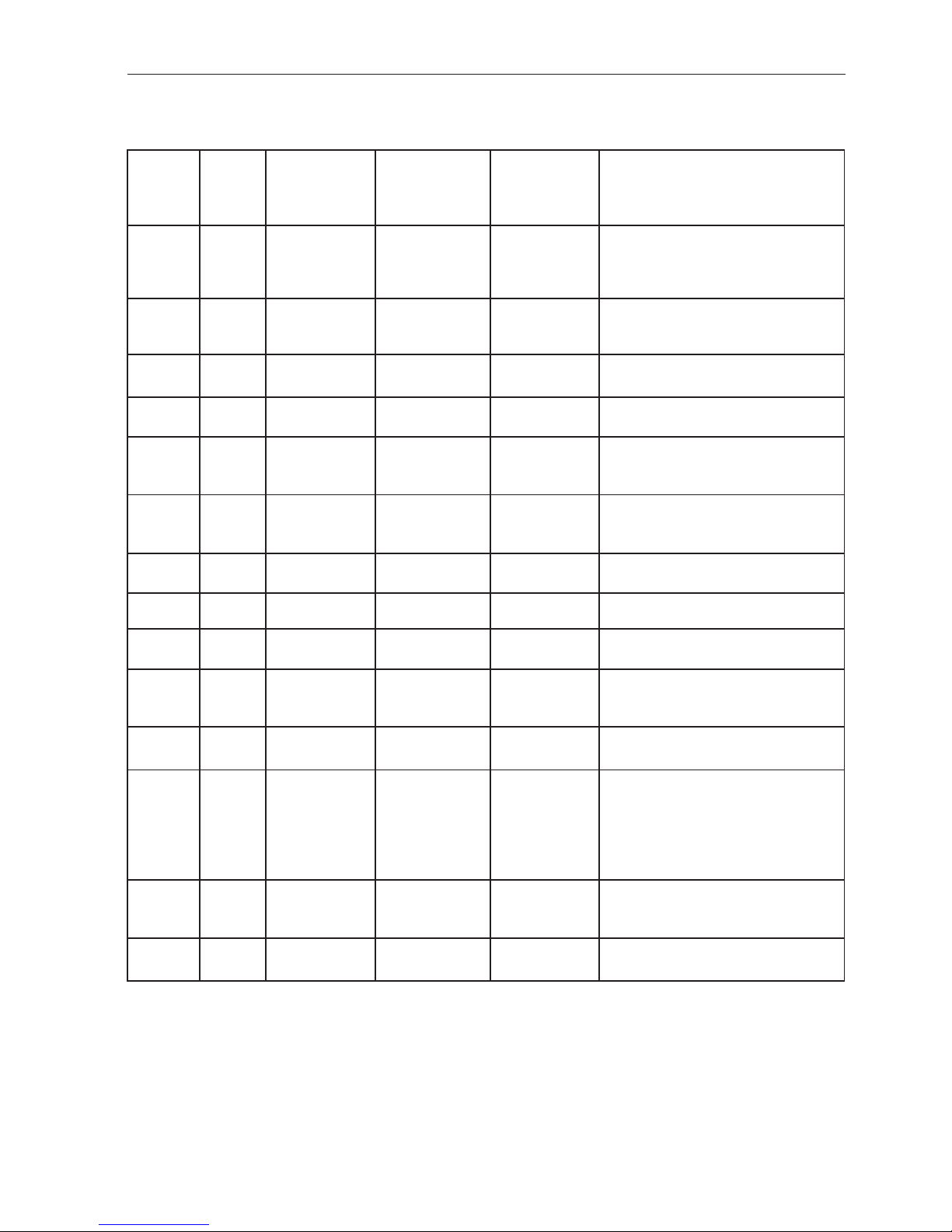

Tightening torques

Tightening torques for vital joints that must be

tightened with a torque wrench are listed in workshop

manual “Technical Data”: “Tightening Torques” and are

contained in work descriptions in this Manual. All torques apply for cleaned threads, screw heads and

mating surfaces. Torques apply for lightly oiled or dry

threads. If lubricants, locking fluid or sealing compound are required for a screwed joint this information

will be contained in the work description and in “Tightening Torques” Where no tightening torque is stated for

a joint use the general tightening torques according to

the tables below. The tightening torques stated are a

guide and the joint does not have to be tightened using

a torque wrench.

Dimension Tightening T orques

Nm lbt.ft

M5 6 4,4

M6 10 7,4

M8 25 18,4

M10 50 36,9

M12 80 59,0

M14 140 103,3

7

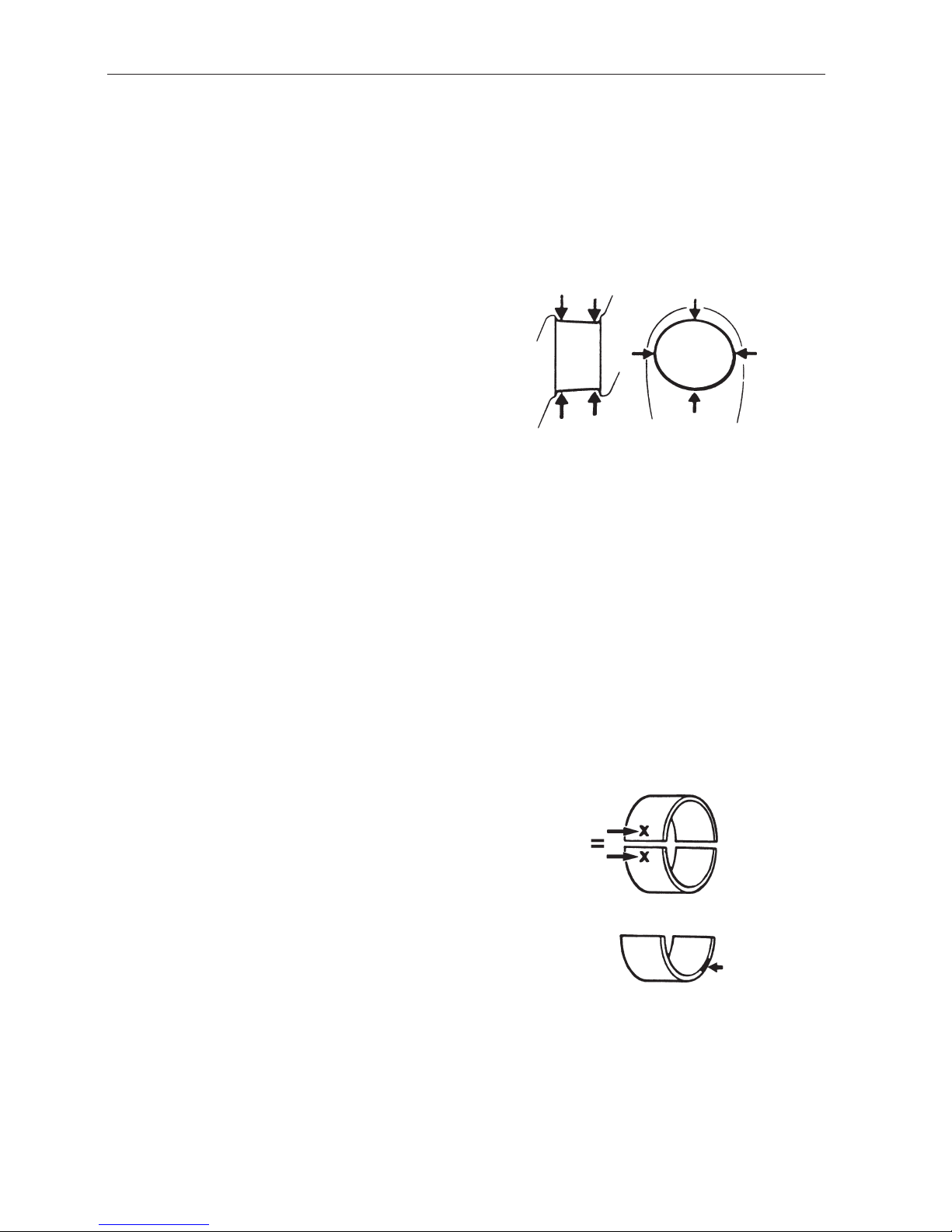

Tightening torques-protractor

(angle) tightening

Tightening using both a torque setting and a protractor angle requires

that first the recommended torque is

applied using a torque wrench and

then the recommended angle is

added according to the protractor

scale. Example: a 90° protractor

tightening means that the joint is

tightened a further 1/4 turn in one

operation after the stated tightening

torque has been applied.

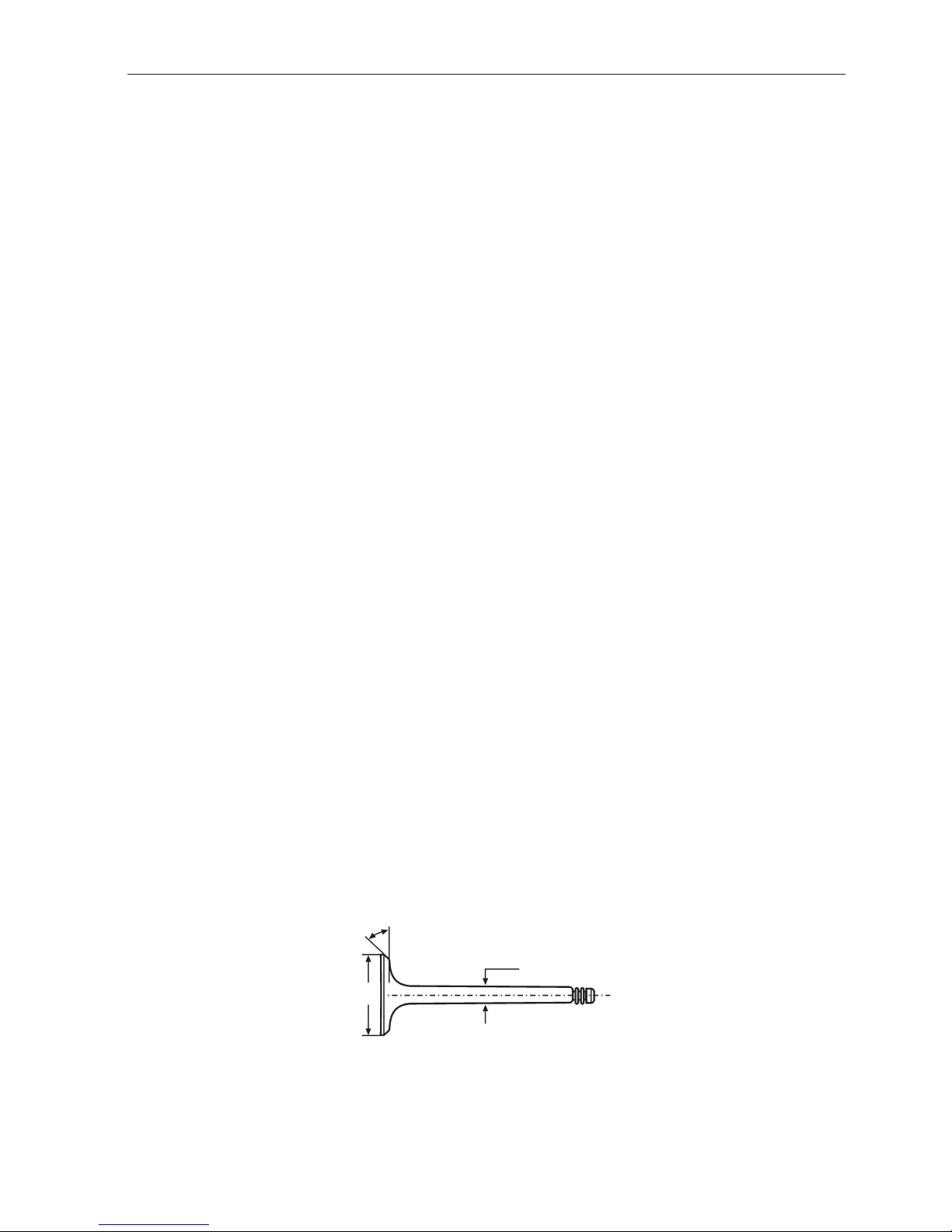

Locknuts

Do not re-use lock nuts that have been removed

during dismantling as they have reduced service life

when re-used – use new nuts when assembling or

reinstalling. For lock nuts with a plastic insert such

as Nylock

®

the tightening torque stated in the table

is reduced if the Nylock

®

nut has the same head

height as a standard hexagonal nut without plastic

insert. Reduce the tightening torque by 25% for bolt

size 8 mm or larger. Where Nylock

®

nuts are higher,

or of the same height as a standard hexagonal nut,

the tightening torques given in the table apply.

Tolerance classes

Screws and nuts are divided into different strength

classes, the class is indicated by the number on the

bolt head. A high number indicates stronger material,

for example a bolt marked 10-9 indicates a higher

tolerance than one marked 8-8. It is therefore important that bolts removed during the disassembly

of a bolted joint must be reinstalled in their original

position when assembling the joint. If a bolt must be

replaced check in the replacement parts catalogue

to make sure the correct bolt is used.

Sealants

A number of sealants and locking liquids are used on

the engines. The agents have varying proper ties and

are used for different types of jointing strengths,

operating temperature ranges, resistance to oil and

other chemicals and for the different materials and

gap sizes in the engines.

To ensure ser vice work is correctly carried out it is

important that the correct sealant and locking fluid

type is used on the joint where the agents are required.

In this Volvo Penta Service Manual the user will find

that each section where these agents are applied in

production states which type was used on the engine.

During service operations use the same agent or an

alternative from a different manufacturer.

Make sure that mating surfaces are dry and free from

oil, grease, paint and anti-corrosion agent before applying sealant or locking fluid. Always follow the

manufacturer’s instructions for use regarding; temperature range, curing time and any other instructions

for the product.

Tow different basic types of agent are used on the

engine and these are:

RTV agent (Room temperature vulcanizing). Use for

gaskets, sealing gasket joints or coating gaskets. RTV

agent is clearly visible when a component has been

dismantled; old RTV must be removed before the joint

is resealed.

The following RTV agents are mentioned in the Service Manual: Loctite

®

574, Volvo Penta 840879-1,

Permatex® No. 3, Volvo Penta P/N 1161099-5, Permatex® No. 77. Old sealant can be removed using methylated spirits in all cases.

Anaerobic agents. These agents cure in an absence of

air. They are used when two solid parts, for example

cast components, are installed face-to-face without a

gasket. They are also commonly used to secure

plugs, threads in stud bolts, cocks, oil pressure switches and so on. The cured mater ial is glass-like and it

is therefore colored to make it visible. Cured anaerobic agents are extremely resistant to solvents and

the old agent cannot be removed. When reinstalling

the part is carefully degreased and then new sealant

is applied.

The following anaerobic agents are mentioned in the

Service Manual: Loctite

®

572 (white), Loctite® 241

(blue).

NOTE! Loctite® is the registered trademark of Loctite Corporation, Permatex® is the registered trademark of the Permatex

Corporation.

8

Presentation

The engines are 4 cylinder gasoline engines. All the

engines are equipped with freshwater cooling in

combination with seawater cooling. The seawater

system is powered by a direct drive impeller pump.

The thermostat controlled freshwater system is powered by a circulation pump.

The engines are manufactured with two different

product designations. During 1989 Volvo Penta began designating engines based on their cylinder displacement according to the ISO norm 8665. The

older product designations of AQ131, AQ151 and

AQ171 (where the number provided an approximate

indication of output) were withdrawn. The new designation 230 replaced AQ131, 250 replaced

AQ151and 251DOHC replaced AQ171.

250, AQ151 and 251DOHC, A Q171 are equipped

with an oil cooler. 230, AQ131 has a single

carburettor and the others have twin carburettors.

The exhaust system has seawater cooled exhaust

pipes. 230, AQ131 and 250, AQ151 models have an

overhead camshaft while 251DOHC, AQ171 has

double overhead camshafts with hydraulic valve lifters. 251DOHC, AQ171 is a 16 valve engine. 230,

AQ131 and 250, AQ151 models have conventional

marine ignition systems while 251DOHC, AQ171

has electronic ignition.

The product plate is located on the cylinder block

beside the starter motor. The product plate provides

the following information;

(1) Product designation, i.e. AQ131D

(2) Product number, i.e 867902

(3) Serial number (10 digit)

(4) Basic engine, serial number

Product plate

230, AQ131

250, AQ151

251DOHC, AQ171

9

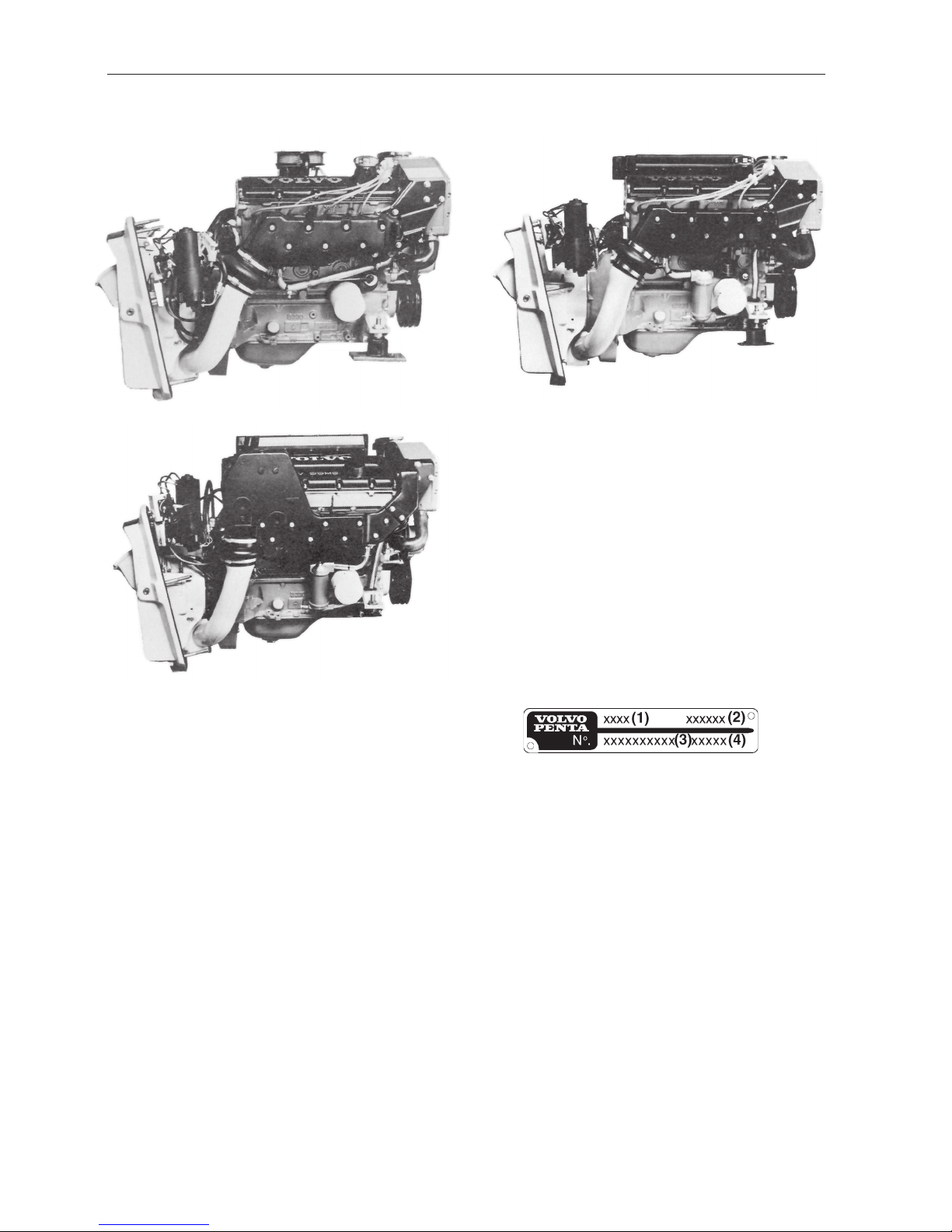

The sea water cooling system

The fresh water cooling system,

thermostat closed

The fresh water cooling system,

thermostat open

1 = Sea-water filter

2 = Heat exchanger

3 = Sea-water pump

4 = Oil cooler

5 = Bypass

6 = Thermostat house

7 = Circulation pump

The Cooling System

10

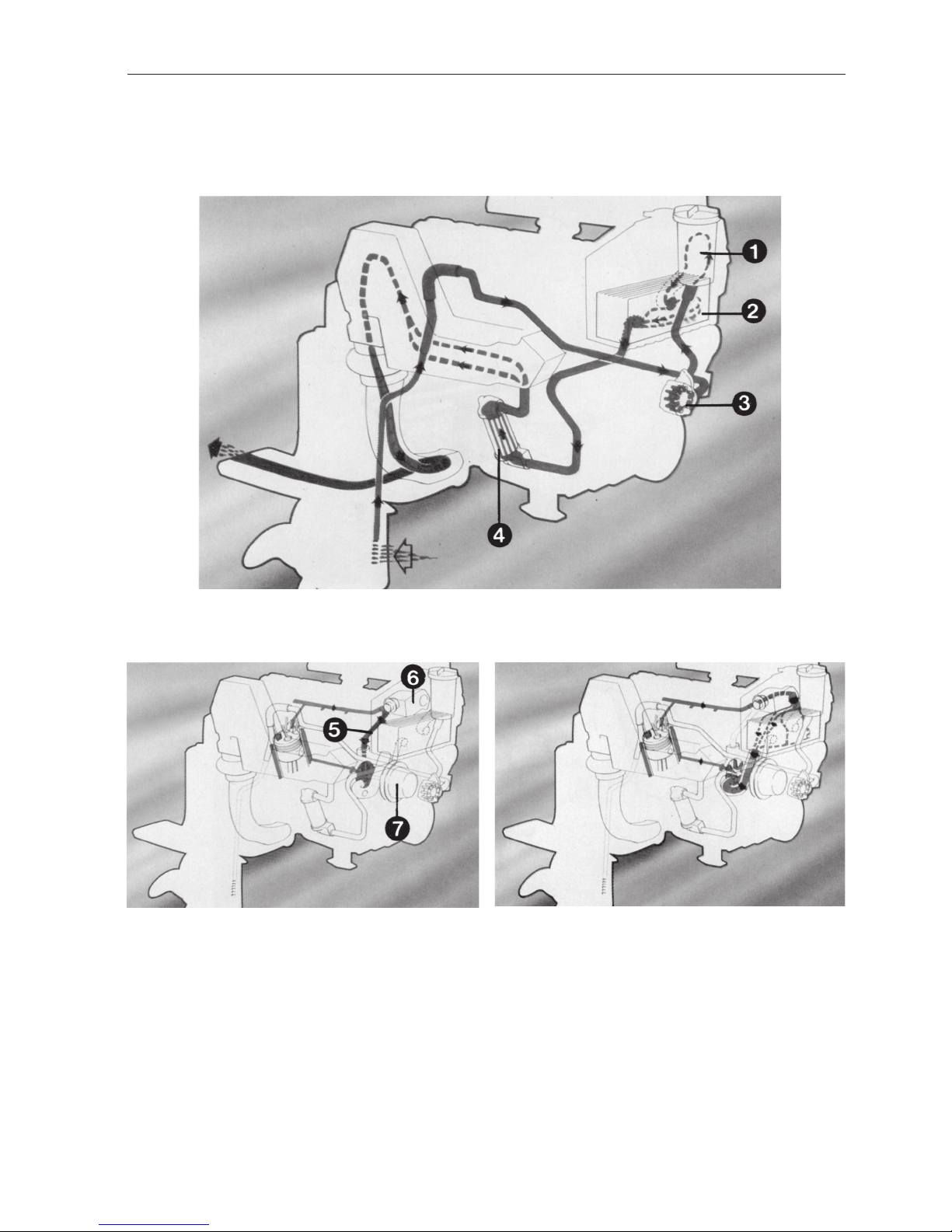

The Lubricating System

The engine lubricating system from strainer to the main gallery

The engine lubricating system from the main gallery to the lubricating points.

1 = Main gallery

2 = Oil pump

3 = Return line

4 = Oil cooler

5 = Oil filter

11

Trouble-shooting Scheme

Main switch open. Battery

discharged. Wires broken or

fuse blown.

Empty fuel tank, closed fuel cock,

clogged fuel filter.

Water or impurities in the fuel.

Faulty spark plugs.

Burned breaker points, moisture

in distributor and ignition leads.

Faulty electronic unit 251DOHC,

AQ171

Idling speed not adjusted properly.

Faulty tachometer.

Boat loaded abnormally.

Growth on boat bottom and

sterndrive.

Damaged propeller.

Clogged cooling water intake, oil

cooler (250, 251DOHC, AQ151,

AQ171) waterjackets. Damaged

impeller or thermostat. Too low

coolant level in expansion tank

Wrong fuel quality in relation to

timing

Toothed belt faulty or not adjusted

properly.

Engine

does not

start

Engine

stops

Engine does

not reach operating speed

at full throttle

Engine runs

rough or vibrates abnormally

Engine becomes abnormally hot

Fault reason

X

X

X

XX

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

12

1. Overhaul Data

Technical Data

230, 250, 251DOHC

AQ131, AQ151, AQ171

General

Type designation ................................................................................. 230, AQ131

Type of engine ..................................................................................... 4 stroke, overhead cam

Speed range full load ........................................................................... 78.3–83.3 r/s (4700–5000 rpm)

Maximum cruising speed .................................................................... 3.33 r/s (200 rpm) lower than the max speed obtained

Compression ratio ............................................................................... 9.7:1

Compression pressure at starter motor speed

1)

.................................. 10–12 kp/cm2 (142–170 psi)

Number of cylinders ............................................................................ 4 in line

Cylinder bore ....................................................................................... 96 mm (3.7795")

Stroke.................................................................................................. 80 mm (3.1496")

Swept volume (displacement) ............................................................. 2.315 dm3 (141.3 in3)

Weight, excluding water and oil, approx. ............................................. 240 Kilos (529.1 lbs)

Idling speed ......................................................................................... 15 r/s (900 rpm)

General

Type designation ................................................................................. 250, AQ151

Type of engine ..................................................................................... 4 stroke, overhead cam

Speed range full load ........................................................................... 80–91.7 r/s (4800–5500 rpm)

Maximum cruising speed .................................................................... 3.33 r/s (200 rpm) lower than the max speed obtained

Compression ratio ............................................................................... 9.7:1

Compression pressure at starter motor speed1).................................. 10–12 kp/cm2 (142–170 psi)

Number of cylinders ............................................................................ 4 in line

Bore..................................................................................................... 96 mm (3.7795")

Stroke.................................................................................................. 86 mm (3.3858")

Swept volume (displacement) ............................................................. 2.49 dm3 (151.9 in3)

Weight, excluding water and oil, approx. ............................................. 250 Kilos (551.2 lbs)

Idling speed ......................................................................................... 15 r/s (900 rpm)

General

Type designation ................................................................................. 251DOHC, AQ171

Type of engine ..................................................................................... 4 stroke, overhead cams

Speed range full load ........................................................................... 83.3–95 r/s (5000–5700 rpm)

Maximum cruising speed .................................................................... 3.33 r/s (200 rpm) lower than the max speed obtained

Compression ratio ............................................................................... 9.7:1

Compression pressure at starter motor speed1).................................. 10–12 kp/cm2 (142–170 psi)

Number of cylinders ............................................................................ 4 in line

Bore..................................................................................................... 96 mm (3.7795")

Stroke.................................................................................................. 86 mm (3.3858")

Swept volume (displacement) ............................................................. 2.49 dm3 (151.9 in3)

Weight, excluding water and oil, approx. ............................................. 289 Kilos (637.15 lbs)

Idling speed ......................................................................................... 15 r/s (900 rpm)

1)

Applies to hot engine, wide open throttle

13

Cylinder block

Material................................................................................................ Cast iron

Bore, standard..................................................................................... 96.00–96.03 mm (3.7795–3.7807")

Bore, oversize 1 .................................................................................. 96.300 mm (3.79133")

Bore, oversize 2 .................................................................................. 96.600 mm (3.80315")

The cylinder bores should be bored at a wear depth of 0.10 mm

(0.004 in) (in case the engine has an abnormal oil consumption).

Pistons

Material................................................................................................ Light alloy

3)

Overall height 230, AQ131 .................................................................. 64.7 mm (2.54724")

Overall height 250, 251DOHC, AQ151, AQ171 .................................. 61.7 mm (2.42913")

Height from gudgeon pin center to top of piston

230, AQ131 ......................................................................................... 39.7 mm (1.56299")

Height from gudgeon pin center to top of piston

250, 251 DOHC, AQ151, AQ171 ........................................................ 36.7 mm (1.44488")

Piston clearance, production ............................................................... 0.010–0.030 mm (0.0004–0.0012")

Piston clearance, service.................................................................... max 0.080 mm (0.0031")

Piston, standard dimension ................................................................. 95.980–96.010 mm4) (3.779–3.780")

Piston, oversize 1................................................................................ 96.280–96.290 mm (3.791–3.7909")

Piston, oversize 2................................................................................ 96.580–96.590 mm (3.802–3.803")

3)

Maximum weight difference between pistons in the same engine is 16 grams (0.56 oz).

4)

See the spare parts catalog for all the products.

Piston rings

Piston ring end gap (oil scraper ring)................................................... 0.30–0.60 mm (0.0118–0.0236")

Piston ring end gap (compression ring) ............................................... 0.30–0.55 mm (0.0118–0.0217")

Oversize piston rings 1 ....................................................................... 0.3 mm (0.0118")

Oversize piston rings 2 ....................................................................... 0.6 mm (0.0236")

Compression rings

The upper ring is chromium plated. The low er ring is marked “T OP”.

Number of rings on each piston........................................................... 2

Height, upper ....................................................................................... 1.728–1.740 mm (0.068–0.069")

Height, lower ....................................................................................... 1.728–1.740 mm (0.068–0.069")

Piston ring clearance in groove, upper ................................................ 0.040–0.072 mm (0.0016–0.0028")

Piston ring clearance in groove, lower................................................. 0.040–0.072 mm (0.0016–0.0028")

Oil scraper rings

Number on each piston ....................................................................... 1

Height.................................................................................................. 3.475–3.490 mm (0.1368–0.374")

Gudgeon pins

Full floating pin. Locked at both ends with circlips.

Fit in connecting rod ............................................................................ Light thumb pressure (push fit)

Fit in piston .......................................................................................... Thumb pressure (slide fit)

Standard diameter ............................................................................... 23.0 mm (0.906")

Oversize diameter ............................................................................... 23.05 mm (0.907")

Length ................................................................................................. 65 mm (2.559")

14

AQ131A, 131B, AQ131C, 131D,

151A, 151B, 151C, 151D, 171C, 171D,

171A, 171B 230, 250, 251DOHC

Crankshaft

Crankshaft, axial clearance................................................................. 0.080–0.270 mm 0.080–0.270 mm

(0.0031–0.0106") (0.0031–0.0106")

Main bearing, radial clearance............................................................. 0.024–0.072 mm 0.024–0.064 mm

(0.00094–0.00283") (0.0009–0.0025")

Crank bearing, radial clearance .......................................................... 0.023–0.067 mm 0.023–0.067 mm

(0.00091–0.00264") (0.00091–0.00264")

Straightness, maximum deviation........................................................ 0.025 mm 0.025 mm

(0.00098") (0.00098")

Taper Out-of-roundness

Main bearings

Main bearing journals

Out of roundness, max........................................................................ 0.004 mm 0.004 mm

(0.00016") (0.00016")

Taper, max. .......................................................................................... 0.004 mm 0.004 mm

(0.00016") (0.00016")

Standard diameter ............................................................................... 54.987–55.000 mm 62.987–63.000 mm

(2.1648–2.1654") (2.4798–2.4803")

0.25 mm undersize (0,0098") .............................................................. 54.737–54.750 mm 62.737–62.750 mm

(2.1550–2.1555") (2.4700–2.4705")

0.50 mm undersize (0,0197") .............................................................. 54.487–54.500 mm 62.487–62.500 mm

(2.1452–2.1457") (2.4601–2.4606")

Seat width on crankshaft for thrust bearings

Standard.............................................................................................. 31.96–32.00 mm 35.46–35.50 mm

(1.2583–1.2598") (1.3961–1.3976")

Oversize 1........................................................................................... 32.21–32.25 mm –

(1.2681–1.2697")

Oversize 2........................................................................................... 32.46–32.50 mm –

(1.2780–1.2795")

The main bearings are available in two mak es. The upper and lower

main bearing shell on the same pivot must be of the same make.

In production matched crankshaft bearing shells are used. The

bearing shells are color coded, red, yellow and blue. They are matched

in accordance with one of the following alternatives:

Alternative 1: Two yellow-marked bearing shells.

Alternative 2: One blue-marked and one red-marked bearing shell. The

blue-marked shell to be located on the crankshaft and the red-marked

shell in the bearing cap.

NOTE! Only yellow-mark ed bearing shells are av ailable f or spare parts

purposes.

Connecting rods

Connecting Rod Bearings

Bearing journals

Out of roundness, max........................................................................ 0.004 mm (0.00016")

T aper, max. .......................................................................................... 0.004 mm (0.00016")

Bearing seat width............................................................................... 23.9–26.1 mm (0.9409–1.0276")

Standard diameter ............................................................................... 48.984–49.005 mm (1.9285–1.9293")

0.25 mm undersize (0.0098") .............................................................. 48.734–48.755 mm (1.9187–1.9195")

0.50 mm undersize (0.0197") .............................................................. 48.484–48.505 mm (1.9088–1.9096")

Axial clearance at the piston ............................................................... 0.25–0.45 mm (0.0098–0.0177")

Length, center to center ...................................................................... 152 mm (5.9843")

Max. weight difference between connecting rods in the same engine . 20 grams (0.7055 oz.)

Color code

15

Camshaft

Number of bearings ............................................................................. 5

Bearing, diameter ................................................................................ 29.95–29.97 mm (1.179–1.180")

Radial clearance ................................................................................. 0.030–0.071 mm (0.0012–0.0028")

Maximum............................................................................................. 0.15 mm (0.0059")

Axial clearance (end play)................................................................... 0.1–0.4 mm (0.0039–0.0157")

Camshaft bearings

Camshaft bearing diameter ................................................................. 30.000–30.021 mm (1.1811–1.1819")

Timing gears, Models 230, 250, AQ131, A Q151

Number of teeth, crankshaft gear........................................................ 19

Number of teeth, intermediate shaft gear ............................................ 38

Number of teeth, camshaft gear .......................................................... 38

Number of teeth, toothed belt .............................................................. 123

Timing gears, Models 251DOHC, A Q171

Number of teeth, crankshaft gear........................................................ 19

Number of teeth, intermediate shaft gear ............................................ 38

Number of teeth, camshaft gear .......................................................... 38

Number of teeth, toothed belt .............................................................. 146

Intermediate shaft

Number of bearings ............................................................................. 3

Front bearing diameter......................................................................... 46.975–47.000 mm (1.849–1.850")

Middle bearing diameter ...................................................................... 43.025–43.050 mm (1.694–1.695")

Rear bearing diameter ......................................................................... 42.925–42.950 mm (1.690–1.691")

Radial clearance ................................................................................. 0.020–0.075 mm (0.0008–0.0030")

Axial clearance (end play)................................................................... 0.20–0.46 mm (0.0079–0.0181")

Intermediate shaft bearing diameter in block:

Front................................................................................................. 47.020–47.050 mm (1.851–1.852")

Middle .............................................................................................. 43.070–43.100 mm (1.696–1.697")

Rear ................................................................................................. 42.970–43.000 mm (1.692–1.693")

Changing the bearings

NOTE! New bearings must be line bored!

Valves 230, 250, A Q131, A Q151

Inlet

Disc diameter ...................................................................................... 44.0 mm (1.7323")

Stem diameter ..................................................................................... 7.955–7.970 mm (0.3132–0.3138")

Valv e seat angle.................................................................................. 44.5°

Cylinder block seat angle .................................................................... 45°

Seat width in cylinder head.................................................................. 1.3–1.9 mm (0.0512–0.0748")

Exhaust

Disc diameter ...................................................................................... 35.0 mm (1.37795")

Stem diameter ..................................................................................... 7.945–7.960 mm (0.3128–0.3134")

Valv e seat angle.................................................................................. 44.5°

Cylinder block seat angle .................................................................... 45°

Seat width in cylinder head.................................................................. 17–2.3 mm (0.0669–0.0906")

44.5°

44.0

New: 7.955–7.970 (0.3132–0.3138")

Min: 7.935 (0.3124")

Inlet valve

16

IMPORTANT! The valves are stellite coated. Therefore they must not be machined, only lapped against the seat!

Clearance when checking:

Cold engine ......................................................................................... 0.30–0.40 mm (0.0118–0.0157")

Hot engine ........................................................................................... 0.35–0.45 mm (0.0138–0.0177")

Clearance when adjusting:

Cold engine ......................................................................................... 0.35–0.40 mm (0.0138–0.0157")

Hot engine ........................................................................................... 0.40–0.45 mm (0.0157–0.0177")

The same clearance for inlet and exhaust valves.

Valve guides (inlet & exhaust) 230, 250, A Q131, A Q151

Length ................................................................................................. 52 mm (2.165")

Inner diameter ..................................................................................... 8.00–8.02 mm (0.275–0.276")

Clearance, valve stem–valve guide, inlet valve................................... 0.03–0.06 mm (0.0012–0.00245")

Clearance, valve stem–valve guide, exhaust valve ............................ 0.04–0.07 mm (0.0016–0.0028")

Clearance, maximum wear.................................................................. 0.15 mm (0.0059")

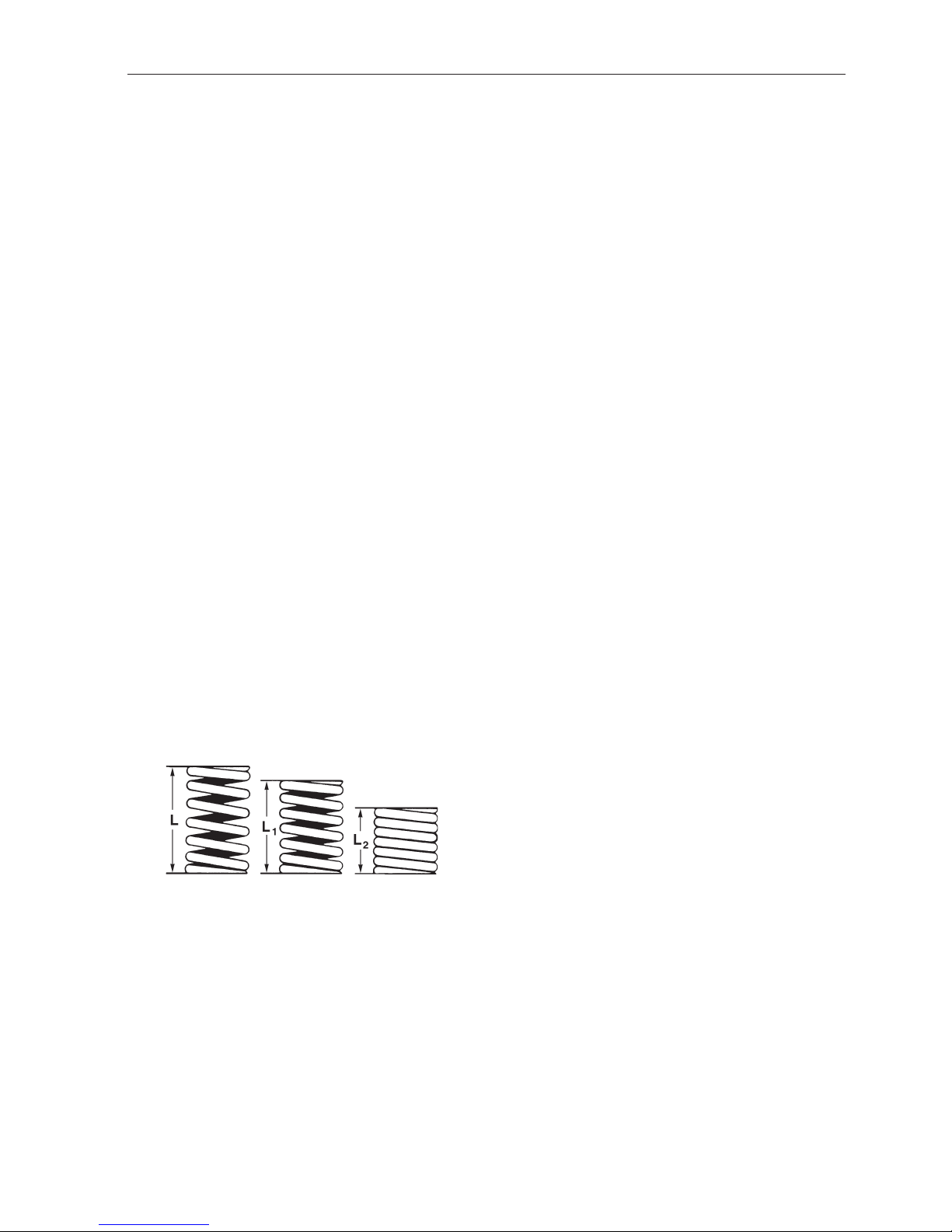

Valve springs, 230, 250, A Q131, AQ151

Length, unloaded ................................................................................. 45.0 mm (1.772")

Length, loaded 285–325 N (28.5–32.5 kp)........................................... 38.0 mm (1.496")

Length, loaded 725–805 N (72.5–80.5 kp)........................................... 27.0 mm (1.063")

Valves 251DOHC, A Q171

Inlet

Disc diameter ...................................................................................... 34.5 mm (1.358")

Stem diameter ..................................................................................... 6.955–6.970 mm (0.2738–0.2744")

Valv e seat angle.................................................................................. 44.5°

Cylinder block seat angle .................................................................... 45°

Seat width in cylinder head.................................................................. 1.3–1.9 mm (0.0512–0.0748")

Exhaust

Disc diameter ...................................................................................... 31.5 mm (1.240")

Stem diameter ..................................................................................... 6.945–6.960 mm (0. 2734–0.2740")

Valv e seat angle.................................................................................. 44.5°

Cylinder block seat angle .................................................................... 45°

Seat width in cylinder head.................................................................. 1.7–2.3 mm (0.0669–0.0906")

IMPORT ANT! The valves are stellite coated. Theref ore they m ust not be machined, only lapped against the seat.

New: 7.945–7.960 (0.3128–0.3134)

Min: 7.925 (0.3120")

35.0

44.5°

New: 6.955–6.970 (0.2738–0.2744")

Min: 6.935 (0.2730")

34.5

44.5°

New: 6.945–6.960 (0.2734–0.2740")

Min: 6.925 (0.2726")

31.5

44.5°

Inlet valve

Exhaust valve

Exhaust valve

17

Valve clearance, 251DOHC, AQ171................................................... Hydraulic valve tappets, no setting is required

Valve guides (inlet & exhaust) 251DOHC, A Q171

Length ................................................................................................. 55 mm (2.165")

Inner diameter ..................................................................................... 7.00–7.02 mm (0.275–0.276")

Clearance, valve stem–valve guide, inlet valve................................... 0.03–0.06 mm (0.0012–0.0024")

Clearance, valve stem–valve guide, exhaust valve ............................ 0.04–0.07 mm (0.0016–0.0028")

Clearance, maximum wear.................................................................. 0.15 mm (0.0059")

Valve springs 251DOHC, A Q171

Length, unloaded ................................................................................. 43.0 mm (1.6929")

Length, loaded 212–252 N (21.2–25.2 kp)........................................... 37.0 mm (1.45669")

Length, loaded 600–680 N (60–68 kp)................................................. 26.5 mm (1.0433")

Lubricating system

Changing oil, oil capacity , e xcluding filter ............................................ 3.5 dm3 (0.88 Imp gall./1.06 US gall.)

Changing oil, oil capacity , including filter ............................................. 4.0 dm3 (0.99 Imp gall./1.19 US gall.)

Oil pressure at 33.33 r/s (2000 rpm), hot engine ................................. 2.5–6.0 kp/cm2 (35–85 psi)

Lubricating oil, alternative 1 ................................................................. Volvo P enta lubricating oil for gasoline engines

Lubricating oil, alternative 2 ................................................................. Lubricating oil SG

Viscosity ............................................................................................. SAE 20 W/50

Oil filter

Type..................................................................................................... Full flow filter

Lubricating oil pump

Axial clearance.................................................................................... 0.02–0.12 mm (0.0008–0.0047")

Radial clearance (excluding bearing clearance).................................. 0.02–0.09 mm (0.0008–0.0035")

Gear backlash (excluding bearing clearance)..................................... 0.15–0.35 mm (0.0059–0.0138")

Bearing clearance, drive shaft............................................................. 0.032–0.070 mm (0.0013–0.0028")

Bearing clearance, idler shaft .............................................................. 0.014–0.043 mm (0.0006–0.0017")

Length of the relief valve spring at different loads:

Length: Load:

47.6 mm (1.874") No load

32.0 mm (1.26") 40–48 N (4.0–4.8 kp)

(29.4–35.2 ft.lbs)

26.0 mm (1.024") 55–67 N (5.5–6.7 kp)

(40.3–49.1 ft.lbs)

Fuel system

Fuel pump

Type..................................................................................................... Diaphragm

Feed pressure ..................................................................................... 0.15–0.28 kp/cm2 (2–4 psi)

Fuel flow .............................................................................................. 1.6–2.0 liter/minute

(0.35–0.44 Imp.gal/min/0.375–0.475 US gal/min)

18

Carburetor 230, A Q131 AQ131A, 131B AQ131C,131D, 230

Type..................................................................................................... Down draught Down draught

Designation ......................................................................................... Model 44 P AI-5 Model 44 PAI-7

Venturi ................................................................................................. 34 34

Main jet................................................................................................ 165 165

Idling jet ............................................................................................... 65 65

Air jet ................................................................................................... 185 1 8 5

Needle valve ....................................................................................... 1.7 2.0

Float, weight in grams (oz’s)................................................................ 7.3 (0.26) 7.3 (0.26)

Acceleration jet.................................................................................... 70 70

Econostat jet ....................................................................................... 110 11 0

Carburetor 250, A Q151 AQ151A, AQ151B AQ151C, AQ151D , 250

Type..................................................................................................... Down draught Down draught

Designation ......................................................................................... Model 44 P AI-4 Model 44 PAI-7

Venturi ................................................................................................. 31 31

Main jet................................................................................................ 145 145

Idling jet ............................................................................................... 62 62

Air jet ................................................................................................... 185 1 8 0

Needle valve ....................................................................................... 1.5 1.7

Float, weight in grams (oz’s)................................................................ 7.3 (0.26) 7.3 (0.26)

Acceleration jet.................................................................................... 60 60

Econostat jet ....................................................................................... – –

AQ171C, A Q171D ,

Carburetor 251DOHC, A Q171 AQ171A, A Q171B 251DOHC

Type..................................................................................................... Down draught Down draught

Designation ......................................................................................... Model 44 P AI-5-6 Model 44 P AI-7

V enturi ................................................................................................. 32 32

Main jet................................................................................................ 147 147

Idling jet ............................................................................................... 65 60

Air jet ................................................................................................... 190 2 0 0

Needle valve ....................................................................................... 1.7 1.7

Float, weight in grams (oz’s)................................................................ 7.3 (0.26) 7.3 (0.26)

Acceleration jet.................................................................................... 70 70

Econostat jet ....................................................................................... – –

Electrical system

Battery

Grounding............................................................................................ Negative

V oltage ................................................................................................ 12 Volts

Capacity .............................................................................................. 60 Ah

Specific weight of the electrolyte

Fully charged battery........................................................................... 1.275–1.285 grams/cm3 (0.0460–0.0464 lb/cu.in.)

Discharged battery.............................................................................. 1.230 grams/cm3(0.0444 lb/cu.in.)

Starter motor

Output ................................................................................................. 0.8 kW (1.1 hk)

Alternator

Output, maximum Amp (W) ................................................................. 50 (14x50)

Ignition system

Cylinder marking ................................................................................. No 4 closest to the flywheel

Spark plugs 230, 250, AQ131, AQ151 ................................................ Part no 875820-3, Bosch W6DC or its equivalent

Spark plugs, 251DOHC, AQ171 ......................................................... Part no 876077-9, Bosch WR6DC or its equivalent

Spark plug gap .................................................................................... 0.7 mm (0.0276")

19

Distributor 230, 250, A Q131, A Q151

Type..................................................................................................... Breaker point system

Type Bosch JF4 .................................................................................. 0231 178 019

Setting for regular gasoline, min 91 octane RO T :

USA: Ignition setting for regular petrol (RON+MON)/2 = min 87 octane

Basic setting........................................................................................ 6° BTDC (0–14.17 r/s = 0–850 rpm)

Stroboscope setting ............................................................................ 32–36° BTDC (70 r/s = 4200 rpm)

Contact gap ......................................................................................... 0.40 mm (0.01575")

Dwell angle.......................................................................................... 62±3°

Distributor , 251DOHC, A Q171

Type Bosch TVX4, Breakerless system.............................................. A 237 540 079

Setting for regular gasoline, min 91 octane RO T :

USA: Ignition setting for regular petrol (RON+MON)/2 = min 87 octane

Basic setting........................................................................................ 10° BTDC (0–15 r/s = 0–900 rpm)

Stroboscope setting (not adjustable) ................................................... 23–25° BTDC (73.33 r/s=4400 rpm)

Cooling system

Thermostat

Type..................................................................................................... Wax thermostat

Starts opening at ................................................................................. 82°C (179.6°F)

Fully open at ........................................................................................ 92°C (197.6°F)

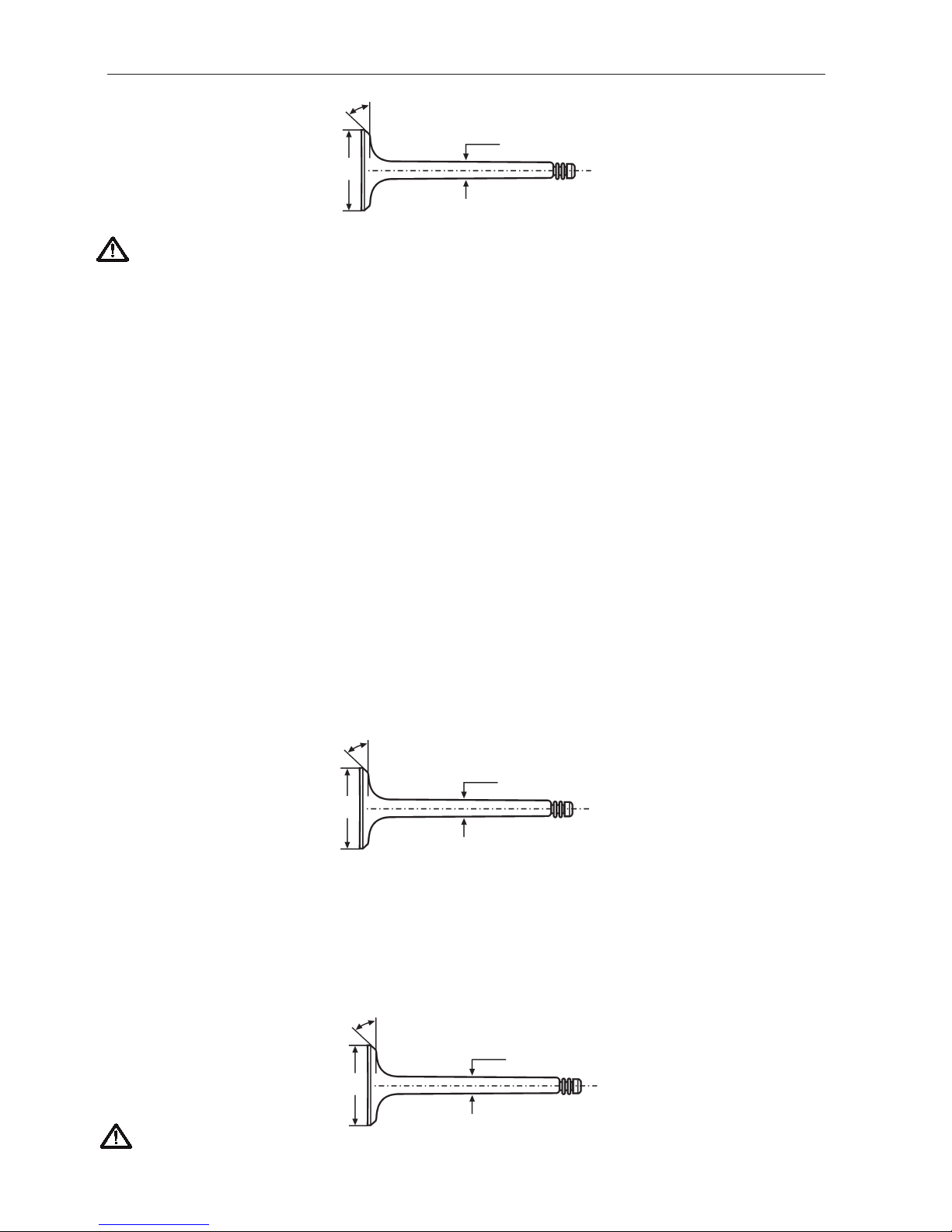

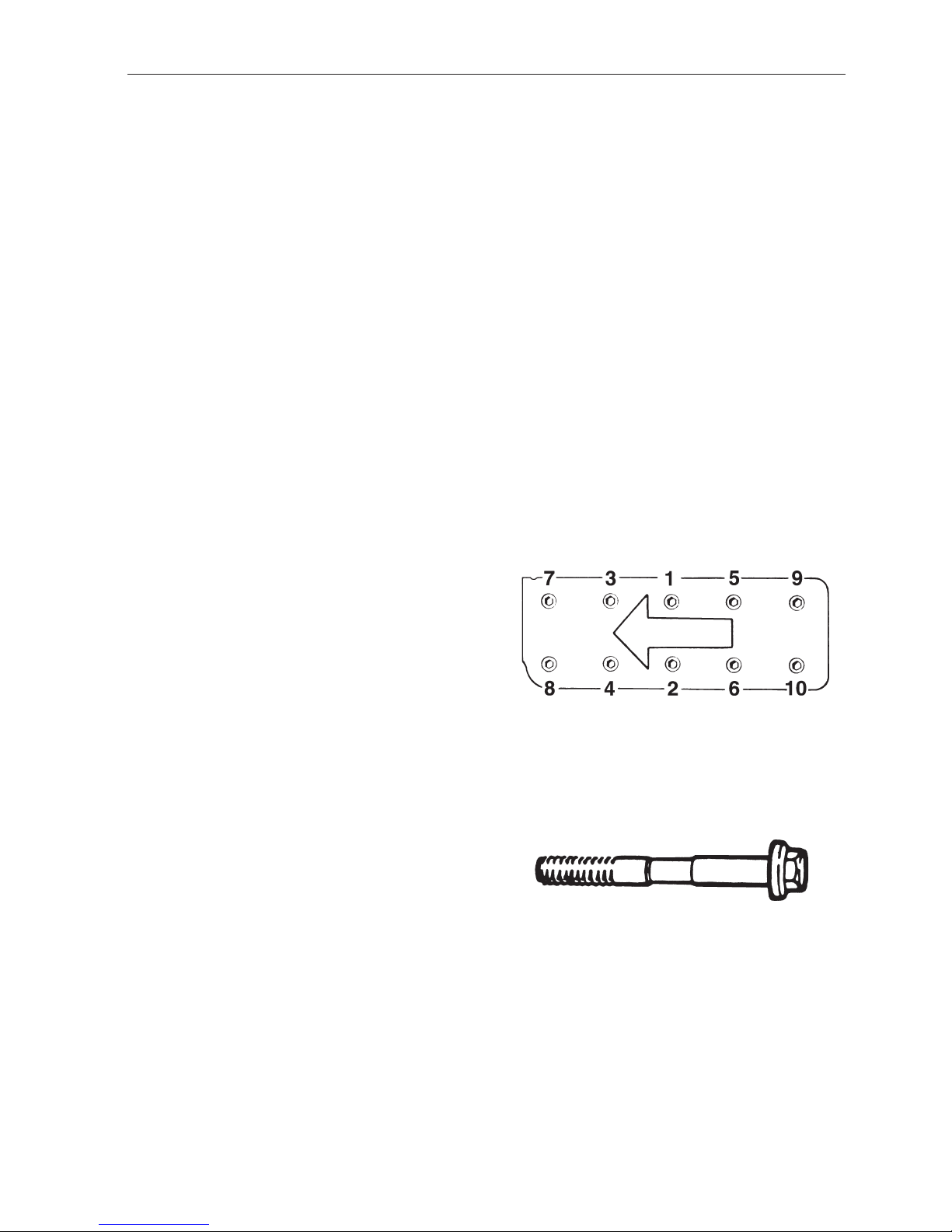

Tightening torques

NOTE! Alwa ys tighten the cylinder head bolts when the

engine is cold. The torque v alues are valid f or bolts and

nuts being well oiled prior to installation.

Parts having been washed should be oiled prior to

the assembly.

Tightening torque for cylinder head bolts:

The cylinder head: To be tightened in stages....................................... 1 = 20 Nm (2.0 kpm) (15 ft.lbs.)

2 = 40 Nm (4.0 kpm) (29 ft.lbs.)

3 = Angle tighten through 120° in one operation!

– Replace the cylinder head bolts if they show signs of being

stretched. If a bolt is “stretched” can clearly be seen on the

“waist” of the bolt, which is then elongated.

– The cylinder head bolts can be “re-used” max 5 times.

Replace the bolts if you feel uncertain on any of these points.

Nm Kpm Ft.lbs.

Main bearings ...................................................................................... 110 11.0 79.5

Crank bearings, 1st stage1)................................................................ 20 2.0 15

2nd stage1)............................................................... through 90°

Flywheel (use new bolts) .................................................................... 70 7.0 51

Spark plugs (do not oil them!).............................................................. 25±5 2.5±0.5 18

Camshaft gear..................................................................................... 50 5.0 36

Intermediate gear ................................................................................ 50 5.0 36

Camshaft bearing cap ......................................................................... 20 2.0 15

Crankshaft, center bolt pulley, stage 1................................................ 60 6.0 43

stage 2................................................ Angle tighten through 60°

1)

Old bolts can be used provided the length does not exceed 55.5 mm (2.185").

20

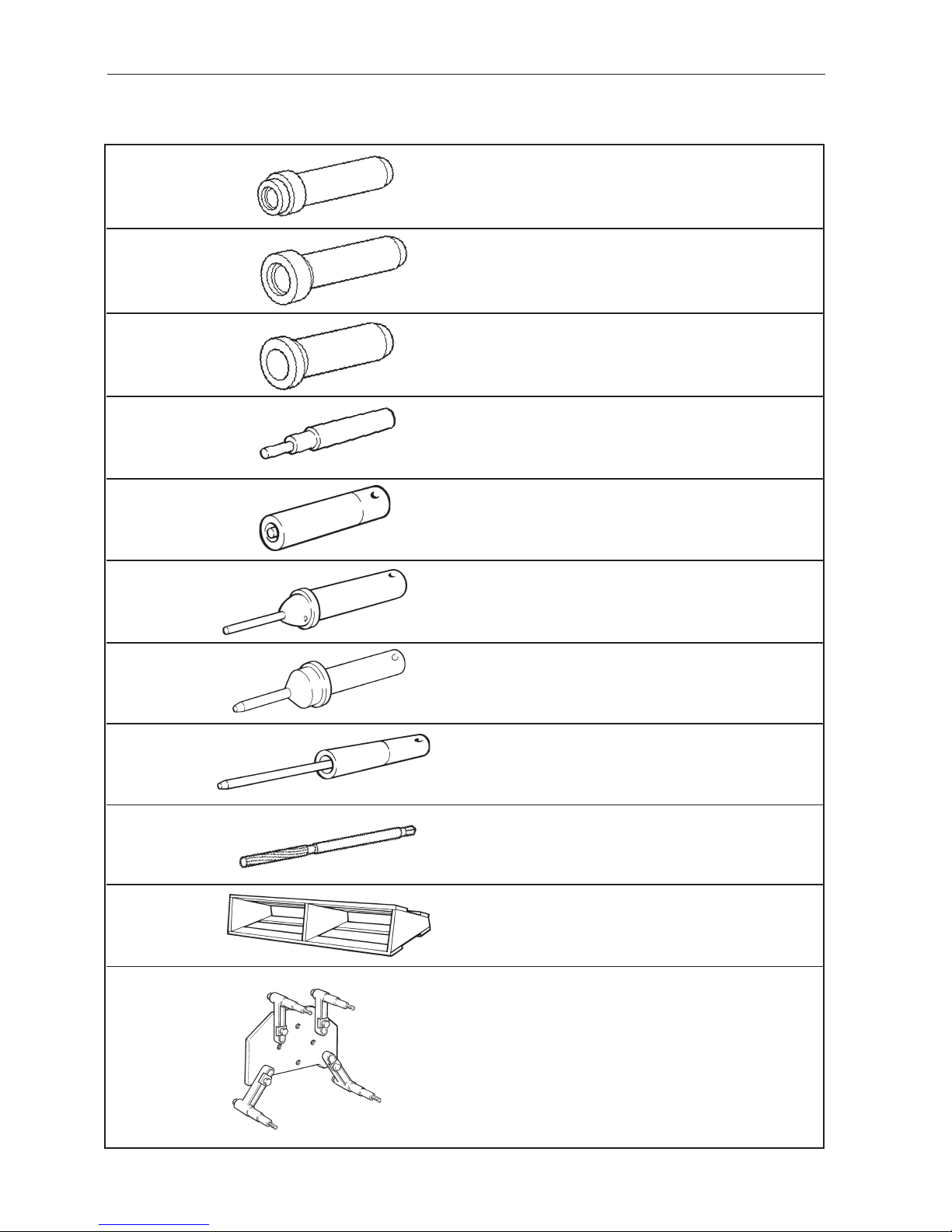

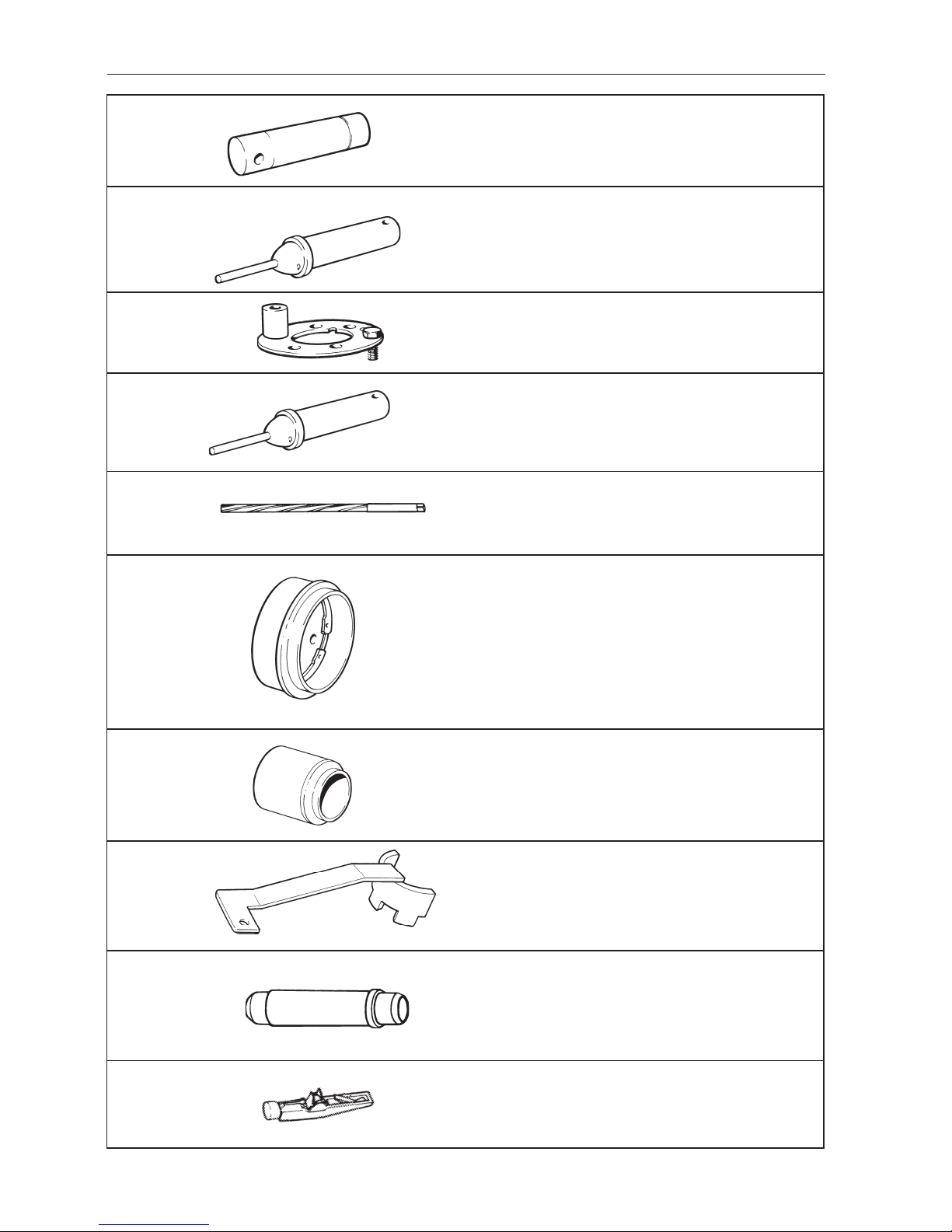

2. Special T ools

884359-1 Drift for the installation of the seal in the flywheel

housing

885050-5

884596-8

884599-2

884958-0

884959-0

884960-6

884961-4

884967-1

884966-3

884979-6

Drift for the installation of the primary shaft in the

flywheel housing

Drift for the installation of the seal in the flywheel

housing

Drift for the changing of valve guides 251DOHC ,

AQ171

Drift for the changing of valve guides 251DOHC,

AQ171

Drift for the changing of valve guides 251DOHC,

AQ171

Reamer valve guides 251DOHC, AQ171

Cylinder head fixture 251DOHC, AQ171

Stand fixture

Installation tool inlet valve seat 251DOHC, AQ171

Installation tool exhaust valve seat 251DOHC,

AQ171

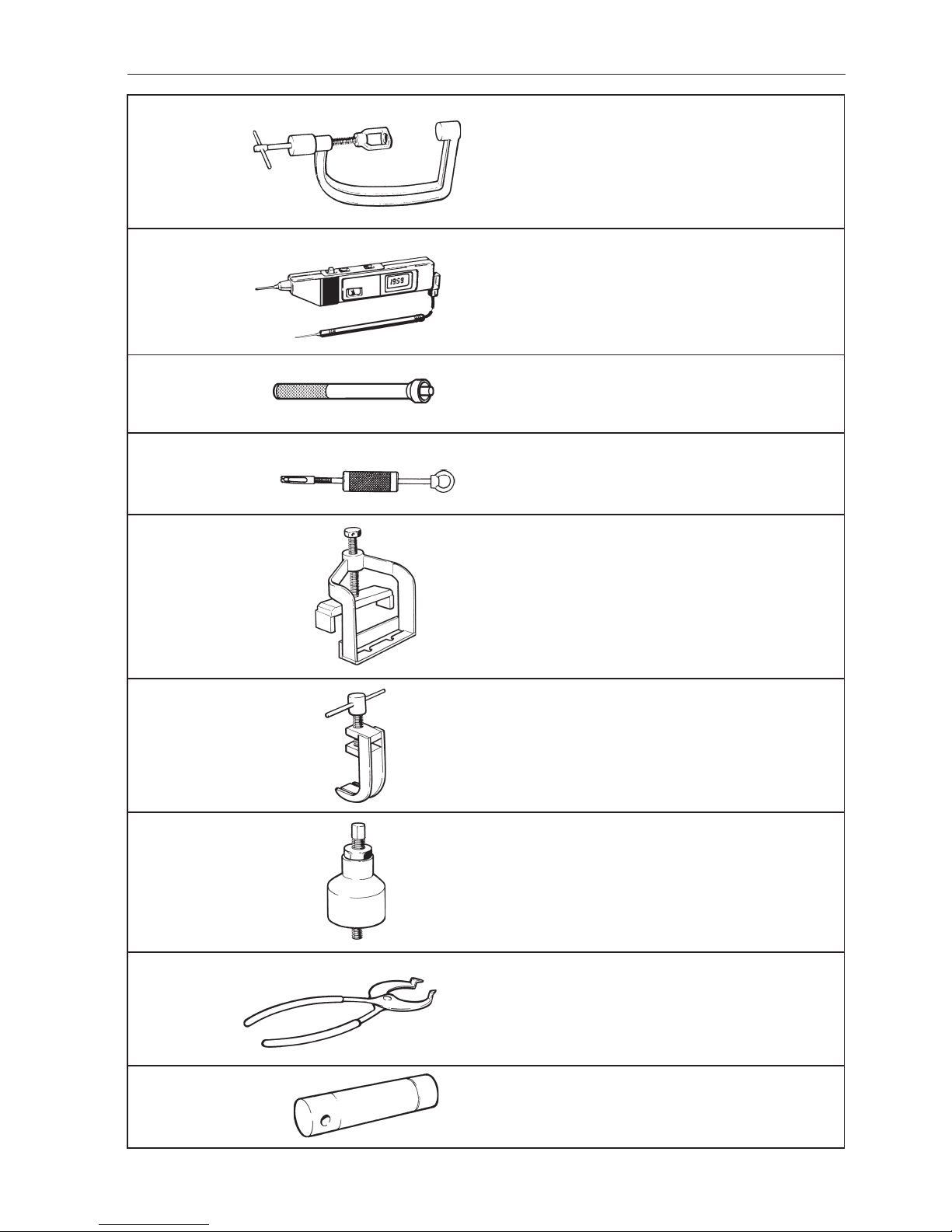

21

9986052-0 Valve com-

pressor

9991426-9

Drift for the installation of support bearing in the flywheel

9994090-0

Puller for support bearing in the flywheel

9995021-4 Press tool for the removal and assembly of the

camshaft, AQ131, AQ151, 230, 250

9995022-2

Tool for depressing valve depressors, AQ131,

AQ151, 230, 250

9995025-5

Installation tool for the intermediate shaft seal

9995026-3

9995027-1

Pair of pliers for adjustment shims AQ131, AQ151,

230, 250

Drift for the installation of valve guides (inlet),

AQ131, AQ151, 230, 250

9988452-0

Digital probe tester

22

9995029-7

9995034-7

9995224-4

9995276-4

9995283-0

9995220-2

9995284-8

9995309-3

1159660-8

Installation tool for valve seats (inlet), AQ131,

AQ151, 230, 250

Counterhold for the camshaft gear and intermediate

gear

Installation tool for valve seats (exhaust), AQ131,

AQ151, 230, 250

Reamer, valve guides AQ131, AQ151, 230, 250

Drift for the installation of sealing in the crankshaft

rear end

Removal tool for the crankshaft front seal

Counterhold for crankshaft pulley

Drift for the removal and installation of bushing in

the connecting rod

Tensioning tool for the toothed belt AQ171,

251DOHC

9995028-9

Drift for the installation of valve guides (exhaust),

AQ131, AQ151, 230, 250

23

3. Electrical System

General

All engines have a single pole electrical system with

an AC generator. The engine main wiring is fused

with a thermic 40 A automatic fuse.

Ignition system

AQ131, AQ151, 230 and 250 have conventional

breaker point ignition systems. See the “Technical

Data” for the setting values. AQ171 and 251DOHC

are equipped with breakerless electronic ignition

systems. The ignition system memory unit has 63

optimal engine speed / ignition values programmed.

The ignition points for other engine speeds is

calculated based on these locked values.

Note! No ignition setting can be carried out on the

distributor. The ignition system has the correct setting when all components are correctly installed. In

order to obtain exact installation there is a certain

amount of adjustment possible in the ignition setting

sender. All operation based adjustment is stopped.

All settings are permanently stored in the control

module and are stable because of the absence of

mechanicals (breaker points, mechanical ignition

setting). The only task of the distr ibutor has is to

distribute the current to the spark plugs via the rotor.

Instrumentation

The engines were manufactured with two types of instrumentation. One earlier type 1 and the later type 2

(for version refer to wiring diagrams). Both the instrumentation types are equipped with two 8 A fuses

for the system voltage (key switch in ignition position) and start voltage (key switch in start position).

Instrumentation type 2 is equipped with 2 connectors

for extra power outputs for accessories. One is

fused via the 8 A fuse for system voltage and has a

maximum permissible voltage output of 5 A (main

panel + any flying bridge panel). The other connector

has a maximum permissible voltage output of 20 A

and is not separately fused (power supply is via the

40 A automatic fuse for the main wiring). There is

also a connector for connecting instrument lighting

for extra instruments (a fuel gauge for example)

fused via the 8 A fuse for system voltage.

Starter motor

There are two versions. VALEO D6RA11 and

Hitachi S114-237.

Minimum length of the brushes:

VALEO = 14 mm

Hitachi = 12 mm.

Generator

The alternating current generator is a 14 V 50 A

VALEO. It is equipped with a charge sensor cable

(yellow) which is connected to the generator

(GEN) B+.

In those cases where the generator is required to

charge several batteries (starter and operational batteries) the charge sensor cable should be disconnected from B+ and connected, using a 1.5 mm

2

extension, to the accessory battery + ter minal using a

double diode.

Minimum length of the brushes: 8 mm

Resistance rotor winding 4,0–6,0 Ω

Resistance stator winding 0,11–0,15 Ω

24

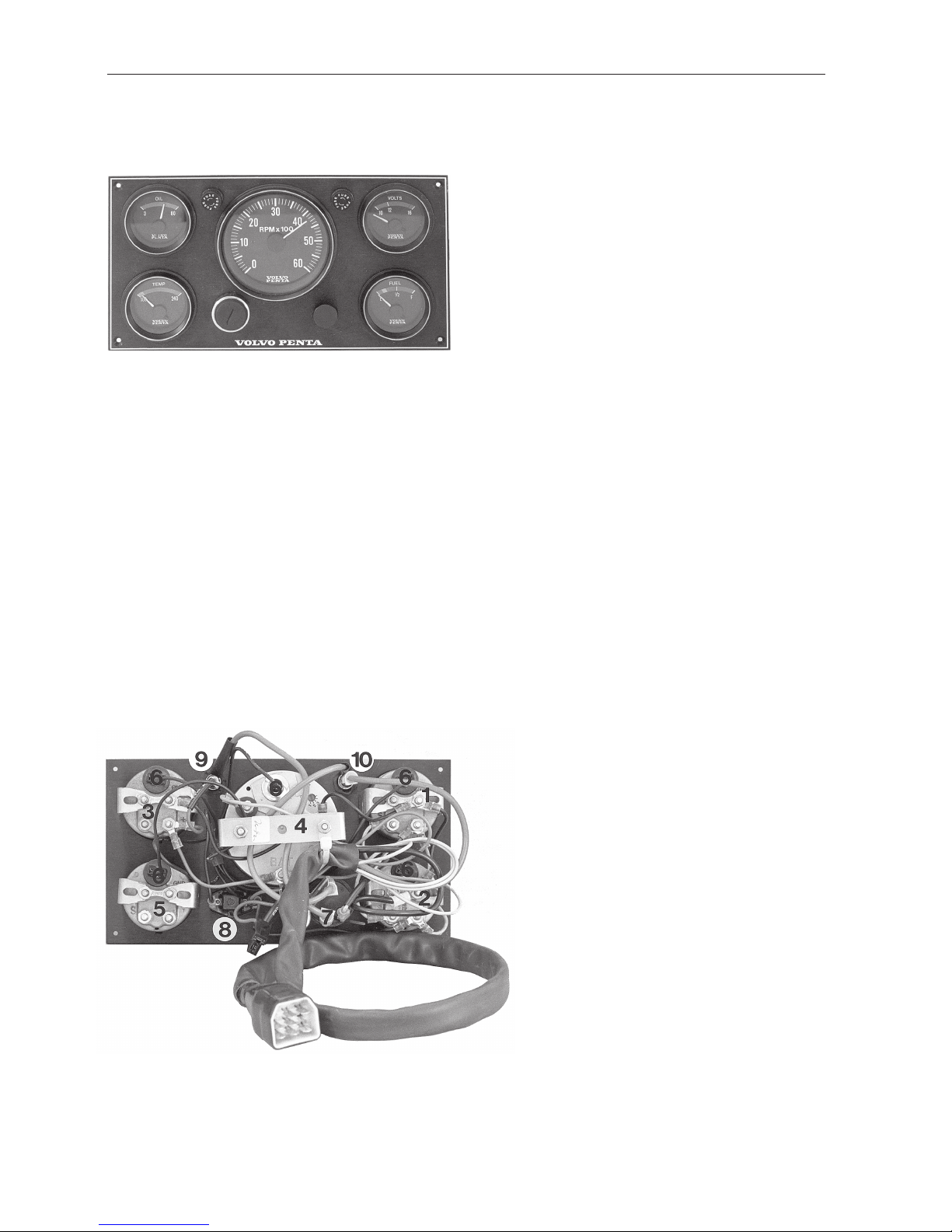

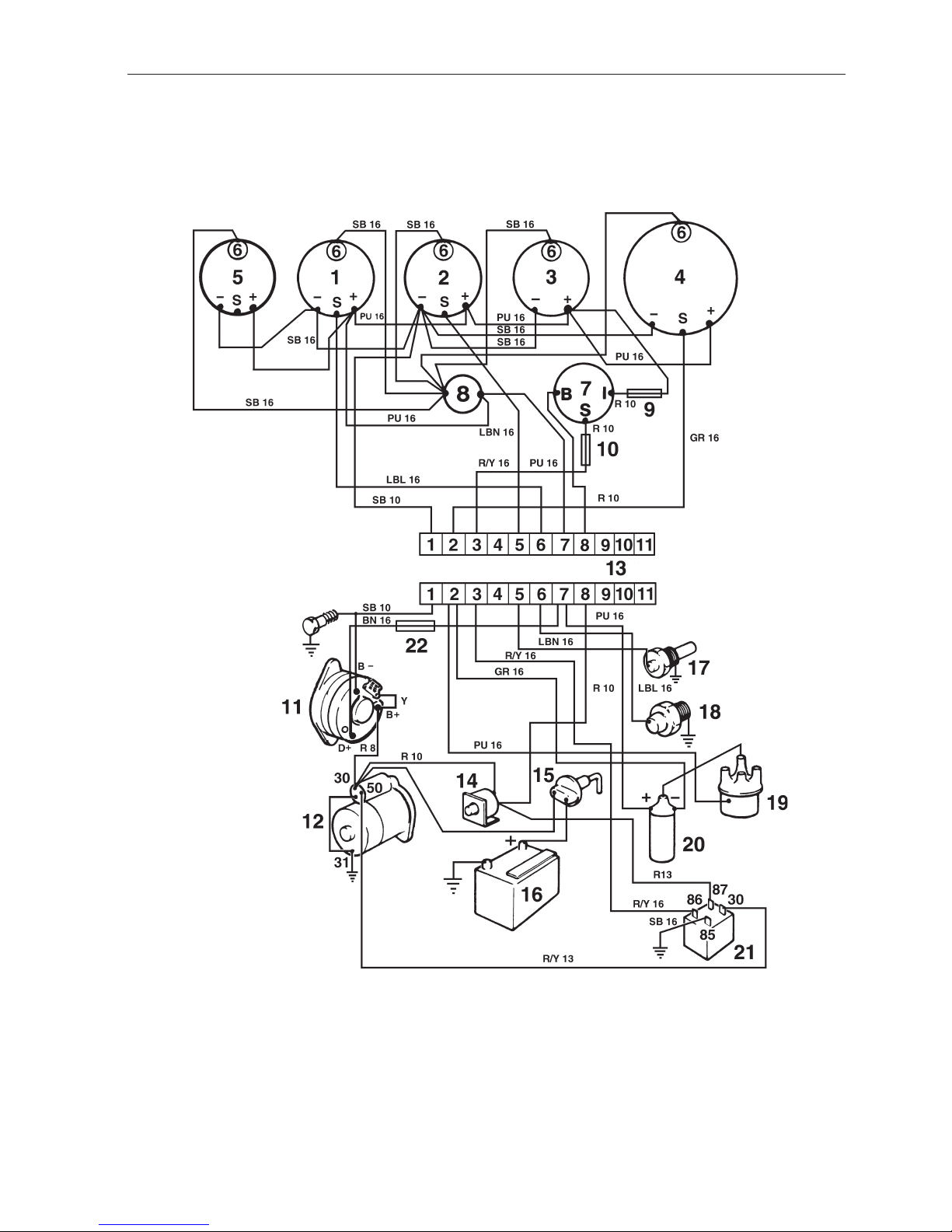

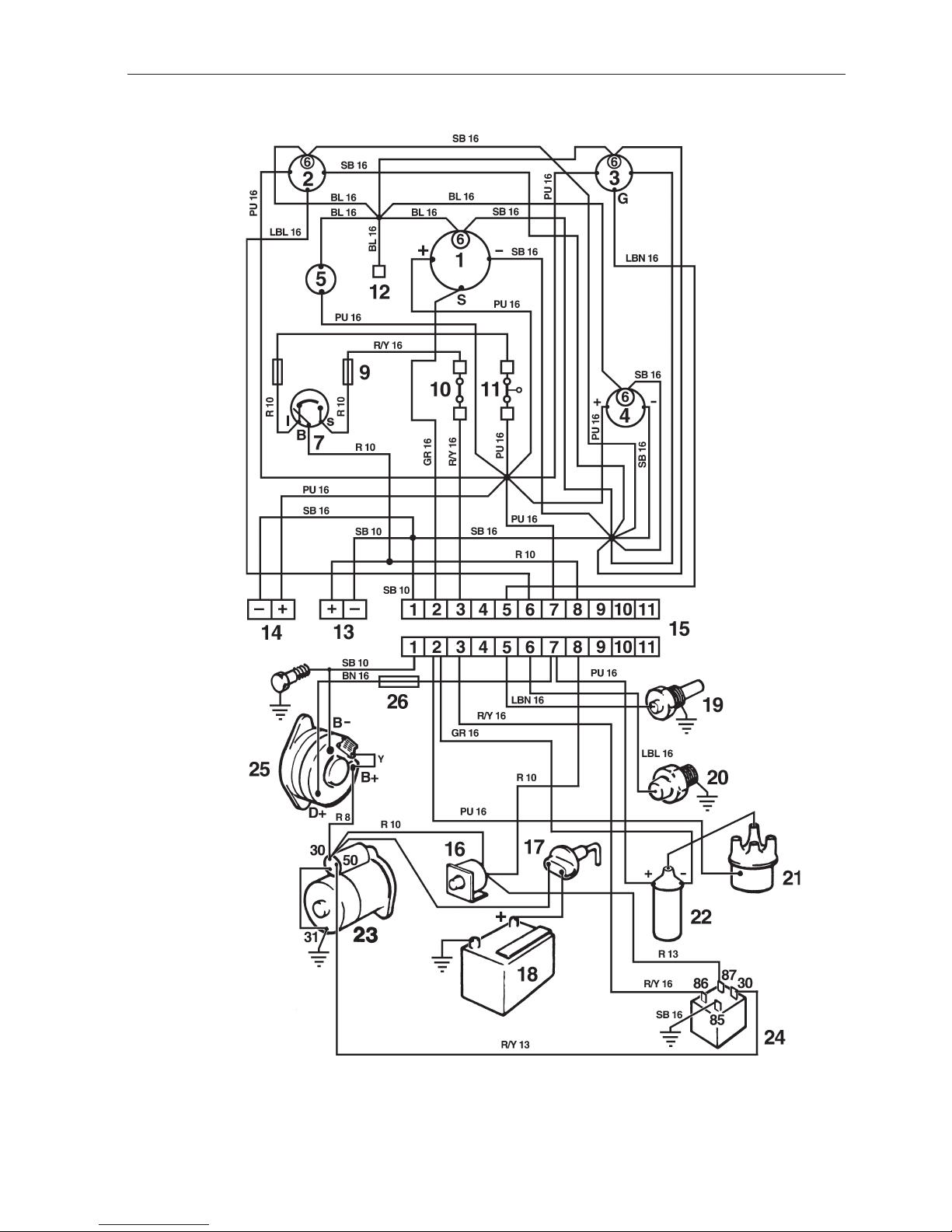

Wiring Diagram AQ131, AQ151, 230, 250

With Instrument panel alternative 1

1. Oil pressure gauge

2. Temperature gauge, coolant

3. Voltmeter

4. Tachometer

5. Fuel gauge (alternative)

6. Instrument lighting

7. Key switch (B=30, S=50, I=15)

8. Switch, instrument lighting

9. Fuse 8 A

10. Fuse 8 A

11. Generator

12. Starter motor

13. Connector engine–instrumentation

14. Automatic fuse 40A

15. Main switch (option)

16. Batte r y

17. Temperature sensor

18. Oil pressure sensor

19. Distributor

20. Ignition coil

21. Relay

22. Resistor

Cable cross sections

AWG mm

2

16 1.5

13 2.5

10 6.0

8 10.0

Cable colour code

SB = Black

PU = Purple

LBN = Light brown

R = Red

GR = Grey

LBL = Light blue

R/Y = Red/Yellow

BN = Brown

W = White

Y = Yellow

13

25

AQ131, AQ151, 230, 250 ALT. 1

26

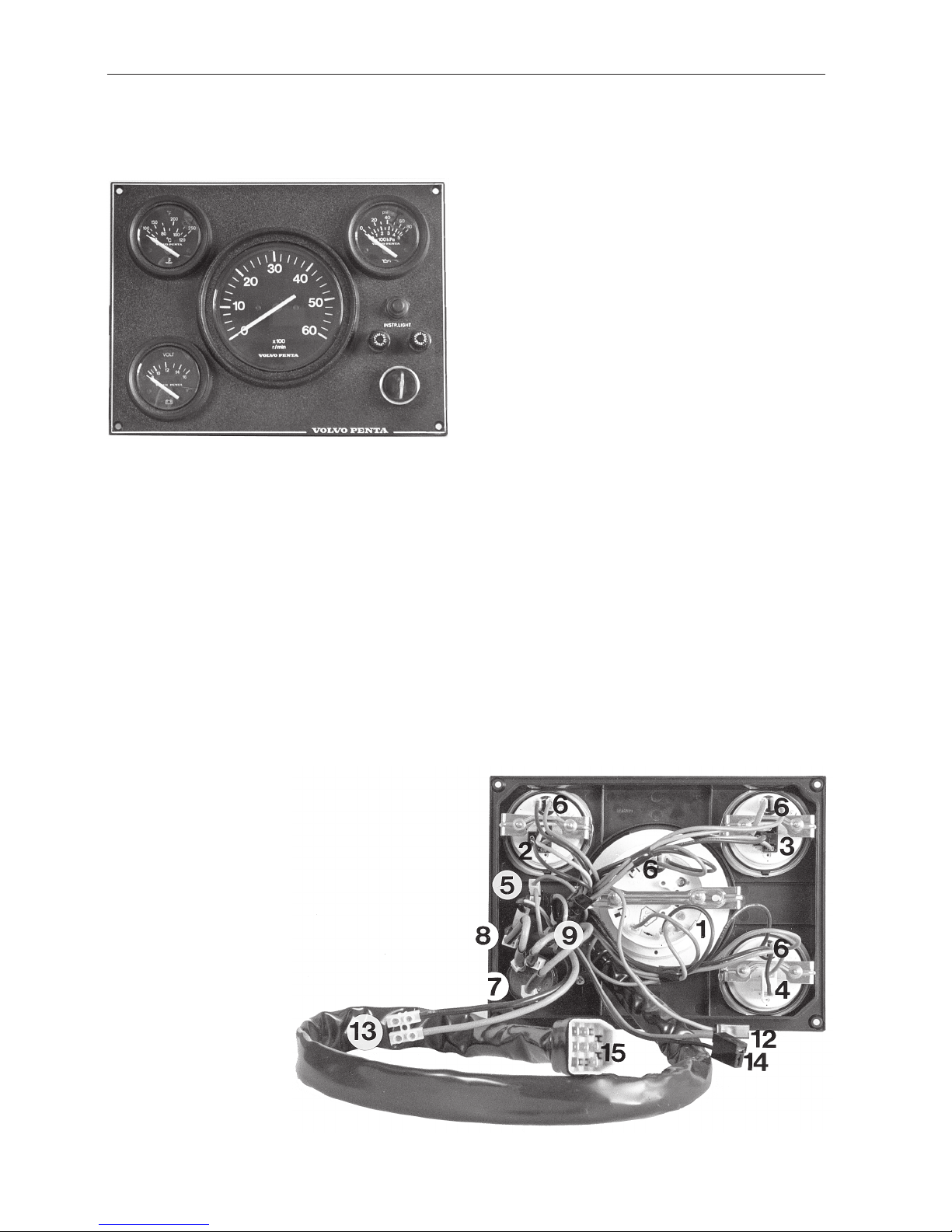

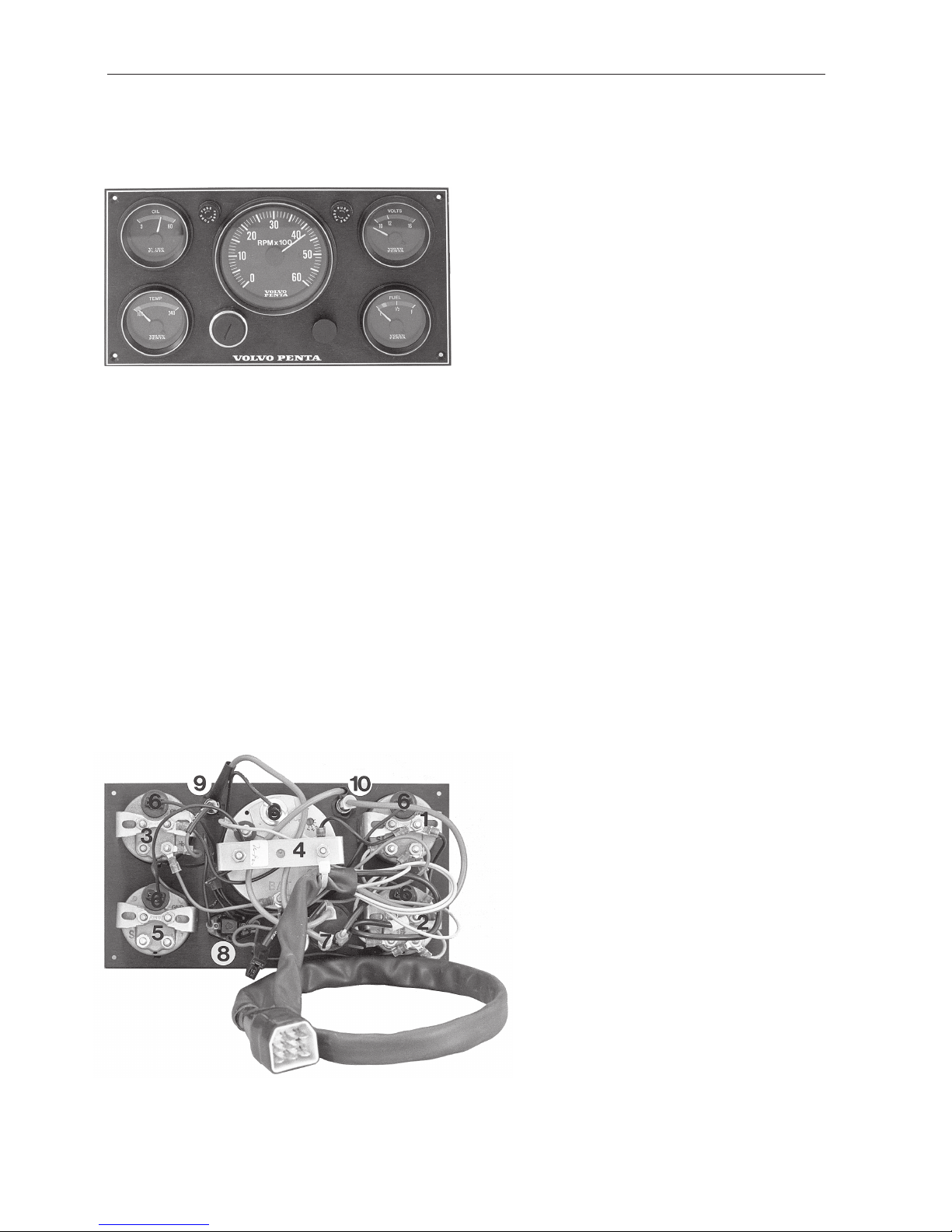

Wiring Diagram 230, 250

With Instrument panel alternative 2

1. Tachometer

2. Oil pressure gauge

3. Temperature gauge, coolant

4. Voltmeter

5. Switch, instrument lighting

6. Instrument lighting

7. Key switch (B=30, S=50, I=15)

8. Fuse 8 A

9. Fuse 8 A

10. Contact terminal neutral position switch

(option/accessory)

11. Contact terminal safety switch (accessory)

12. Connector instrument lighting accessory

13. Connector power output, maximum 20 A

14. Connector power output, maximum 5 A

(main panel + flying bridge panel)

15. Connector, engine–instrumentation

16. Automatic fuse 40A

17. Main switch (option)

18. Batte r y

19. Temperature sensor

20. Oil pressure sensor

21. Distributor

22. Ignition coil

23. Starter motor

24. Relay

25. Generator

26. Resistor

Cable cross sections

AWG mm

2

16 1.5

13 2.5

10 6.0

8 10.0

Cable colour code

SB = Black

PU = Purple

LBN = Light brown

R = Red

GR = Grey

LBL = Light blue

R/Y = Red/Yellow

BN = Brown

W = White

Y = Yellow

27

230, 250 ALT. 2

28

Wiring Diagram AQ171, 251DOHC

With Instrument panel alternative 1

1 . Oil pressure gauge

2. Temp gauge

3. Voltmeter

4. Tachometer

5. Fuel gauge (alternative)

6. Instrument lights

7. Key switch (B = 30, S = 50, I = 15)

8. Switch, instrument lights

9. Fuse 8 Amp

10. Fuse 8 Amp

11. Alternator

12. Starter motor

13. Terminal block

14. Automatic fuse 40 Amp

15. Main switch (optional)

16. Battery (optional)

17. Temp sender

18. Oil pressure sender

19. Distributor

20. Electronic ignition unit

21. Relay

22. Resistor

23. Impulse sender, ignition unit

24. Ground (screw)

25. Solenoid valve

Cable cross sections

AWG mm

2

16 1.5

13 2.5

10 6.0

8 10.0

Cable colour code

SB = Black

PU = Purple

LBN = Light brown

R = Red

GR = Grey

LBL = Light blue

R/Y = Red/Yellow

BN = Brown

W = White

Y = Yellow

13

Loading...

Loading...